Control UBTECH Alpha UBT-12HC smart servos via ARC using EZ-B v4/IoTiny UART, assign virtual ports, set baud, custom bits and position mapping.

How to add the UBTECH Alpha Servos UBT-12HC robot skill

- Load the most recent release of ARC (Get ARC).

- Press the Project tab from the top menu bar in ARC.

- Press Add Robot Skill from the button ribbon bar in ARC.

- Choose the Servo category tab.

- Press the UBTECH Alpha Servos UBT-12HC icon to add the robot skill to your project.

Don't have a robot yet?

Follow the Getting Started Guide to build a robot and use the UBTECH Alpha Servos UBT-12HC robot skill.

How to use the UBTECH Alpha Servos UBT-12HC robot skill

Control the UBTECH Alpha Robot Digital smart Servos (UBT-12HC) with ARC. The servos must be powered appropriately, and connected to the EZ-B v4 or IoTiny with the respective port. Visit the Config menu of this plugin to view the port configuration.

The Virtual Ports (V0..V99) in ARC can be assigned to the UbTech servos.

UART Ports

This plugin requires the RX signal wire of the servo be connected to TX of the selected UART or digital port (if Software UART is selected on IoTiny)

Hardware UART is for the EZ-B v4 only. Do not use software UART on EZ-B v4. View the EZ-B v4 datasheet to identify the UART ports (0, 1, or 2). EZ-B v4 datasheet can be found here: https://www.ez-robot.com/Tutorials/Lesson/18

Software UART should only be used with IoTiny

Default baudrate of UBTECH servos is 115,200

Bind To Virtual Servos

- The configuration menu also provides an option to select the Virtual Ports, which correspond with the ID's of the UBTech servos. If the UBTECH servo ID #0 is connected, select V0. #1 = V1, #2 = V2, etc..

Additional Info

- Discussion on these servos is here: https://synthiam.com/Question/3932

Custom Bit Settings There are 3 bits that seem to not be understood for the protocol. Since UBTech does not release the protocol for their products, the community is working to better understand what the parameters are. The configuration menu of this plugin allows you to set hardcoded values for those bits. The bits are for 5, 6 & 7.

Custom servo Position Mapping The UB Tech servos have their own position range, and we don't know what it is. So, the configuration menu allows you to specify the min and max positions for the range. This will be mapped to the ARC servo position range. Meaning, if you set the range in this plugin, it will be mapped to the range for all ARC servo controls.

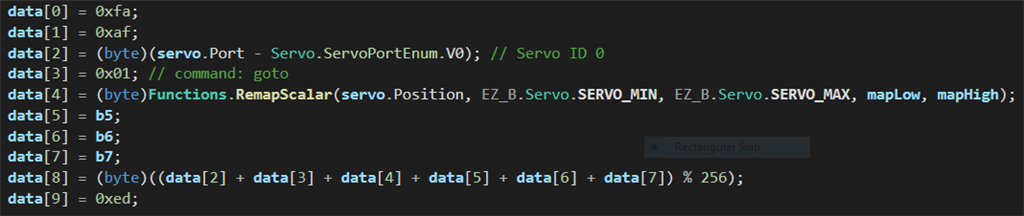

Protocol Packet Code Here's a copy and paste from the plugin code. This is how the packet is being assembled to be sent to each servo. The values specified by you in the configuration menu are b5, b6, b7, mapLow and mapHigh.

Does someone know about UBTECH Alpha 1S robot and its possible use with EZB ? What kind of servos and servo protocols does it use ? I can get it for a low price and I would like to use it with EZB , my beloved controller.

Look at the description in the top of this message - there's instructions on how to connect and use the UBTech servos with the EZ-B and ARC

OK, DJ. No doubt you had an answer for any robot issue ! I have EZB V4, but never used UART communication, only usual PWM servo control. I'll probably ask for some support when I get the ubtech robot.

I don't have any experience with that robot - nor have i used the servos. There's a link in the description to a thread on this servo type, you can re-visit that thread and see if anyone there can help. I won't be able to assist any further than this

OK. There are many people working on that issue and information in that link.

Geez that robot looks fairly tall and fast in a youtube demo ,wondering if it could still be hacked to be even taller without effecting the center of Gravity (The arch enemy of all tall robots). Oh wait no that's just a camera trick I saw,put the camera Low down and you can make any robot look Gigantic. I saw another video that showed JD in the background about the same height so it does look like there is a height barrier to getting a tall one at a reasonable price unless you design one for yourself that is.

Hi, robo rad, the exact height of alpha 1S is 398 mm (ubtech specs). servo speed and torque are similar to usual servos (0.198 s x 60, 12 kg.cm at 8.5 V). But it performs high speed and stability. What's the secret ? Probably the sophisticated design of the control system, taking in consideration weights, inertia,etc. for that specific mechanical structure. I made a 720mm tall robot , similar to JD, simply actuating powerful servos (Hitec HS 805BB) as required, but it's much slower and unstable !

I am students from indonesia, i have read your command in forum" how to control UBTECH servo's 12 HC for Alpha 1s, can you help me show to control them, i need this to do my project, so that i can finish my bachelor education.

thank you for attention