Arduino UNO wheel encoder interface: reads left/right encoder ticks, outputs wheel counts, configurable for accurate NMS pose telemetry and SLAM.

How to add the Wheel Encoder Counter robot skill

- Load the most recent release of ARC (Get ARC).

- Press the Project tab from the top menu bar in ARC.

- Press Add Robot Skill from the button ribbon bar in ARC.

- Choose the Navigation category tab.

- Press the Wheel Encoder Counter icon to add the robot skill to your project.

Don't have a robot yet?

Follow the Getting Started Guide to build a robot and use the Wheel Encoder Counter robot skill.

How to use the Wheel Encoder Counter robot skill

This skill is compatible with Arduino UNO firmware that counts wheel rotation for left and right wheels.

Firmware

This robot skill requires supporting capability on the EZB with firmware. The firmware is open-source so that you can modify it for different Arduino's and microcontrollers. The Wheel Encoder Arduino UNO firmware can be found here: https://synthiam.com/Firmware/Wheel-Encoder-Firmware-NVXCXGPCQMJ

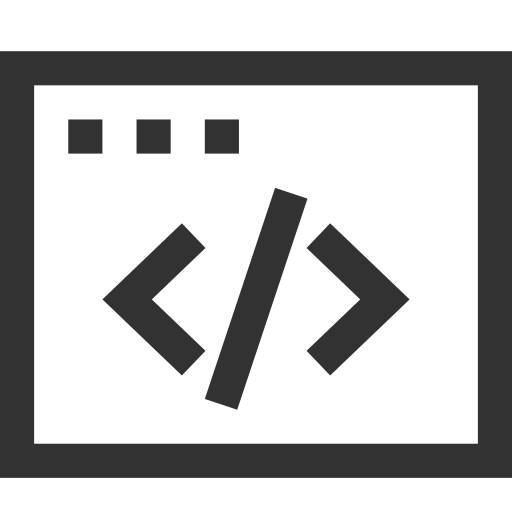

Main Window

1. Get Wheel Values Button Manually requests the encoder values for each wheel. Please do not use it when pushing to NMS because this is done automatically with an interval timer.

2. Reset Values Button Resets the encoder values back to zero. Please do not use it when pushing to NMS because it will break the current pose.

3. Get Wheel Values & Reset Button Resets the encoder values back to zero then starts acquiring the encoder values again. Please do not use it when pushing to NMS because this will break the pose.

4. Status Display When the debug checkbox is checked, this will display a text readout of the encoder values.

Configuration

Settings - General

Poll Interval How often to poll the wheel encoder values from the Arduino.

Display debug information This will display the wheel encoder values to the log file for debugging in real-time.

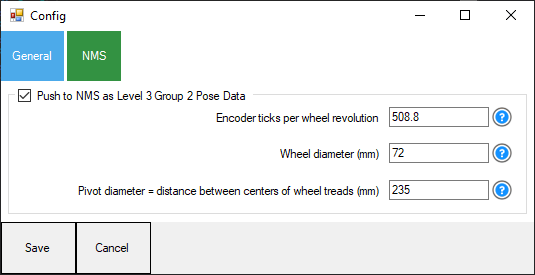

Settings - NMS

Push to NMS Enabling this checkbox will push the data to the NMS as a Level 3 Group 2 sensor, updating the robot's positioning pose telemetry.

Encoder ticks per wheel revolution How many encoder ticks for one revolution of the wheel. This is used for the NMS pose calculation if enabled.

Wheel diameter (mm) The diameter of the wheel is in millimeters. This value must be precise because it is important to the pose calculation. If it is off by 1 mm, it will produce errors in the calculation. If you are using a known wheel product, use the datasheet to obtain the diameter. Otherwise, there are several methods to measure a wheel diameter. This is only used for the NMS pose calculation, if enabled.

Pivot diameter (mm) The distance between centers of wheel treads. Similar to the wheel diameter, this is absolutely important to be as accurate as possible. If using an existing robot product, consult the datasheet to obtain the pivot diameter, which is the distance between the center of each wheel tread. This value must be accurate and not have any errors. This is used for the NMS pose calculation.

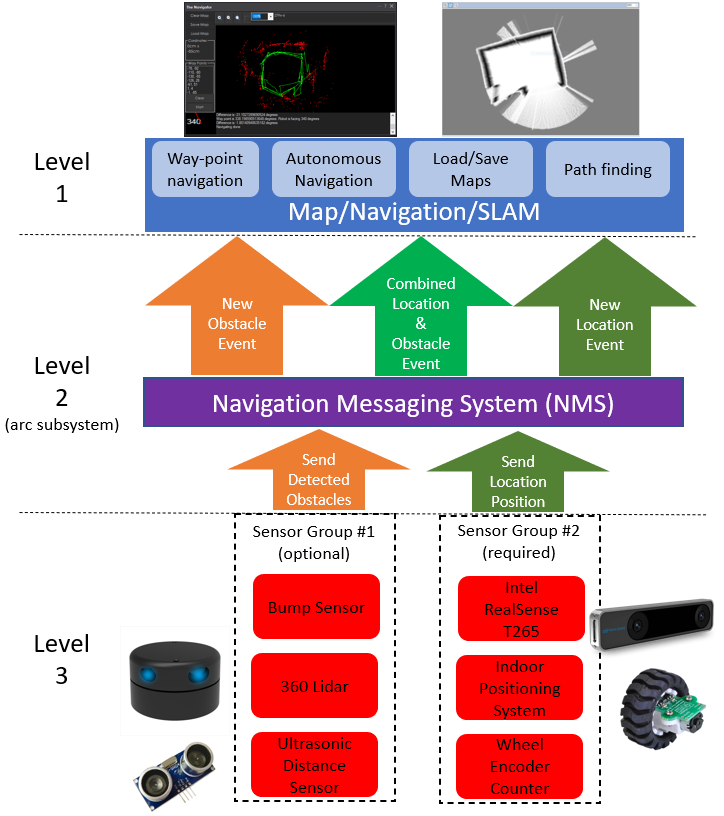

NMS

The Navigation Messaging System (NMS) is built into the ARC framework. It allows skills to push data (location & obstacle detection) into the messaging system. Then, mapping/navigation SLAM skills can subscribe to the navigation events. The NMS was designed to provide ARC users with transparent navigation. You do not have to write any complicated code because the robot skills will work for navigation and obstacle avoidance.How to Use Wheel Encoder Counter

Download the Arduino firmware onto a UNO (or edit for your Arduino version). The Wheel, Encoder Arduino UNO firmware, can be found here: https://synthiam.com/Docs/Hardware/Arduino-Genuino-Uno

Connect your wheel encoders to ports D2 (left wheel) and D3 (right wheel) on the UNO.

Add the Wheel Encoder Counter Skill (Project -> Add Skill -> Navigation -> Wheel Encoder Counter). Two script variables will now be created that hold each wheel's encoder values, respectively ($LeftWheelCount & $RightWheelCount). Or, you can enable the NMS checkbox in the configuration settings to push the pose to NMS as a Level 3 Group 1 sensor.

Connect the UNO to ARC.

Video

Resources

The Wheel Encoder Arduino UNO firmware can be found here: https://synthiam.com/Firmware/Wheel-Encoder-Firmware-NVXCXGPCQMJ

There is a ControlCommand() to reset the $LeftWheelCount and $RightWheelCount values or force-get the values on demand rather than automatically on a timer. Do not reset or manually poll the wheel count using the NMS because it will affect the current pose data.

You can see how this skill was created by watching the live hack event here: synthiam.com/HackEvent/Dj-s-5th-Live-Hack-Session-17578

Control Commands for the Wheel Encoder Counter robot skill

There are Control Commands available for this robot skill which allows the skill to be controlled programmatically from scripts or other robot skills. These commands enable you to automate actions, respond to sensor inputs, and integrate the robot skill with other systems or custom interfaces. If you're new to the concept of Control Commands, we have a comprehensive manual available here that explains how to use them, provides examples to get you started and make the most of this powerful feature.

Control Command ManualcontrolCommand("Wheel Encoder Counter", "GetValues") Query the EZB firmware and get the latest encoder values. Set the values to the NMS (if checked) and populate the global variables.

controlCommand("Wheel Encoder Counter", "GetValuesAndReset") Query the EZB firmware and get the latest encoder values. Set the values to the NMS (if checked) and populate the global variables, and reset the values to zero.

controlCommand("Wheel Encoder Counter", "ResetValues") Reset the counter values to zero.

Related Hack Events

Related Questions

What Is Really Needed For Indoor Navigation?

Arduino EZB Firmware To ARC Communication

Upgrade to ARC Pro

Discover the limitless potential of robot programming with Synthiam ARC Pro – where innovation and creativity meet seamlessly.

Source Code

Source Code

YES! Very nice.

It was a post several years back about motors and wheel encoders. I believe ToyMaker and Dave were discussing it. Toymaker had motors with 64000 clicks for just one wheel revolution.

How many clicks per/revolution do you think a Arduino can handle? If this makes any sense.

That seems quite high - of 64,000 ticks per rotation. The firmware associated with this plugin counts with an unsigned 16bit integer, so the maximum count is 65535 per wheel. It would be easy to change to 32bit unsigned integer, which the maximum count would be 4,294,967,295 ticks

To see how i made the firmware and plugin, watch this live hack event here: https://synthiam.com/HackEvent/Dj-s-5th-Live-Hack-Session-17578

Unable to find the answer to this, so here it is to you guys. I have no experience encoders.

Motor add: This gear motor is a powerful 12V brushed DC motor with a 131.25:1 metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft, which corresponds to 8400 counts per revolution of the gearbox’s output shaft.

Since the encoder is on the back of the motor shaft does it only read the 64 counts per revolution? How can you tell, with accuracy what the counts per revolution is at the gearbox's output shaft?

Hope this is clear?

Yah - you answered yourself in the question . The shaft on the motor spins 131.25 times per 1 revolution of the output wheel shaft. Therefore if it’s 64 counts in a motor shaft revolution, you multiple 64 by 131.25 to get 8400. So if you used this arduino firmware, every 8400 counts is one wheel rotation.

. The shaft on the motor spins 131.25 times per 1 revolution of the output wheel shaft. Therefore if it’s 64 counts in a motor shaft revolution, you multiple 64 by 131.25 to get 8400. So if you used this arduino firmware, every 8400 counts is one wheel rotation.

I understood all that. BUT (lol) The encoder reads the main shaft rotation (at rear) not the output shaft rotation. How does the encoder know where, lets say, count/click 8399 is at?

Does this make sense?

The encoder doesn't - you can't easily use an encoder as a servo, if that's what you're asking. If you're attempting to use a wheel encoded motor as a servo, you'd need to first initialize the position and start counting from there.

Are you asking to use a encoded motor as a servo?

Because an encoded motor is designed for odometry.. just like your car. To count the number of wheel rotations so you can increase the confidence of how far your robot has traveled for navigation purposes.

Understood

You said "To count the number of wheel rotations so you can increase the confidence of how far your robot has traveled for navigation purposes." So as I understand, if it counts the number of clicks, say 32, we know that the motor has turned half way around.

Then why would I care anything about 8400 COUNTS at the OUTPUT shaft?

It seems to me the only important number here is the counts per rotation of the rear shaft.

MMMM I'm starting to even confuse myself here ... lol.