Control UBTECH Alpha UBT-12HC smart servos via ARC using EZ-B v4/IoTiny UART, assign virtual ports, set baud, custom bits and position mapping.

How to add the UBTECH Alpha Servos UBT-12HC robot skill

- Load the most recent release of ARC (Get ARC).

- Press the Project tab from the top menu bar in ARC.

- Press Add Robot Skill from the button ribbon bar in ARC.

- Choose the Servo category tab.

- Press the UBTECH Alpha Servos UBT-12HC icon to add the robot skill to your project.

Don't have a robot yet?

Follow the Getting Started Guide to build a robot and use the UBTECH Alpha Servos UBT-12HC robot skill.

How to use the UBTECH Alpha Servos UBT-12HC robot skill

Control the UBTECH Alpha Robot Digital smart Servos (UBT-12HC) with ARC. The servos must be powered appropriately, and connected to the EZ-B v4 or IoTiny with the respective port. Visit the Config menu of this plugin to view the port configuration.

The Virtual Ports (V0..V99) in ARC can be assigned to the UbTech servos.

UART Ports

This plugin requires the RX signal wire of the servo be connected to TX of the selected UART or digital port (if Software UART is selected on IoTiny)

Hardware UART is for the EZ-B v4 only. Do not use software UART on EZ-B v4. View the EZ-B v4 datasheet to identify the UART ports (0, 1, or 2). EZ-B v4 datasheet can be found here: https://www.ez-robot.com/Tutorials/Lesson/18

Software UART should only be used with IoTiny

Default baudrate of UBTECH servos is 115,200

Bind To Virtual Servos

- The configuration menu also provides an option to select the Virtual Ports, which correspond with the ID's of the UBTech servos. If the UBTECH servo ID #0 is connected, select V0. #1 = V1, #2 = V2, etc..

Additional Info

- Discussion on these servos is here: https://synthiam.com/Question/3932

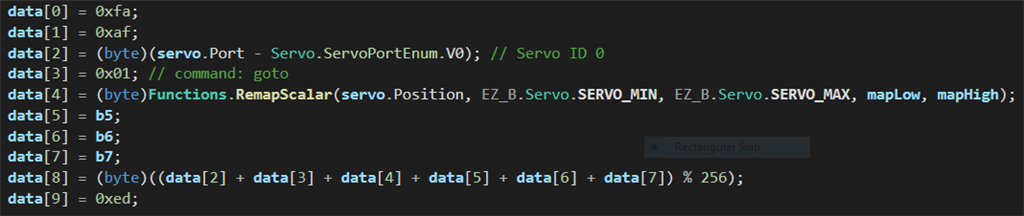

Custom Bit Settings There are 3 bits that seem to not be understood for the protocol. Since UBTech does not release the protocol for their products, the community is working to better understand what the parameters are. The configuration menu of this plugin allows you to set hardcoded values for those bits. The bits are for 5, 6 & 7.

Custom servo Position Mapping The UB Tech servos have their own position range, and we don't know what it is. So, the configuration menu allows you to specify the min and max positions for the range. This will be mapped to the ARC servo position range. Meaning, if you set the range in this plugin, it will be mapped to the range for all ARC servo controls.

Protocol Packet Code Here's a copy and paste from the plugin code. This is how the packet is being assembled to be sent to each servo. The values specified by you in the configuration menu are b5, b6, b7, mapLow and mapHigh.

the Bluetooth protocol header starts with 0xFB, 0xBF and the command code 1 is an handshake, the servo serial protocol starts 0xFA 0xAF and the servo position command is 1.

I have here the dynamixel serial protocol, maybe we can try ? Is also a serial servo protocol does it make sense to try ? No.

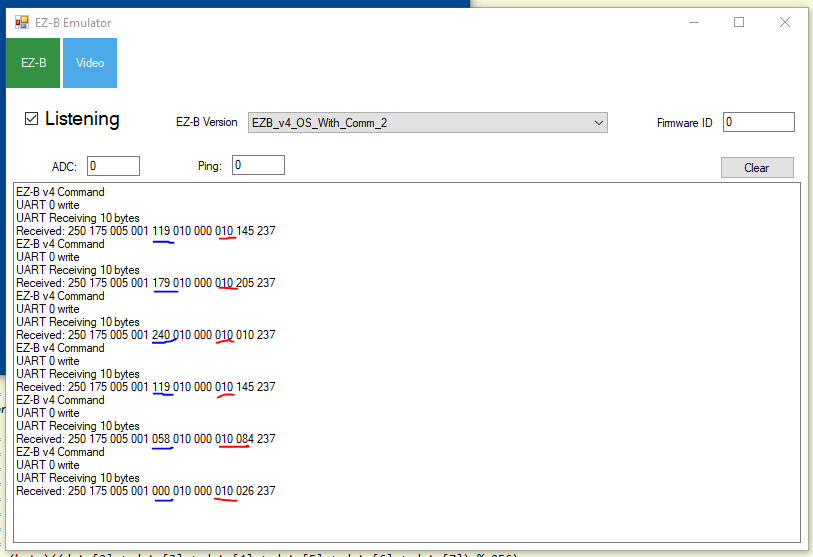

You should try the EZB emulator maybe you can check the bytes sent per action, and double check if they match the number of servos.

response to post 103. message length is variable. A message of 10 bytes is for positioning a single servo. 20 bytes is for positioning all 16 servos , giving all the angles. But, indeed, ezb sends much more than 10 or 20 bytes it sends about 170 ( I observed with an oscilloscope ). this makes servos not to work well.

I must go to bed. I'd be happy to go on tomorrow.

To summarize the only thing i see wrong is the servo range.

Please re-read my posts, you keep repeating the same thing based in different information.

Good luck with the emulator.

I'll summarize the relevant parts:

1) https://alexsonea.com/2017/10/15/jimu-hacking-the-communication-protocol/ this is relevant part:

based on the above information there is no parameter "running time", maybe you based your guess on the bluetooth protocol, but, if the things don't work don't blame the UBTECH.2) https://alexsonea.com/2017/10/24/jimu-hacking-the-communication-protocol-2/ https://videos.files.wordpress.com/BkEIYNwW/pgz3tqwos4279eeqz27xda_dvd.mp4

Based on the above information from the same source: 0 = 79 hex = 120 dec +45 = A5 hex = 165 dec +90 = D2 hex = 210 dec

Switching to ARC's plugin:

EZ-script to move the servos to the left 0, 45, 90, and right 0, -45, -90:

EZB serial output:

byte #8: I don't know why 10 is being sent when the safe (known) value is 01, without any other info I would stick with 1 to avoid unpredictable results.byte #4 blue is the position and i believe the value is wrong: for 3 positions tested in the video should be 120, 165, 210 and the plugin is sending 119 (close), 179, 240

If I'm wrong please provide more information.