Finger Mechanisms For Servo Protection

Let's discuss designing a robot hand finger mechanism with mechanical and electronic compliance strategies to protect servos. Robotic hands frequently rely on small hobby servos to articulate individual fingers and perform grip actions. Because many of these servos do not support torque sensing, current monitoring, or stall detection, they can easily become overloaded when gripping objects. This can lead to stripped gears, overheating, premature wear, high power consumption, and unpredictable grip forces.

This article outlines multiple engineering approaches — mechanical and electronic — to protect servos from excessive load. Whether designing a simple 3D-printed gripper or a complex humanoid hand, these solutions help improve reliability, lifespan, and performance when used with Synthiam ARC.

Why Mechanical Compliance Is Critical

In the absence of torque feedback, a typical servo will attempt to reach its commanded position even when the finger cannot move further. When gripping an object, this can cause:

- Excessive torque leading to gear damage

- Stall conditions that overheat motors

- High battery drain

- Reduced servo lifespan over repeated cycles

- Inconsistent grip force

Mechanical compliance — a way for the system to “give” under stress — is one of the most effective methods to prevent damage. There are many ways to implement compliance, depending on design constraints and performance goals.

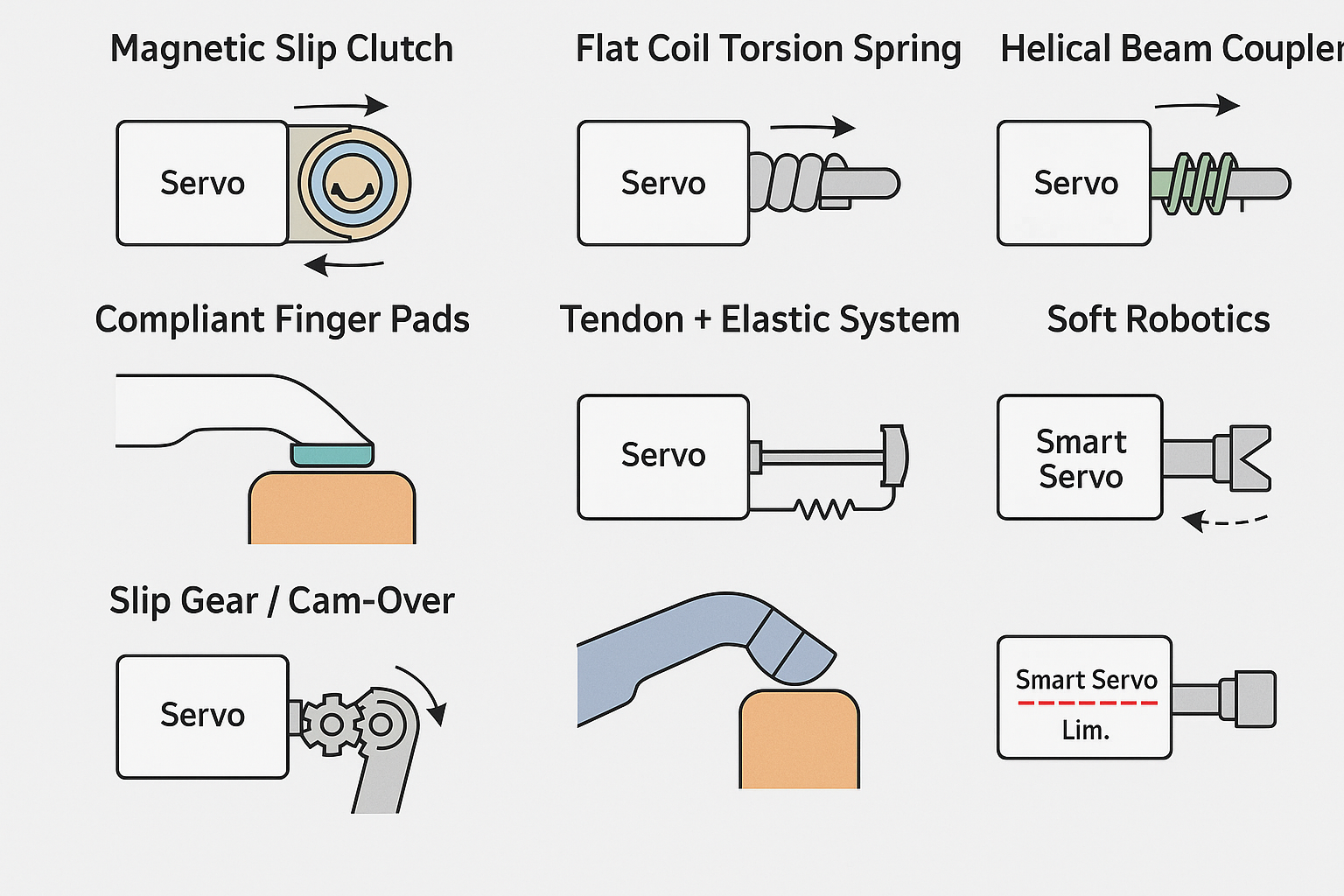

Mechanical Compliance Solutions

Below are multiple approaches you can integrate into a servo-driven finger design. Many can be mixed or layered for additional protection.

1. Magnetic Slip Clutch

This method uses two concentric plates with embedded magnets. Under normal operation, magnetic attraction keeps the plates coupled, transmitting torque. When the load exceeds a threshold, the plates slip, preventing servo overload.

Pros

- Excellent overload protection

- Low mechanical wear

- Smooth and predictable slip behavior

Cons

- Finger position becomes out of sync after slipping

- Requires mechanical stop at “fully open” for auto-realignment

- Larger axial space required

2. Flat Coil (Disc-Style) Torsion Spring

This compact disc-shaped spring functions like a clock spring. The inner hub connects to the servo; the outer ring connects to the finger. When gripping, the spring absorbs torque by twisting slightly.

Pros

- Compact and thin profile

- Maintains finger alignment (elastic deformation only)

- Smooth, gentle grip pressure

Cons

- Limited torque absorption range

- 3D-printed versions may fatigue over time

Works best in tight spaces such as humanoid hand knuckles or finger bases.

3. Helical Beam Coupler

A helical coupler (sometimes called a “beam coupler”) consists of a solid cylinder with a laser-cut or CNC-cut spiral pattern. This creates a flexible torsion section that can bend, twist, and absorb shock loads.

Pros

- Can flex in torsion, angular offset, and slight axial compression

- Maintains rotational connection without slipping

- Printable or easily purchased

Cons

- Longer axial length than a disc spring

- Torque capacity depends on material and cut geometry

Ideal for finger joints that require both torsional and slight misalignment compensation.

4. Compliant Finger Pads and Gripper Surfaces

One of the simplest strategies is to add compression material where the finger contacts the object. This was used on the EZ-Robot JD grippers using foam inserts.

Materials include:

- High-density EVA foam

- Rubber pads

- Silicone inserts

- TPU-printed flexible pads

Pros

- Easy to implement

- Improves grip stability and traction

- Reduces peak load on servos

Cons

- Limited torque absorption

- Does not protect from full stalls

5. Slip Gears / Cam-Over (Detent) Mechanisms

In a cam-over gear, the gear “jumps” teeth or disengages when the torque exceeds a threshold. This protects the servo by mechanically limiting force.

Pros

- Strong overload protection

- Simple mechanical concept

Cons

- Produces audible clicks when triggered

- Finger will lose tracking until reset

This is commonly used in consumer torque-limited screwdrivers and some industrial grippers.

6. Tendon-Driven Fingers with Elastic Back-Tension

Instead of directly mounting fingers to servo horns, many hands use tendons (cables) to pull the fingers closed. An elastic or spring-loaded mechanism pulls the fingers open.

Pros

- Cables naturally slip when overloaded

- Servos are isolated from impact loads

- Allows very compact finger joints

Cons

- Cable stretch must be calibrated

- Finger position tracking requires careful tensioning

This mimics biological tendons, making it popular in humanoid robotics.

7. Soft Robotics Finger Elements

Soft robotics uses silicone, TPU, or pneumatic structures instead of rigid linkages. These are inherently compliant and protect servos by absorbing forces.

Pros

- Virtually impossible to damage a servo through gripping

- Human-safe and forgiving

- Conforms naturally around objects

Cons

- Lower precision without sensors

- Requires entirely different design philosophy

A hybrid rigid/soft design can combine precision with safety.

Electronic and Software-Based Protection

Mechanical solutions are ideal, but electronics and firmware can also help prevent overload.

8. Smart Servos with Torque Sensing

Upgrading to “smart servos” provides built-in torque feedback and overload protection. Many digital servo ecosystems (e.g., Dynamixel, LewanSoul/HiWonder LX series, Robotis, Hitec D-series, etc.) offer:

- Torque limiting

- Temperature monitoring

- Stall detection and shutdown

- Current monitoring

- Closed-loop position control with feedback

Pros

- No need for mechanical clutches

- Precise grip force control

- Highly reliable and long-lasting

Cons

- More expensive

- Sometimes larger than hobby servos

Synthiam ARC supports many smart servo families directly or through robot skill plug-ins.

9. External Current Limiting or Servo Drivers

Adding a current-limiting driver board or using custom electronics can prevent servo burnout by reducing voltage or cutting power during overload.

Examples:

- Electronic current-limited servo controllers

- MOSFET-based stall detectors

- Thermal fuses on servo power lines

While not as precise as torque sensors, these methods still protect the servo during severe stalls.

10. Software-Based Grip Control in ARC

Even without special hardware, Synthiam ARC can improve servo safety through scripting and timing.

Recommended practices:

- Use timed gripping: close the finger for a fixed duration rather than commanding a full rotation.

- Insert small delays between incremental position commands.

- Use

ServoReleaseafter completing grip actions to prevent constant force loading. - Create safe zones, limiting fingers to positions that do not cause servo stall.

Software mitigation does not replace mechanical compliance, but it further reduces wear.

Comparison Summary

| Solution | Alignment Kept? | Protection Level | Complexity | Best Use Case |

|---|---|---|---|---|

| Magnetic Slip Clutch | Sometimes (requires reset) | High | Medium | High-force robotic hands |

| Flat Disc Torsion Spring | Yes (elastic only) | Medium | Low | Compact humanoid fingers |

| Helical Beam Coupler | Yes | Medium | Low/Medium | Fingers needing alignment flexibility |

| Compliant Pads | Yes | Low | Very Low | Simple grippers |

| Tendon + Elastic System | Yes | Medium | Medium | Human-like hand articulation |

| Smart Servos | Yes | Very High | Medium/High | Professional robotic hands |

Final Recommendations

Every robotic hand benefits from mechanical compliance to protect servo motors. For most 3D-printed hands, we recommend:

- Flat disc springs for compact compliance and alignment.

- Helical couplers for flexible and forgiving finger movement.

- Magnetic clutches for high load applications where slippage is acceptable.

- Smart servos if budget allows, providing built-in torque control.

- Compliant finger pads as a simple enhancement for grip comfort.

Combining multiple approaches often yields the best results. For example: a tendon-driven finger with a flat disc spring and compliant pads will have excellent durability, accuracy, and protection.

Before publishing STL files or deploying a robotic hand in a real environment, incorporating at least one overload-protection system is strongly recommended.