Hi all,

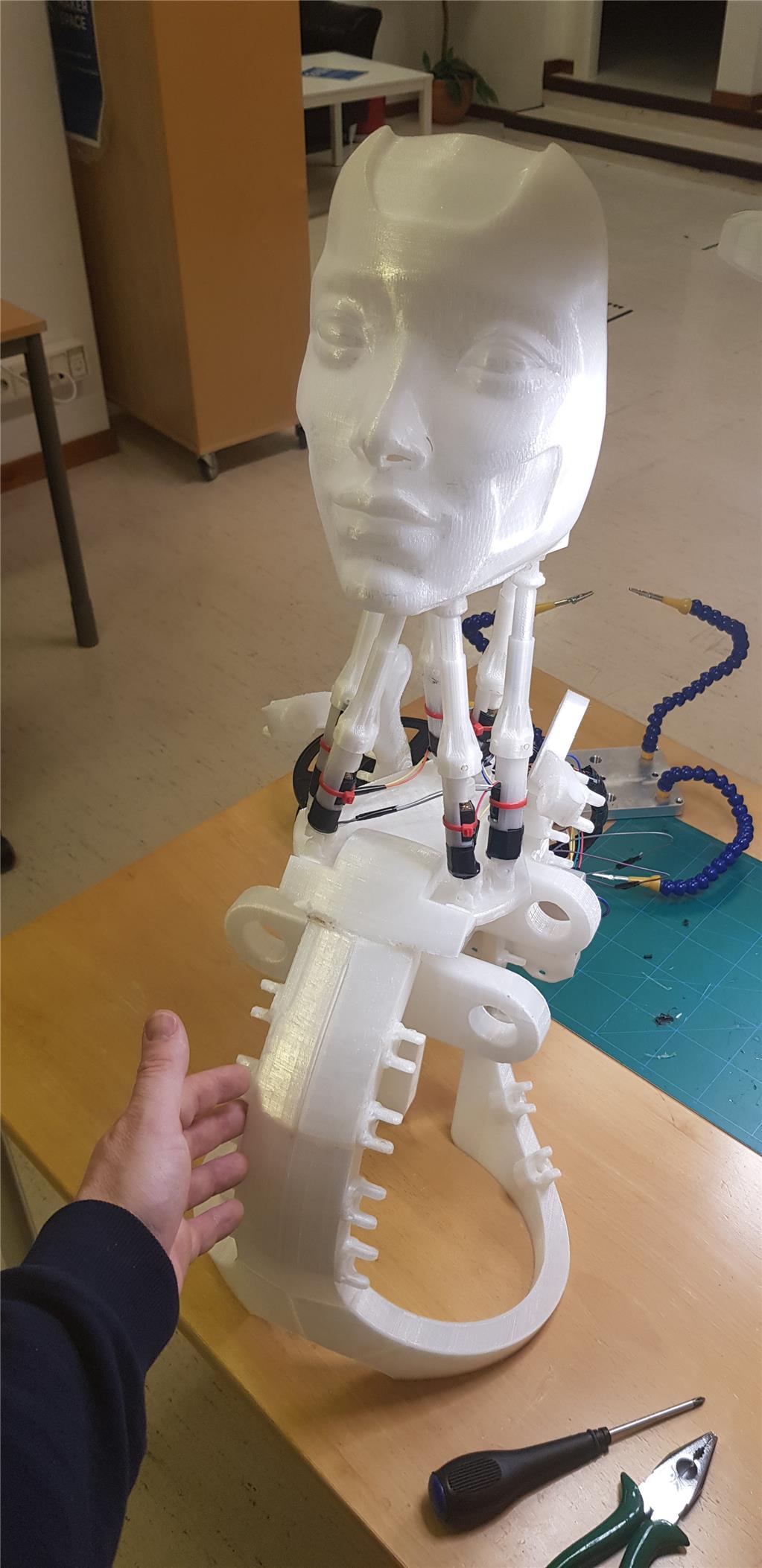

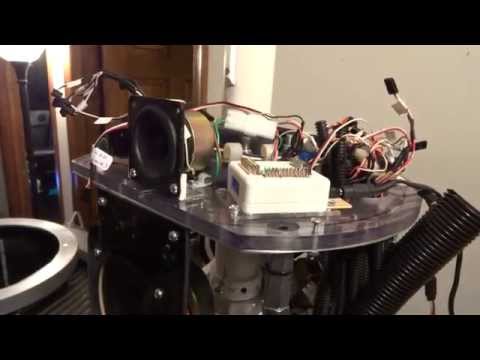

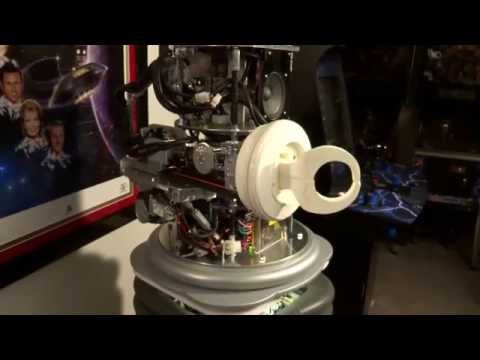

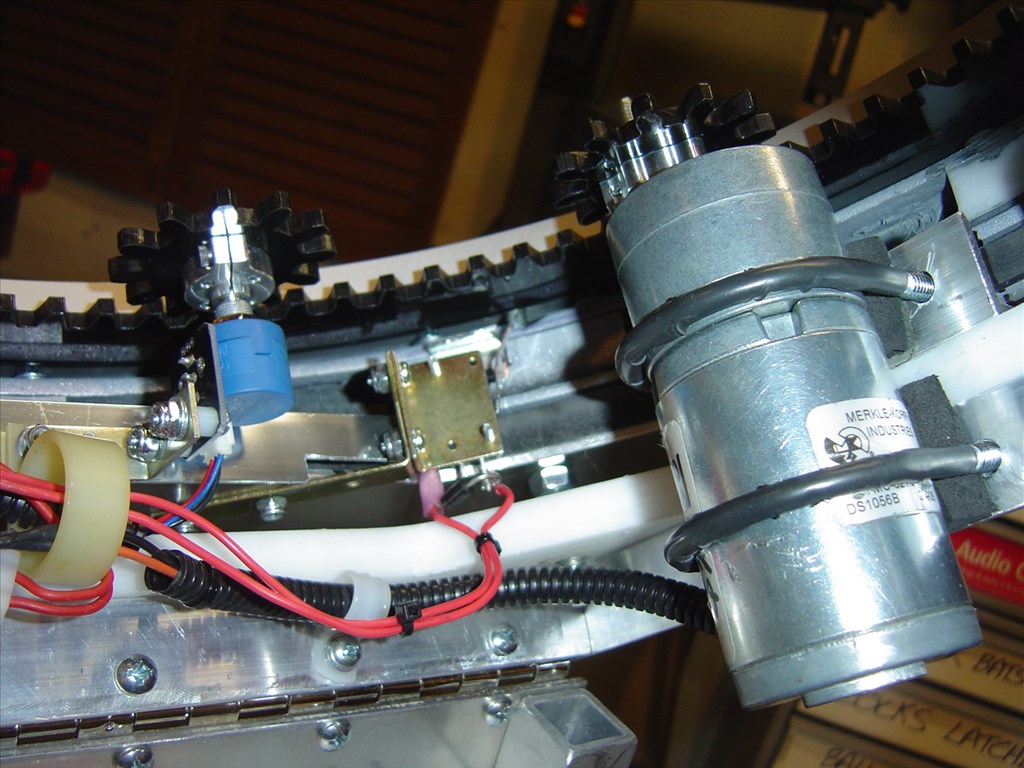

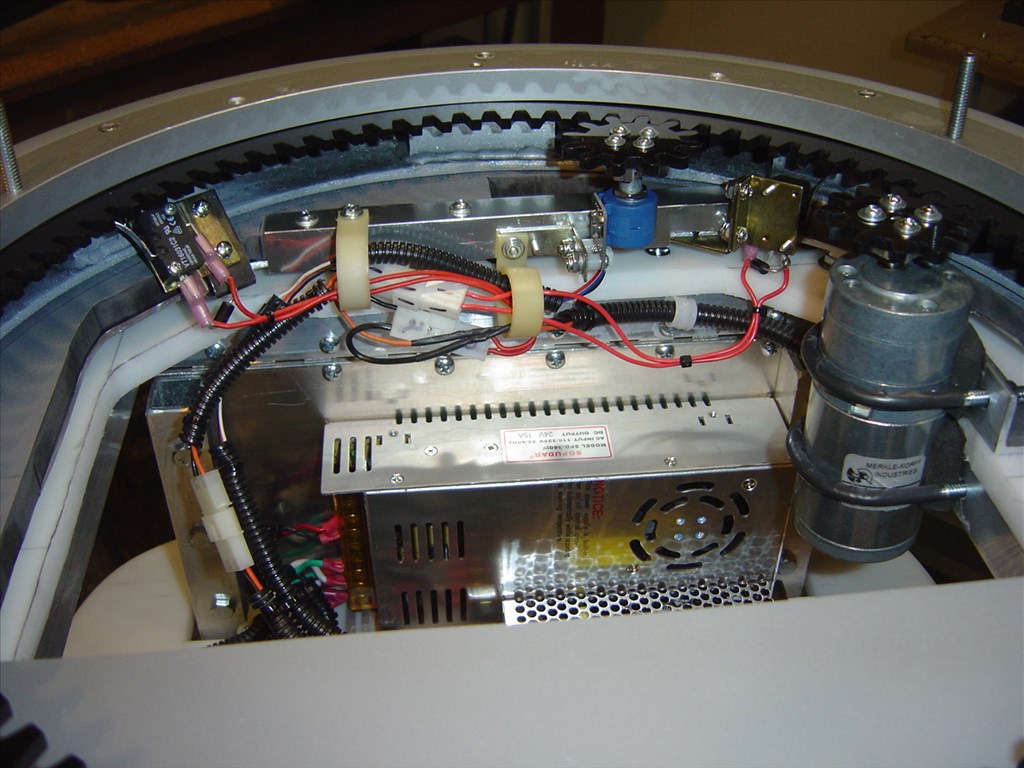

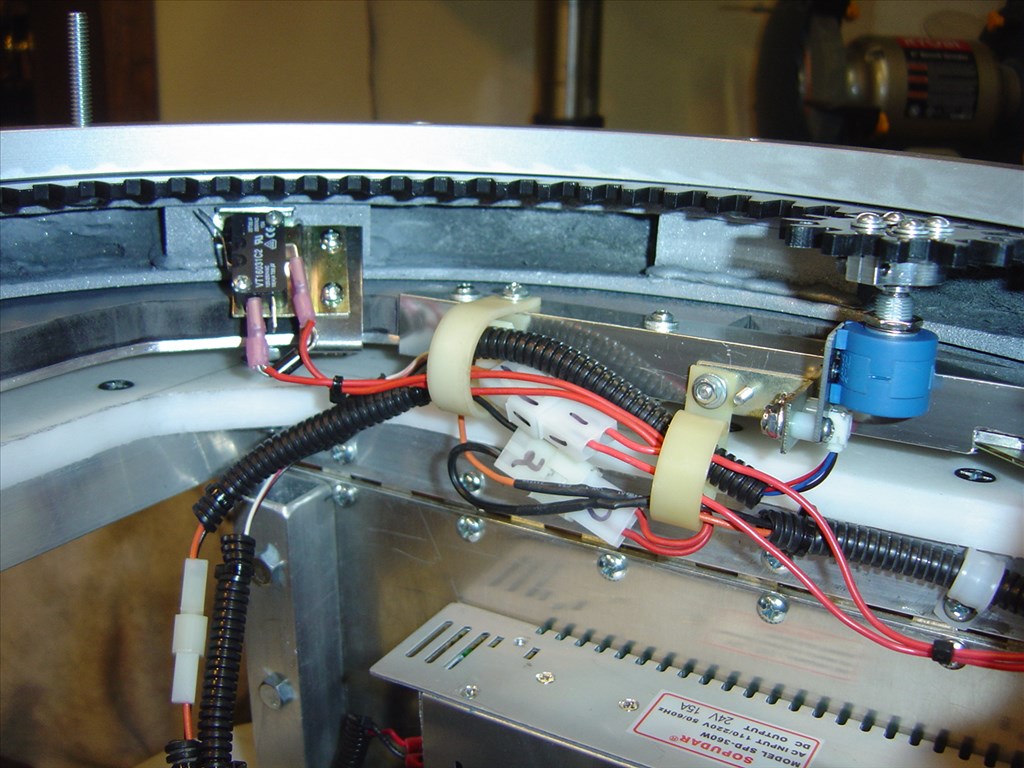

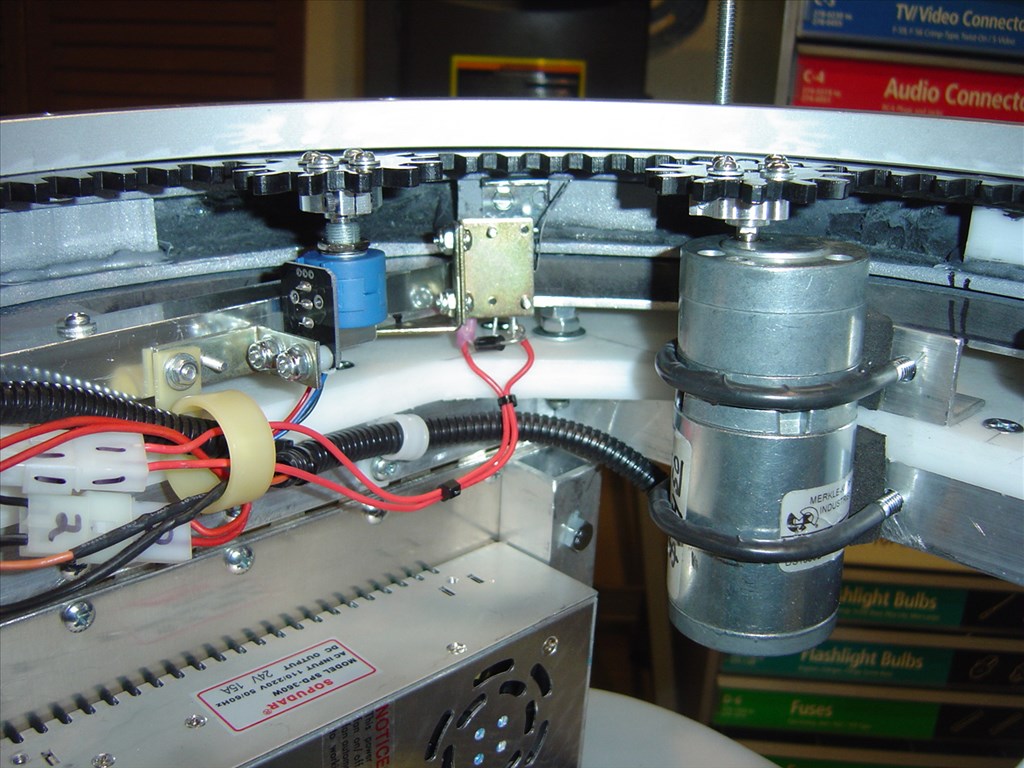

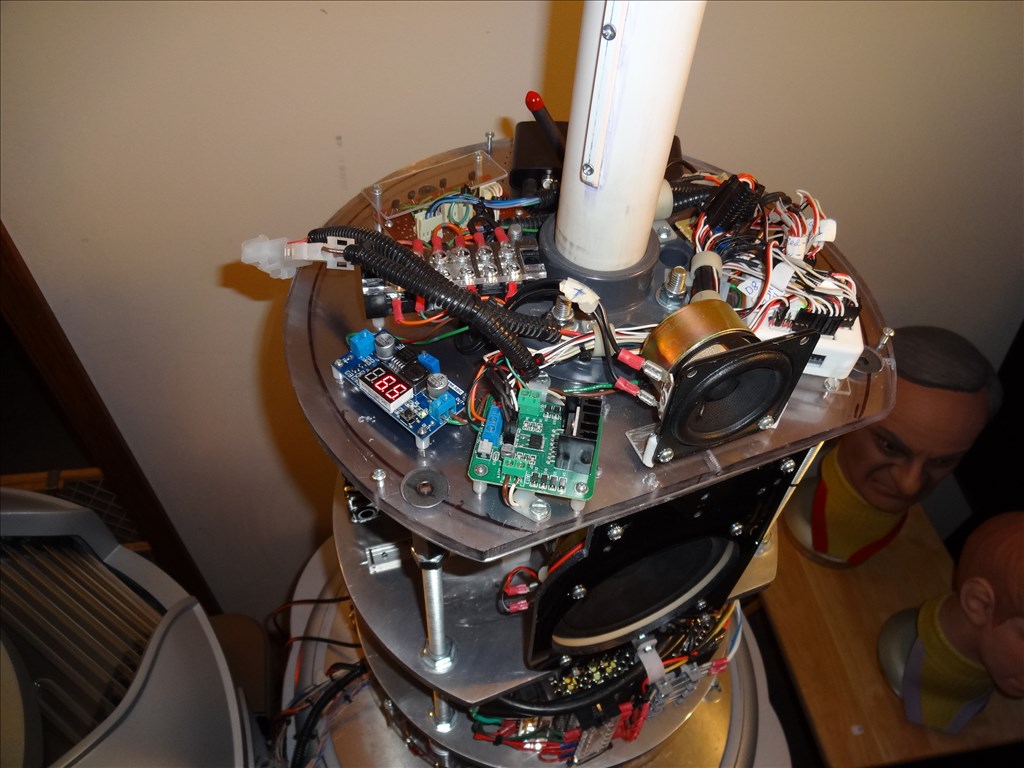

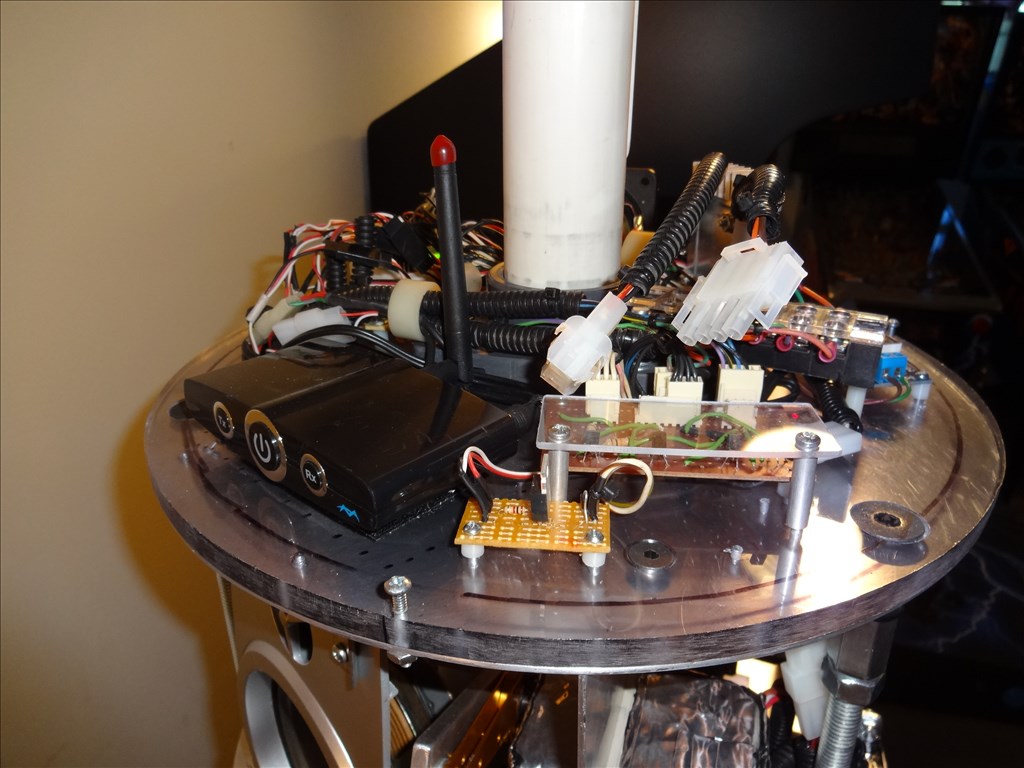

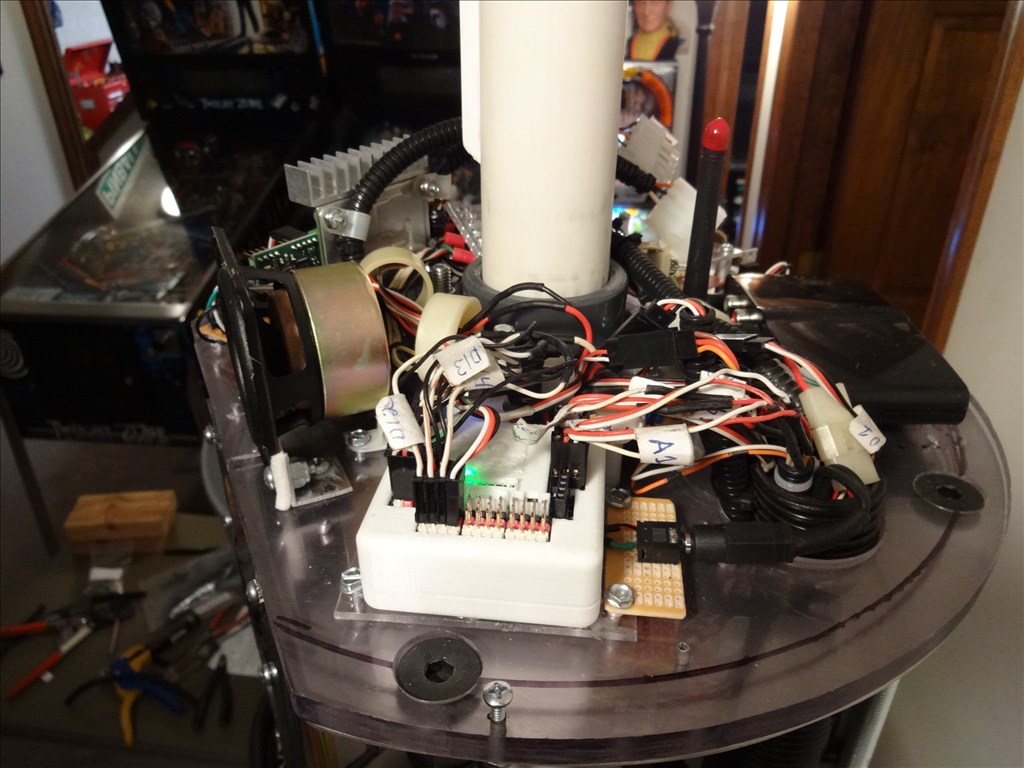

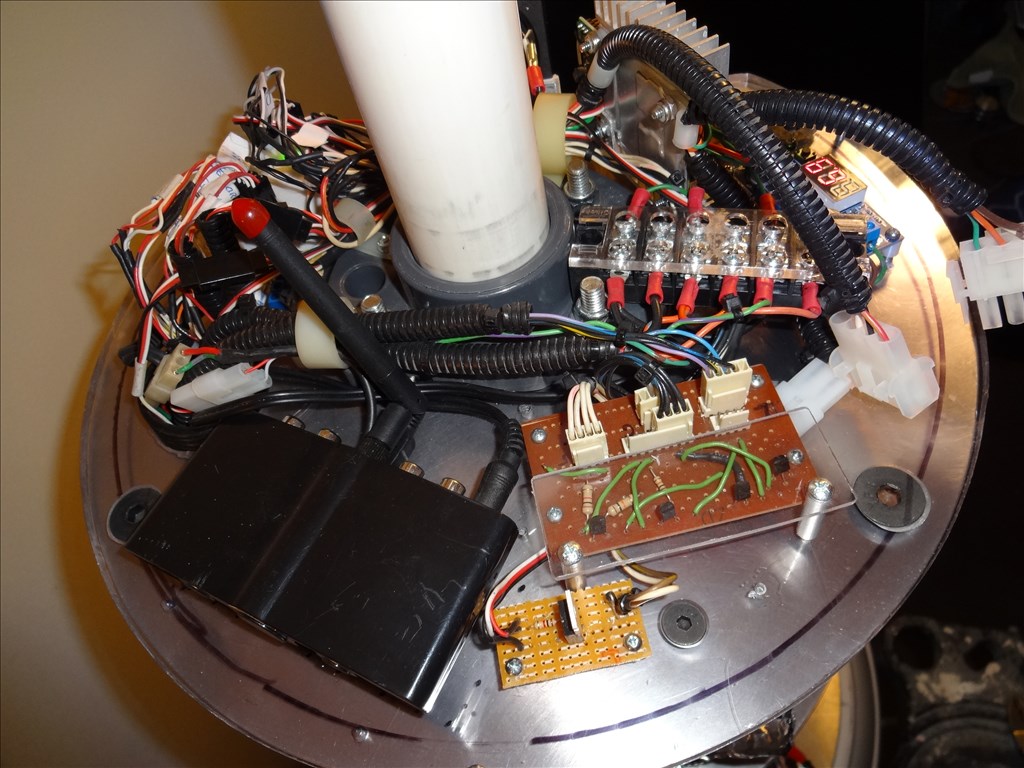

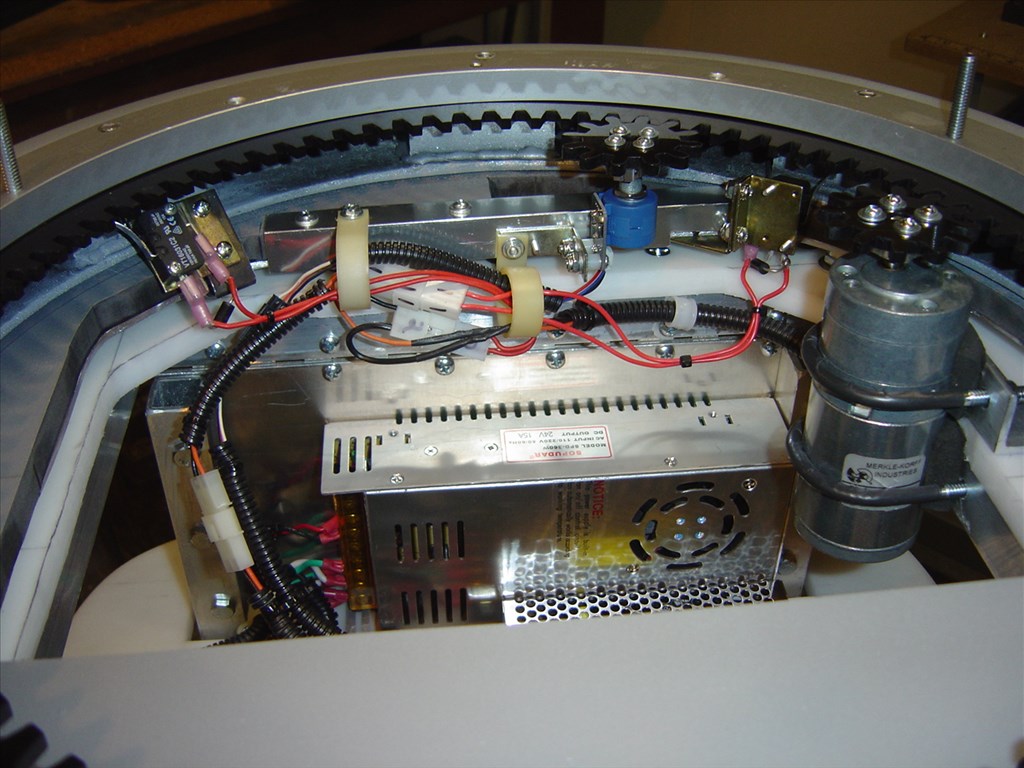

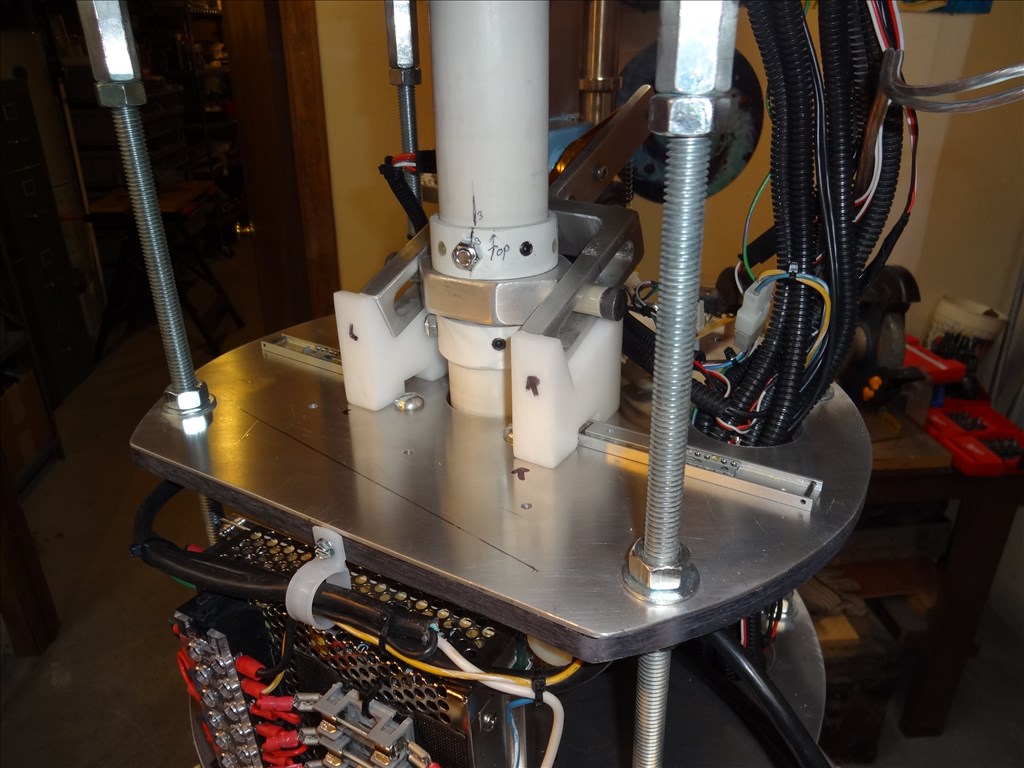

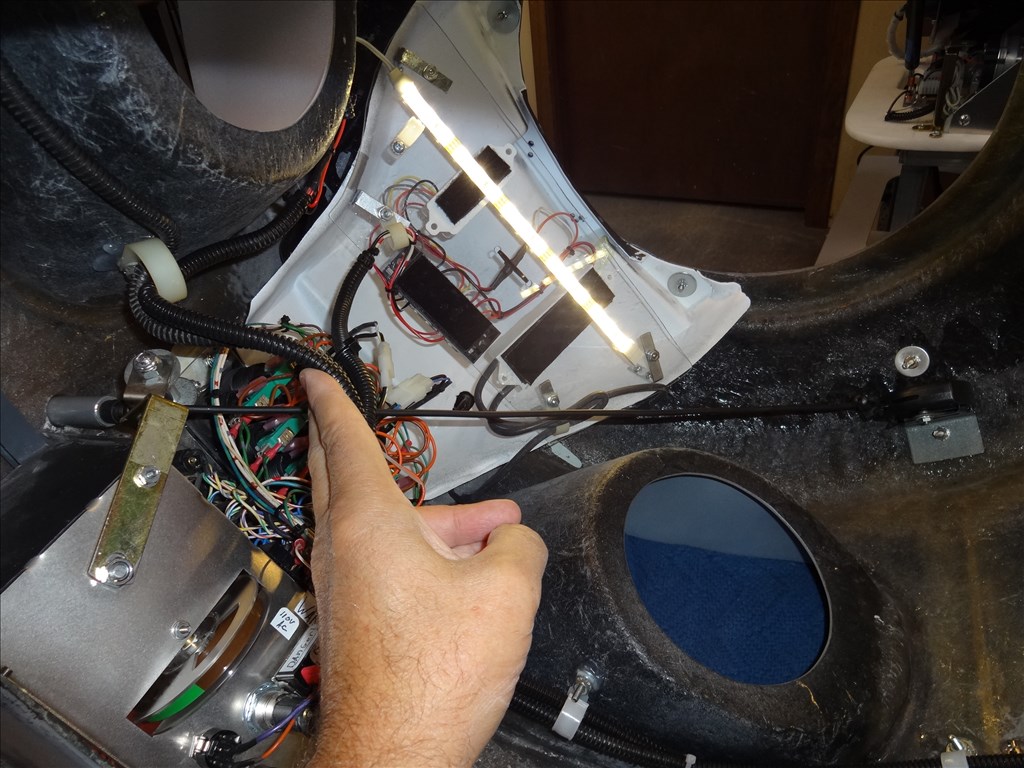

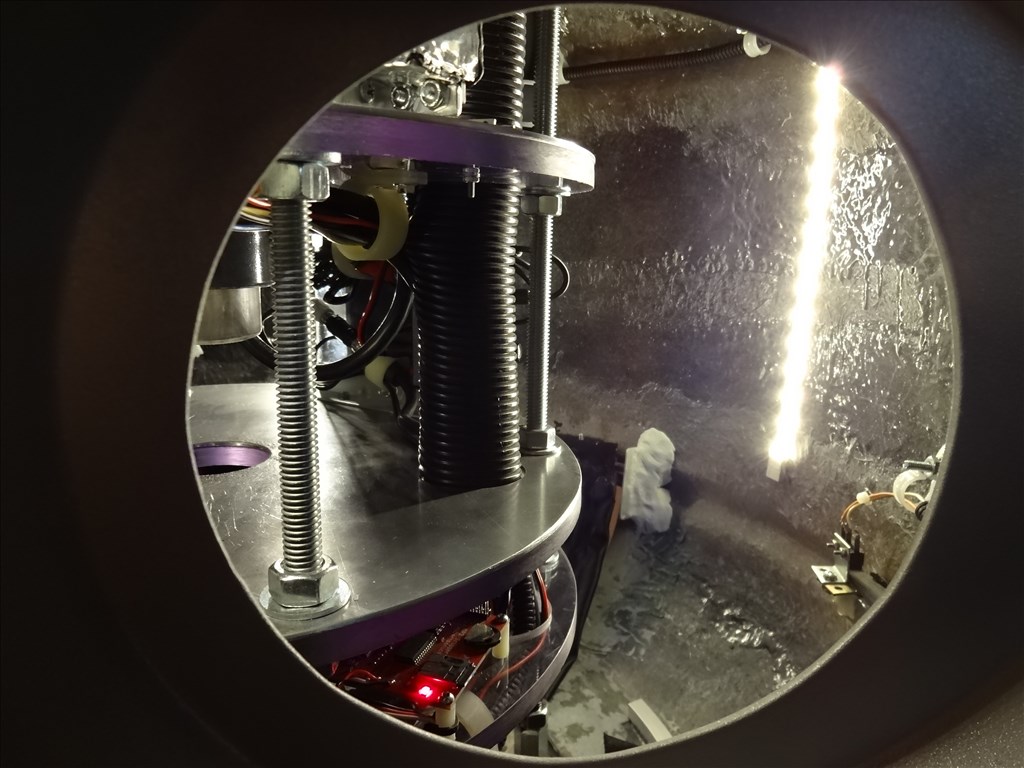

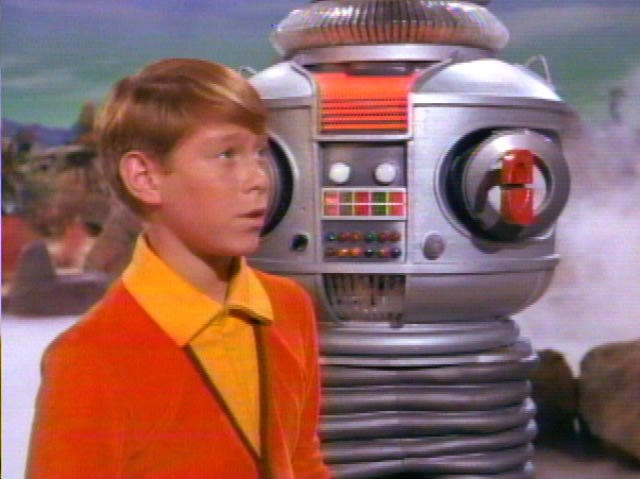

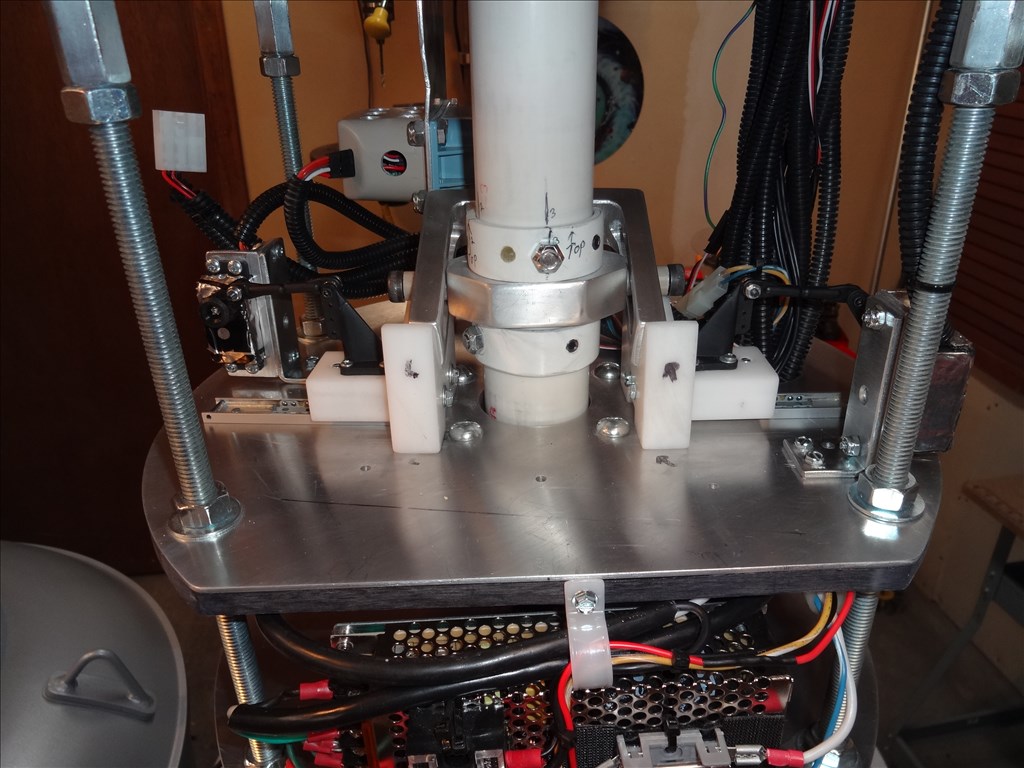

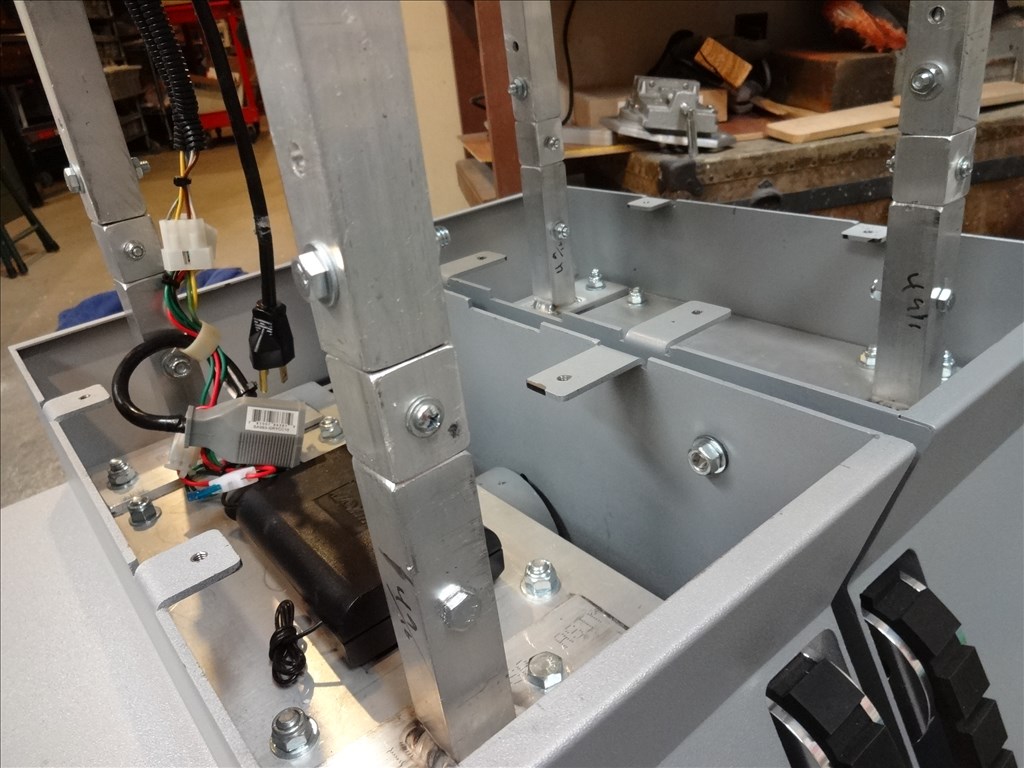

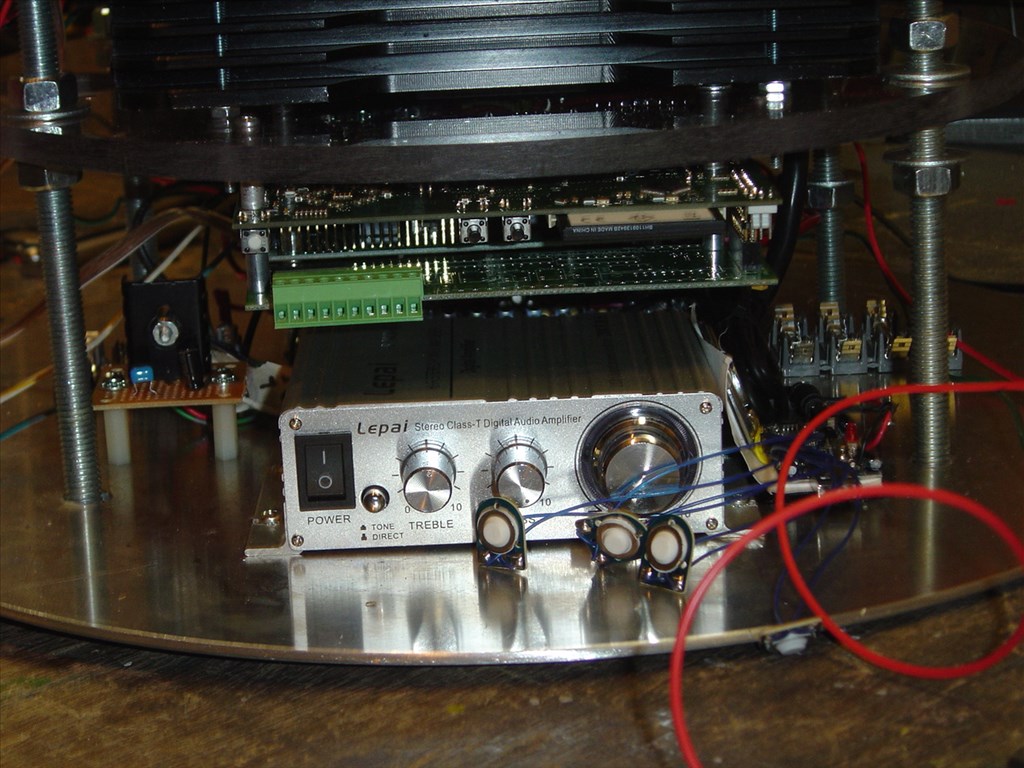

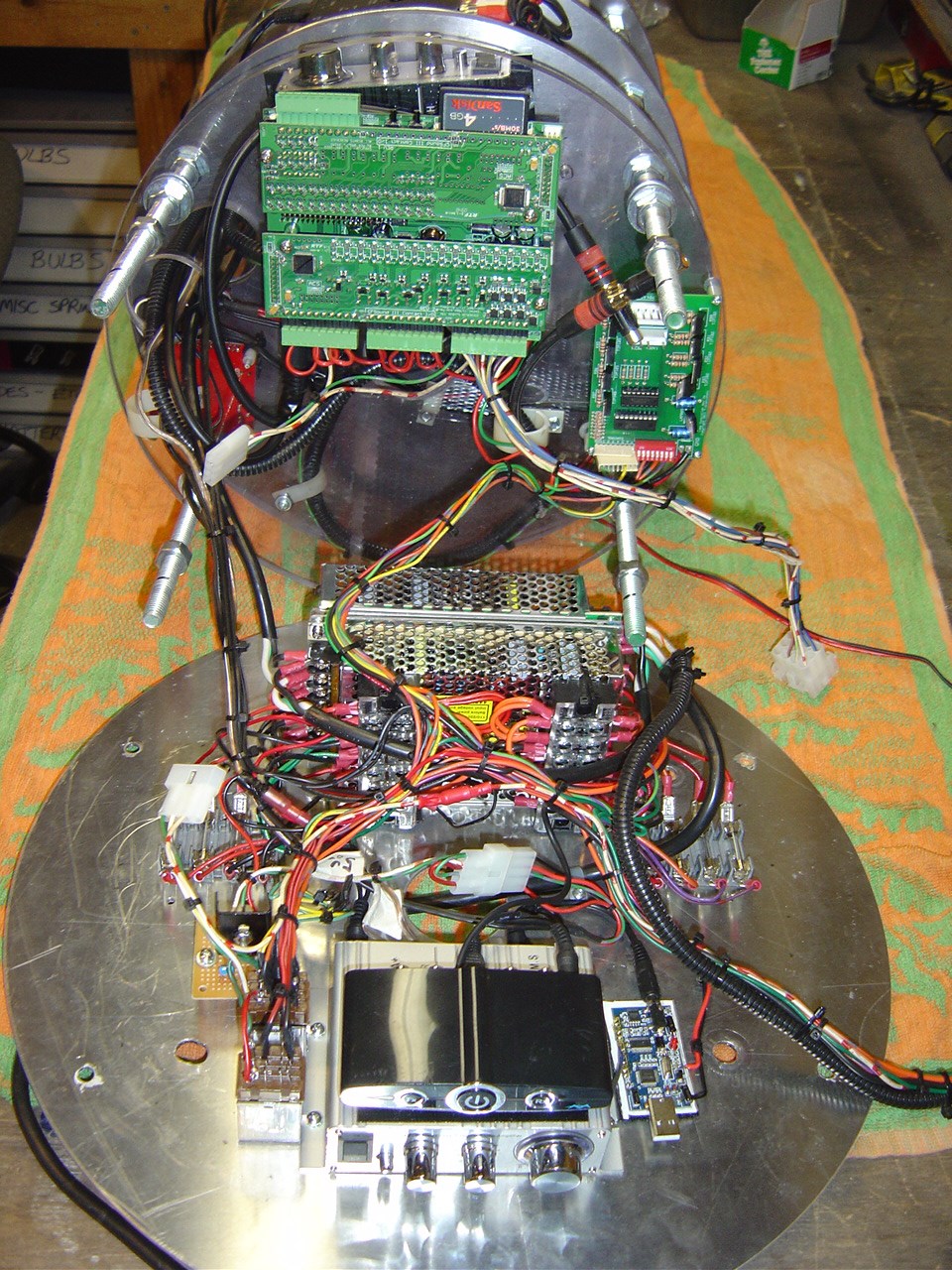

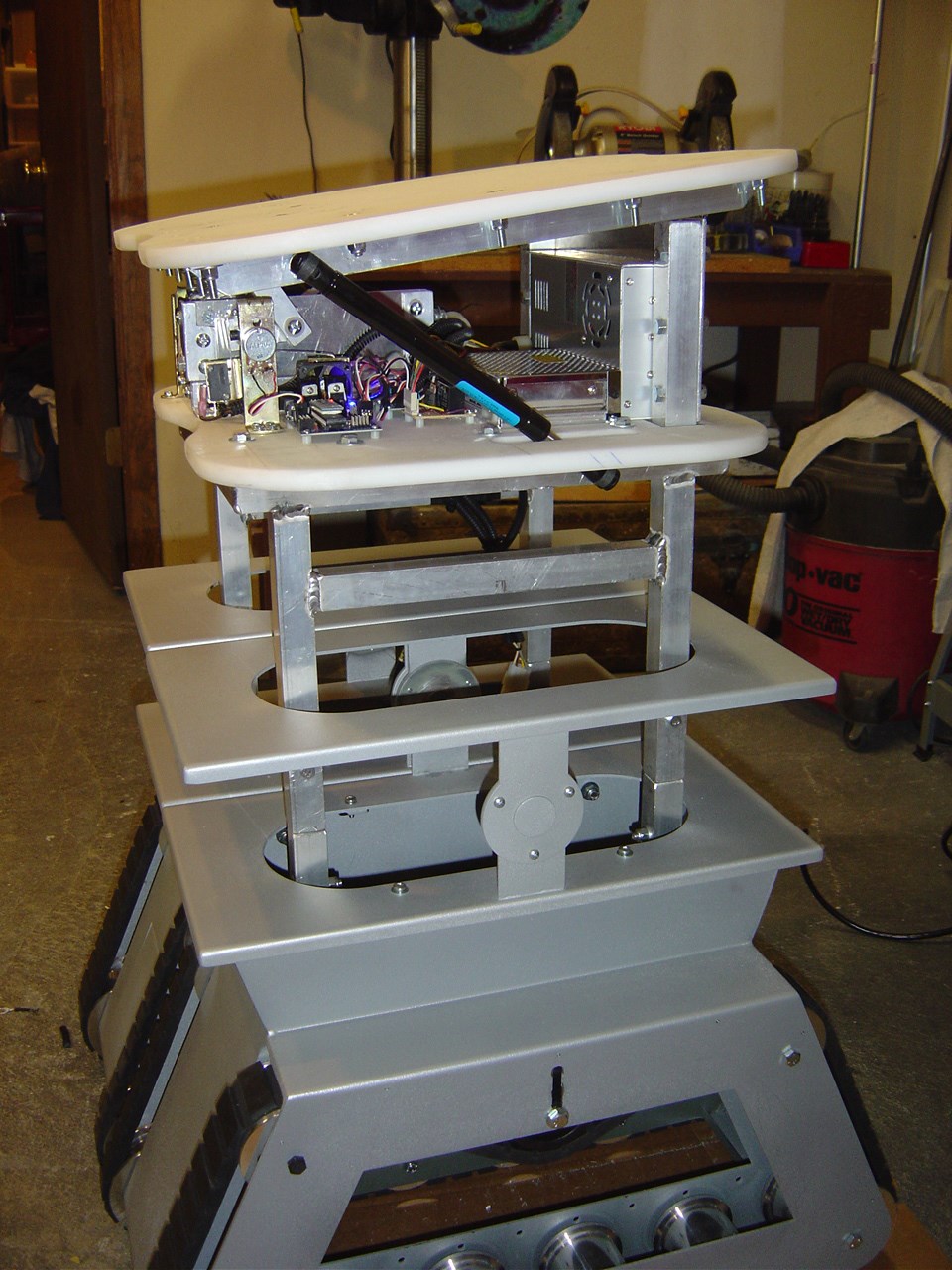

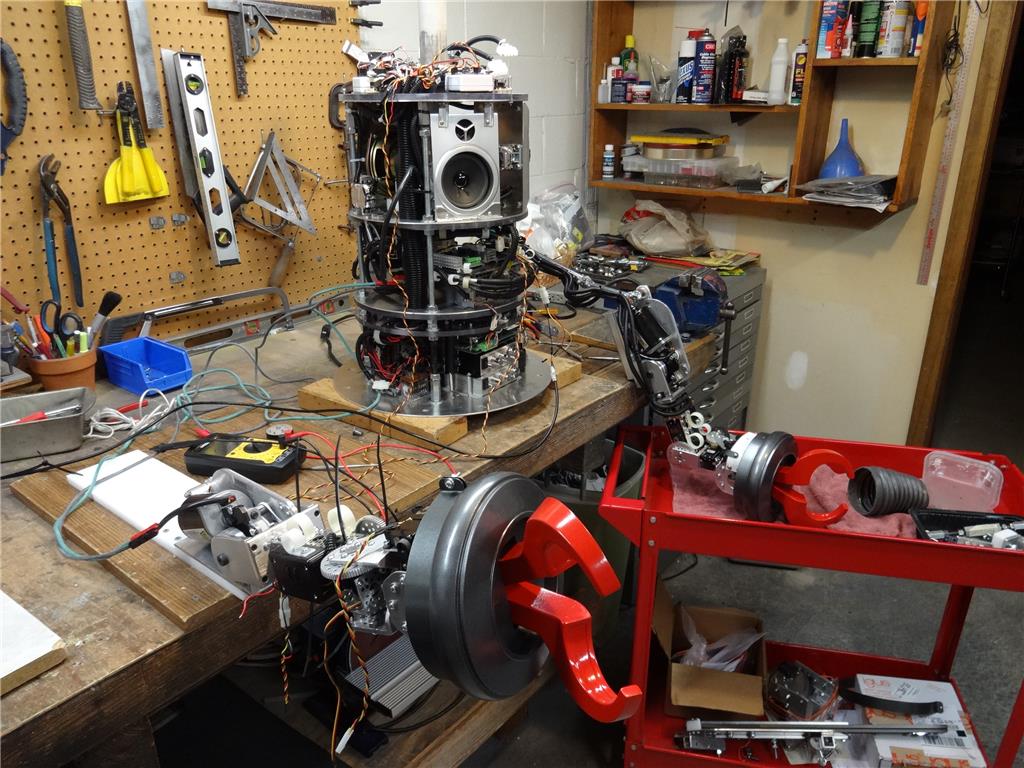

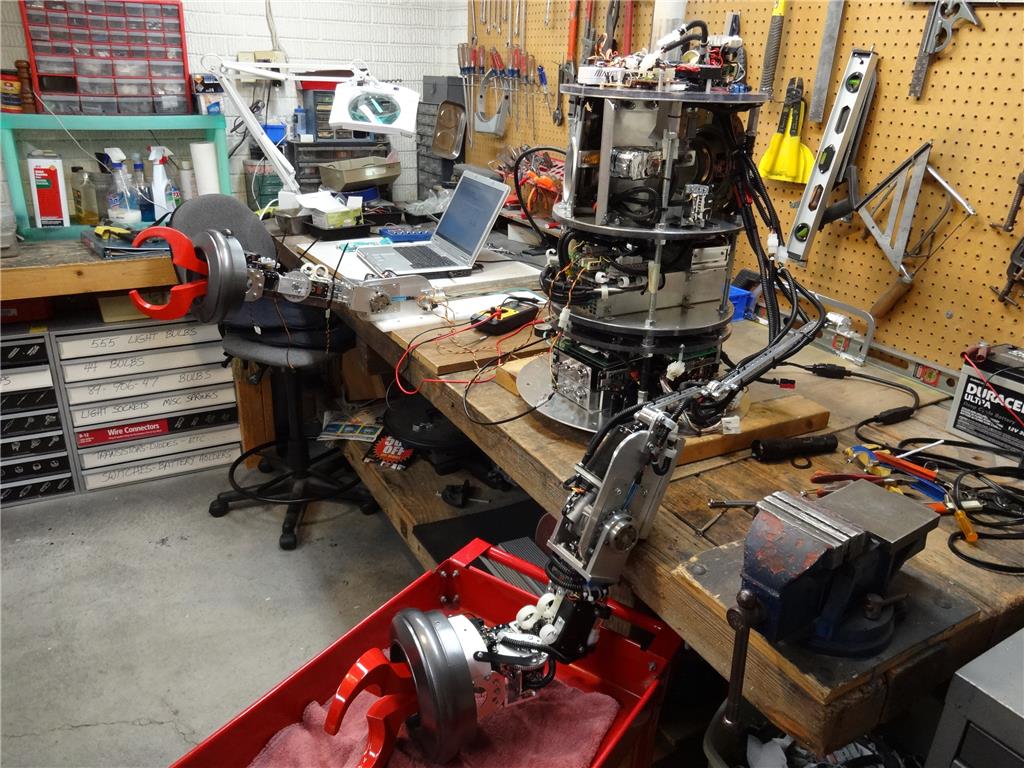

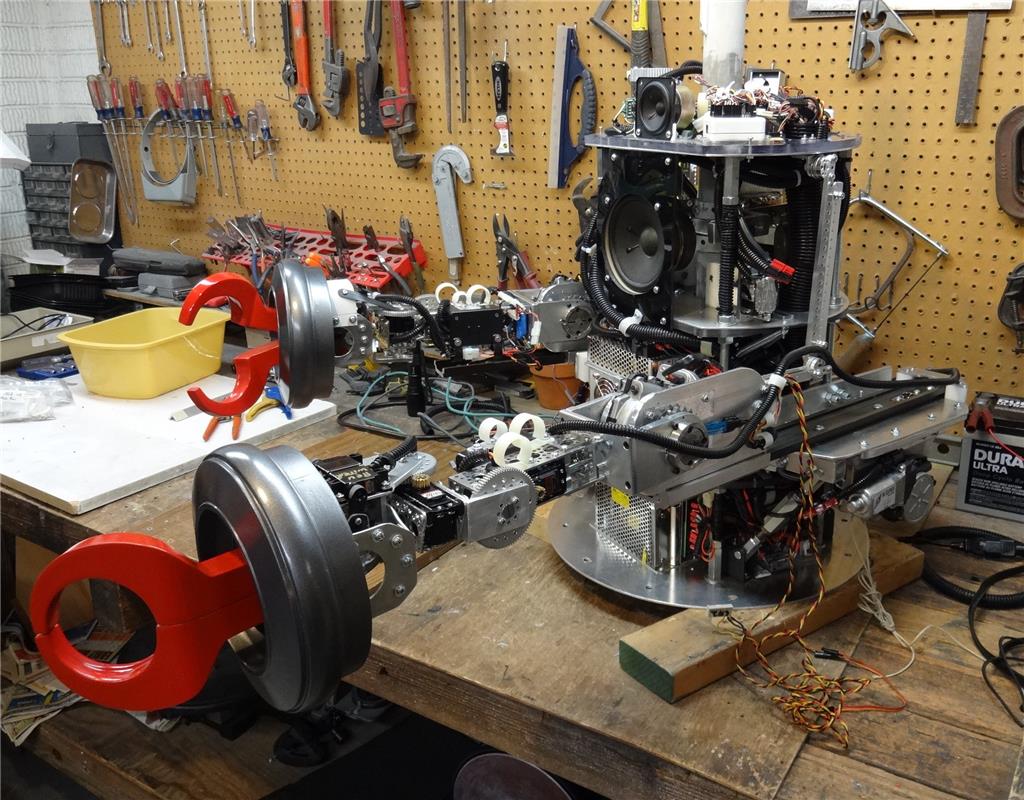

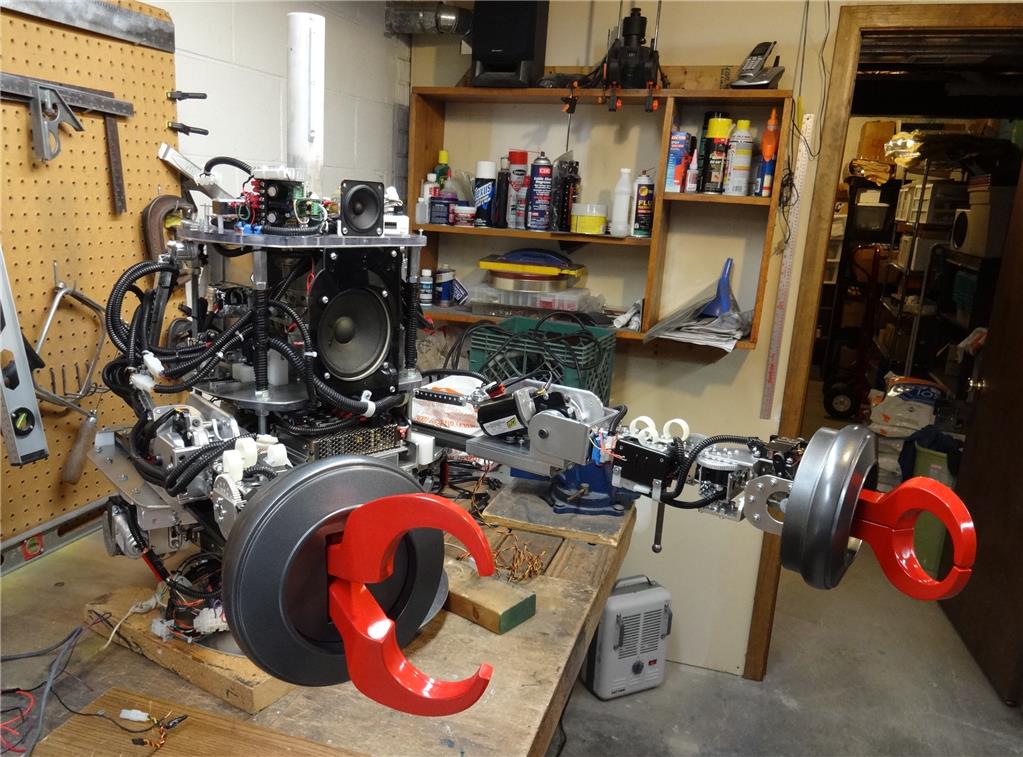

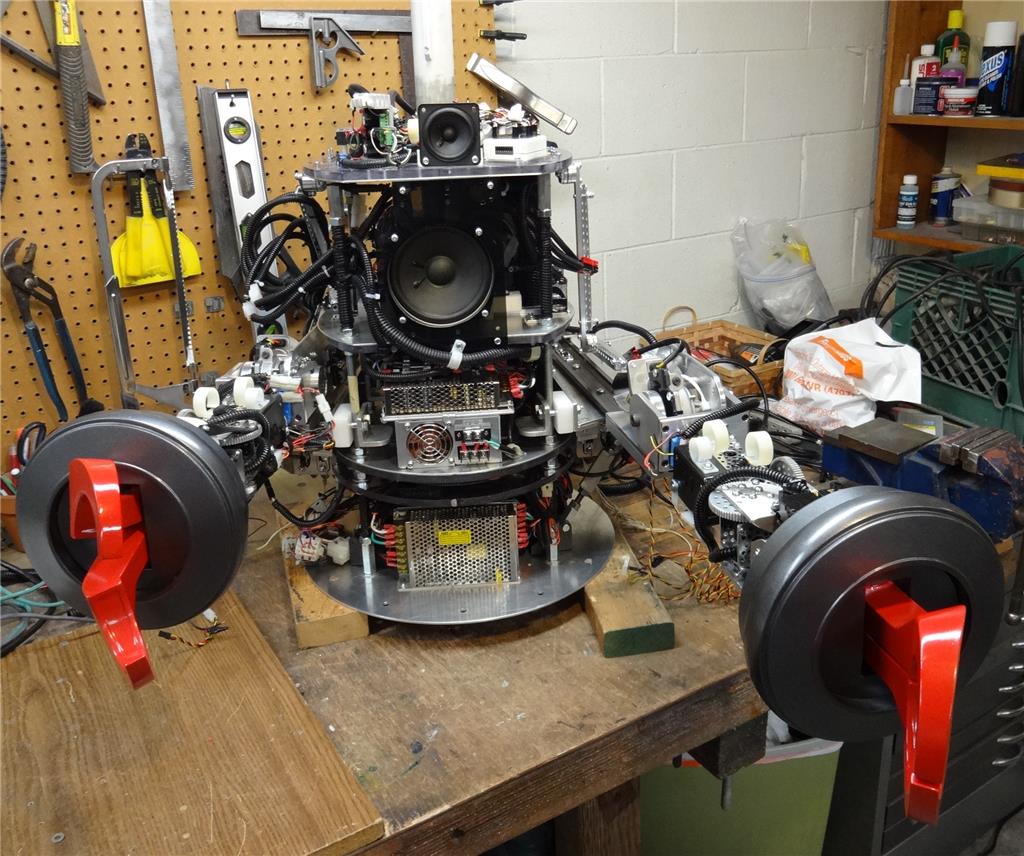

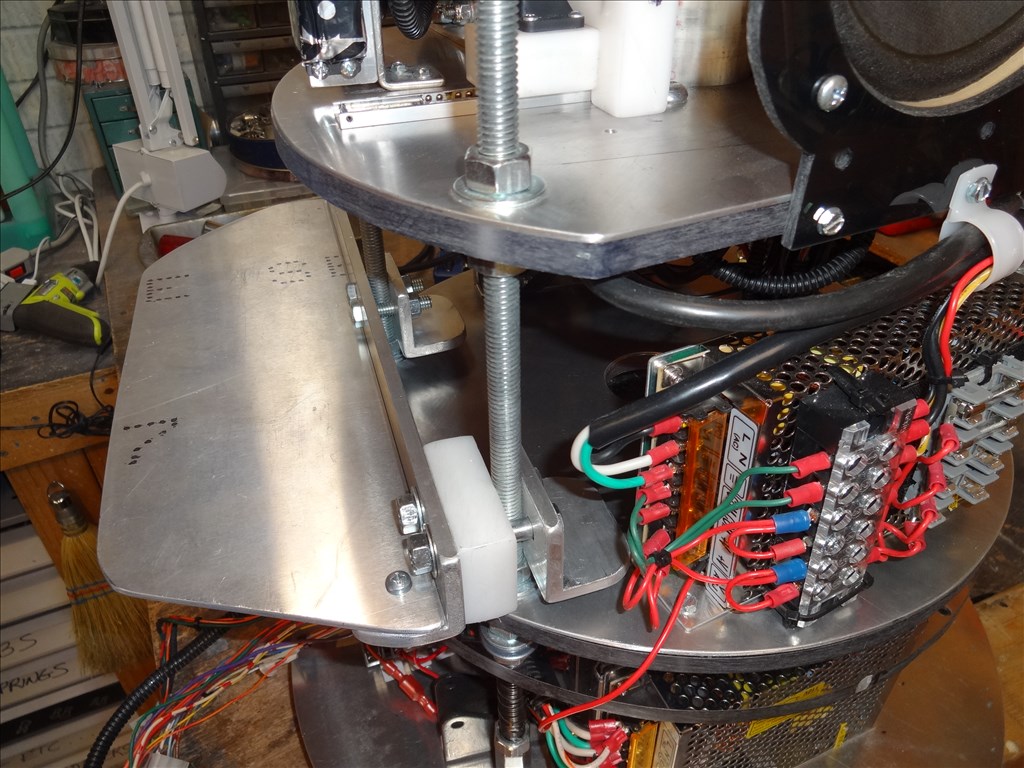

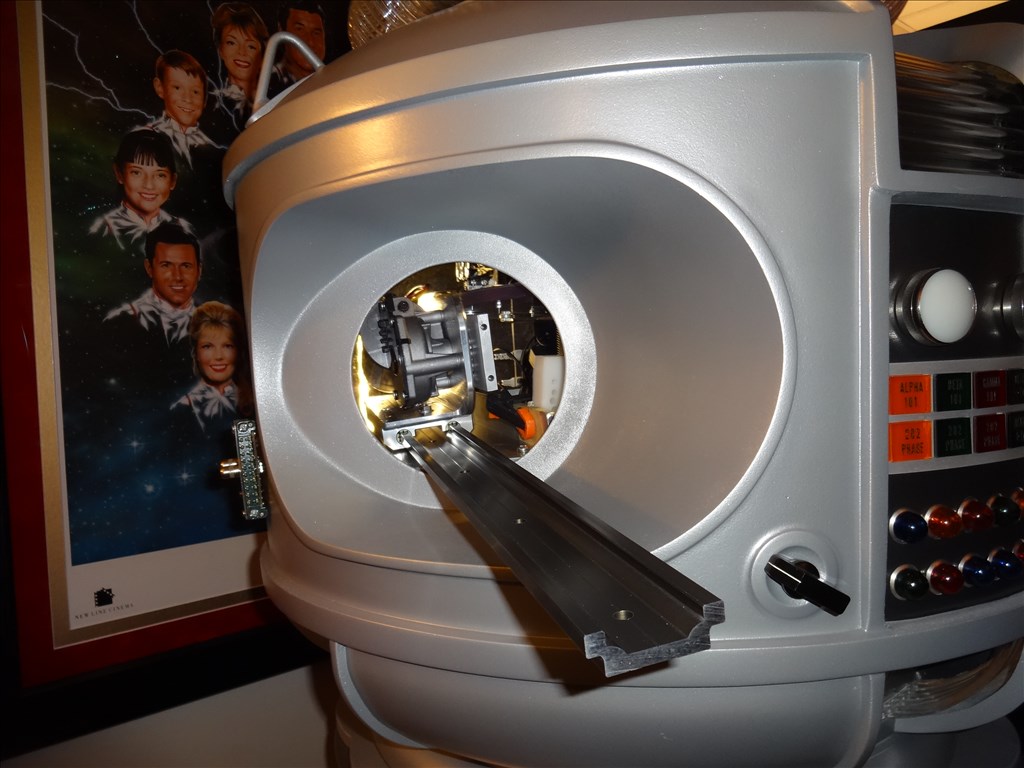

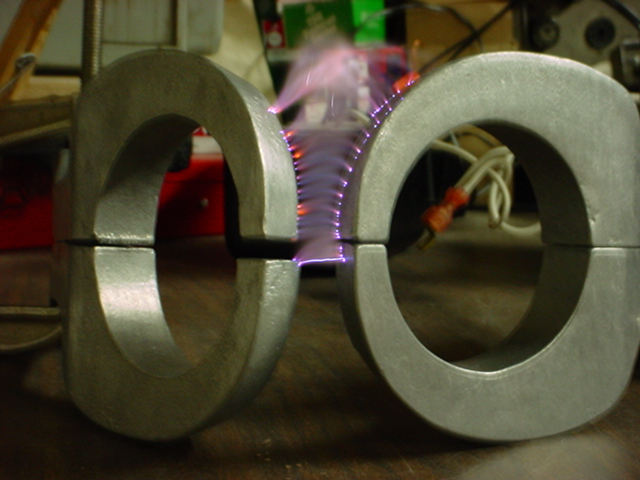

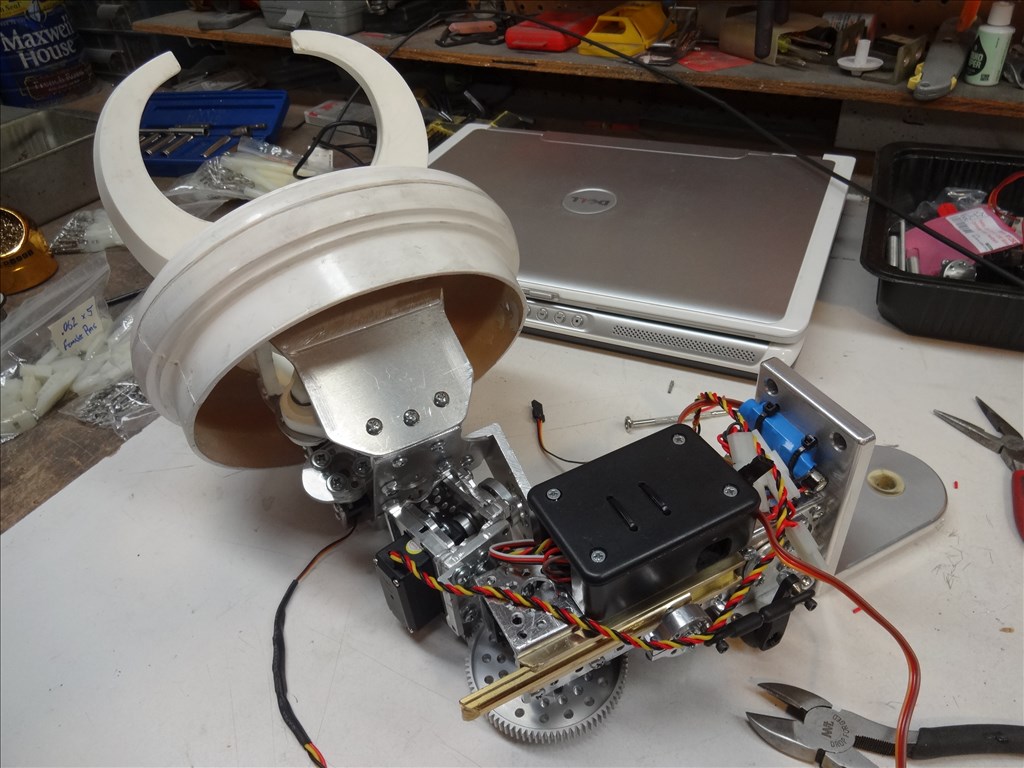

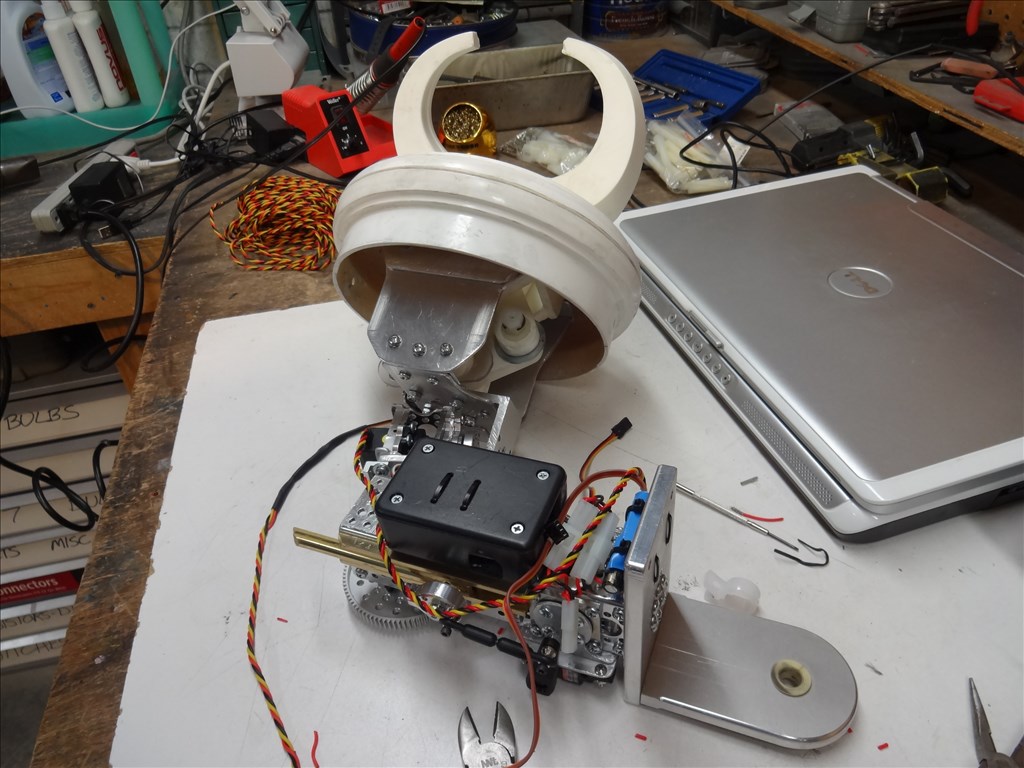

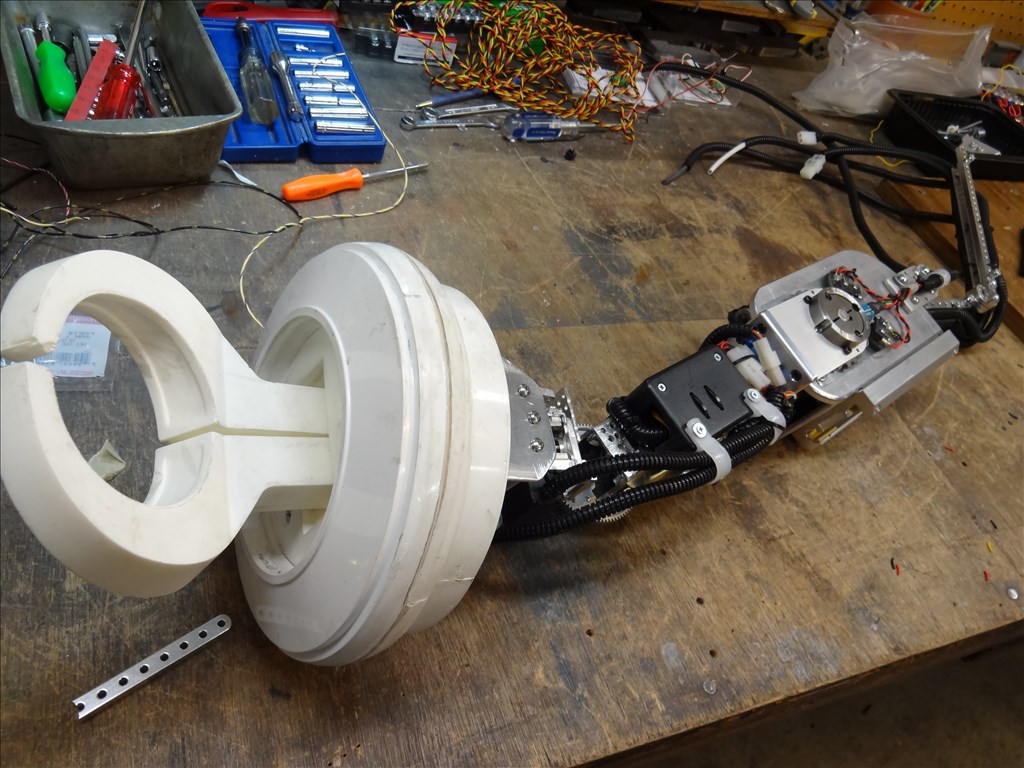

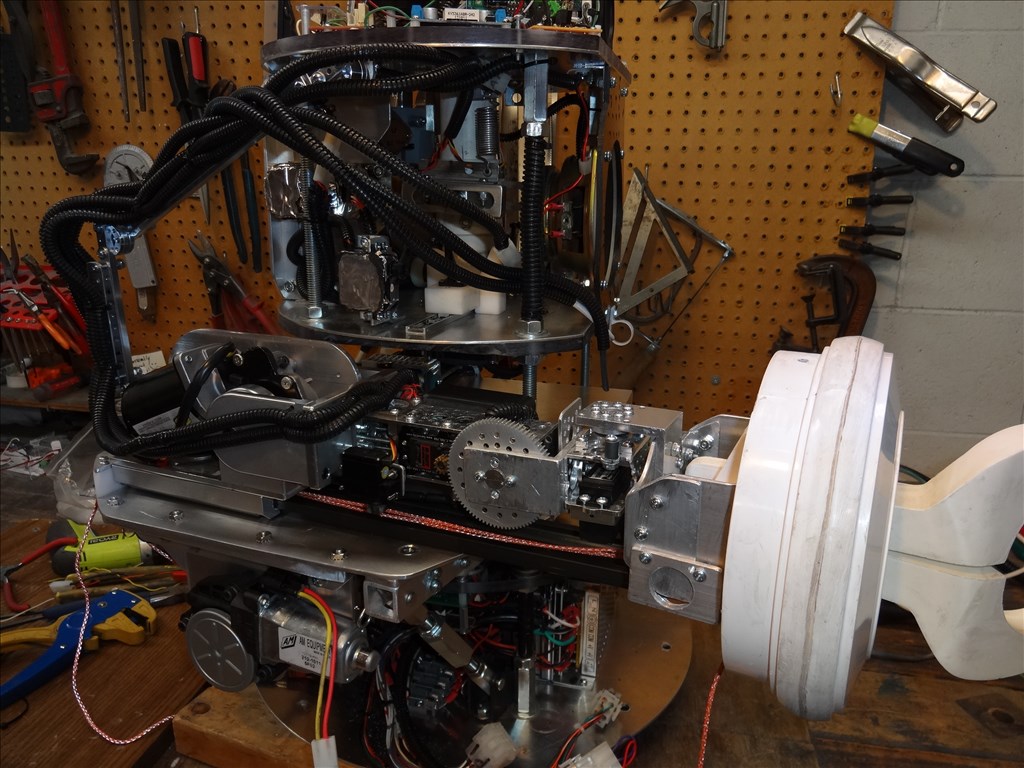

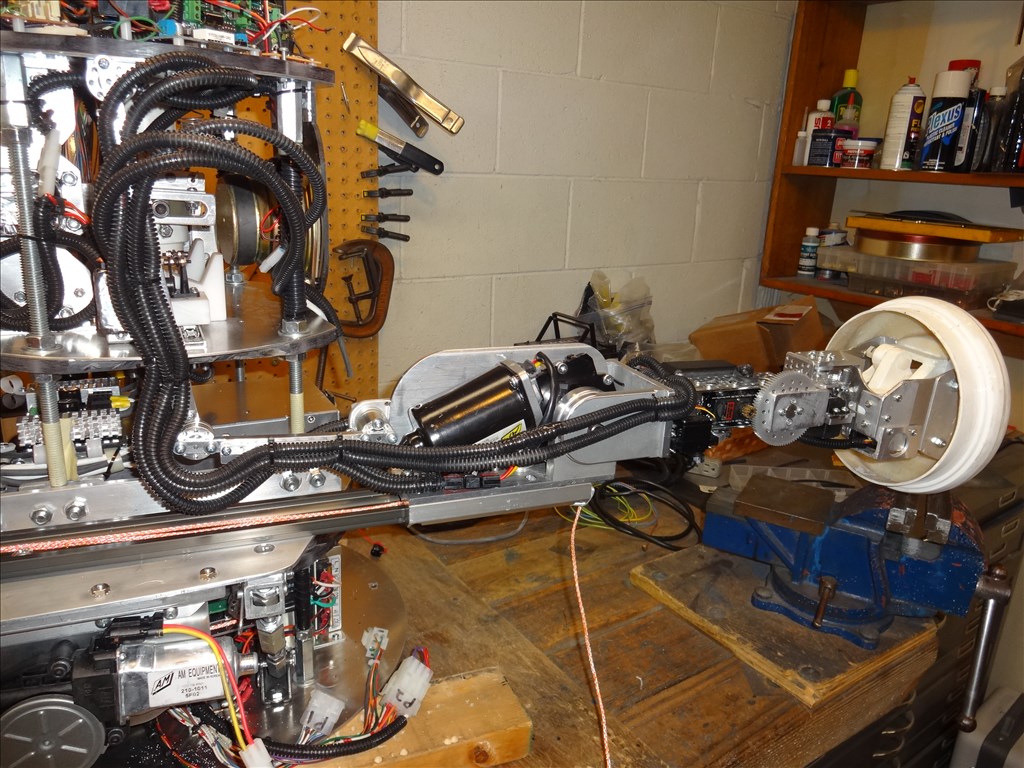

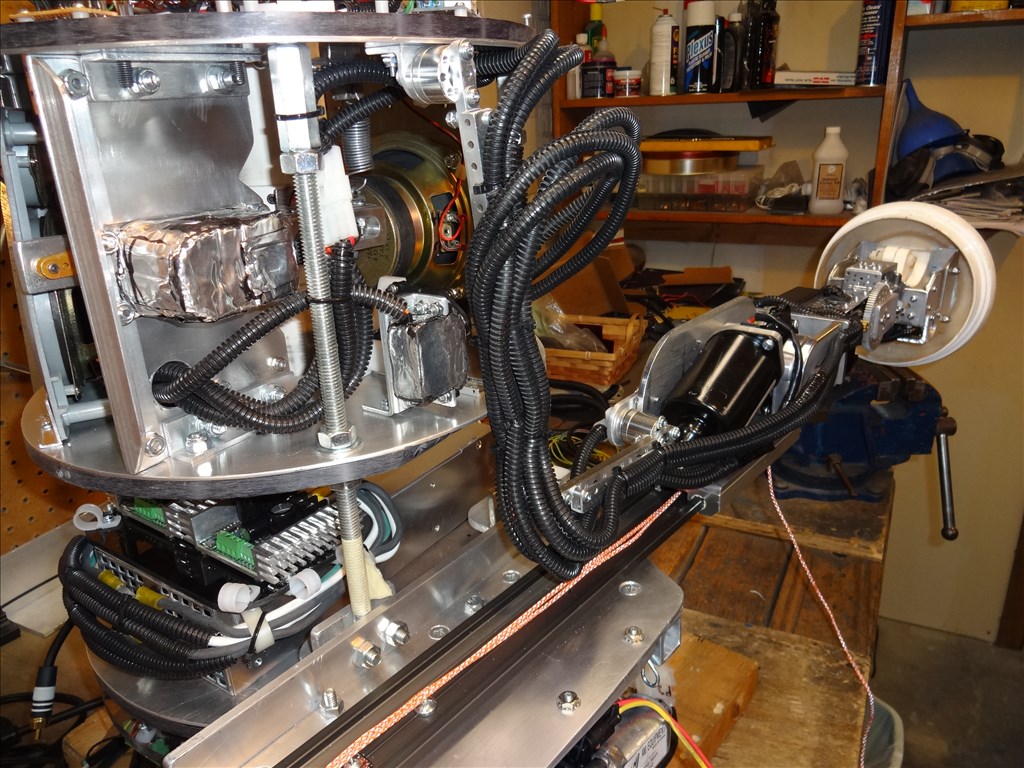

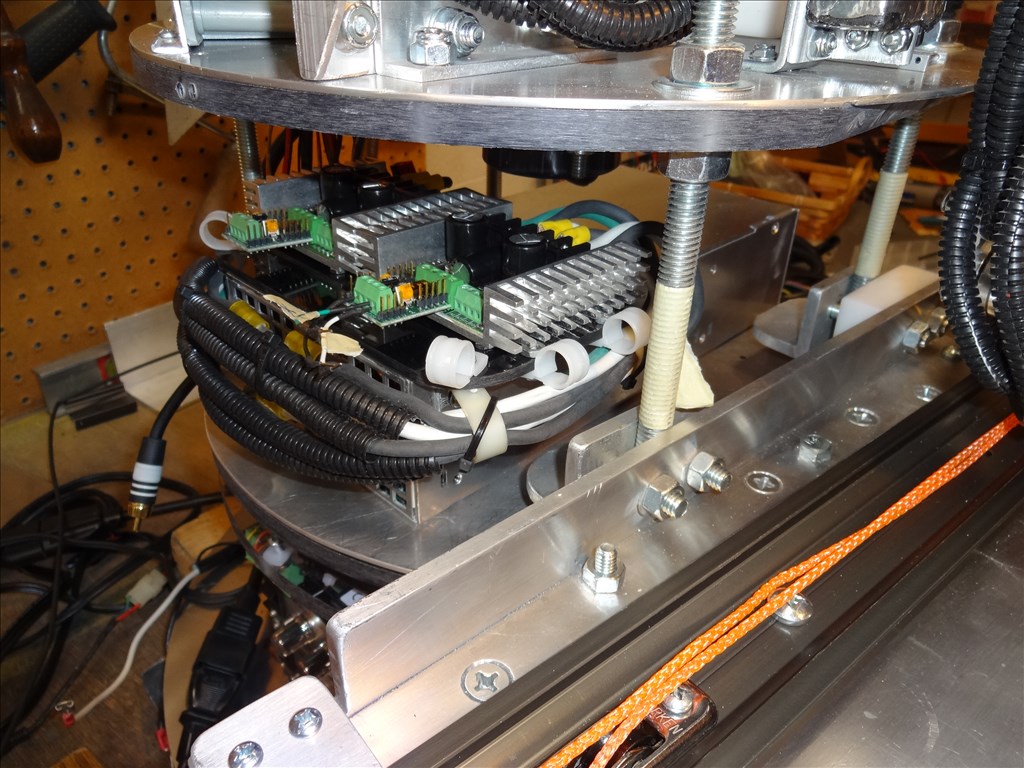

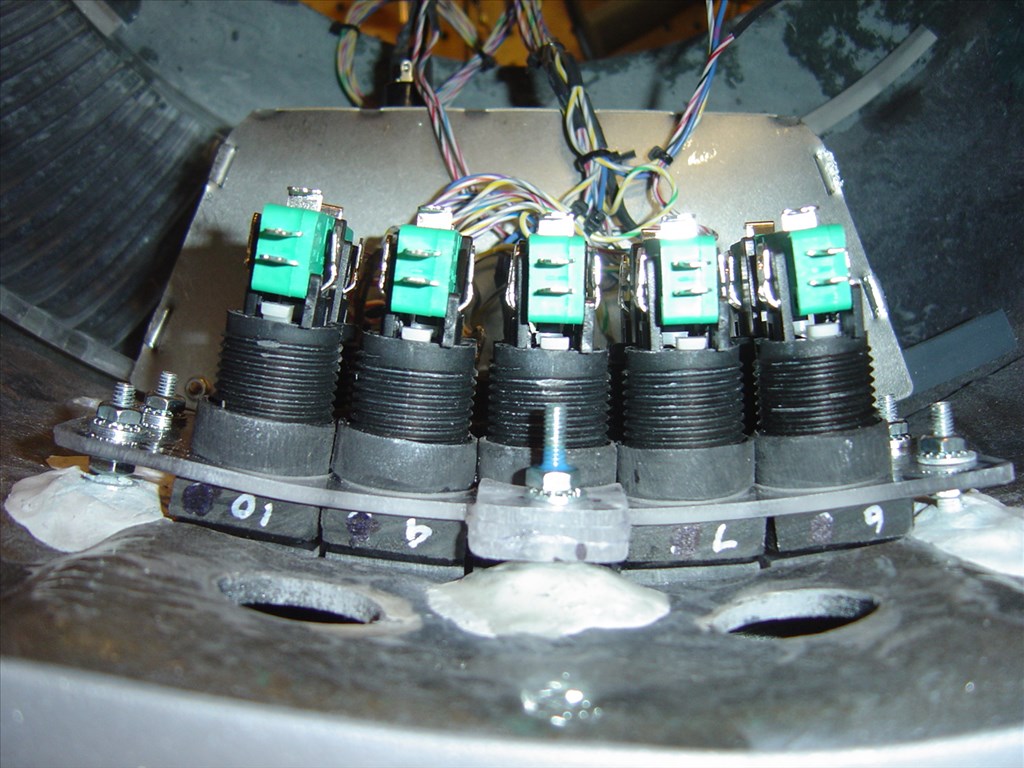

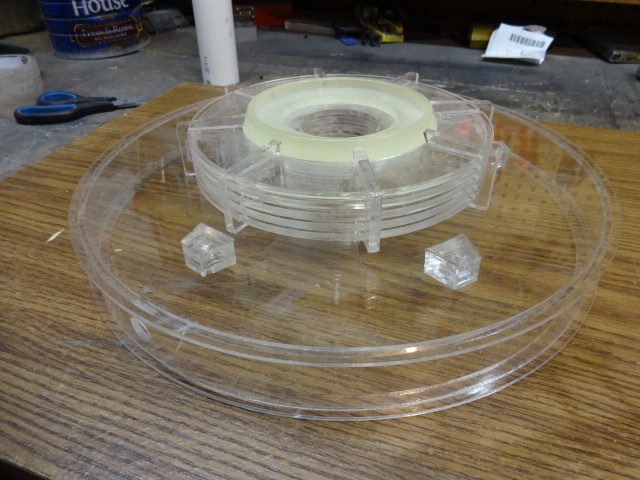

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

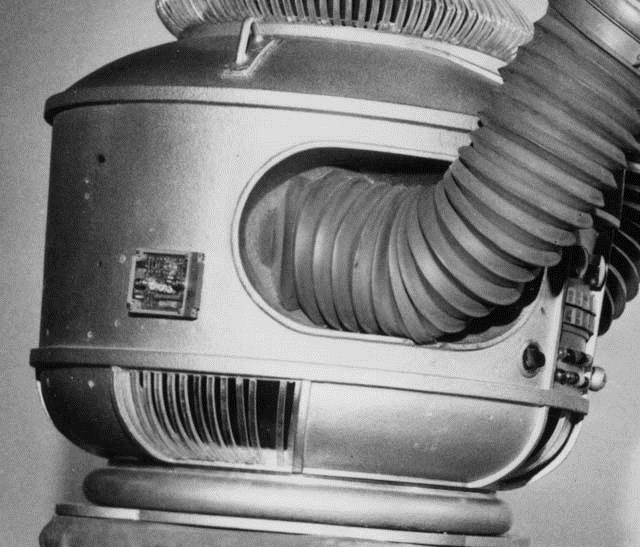

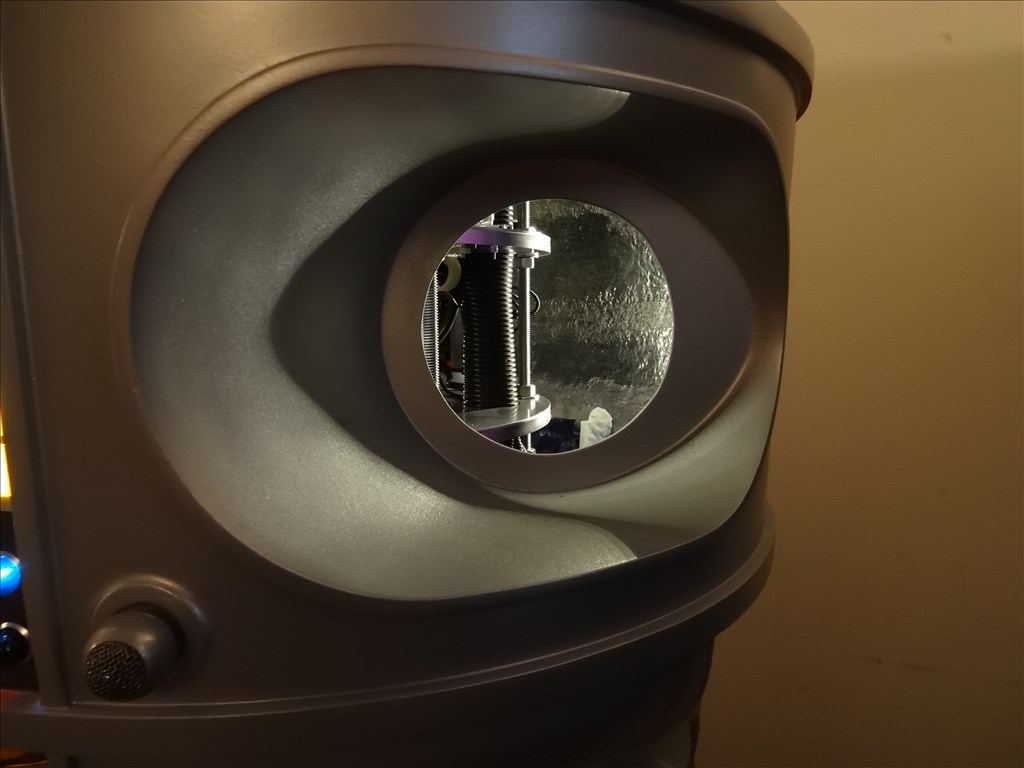

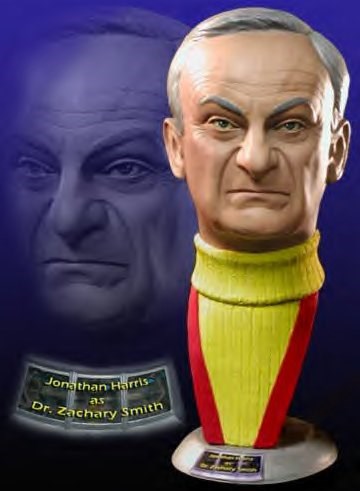

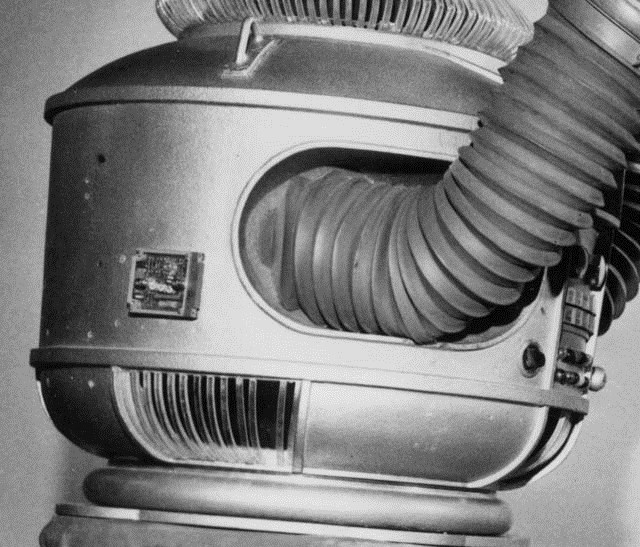

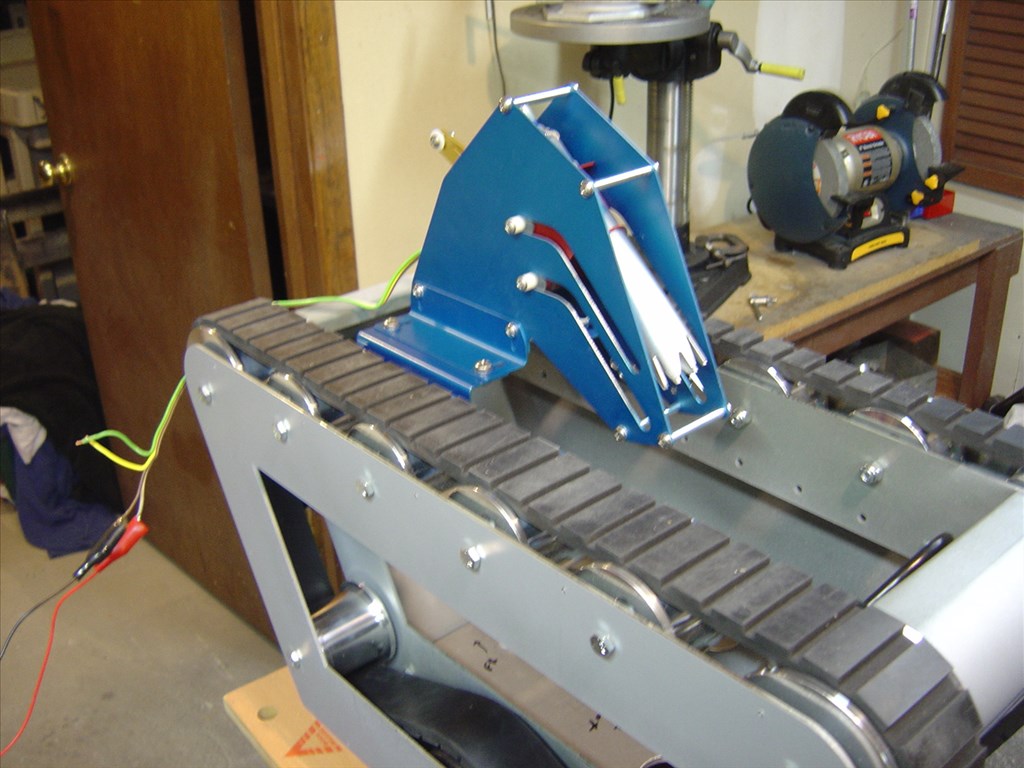

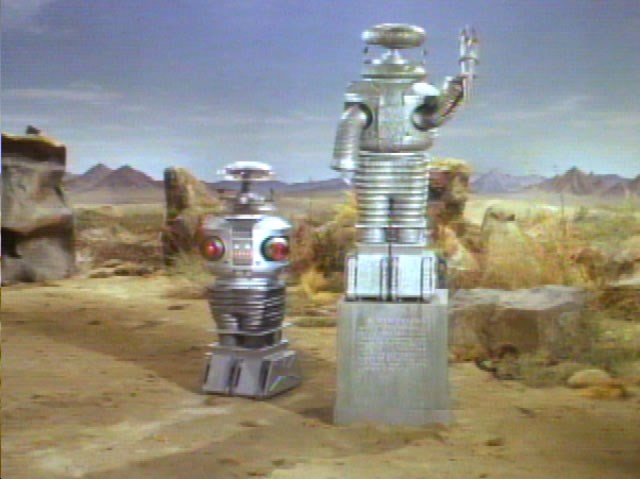

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

Jdebay's Garden-Bot Aka Gb Robot

Animator28's AVA (Advanced Visual Android) Update

-635353562186322812.png)

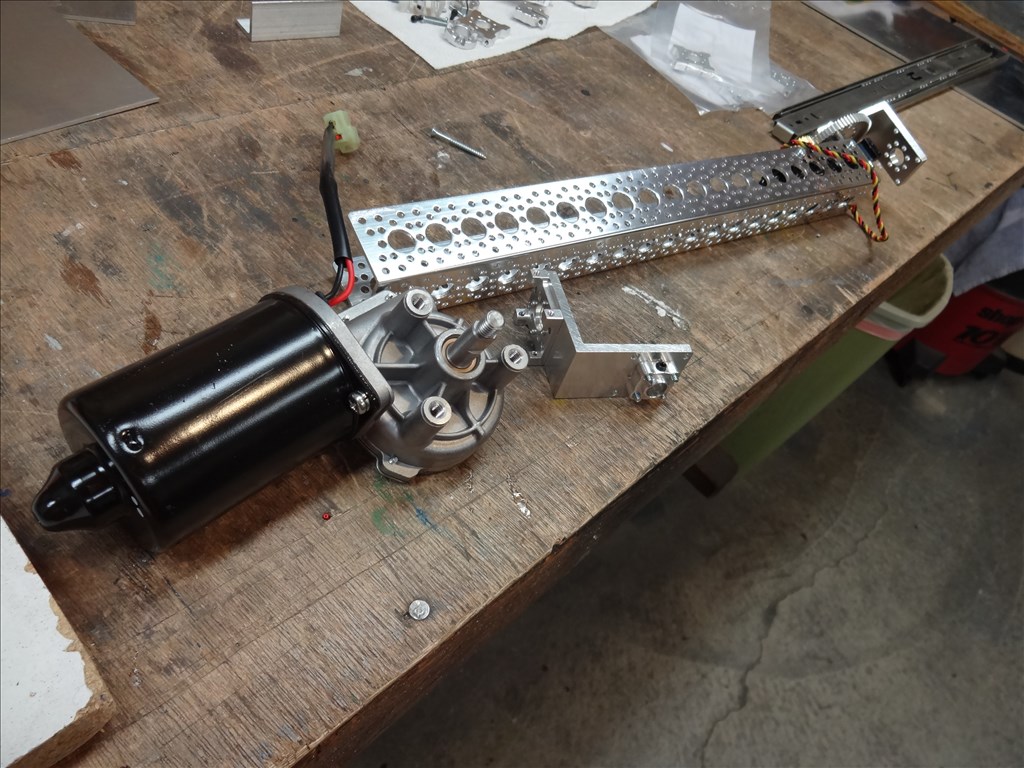

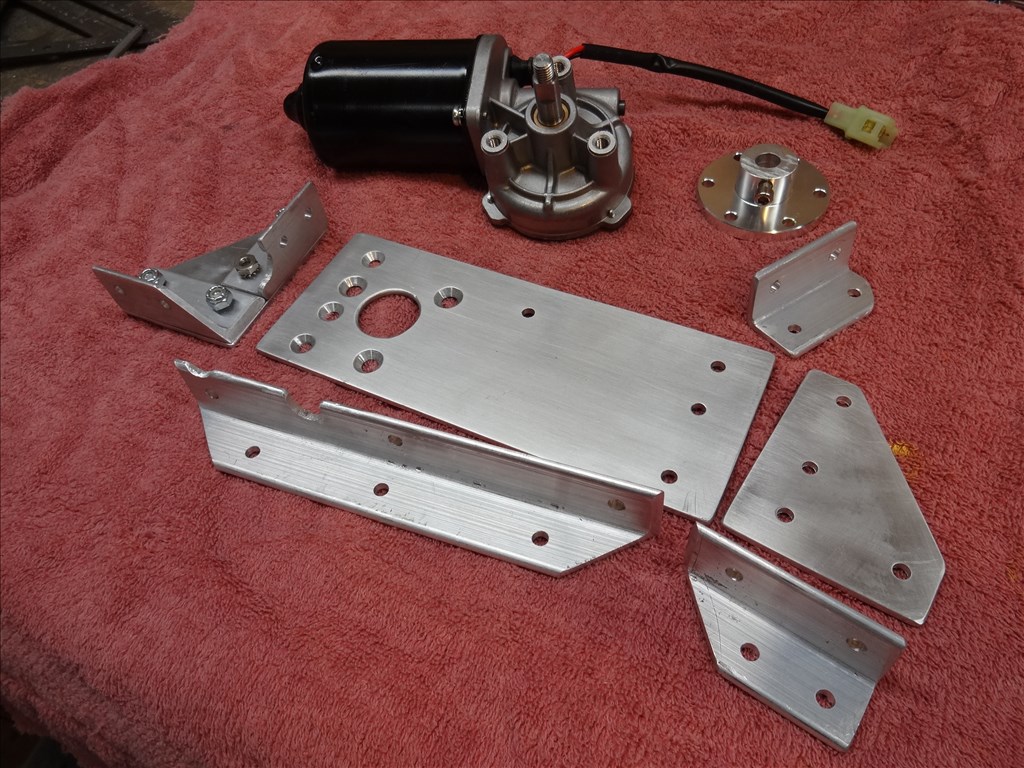

Thanks Dave for the detailed reply and video. That helps a lot! I am very interested in the power window motor. What size hub are you using for them? I assume they are from RobotMarketPlace.com as well?

@Dave

Great Video's, your B9 robot looks very neat!

Chris.

[b]Dave[b/], your B9 is stunning and demonstrates the utmost in engineering success and unusual solutions with professional designs.

Your project is very inspiring! Thanks for posting.

Dave, Your robot shows so much determination for quality, and displays your hard work. Awesome work down to the details! Thanks for the updates. Steve S

Hi Dave, This is a thing of absolute functional beauty. When I first explored this platform a few weeks ago I found your post and spent a couple of hours watching videos on your youtube channel. Mesmerized, watching that amazing arm move around so smoothly, etc. I'm 51 and loved this robot as a kid. While I don't have your level of mechanical brilliance, you are an awesome inspiration in terms of the world of possibilities with the EZB at the core. I'll have to dig around to find your video/info on the power subsystem. It looks like you have AC supplies in various places. I'm wondering if your B9 will have a lithium (or other) battery system. Anyway, I love all of the attention to detail. And I have to say, I LOVE the incandescent lights on that front panel. There's nothing like that inherent ramp up/down, non-pwm incandescent glow. Thank you for sharing your experience and passion. Say hello to Elvira for me .

Cheers!

Mike

.

Cheers!

Mike

Again, Thanks all for the words of encouragement. I'm glad your enjoying my progress.

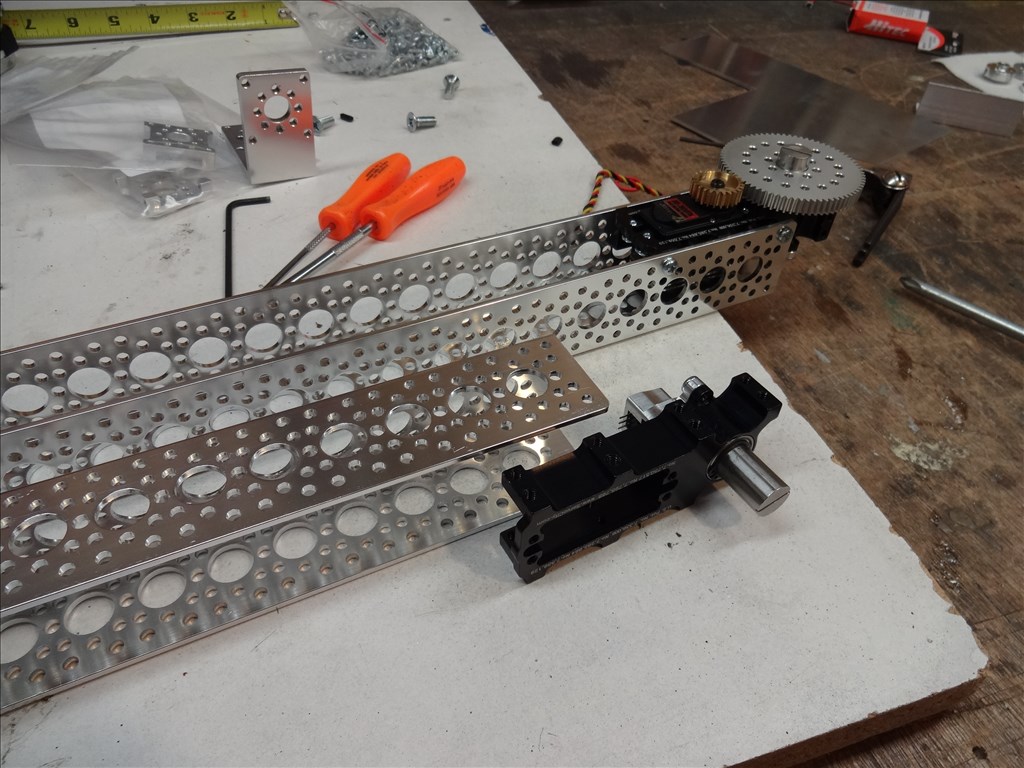

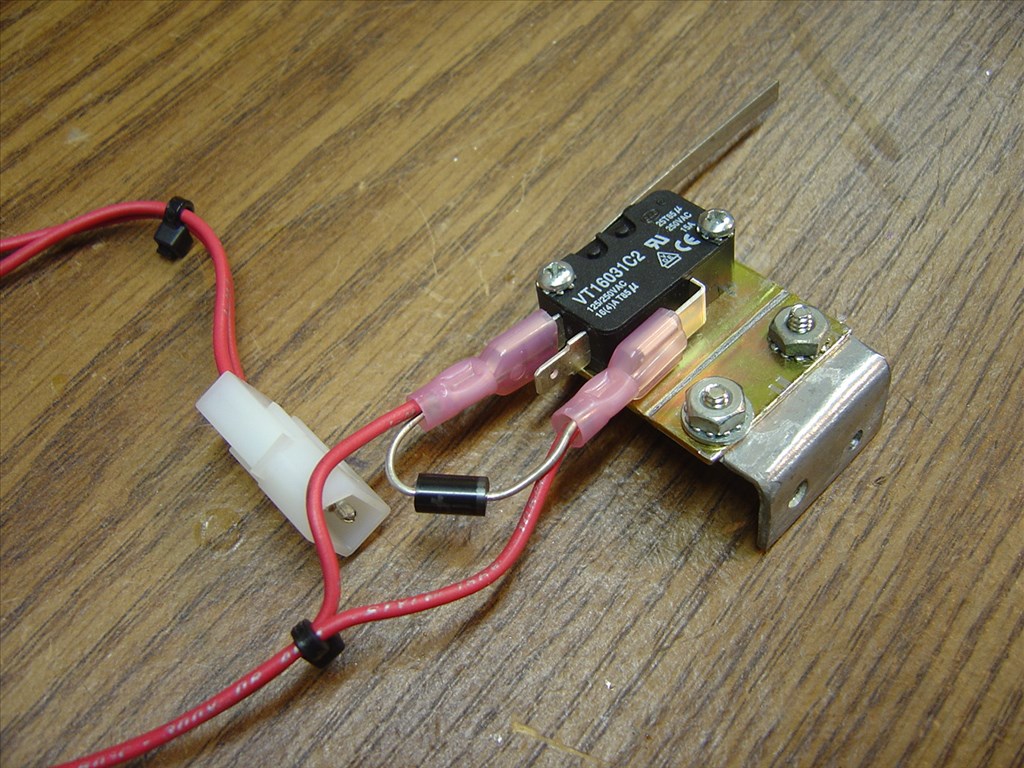

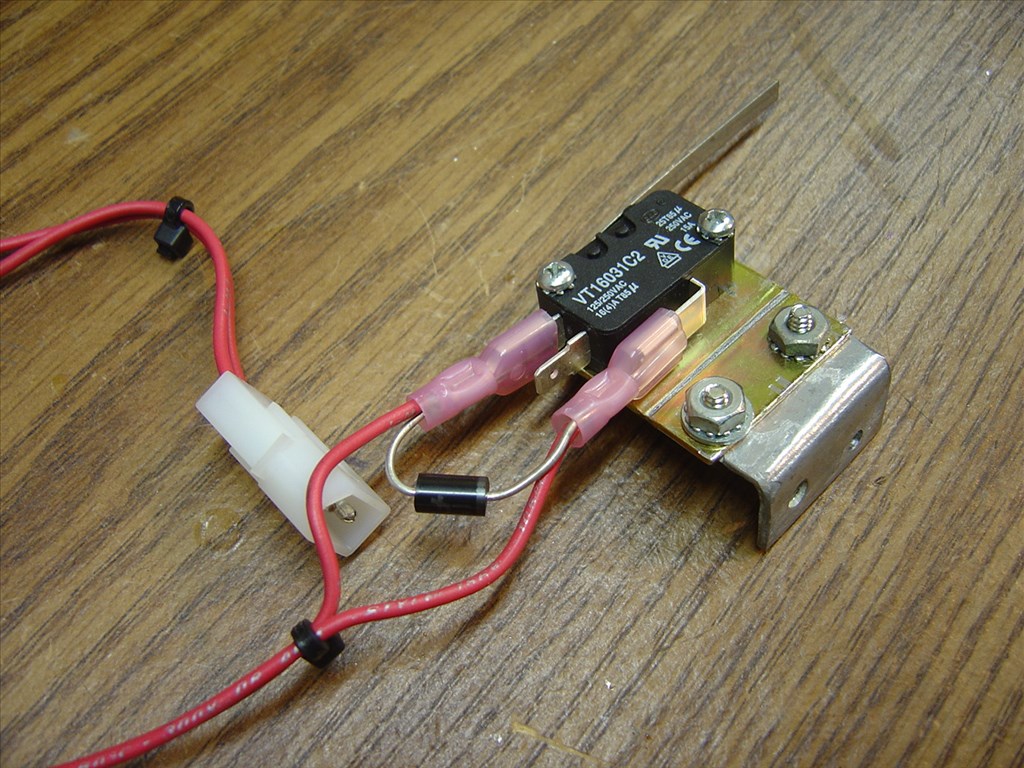

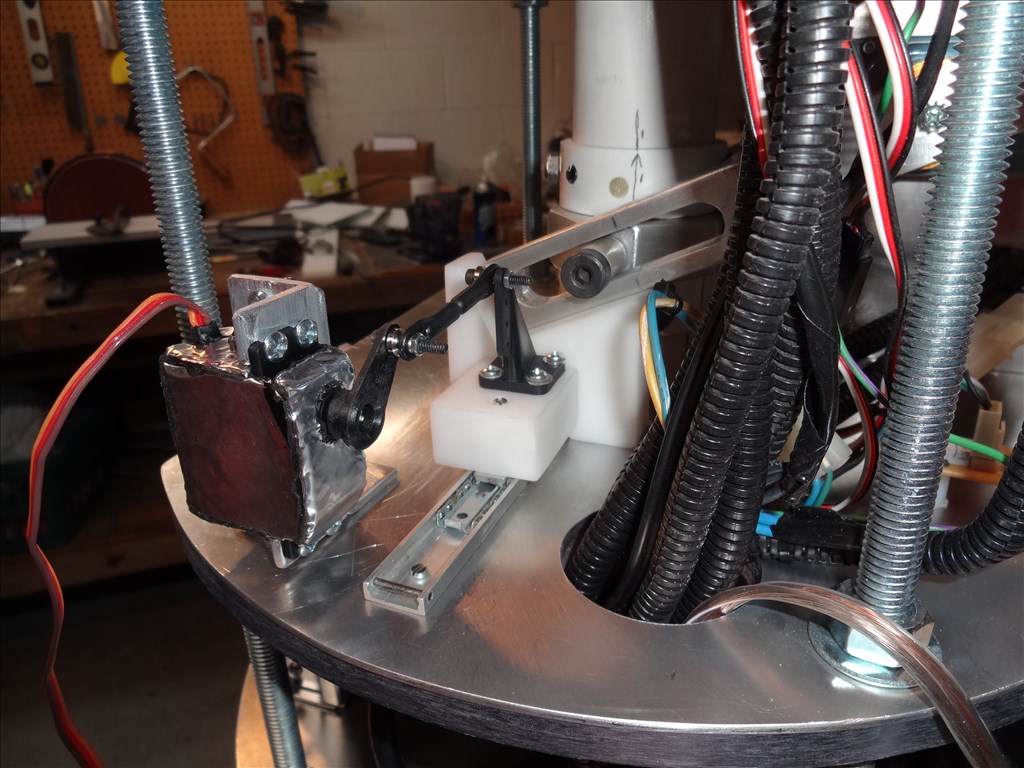

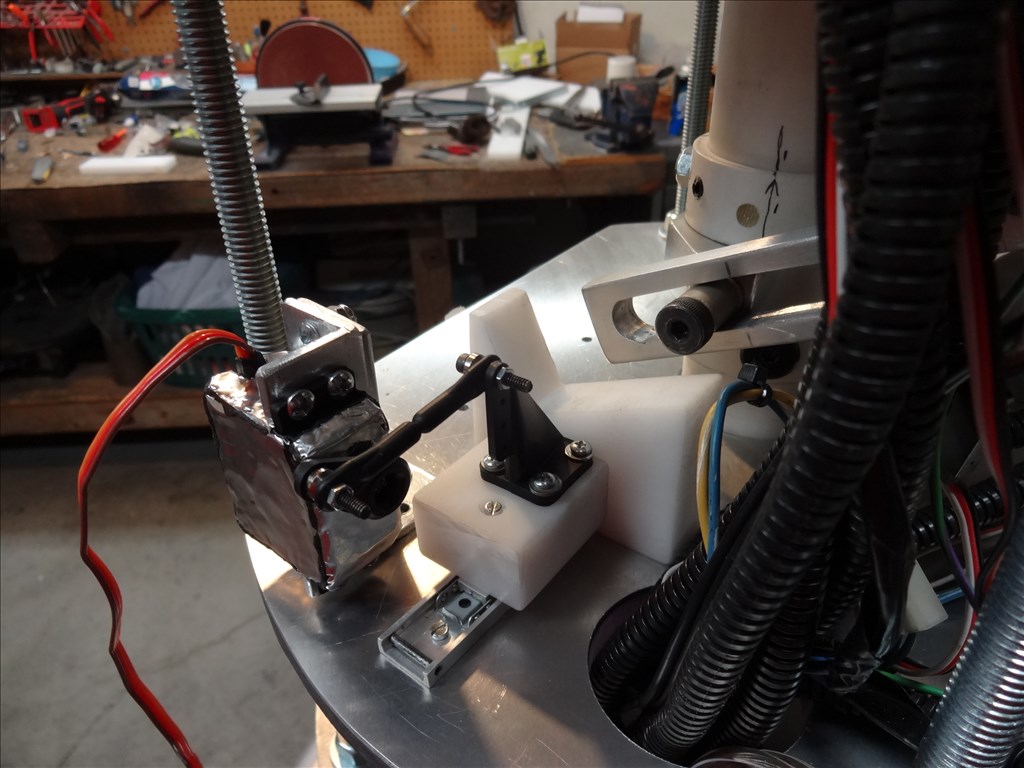

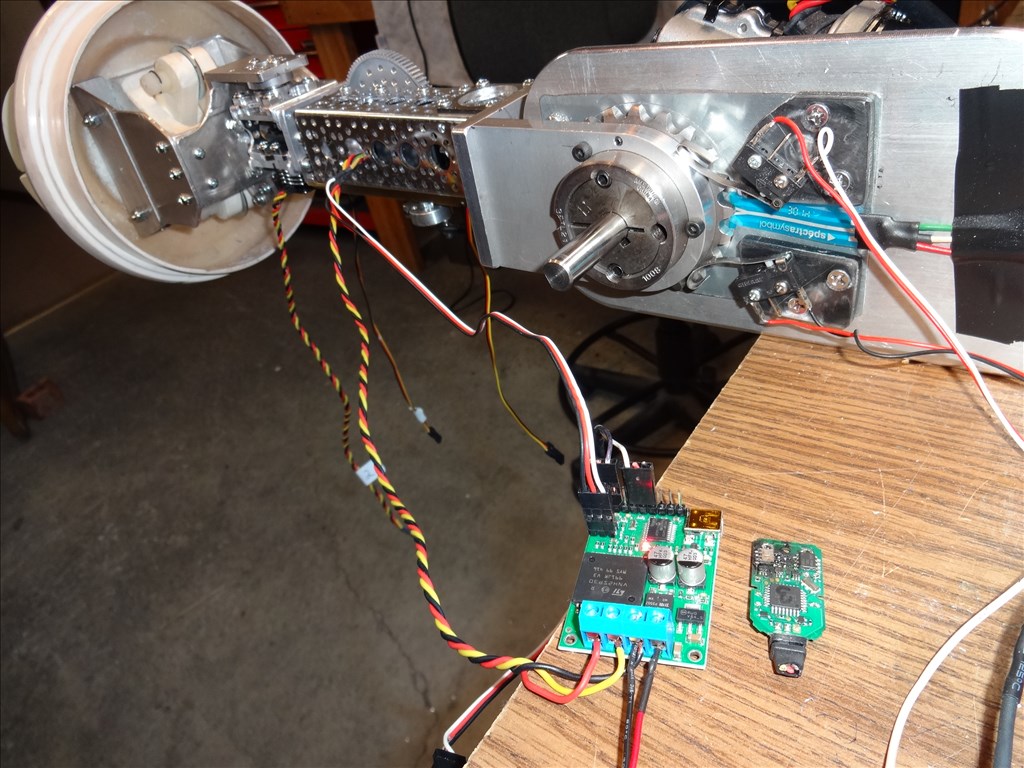

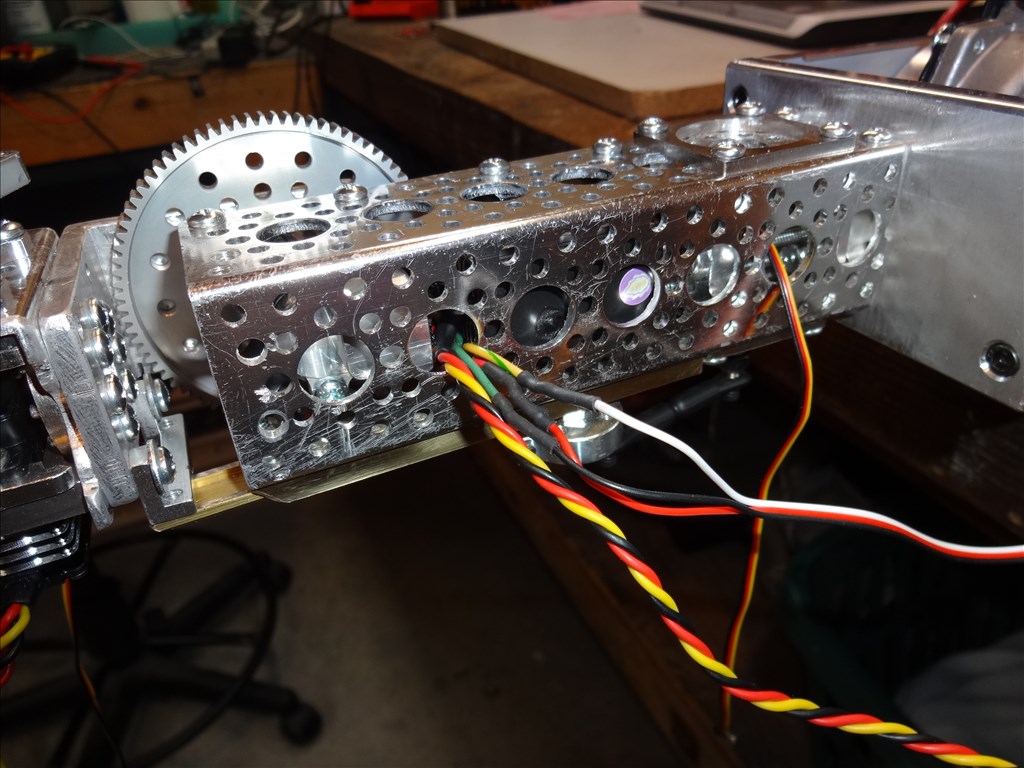

@Rex, Lets talk hubs. I'll share with you what I've learned. Hubs have been one of the biggest problems I've had to overcome when building a robot.

Hubs have been one of the biggest problems I've had to overcome when building a robot.

*Keyed hubs and shafts are great and will stand up to any type of load if the key and hub is made of strong material and is tightly fit. If you don't have a keyed motor shaft this type is not a possibility unless you can have a machinist cut a key way for you.

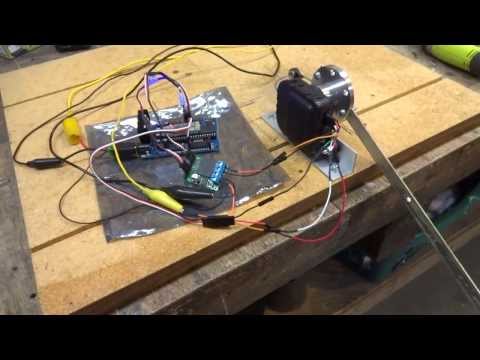

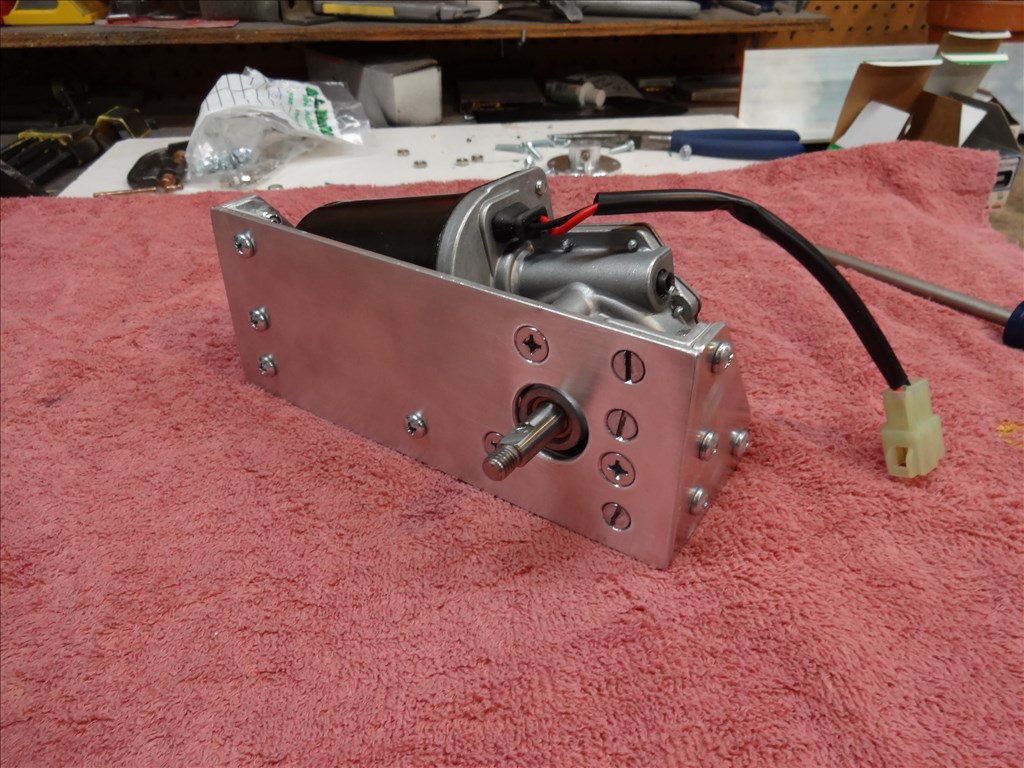

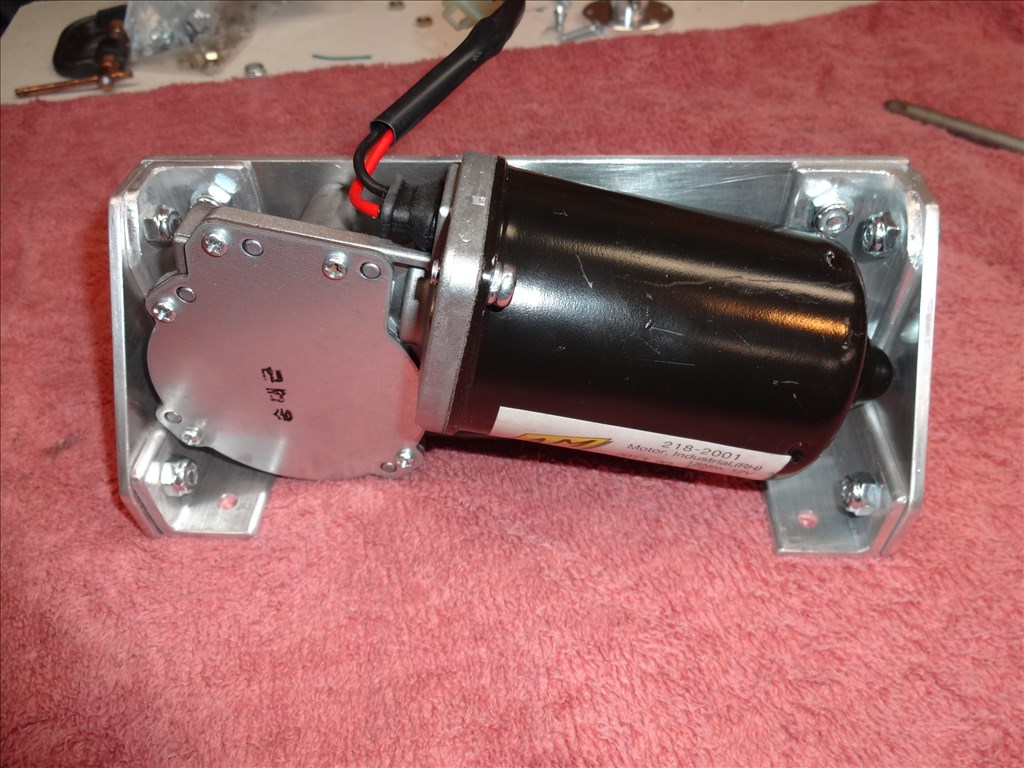

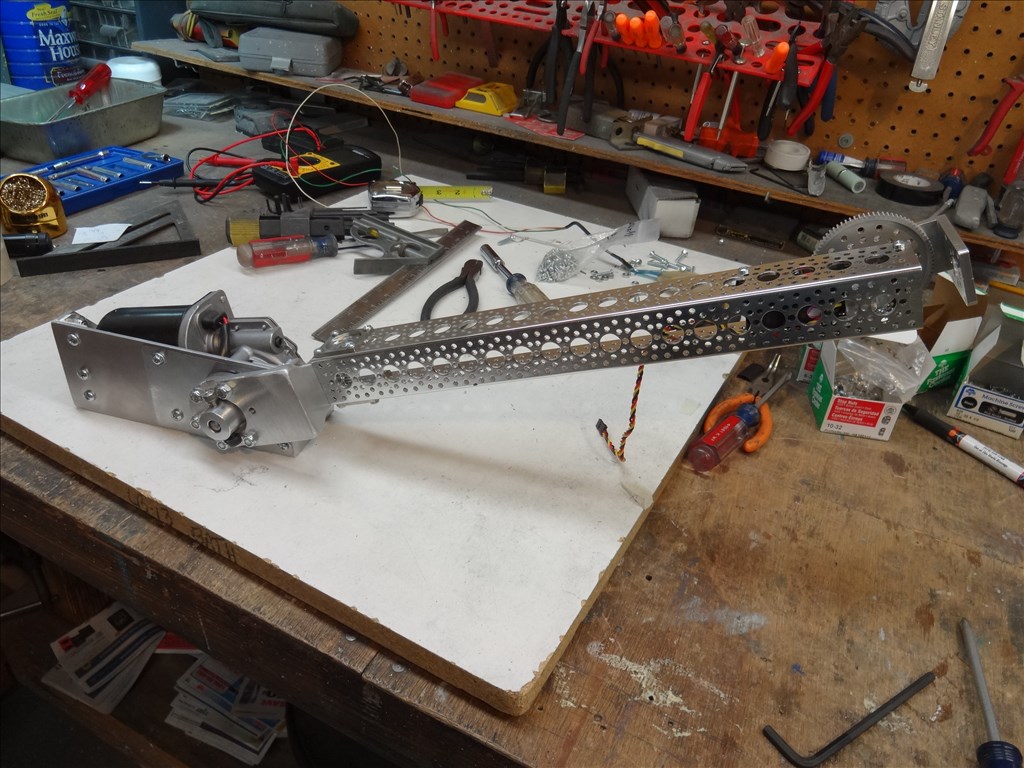

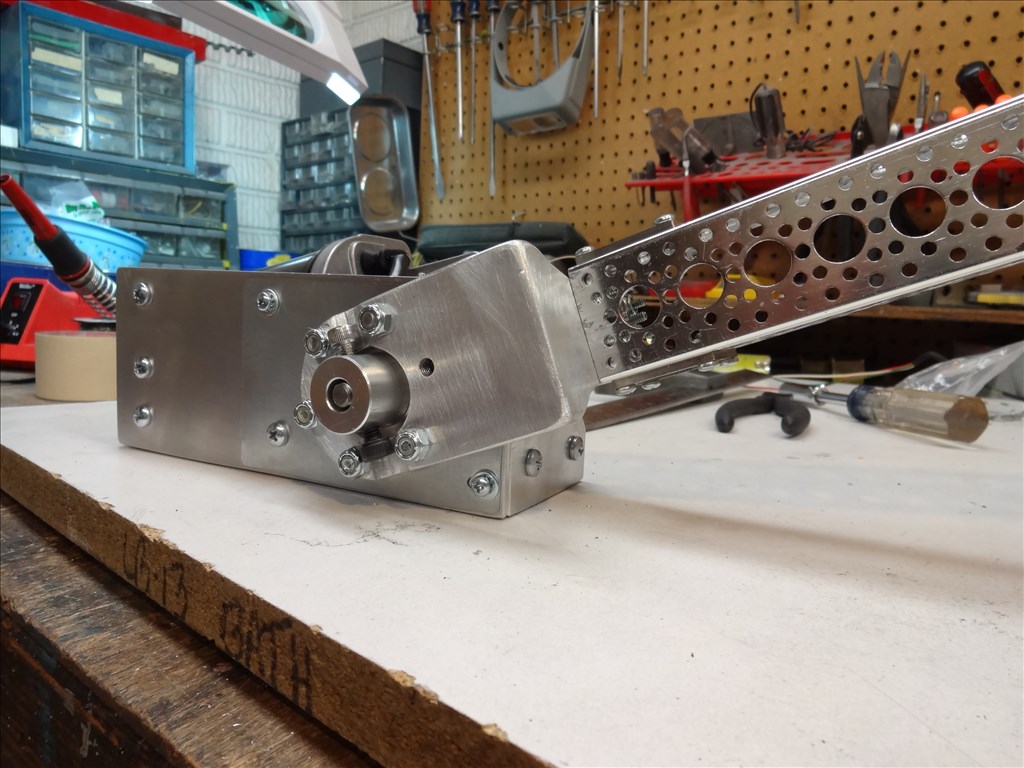

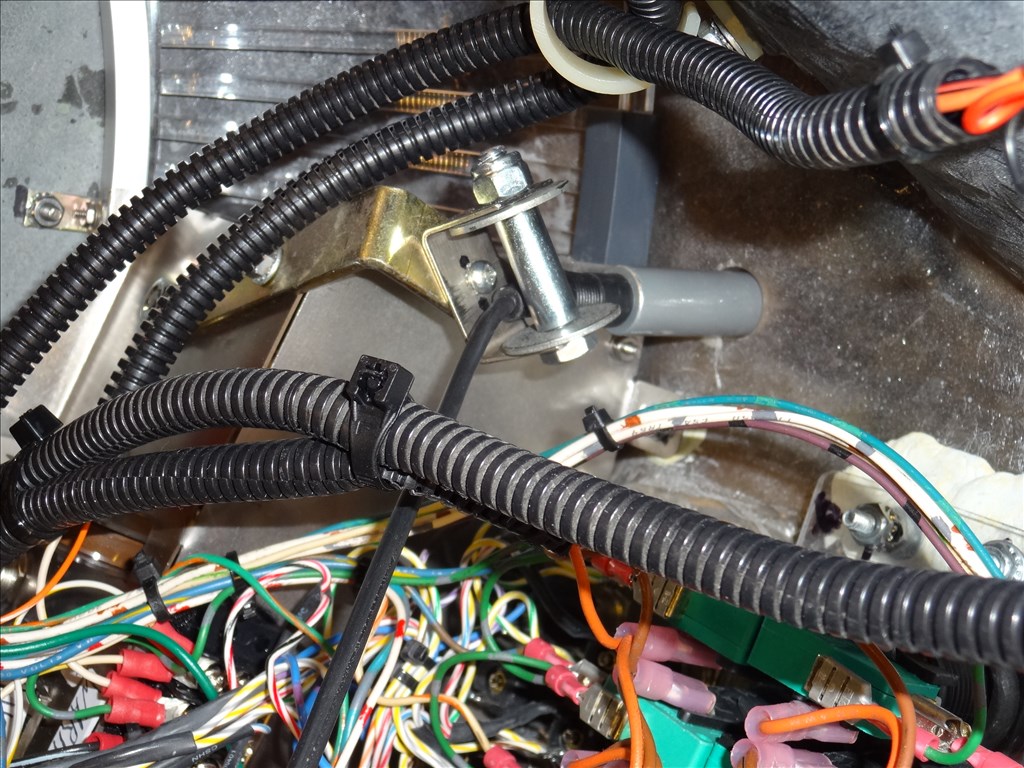

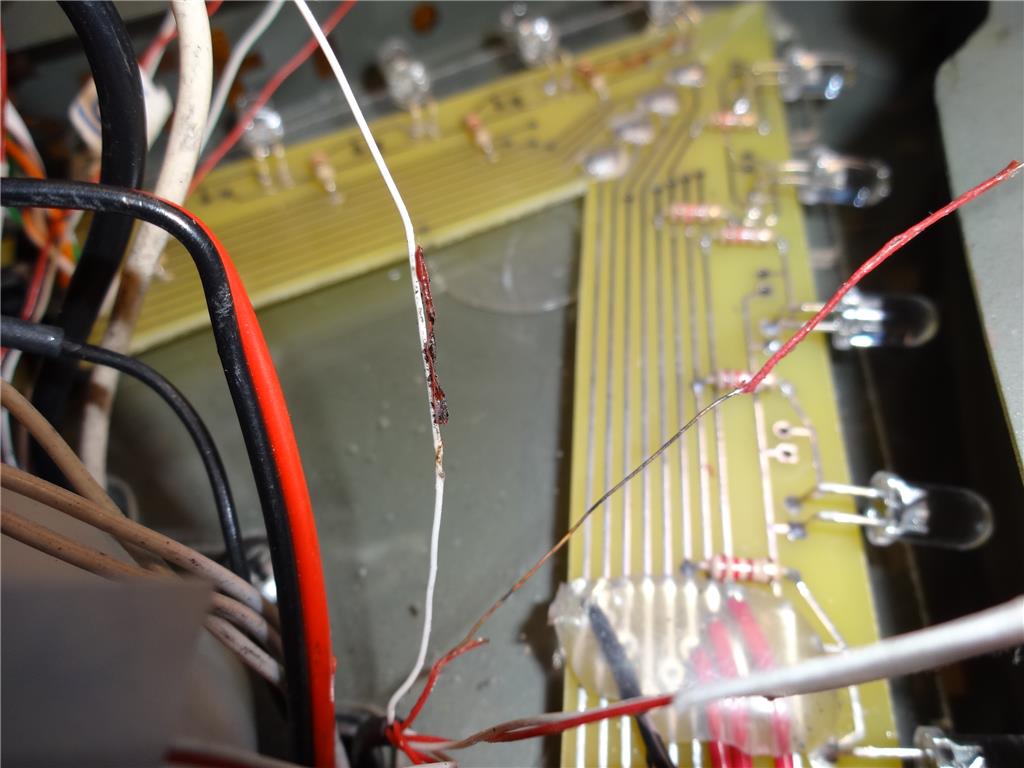

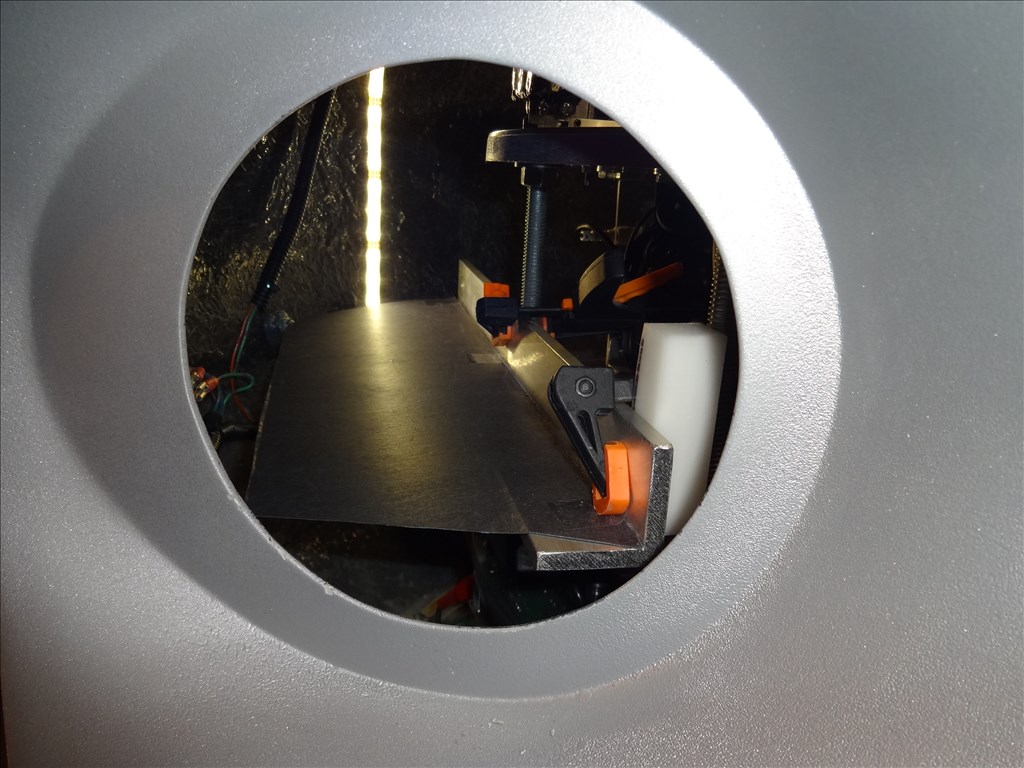

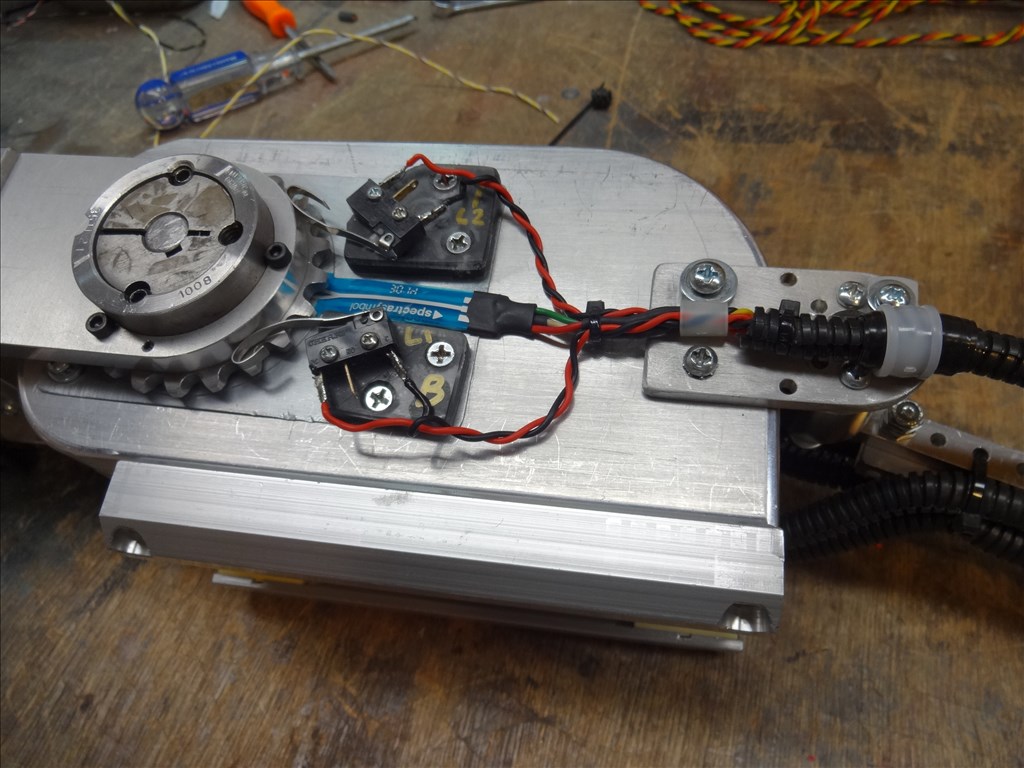

With that all said. In this setup I am trying to use a set screw hub with this car window motor. However it's not the usual aluminum hub you'll find on the online supply stores. It''s a stainless steel hub with a stainless setscrew. I hope it will hold tight if I get it properly tightened with Locktight to the steel shaft of the motor. I think the relatively slow speed and low drag of the rail system wont overload this hub. If I do have problems this hub also has a key way so I may be able to get my machinist to cut on into the motor shaft.

To quote Indiana Jones; "I don't know! I making this up as I go!"

Anyway, if your going to get these car electric window motors I listed above, the motor shaft is 10mm. The RobotShop has the Stainless Hubs I'm using in stock now. Their hard to get if they run out. I had to wait a few months to have them made when I ordered them. The product code is: 4x RB-Nex-99. Here's the link:

Stainless Steel 10mm Set Screw Key Hub

If you want to give a clamping hub a try then ServoCity has a small hub that will fit this motor shaft. Depending on your application this may or may not work:

Aluminum clamping hub

Good luck and have fun. Dave

Hey @walunit. Glad your enjoying the videos. I wish I was a better movie maker but I do the best I can. Trying to explain all that stuff on the fly without a script is a little overwhelming at times. LOL blush

Ya, LIS was cutting edge back then. We had no idea if people could even get into outer space yet alone travel to another planet. Heck, we didn't even have microwaves, home computers or the internet yet. Seeing that big bubble headed computer called a "Robot" that could walk around and talk with light blinking all over was amazing back then. What dreams of little boys used to be made of.

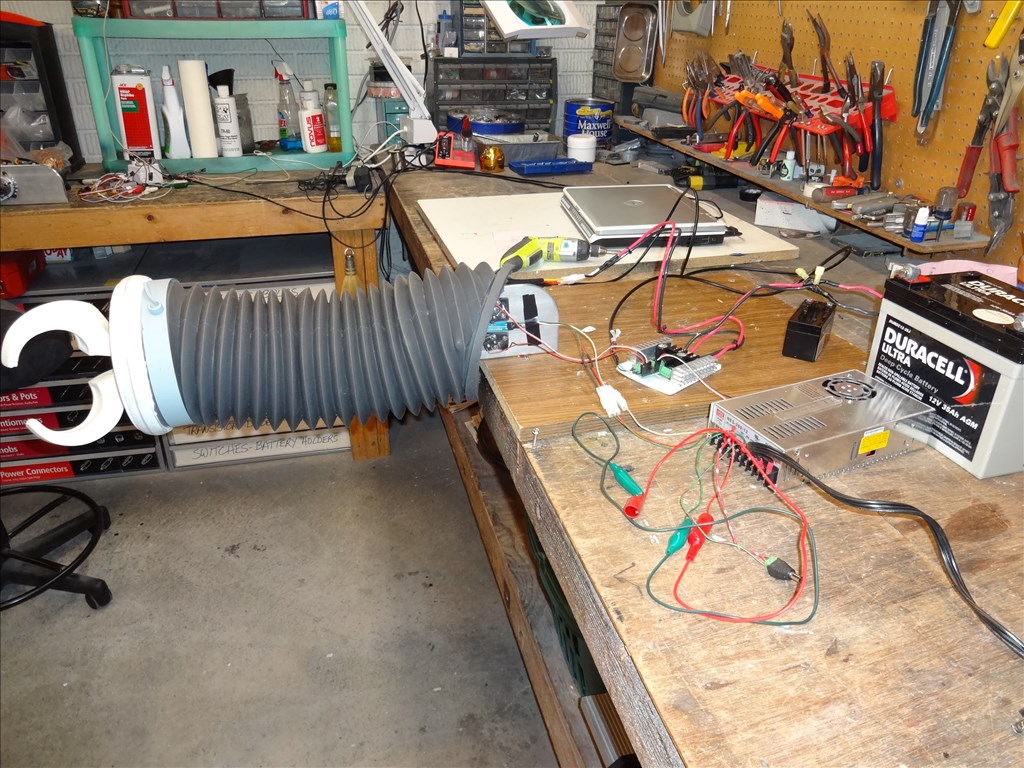

No, I'm not using any batteries in this robot. All plug in the wall AC to DC power converters.

Thanks for the kind thoughts and words. Stay tuned.