Hi all,

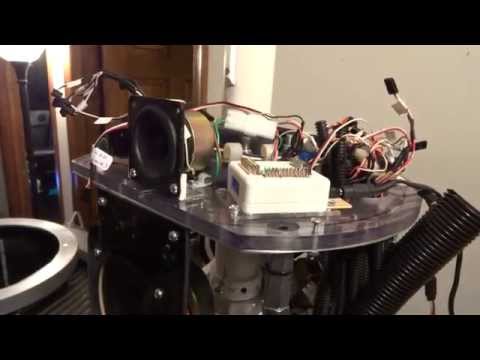

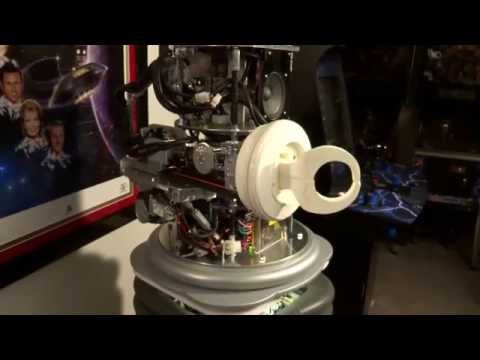

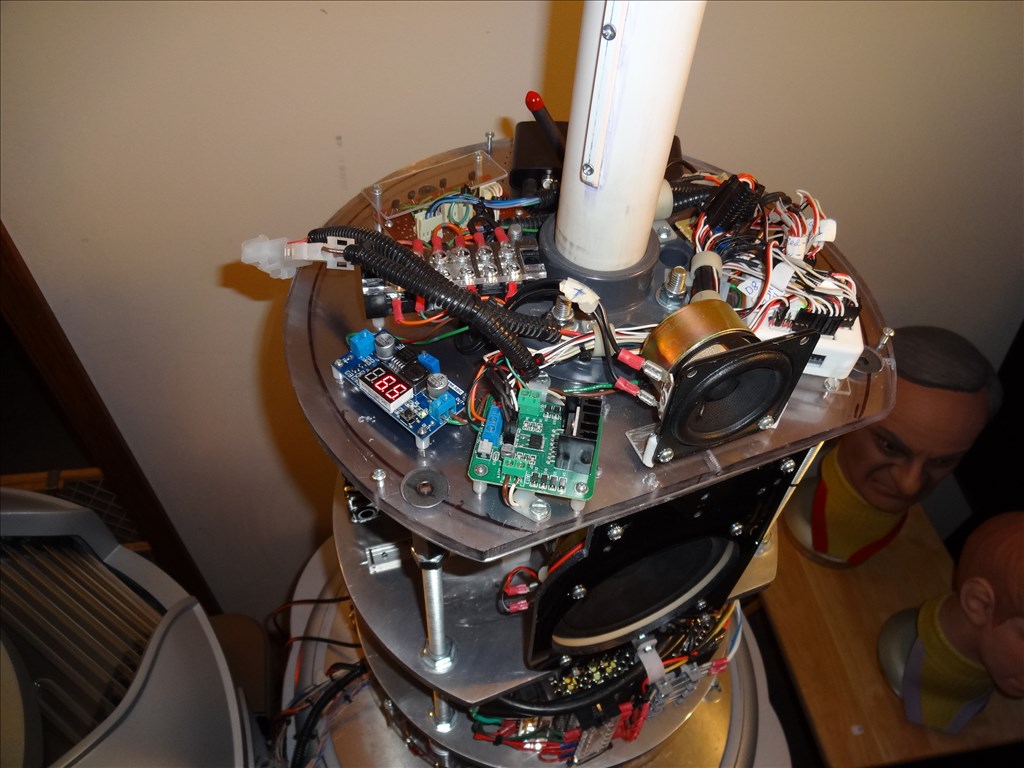

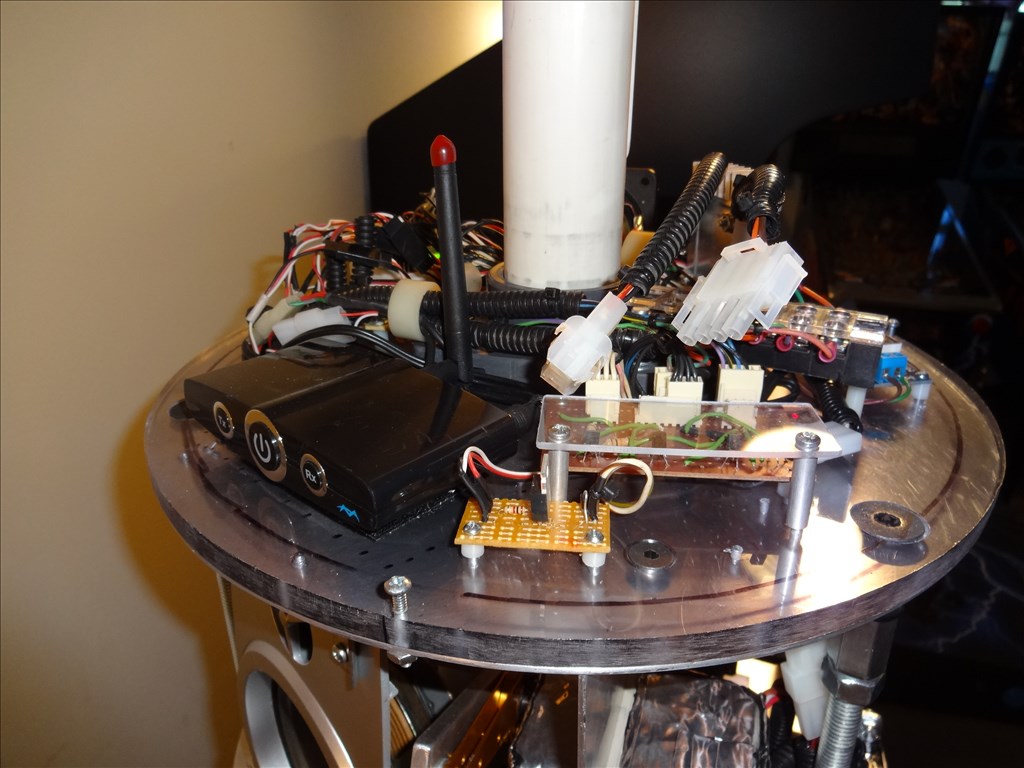

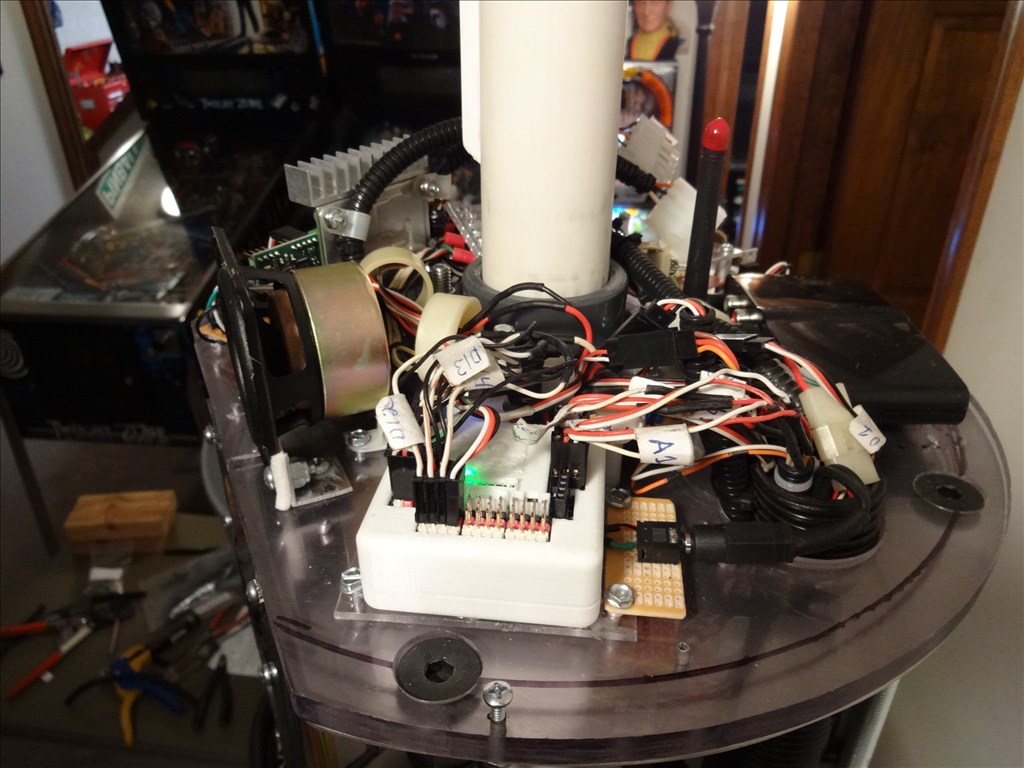

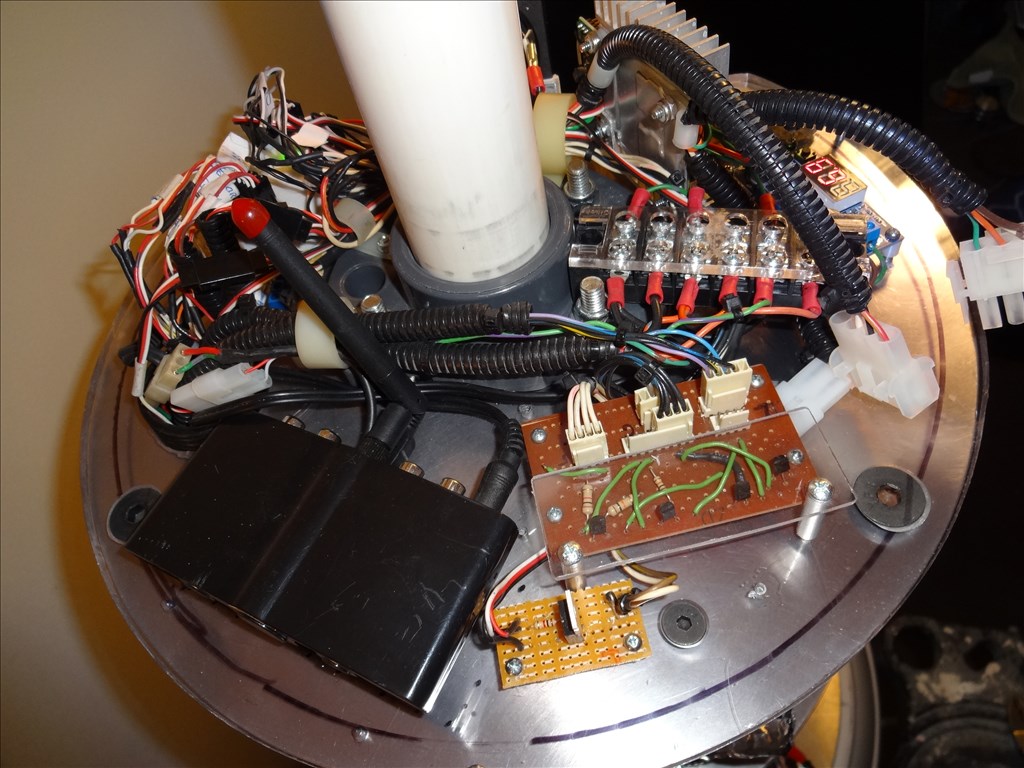

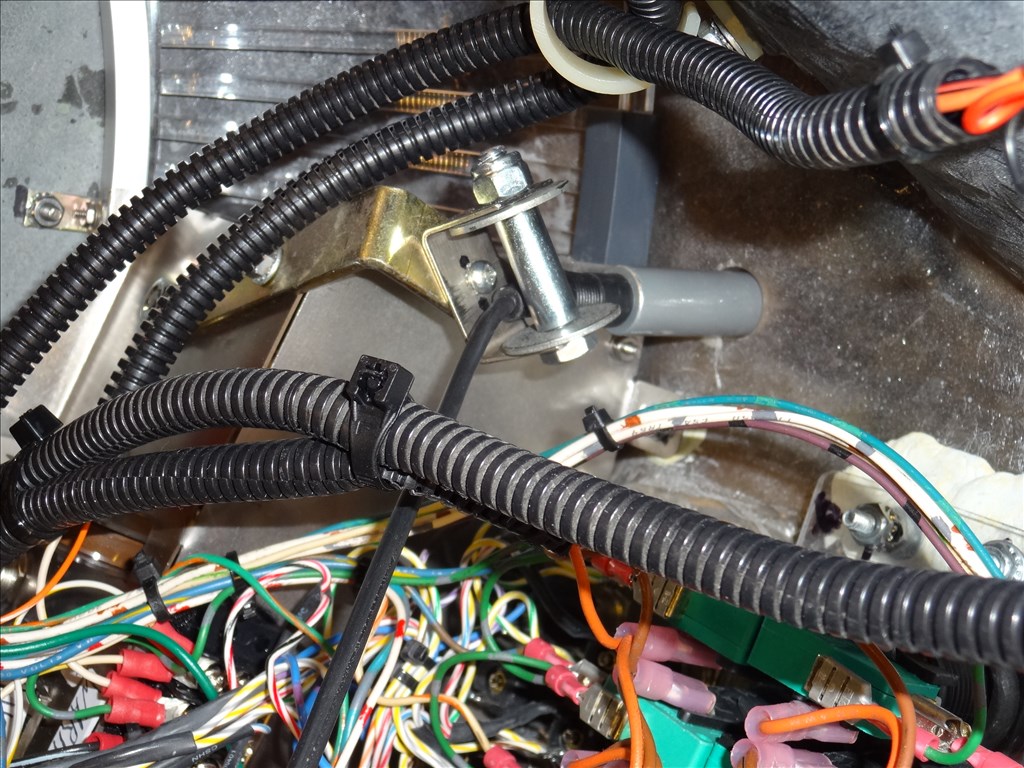

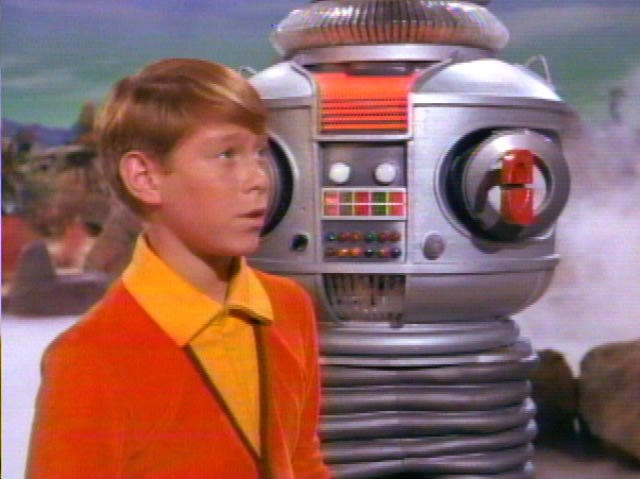

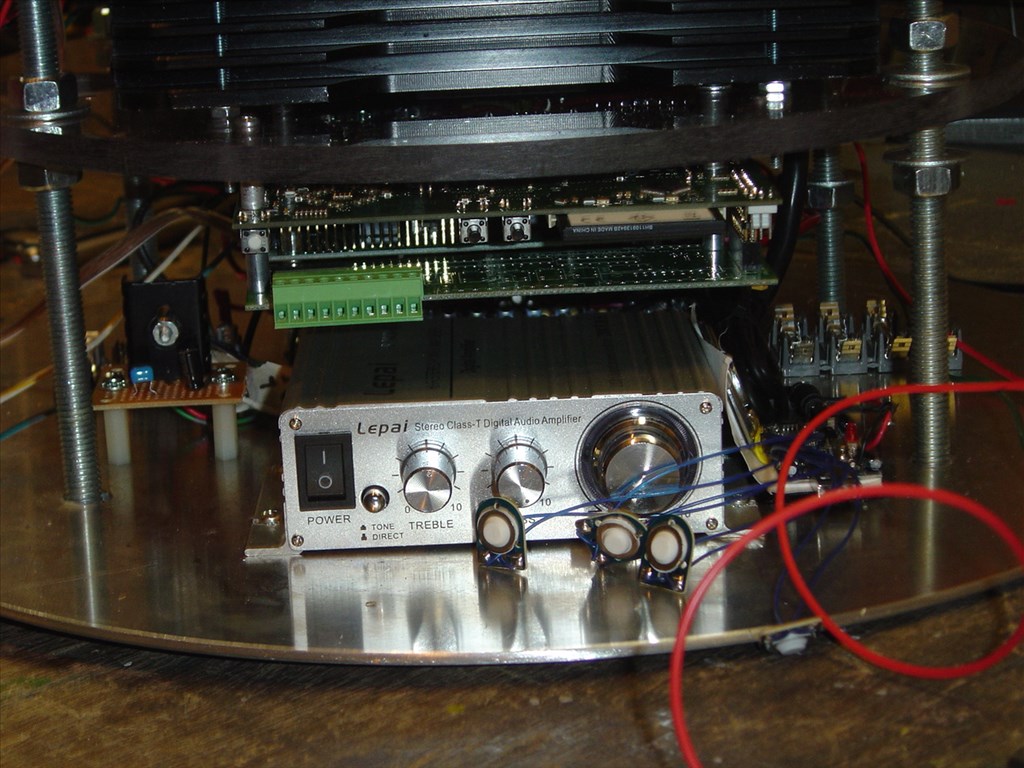

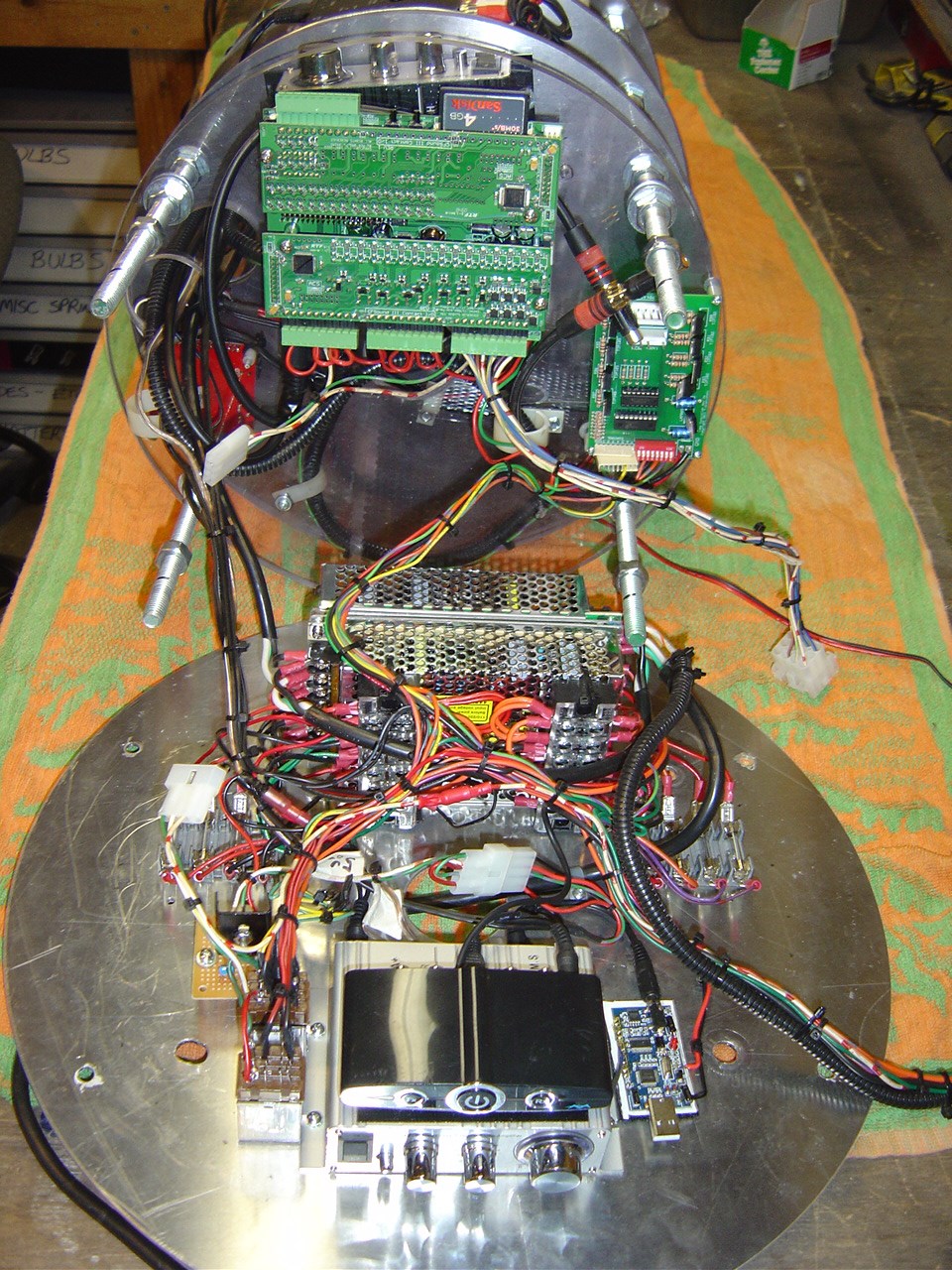

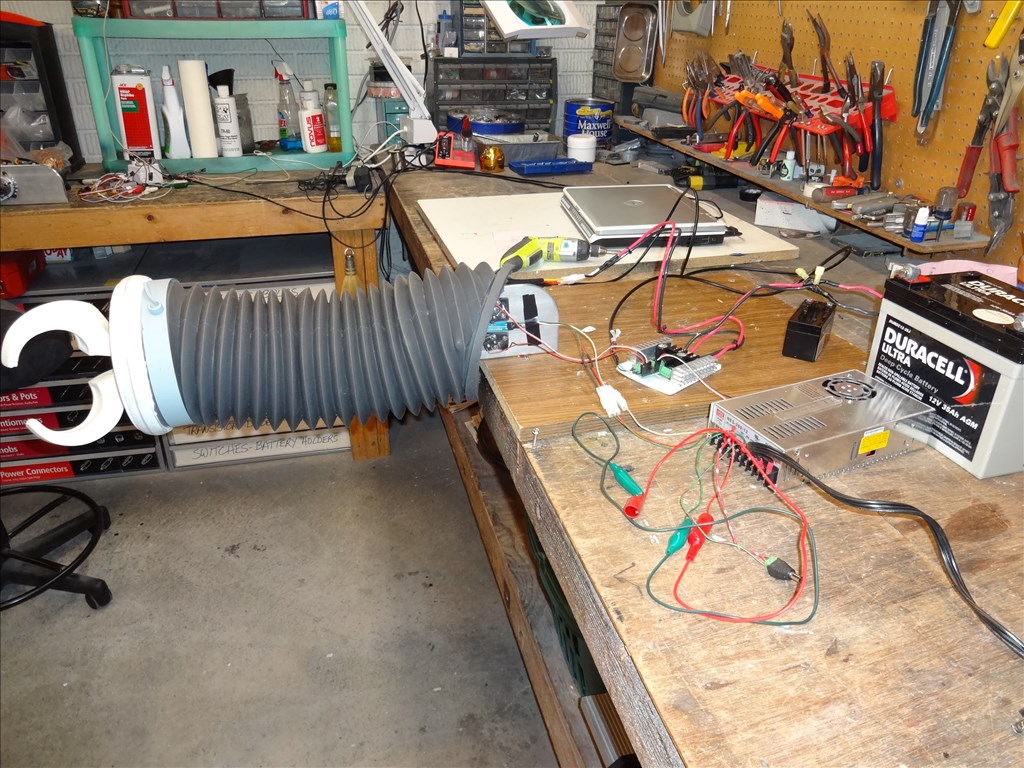

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

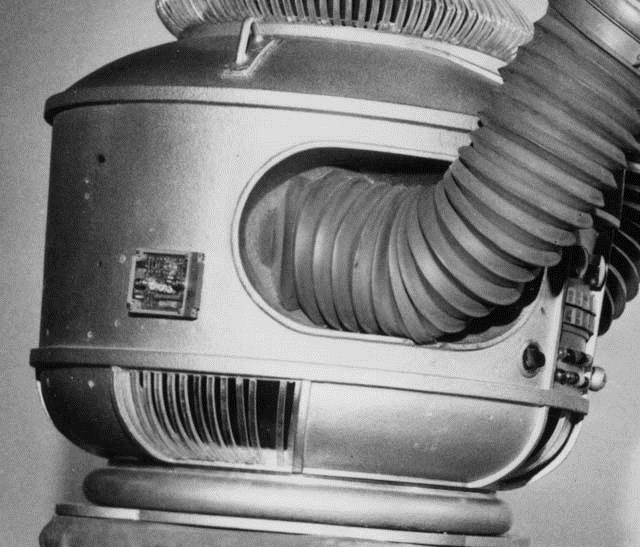

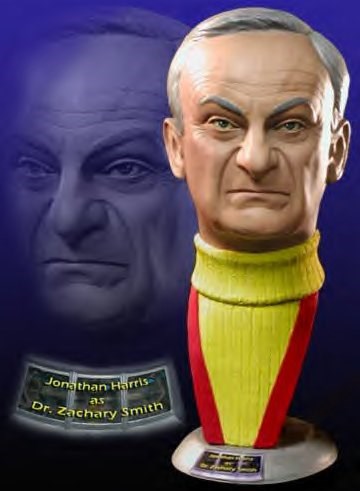

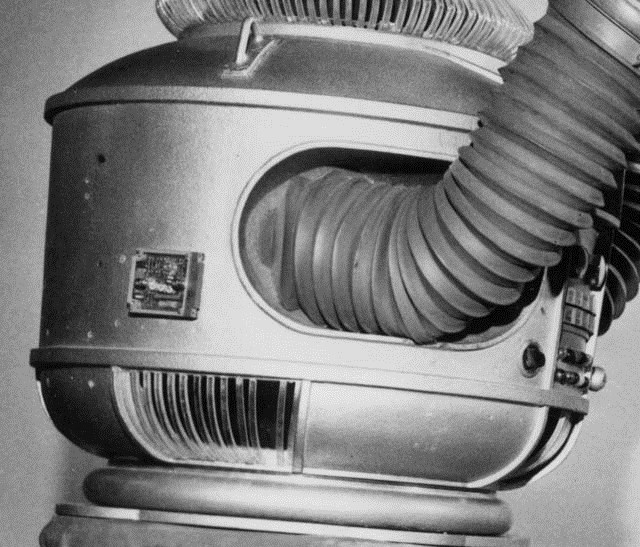

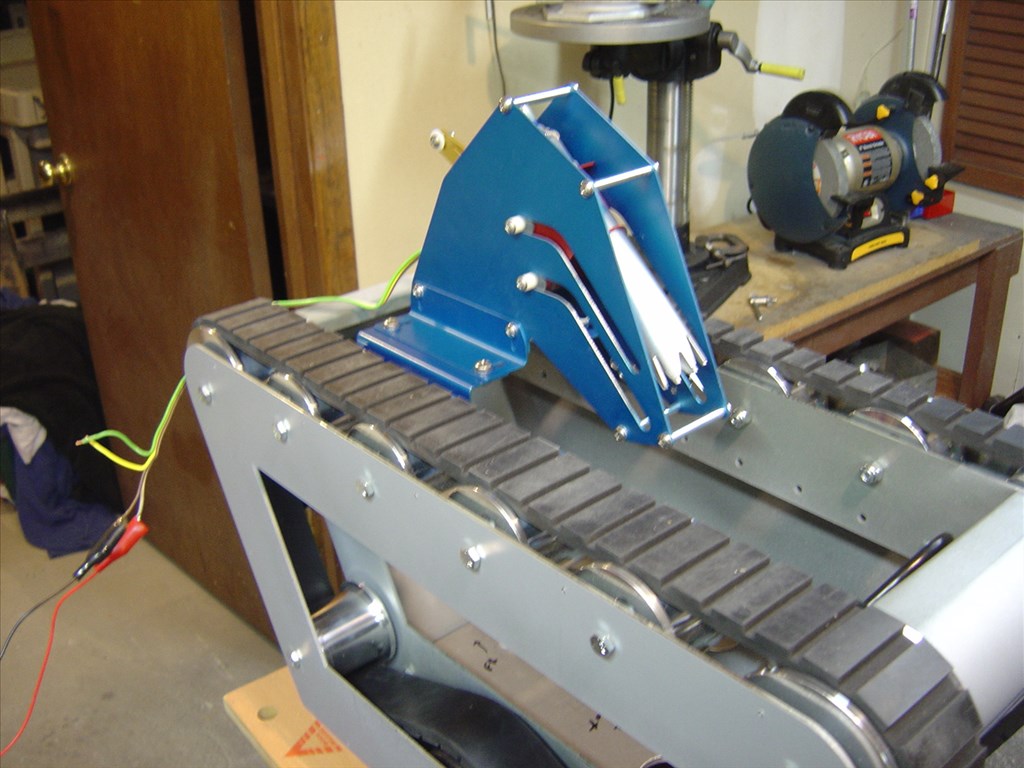

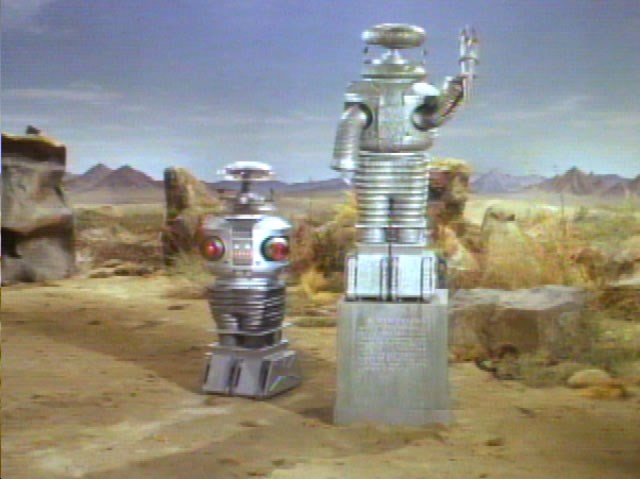

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

Hazardbt's I Have A Telemetry Suit-Contro

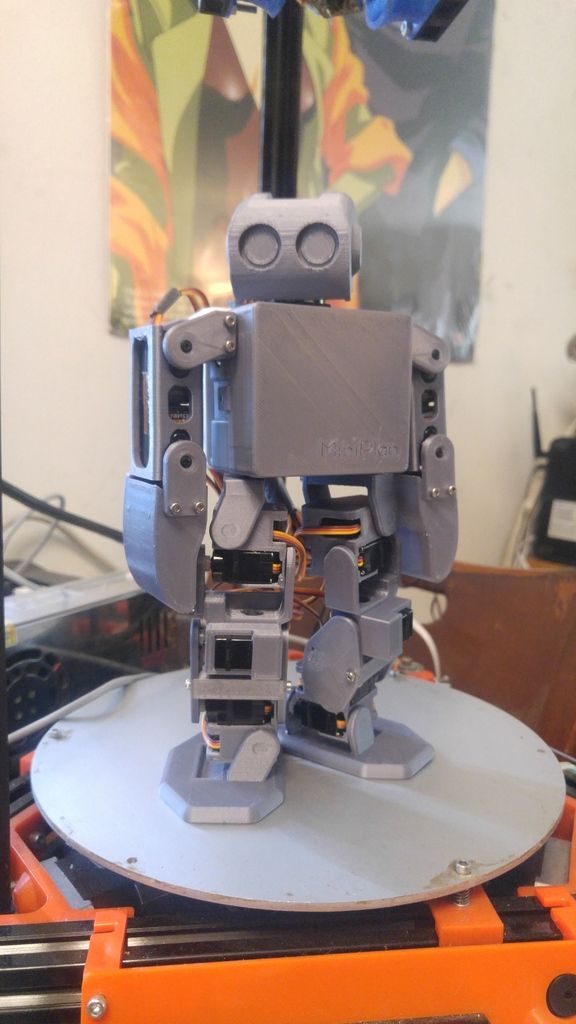

Kenny's Humanoid #3, The Miniplan

-635353562186322812.png)

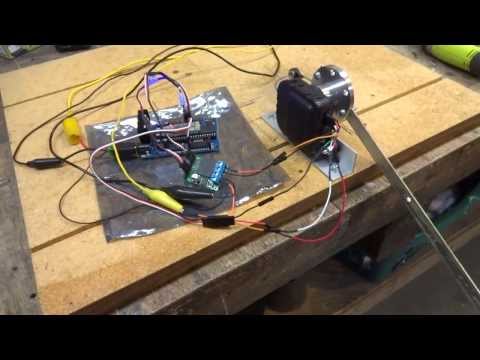

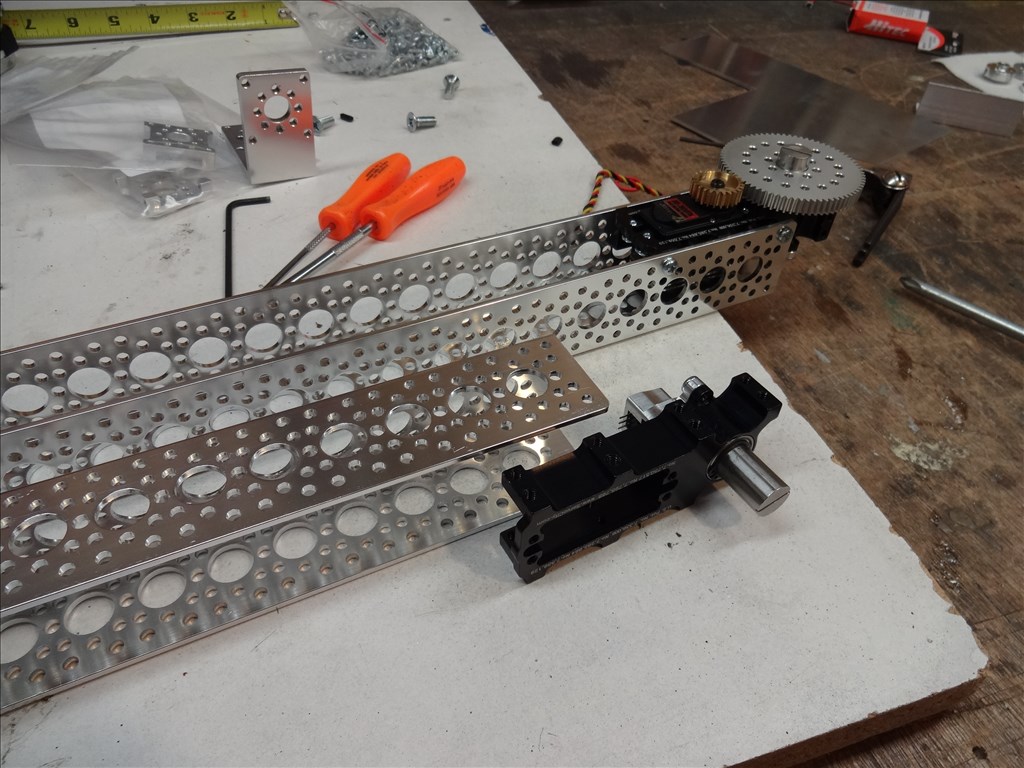

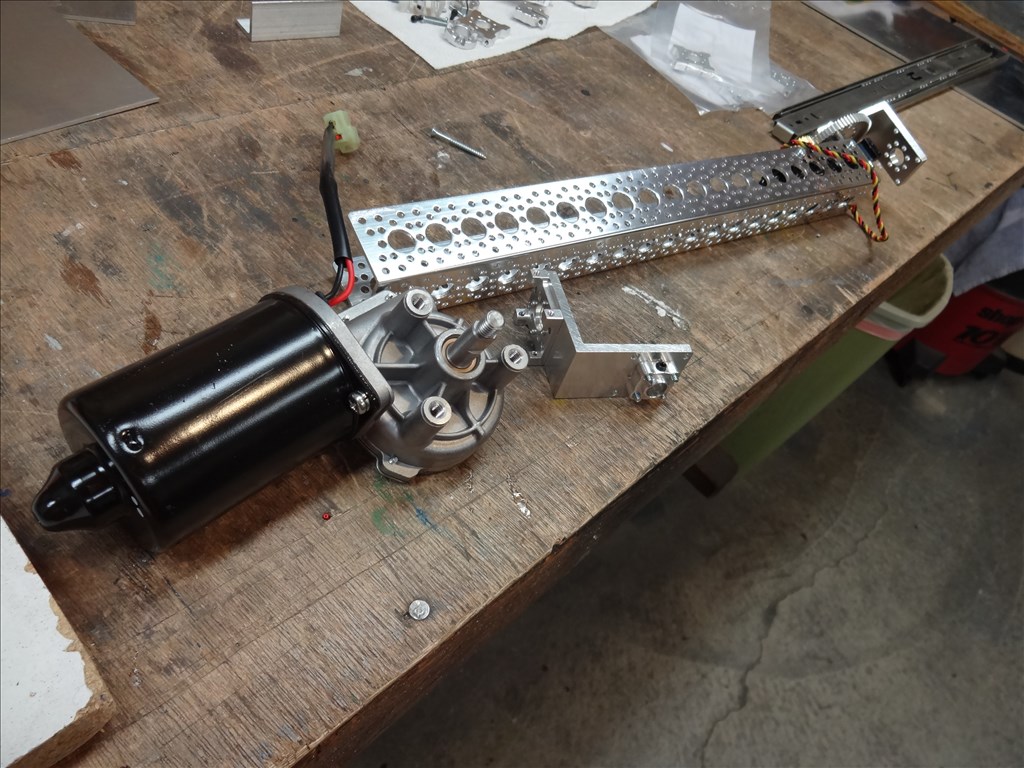

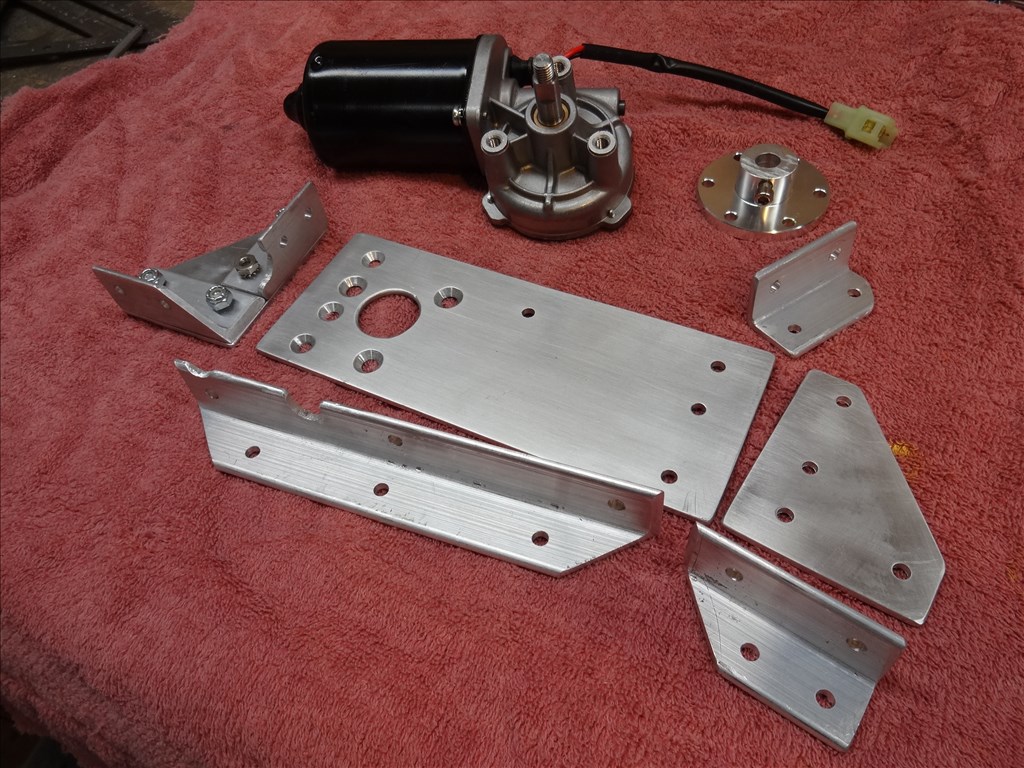

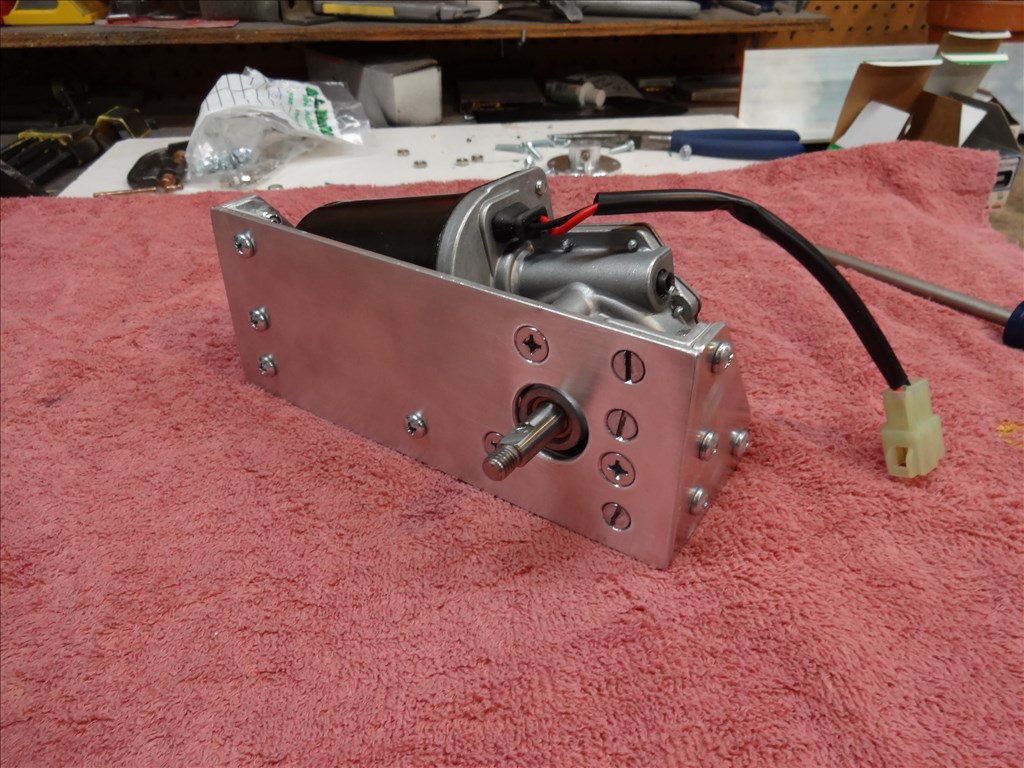

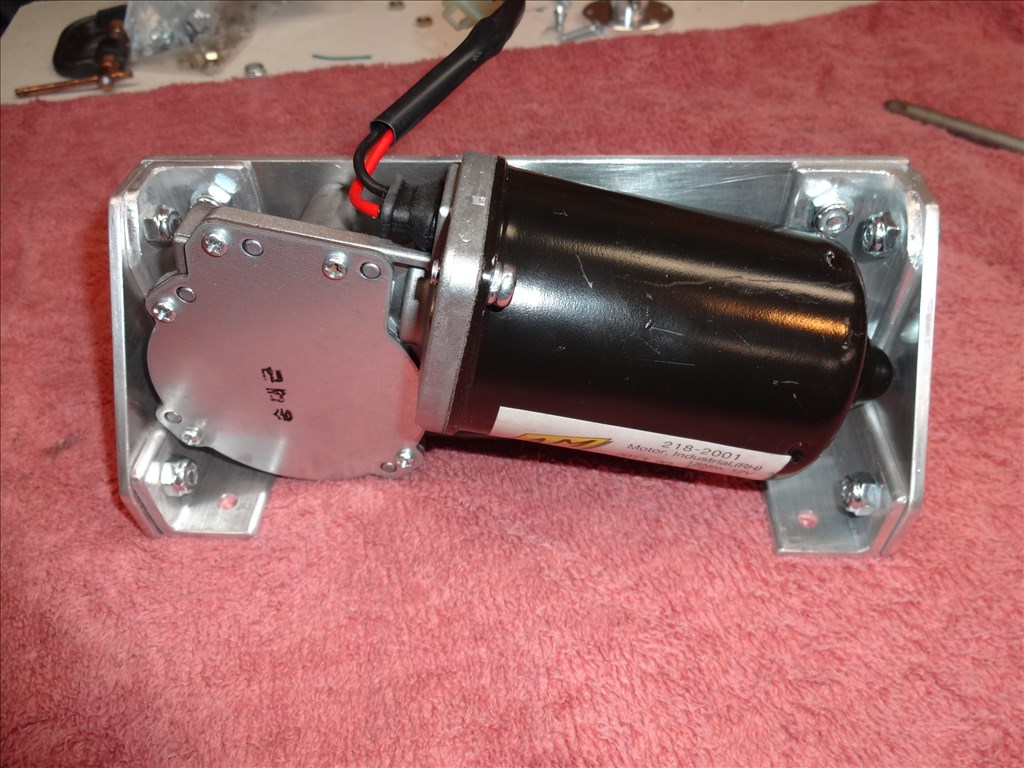

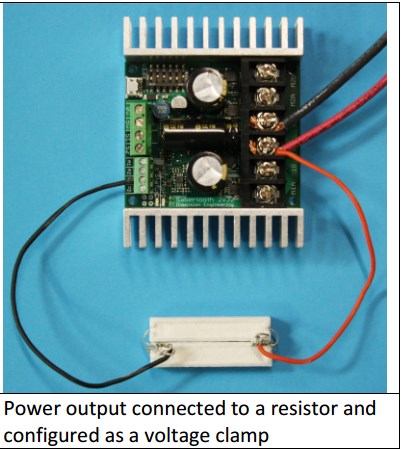

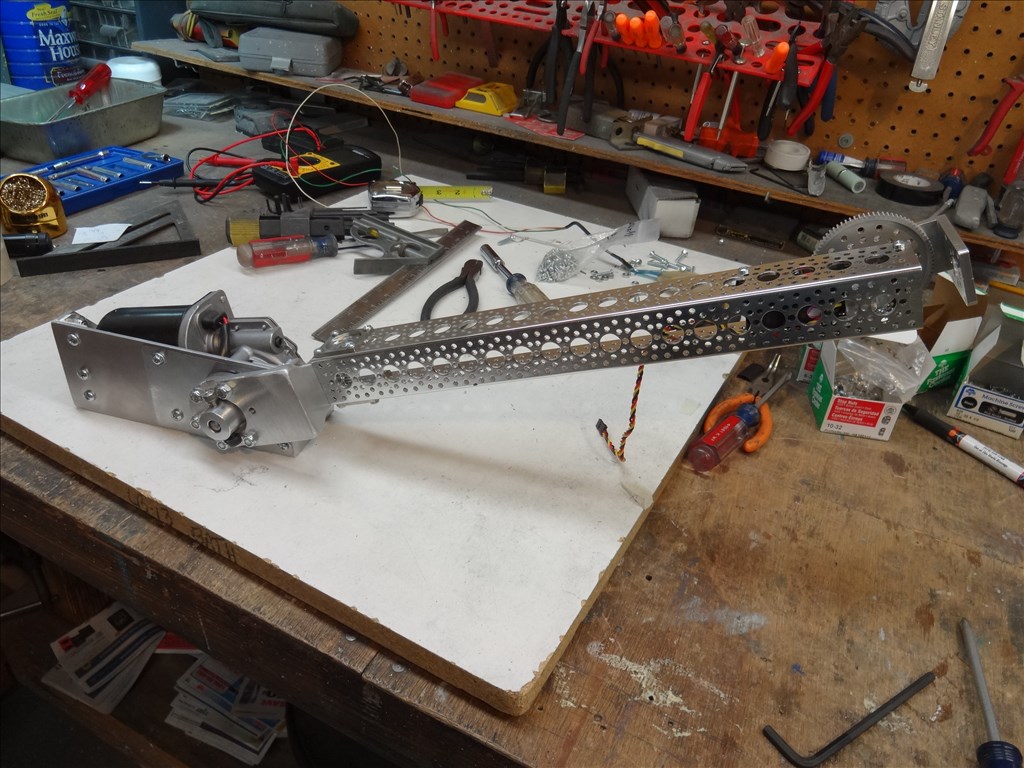

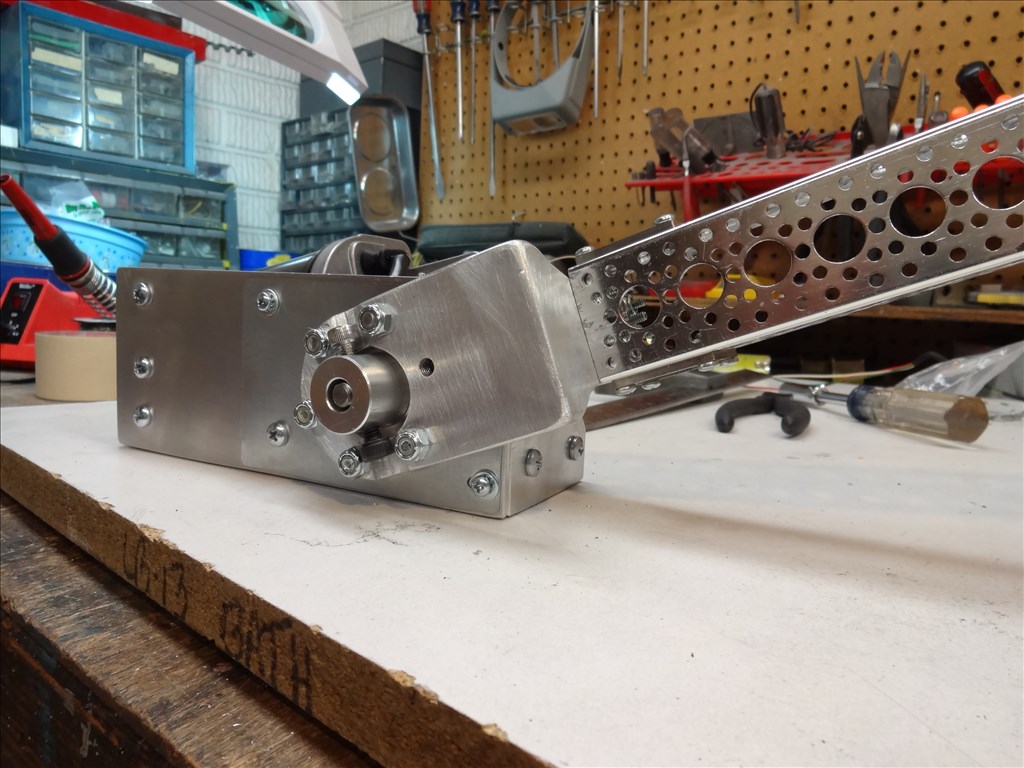

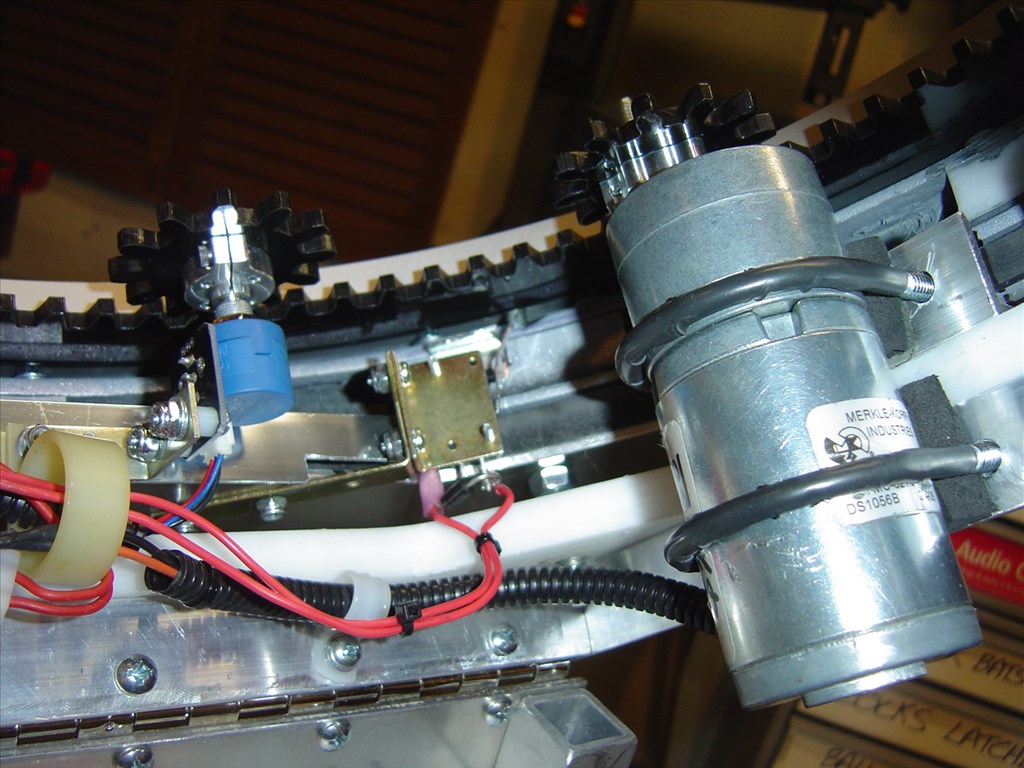

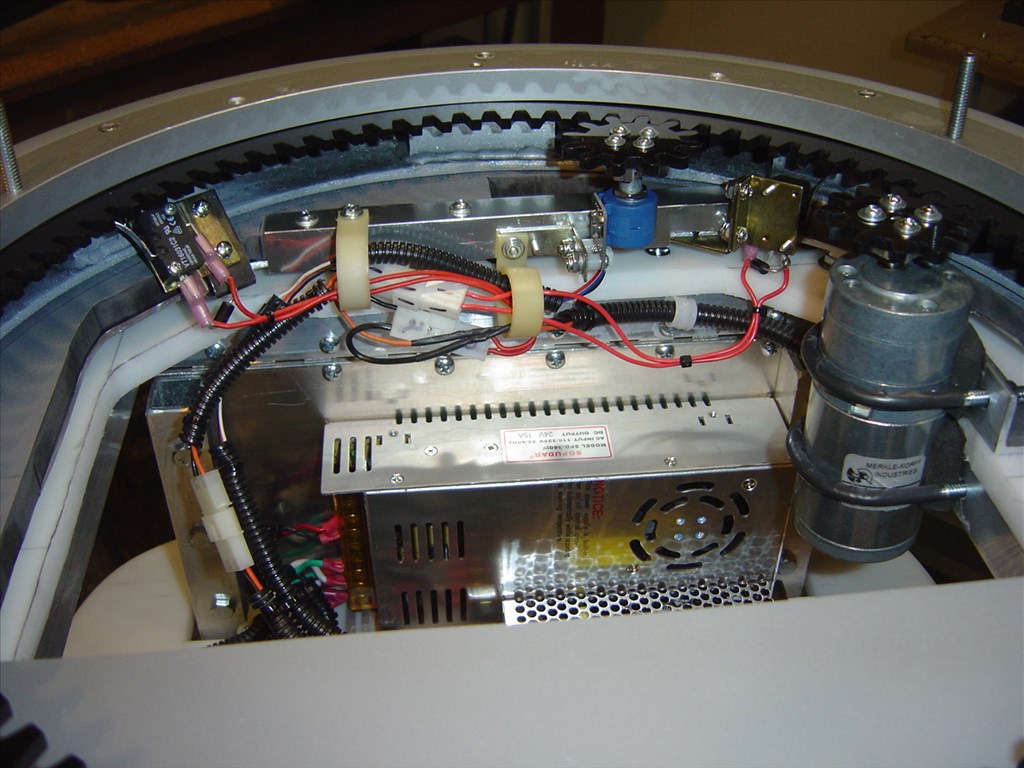

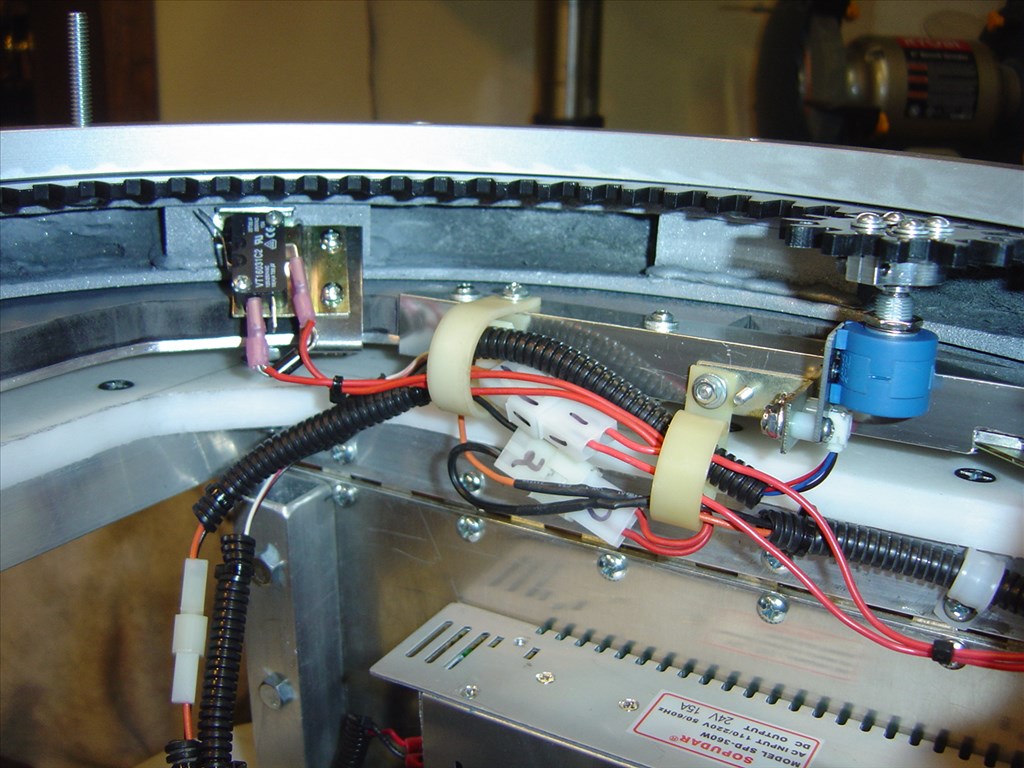

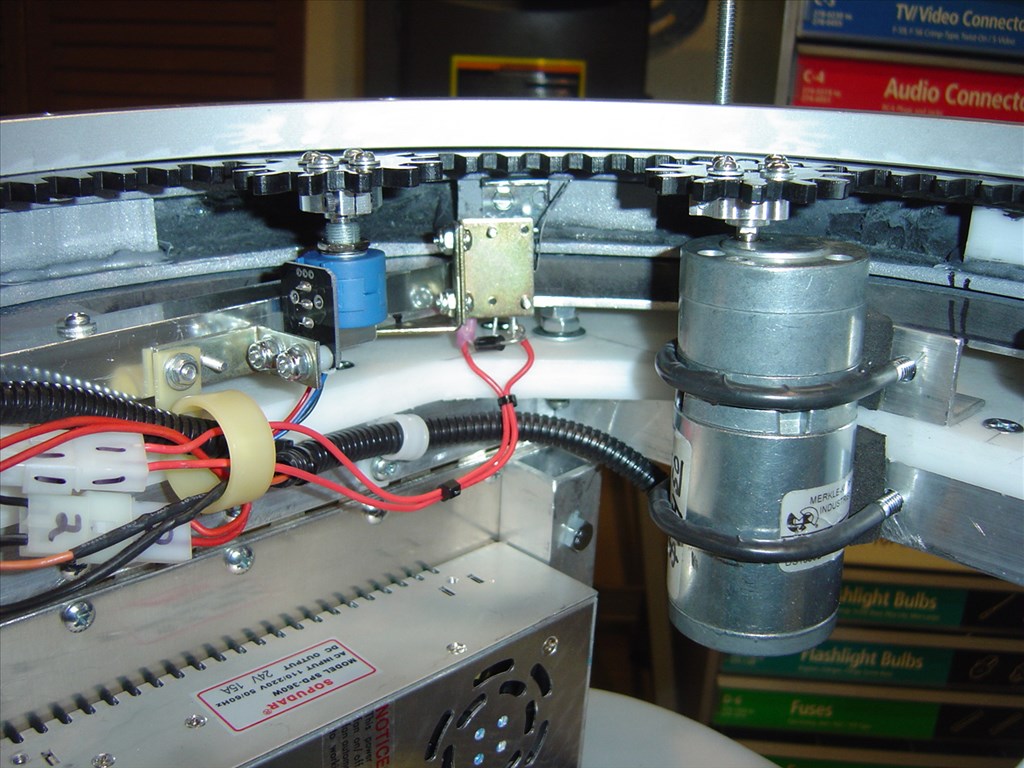

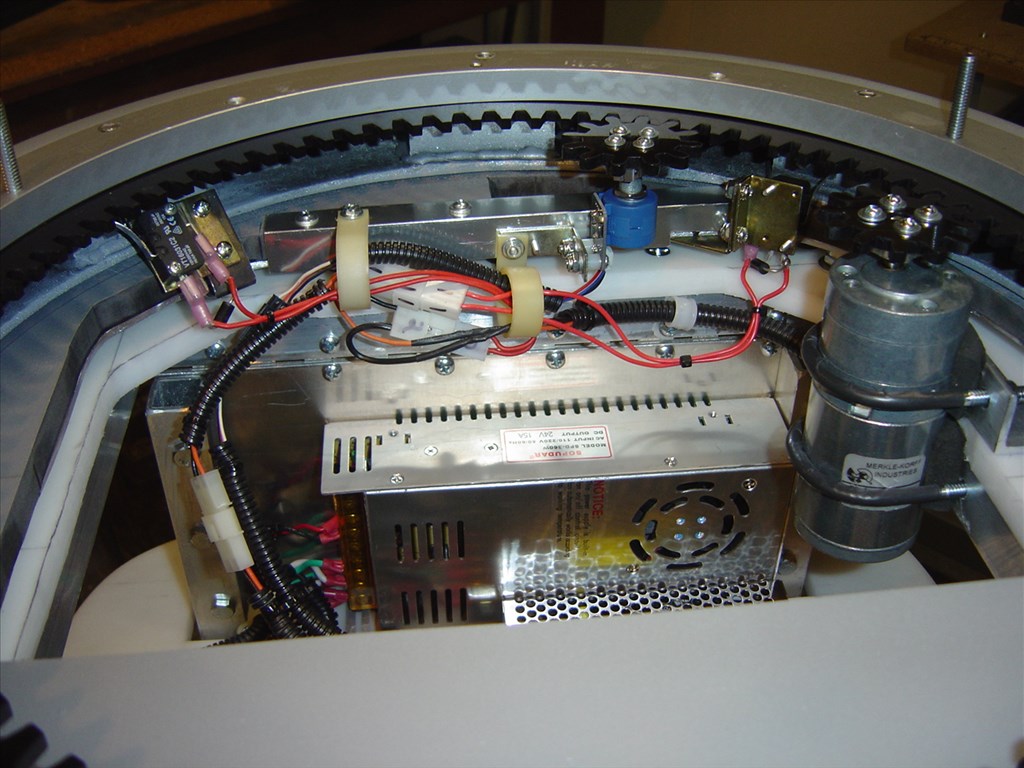

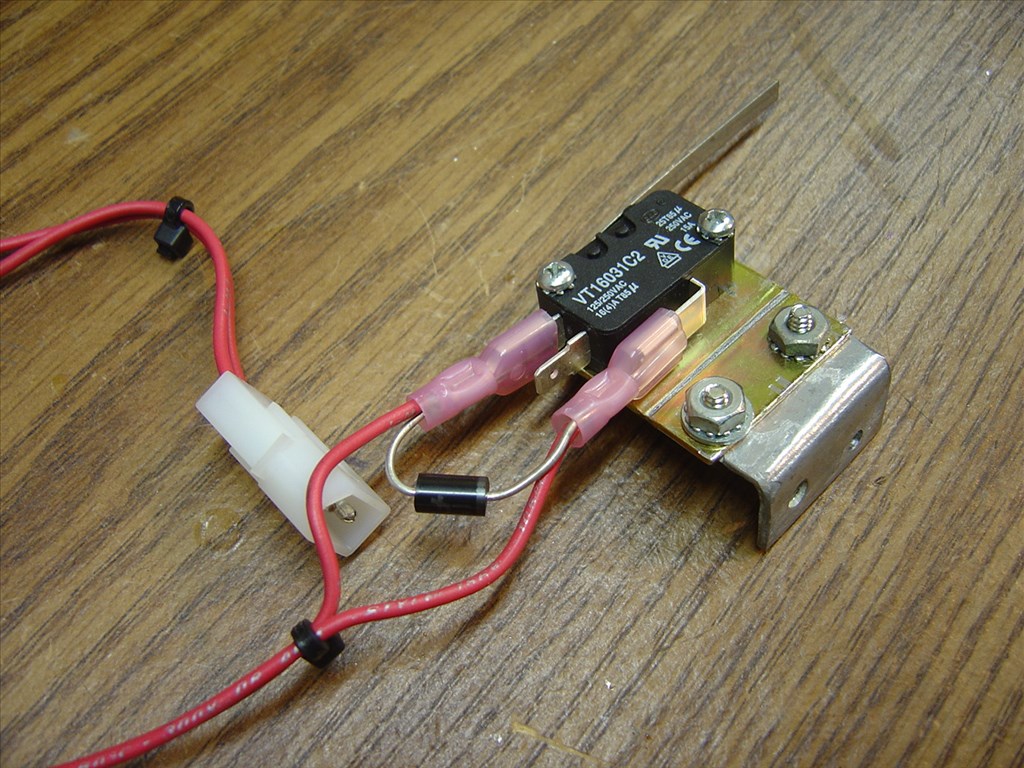

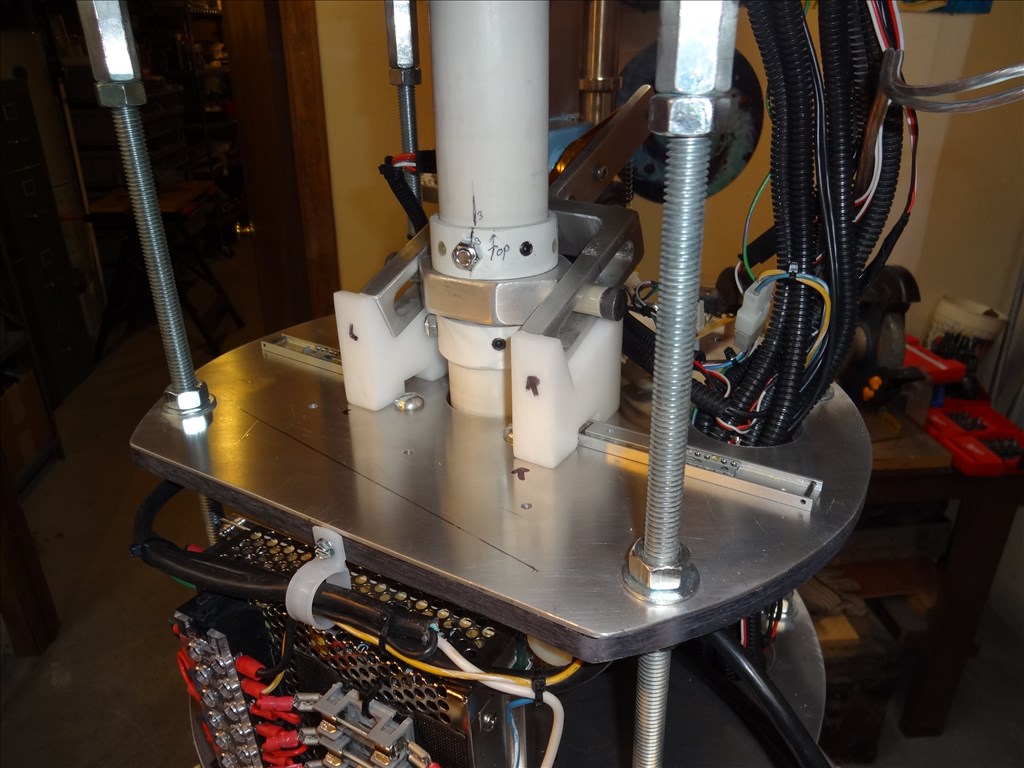

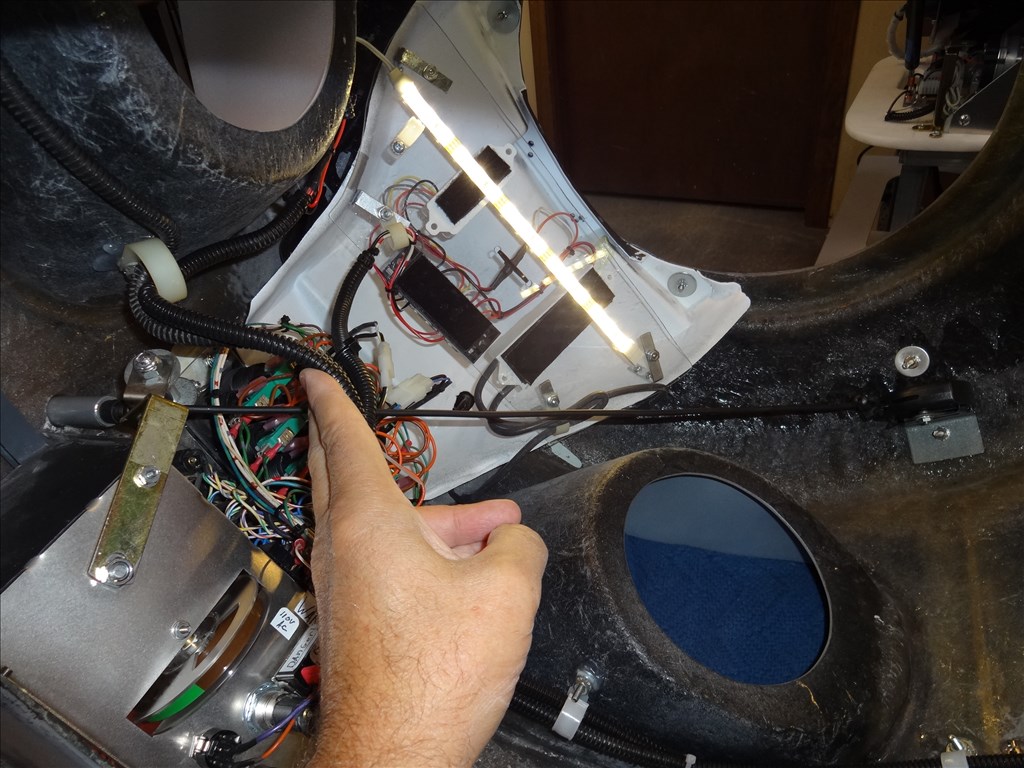

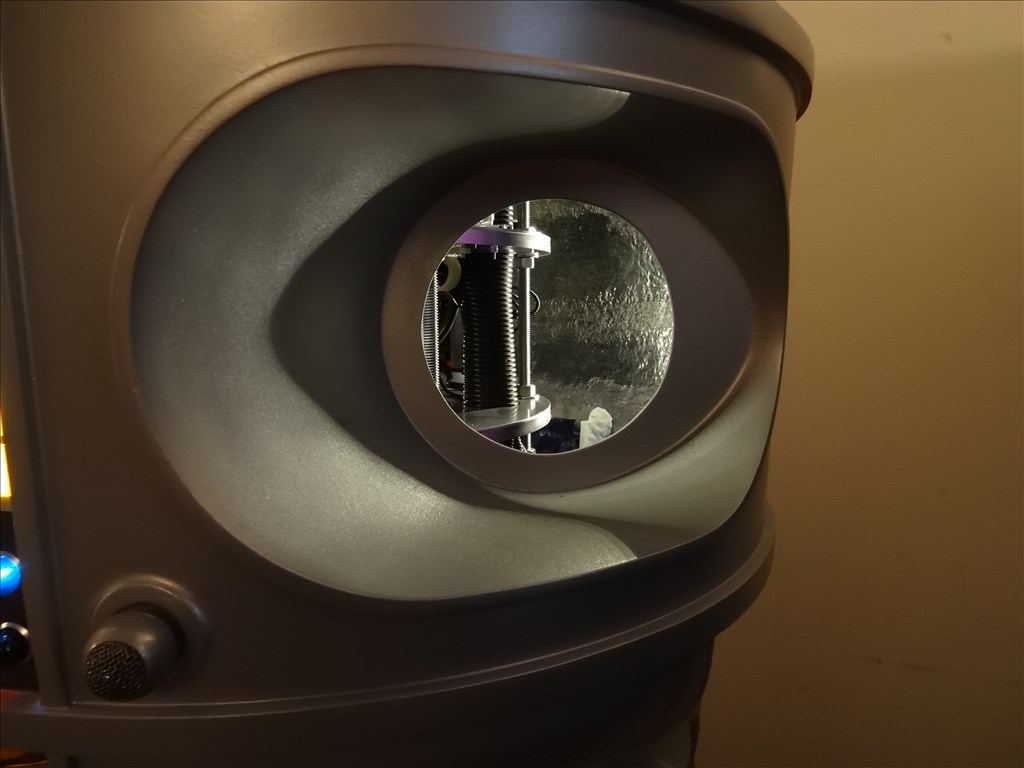

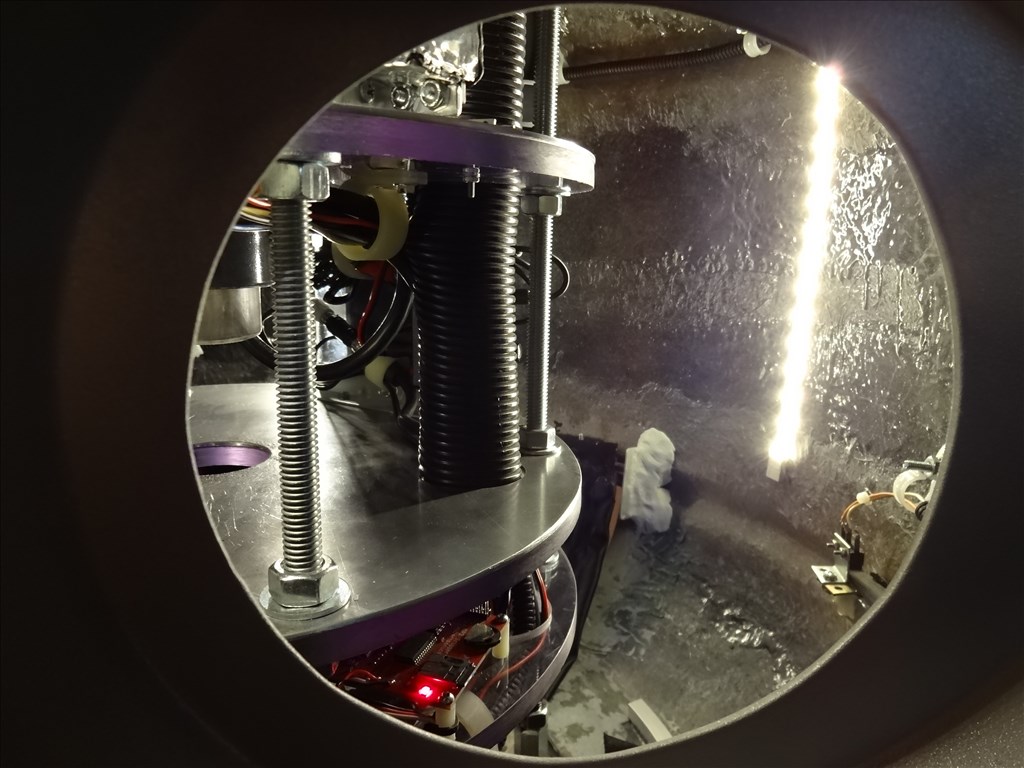

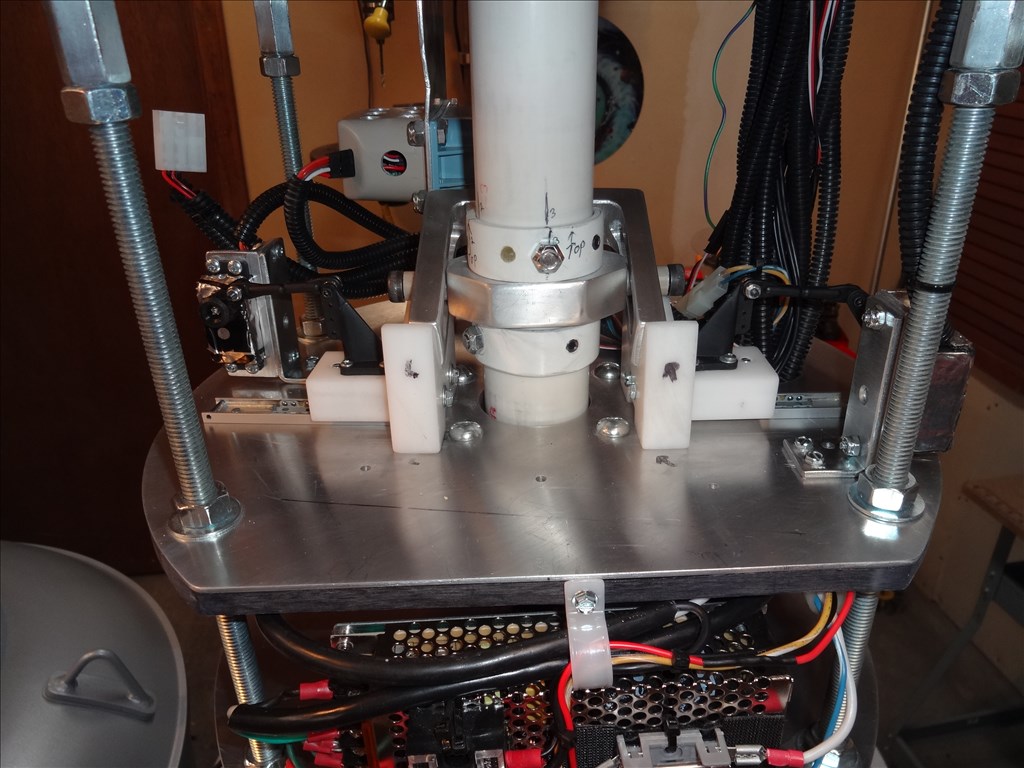

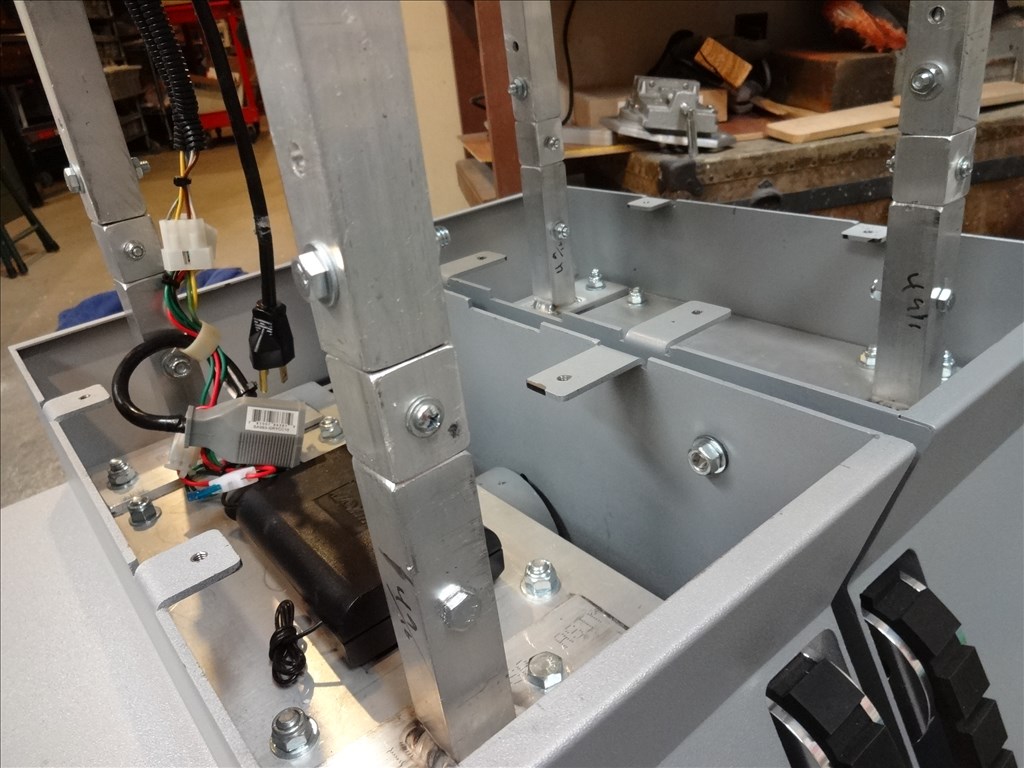

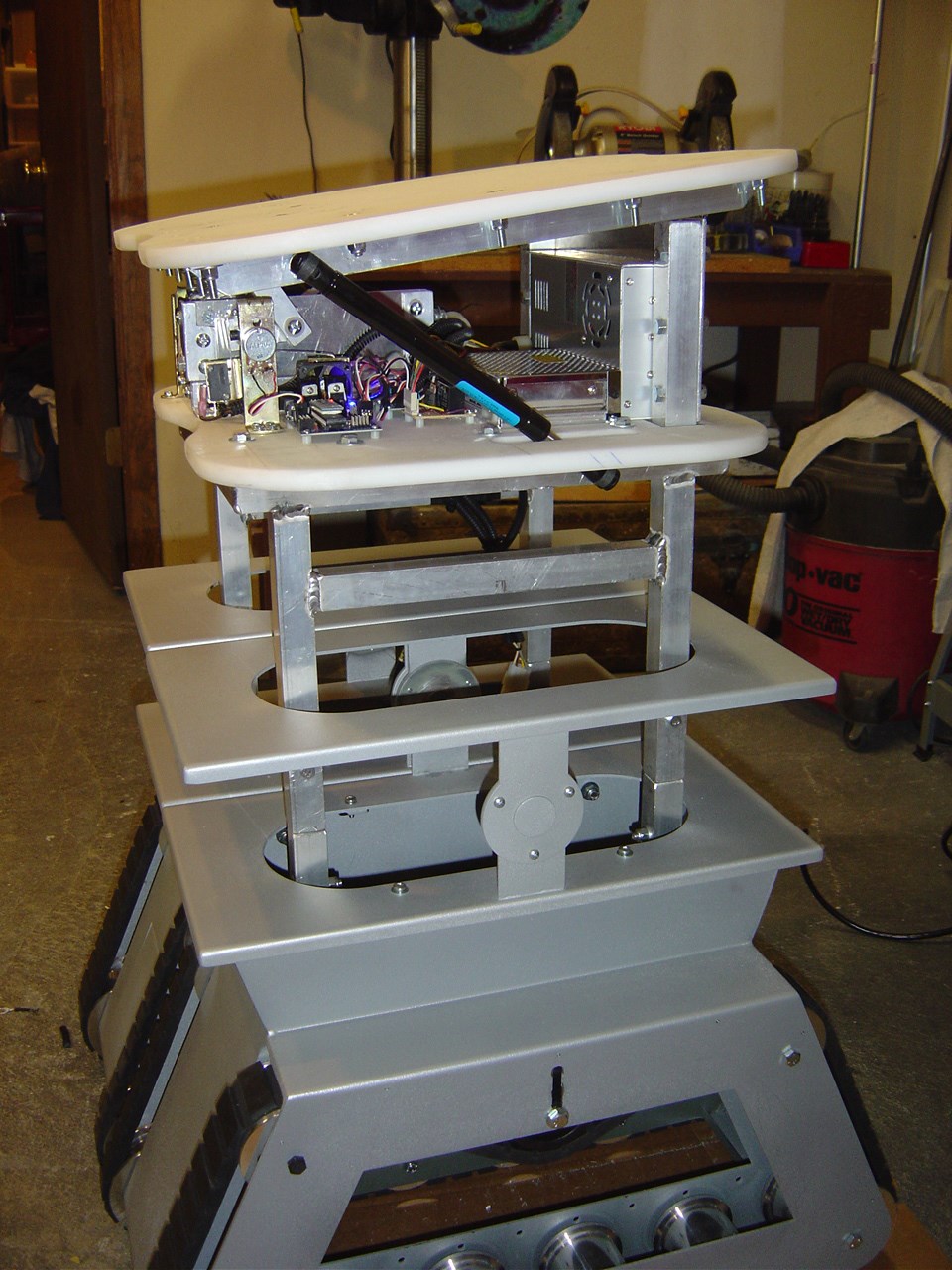

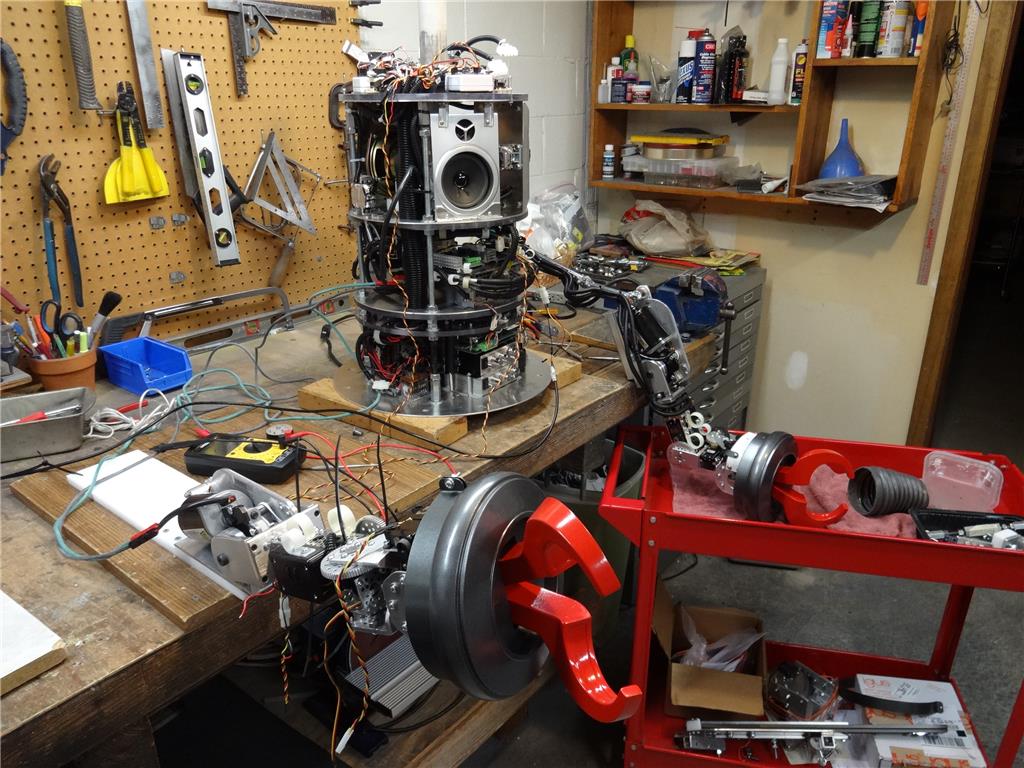

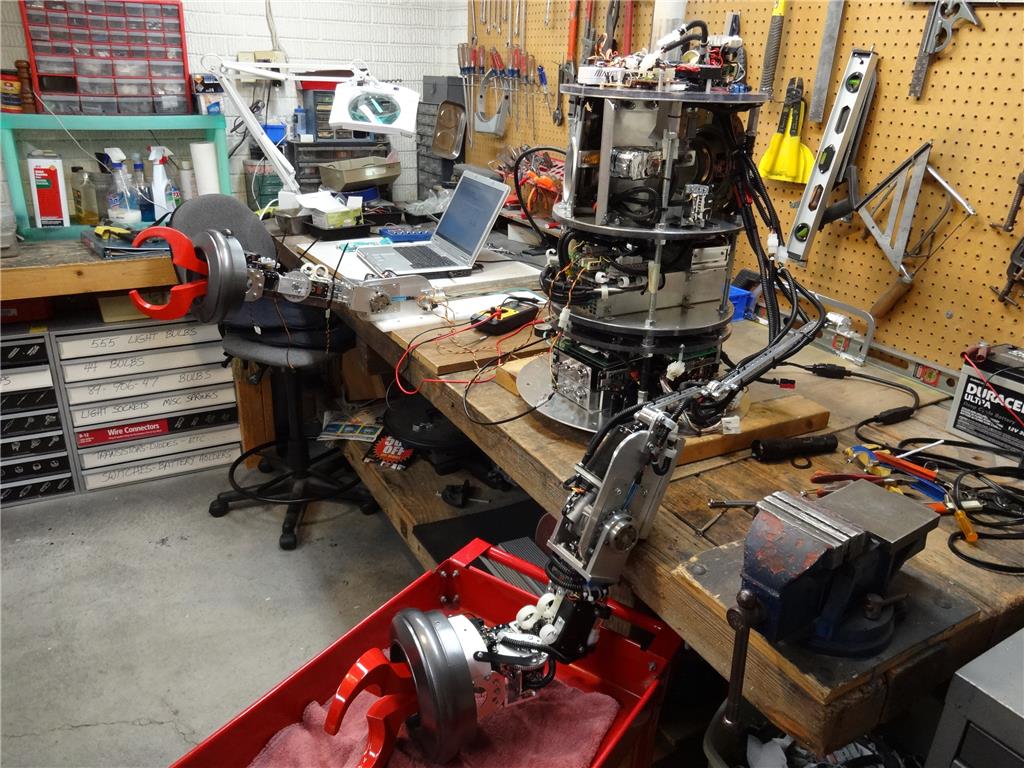

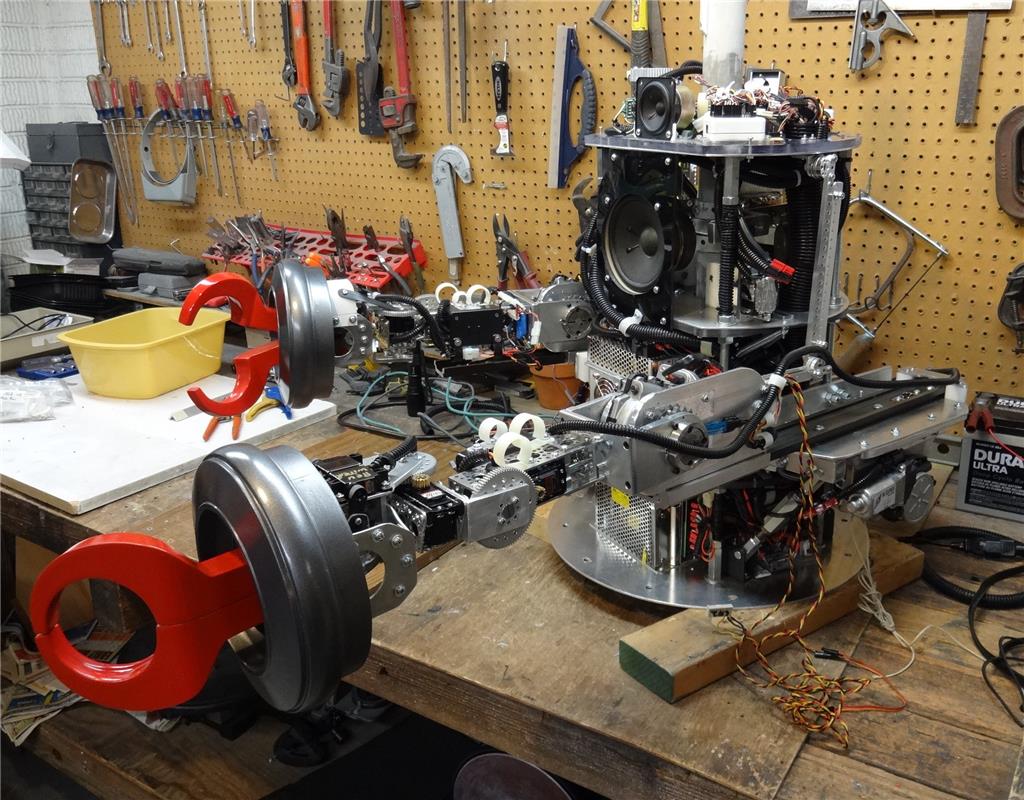

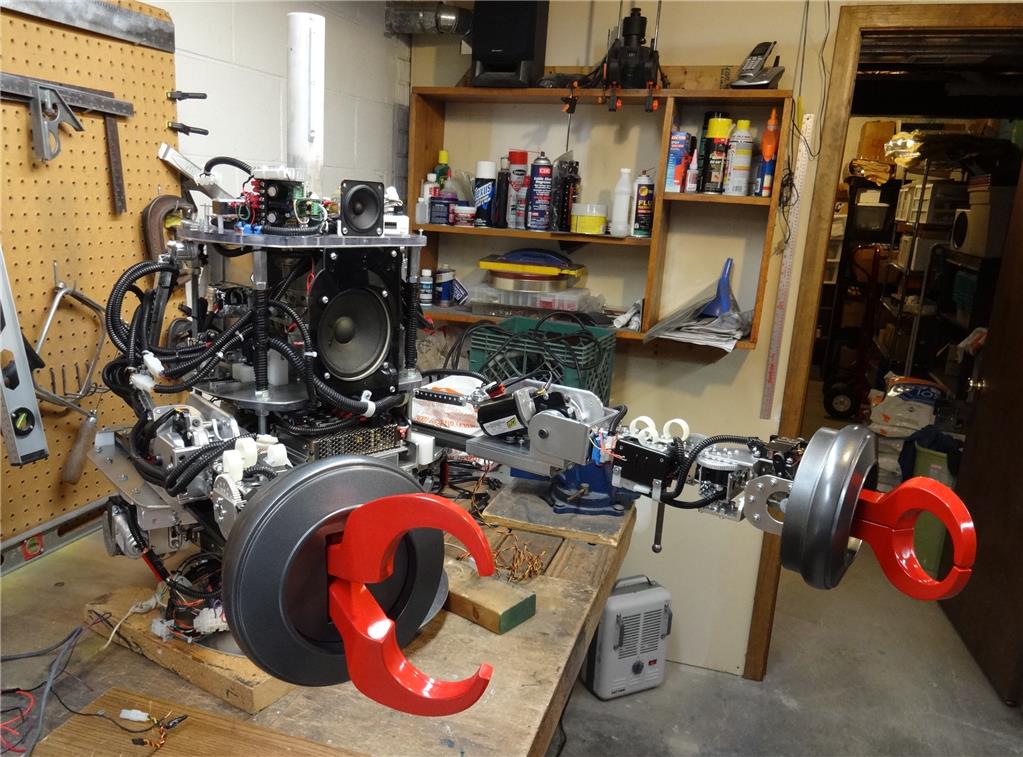

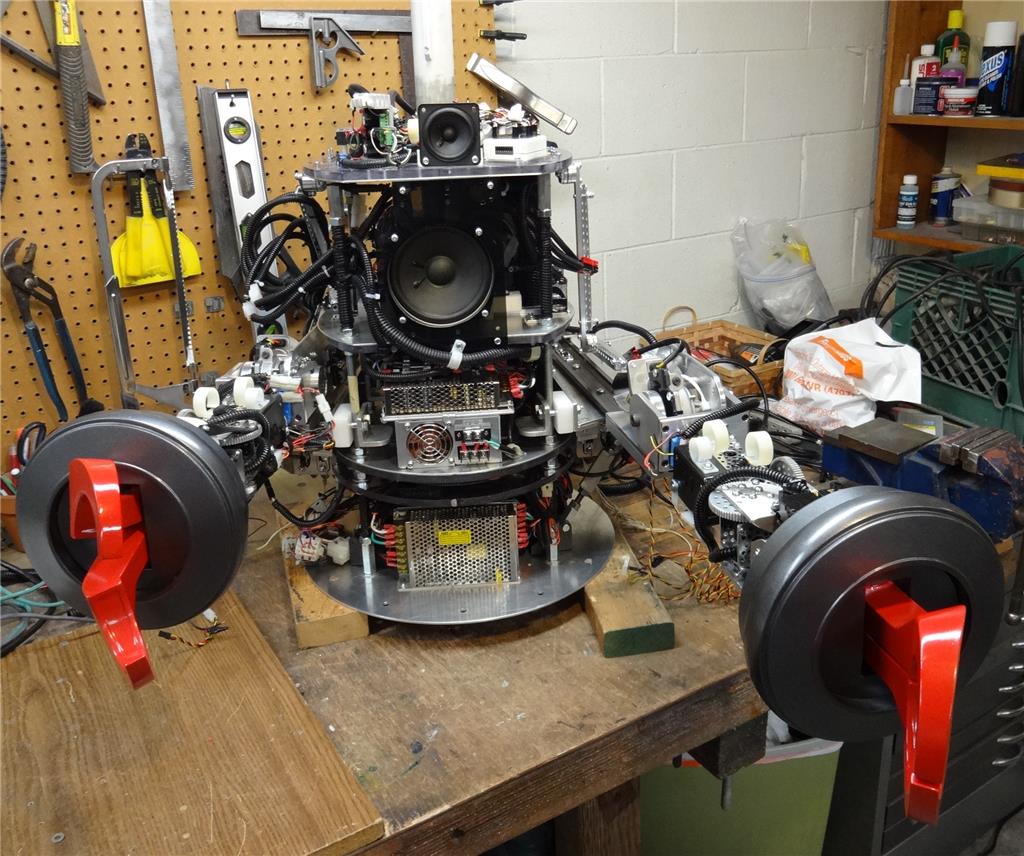

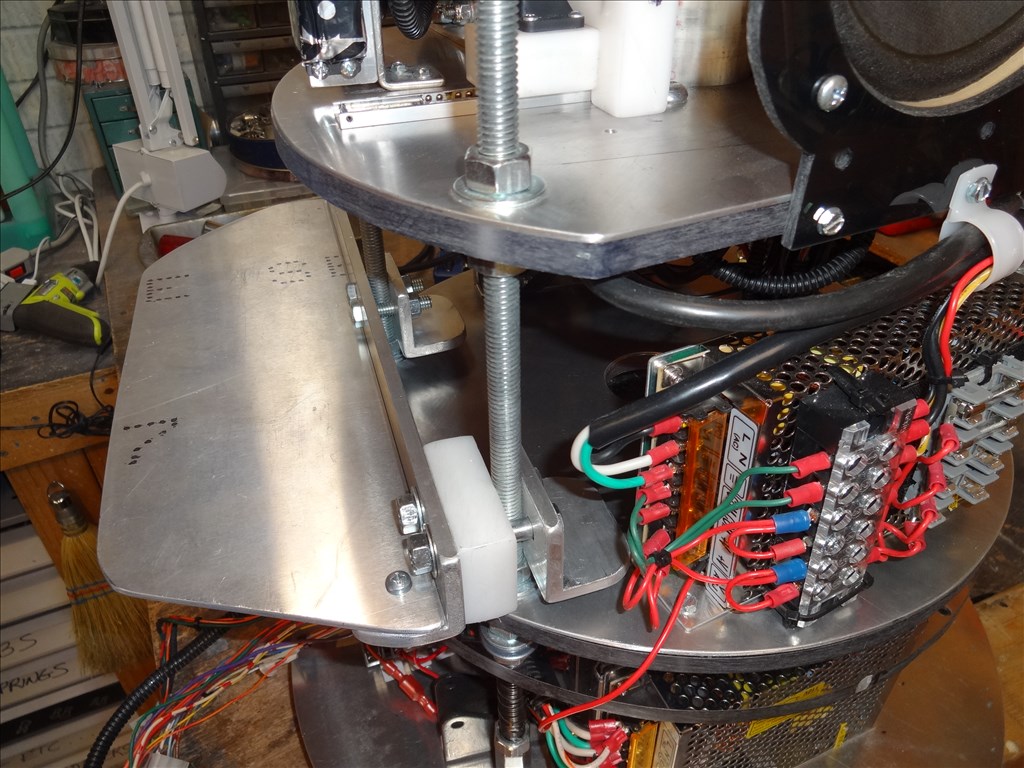

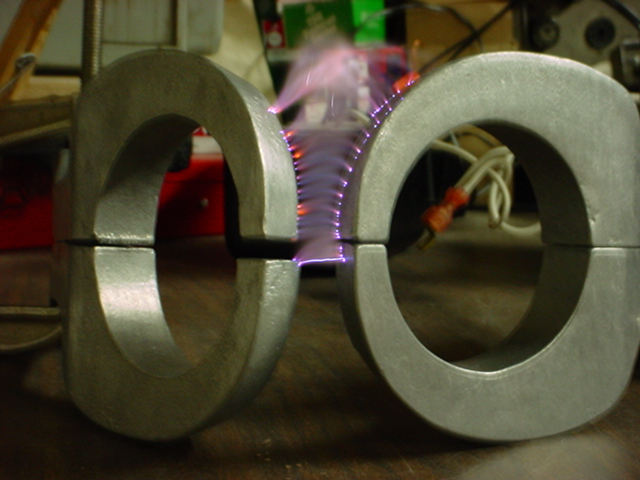

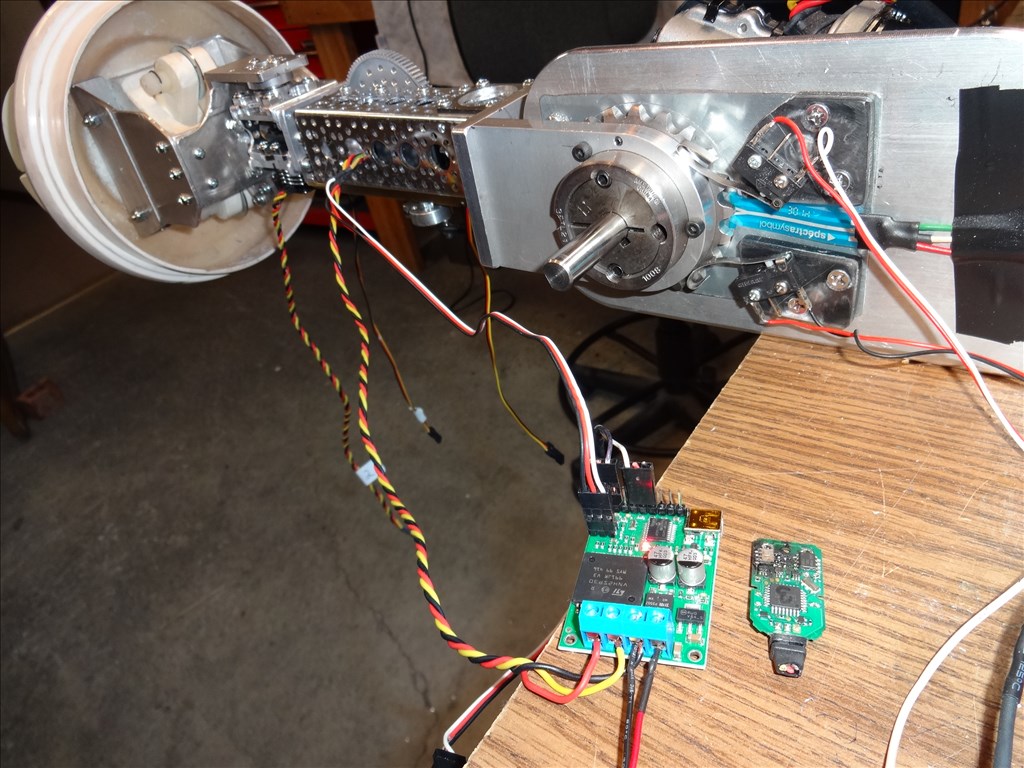

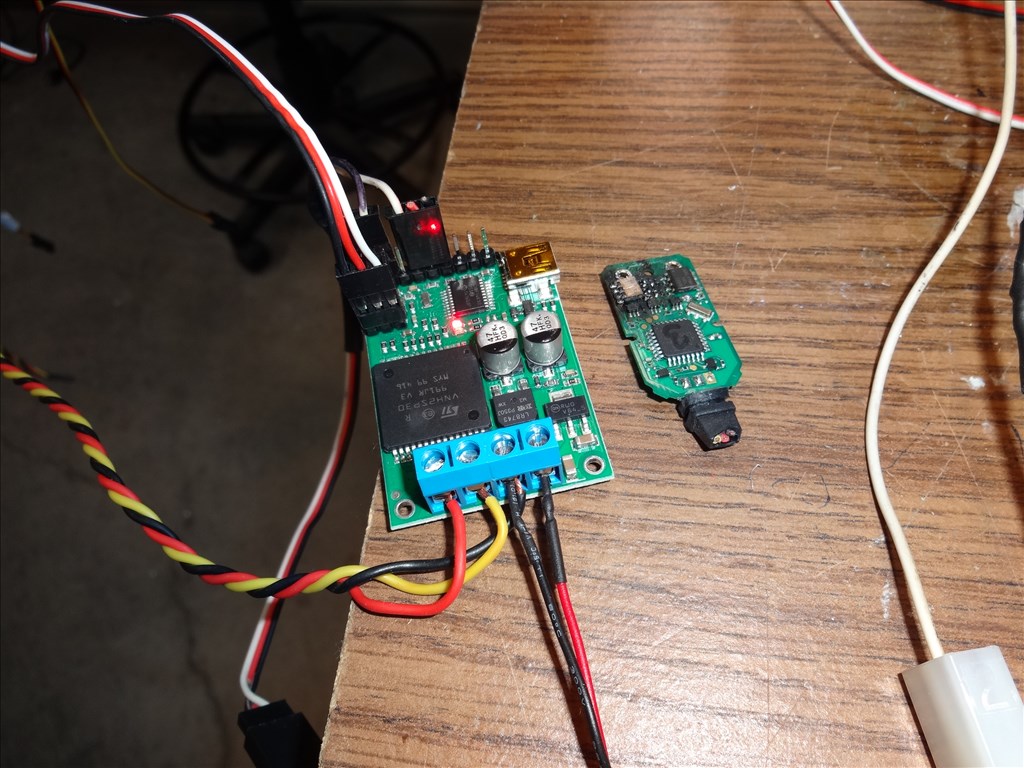

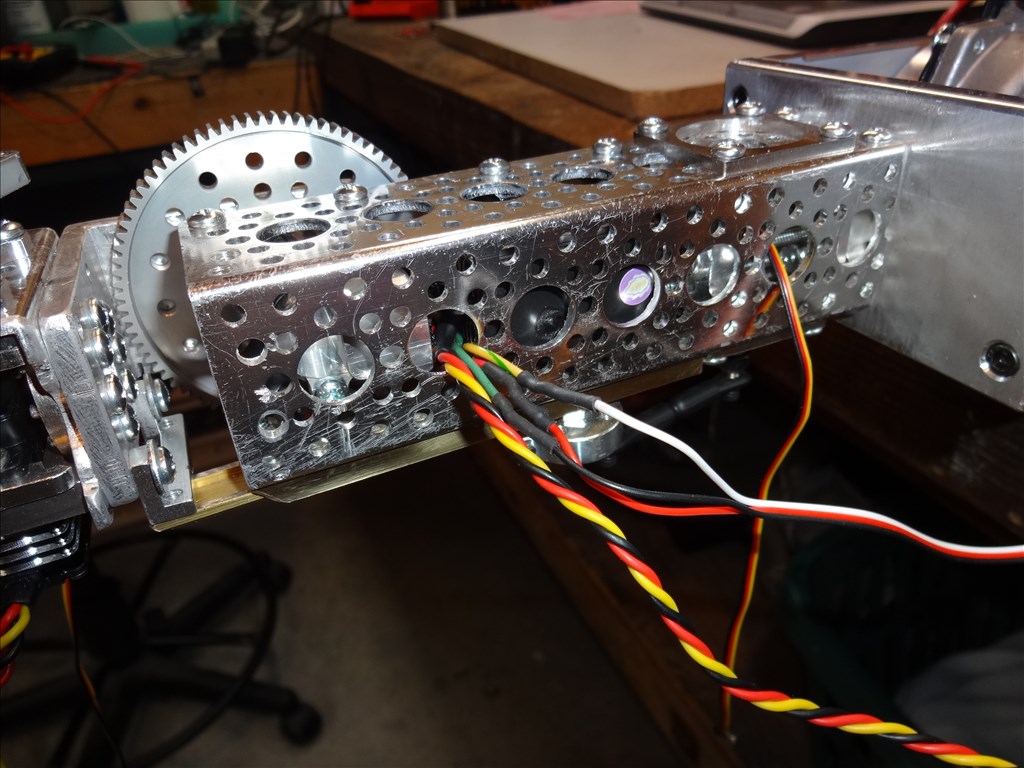

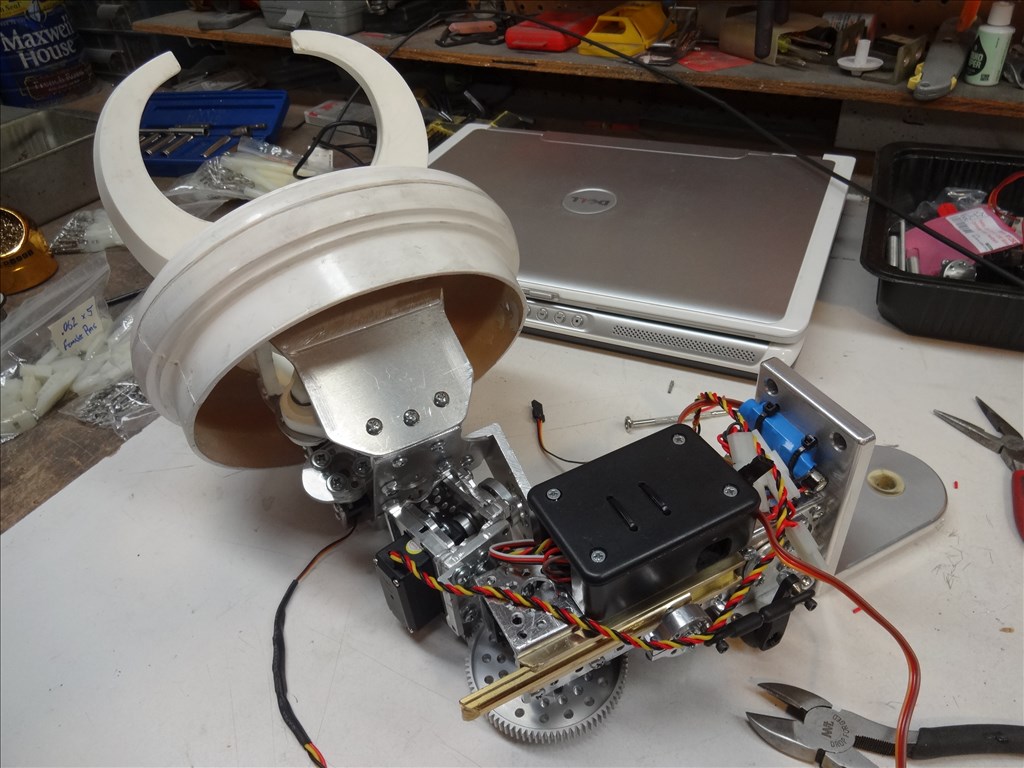

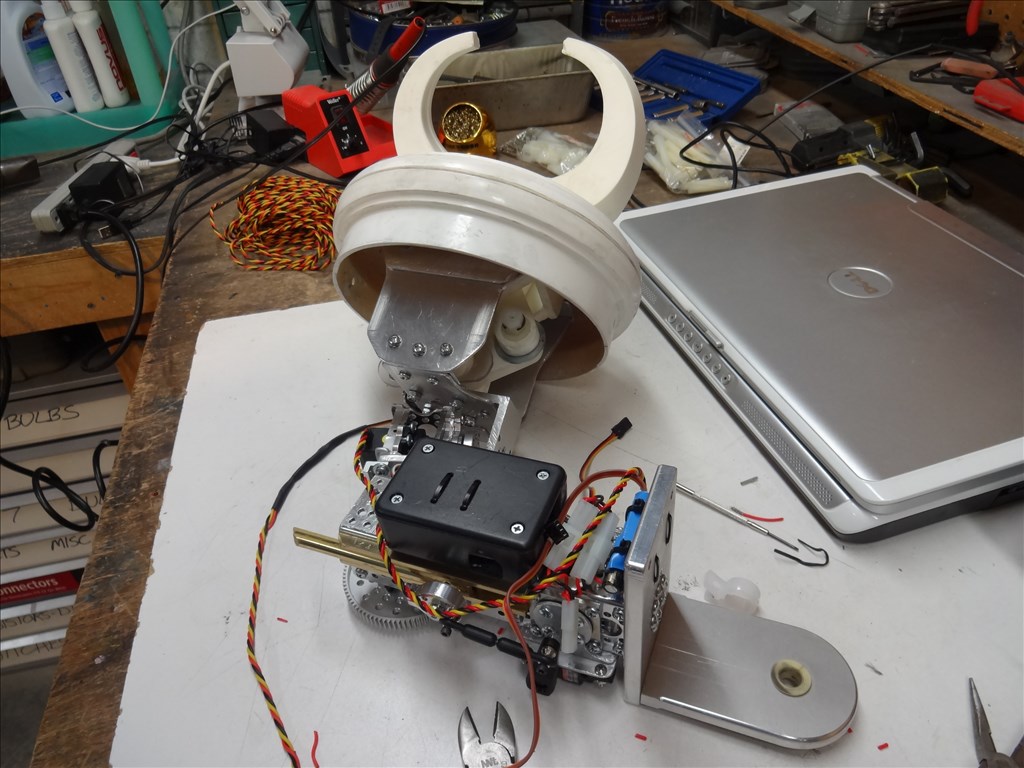

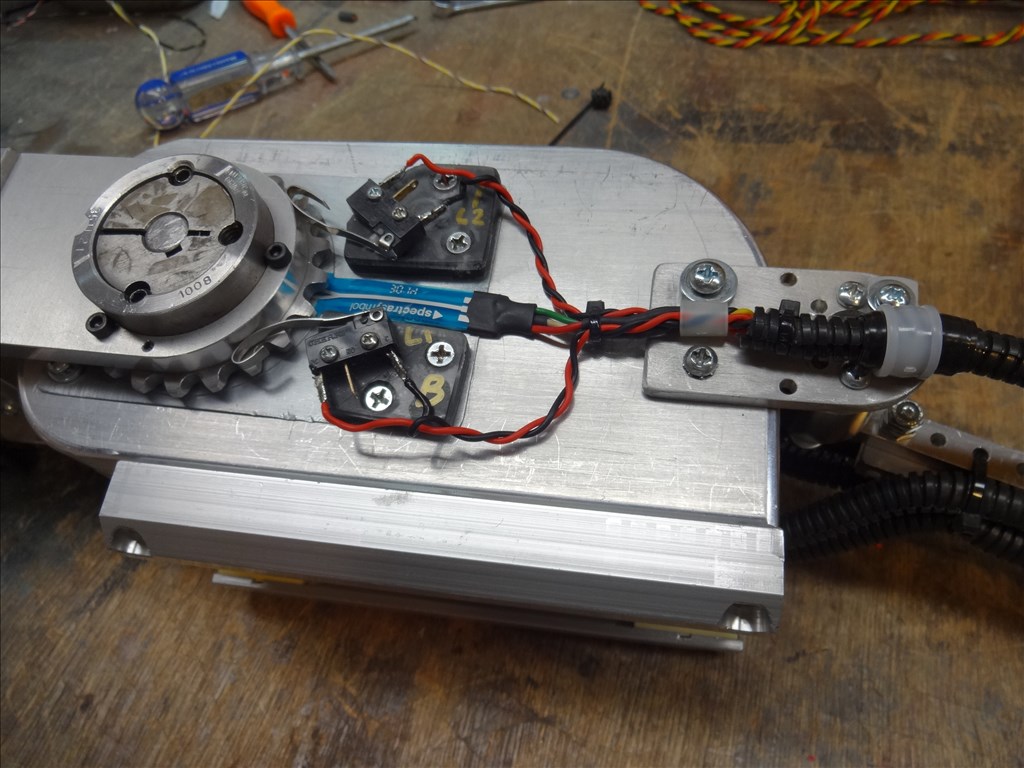

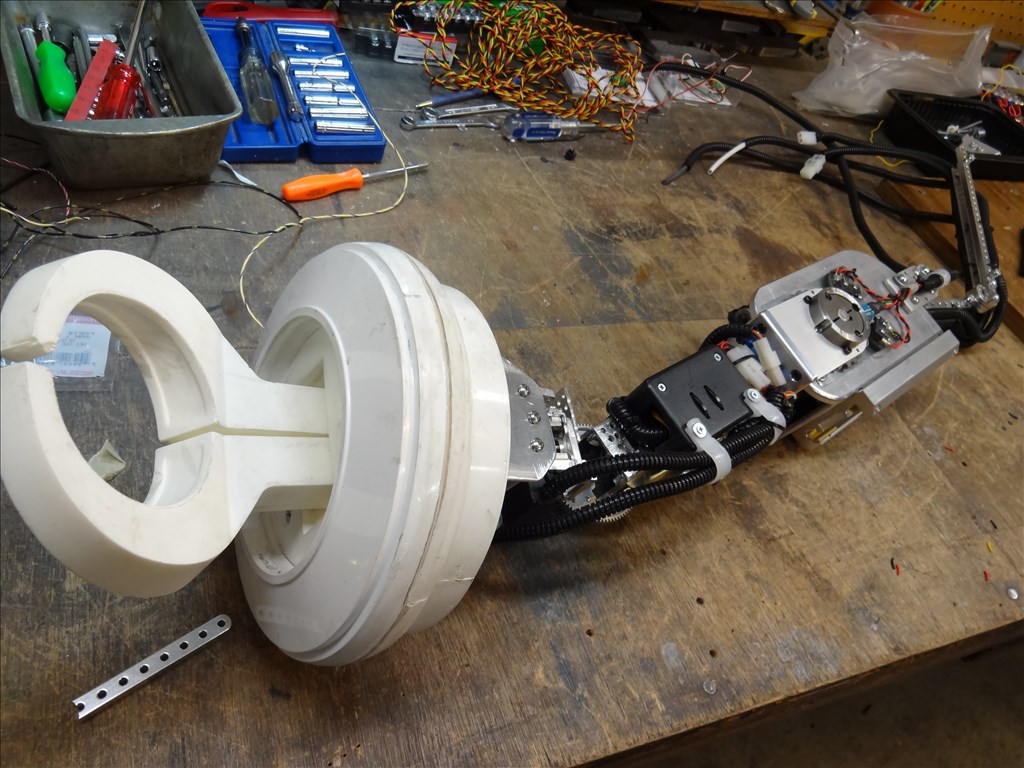

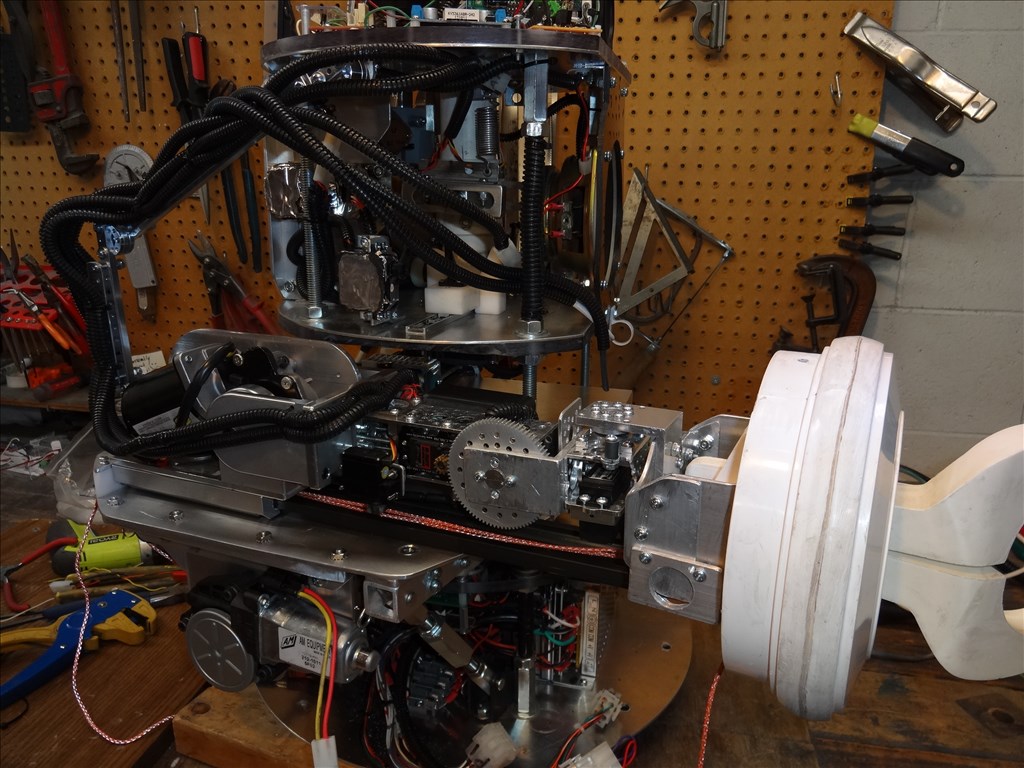

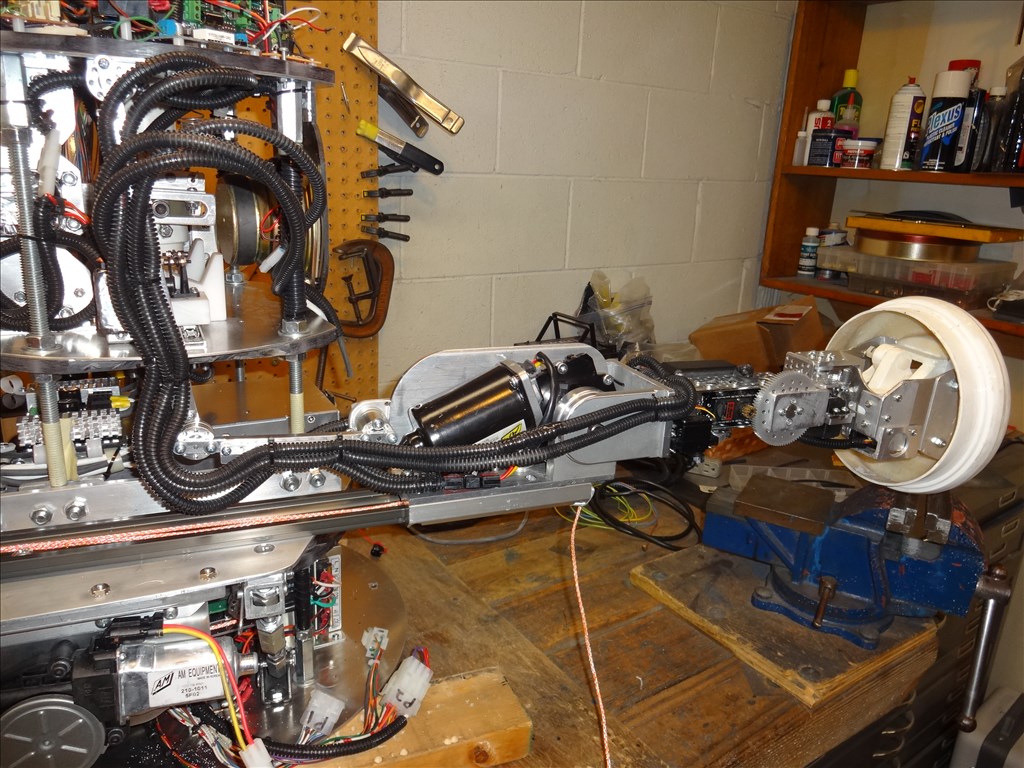

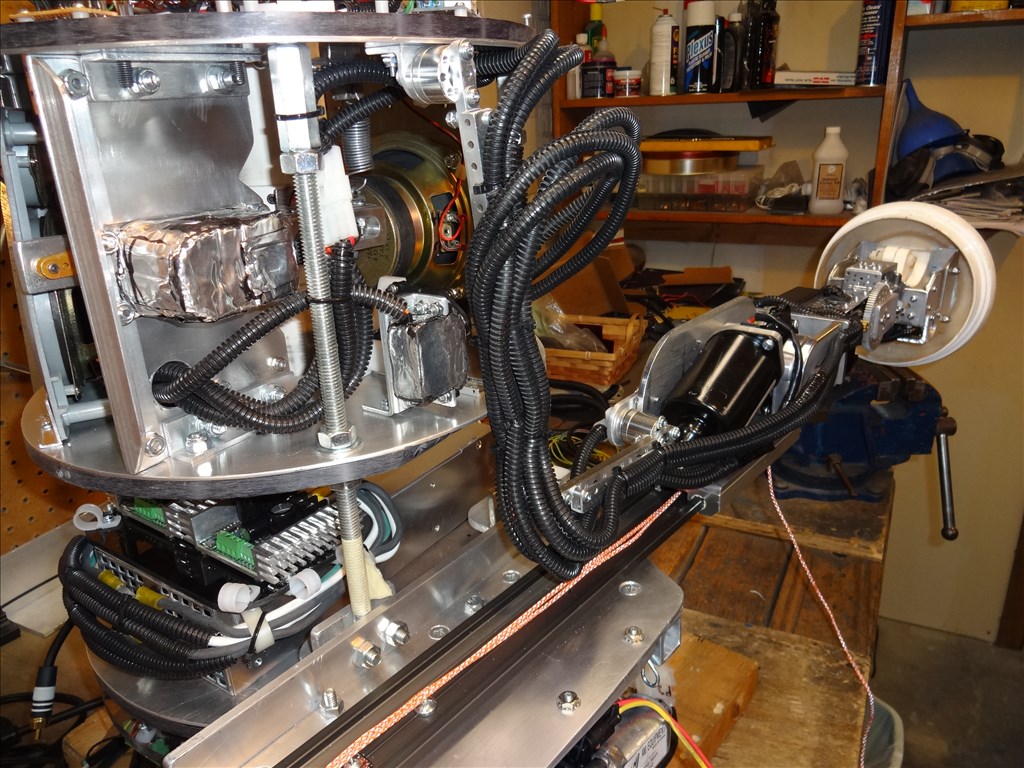

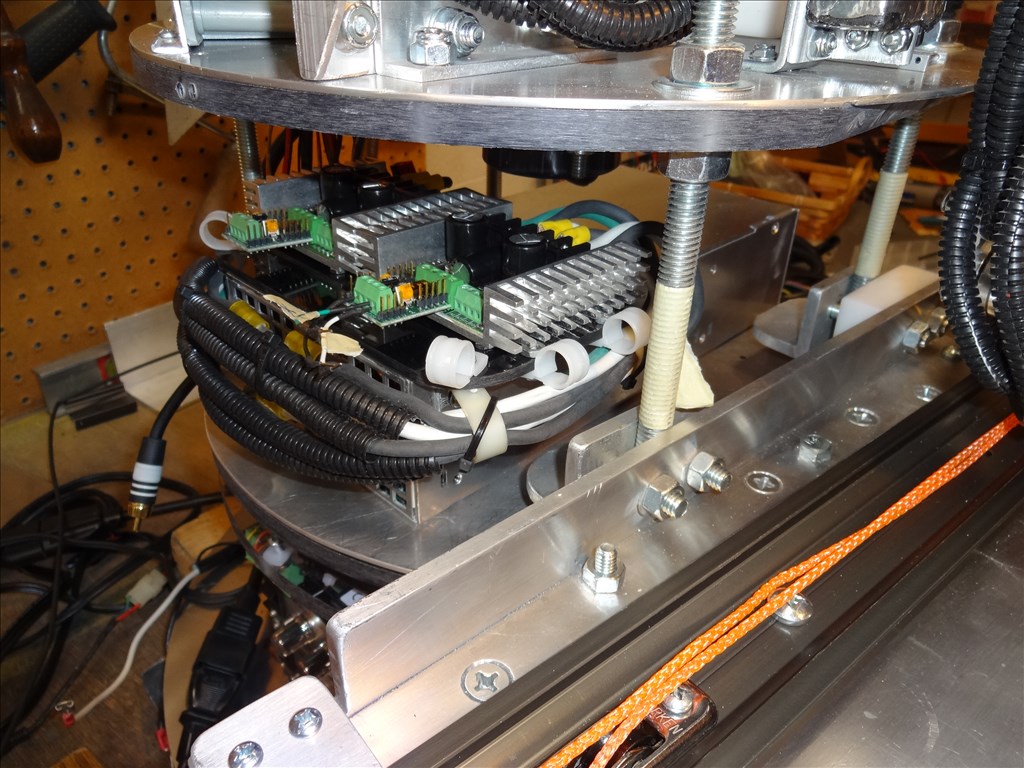

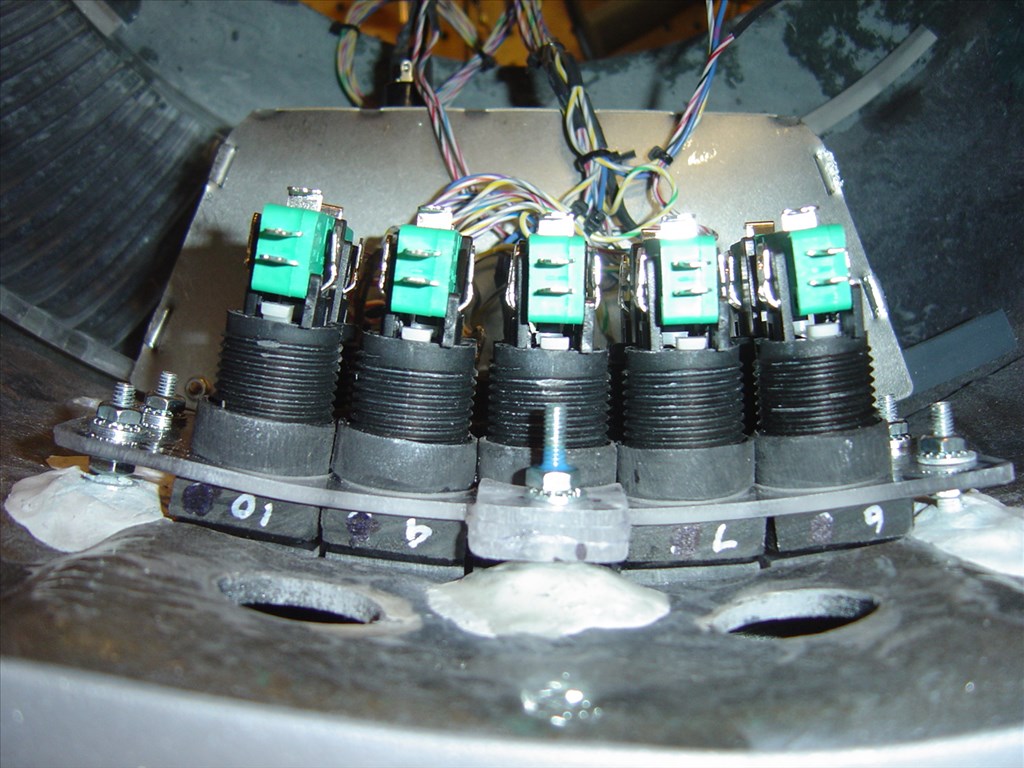

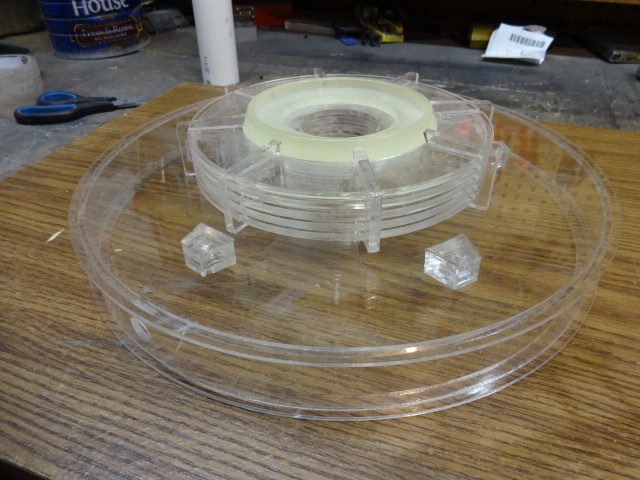

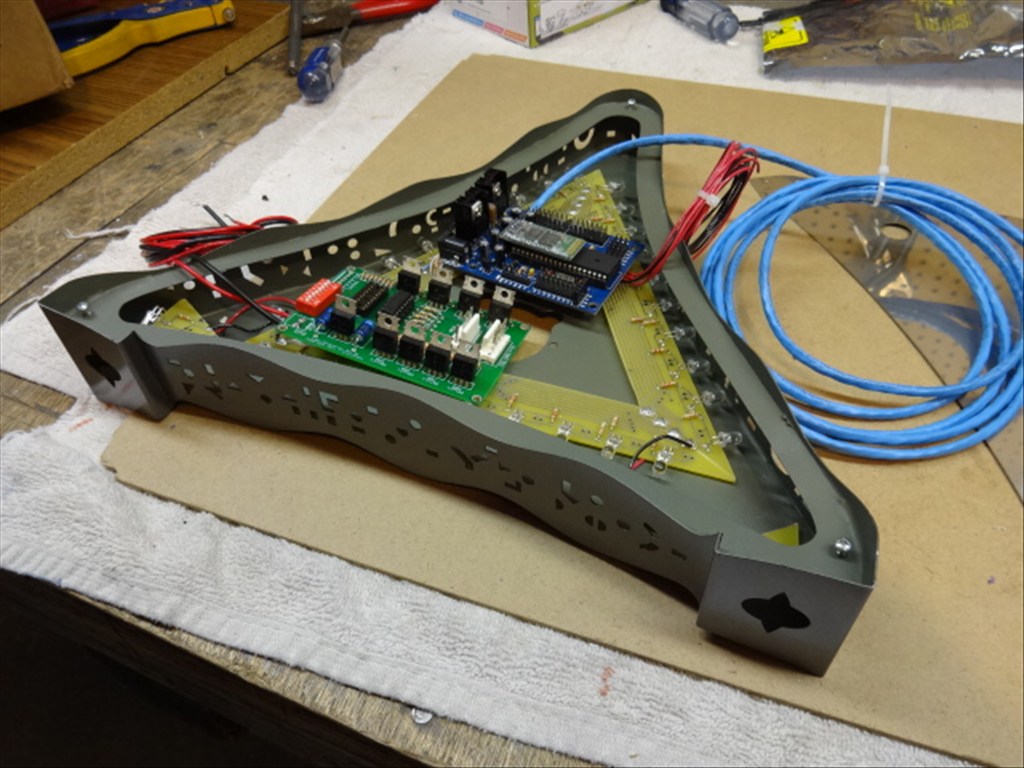

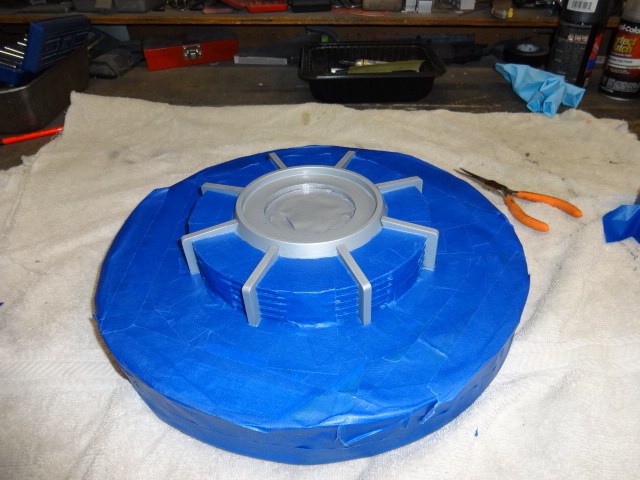

It's been a while since my last post to this thread. Life is busy and I've also been designing this mounting and delivery system for the arms. I did't want to post anything till I had something worth looking at. I still have a lot of work ahead of me and still have parts to add to the "shelf". I need to add more supports on the outer edge but here's a peek at where I'm at as of last night with mounting my B9 arms onto my CSS . Cant wait to get it all hooked up to the Sabertooth/Roo/EZB and see this bad boy suck in and out and wiggle around like a Night Crawler on a hot summer night after a heavy rain.

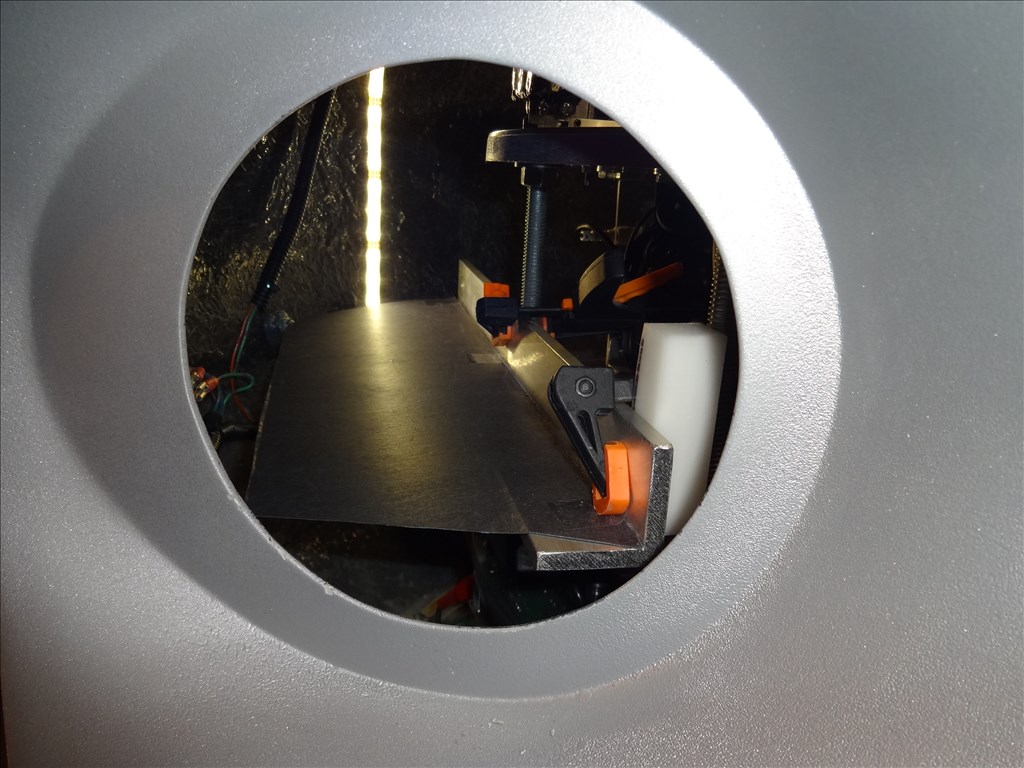

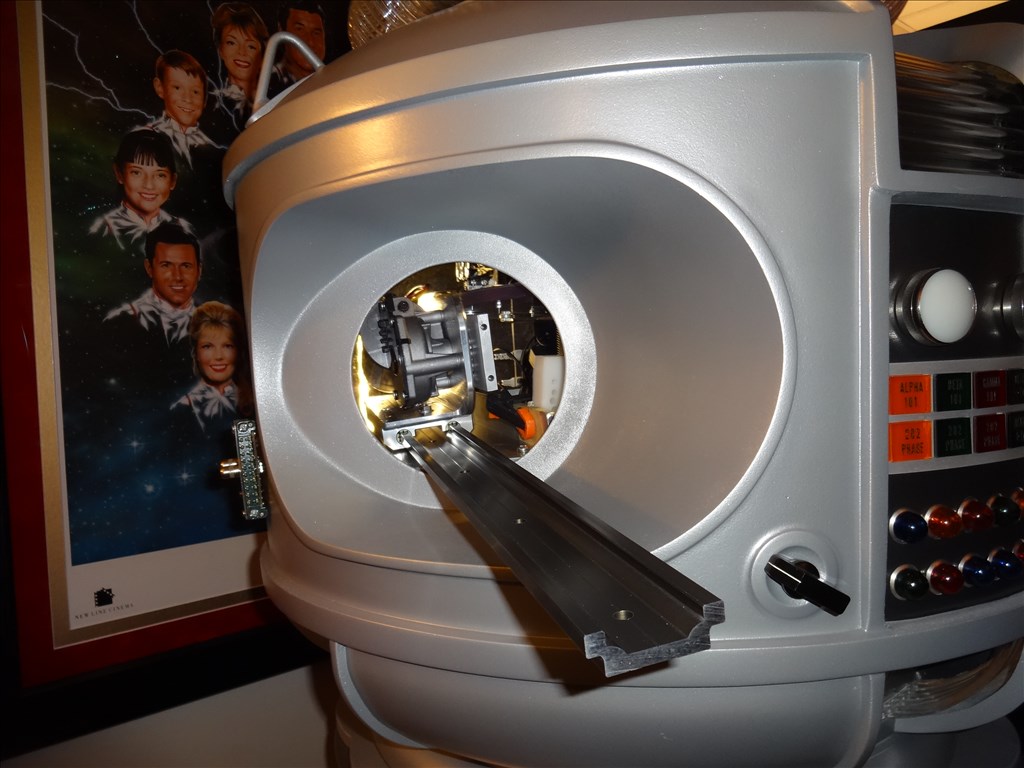

Final Mounting position. However it will need to be "fine tuned" to move in and out of the arm hole and rubber skin.

Shelf mounted on the CSS. Rails and motor on it's mount are just set on shelf for now to see how it will fit

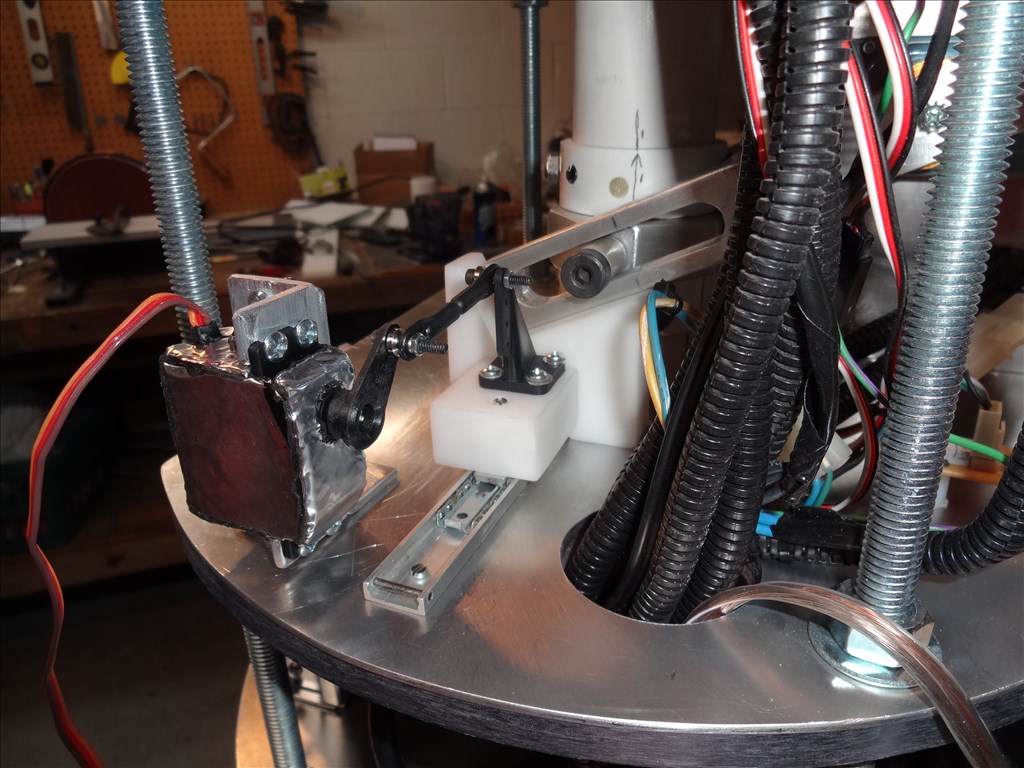

This pic was taken before I mounted the shelf on the CSS. I was test fitting for size and position

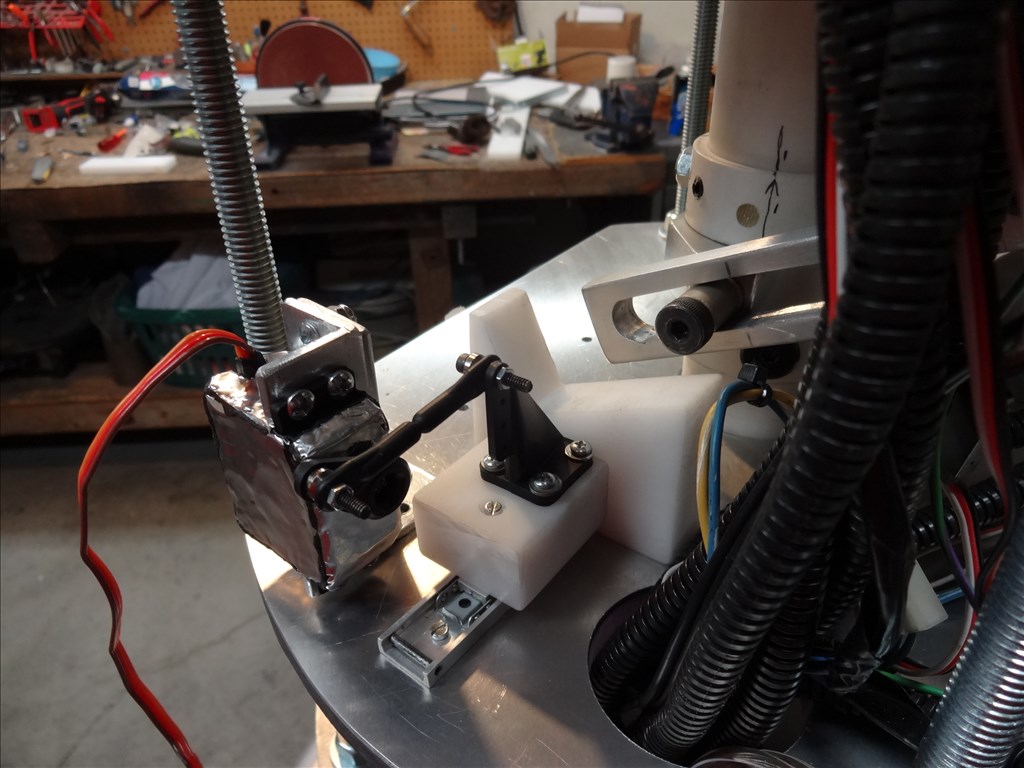

The next two pics are another test fit of the motor and rail system. It's a tight fit but will just make it through. It's even going to fit with Will Hoff's fabulous rubber skin in place. The rail still needs to be cut back to proper length. When cut back it's still going to stick out of the hole by about 9". The motor will need to move completely out of the torso so the elbow can have proper range of movement.

Awesome Dave, looking forward to that moving!

Incredible work Dave Looks like a tight fit through the arm hole. Beautifully done

Looks like a tight fit through the arm hole. Beautifully done

Thanks gentlemen. It's coming along slowly but surly. I have more hardware arriving from McMaster Carr tomorrow and should be able to get the supports for the outer edge of the shelf installed. This should complete the shelf part of the build unless I get a wild hair and do a redesign.

The outer edge supports are going to be installed on an angle and using a "hing" joint and turnbuckle center design to allow adjustments and aliments. However I've been toying with a different design. I'm afraid the hinged joint will allow too much flexing when the motor and arm is extended. All the weight of the arm unit mounted on the rail will be outside the robot at this point. The far end of the rail attached to the shelf will have a lot of upward force due to the weight on the other end (gravity sucks) and want to deflect and bend the rear of the shelf up. A hing may allow that to happen. Perhaps a stiff arm support that is static would be a better choice. The problem is I have little room for a design like that because of the curved part of the lower torso. The angled design fits better but will allow movement (this is both good and bad as I described above). We'll see how it all works out.

Yes, I'm amazed at how close the tolerances are and still let the motor through the arm hole. I just got lucky on this one. It would be nice to have another 1/2" headroom between the motor mount and Will's rubber arm skin but I'll take close enough anytime. Maybe I can convince the maker of the arm skin to enlarge the attachment end of the arm just a little on future runs to allow for this (wink, wink......Will?

It would be nice to have another 1/2" headroom between the motor mount and Will's rubber arm skin but I'll take close enough anytime. Maybe I can convince the maker of the arm skin to enlarge the attachment end of the arm just a little on future runs to allow for this (wink, wink......Will? )

)

Sigh......... One of the truths I've learned about building custom robots is custom brackets. Everything needs to be mounted somehow and usually off the shelf mounts and brackets don't work. I think I've spent about 80% of my robot building time designing and making custom brackets.

Thanks for listening. Just blowing off steam.

Hang in there, Dave! In all my years of building robots, I have learned a thousand ways NOT to do it.

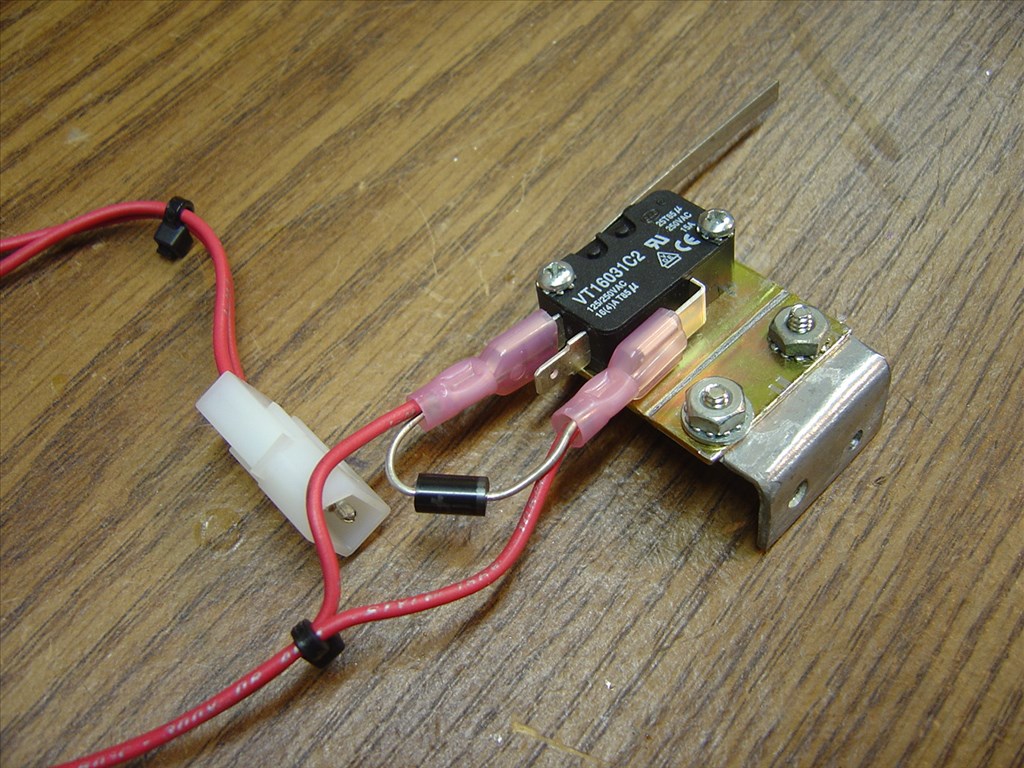

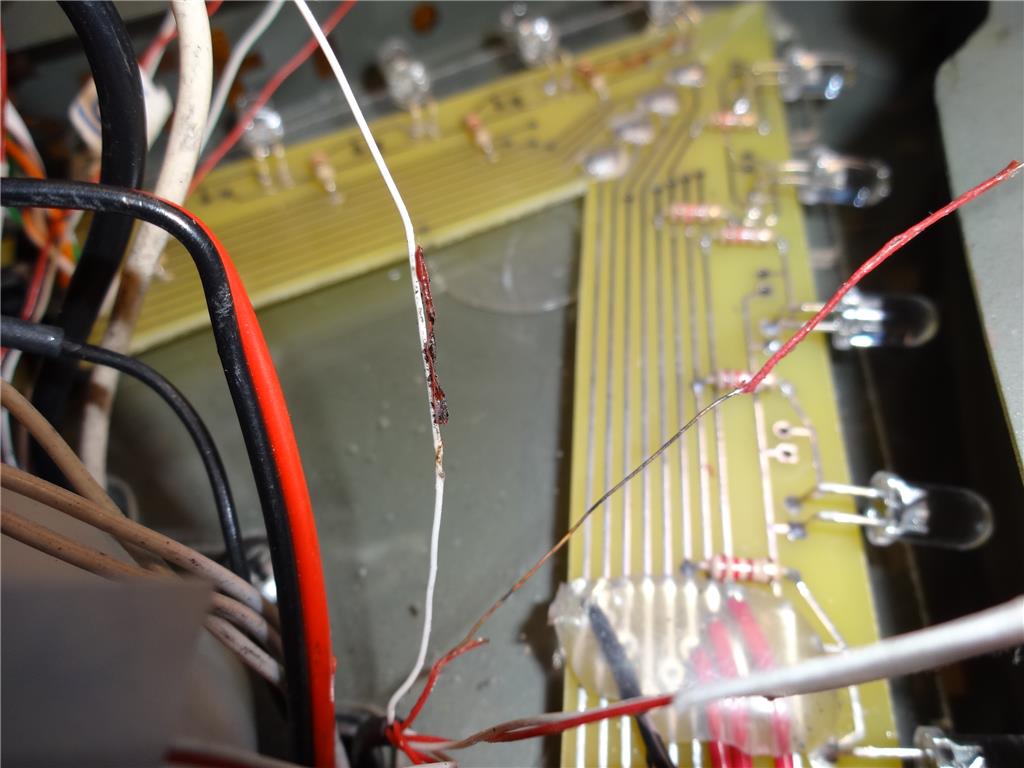

One of the reasons I have almost gotten out of this field is in the past I have built machines that work the first time I turn them on. But, the last four machines I built worked for a little while and then burned up. I finally found the culprit. It was a power plug that I wired the standard way (Red=positive) (Black= minus). Inside the plug, the wires were reversed!

Now I have gotten rid of most of my stuff. I plan to have another sale and get rid of the rest of it. But, I am keeping my last build Sally. I may also keep the EZB 4 just to play with.

I am also looking to buy the robot PEPPER. It is already assembled, so no problems with my arthritis or sight building it.

Take care and don't give up.

Mel

@Dave.

I've been away from the forum for a lil while, and I was really pleased to see your thread update of the progress you have made so far. I really like the look of the arm mechanism. It shows that you have put a lot of work in to it. Don't worry about the "steam blowing". I'm sure most, if not all of us have been their at some point designing or building something that has those pesky little jobs that ain't that fun to do, but needs doing. It will be well worth it in the long run.

Hang on in here buddy. What you have done so far is truly stella work.

Thanks for the encouragement guys. No worries, I'm nowhere near giving up and was not really off balance. However when I started this build three years ago and with doing pretty much constant work and research on it I never thought I would have to build so many dam brackets. My motto is (one of them anyway); ya gota have a good foundation. Brackets and bases are part of what that's all about. It's kinda funny really and I'm getting pretty good at it. I've learned to have on hand plenty different sizes of angle, square, flat aluminum stock and lots of different nuts and bolts. Oh ya, I cant forget to mention the daily trips to various hardware stores and McMaster Carr orders.

@Moviemaker, Glad your still hanging around this forum and interested in this cool hobby. Your an inspiration to me. I'm really not to far behind you in age (very late fifties) and it's good to know the passion never goes away. Our eye's and hands may turn against us but you thought me that the heart never fails. Please stay in touch.

@Steve, Your reminder of "the little things we hate to do but have too" really strikes home. There have been things I really don't like to do in the building process. At times I actually to have push myself to get to work on one of these "don't want to do" things so I can get past it and get the build moving again. The feeling of accomplishment after successfully finishing a step like that to my satisfaction is huge! cool It helps to keep an eye on my goal and to see how far this robot has come so far.