Hi all,

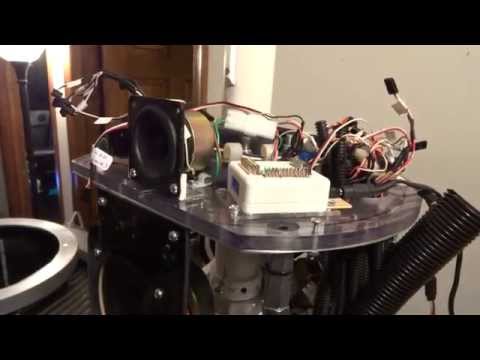

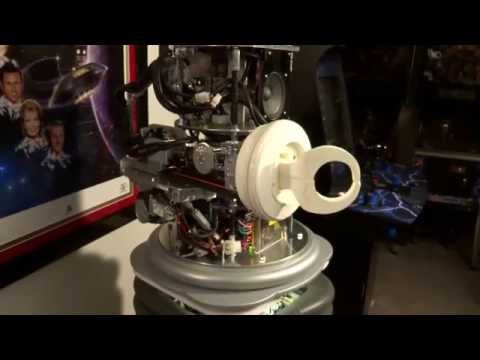

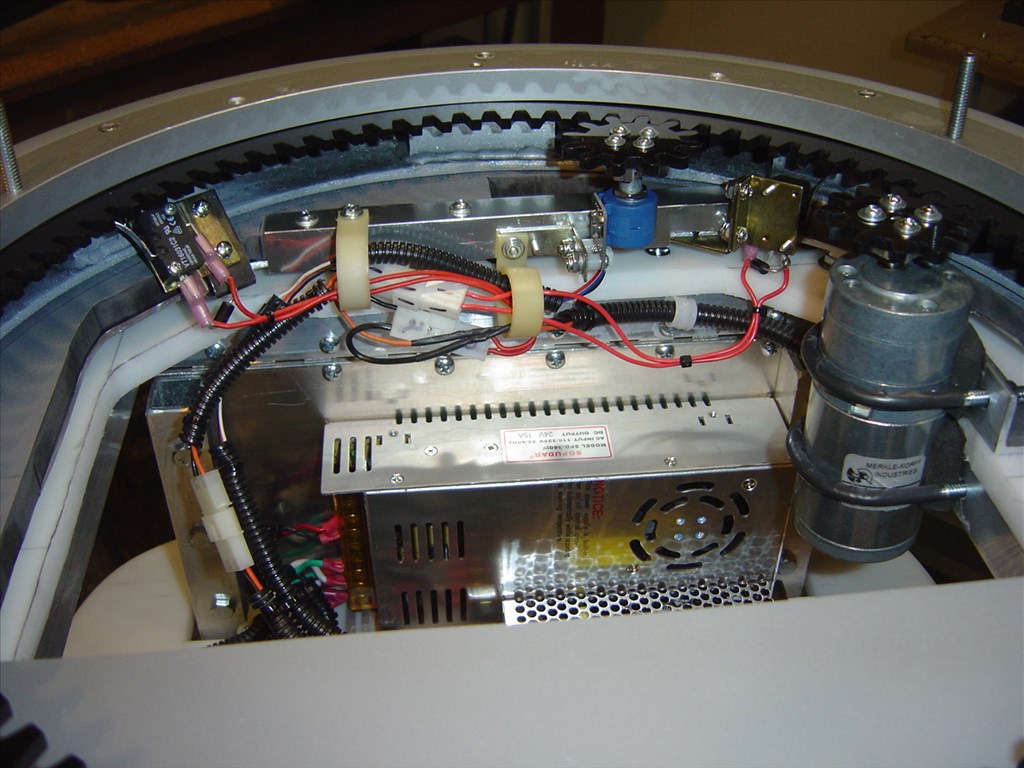

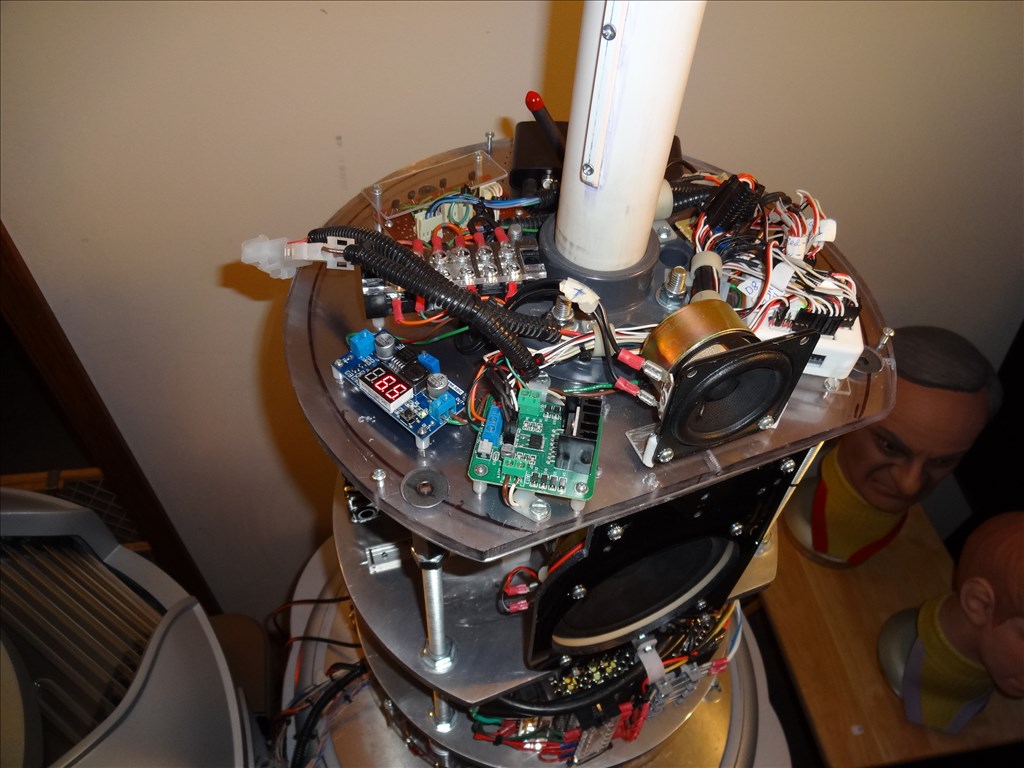

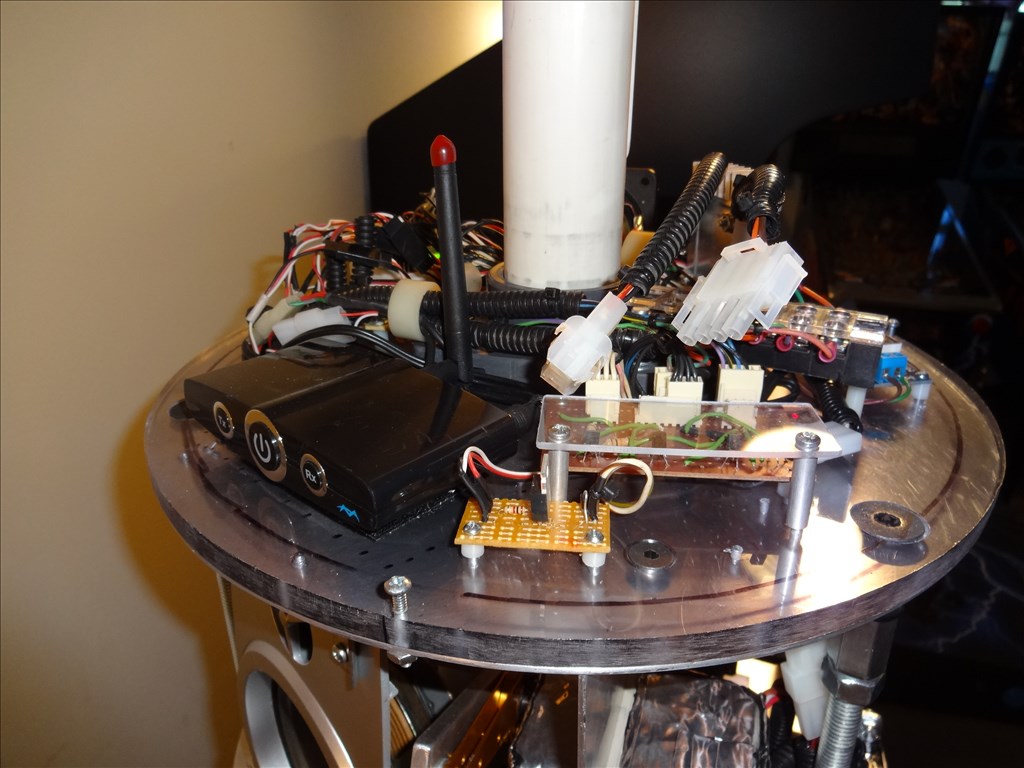

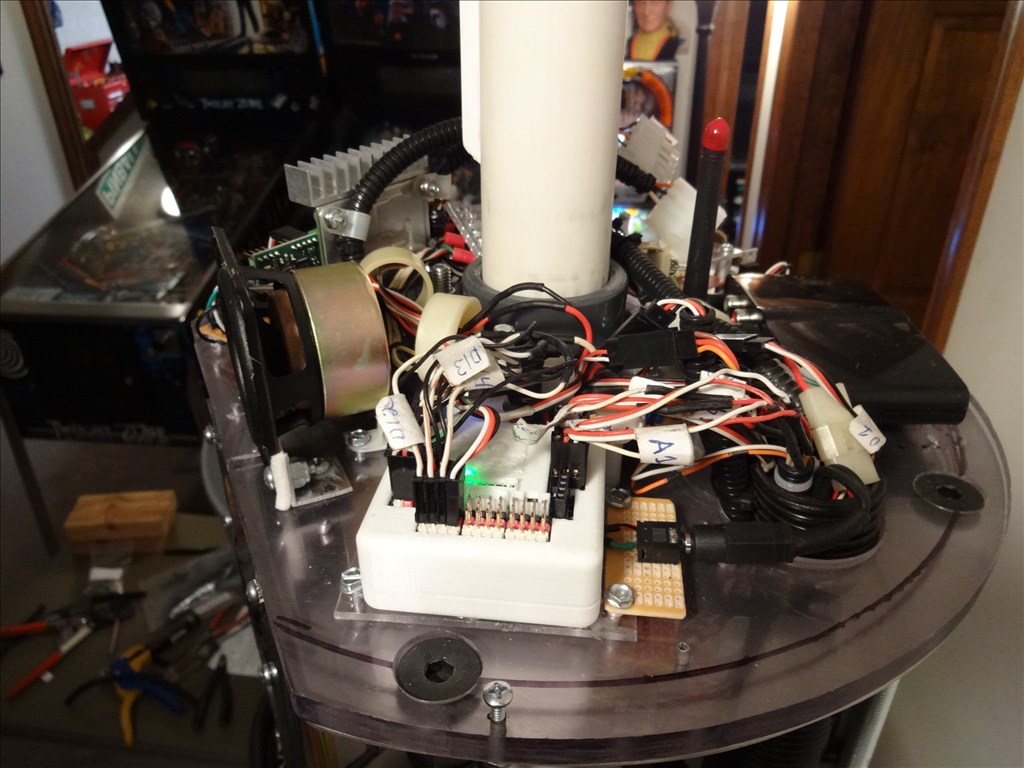

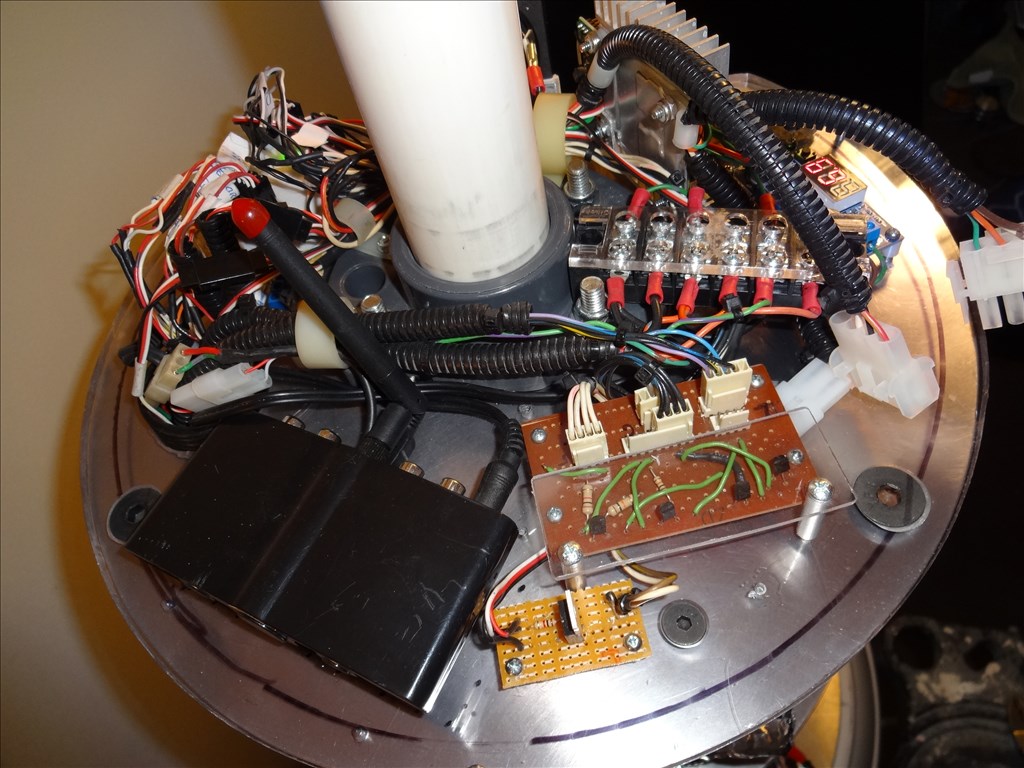

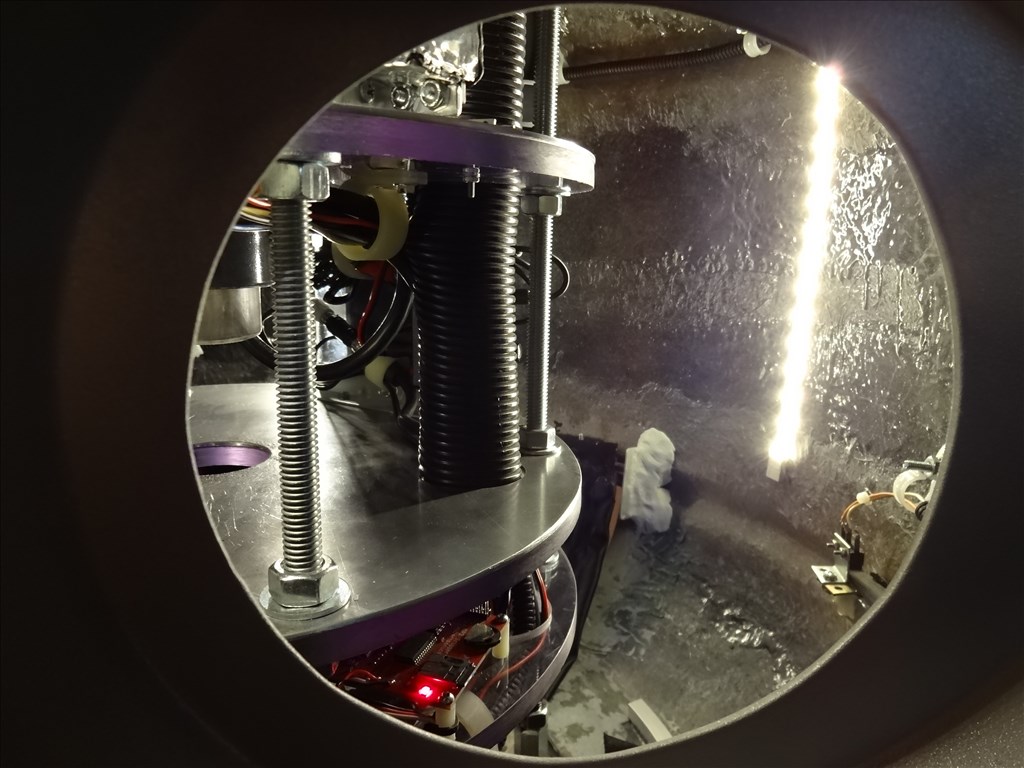

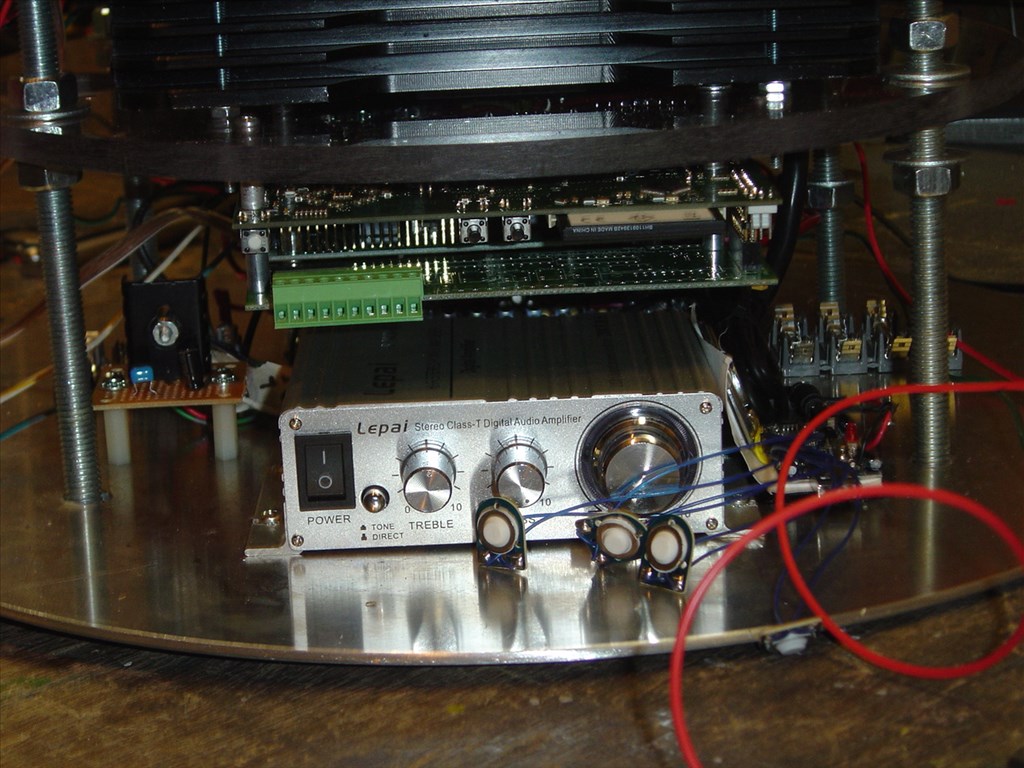

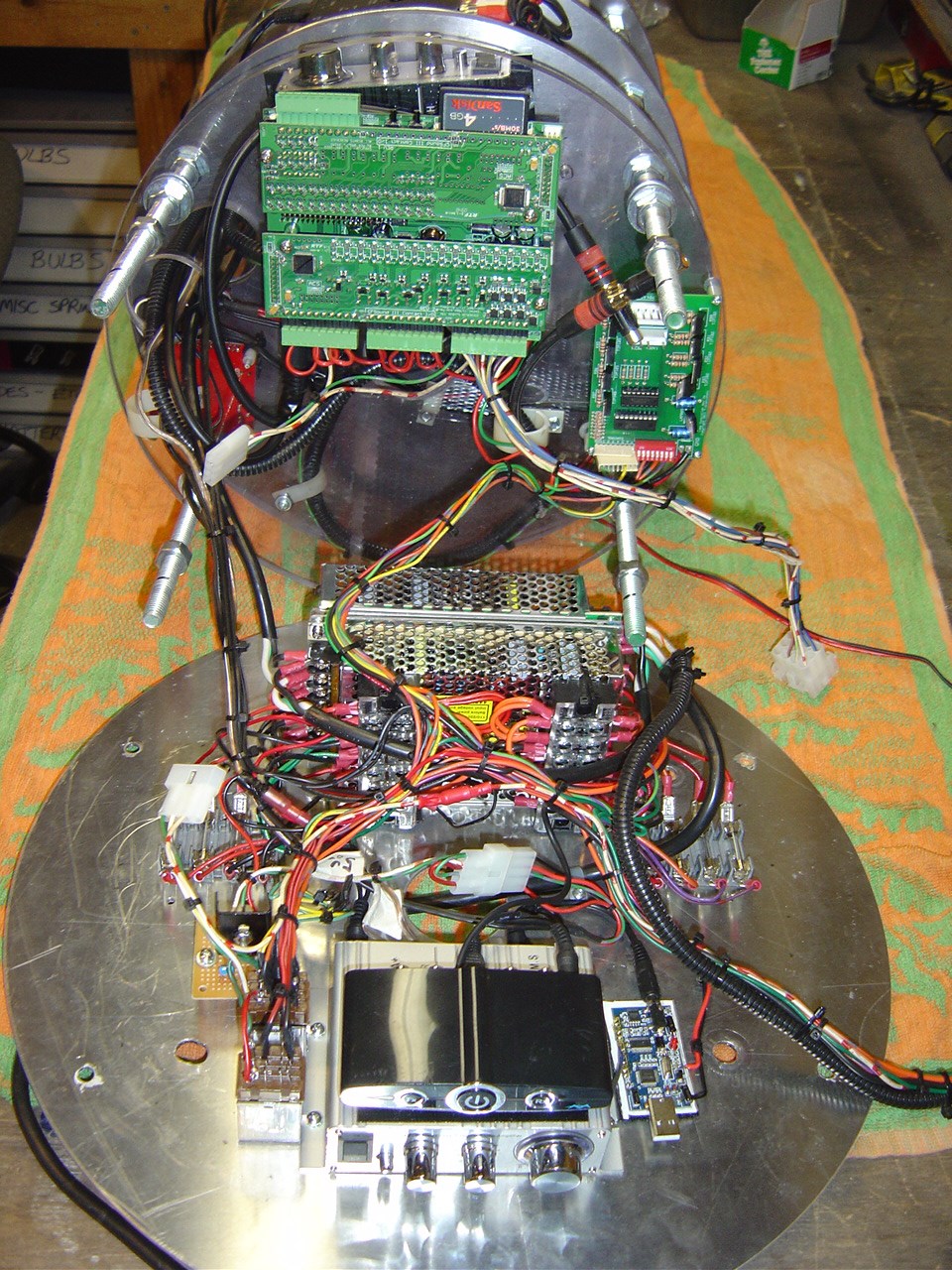

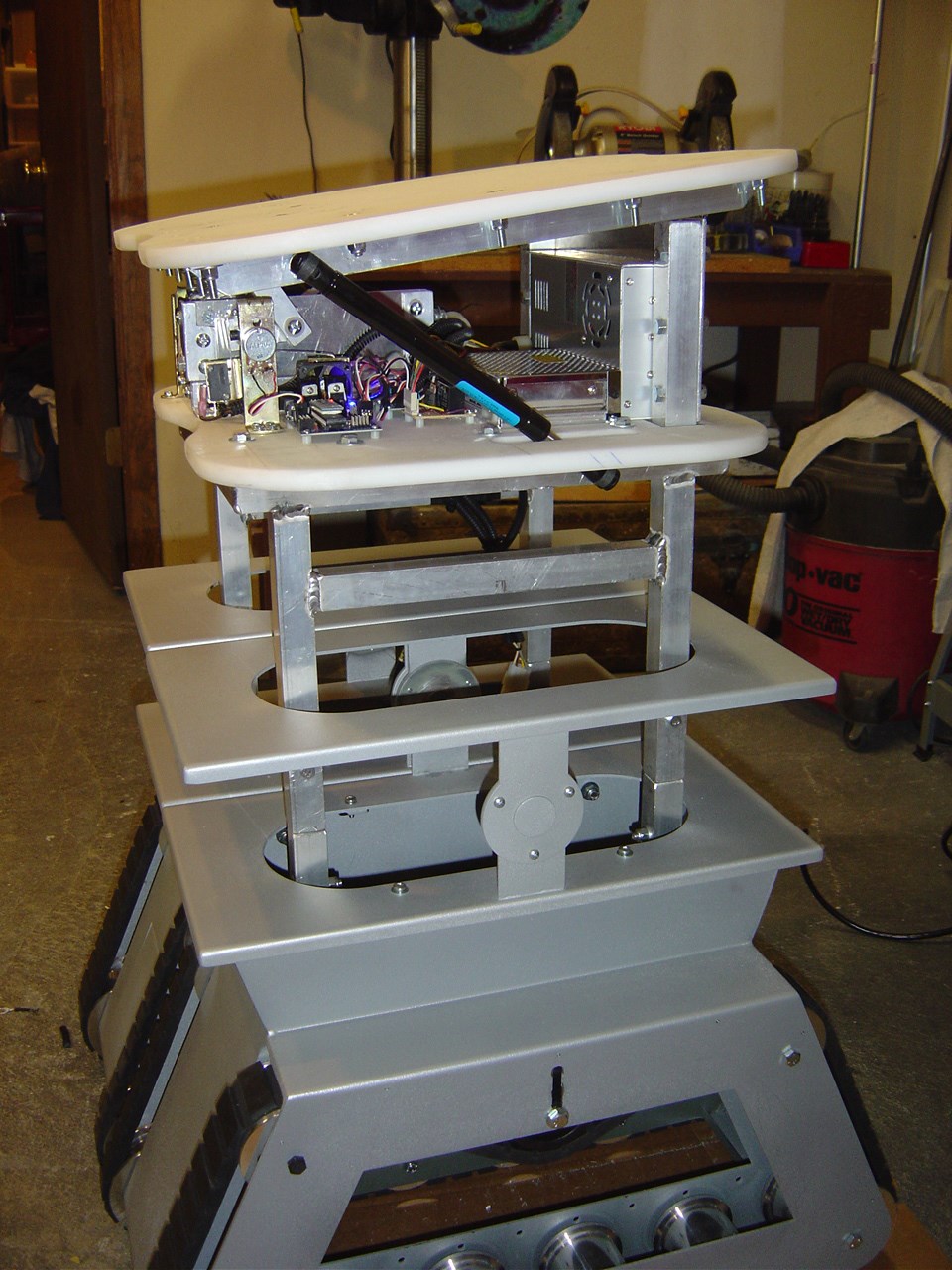

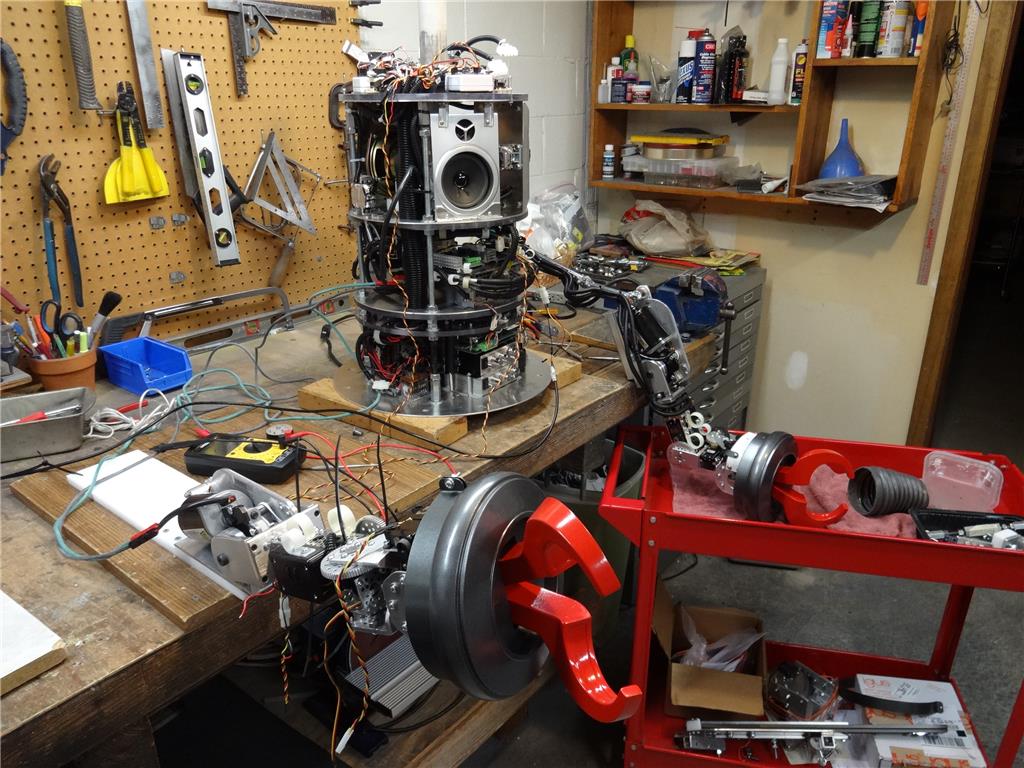

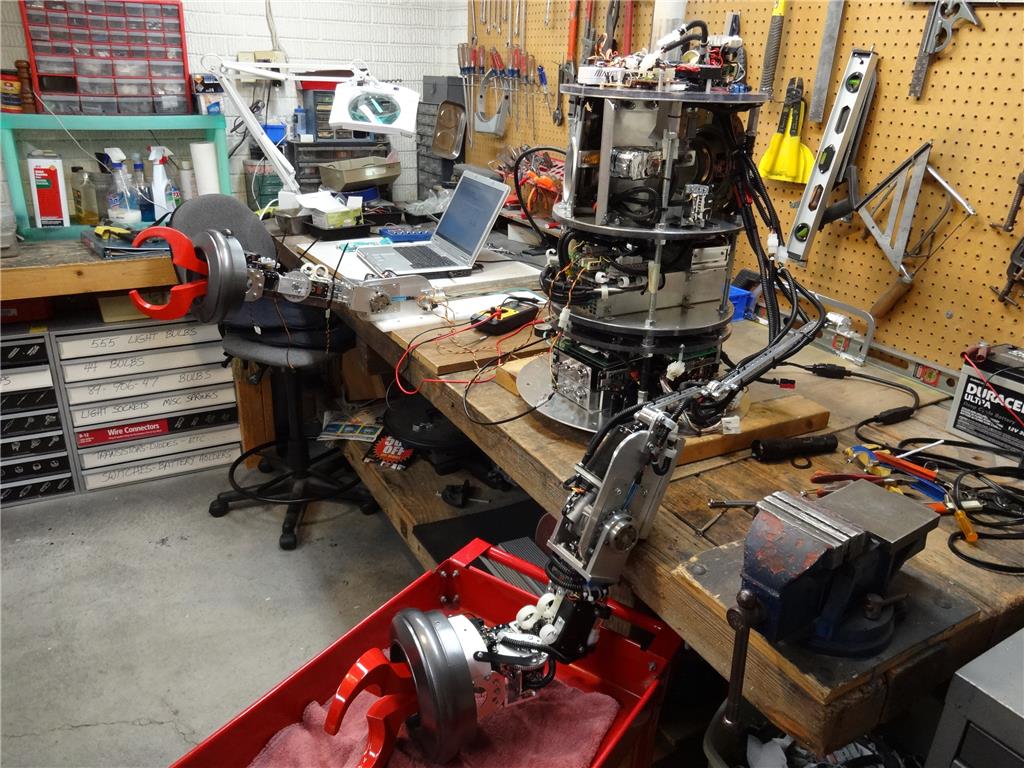

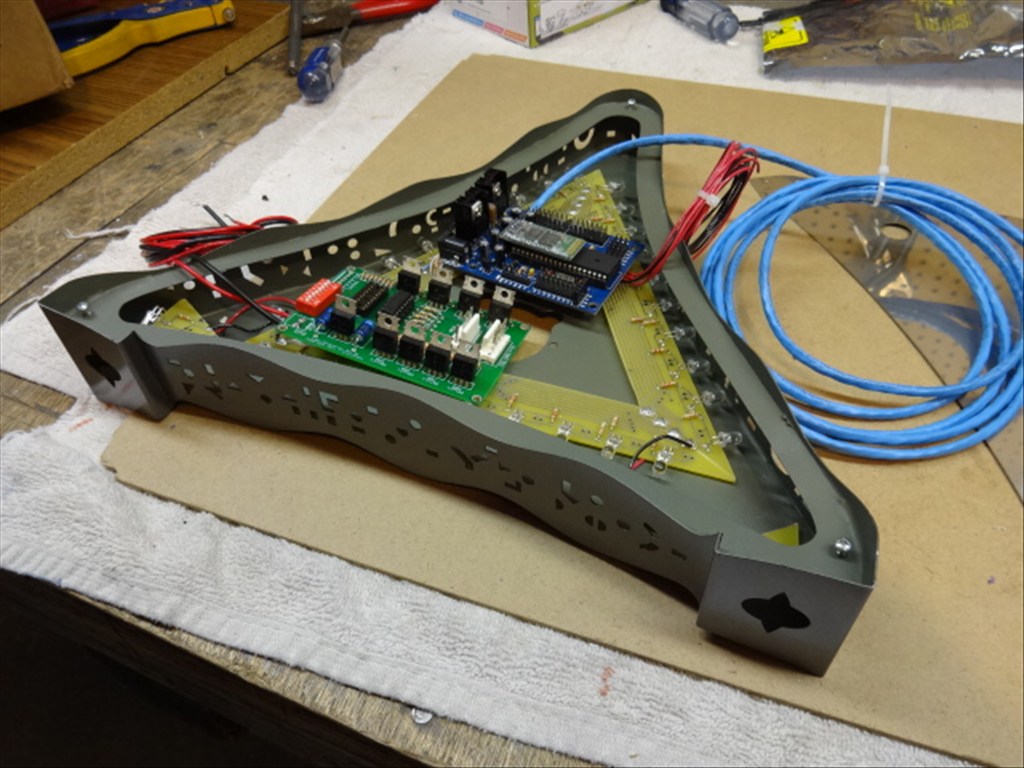

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

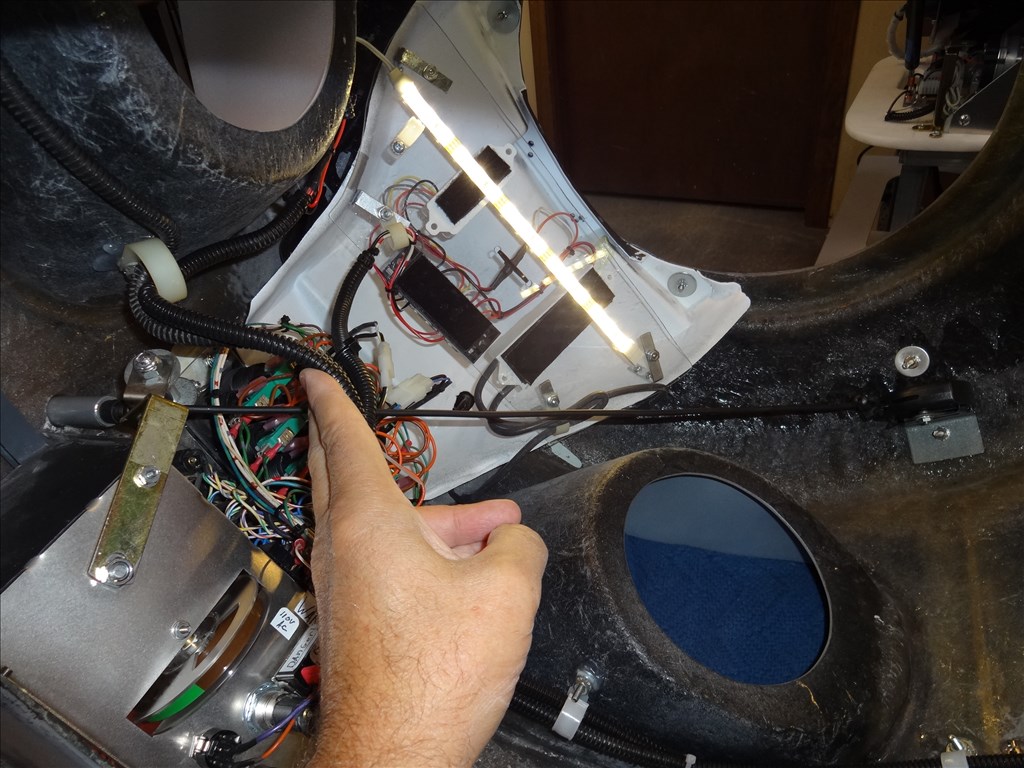

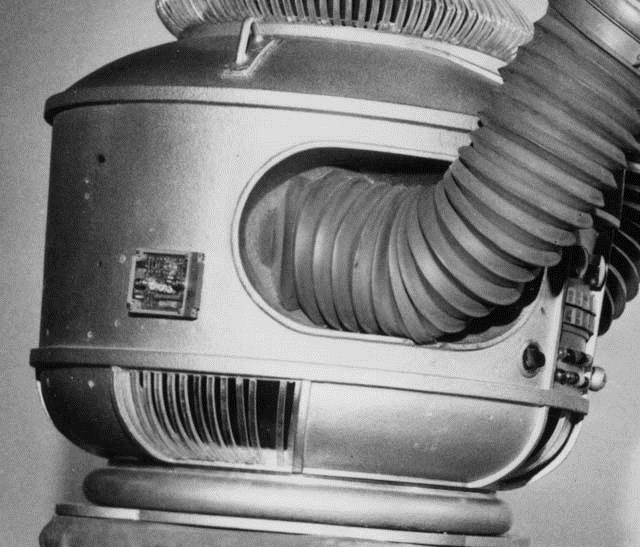

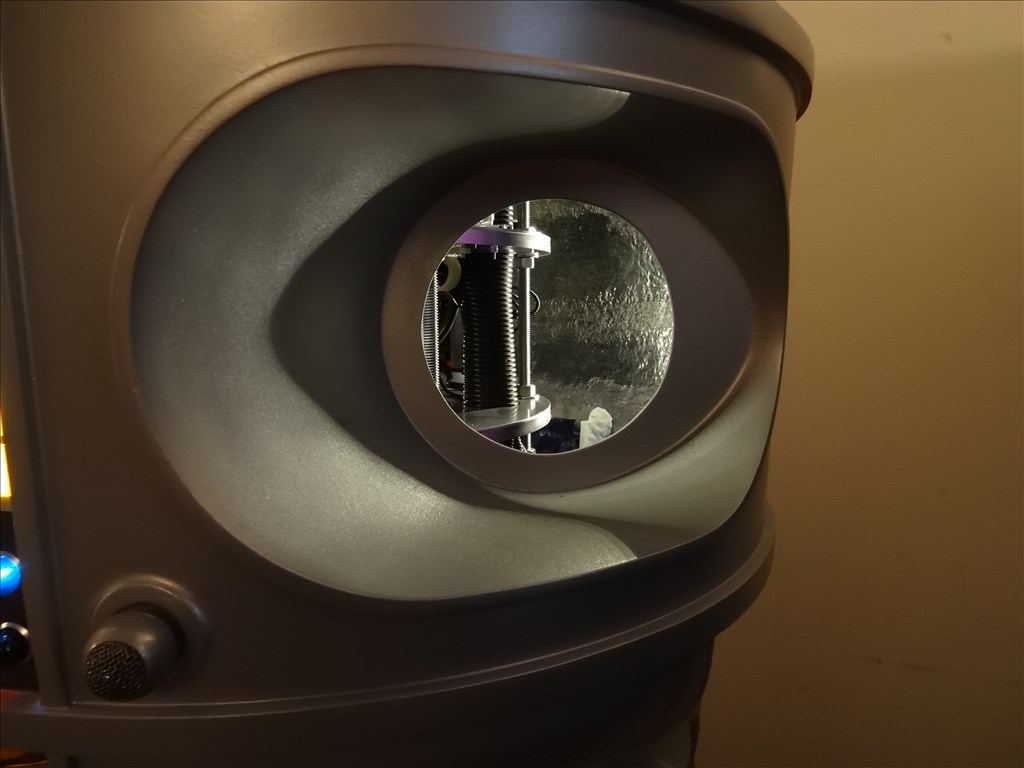

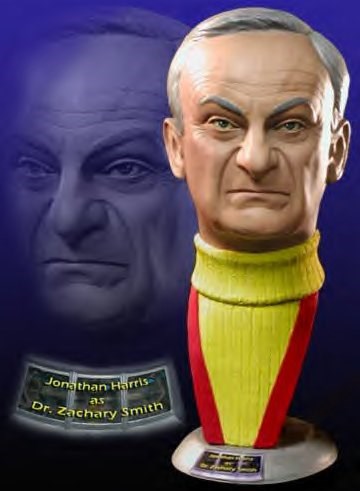

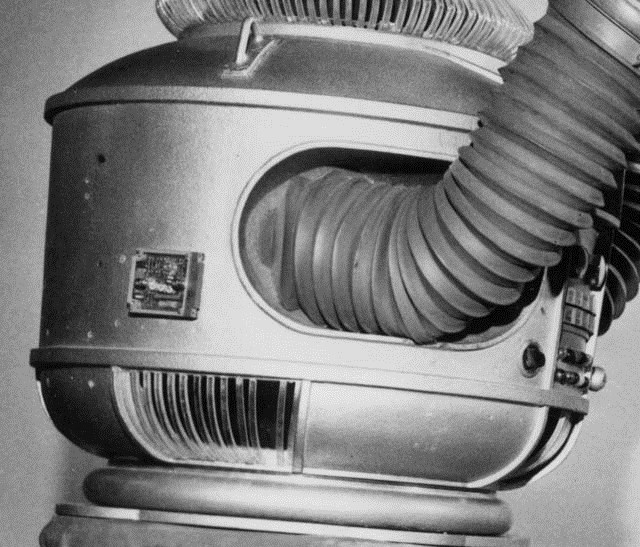

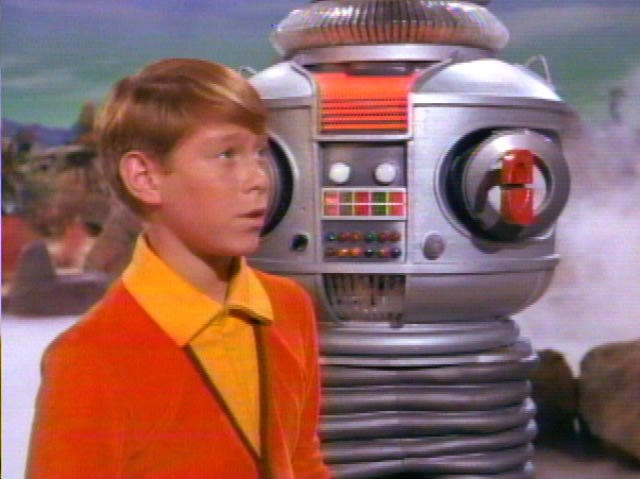

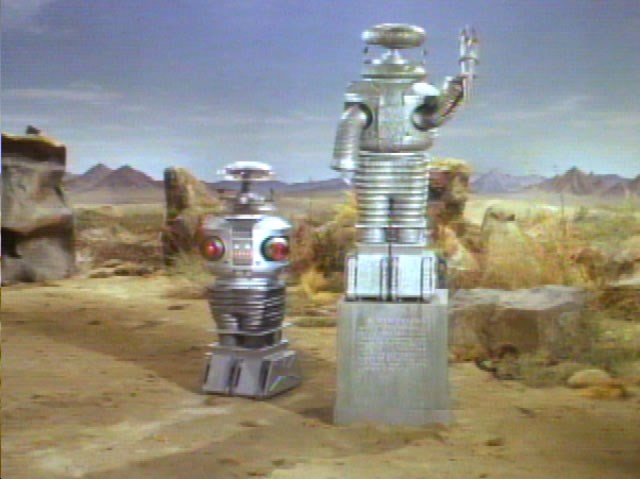

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

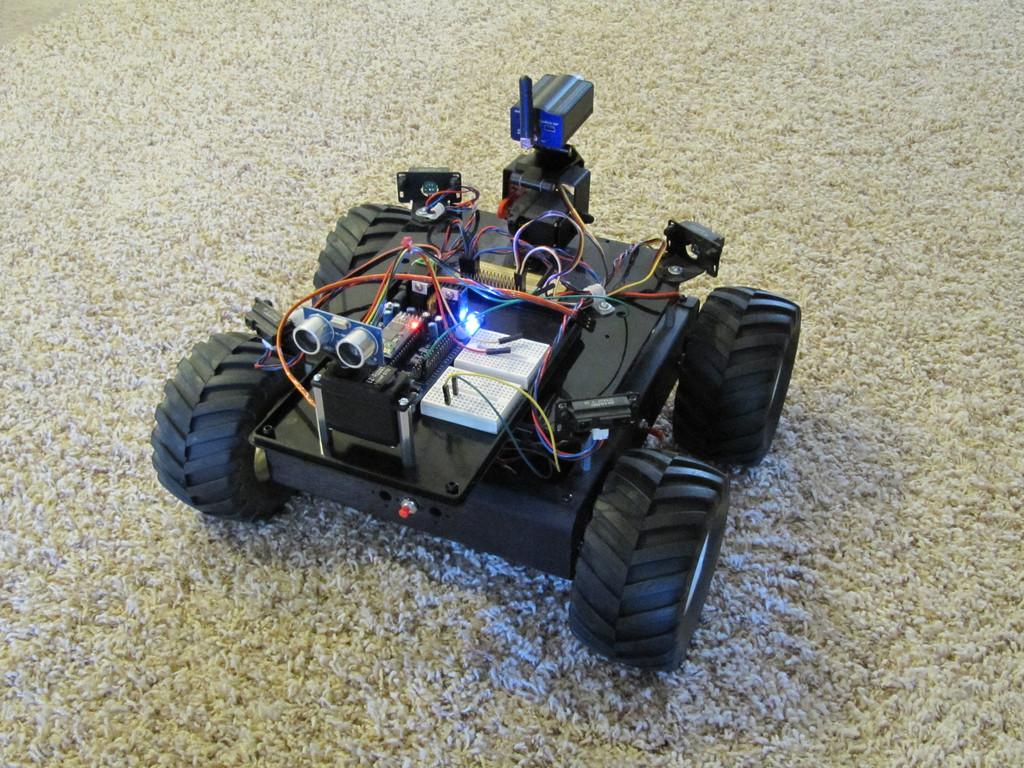

Other robots from Synthiam community

Nekoeccentric's Dr.Who's Nsd Dalek

Wiinteru's Blue Irobot Roomba Hack

-635353562186322812.png)

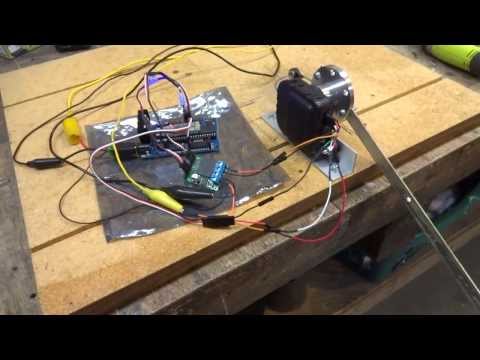

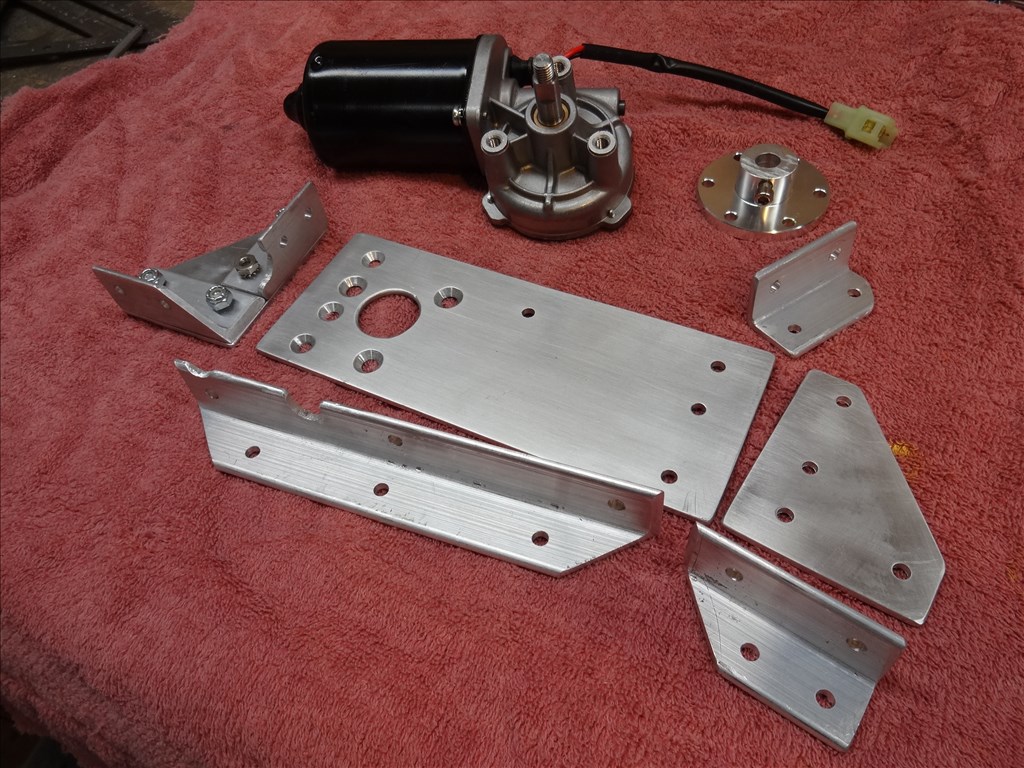

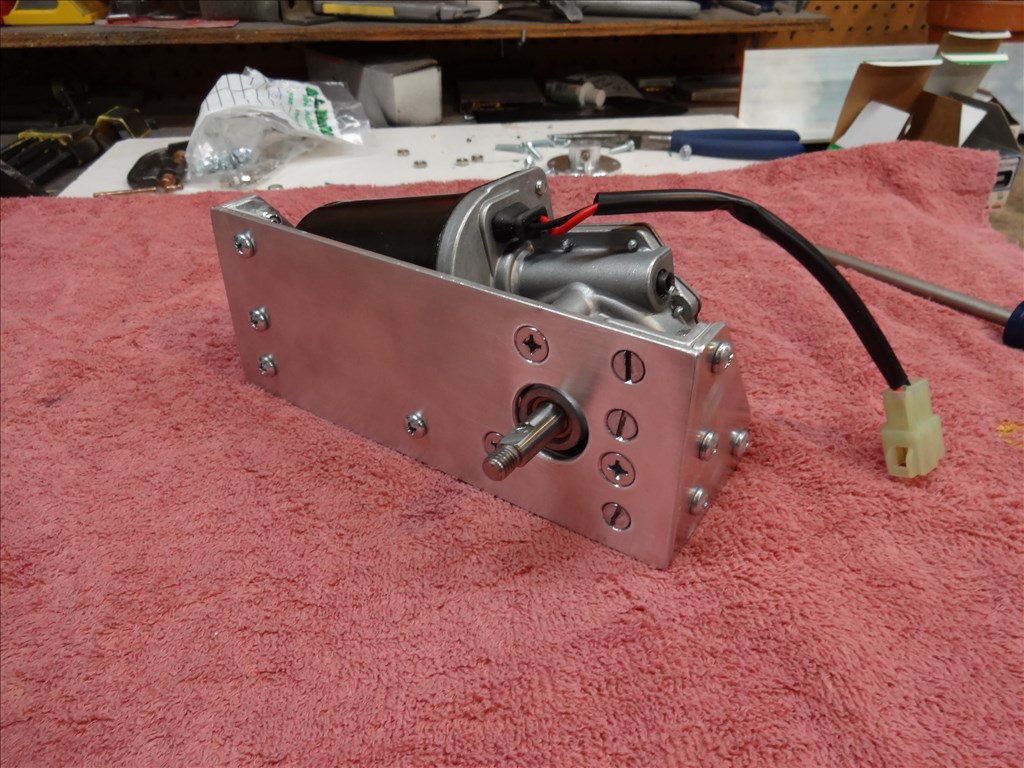

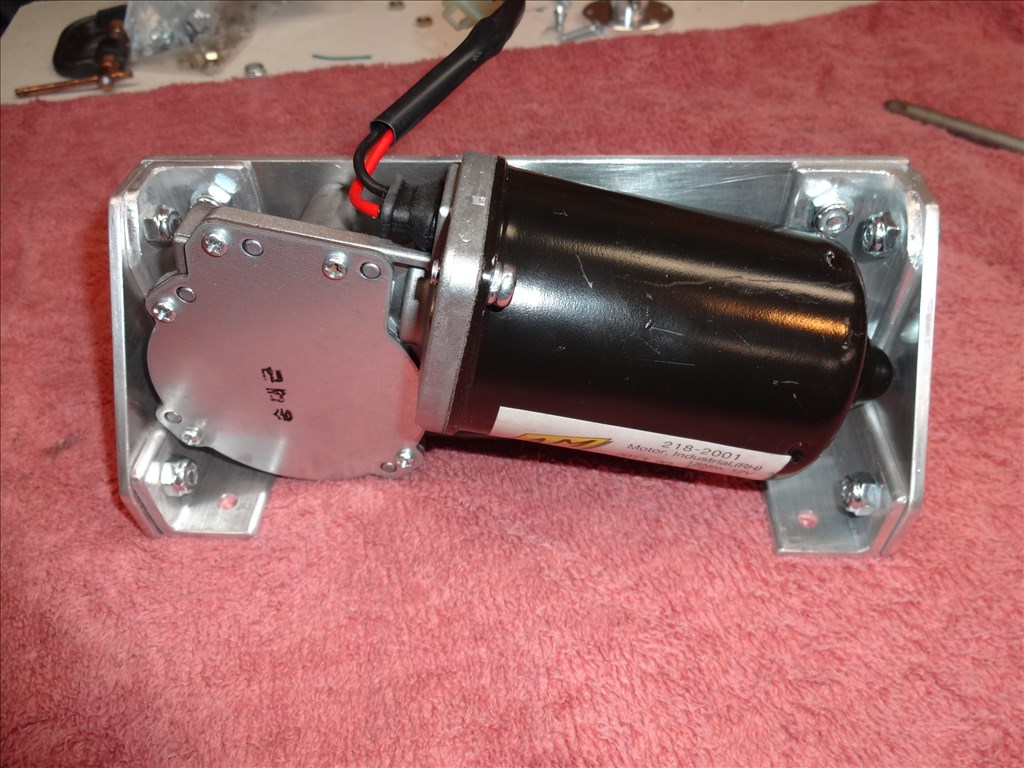

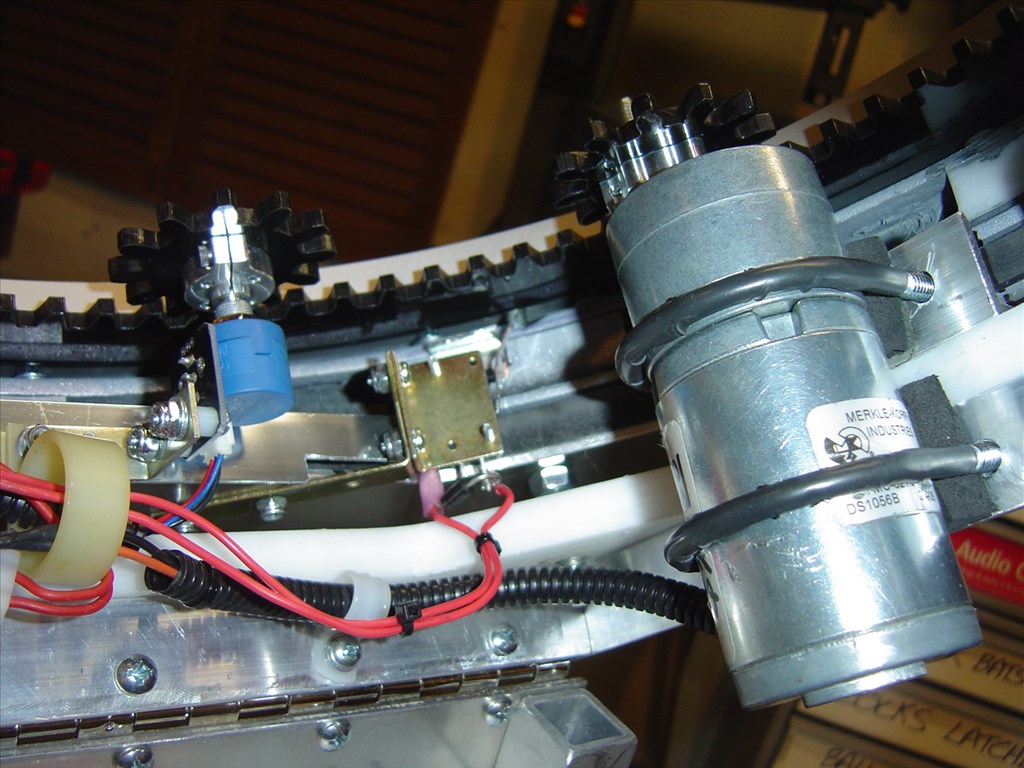

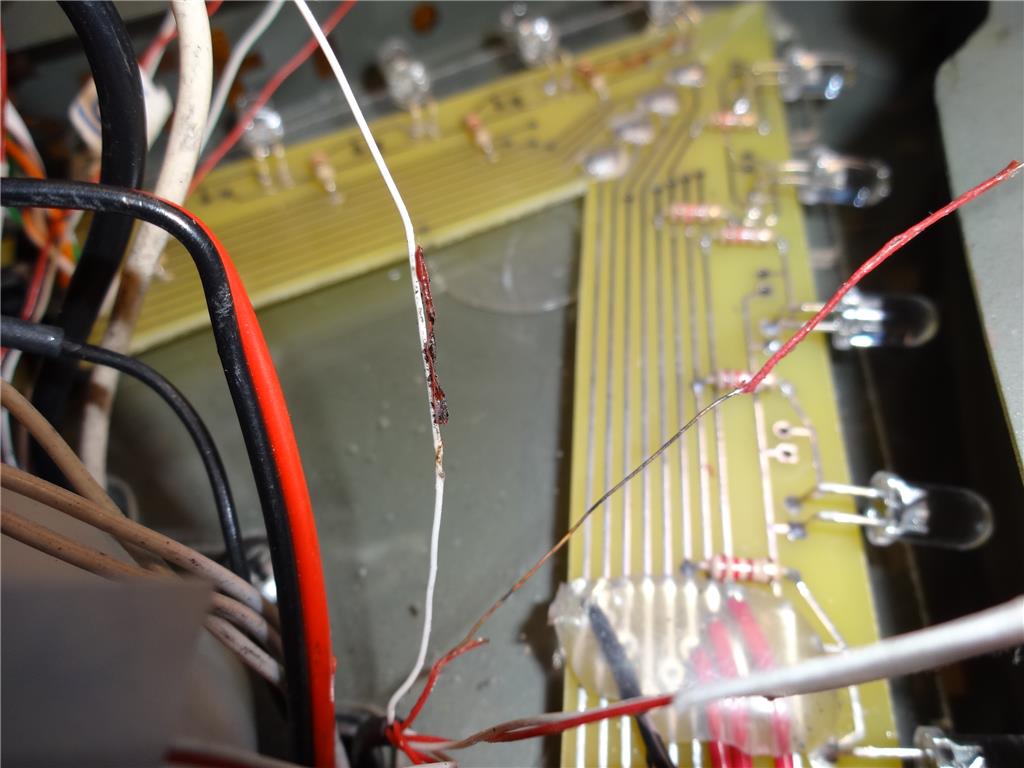

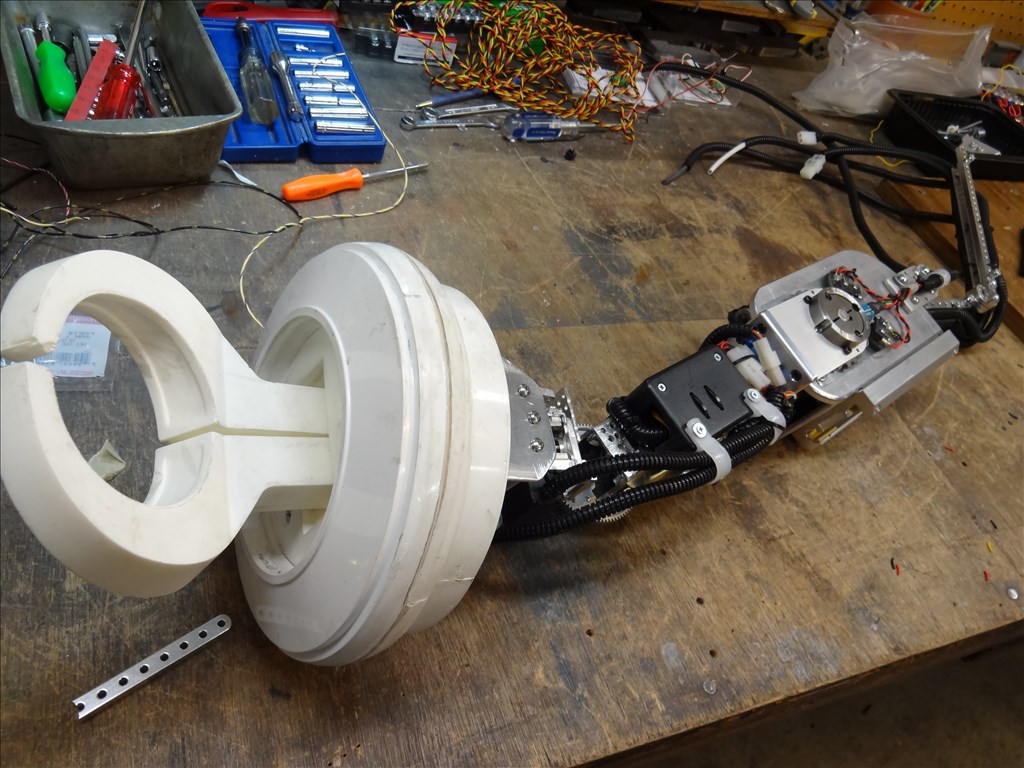

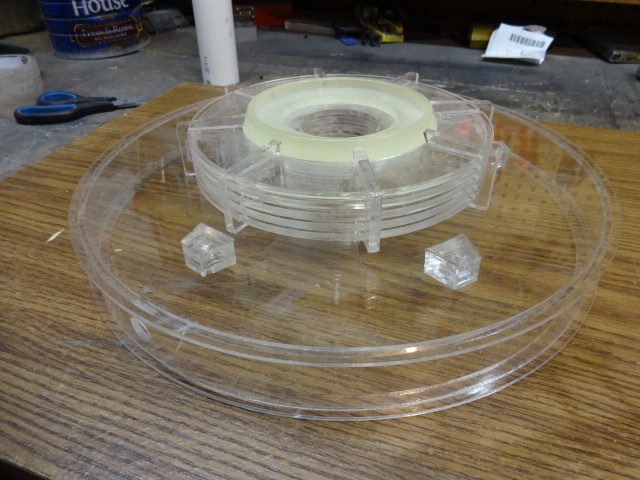

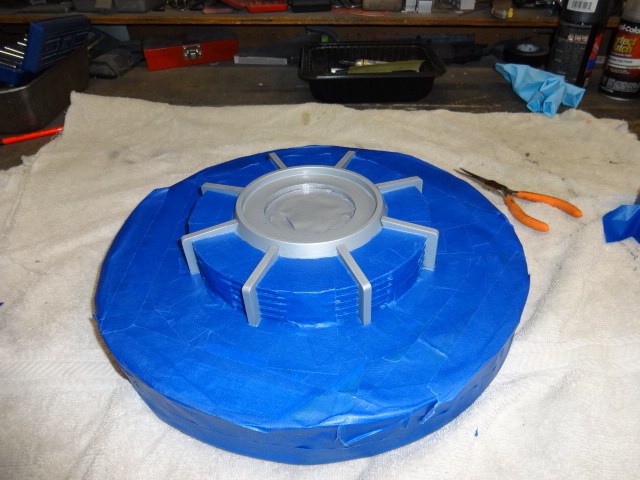

OK, I'm scrapping the ABS plastic weed wacker double pulley idea. I was able to attach it to a hub by sandwiching it between the Stainless Steel hub and a peace of aluminum plate with some #8 x 2" machine bolts. However I'm really not happy with it. When I tighten everything down I get some deformation of the ABS and it wont turn level. I'm afraid over time the ABS will weaken and give way under the load of the weight of the arm being pulled back and forth. I need to use metal to stand up to the pressure.

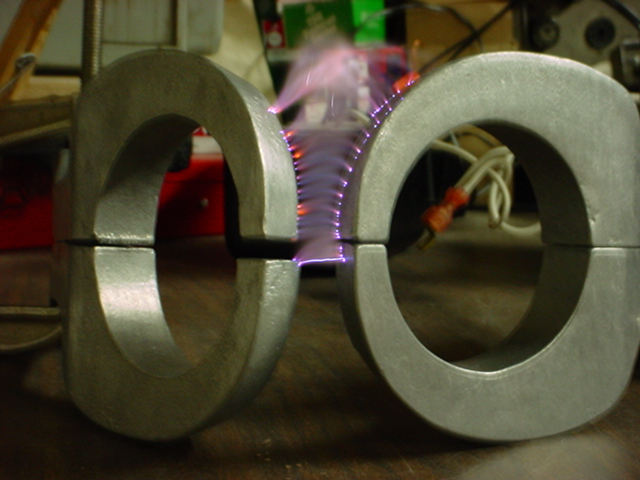

So, I've decided to use Die Cast Zinc pulleys. I need it to be a double pulley so I've gotten two 3 1/2" single A section pulleys and I'll bolt them back to back and attach them to the 10mm hub so I can attach them to my motor. Should work like a charm.

Thanks Dave for the information. You are extremely helpful as always good sir. I am currently looking at these power window motors for use as shoulder and elbow motors on Questor 2.0. These may be easier to use than the Bosh motors.

Keep those videos coming of my favorite robot B9! You are setting the standard!

BTW...I agree with your choice of the metal pulley idea. It is a much better choice and should provide more stability.

Rex

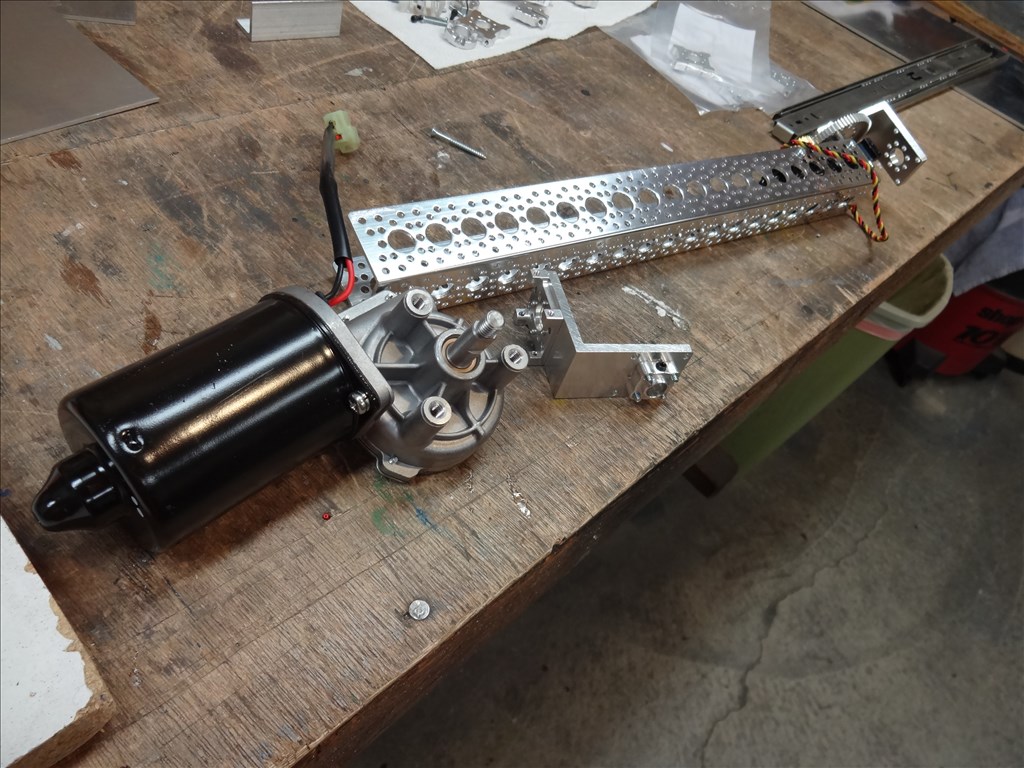

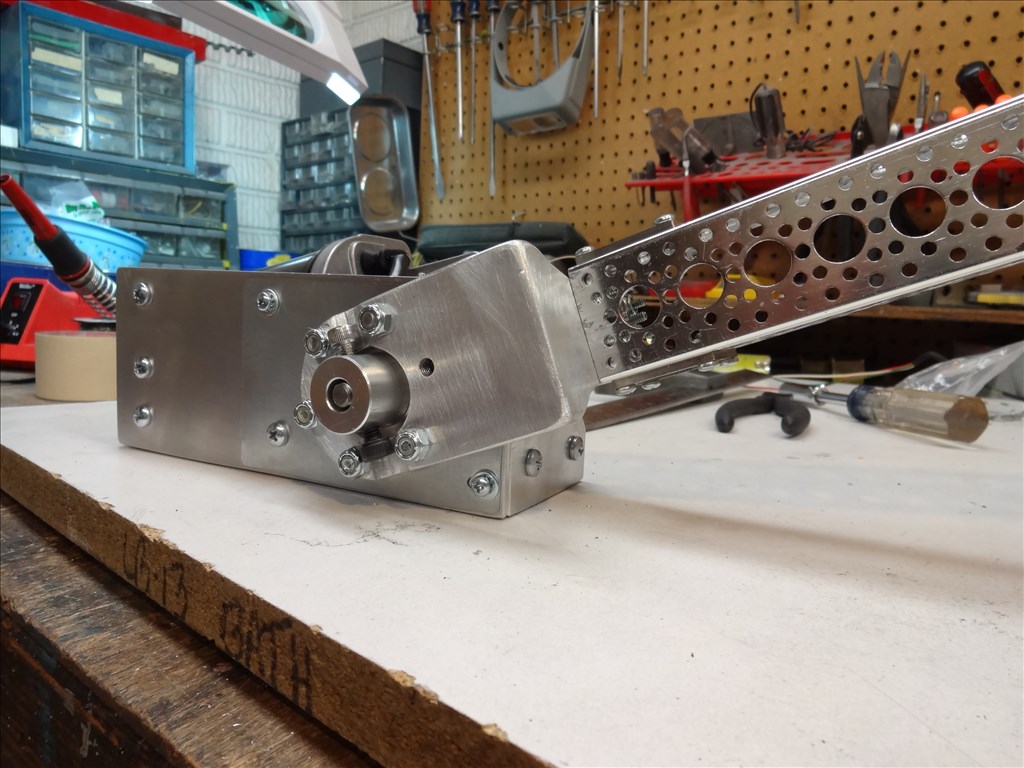

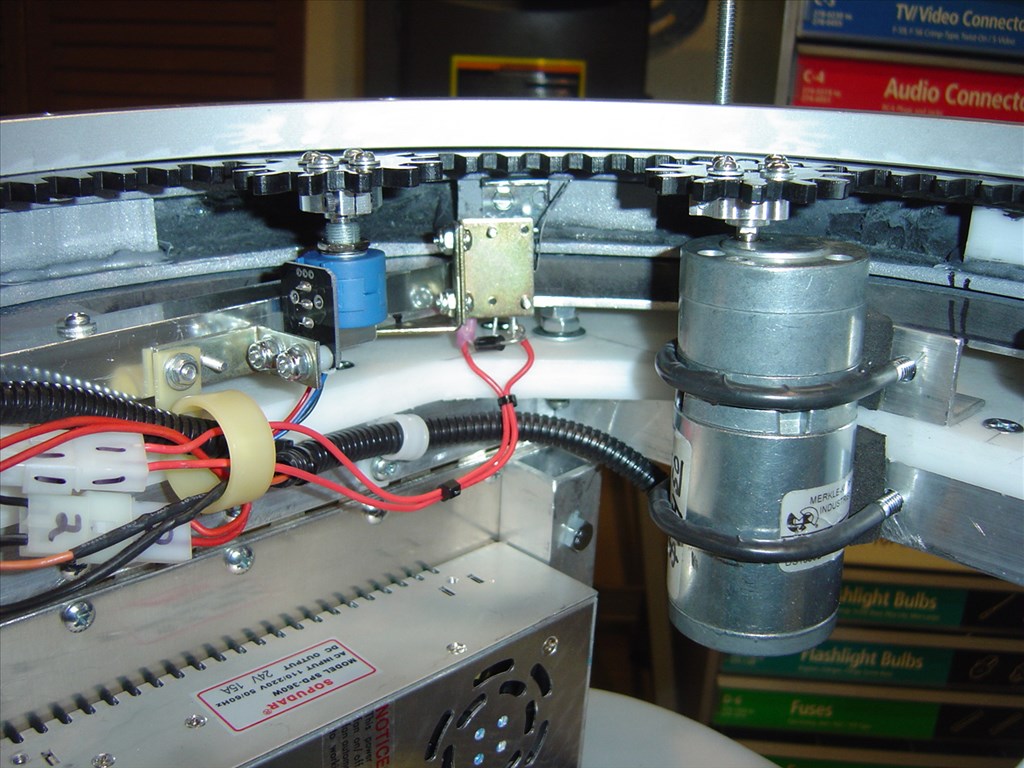

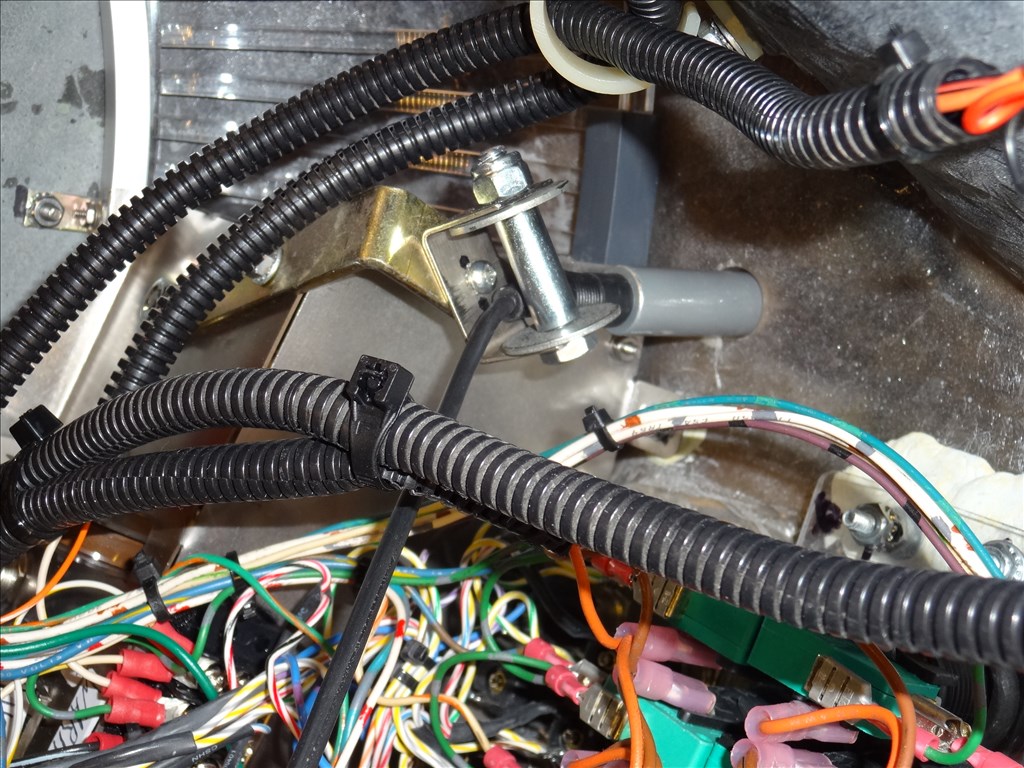

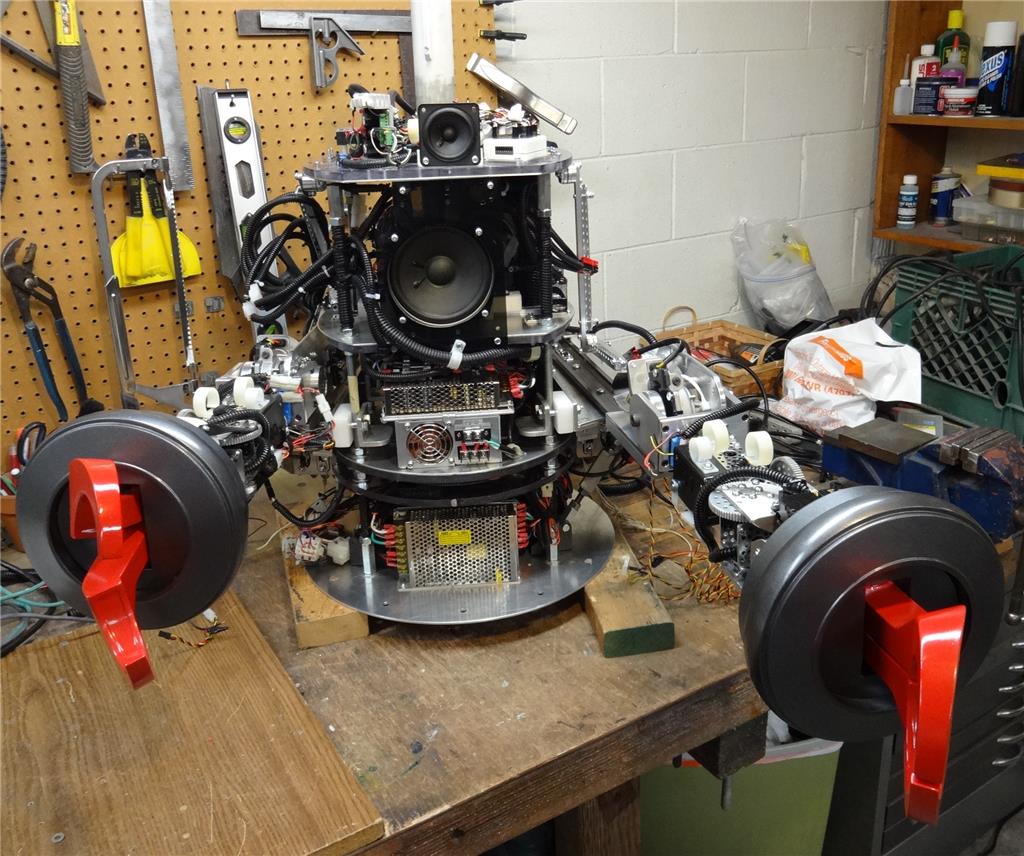

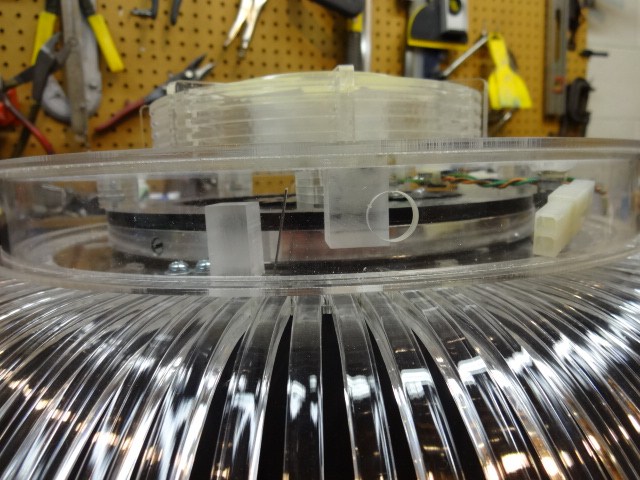

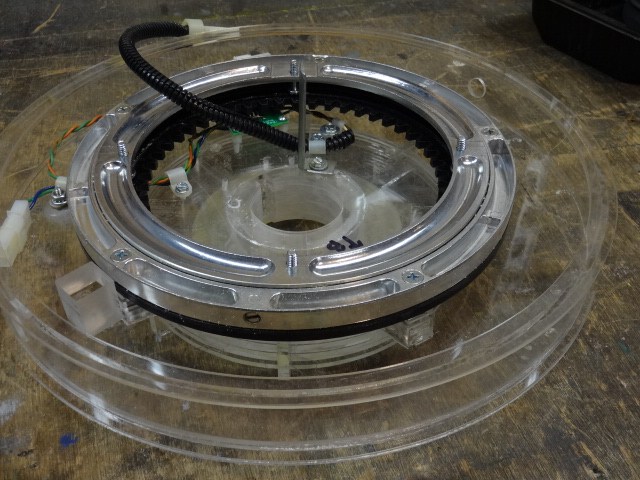

@Rex, I haven't battle tested these power window motors yet but I'm sure they will do the job I want them to. If it helps they are rated at 88 lbs per inch. That's pretty strong. I was able to stall one yesterday after I got the metal hub and double pulley mounted. It took a good grip on the outside of the 3 1/2" pulleys to do it though. Compare that to the windshield wiper motors I'm using (AME-226-series 12V Utility Gearhead Motor) for my arm elbow motor. That one is rated at 230 Lbs per inch and lifts my 2' long 7 lb arm without breaking a sweat.

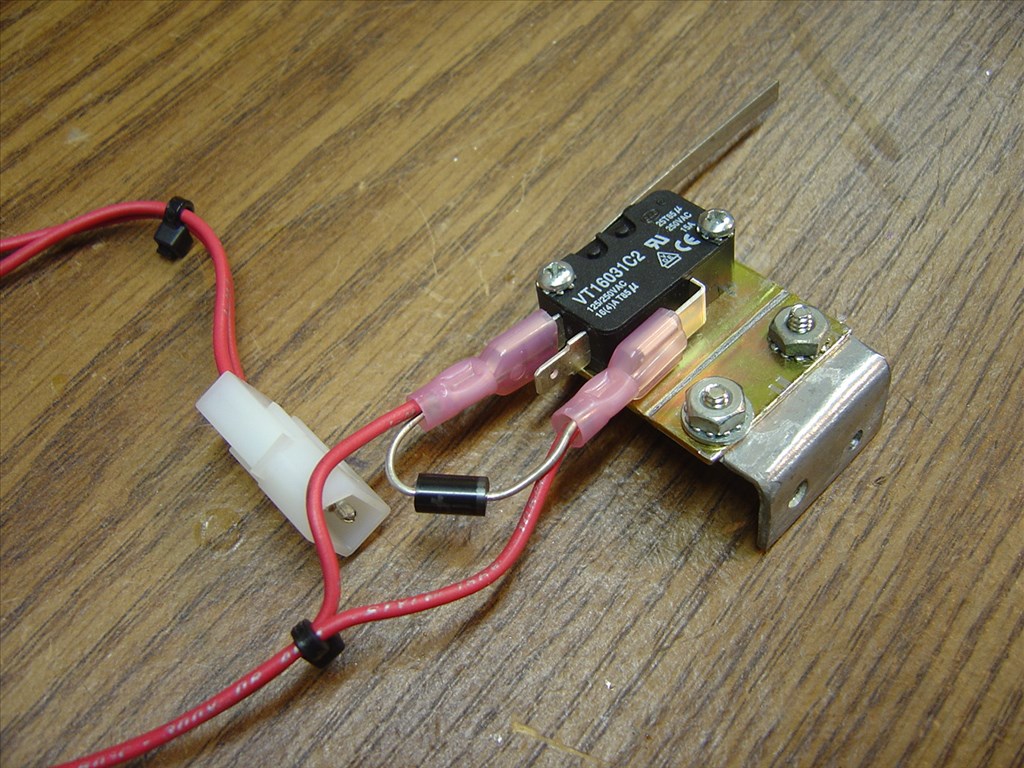

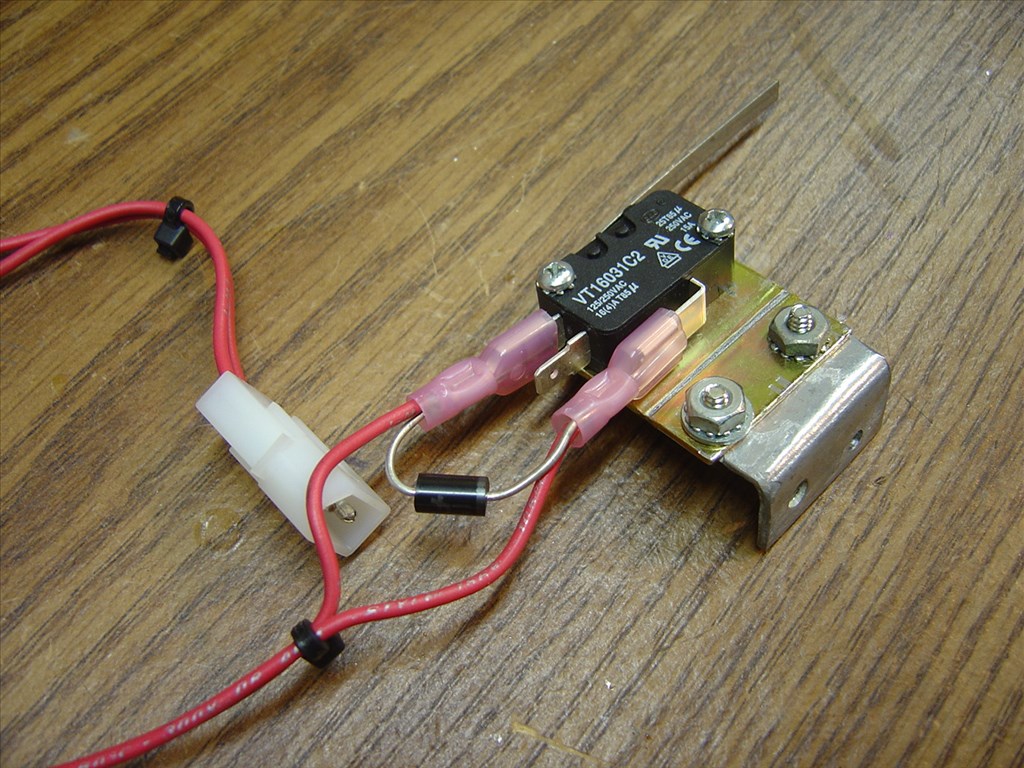

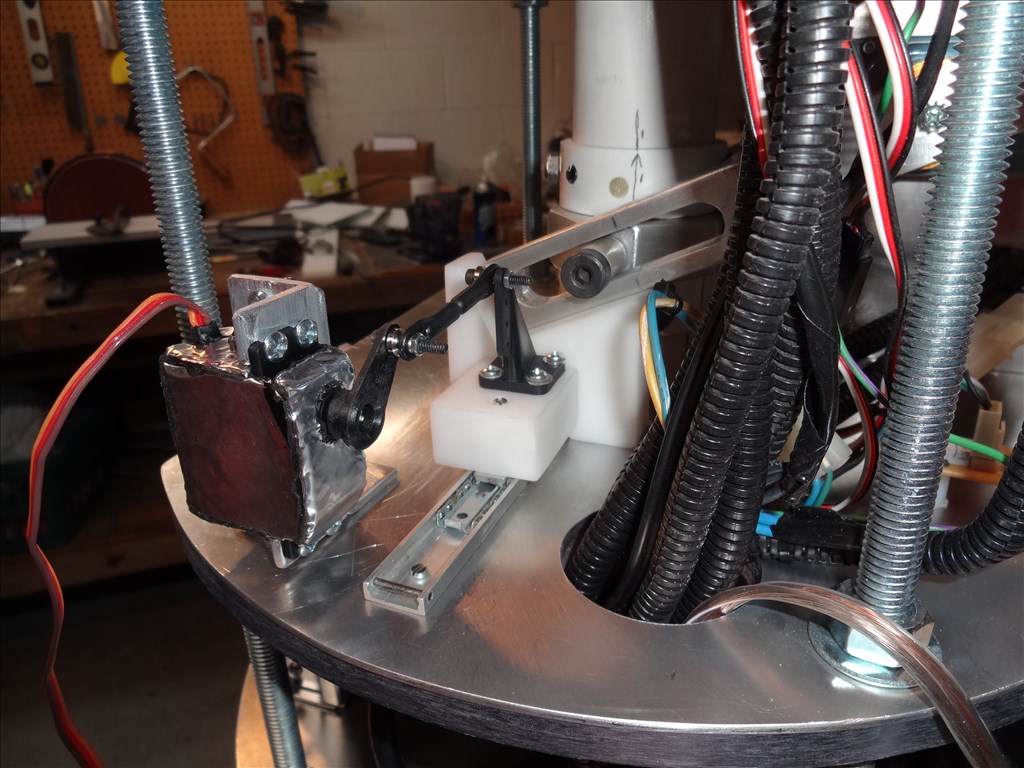

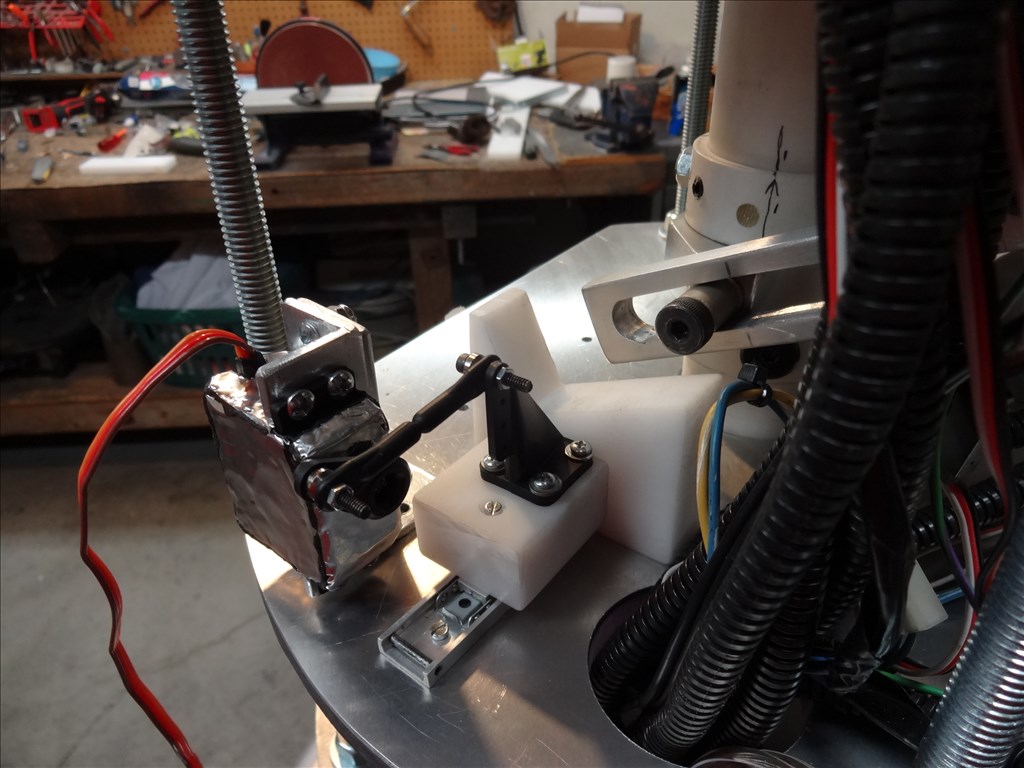

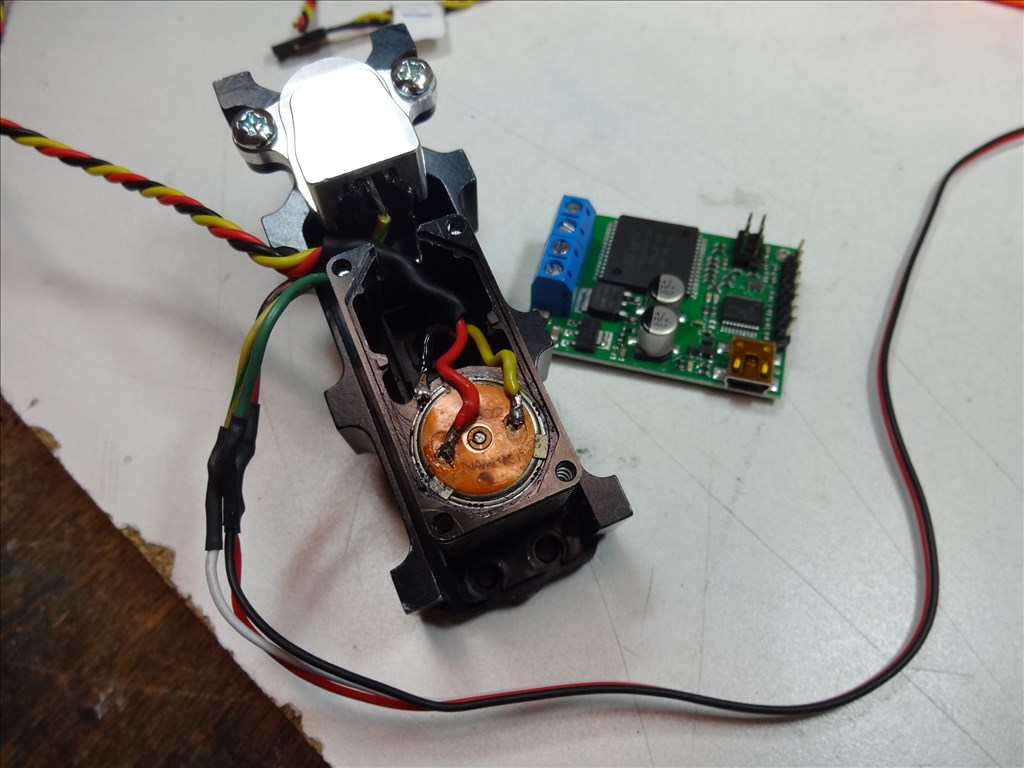

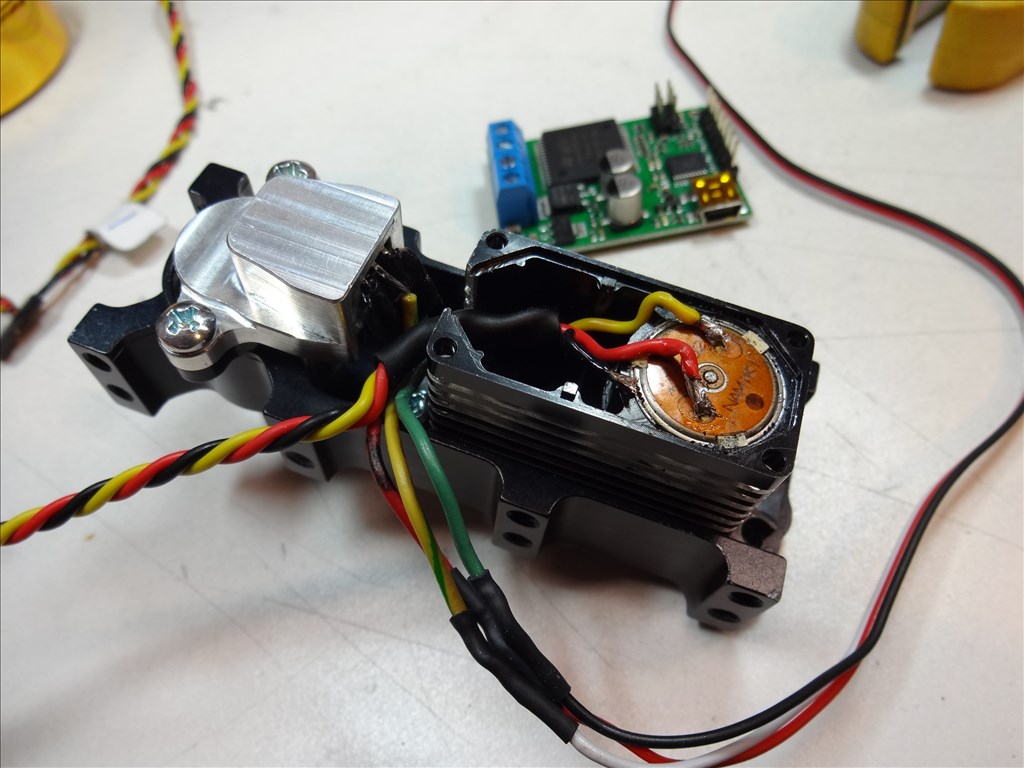

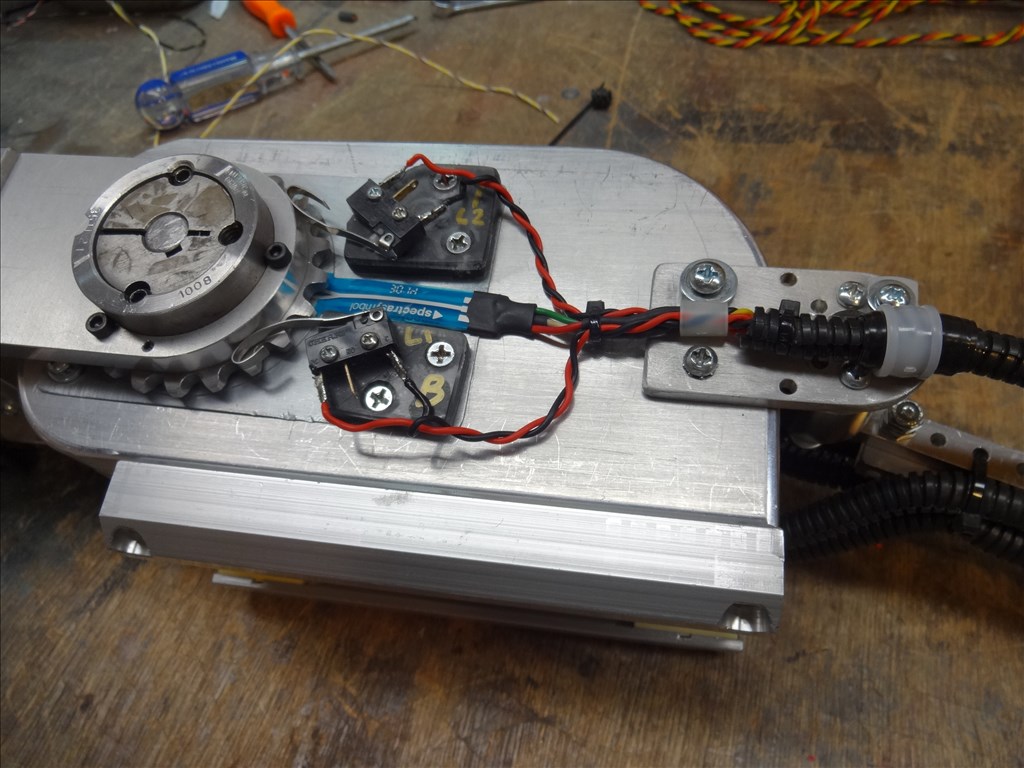

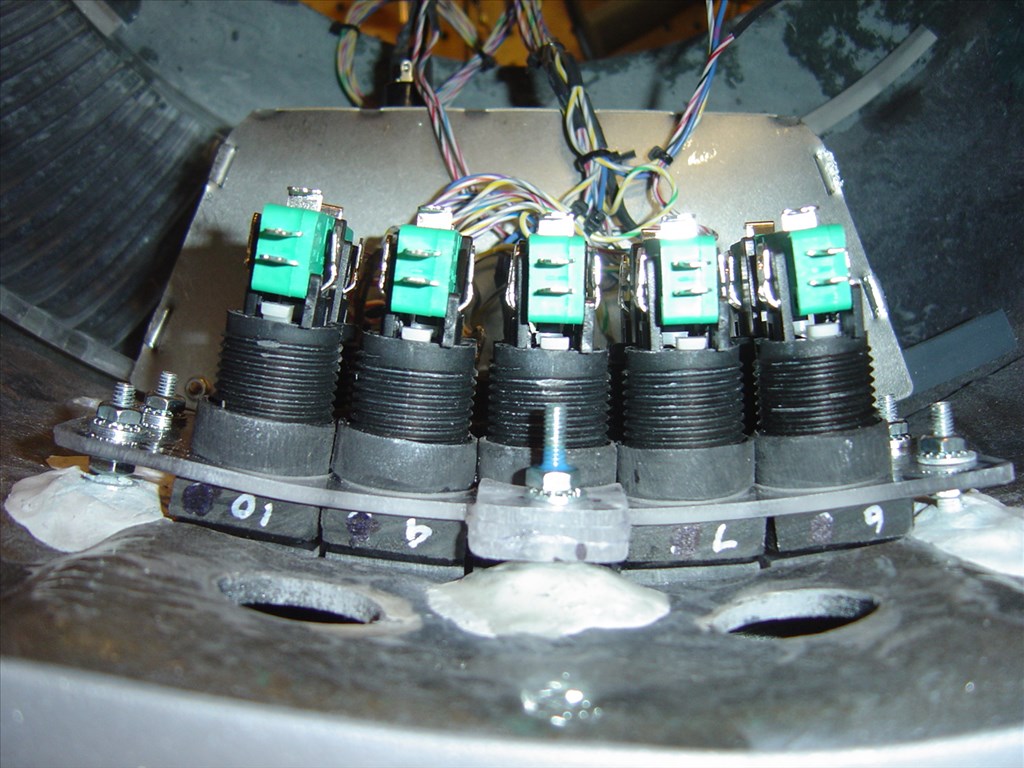

The drawback with using these motors over the Bosh Motor is there is no internal pot for feedback. However I've figured out tonight how to mount a encoder on the double pulley assembly. The trick was getting it to turn as level as possible so the encoder will read properly.

I'll do another quick video in a few days showing this setup and the prototype I made trying to figure this all out.

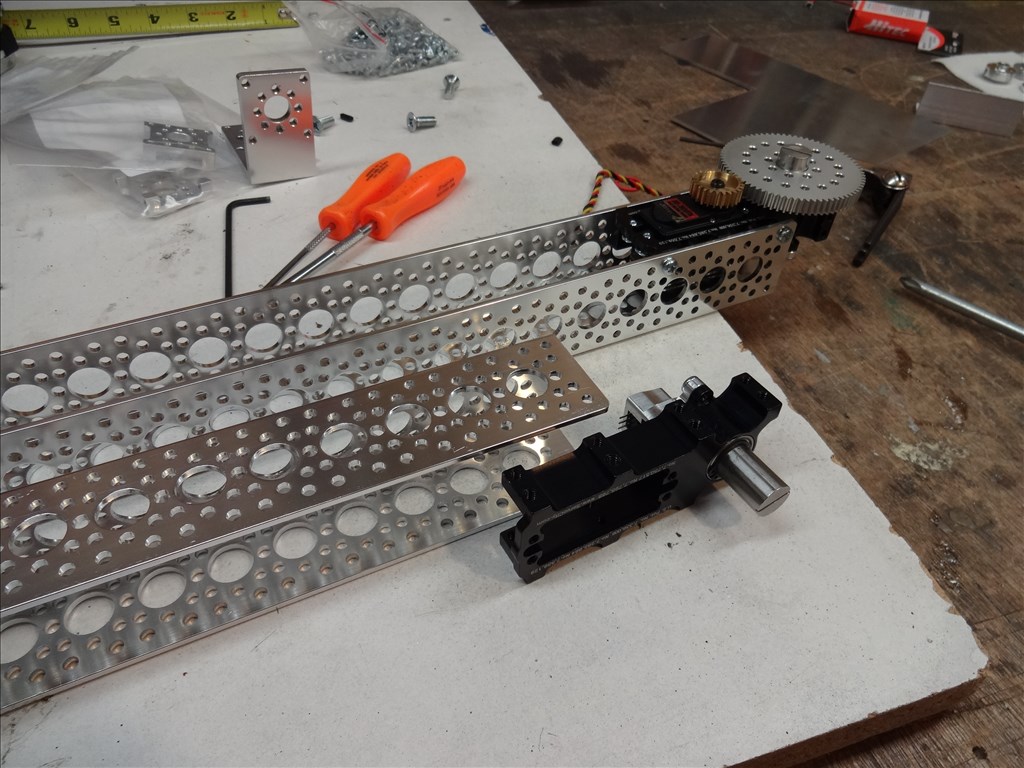

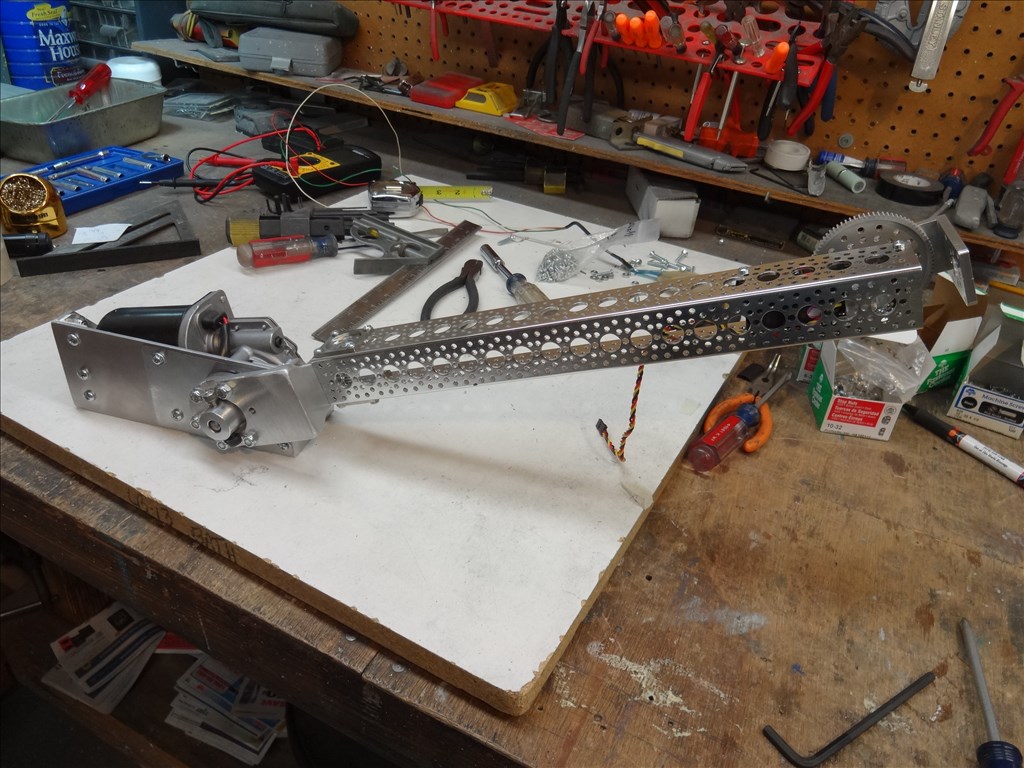

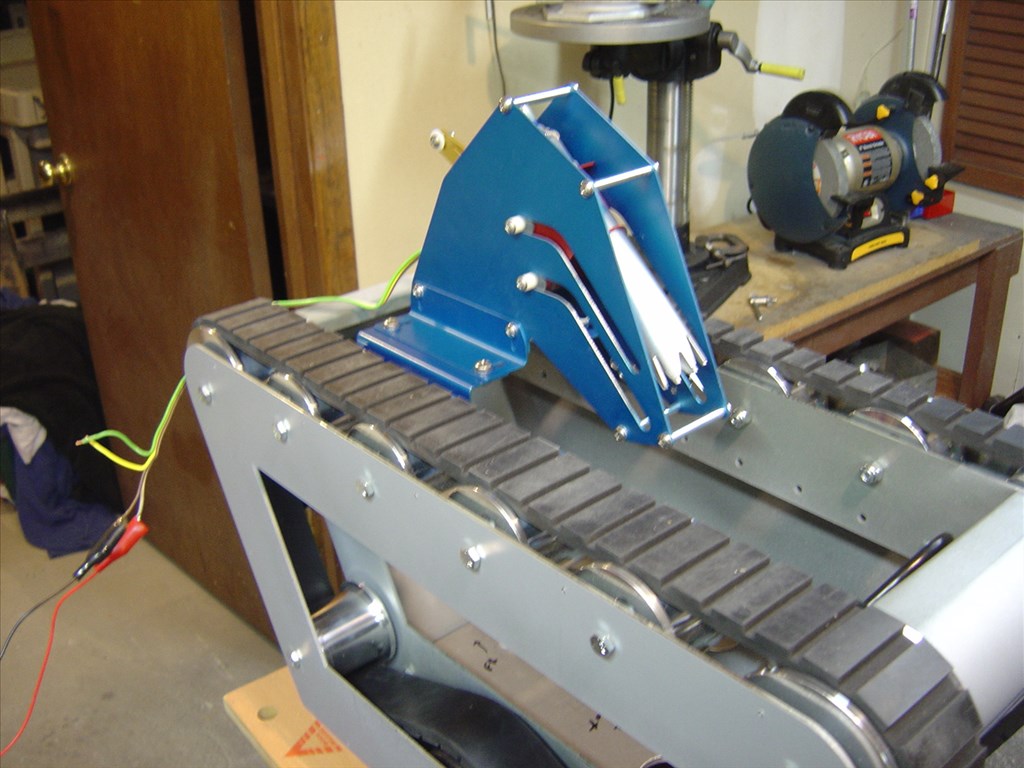

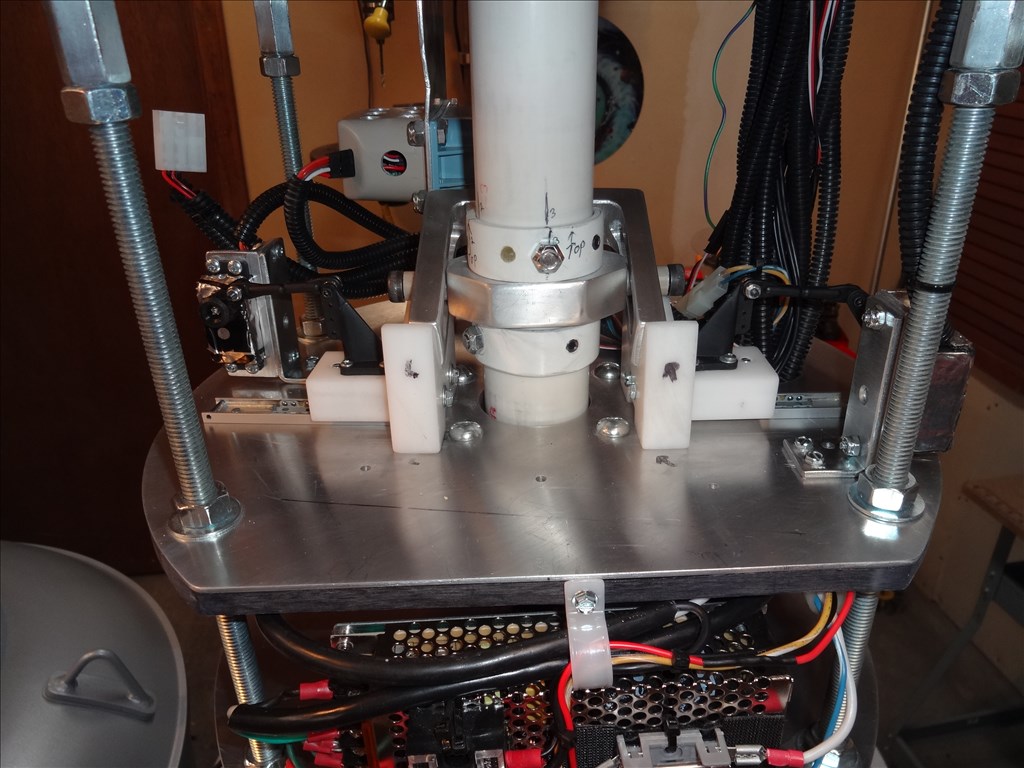

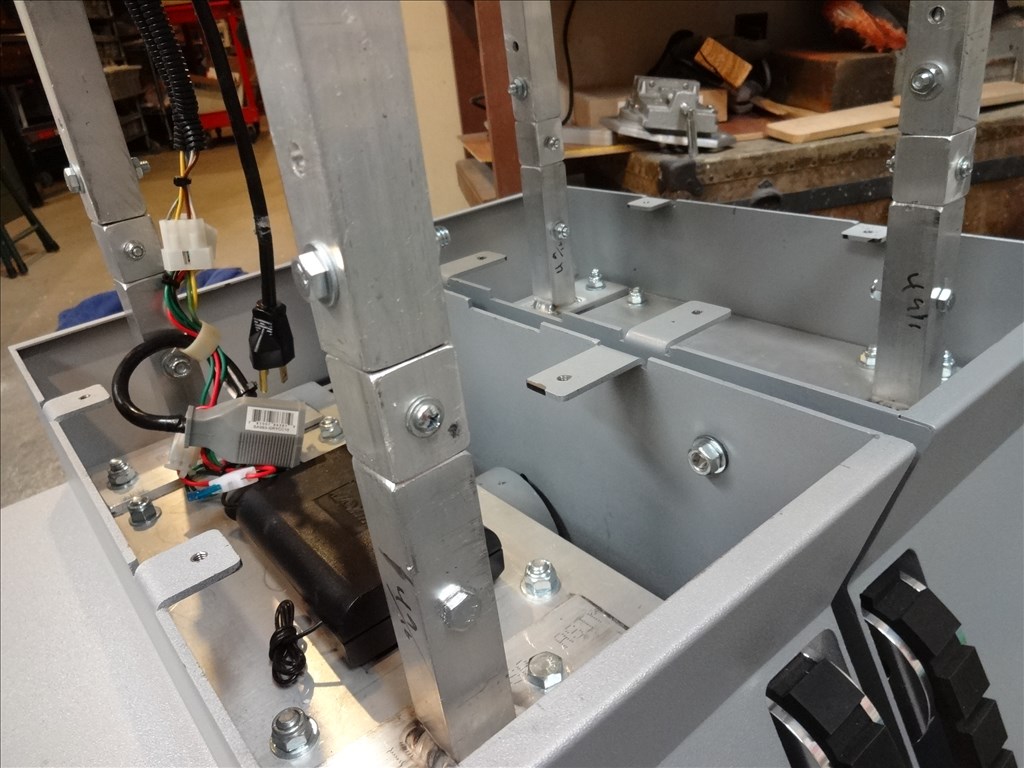

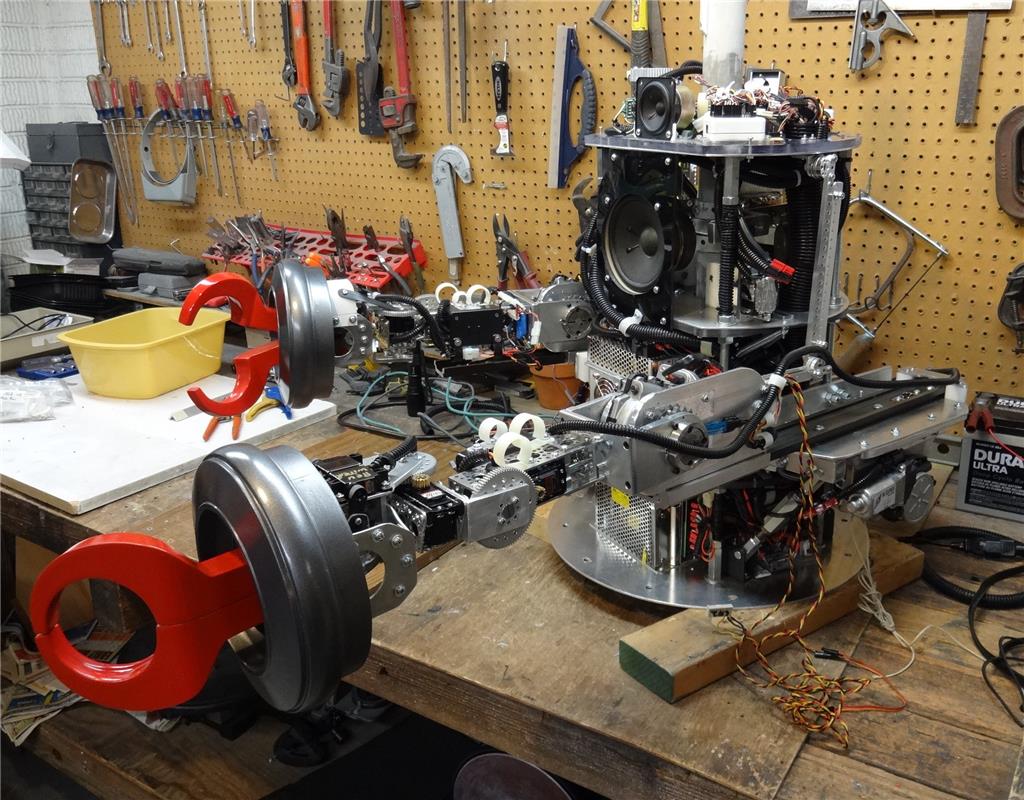

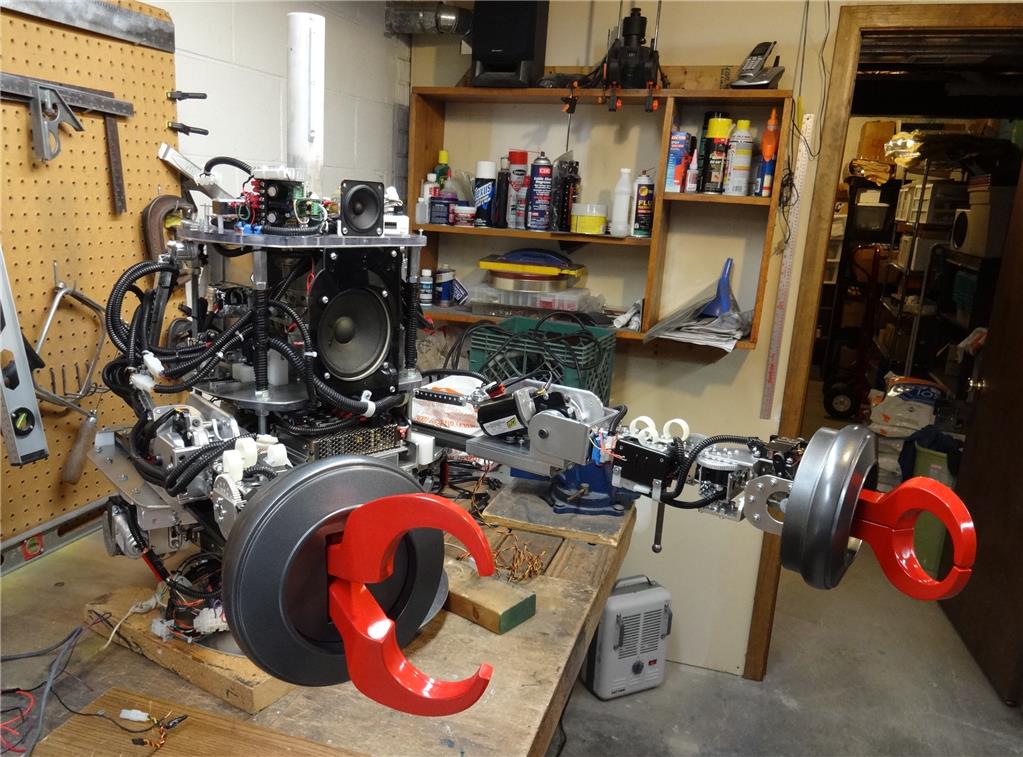

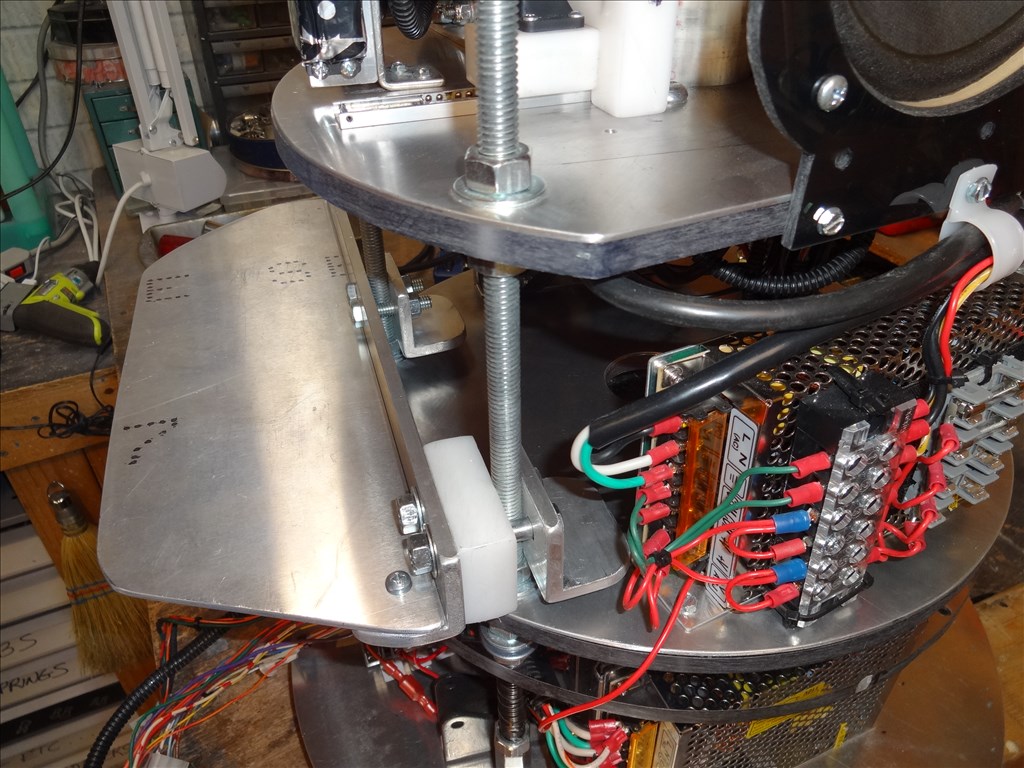

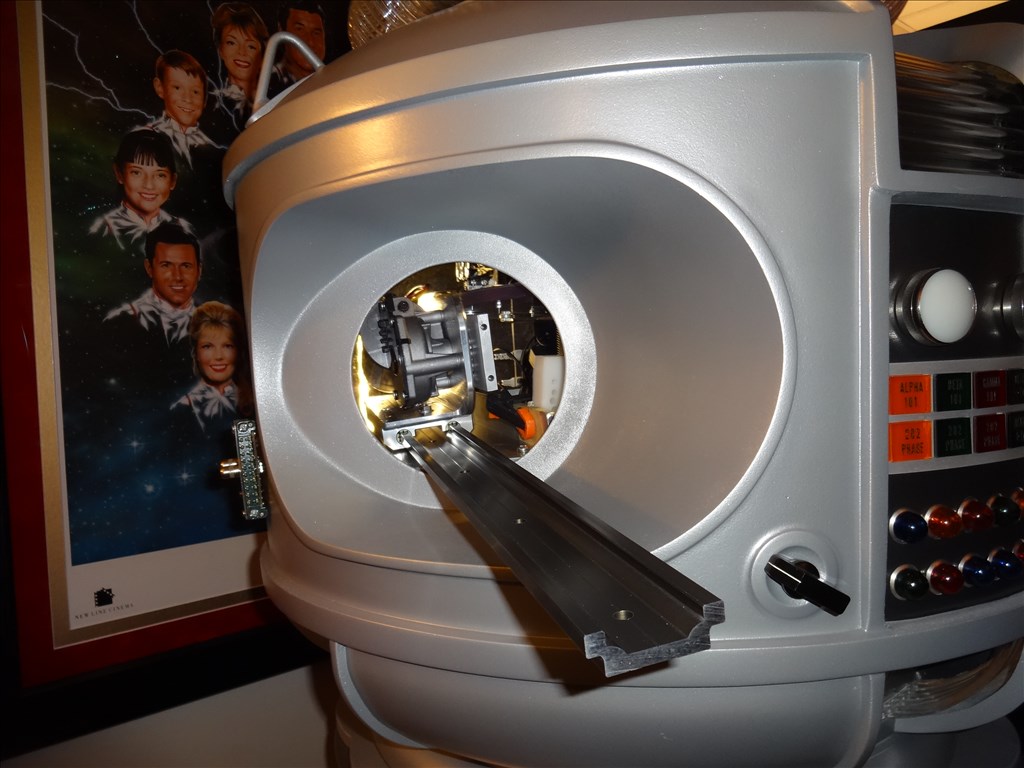

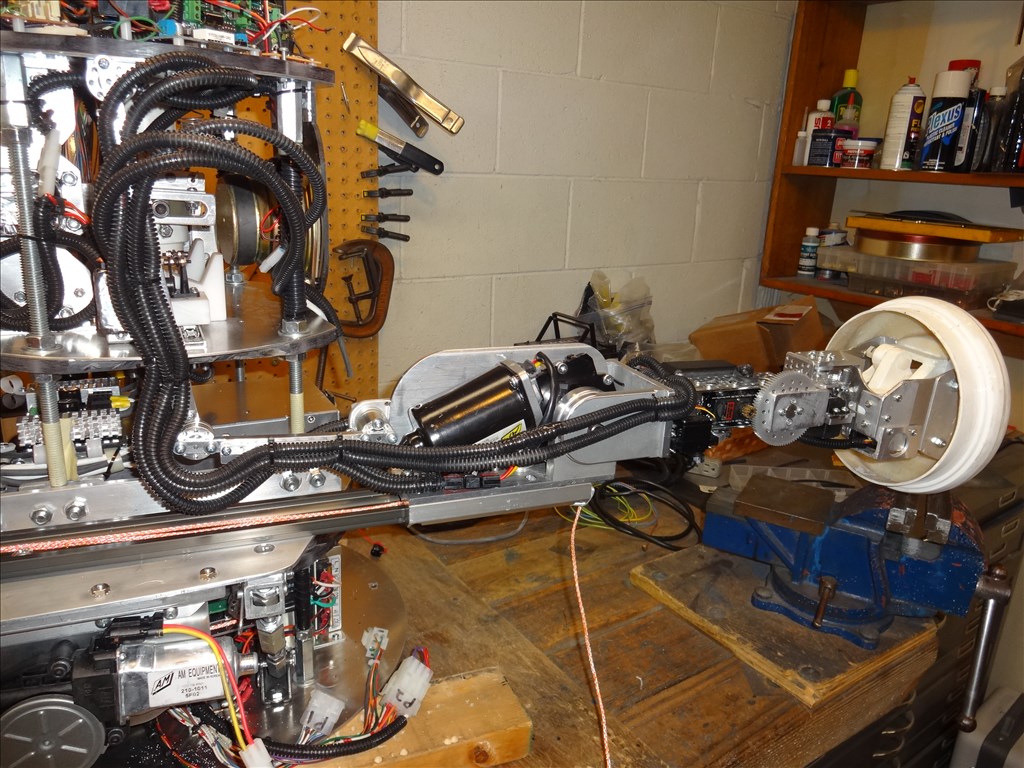

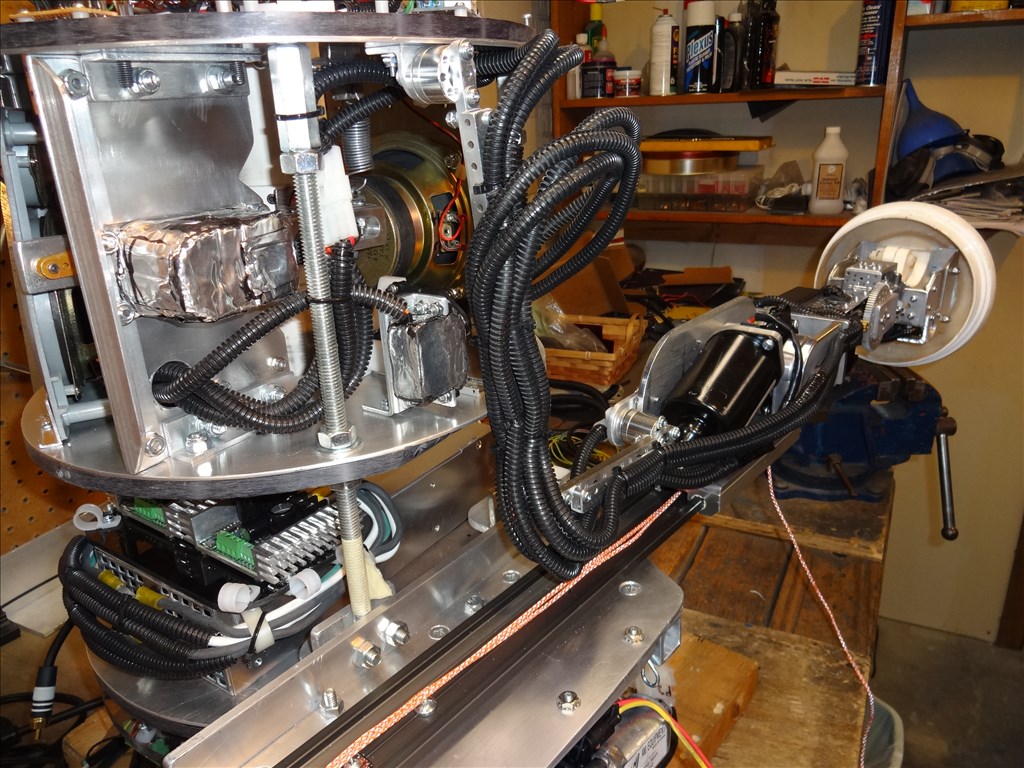

Here's a shout update on my Lost In Space B9 arm rail system. This rail system hopefully be pulling the heavy arm I designed in and out of the B9 torso. This update is all about the twin pulleys I built that will mount on the motor to winch the synthetic cable back and forth. Enjoy!

Great video Dave. Looking forward to seeing this in action. Two things that give me the most headache when building things from scratch are getting things centered properly and designing things so that they can be disassembled to be worked on easily. Many times I have come up with great ideas only for it to dawn on me later that hey....I've got to be able to take this thing apart to be able to work on it at some point. Unfortunately (sigh....), I usually way over complicate my designs. Spending (wasting) many hours re-doing things that I should have left to common sense. Worrying about....what will others think when they see what I have come up with.

I want you to know that I enjoy watching your videos and they are teaching me good things. Your B9 is awesome! Keep them coming...

Thanks Rex. Wow, we must be twins. I do these same things. I always over build and complete. Maybe after I get this contraption working someone will suggest a much simpler method. "Why didn't you. .........." . All I'll be able to do is slap my forehead and walk away with my head hanging low. However, you gotta love watching complicated stuff work. All thouse moving shiny parts.

I like shiny things...

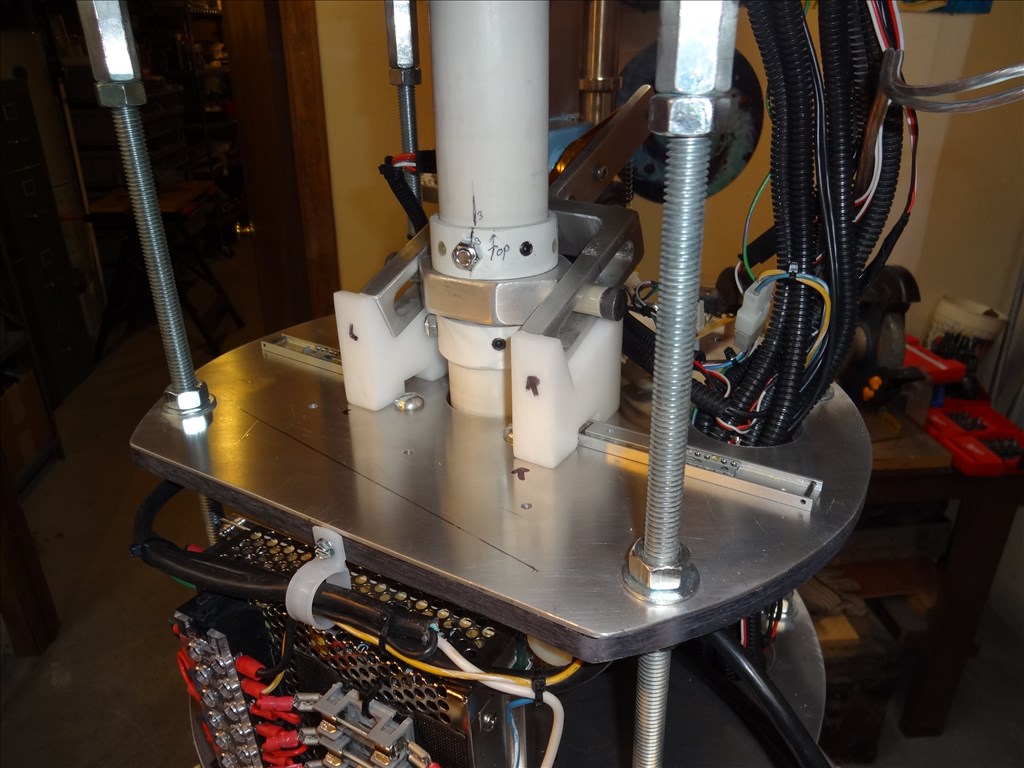

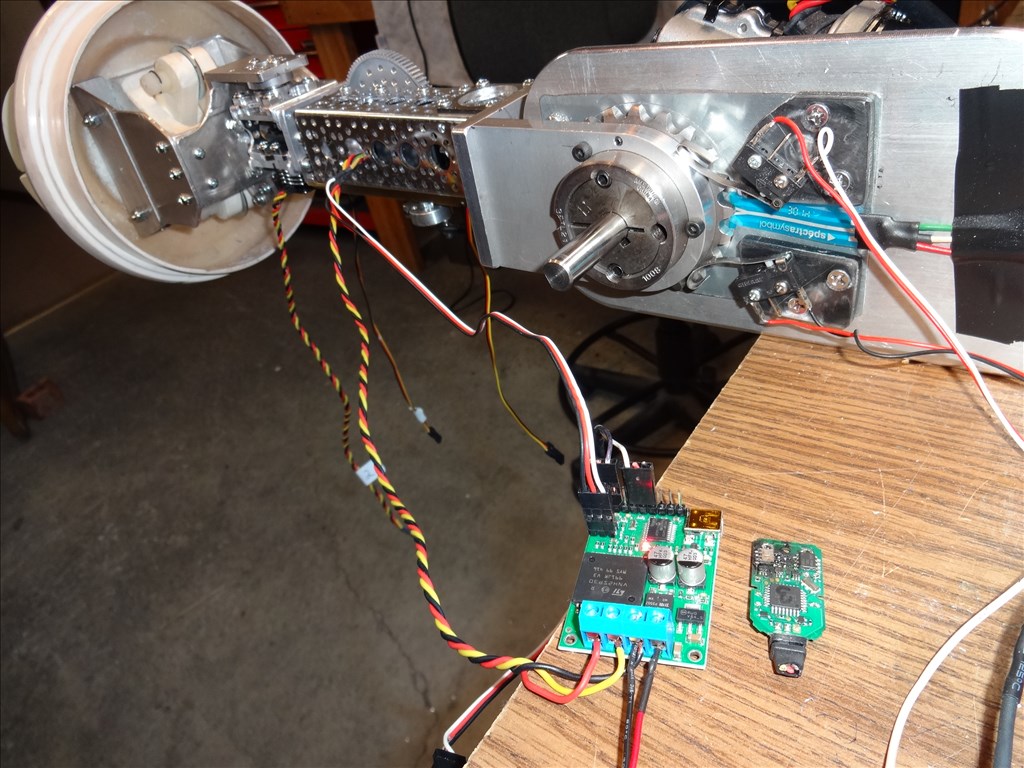

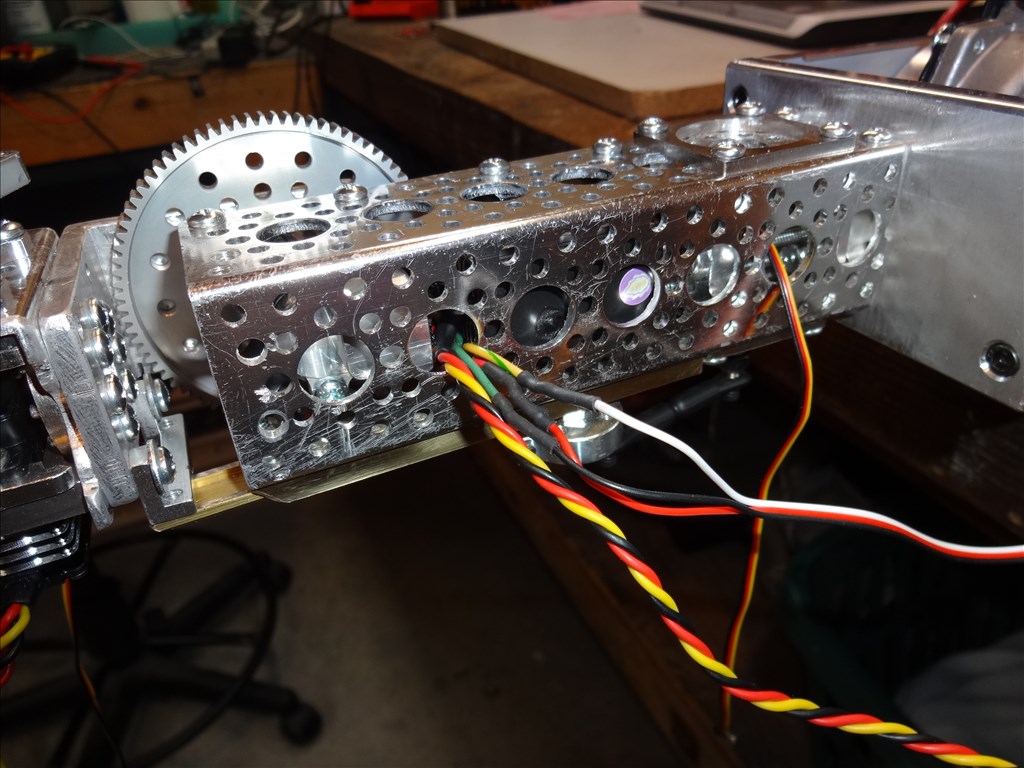

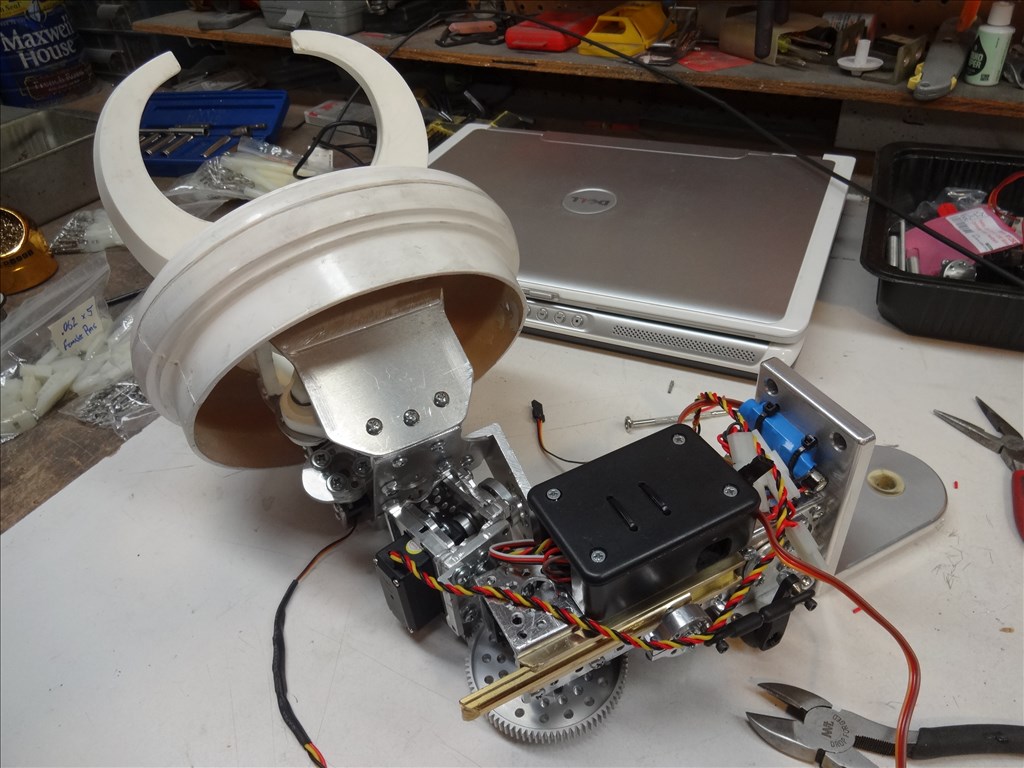

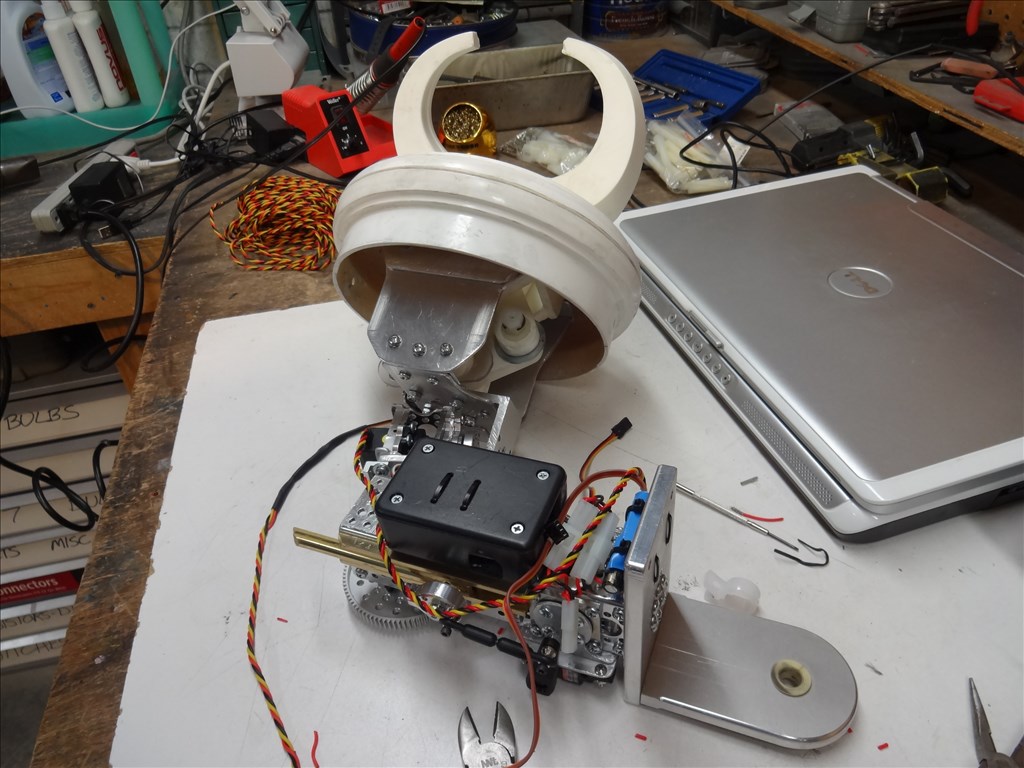

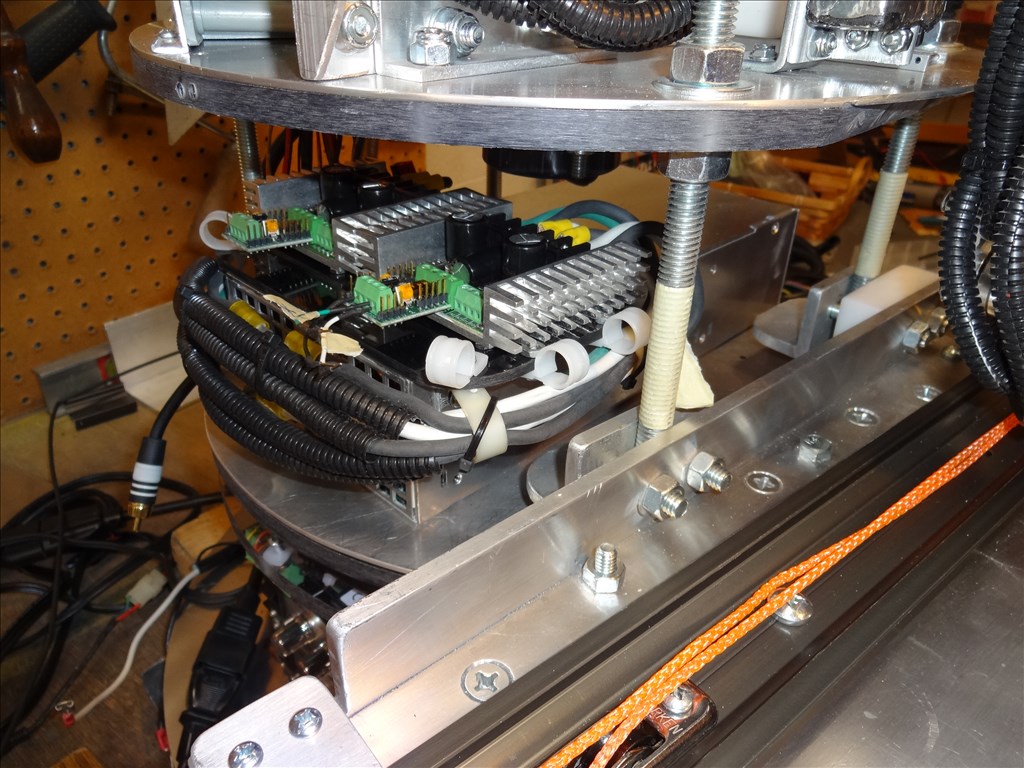

I'm very excited. Good things are happening in my robot shop. I'm just a few connections away from having a fully functioning B9 arm, mounted on the central support system that moves in and out of the torso smoothly and articulates with 4 other joints.

The B9 builders here should know what I'm talking about and why I'm so excited about this.

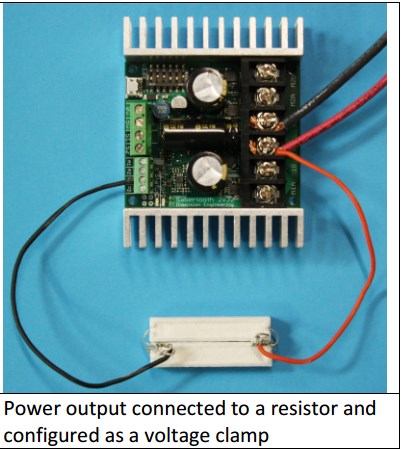

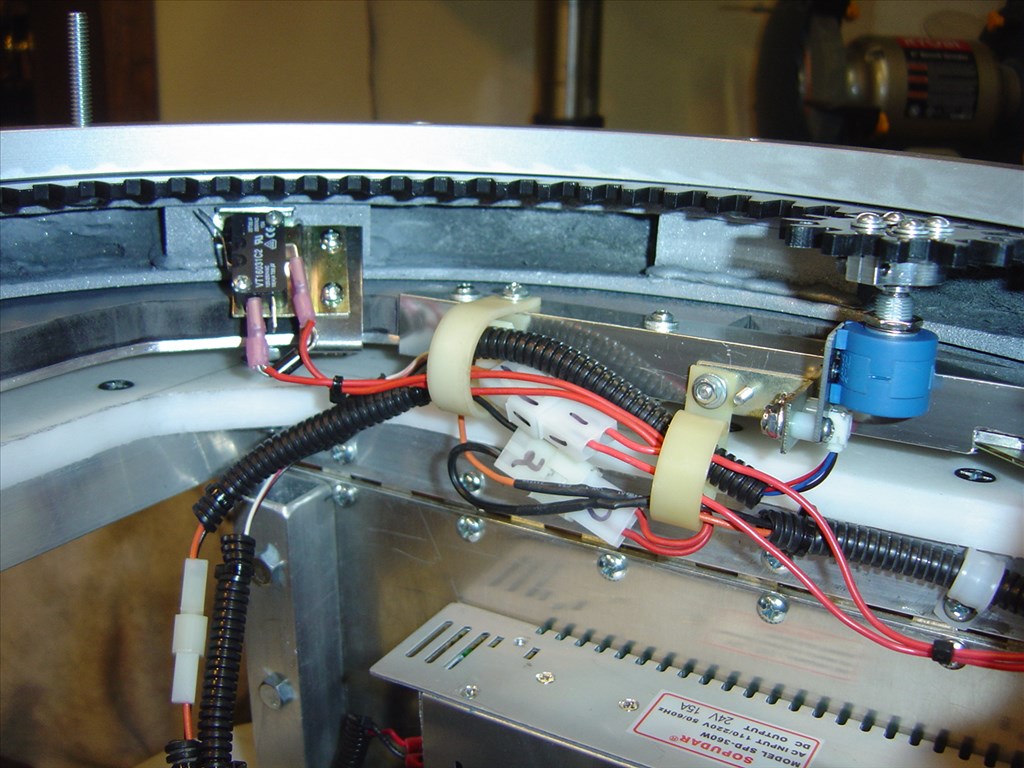

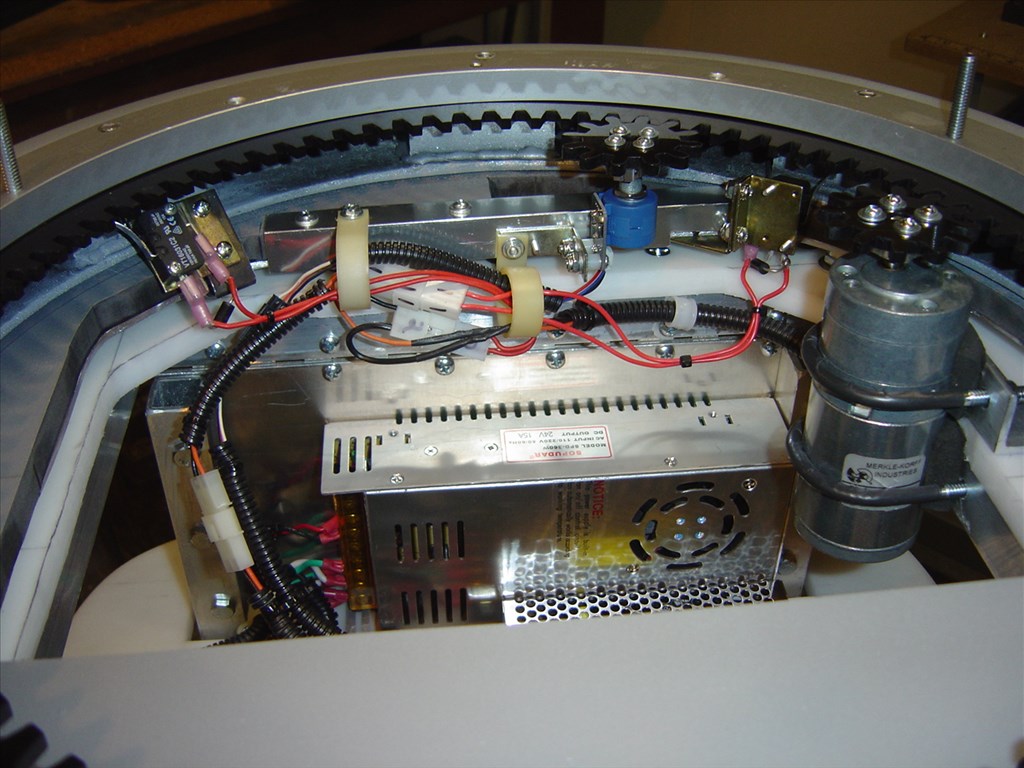

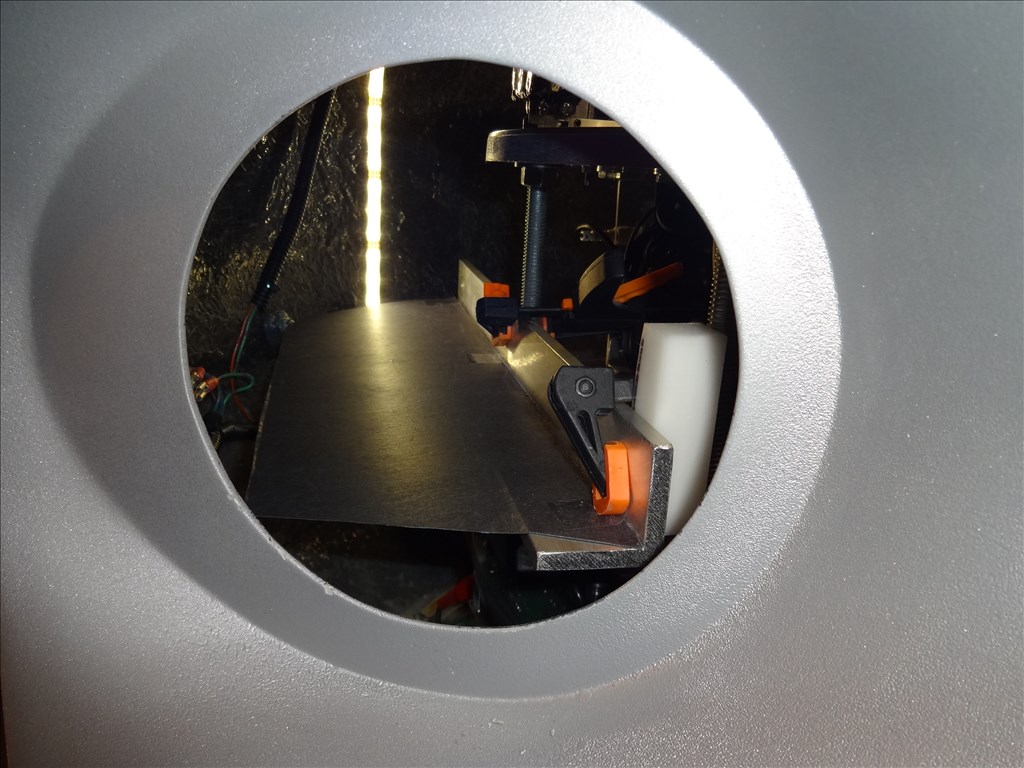

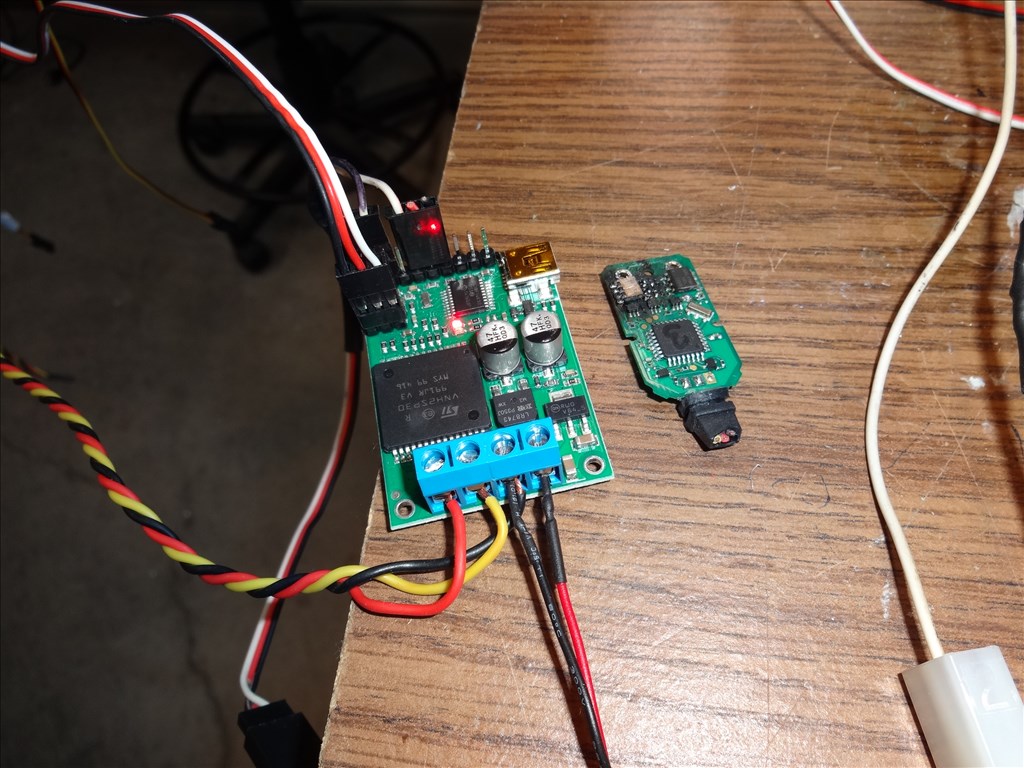

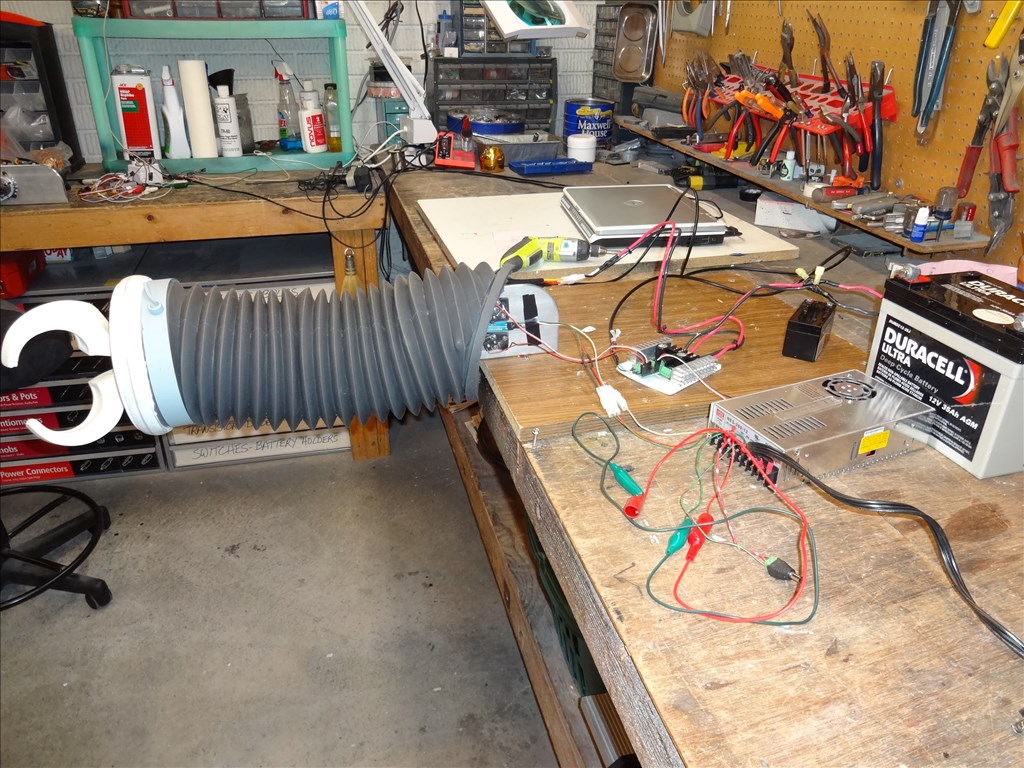

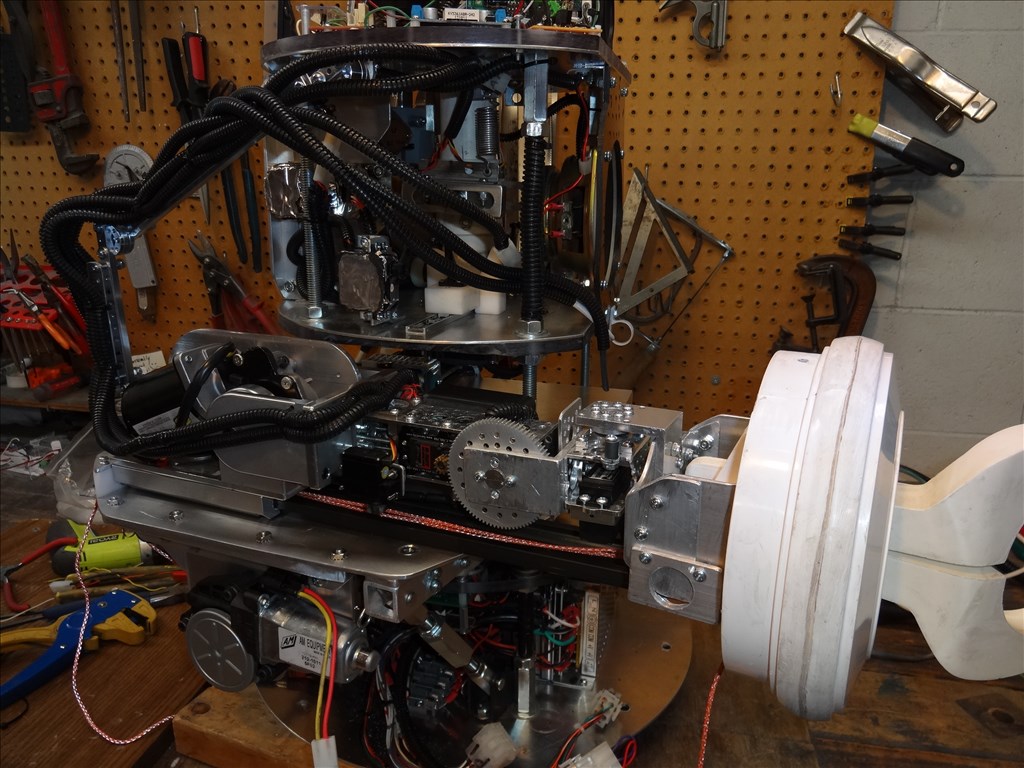

It's Alive! After months of R&D, testing, building and a lot of dreaming my B9 Arm Rail System is working. Until i actually saw it moving I had doubts it would actually work. Not only did it move but it slides back and forth on the DryLin W Mono-Slide guide rail system by Igus like it's a cat on ice! This rail system will deliver my B9 arm (I also designed and built) in and out of the torso of my full scale B9 robot from the 60's TV show Lost in Space. I still have to wire in the motor control system that will consist of (hopefully) a Sabertooth 2x32 motor controller with a Kangaroo X2 attached for speed and position control. I'm no movie star in this one but please have a watch and enjoy.