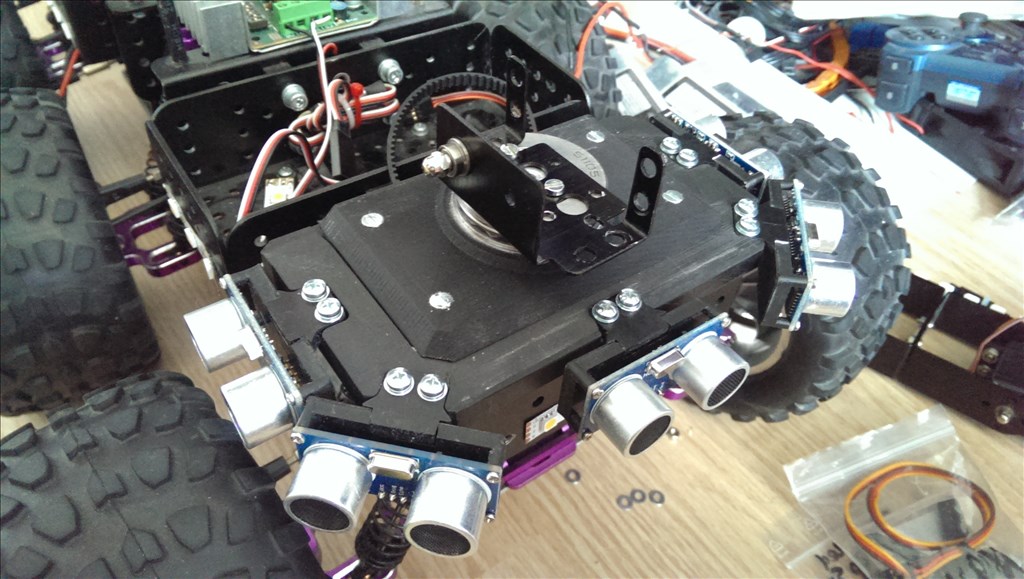

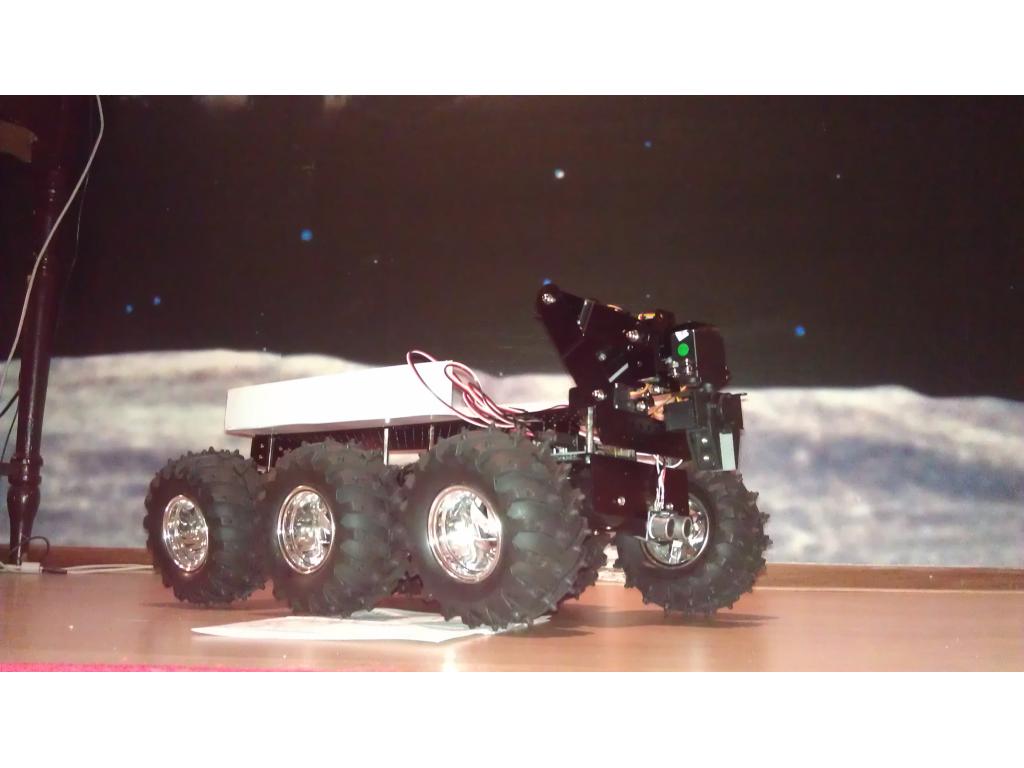

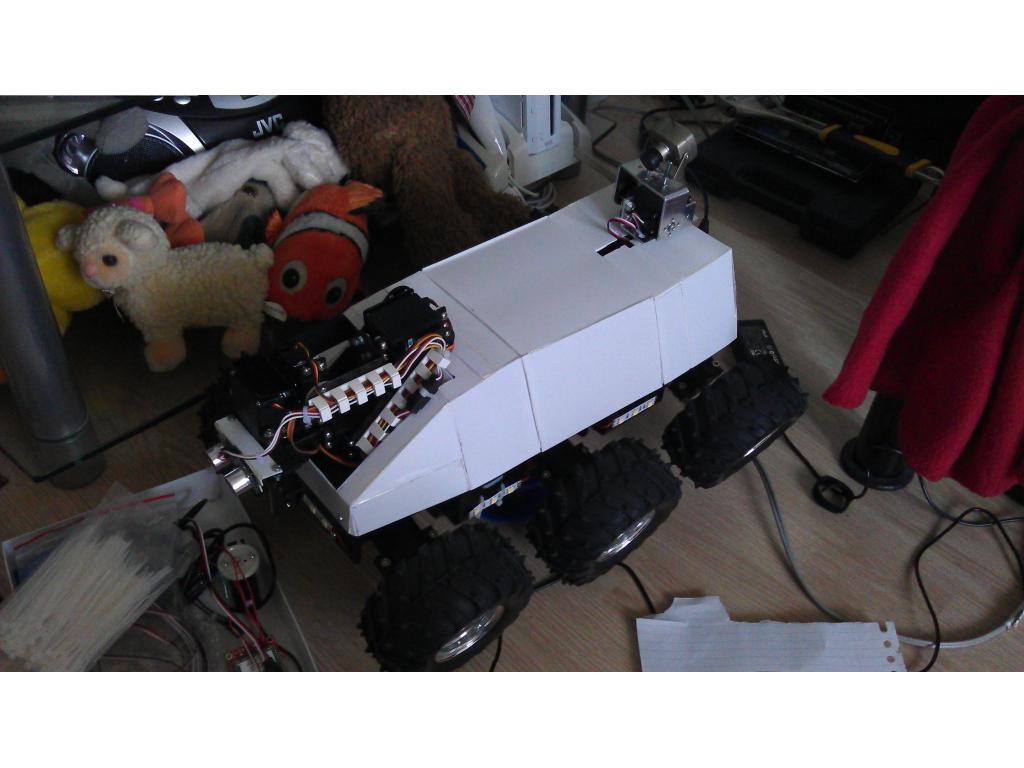

Hello fellow EZ-B'rs, As I finally discovery how to upload photos I thought it was time to share my robot with the world. It's called R.O.O.S.T.E.R which stands for: Remote Online Operating Scientific Testing Electronic Robot (took me about an hour to come up with that, but I like it).

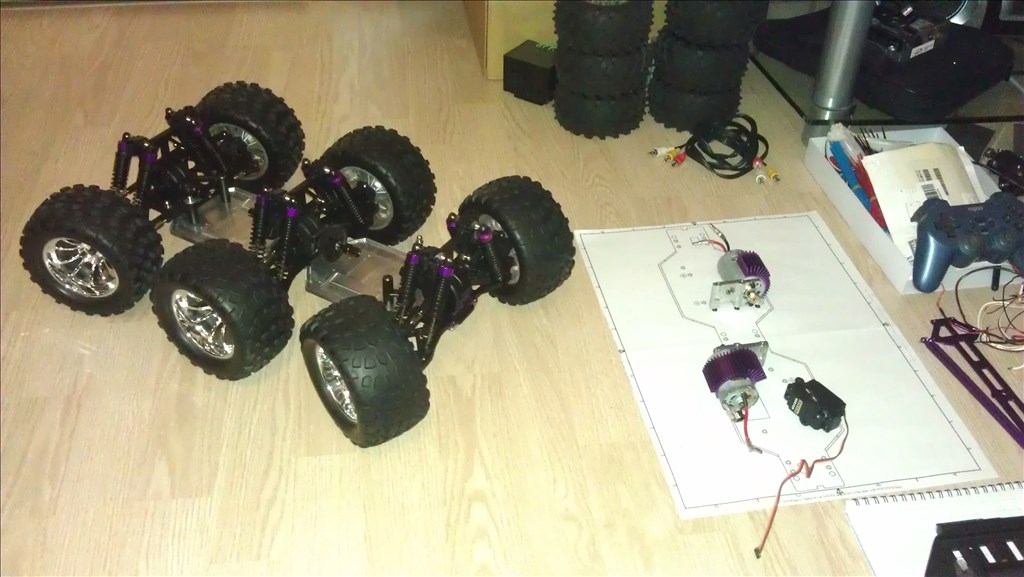

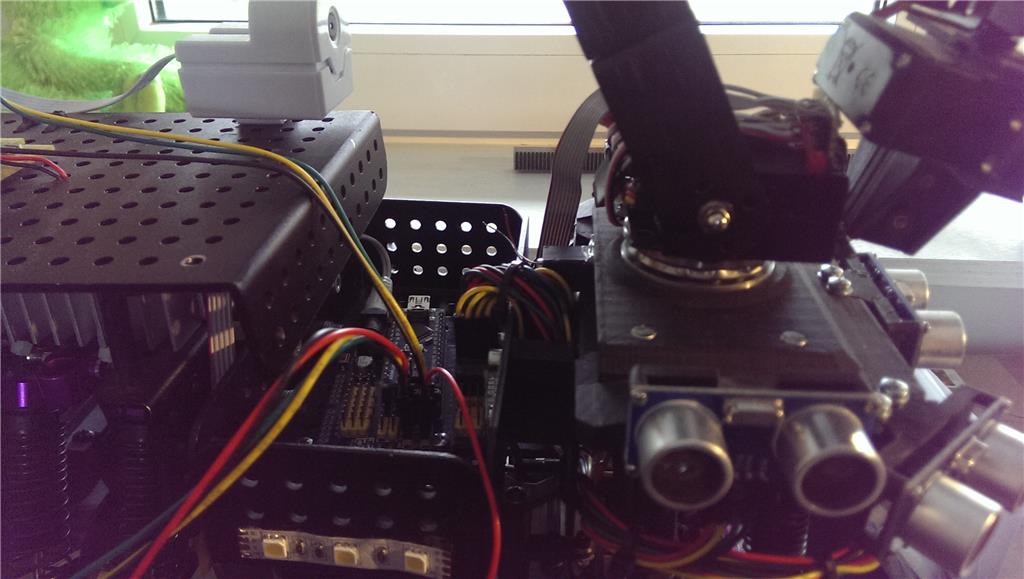

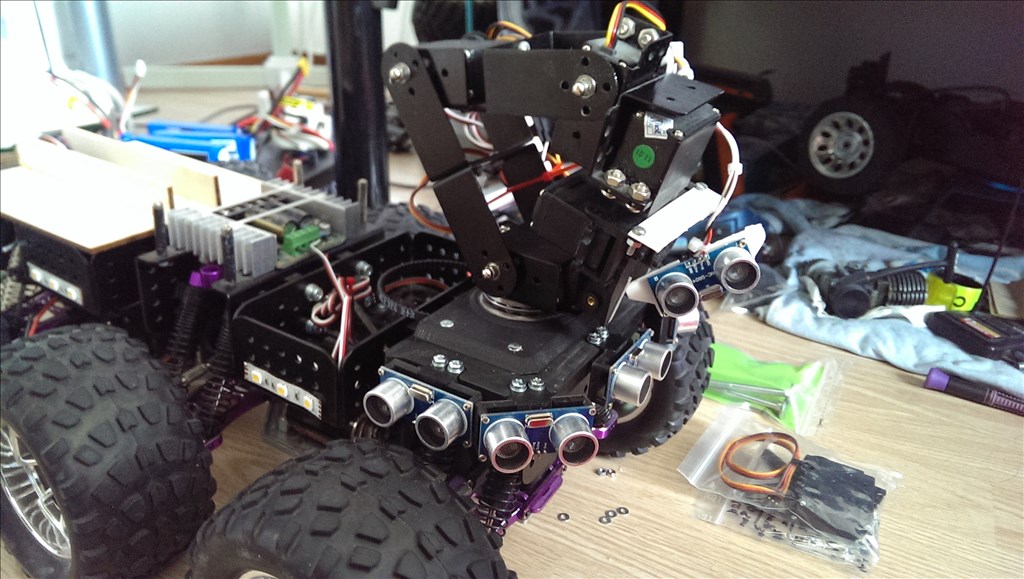

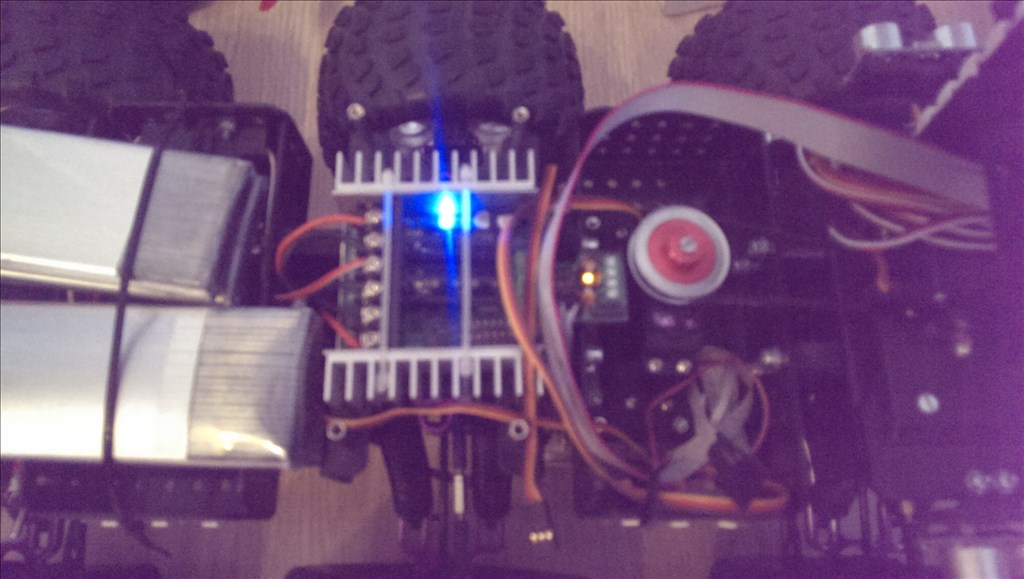

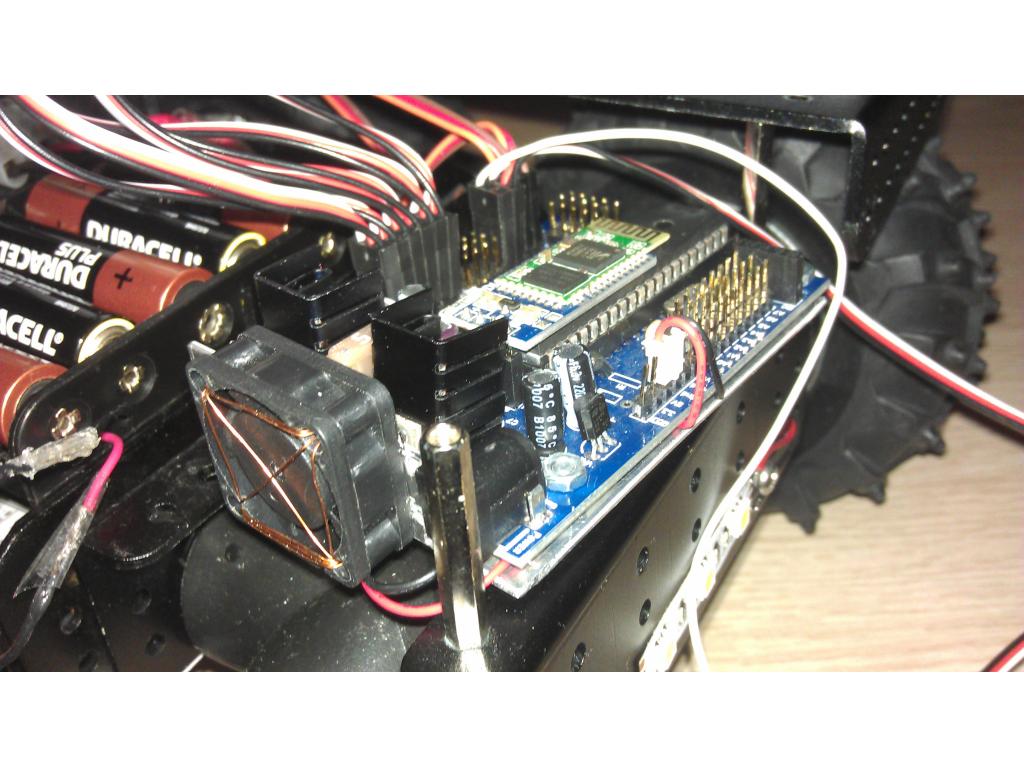

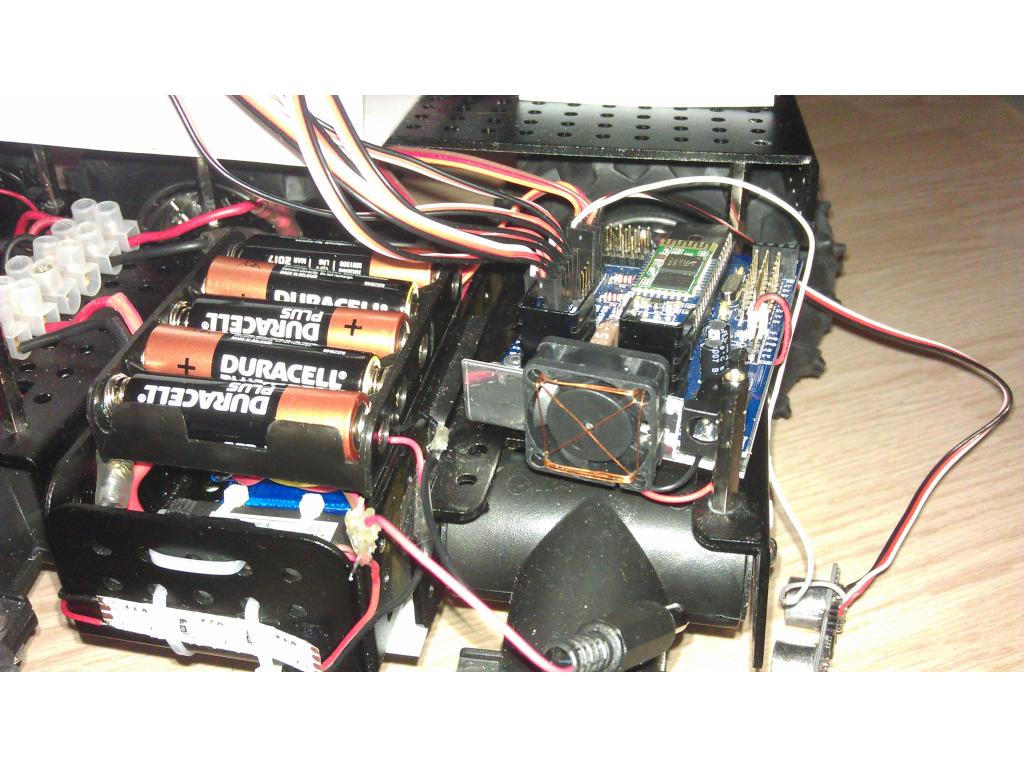

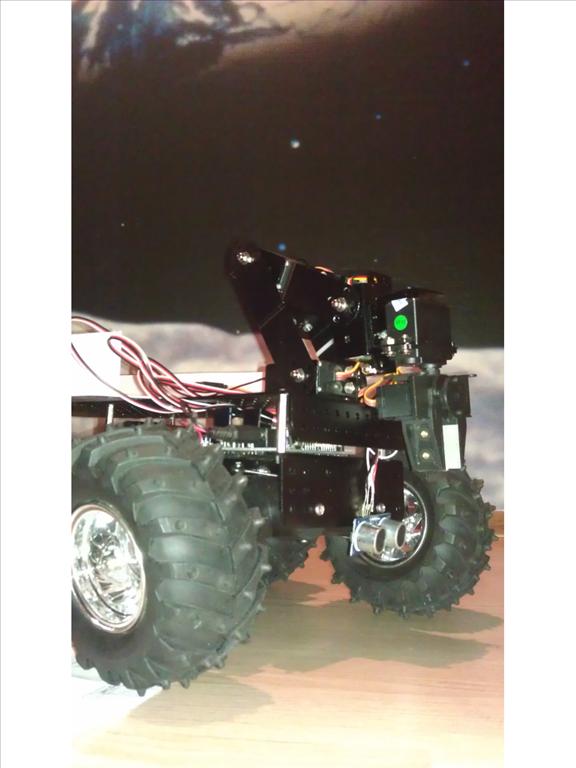

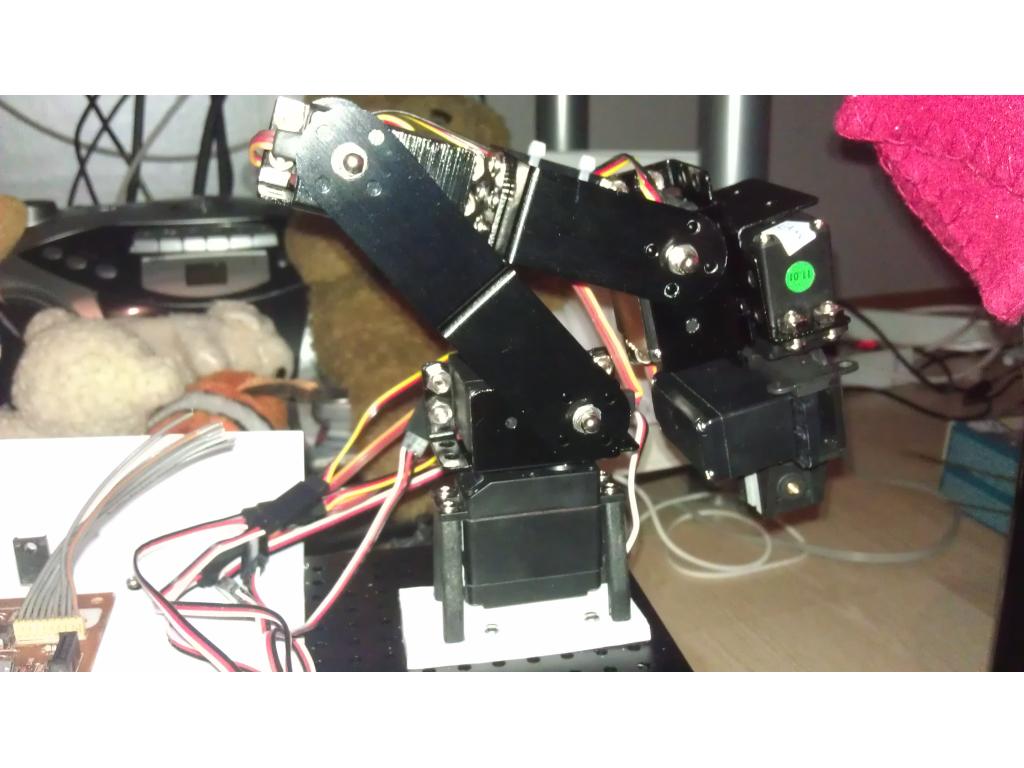

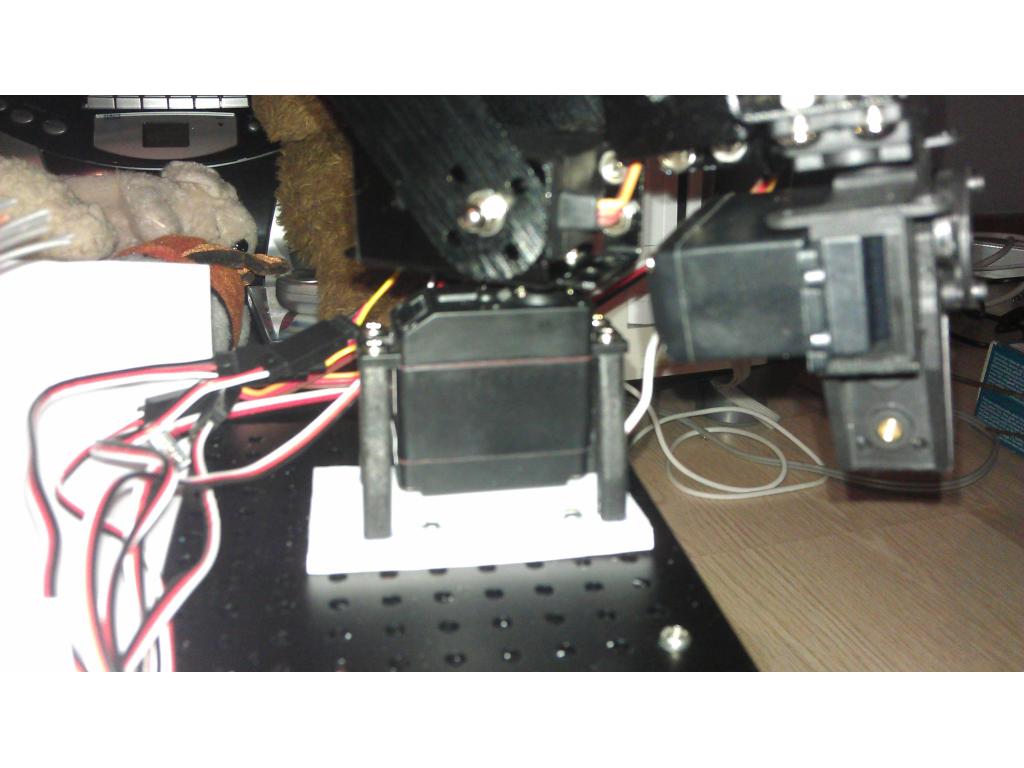

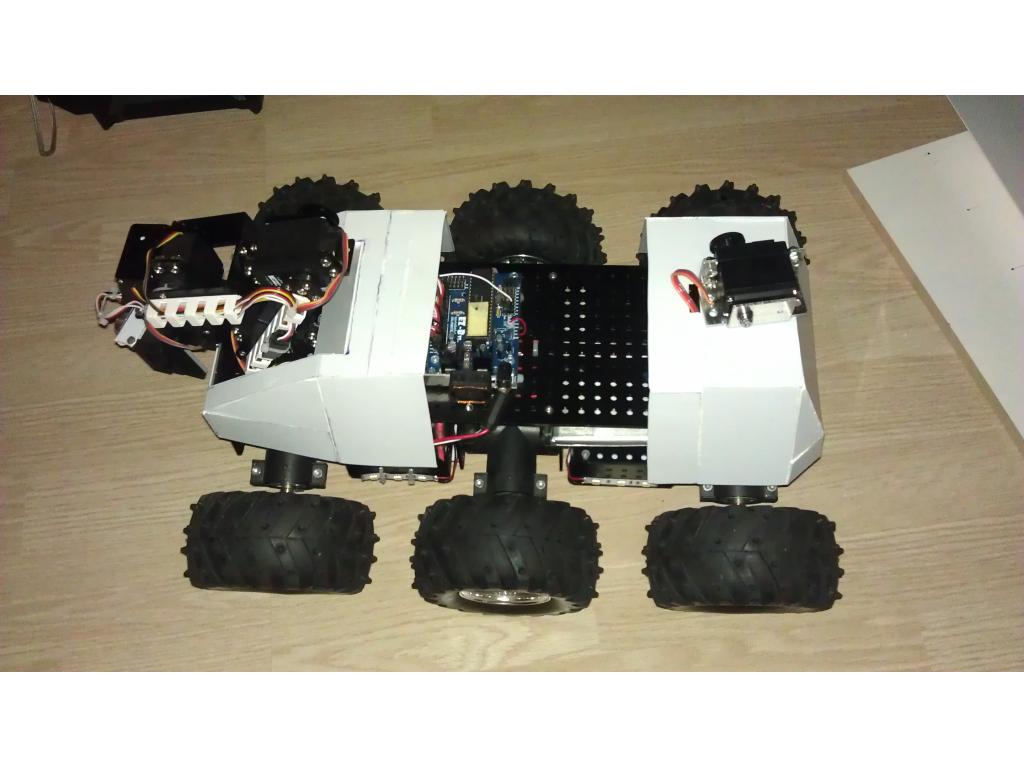

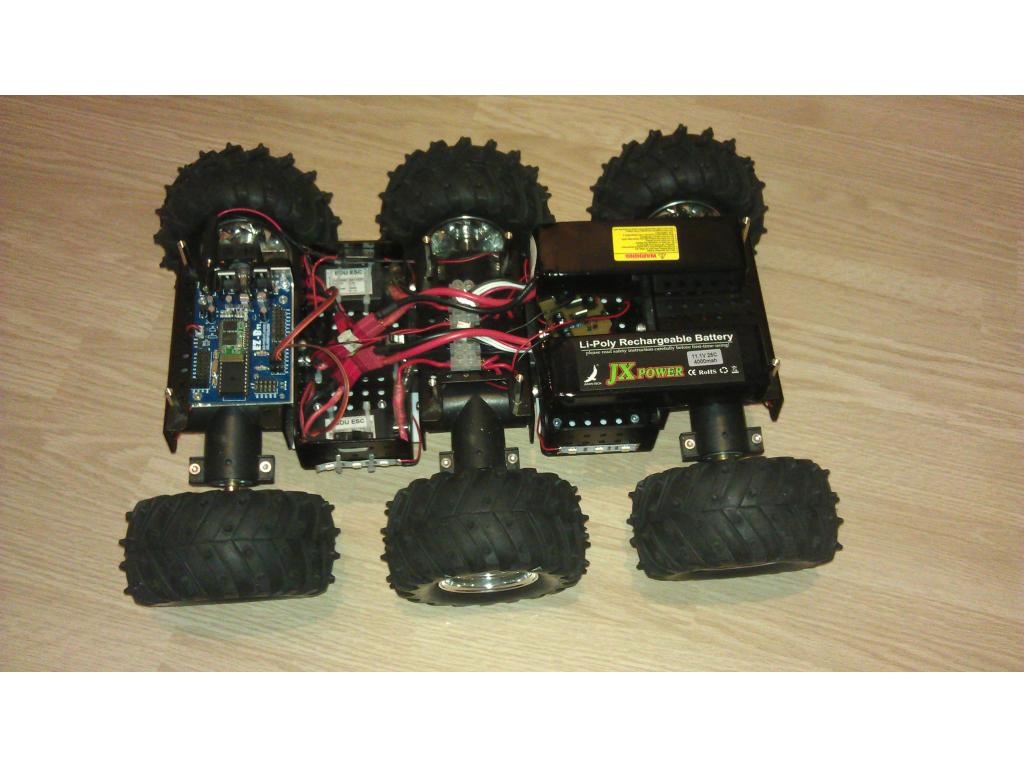

It's based on the 6 wheeled Dagu Wild Thumper kit. On top of that I added a 5 DOF robotic arm and a netbook.The specs:

- 6x 6v 6A motors

- 2x 20A Rc Car ESCs

- 2x Reddragon 2s 25c 1200mAh

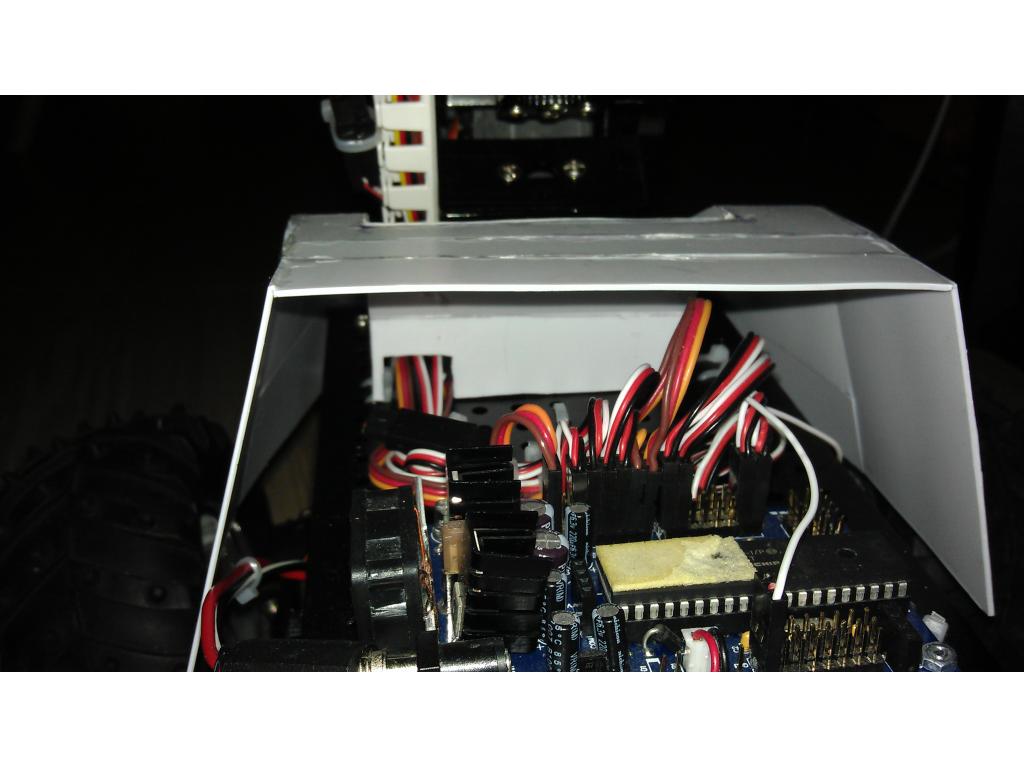

- Ofc the Ez- B

- Dfrobot 5dof robotic arm

- Asus Eee pc 900hd

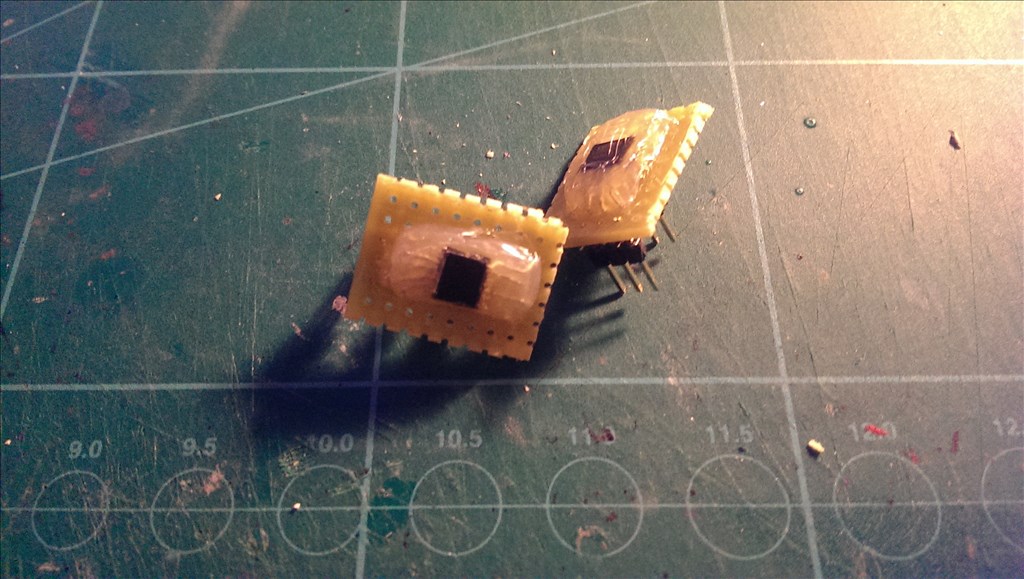

- Ping sensor (well... I sort of broke it... It got stuck between the robot and the wall...)

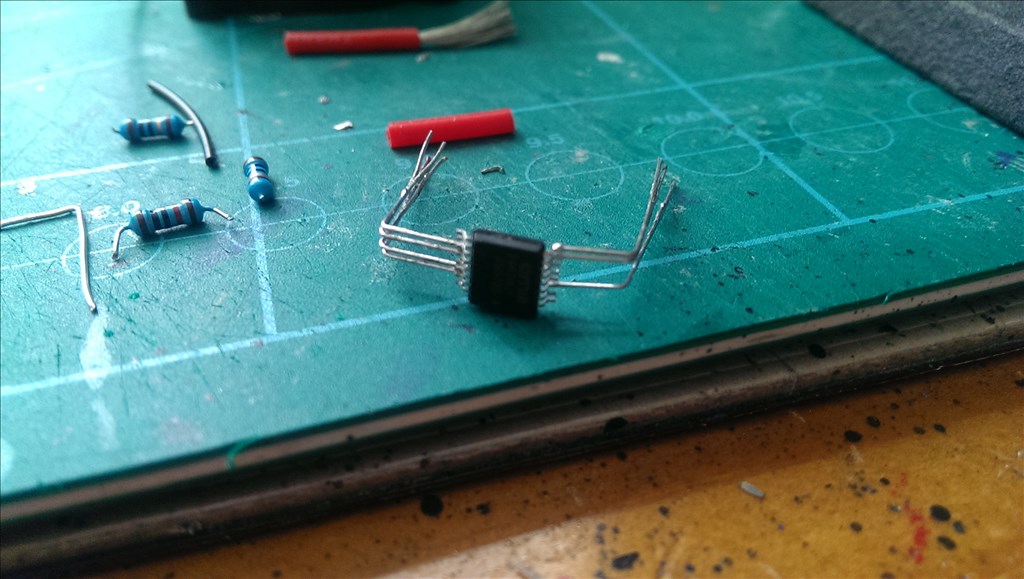

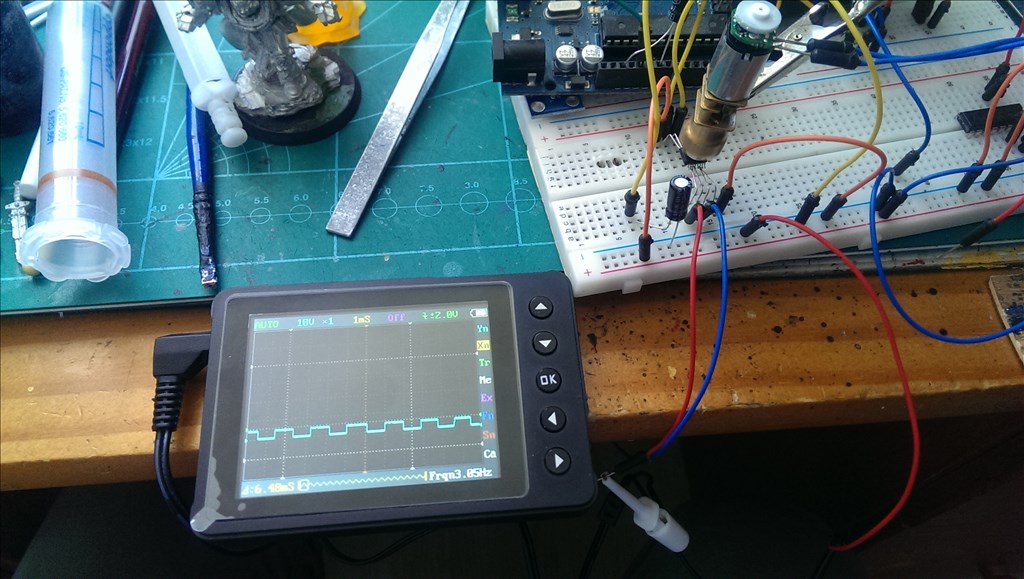

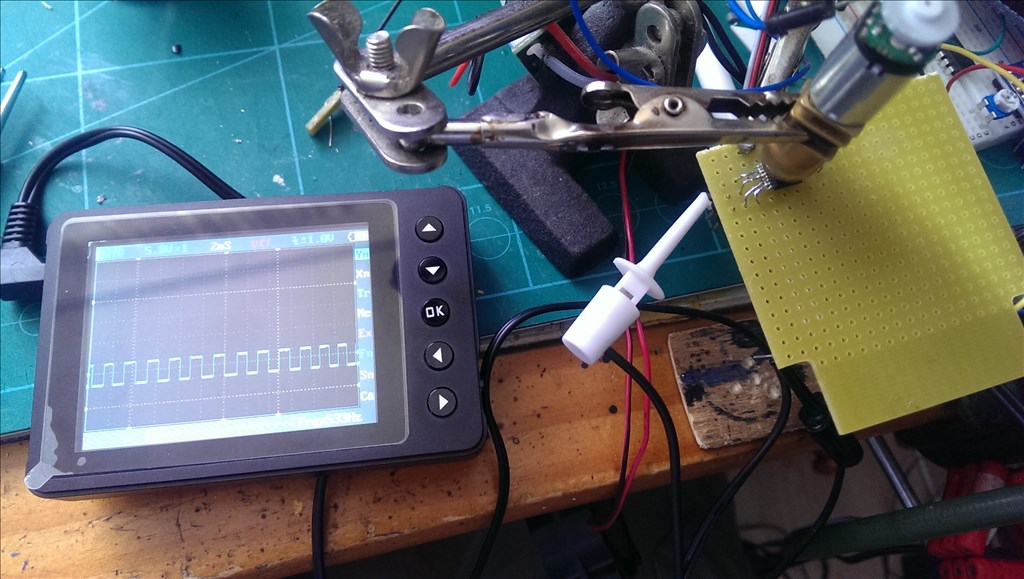

Why I'm building it? Because I can, robots are Awsome, the EZ-B rules and I got tired of burning/shocking myself when I'm testing one of my "crazy" contraptions.

Up coming updates for robot:

- A rotationplatform for the arm.

- 2 gigantic lipo batteries.

- camera+ pan/tilt turret.

- Small rockets

- mini mini-gun

- Flamethrowler (a failed version of a liquid fueled rocket, but it's working if you call it something else)

- coilgun

- railgun

- Lots of other things I can come up with.

By budel0

— Last update

Other robots from Synthiam community

Cardboardhacker's Rover Ad

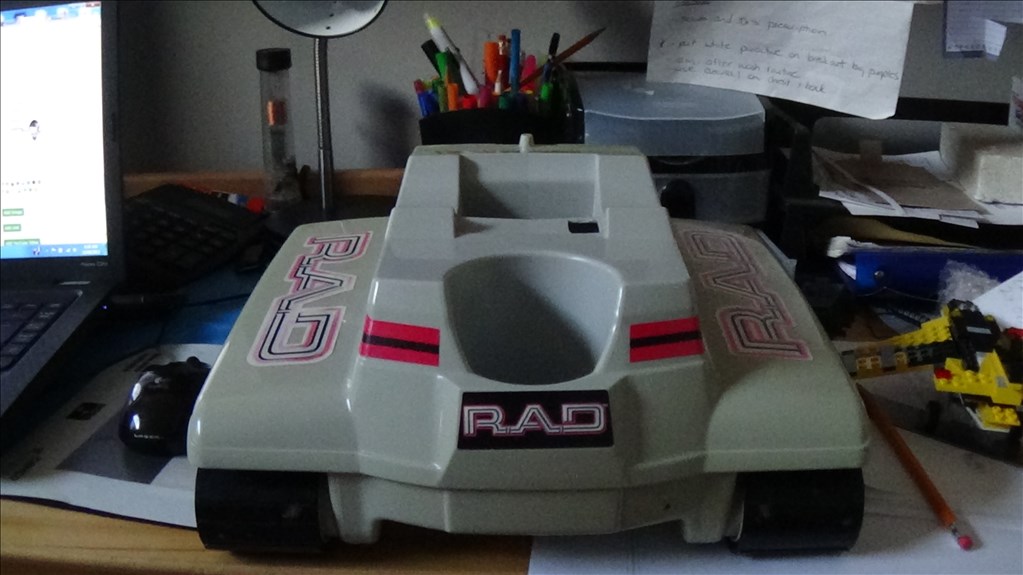

Dewy, a tall robot built from RAD parts modeled after an Omnibot, showcasing teardown steps and rebuild photos.

Jstarne1's Invisible Qr Code Project For Hackaday...

Custom invisible QR codes for discreet home marking visible only under 405nm UV or 780nm IR light; EZ-Robot compatible

Ezang's Roman With New Head Movements And More...

Synthiam ARC controls Arduino robot with eyes, head and mouth synced to speech, using AIML/Bing speech recognition for...

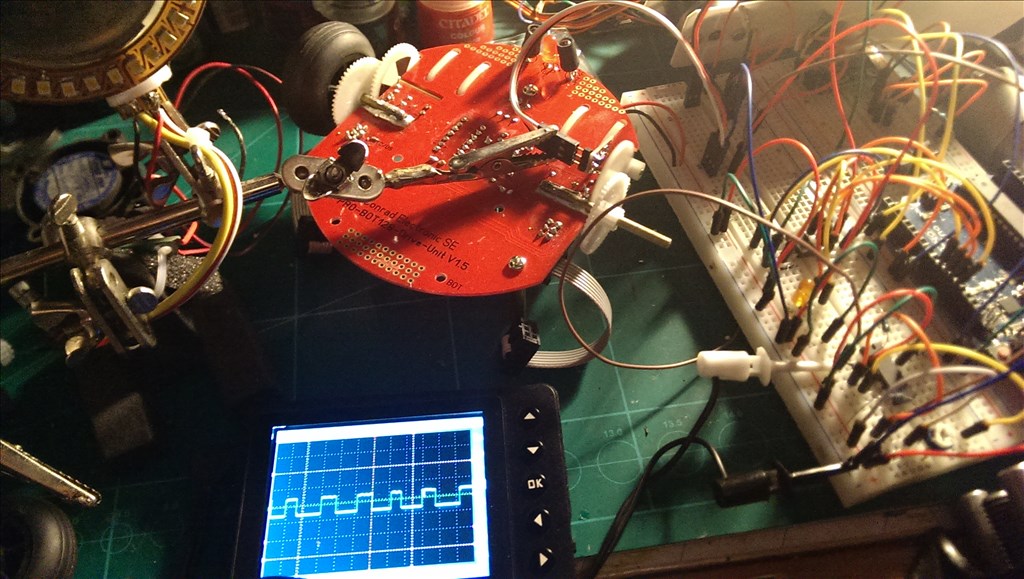

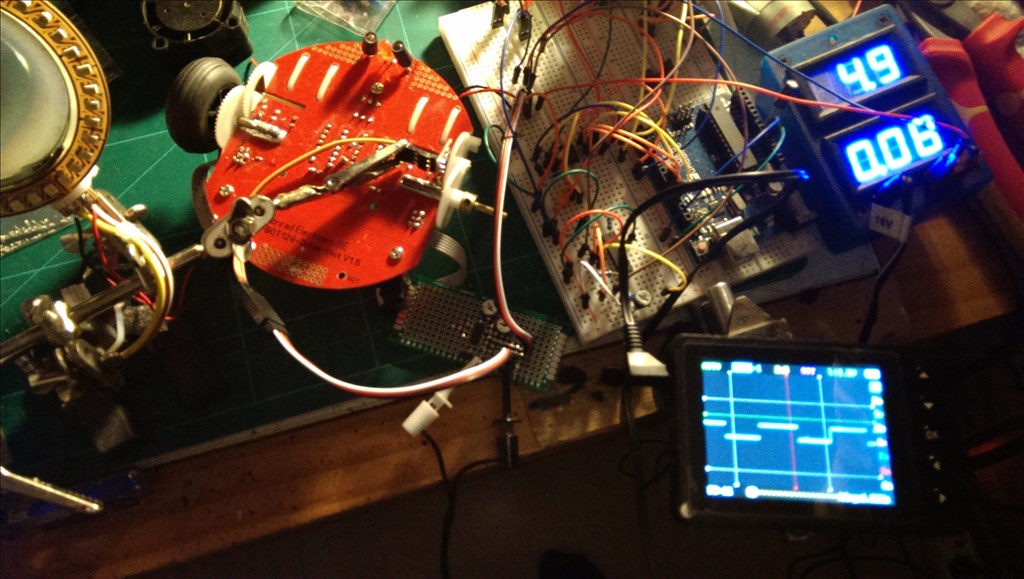

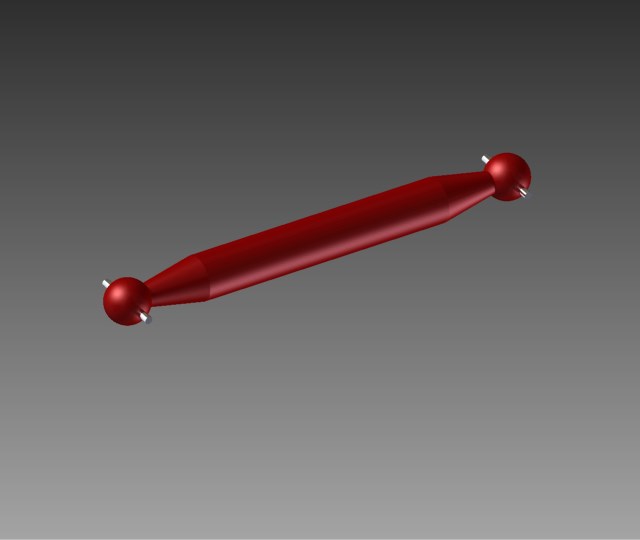

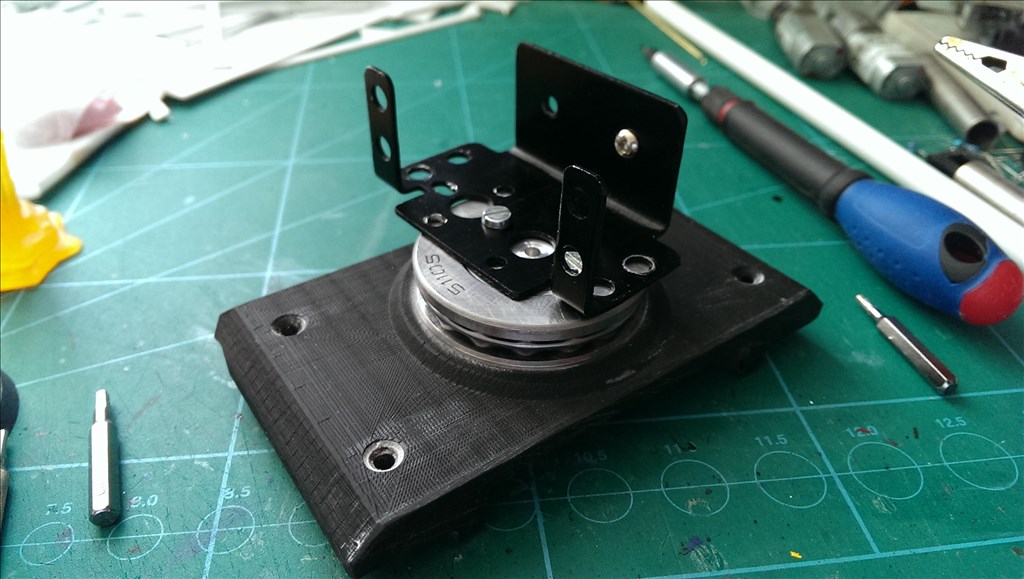

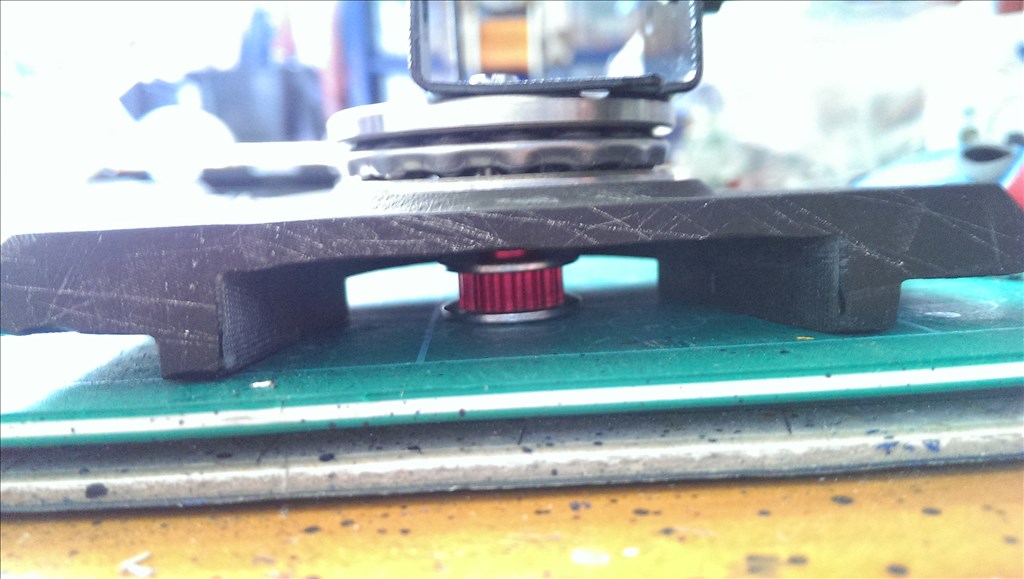

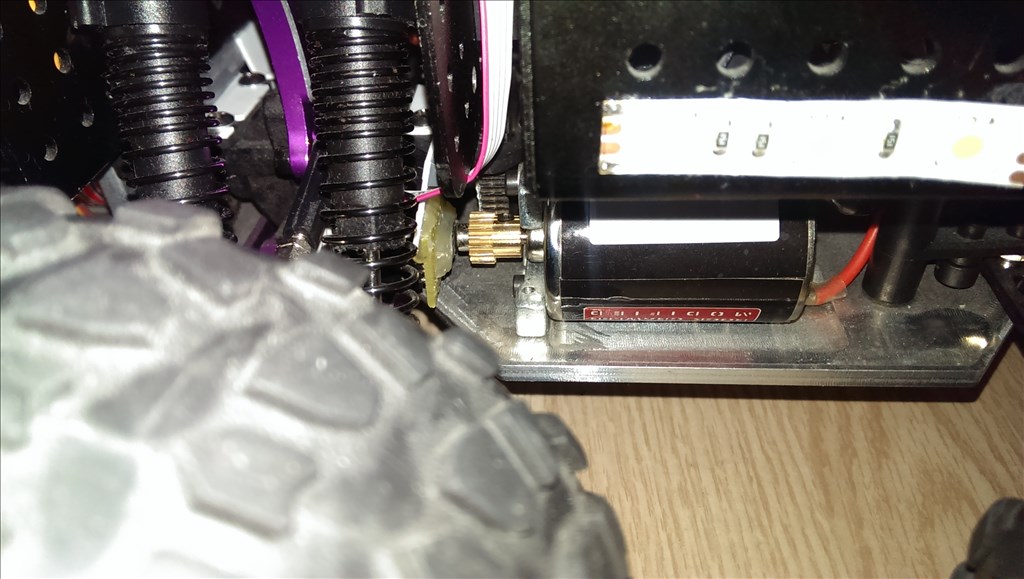

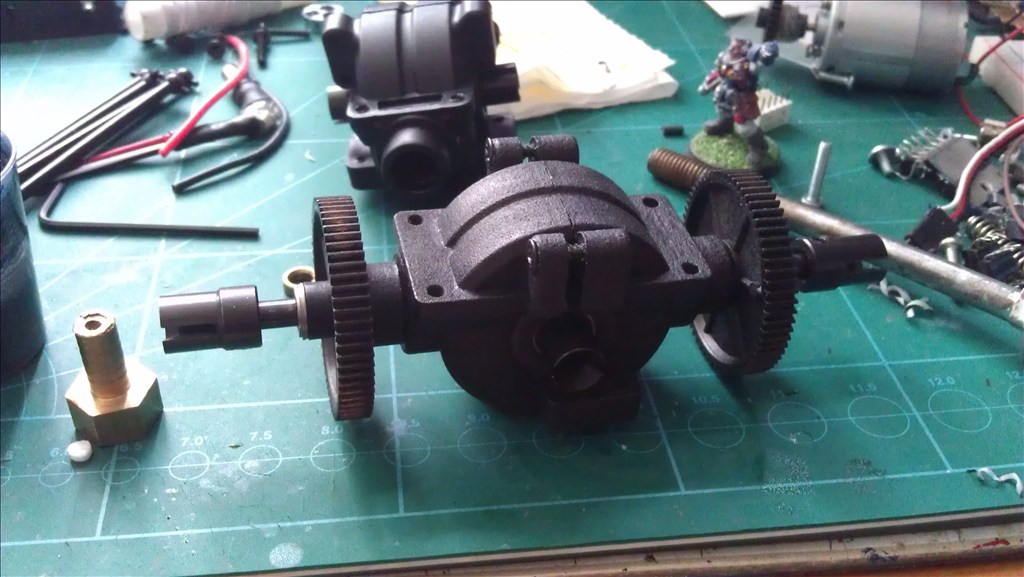

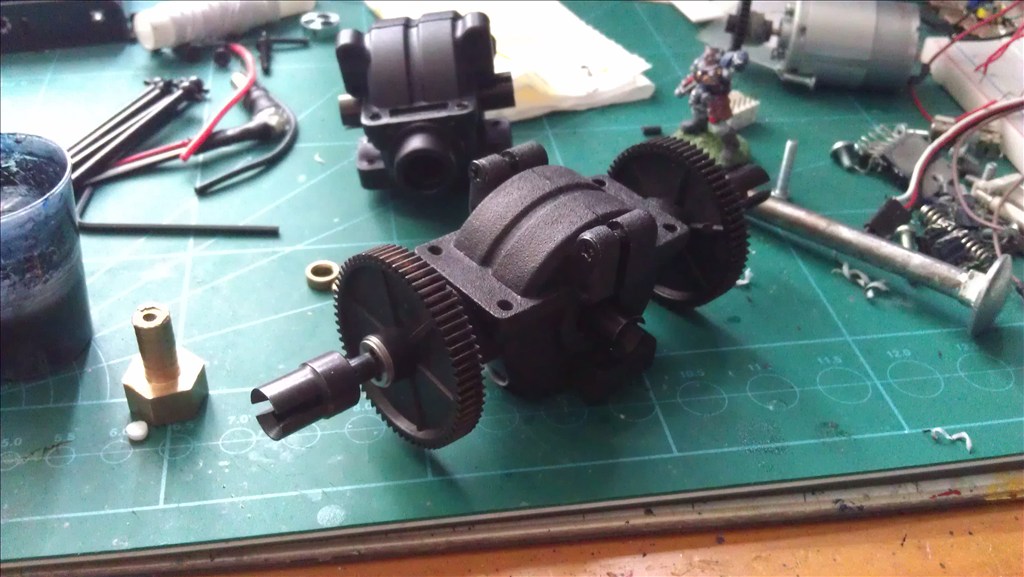

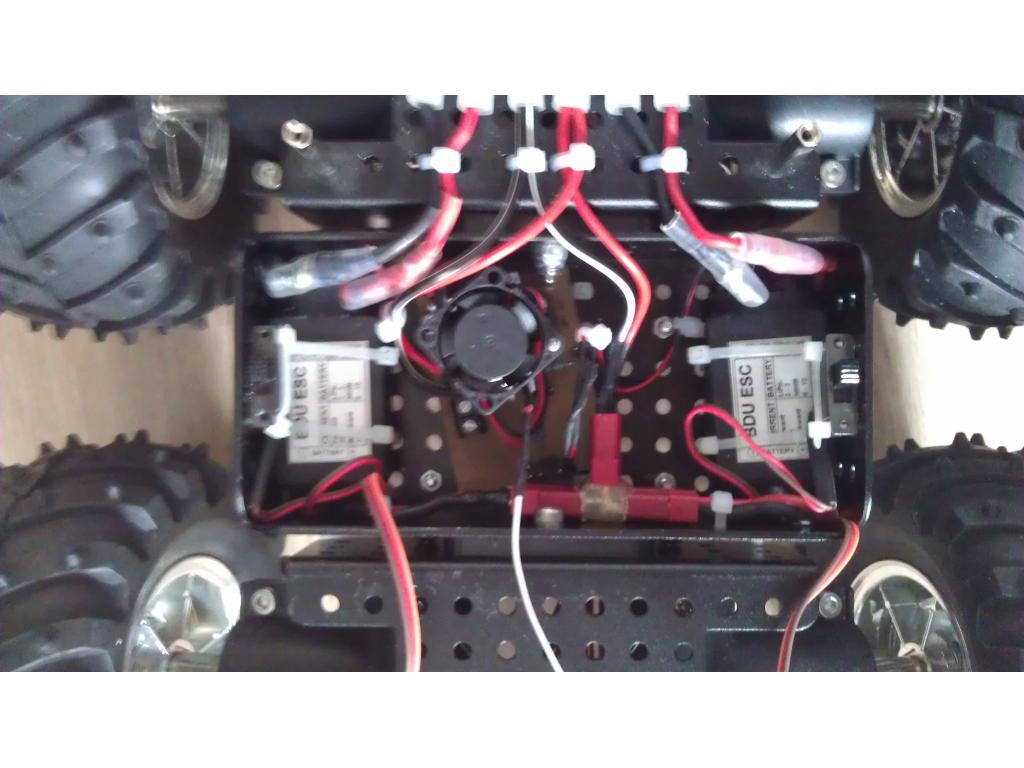

Little update: I've finished up the differential. And I have to say it's looking great. Most important part, it even works, it just needs a little more grease.

For the next update I'll befinishing the design for the base.

looking great!

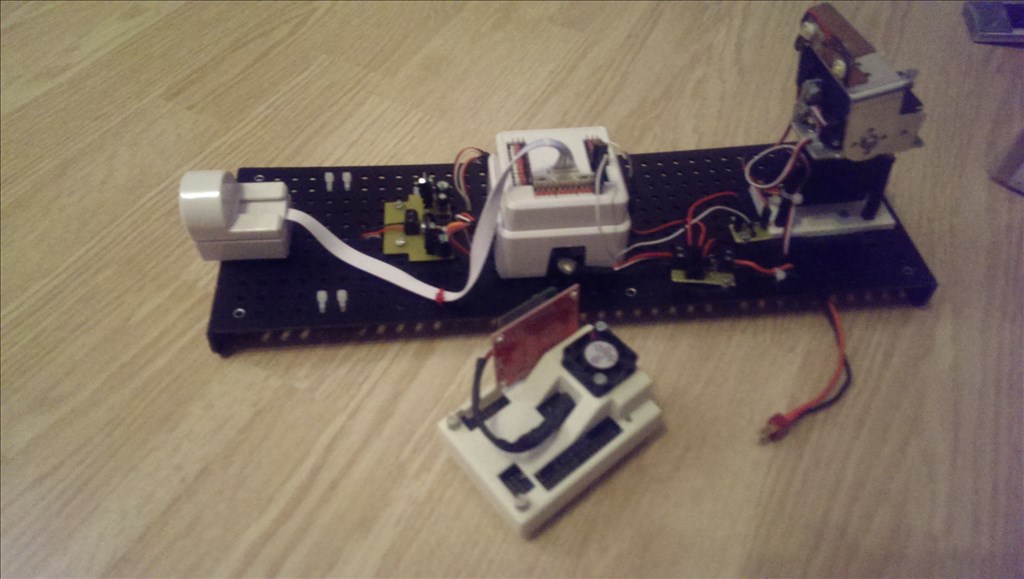

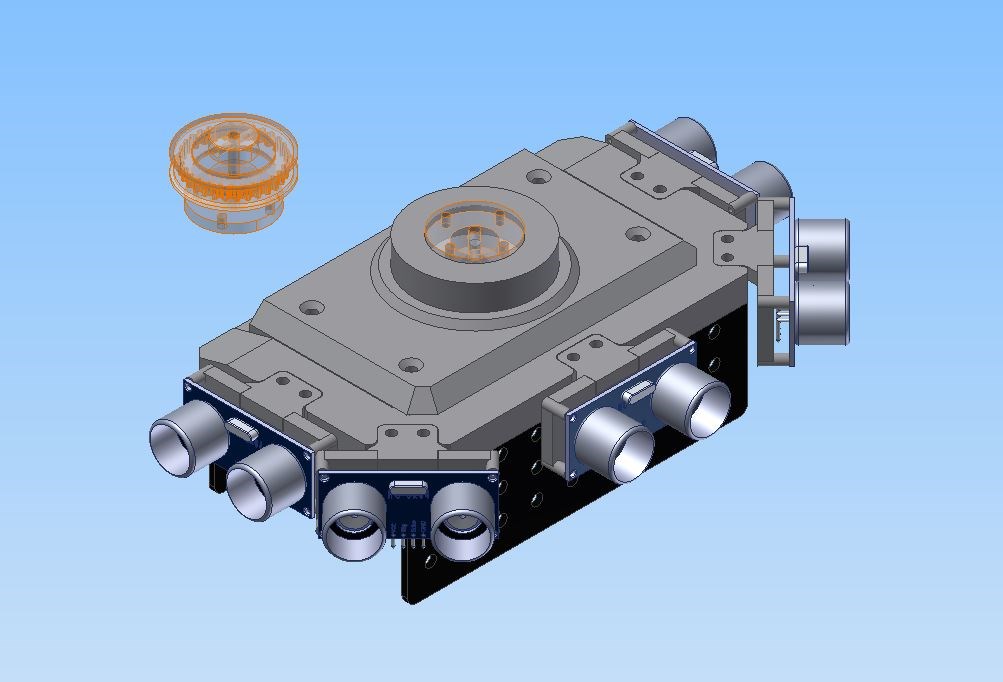

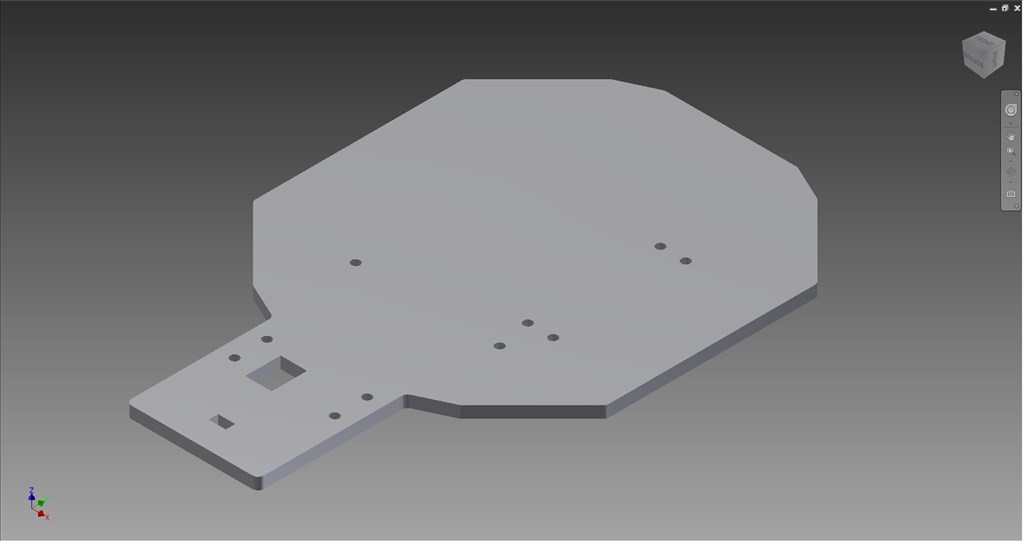

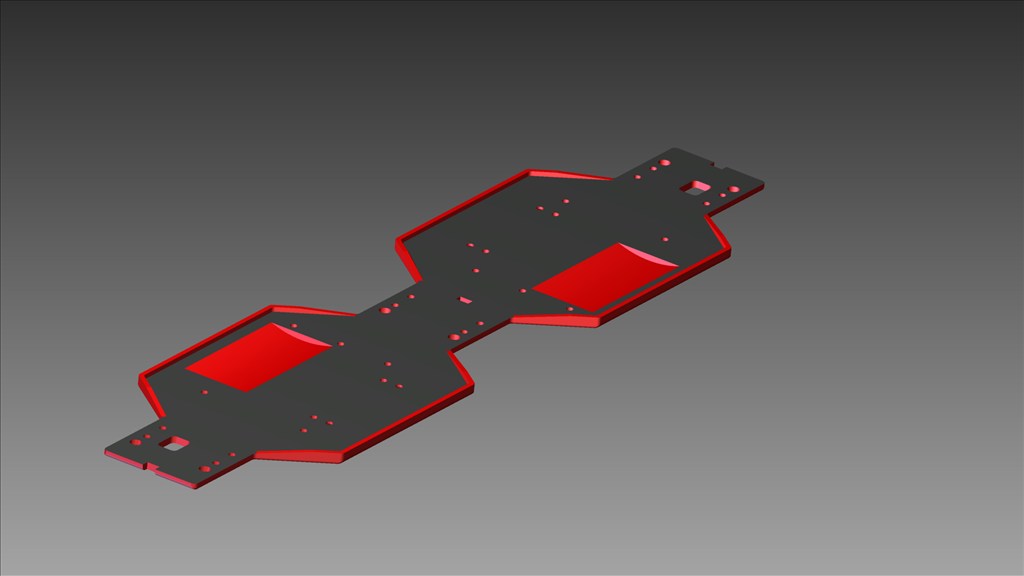

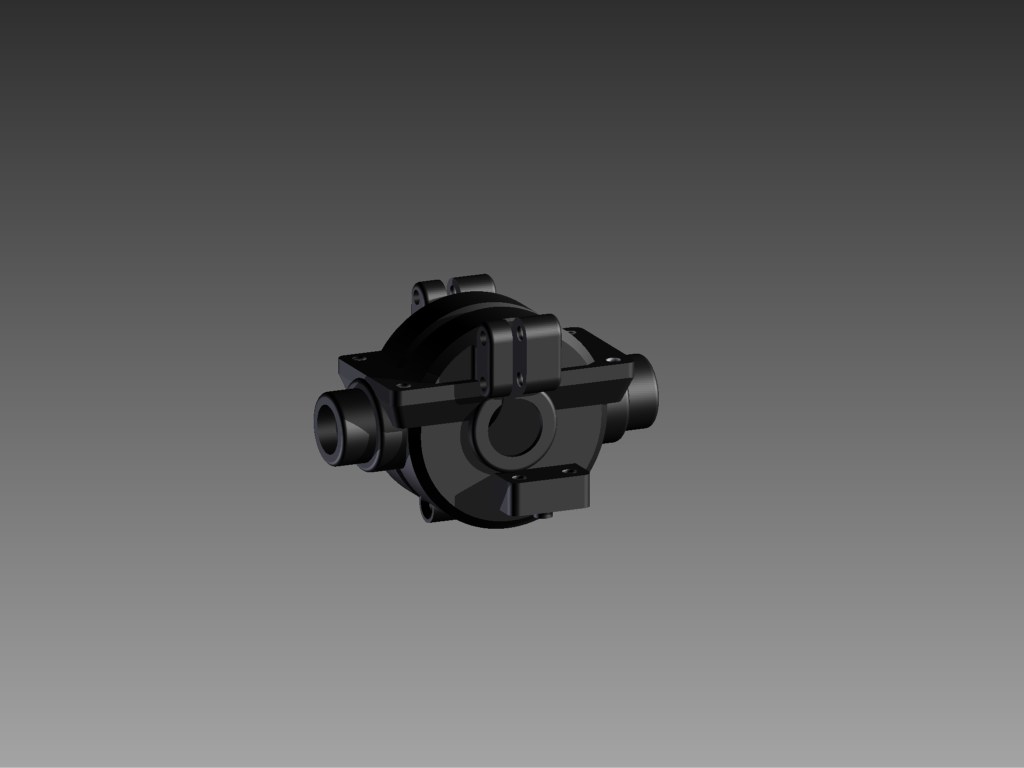

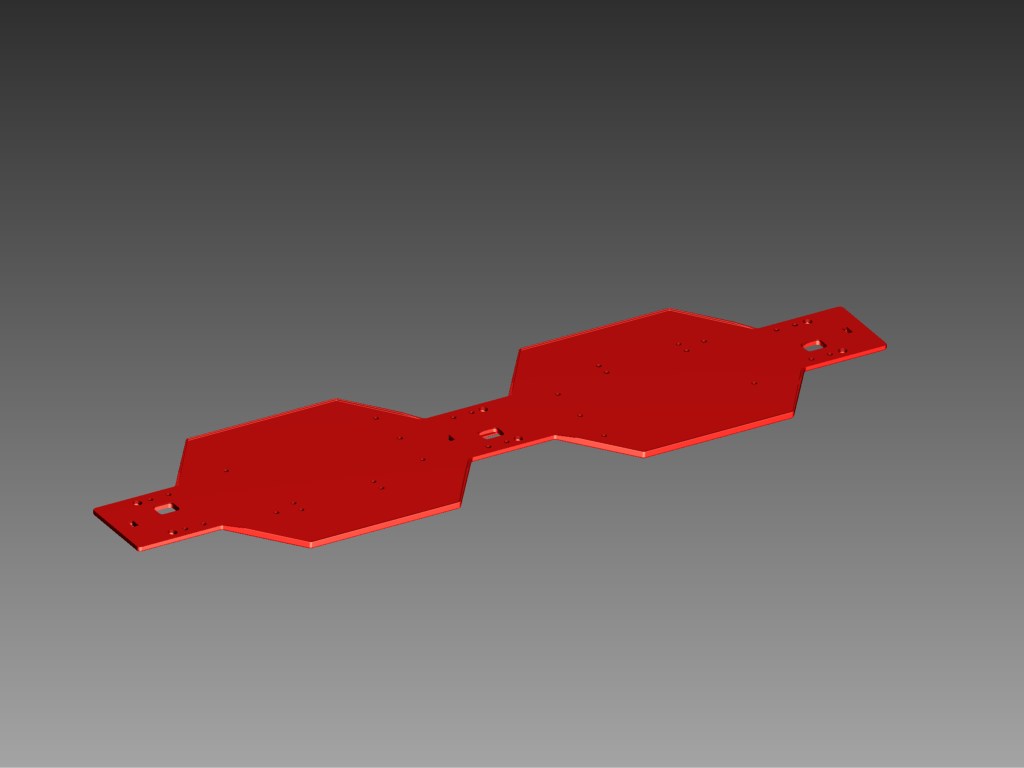

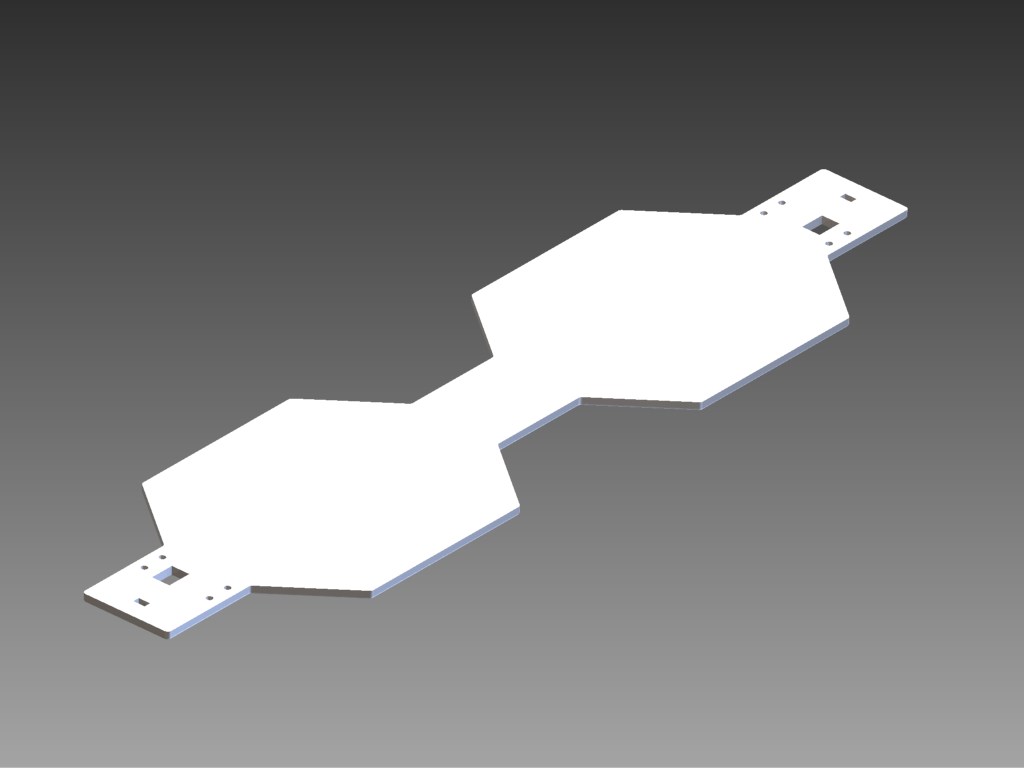

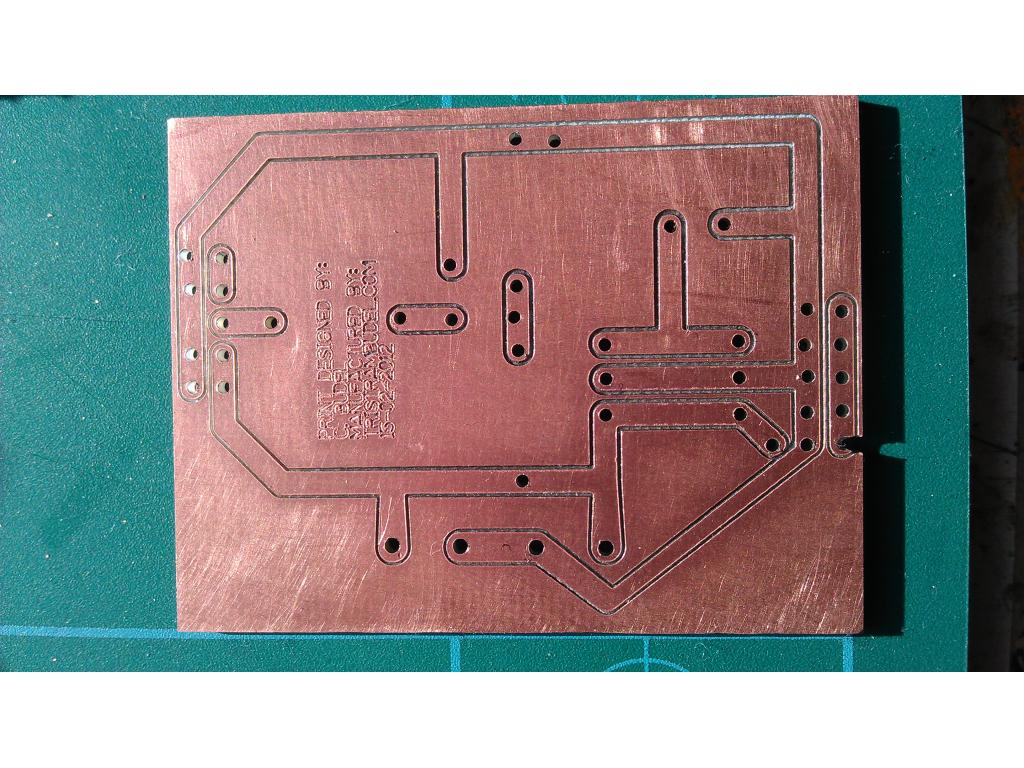

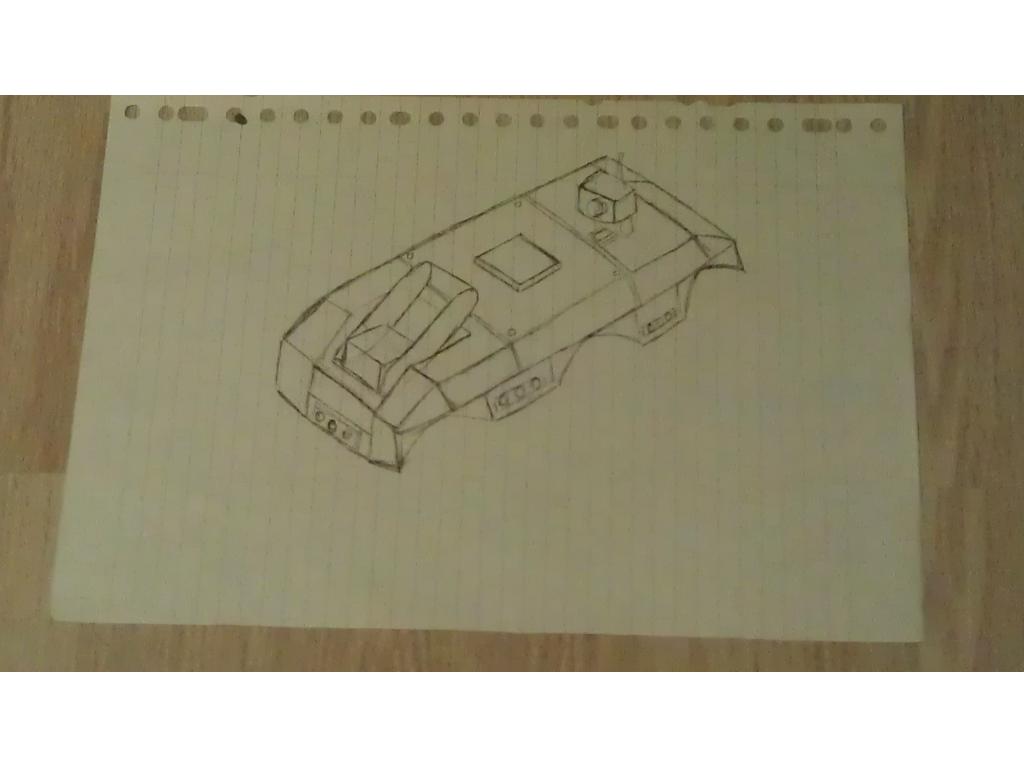

So after 6 revisions of the base plate, I have finally finished the design. It took me about 20 hours to complete, but after so much work you'll end up with the ideal design. The plan is to get it CNC'd out of a 3 or 5mm thick sheet aluminum and annodise it black. I had thought about 3D printing it, but 3D printing metal is insanely expensive($700,-...) and plastic isn't strong(only 43N/mm^2) enough.

I tried to shove everything together as much as possible, it's about 6cm shorter and 2cm less wide than my earlier versions. This saves weight(it should be +-200 grams) and costs.

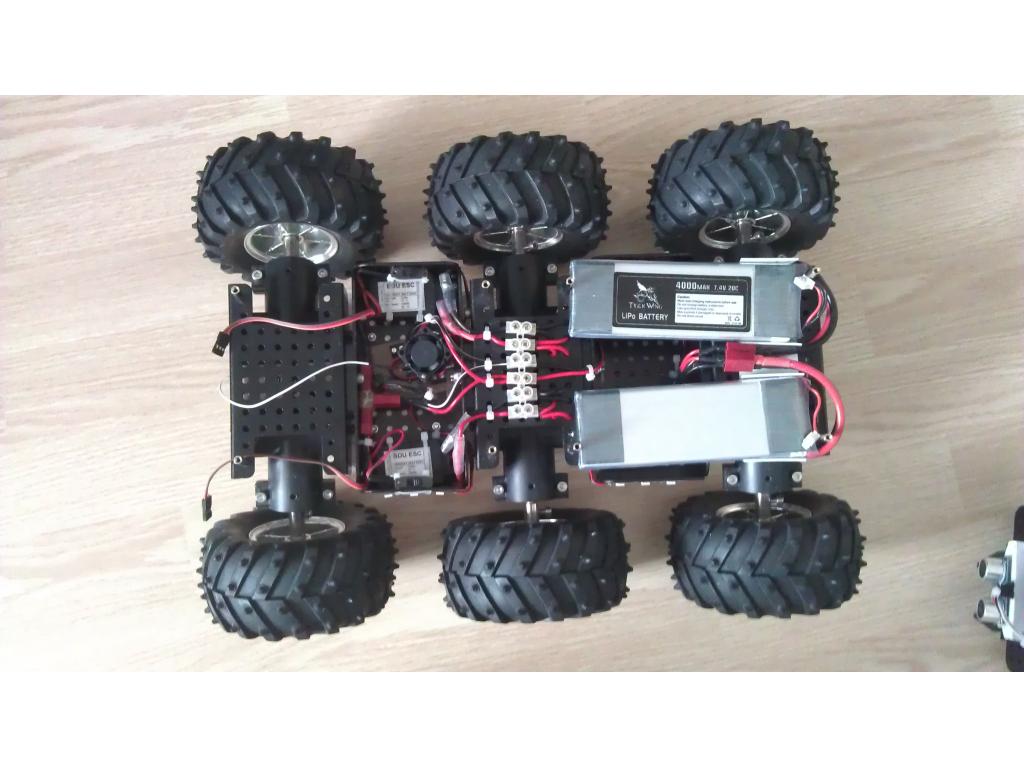

So to get an idea about how big this is going to be, I placed everthing where it should be at about the right distance from one another. It should become about 500mm long, increasing the length of my robot by 80mm. Which is more than enough space to place the arm on and move the EZ-b away from the camera turret. Hopefully this will help with my jamming problem or it'll just make space for something else (maybe the cannon I've been playing with).

For now, To be continued.

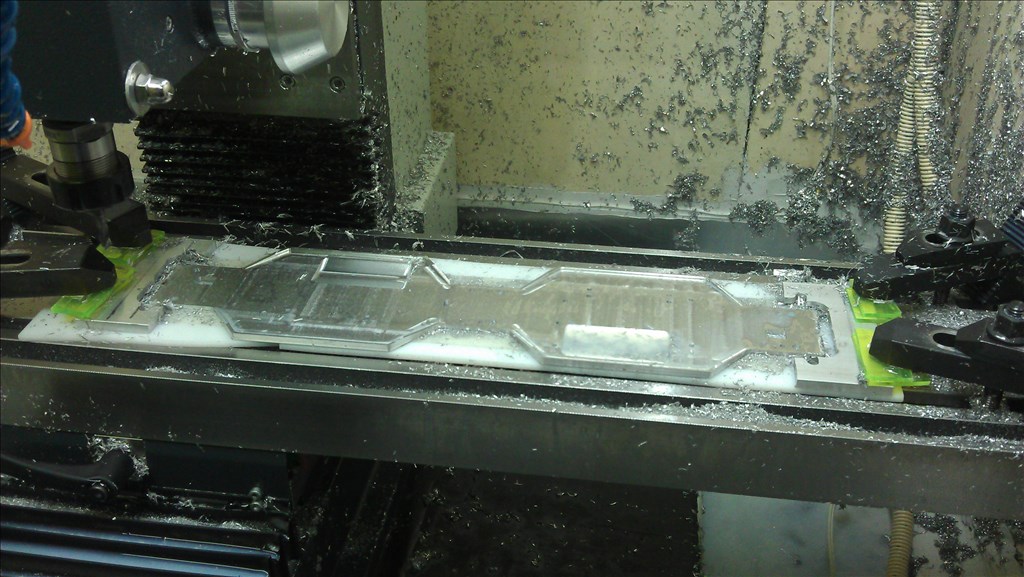

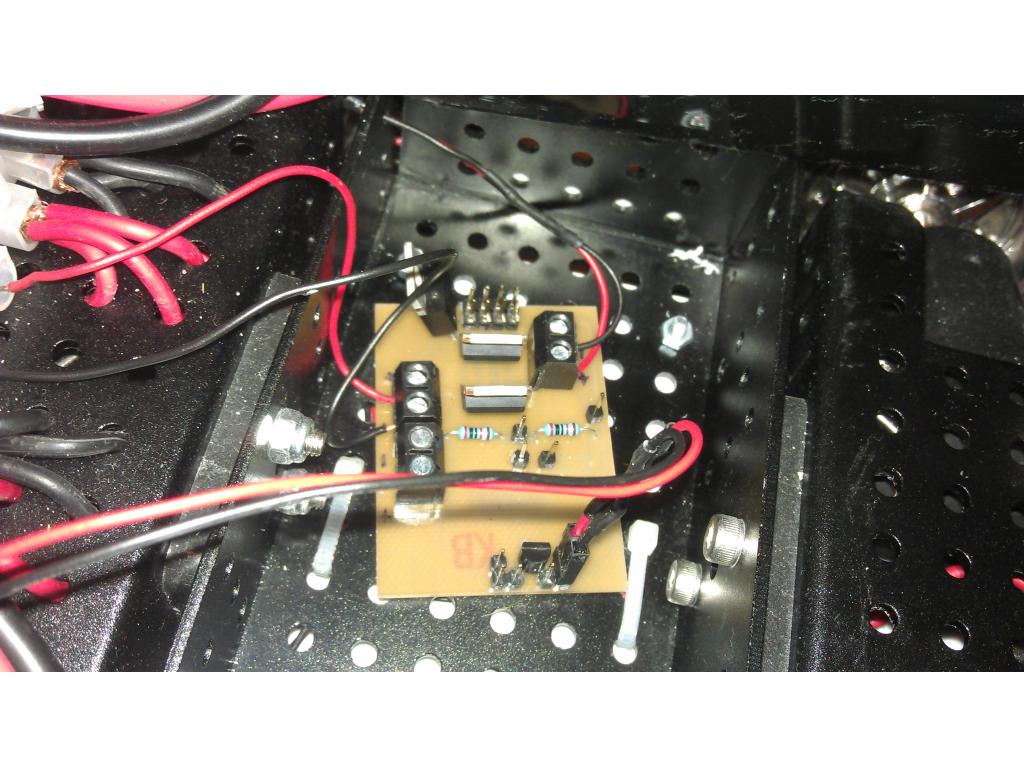

After a few days, I finally have my baseplate/chassis. It still needs some external changes (paint or annodizing), but it's looking great already and it's super shinny.

Behold: Just after it had been machined(took about 7 hour of milling)

After a quick wash and deburring

I had it machined at tristrambudel.comFor the next update: ASSEMBLY! And maybe a video with a test drive, but I might need to design some more parts for that.

And maybe a video with a test drive, but I might need to design some more parts for that.

This is so cool!

So impressive. I wish I had a clue on how to do that, it would make a lot of things I plan to do so much easier.

Great work!

This is a great build! Very impressive!

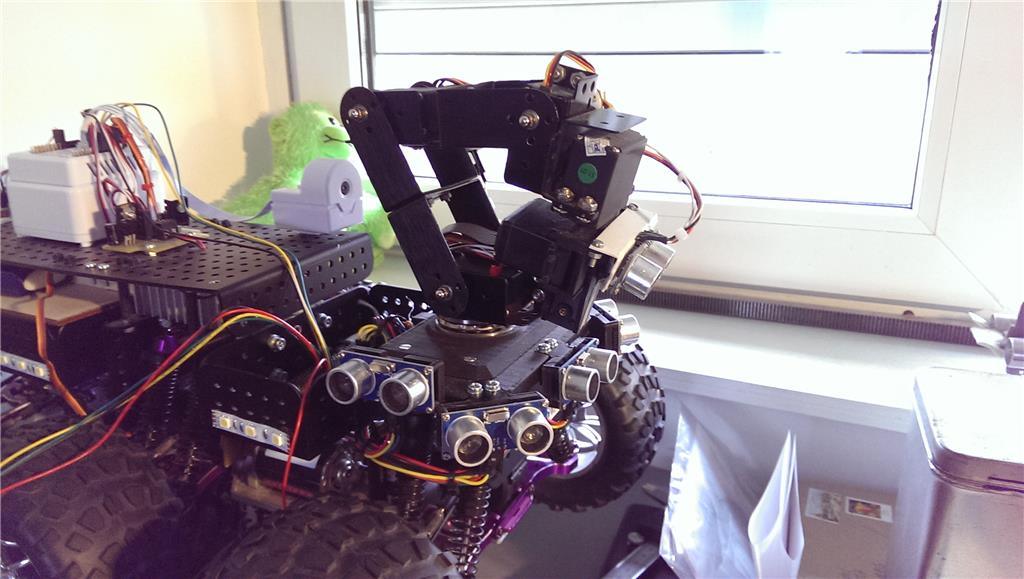

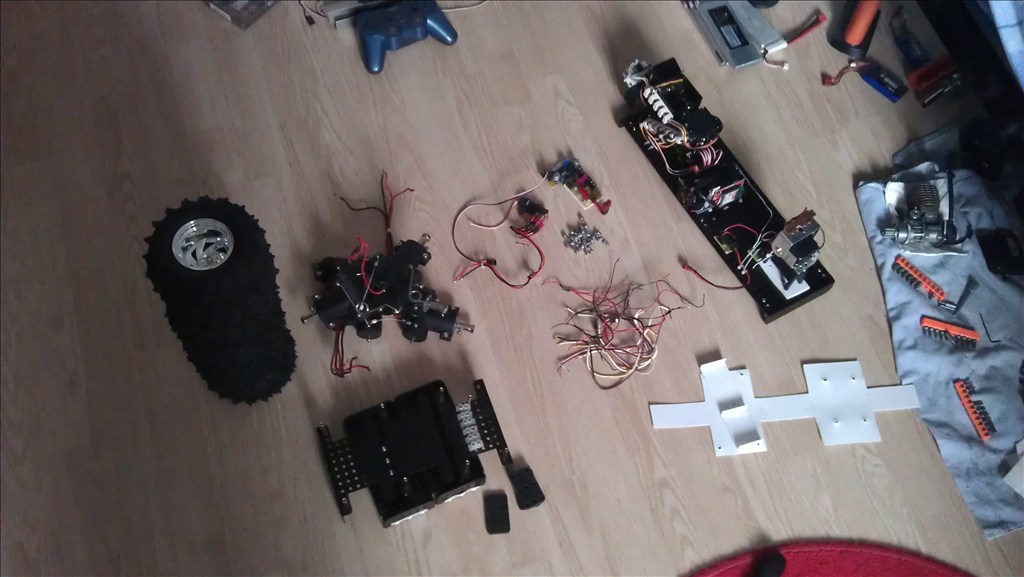

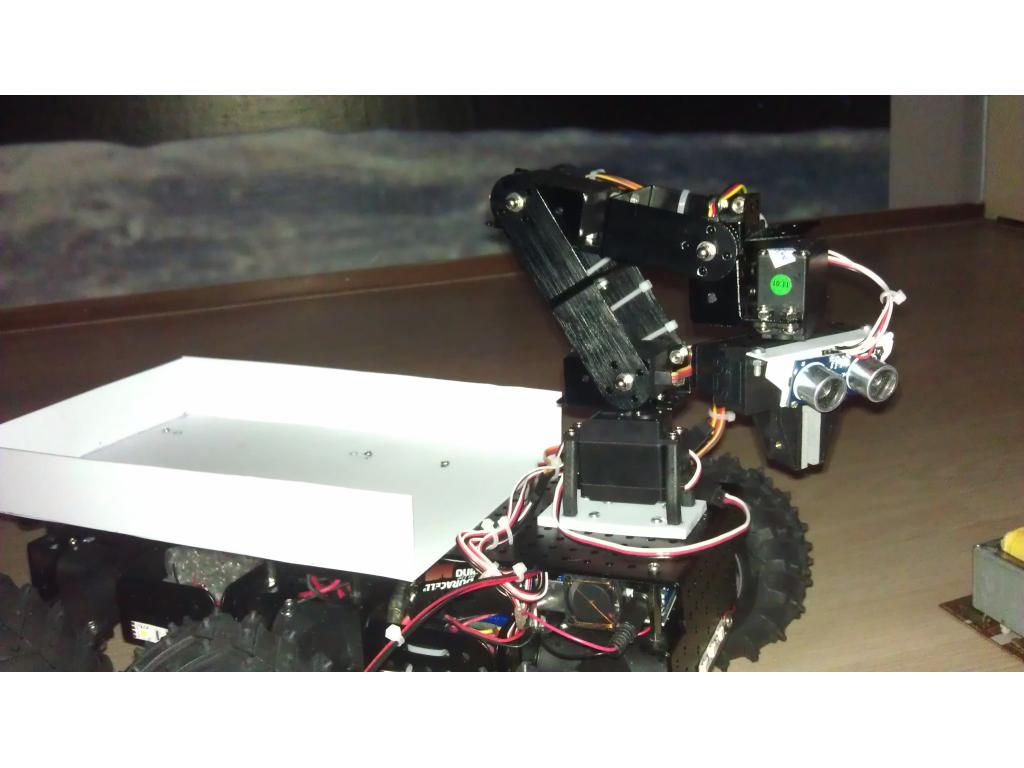

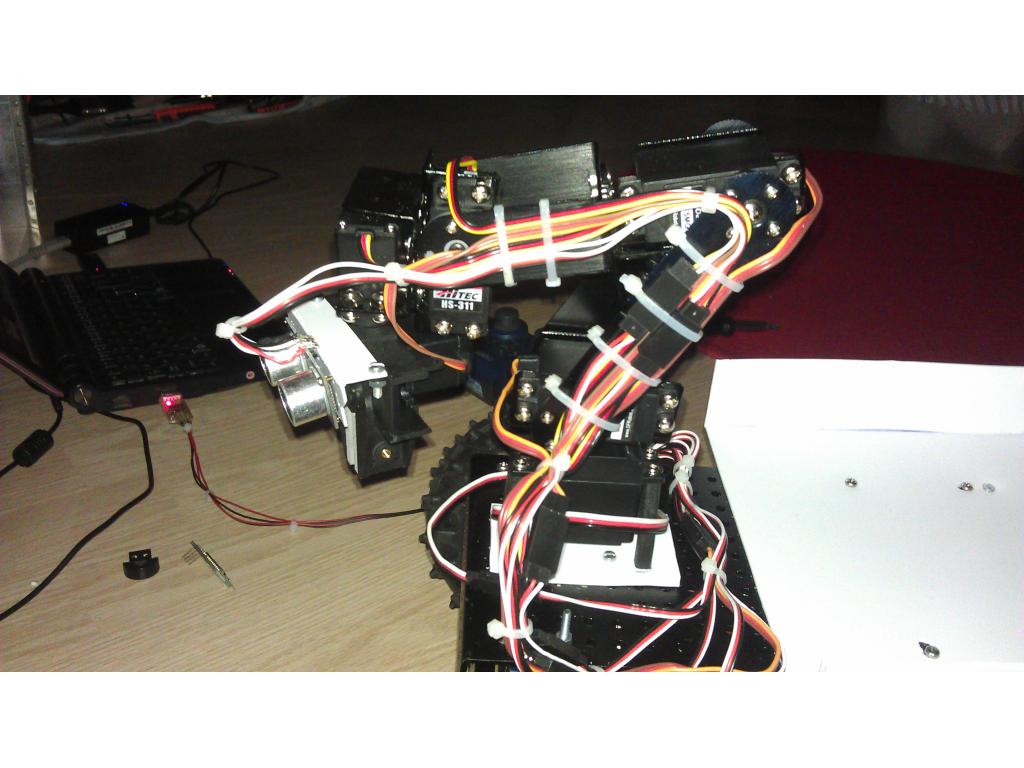

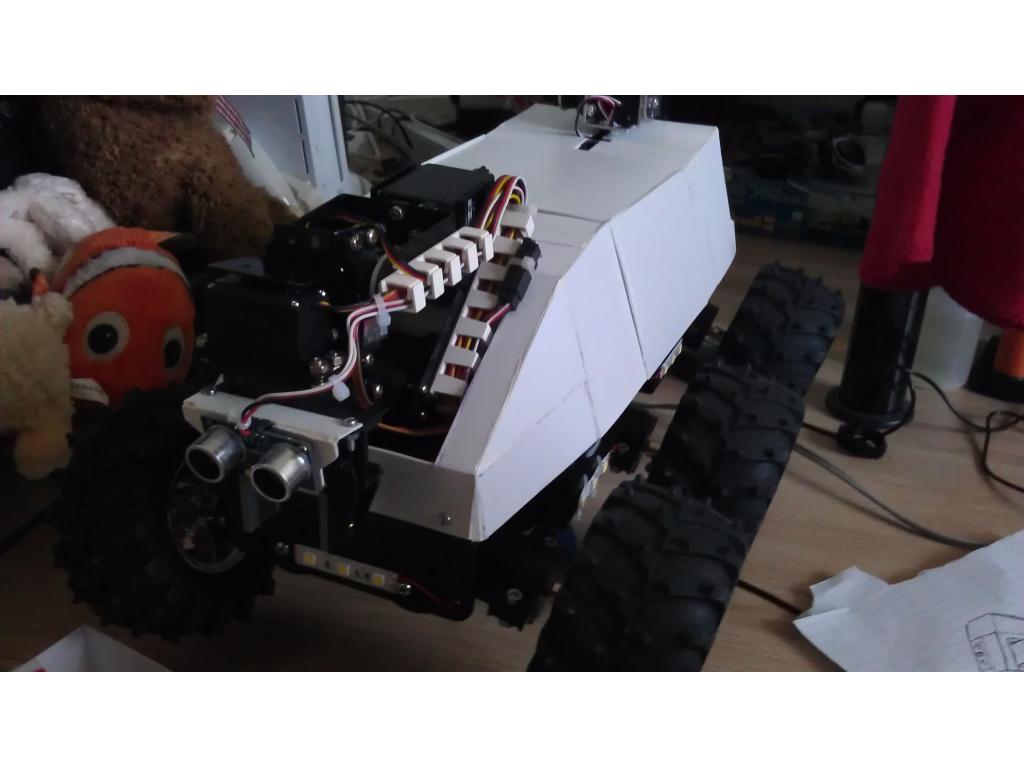

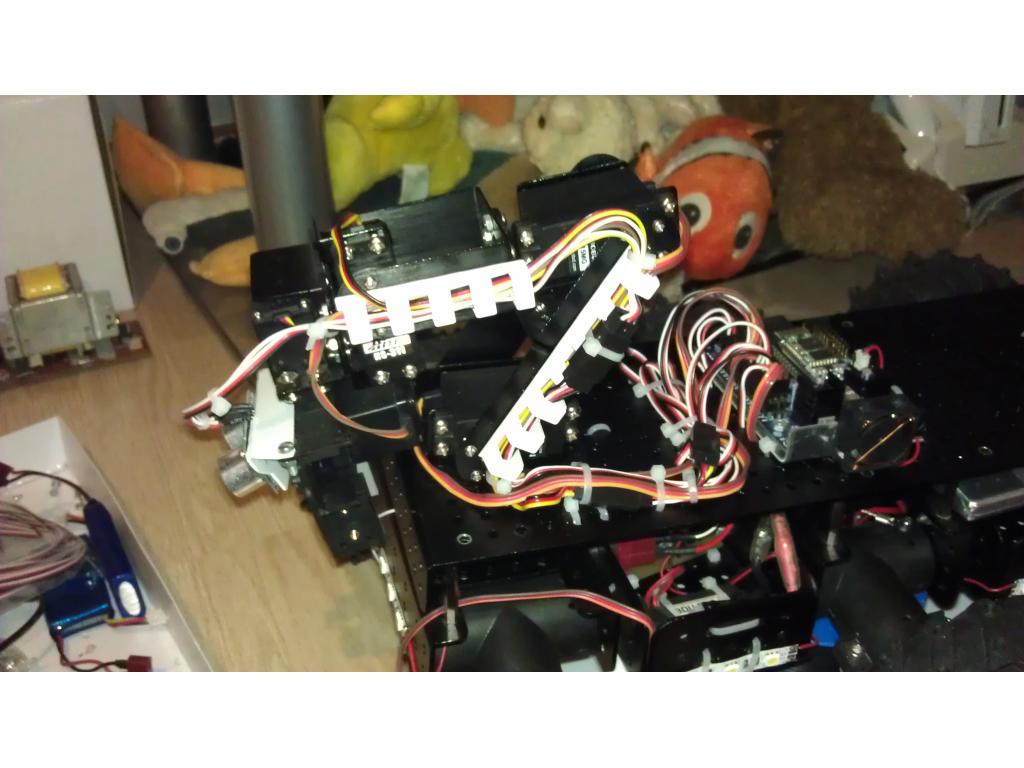

Thanks guys for the complements, now behold THE (partly) ASSEMBLED MACHINE

A few interesting notes: As with all prototypes nothing will ever fit in one shot(if it does, something else won't fit).

Next project update(s) *Designing/Fabrication:

More Assembling!

TEST DRIVE!