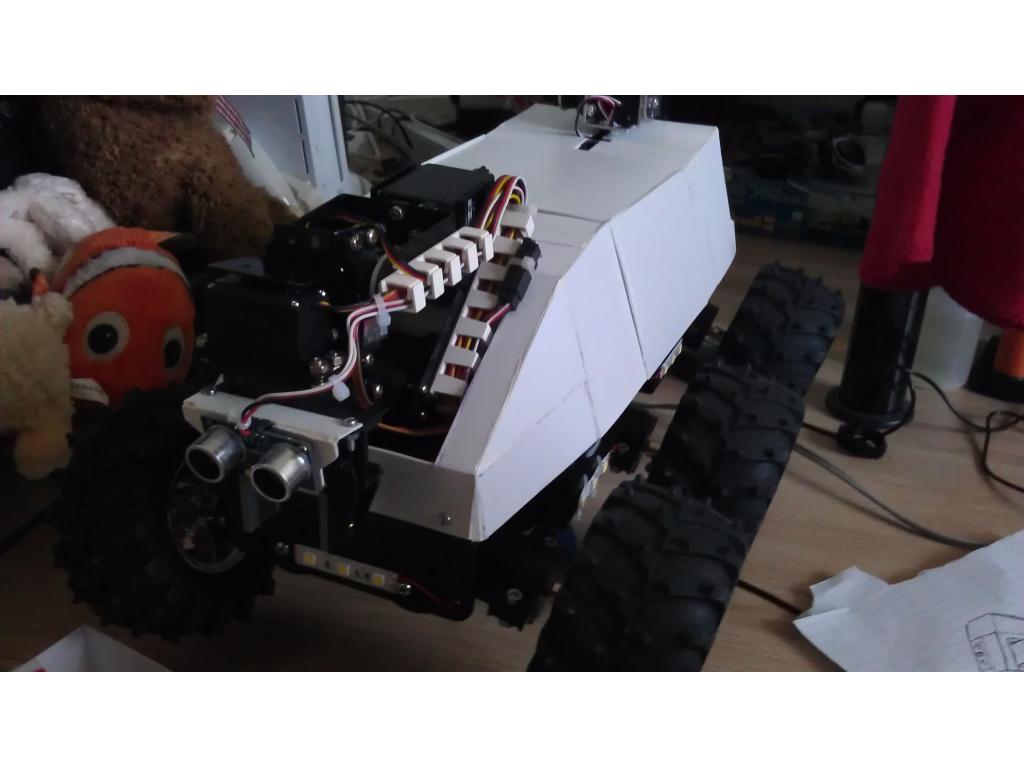

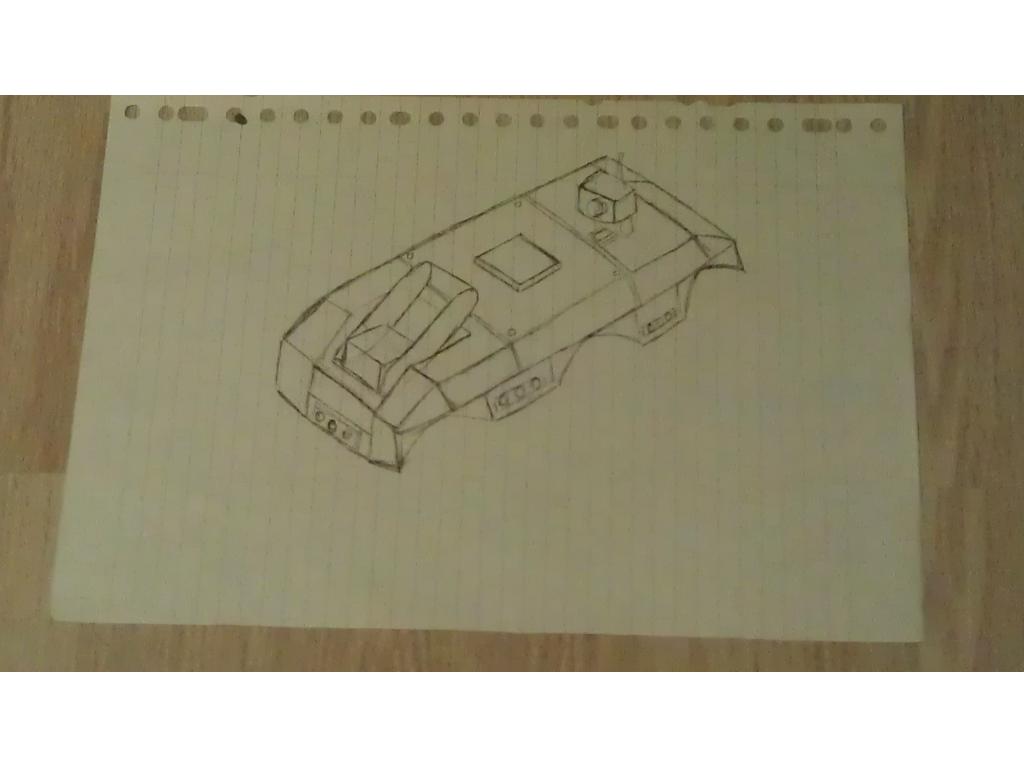

Hello fellow EZ-B'rs, As I finally discovery how to upload photos I thought it was time to share my robot with the world. It's called R.O.O.S.T.E.R which stands for: Remote Online Operating Scientific Testing Electronic Robot (took me about an hour to come up with that, but I like it).

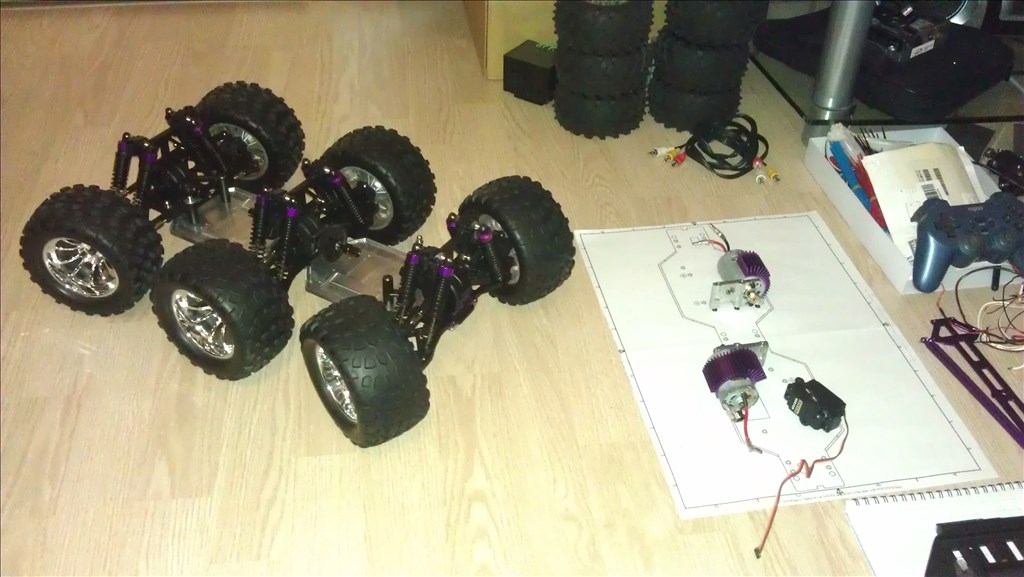

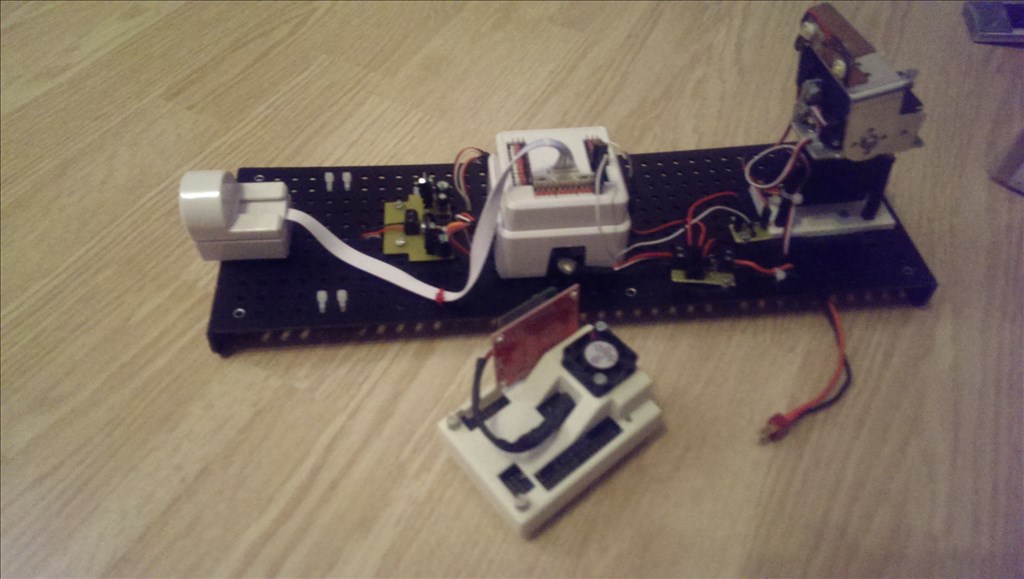

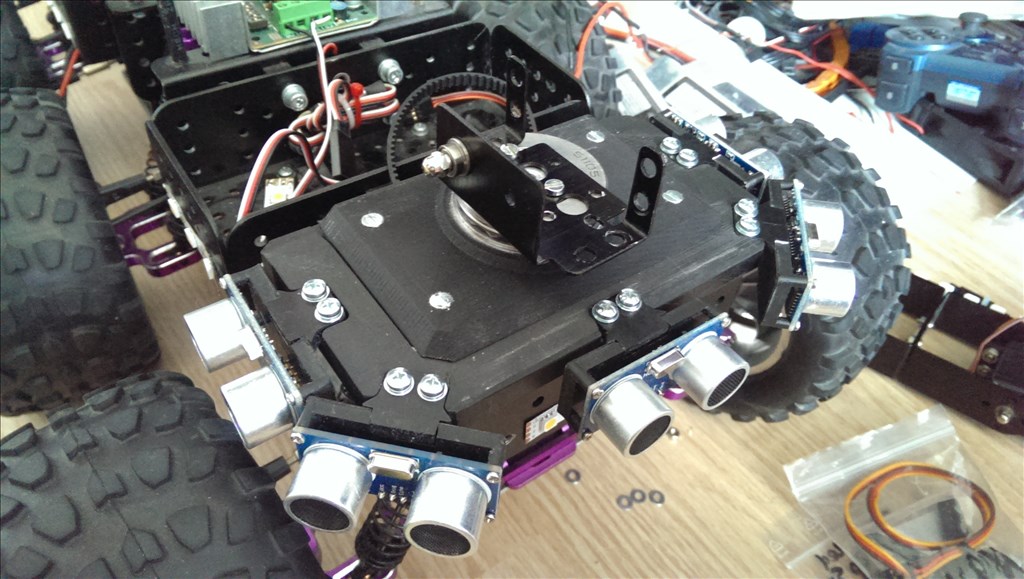

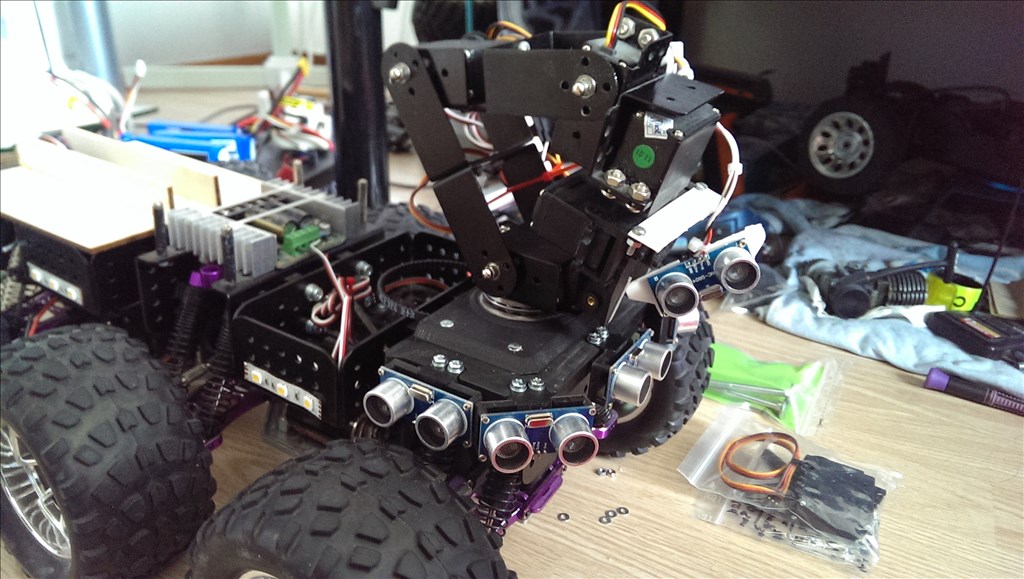

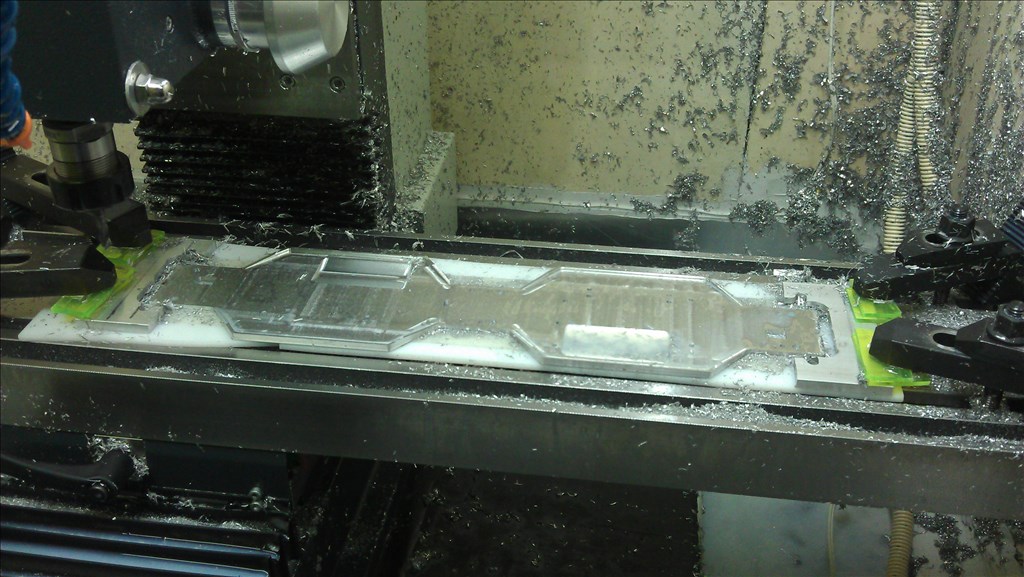

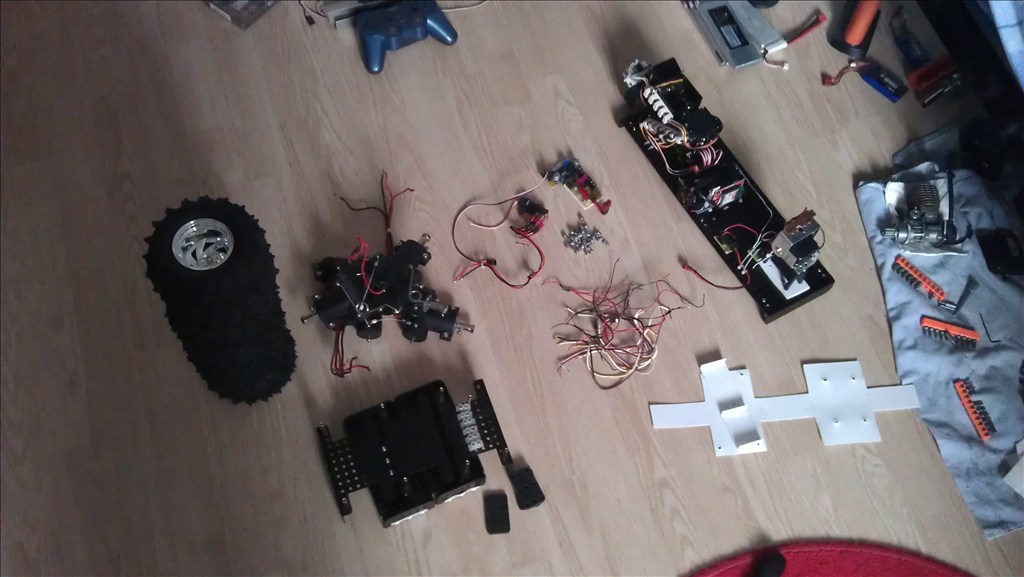

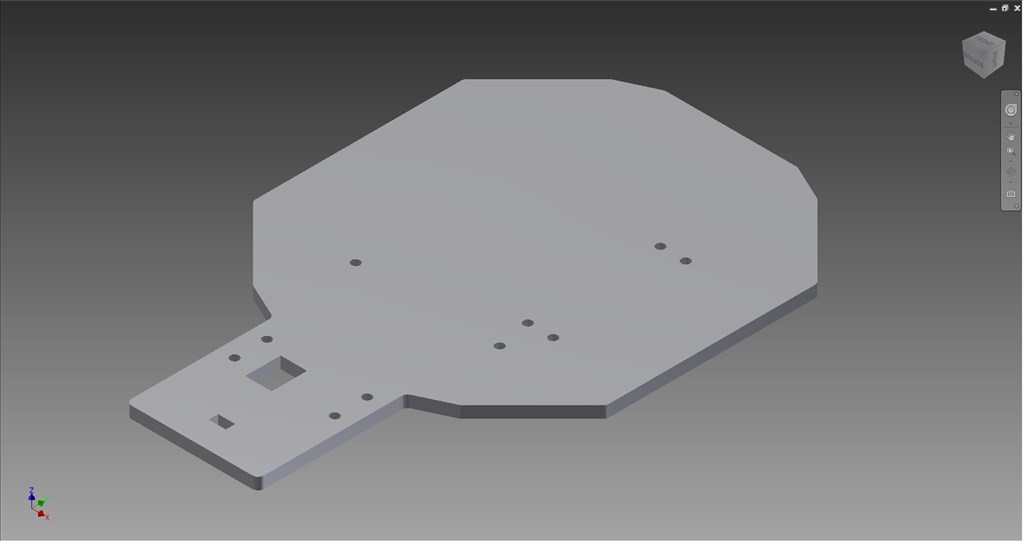

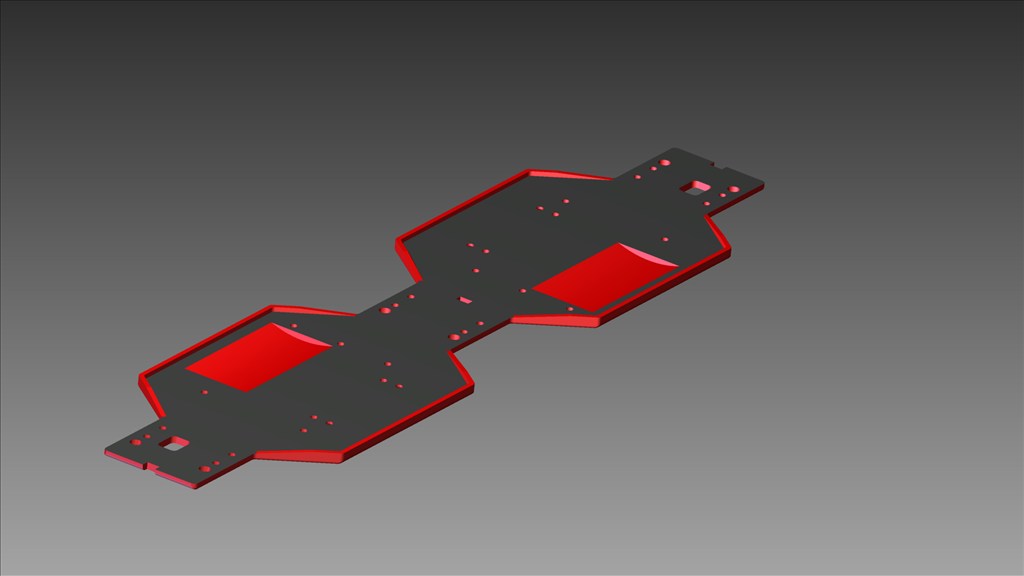

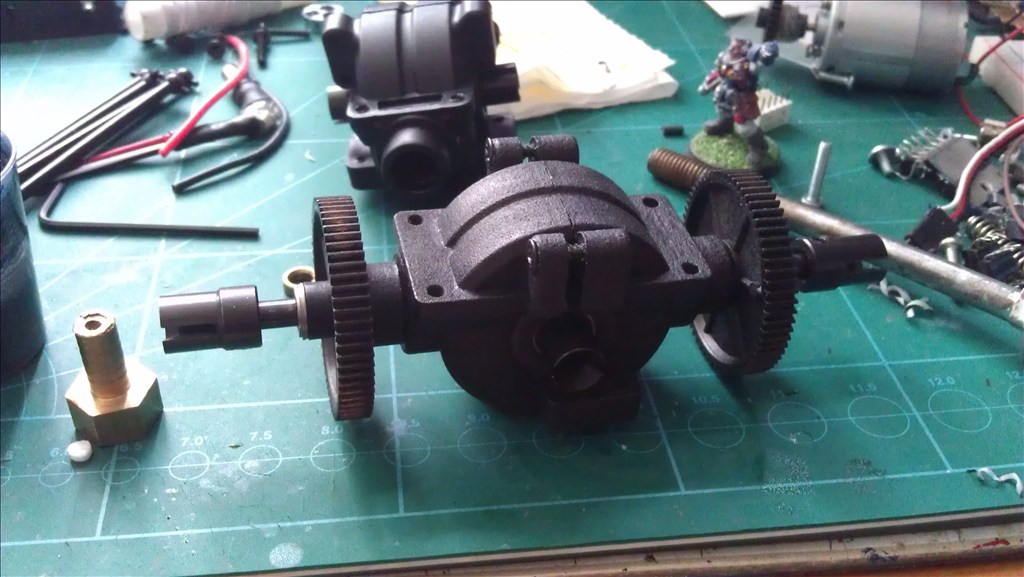

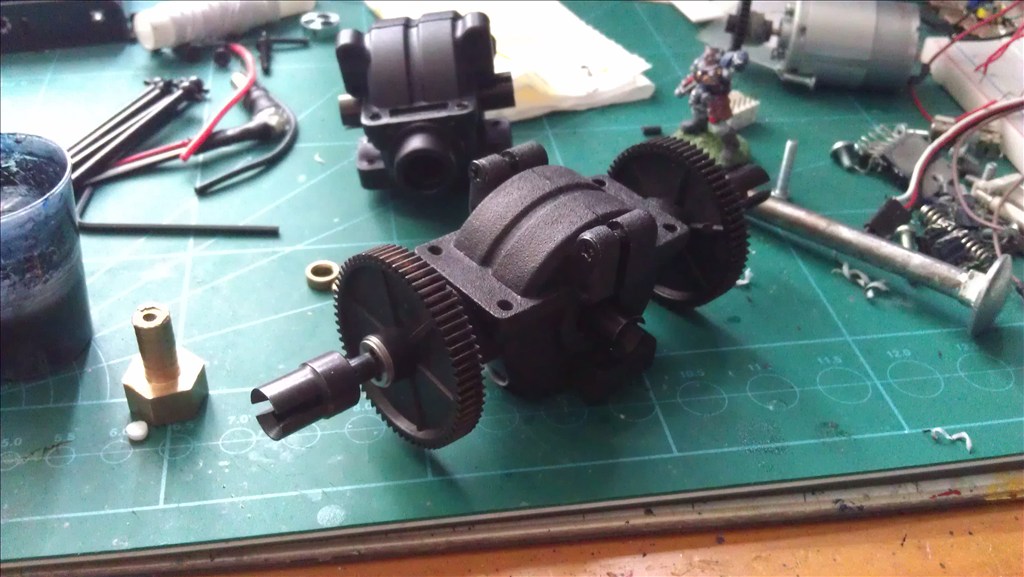

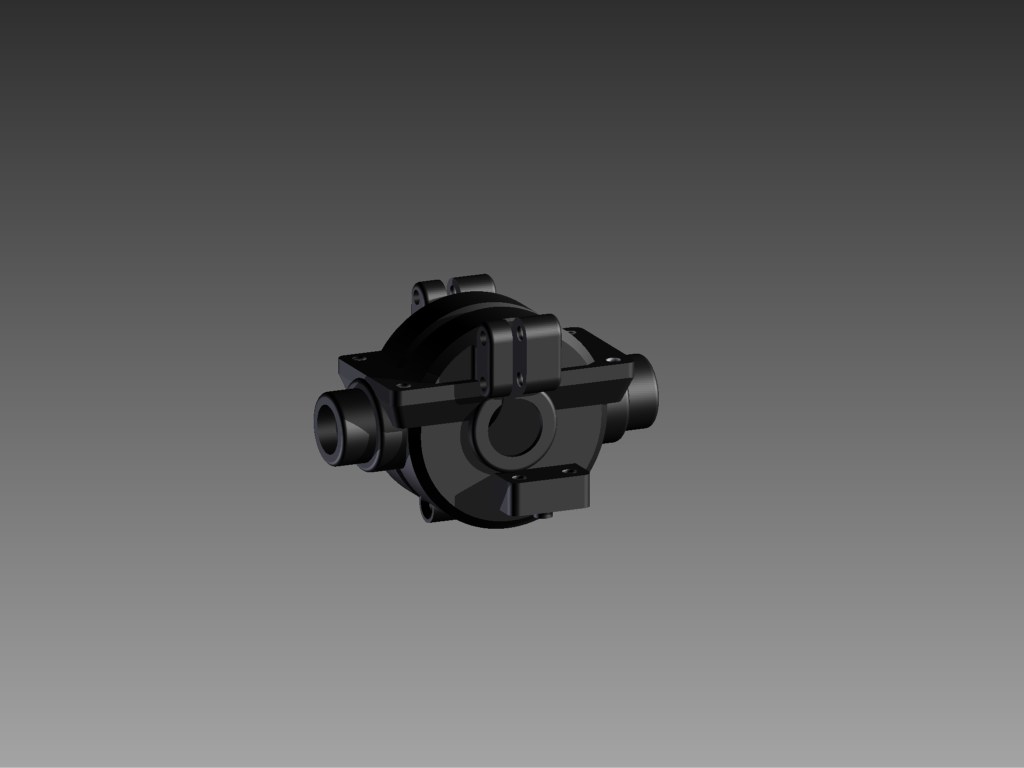

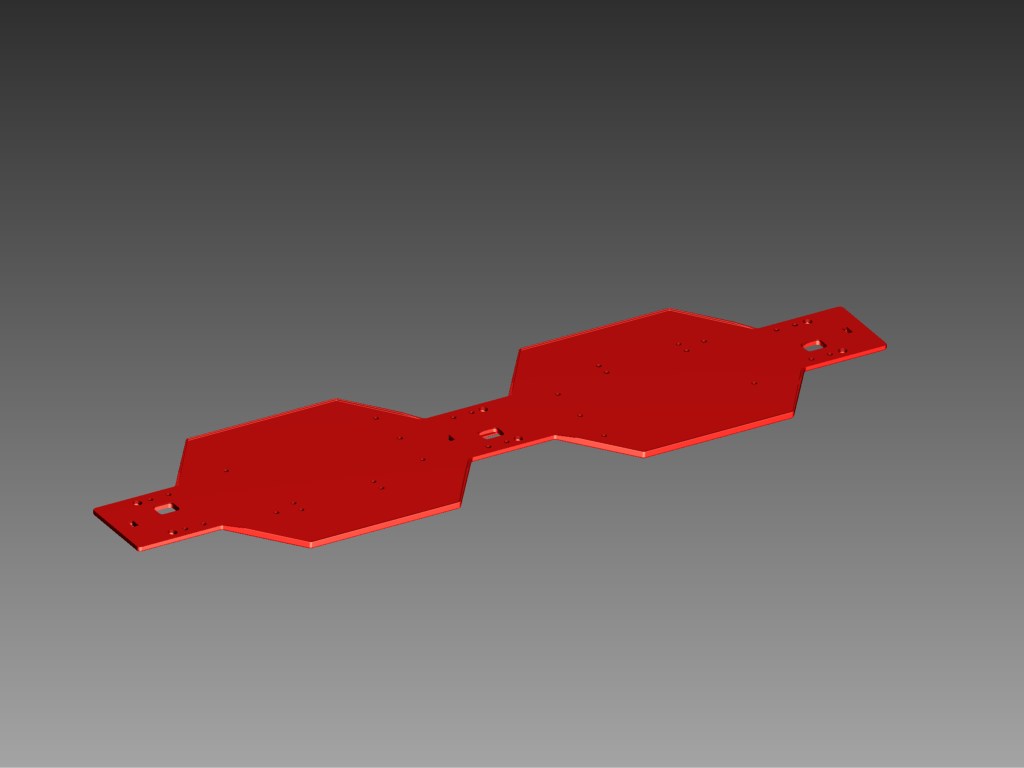

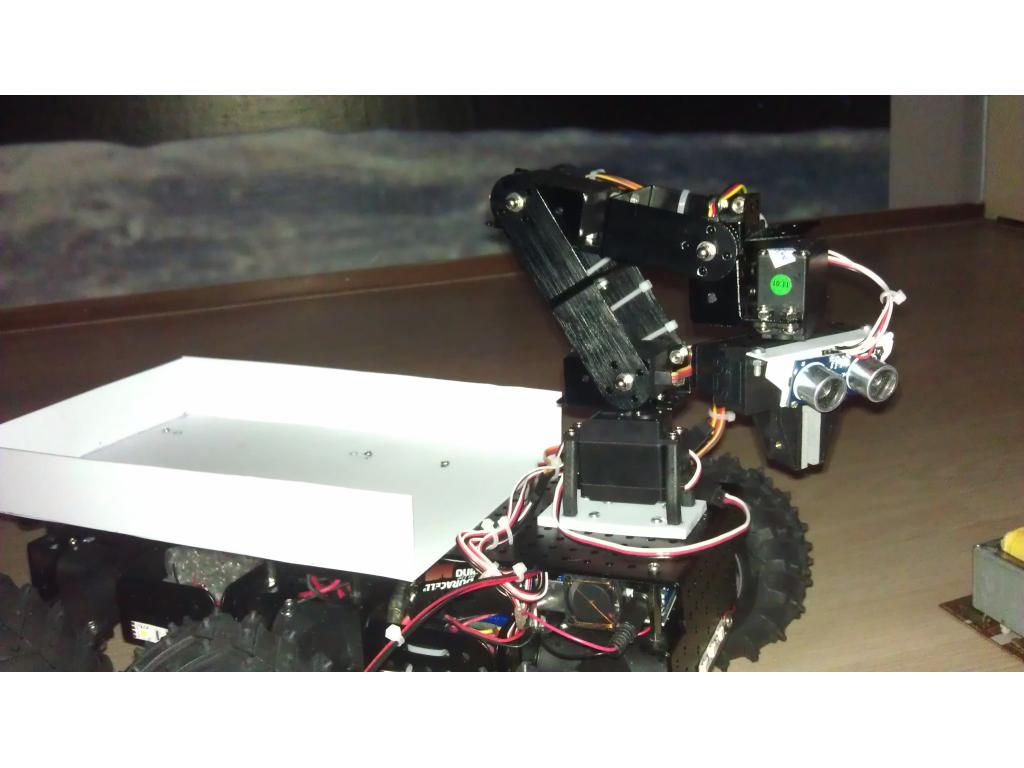

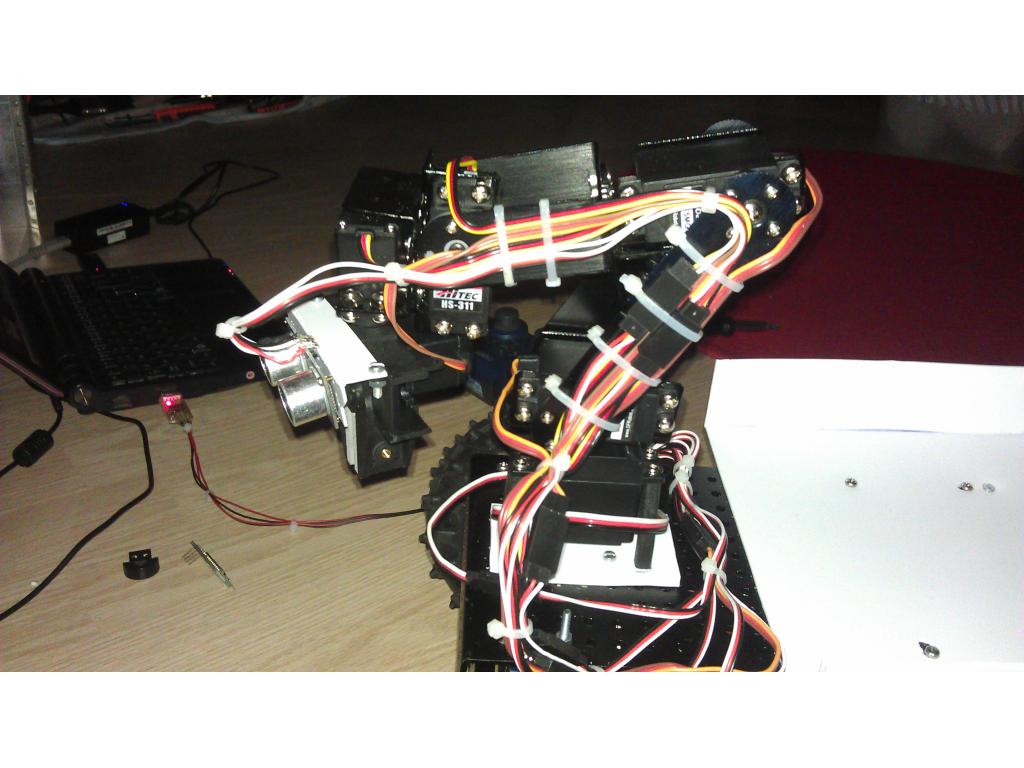

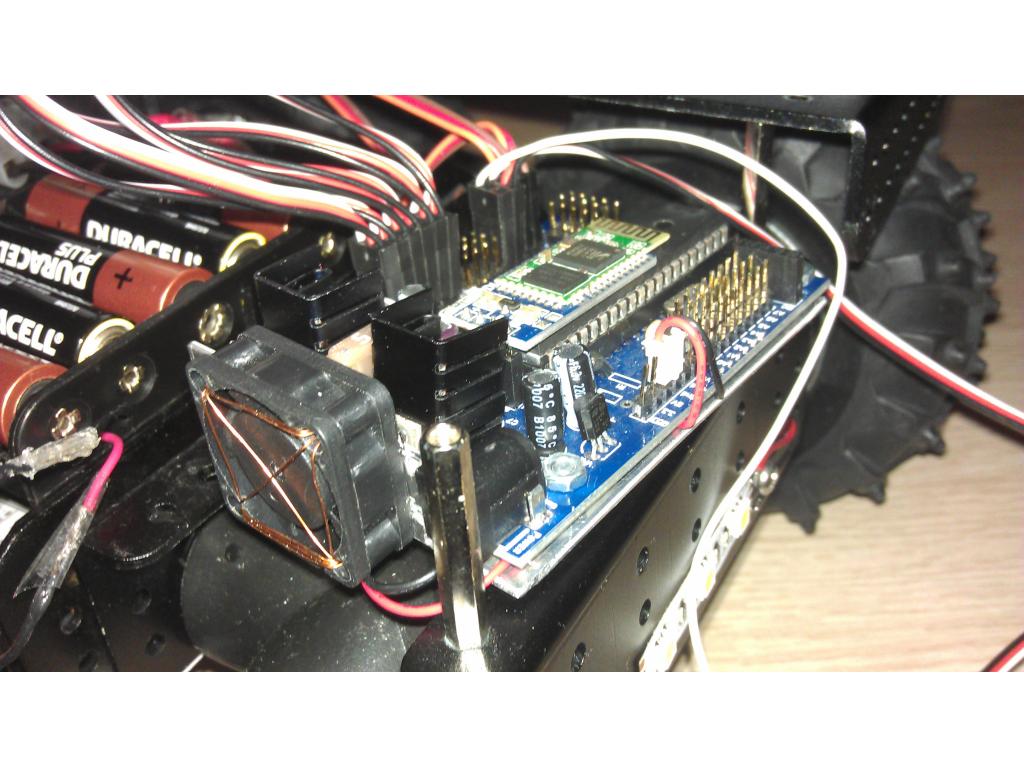

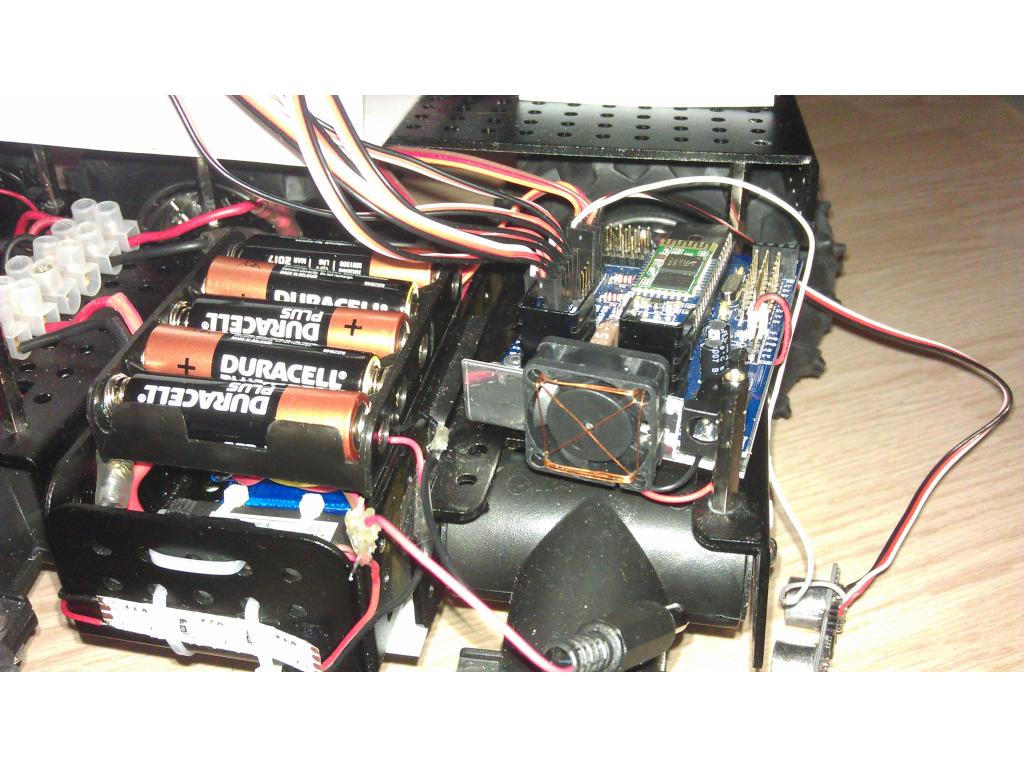

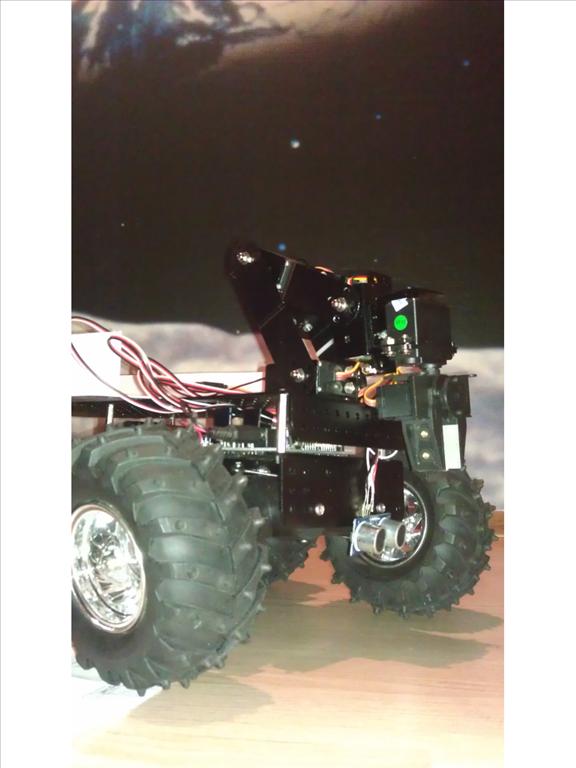

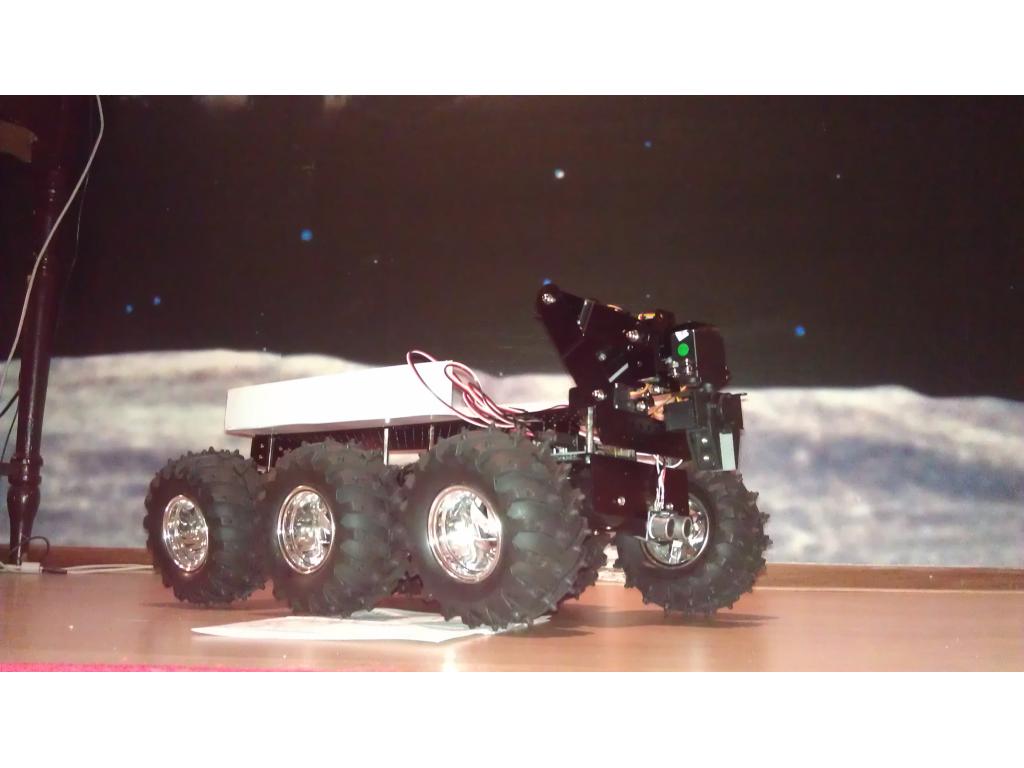

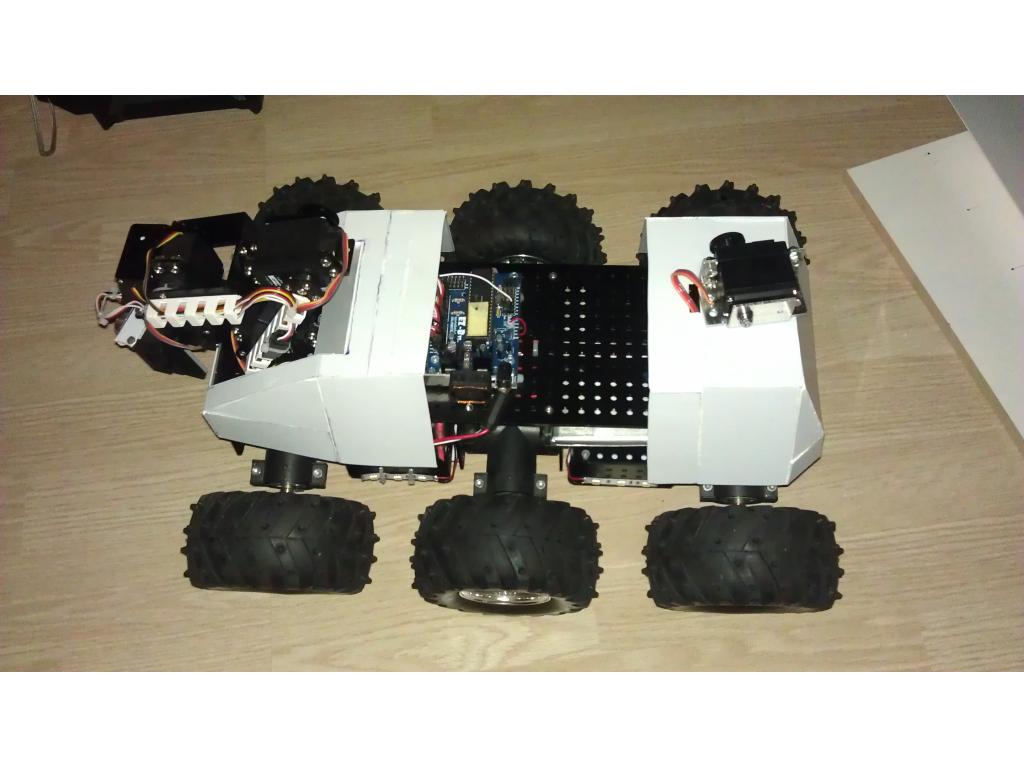

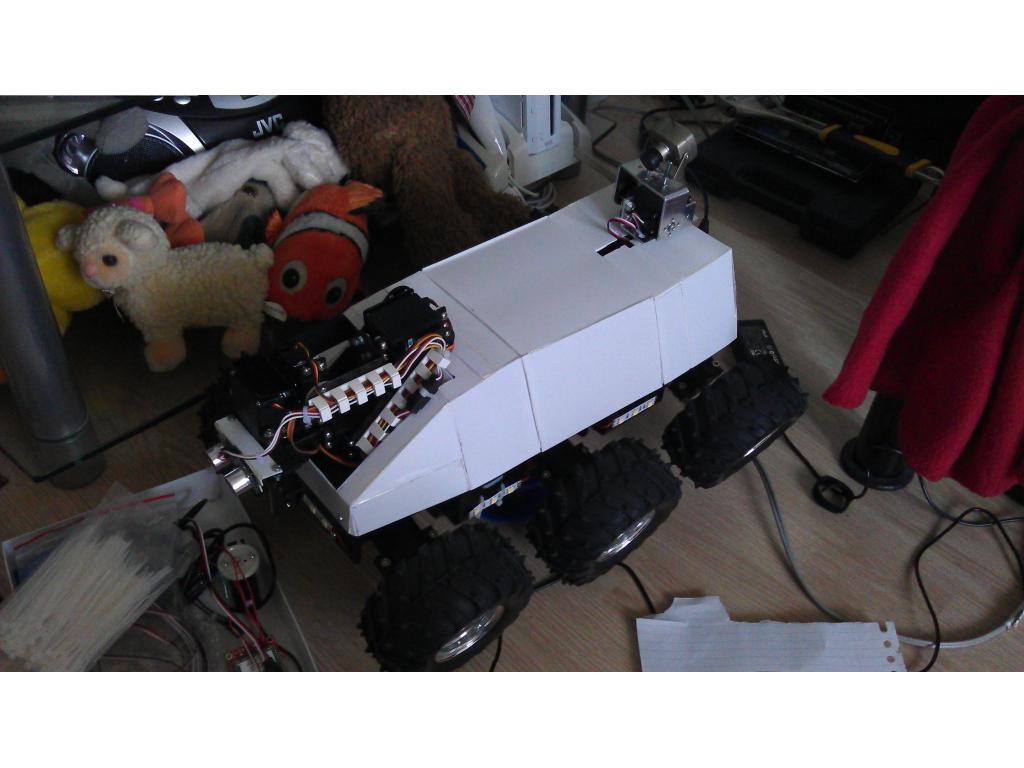

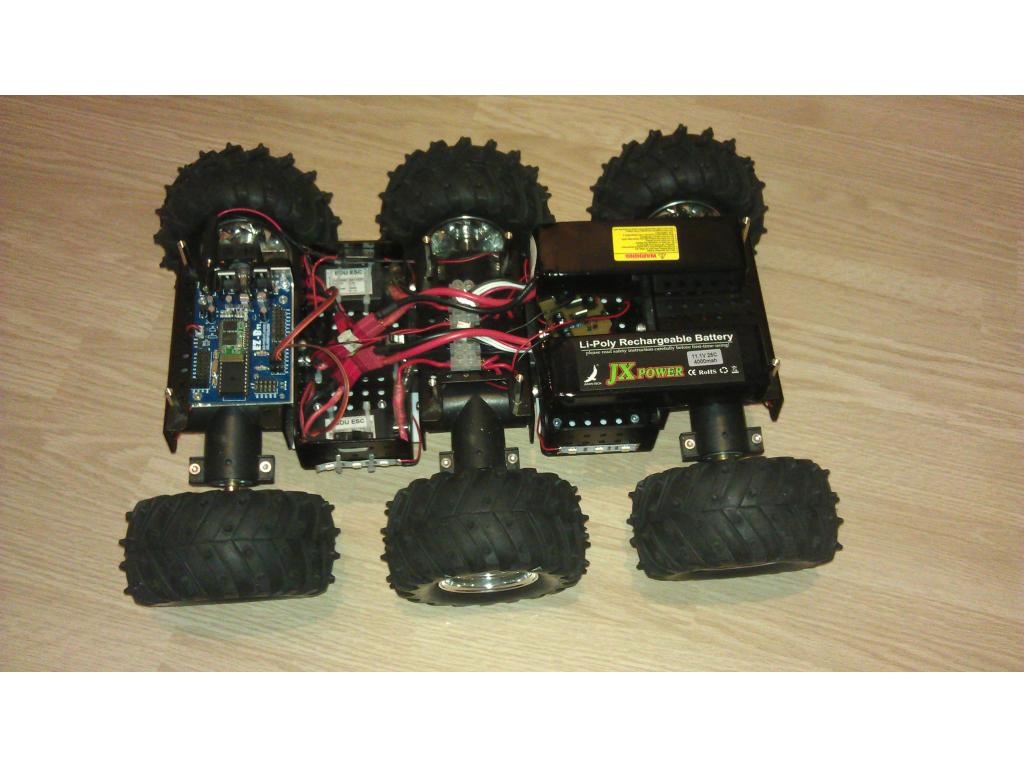

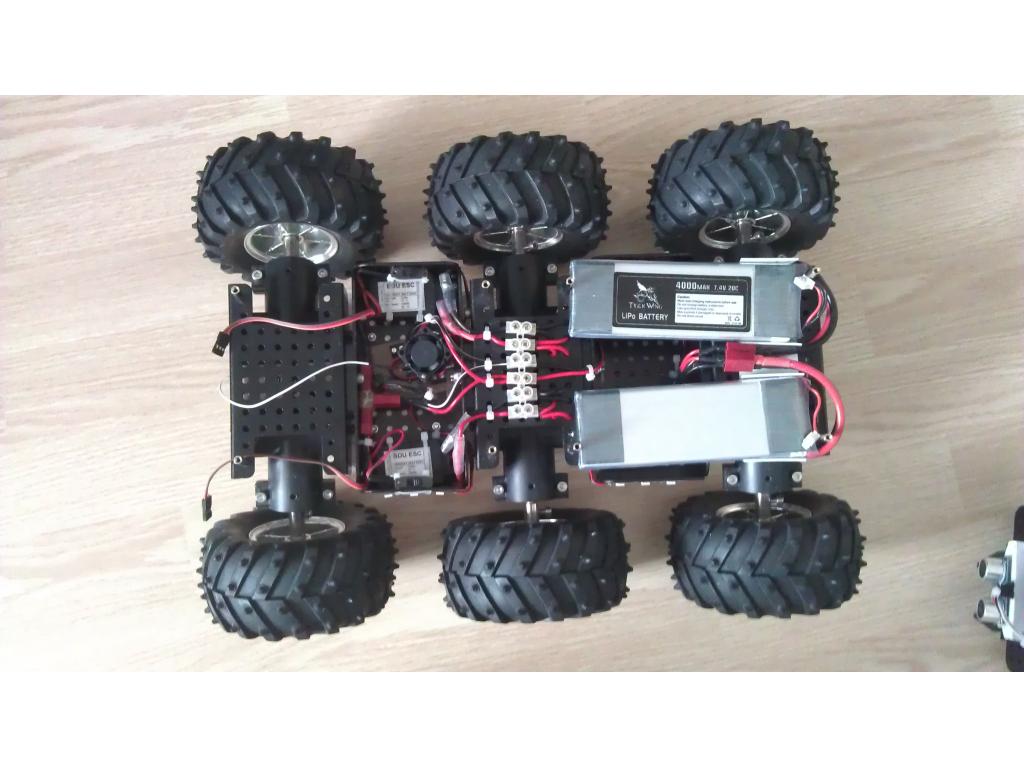

It's based on the 6 wheeled Dagu Wild Thumper kit. On top of that I added a 5 DOF robotic arm and a netbook.The specs:

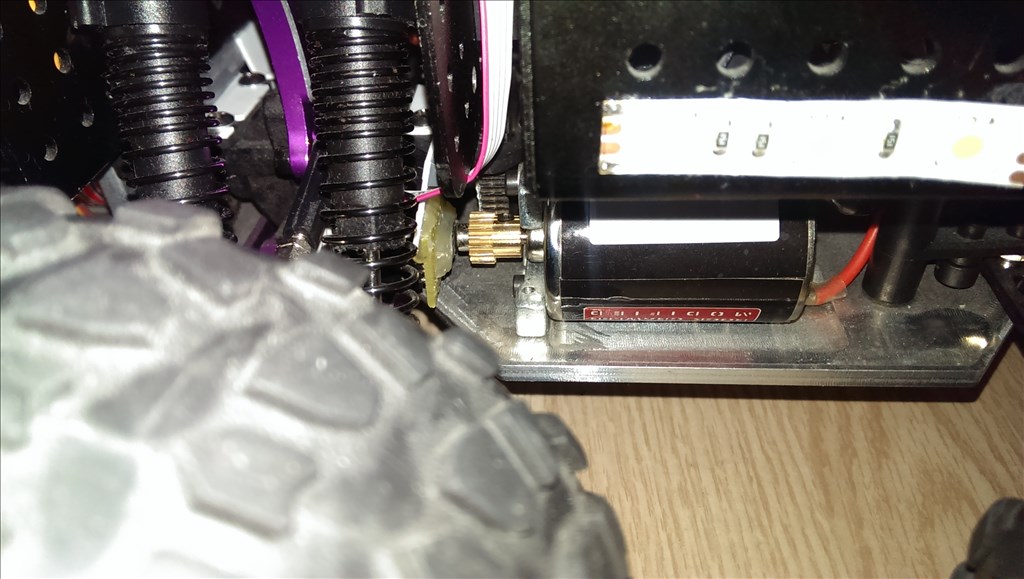

- 6x 6v 6A motors

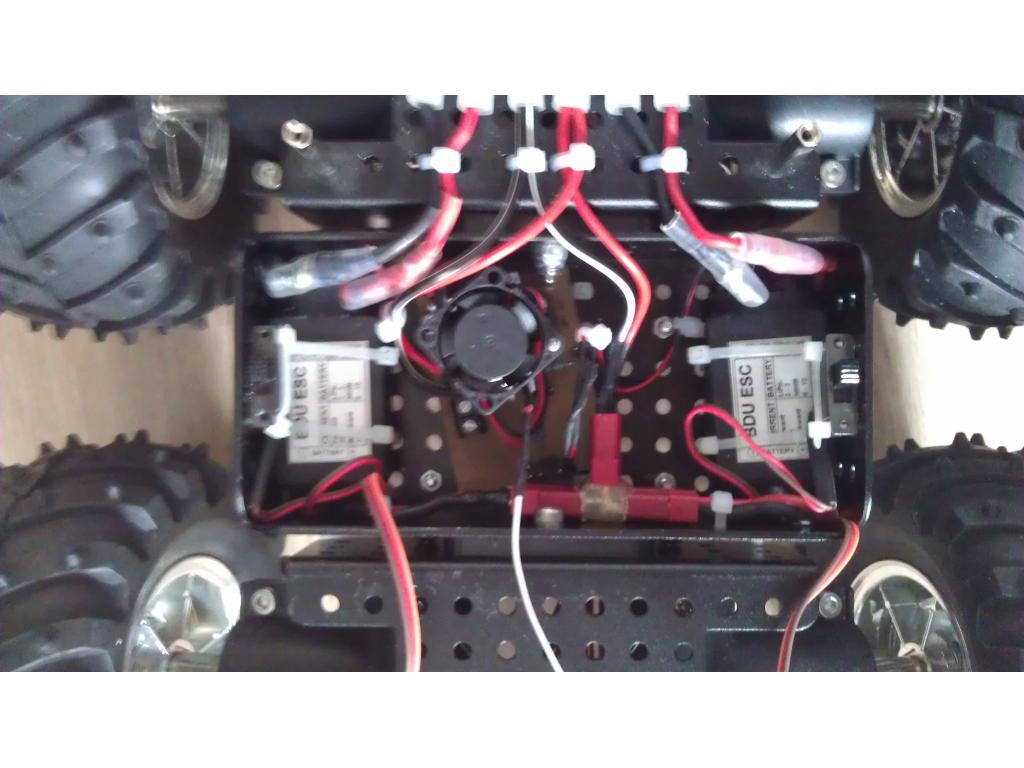

- 2x 20A Rc Car ESCs

- 2x Reddragon 2s 25c 1200mAh

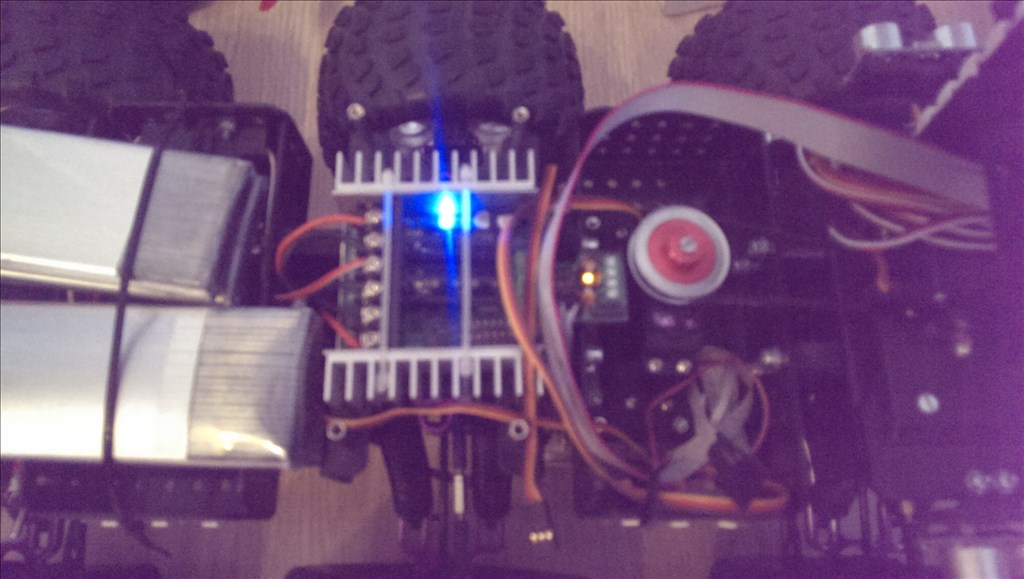

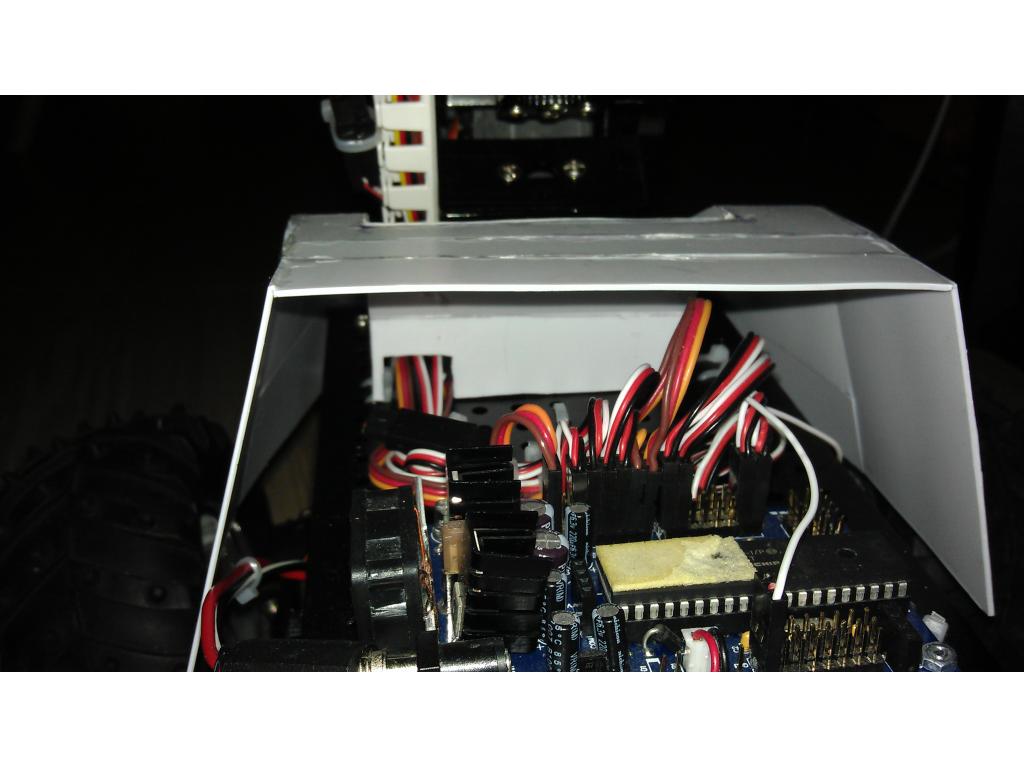

- Ofc the Ez- B

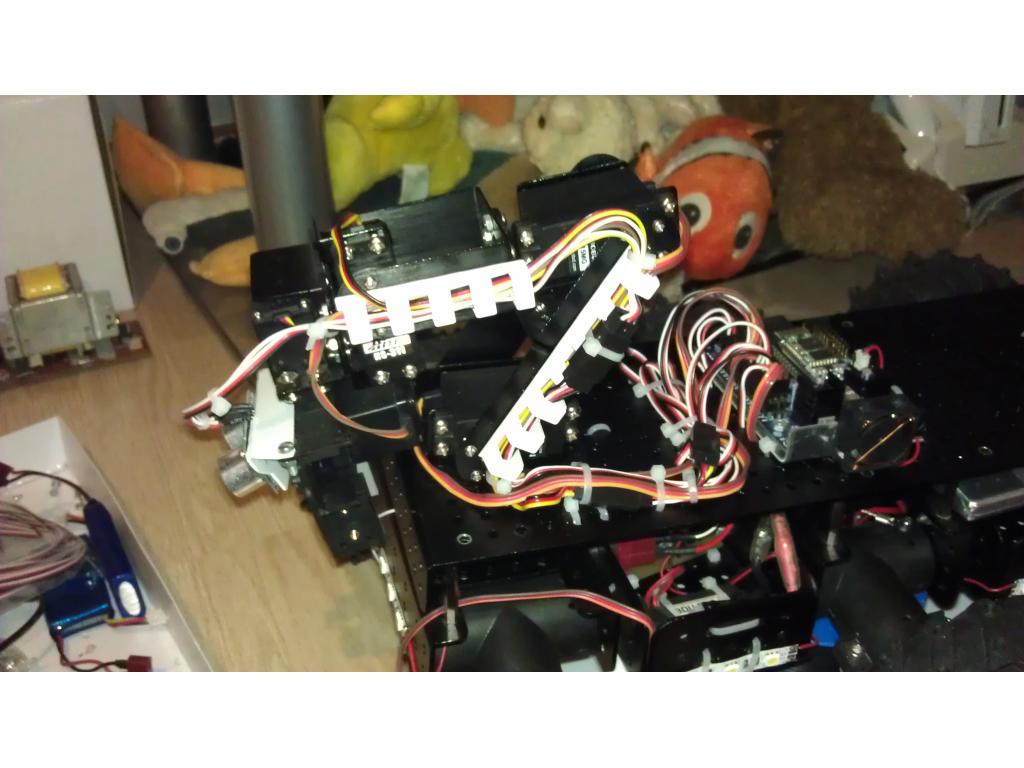

- Dfrobot 5dof robotic arm

- Asus Eee pc 900hd

- Ping sensor (well... I sort of broke it... It got stuck between the robot and the wall...)

Why I'm building it? Because I can, robots are Awsome, the EZ-B rules and I got tired of burning/shocking myself when I'm testing one of my "crazy" contraptions.

Up coming updates for robot:

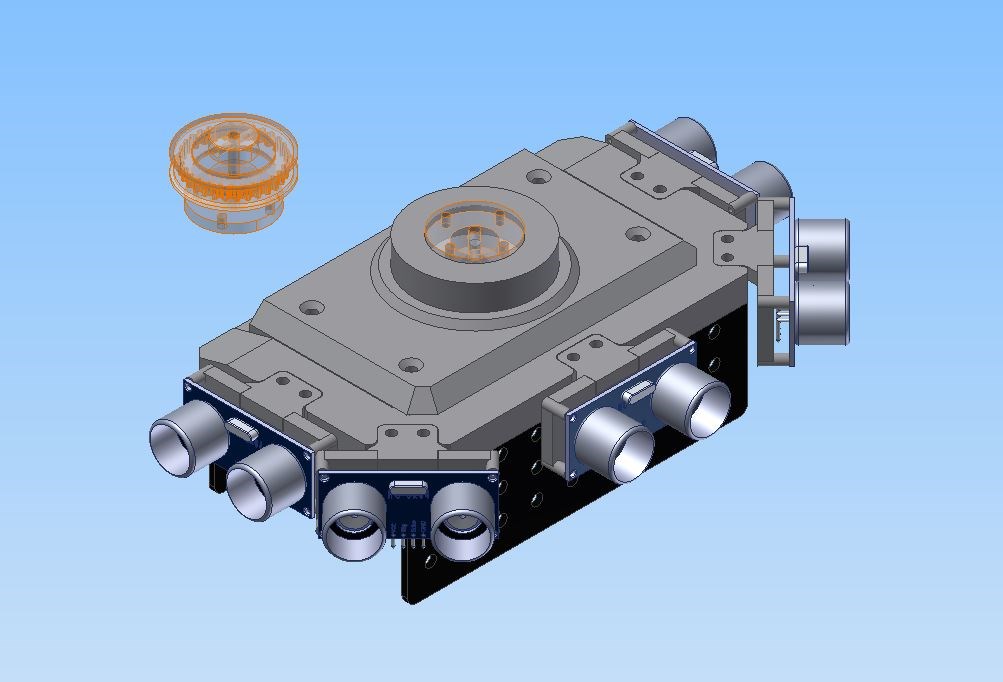

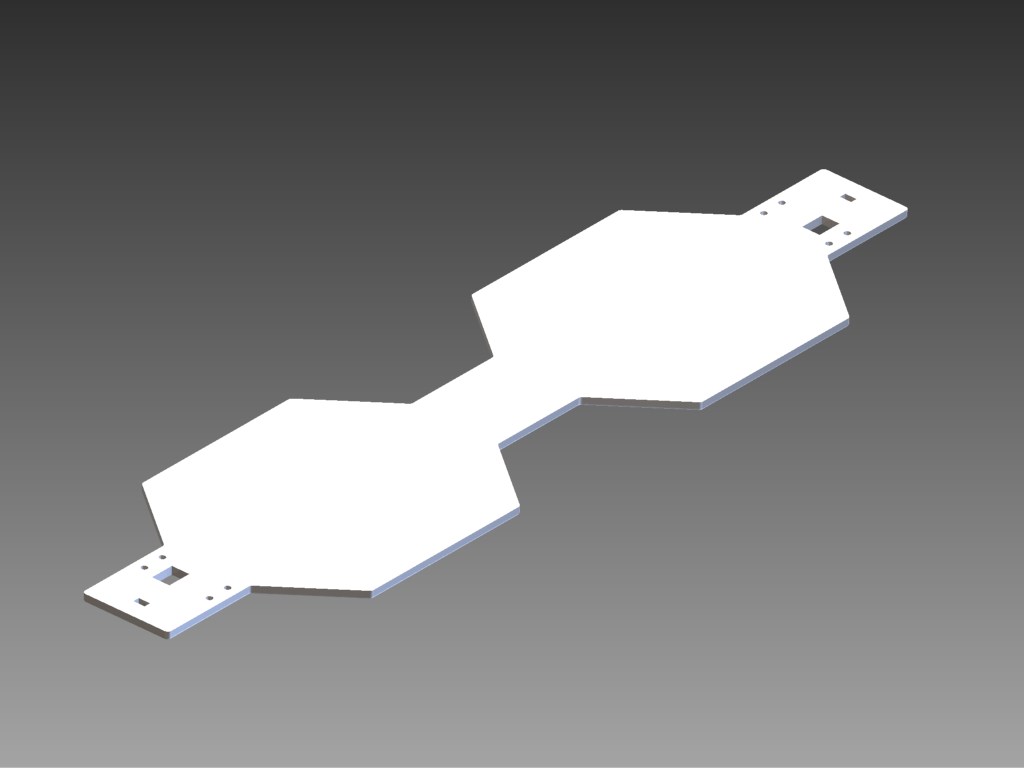

- A rotationplatform for the arm.

- 2 gigantic lipo batteries.

- camera+ pan/tilt turret.

- Small rockets

- mini mini-gun

- Flamethrowler (a failed version of a liquid fueled rocket, but it's working if you call it something else)

- coilgun

- railgun

- Lots of other things I can come up with.

By budel0

— Last update

Other robots from Synthiam community

Robot's Irobot Create With An Arm

Control iRobot Create with V3 EZ-B and a 6-servo arm to help a Roomba clear obstacles in its cleaning path

Gwen4156's The G-Bot (Gwen's B9 Robot Project) Gets His...

G-Bot outdoor test: handling lag and ramping issues, tips to use wireless controller and prevent tread snags, successful...

DJ's The Real Wall-E

Wall-E using EZ-B and Synthiam ARC tracks faces, color and motion with camera, vertical head servo, voice control and...

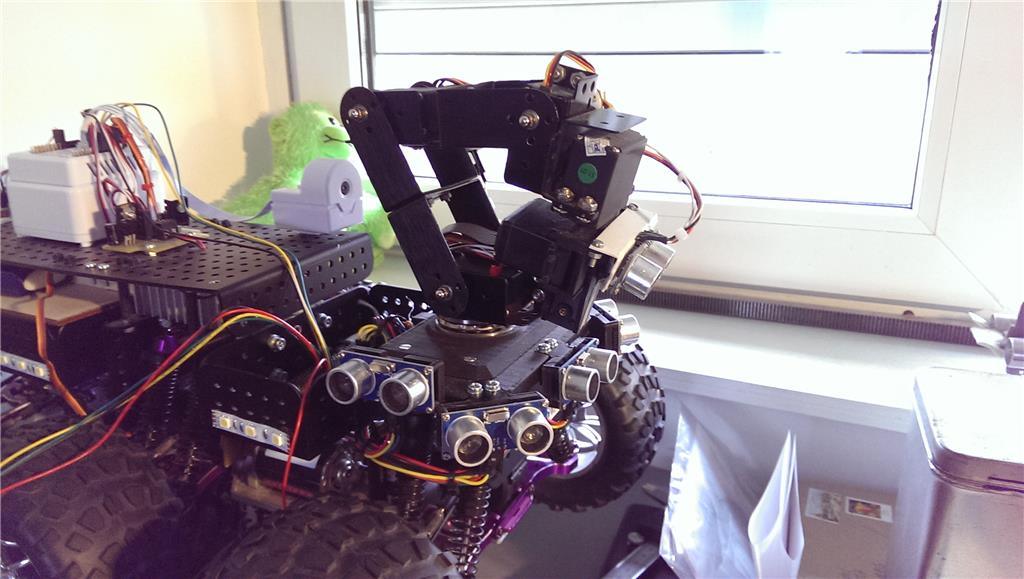

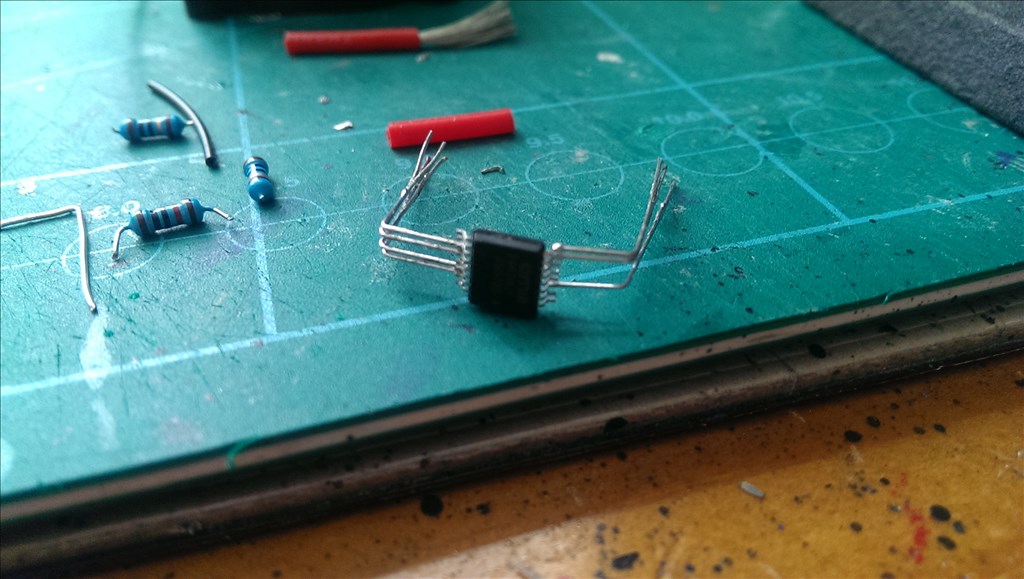

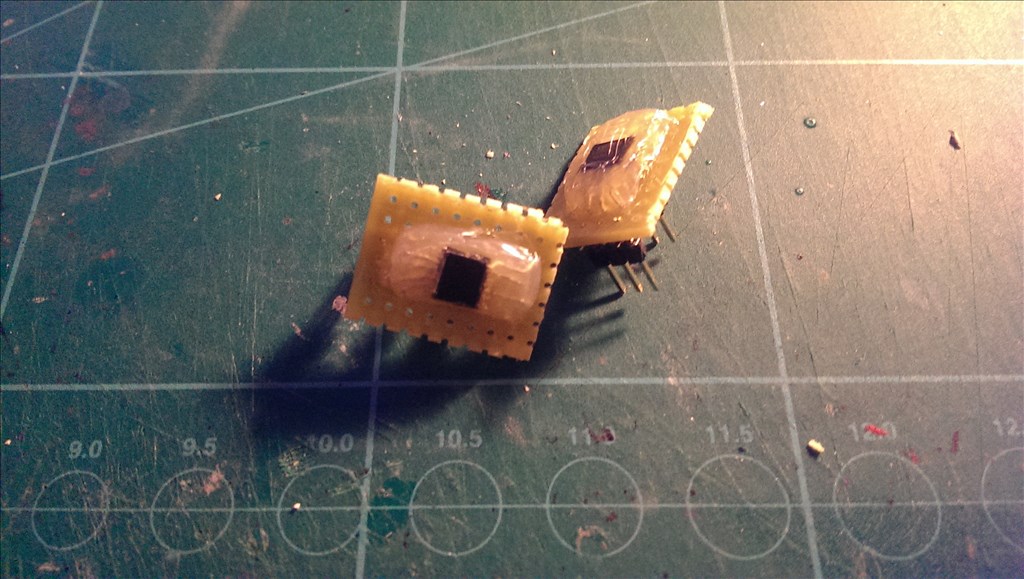

Some extra pictures.

that's a sweet looking bot

Very cool! That looks like it should be on the moon roving around

That arm is looking good

I'm really liking your bot! I was actuallyt looking at that platform a couple days ago. It's a little to expensive for my tastes, but would love to have one! Where did you get the arm? Can you post a link? Great work!

Oh thanks man! I've been working on it for quite a while now. I bought the robot arm from EBay. It's quite expensive though. But after doing lots of calculations and research I figured that if I'd just buy it as a set it would be cheaper for me. It depends in what country you live... If I buy something from outside the EU I have to pay 20% taxes over the complete amount I've payed including shipping when I receive it! If the object is over 20,-. And if I would buy it in parts I would probably go over that eventhough everything is cheaper outside the EU if you don't count shipping...

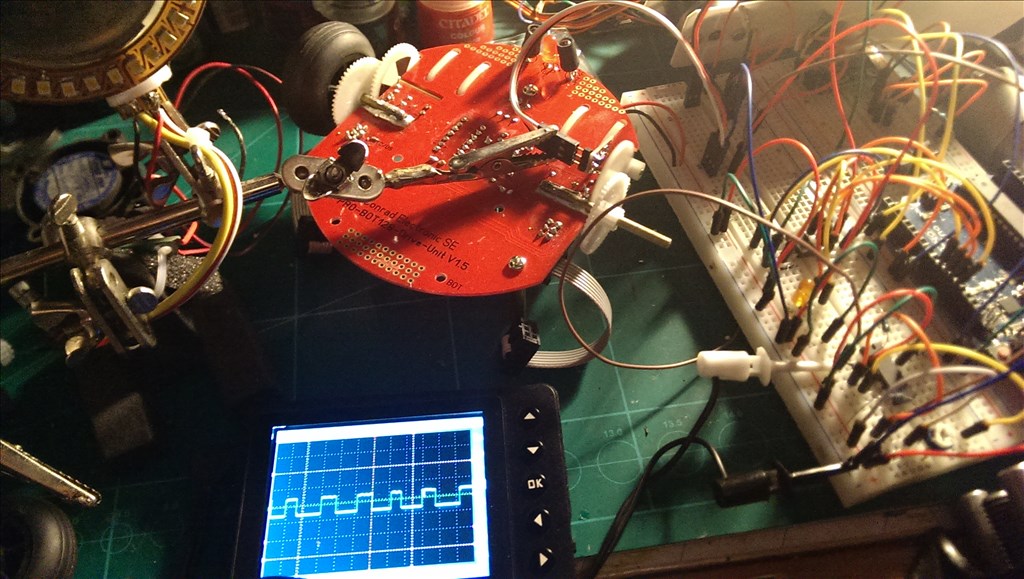

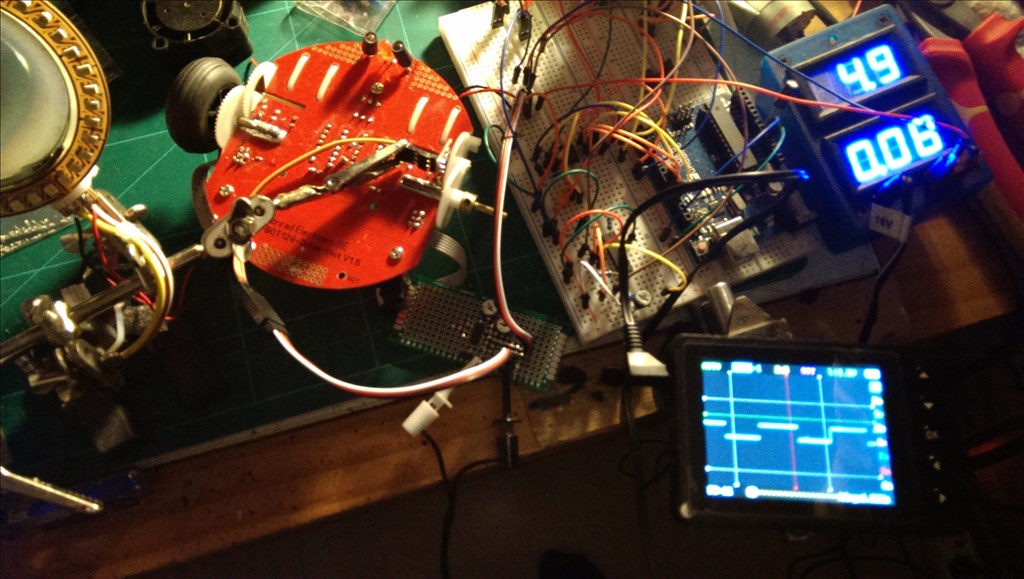

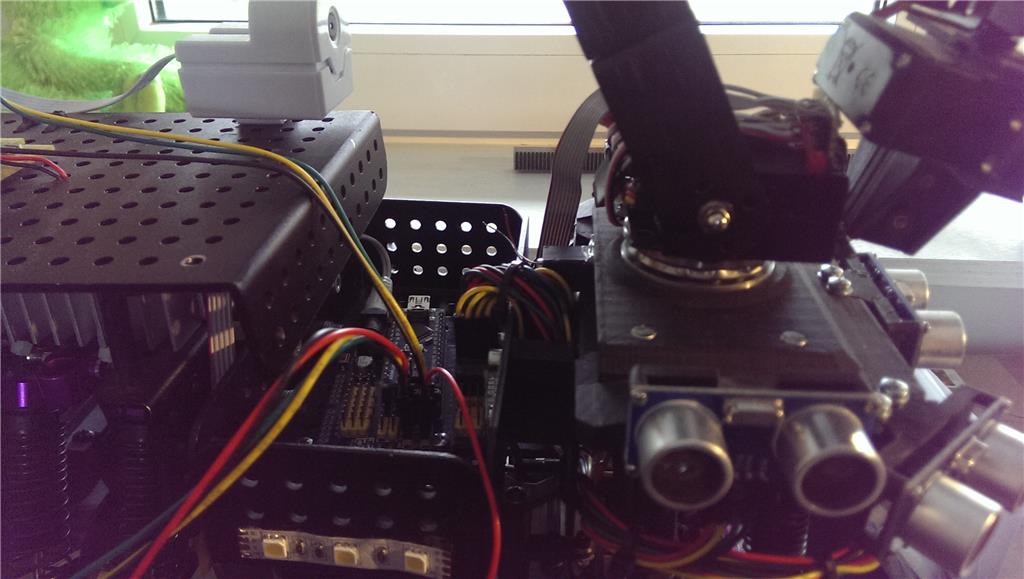

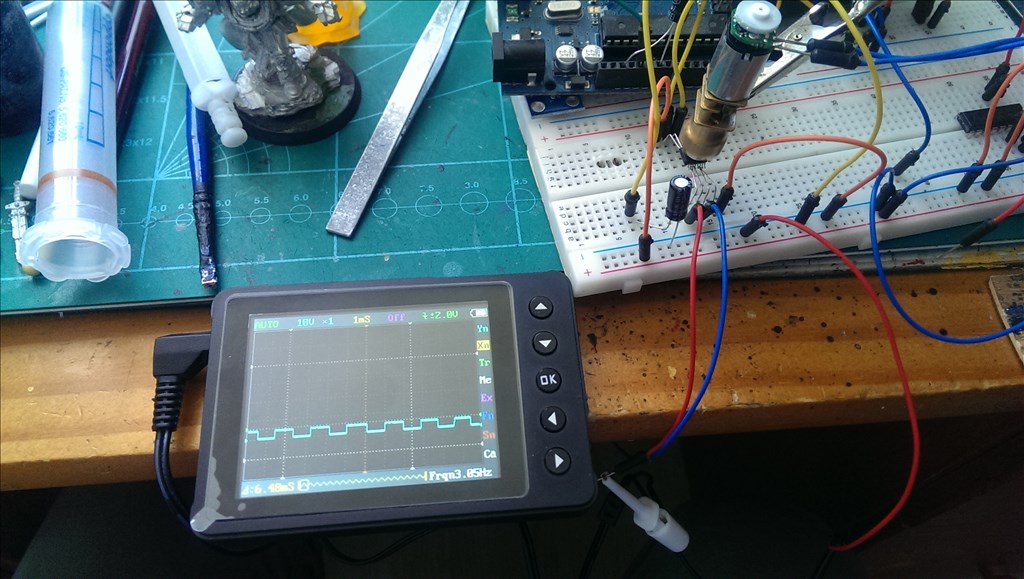

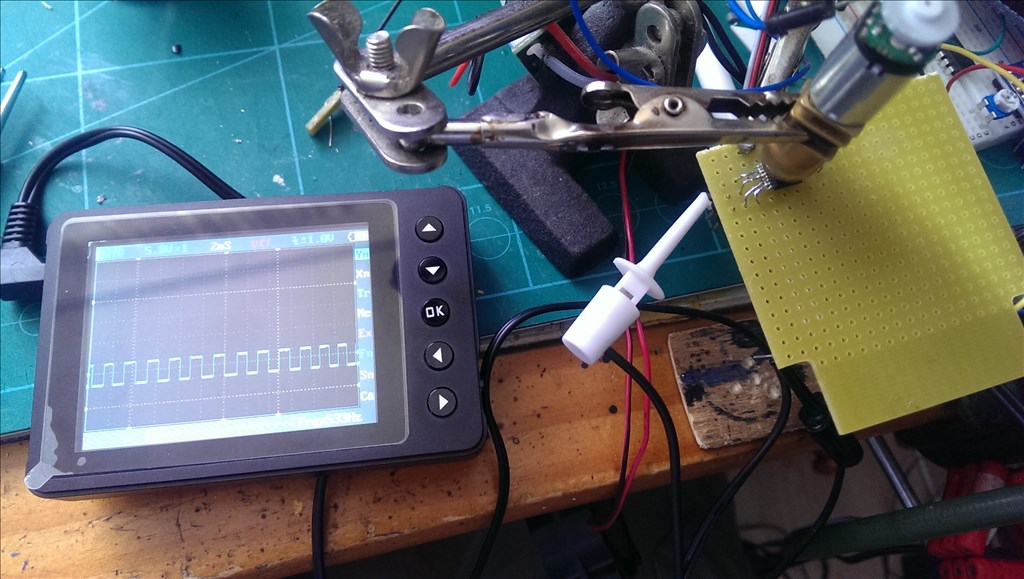

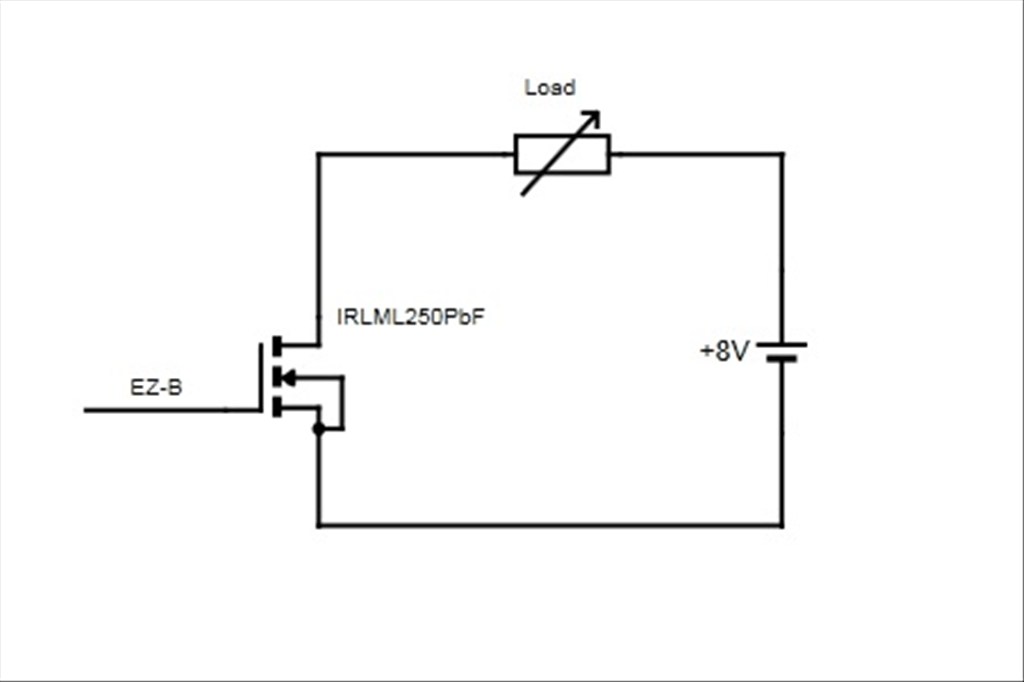

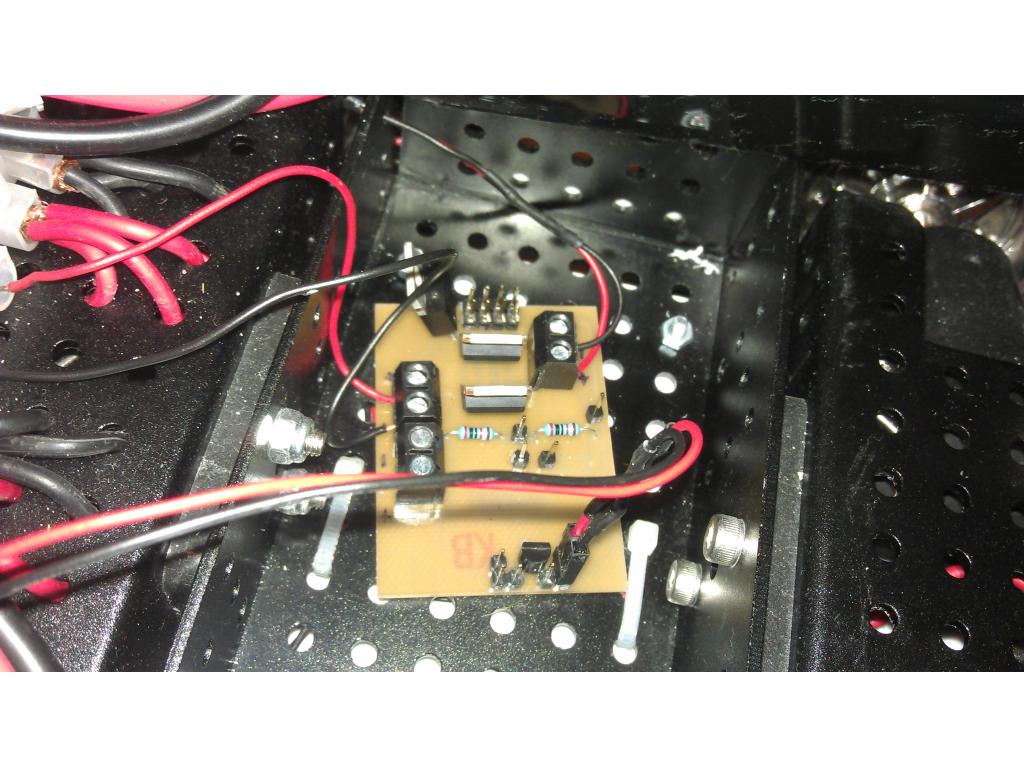

A few days ago my brother gave me a peace of LED-strip and a few LEDs, that gave me an idea.

Nightmode:

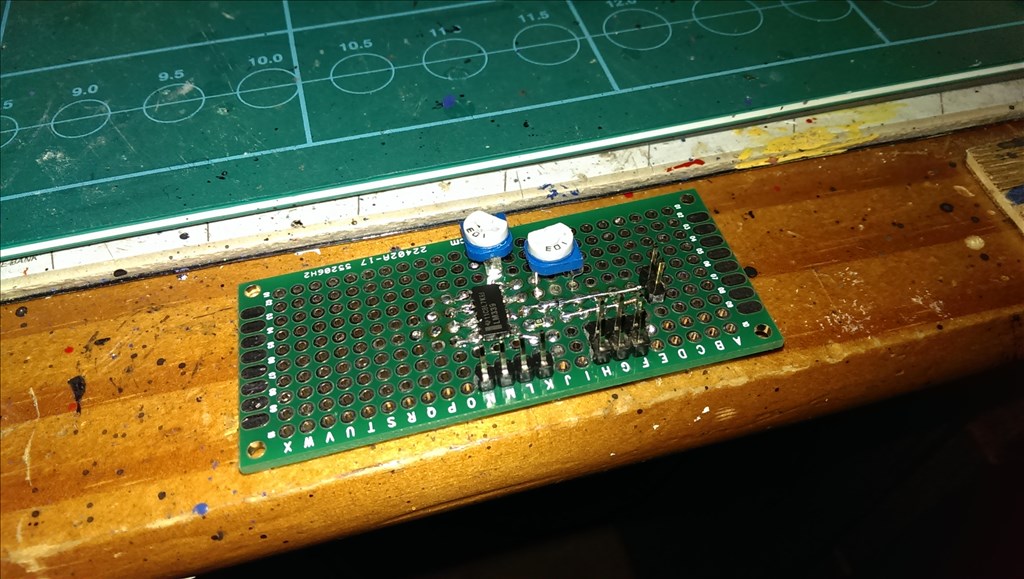

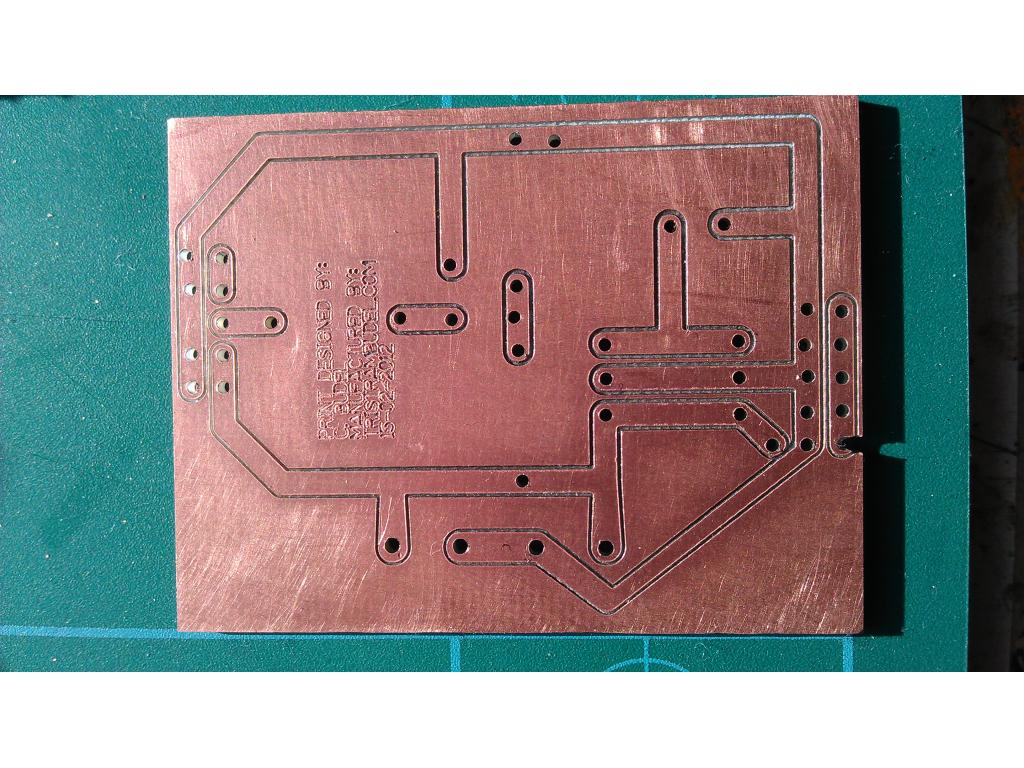

It's still in its testing phase and I still have cleanup the wiring, but it looks cool. I might even design a small board to distribute power from my Lipos to everything. More coming soon!

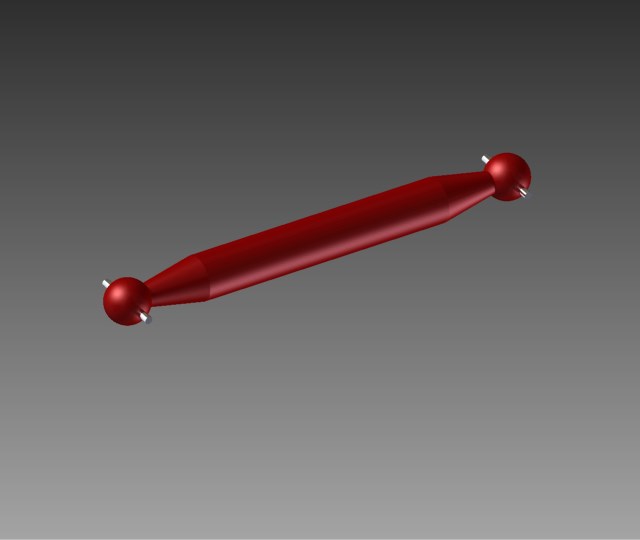

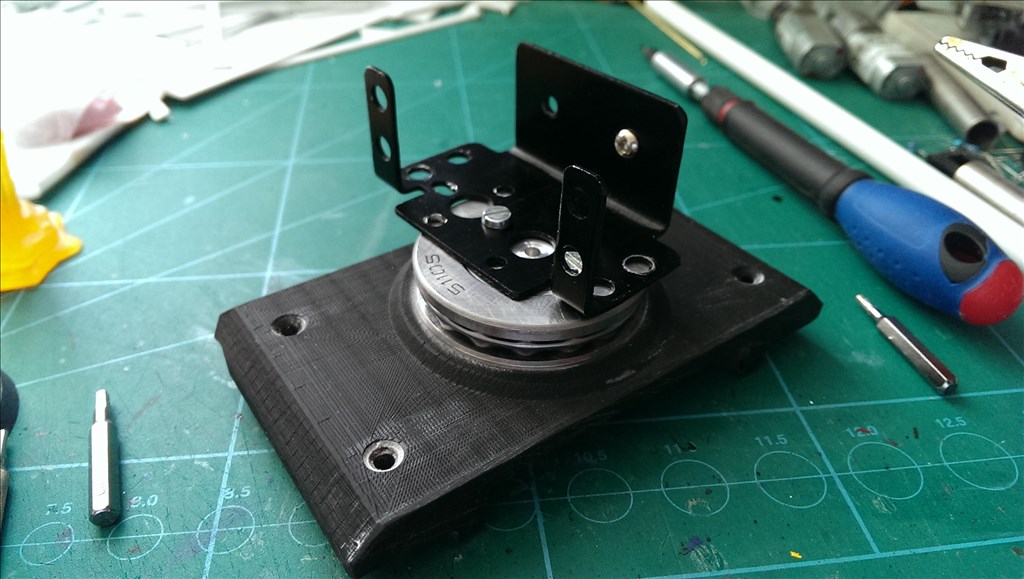

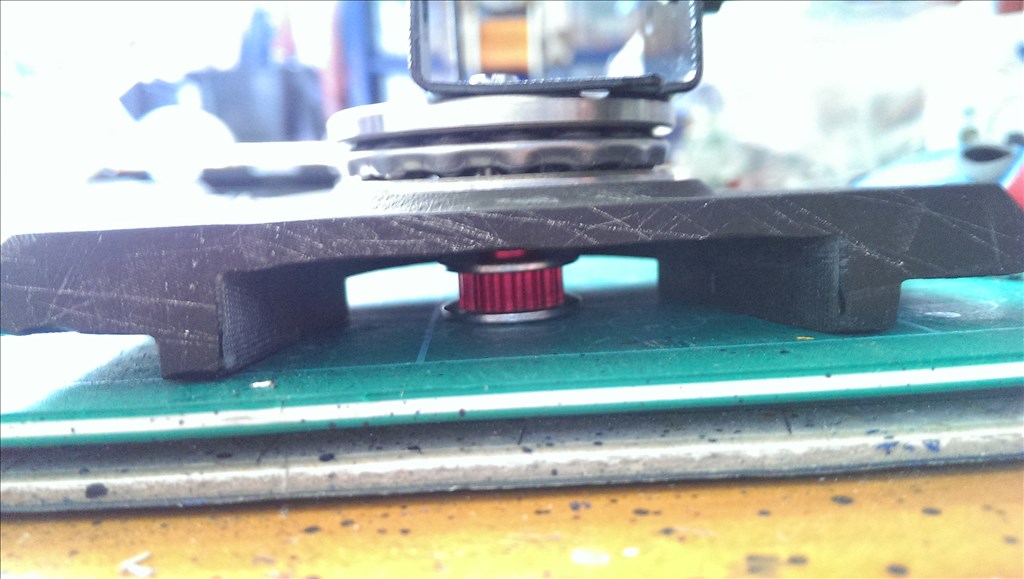

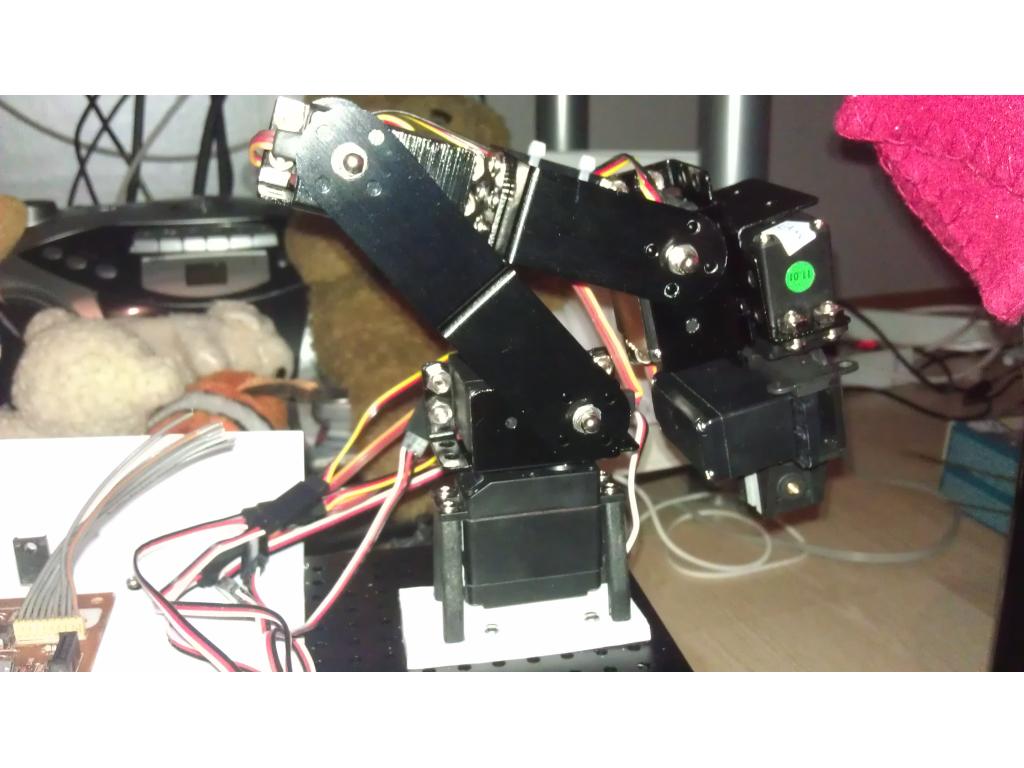

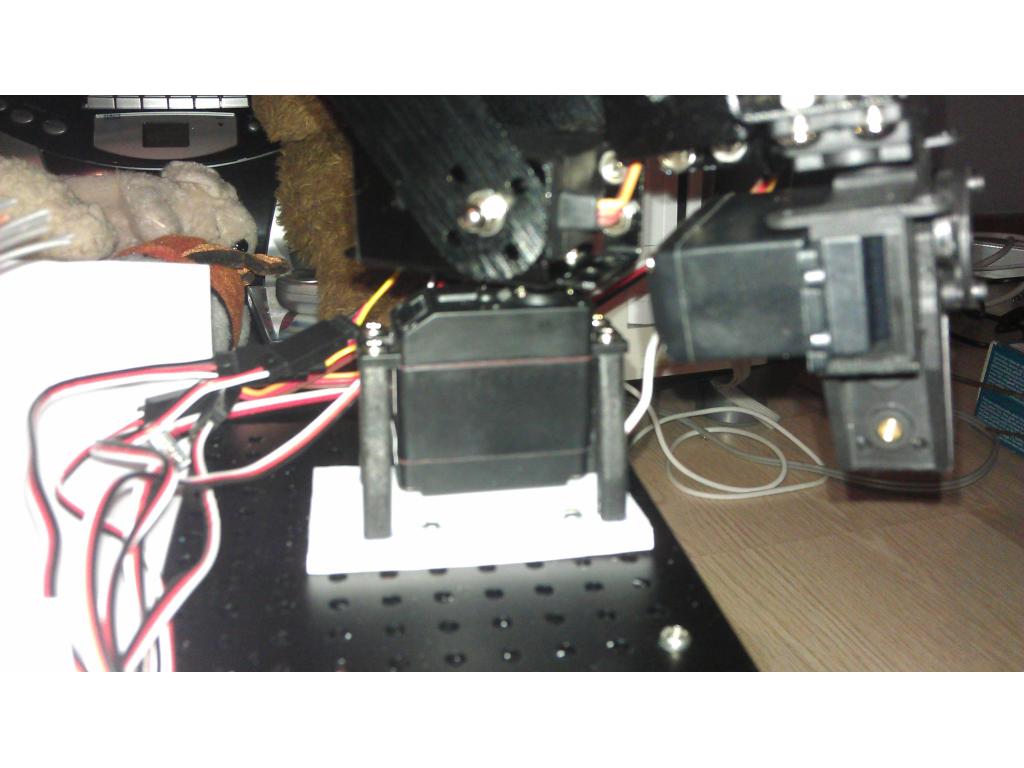

Latest update: I finally finished my robotarm. It now has 6 DOF! Under the existing arm I mounted a servo. It's a simple design, which I might change in the future to lower the height of the arm. I was planning to use a servo that could do 360 degrees, but I probably mixed something up and accidentally bought a modified servo... But It's oke... To fix this problem I'll mount in 1 or 2 microswitches to define a starting position.

Here some photos: