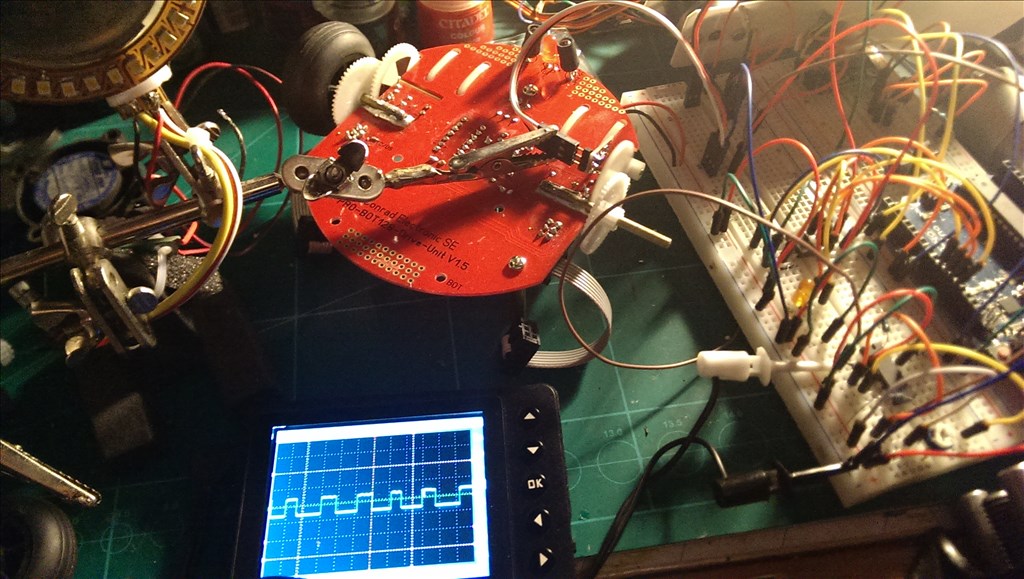

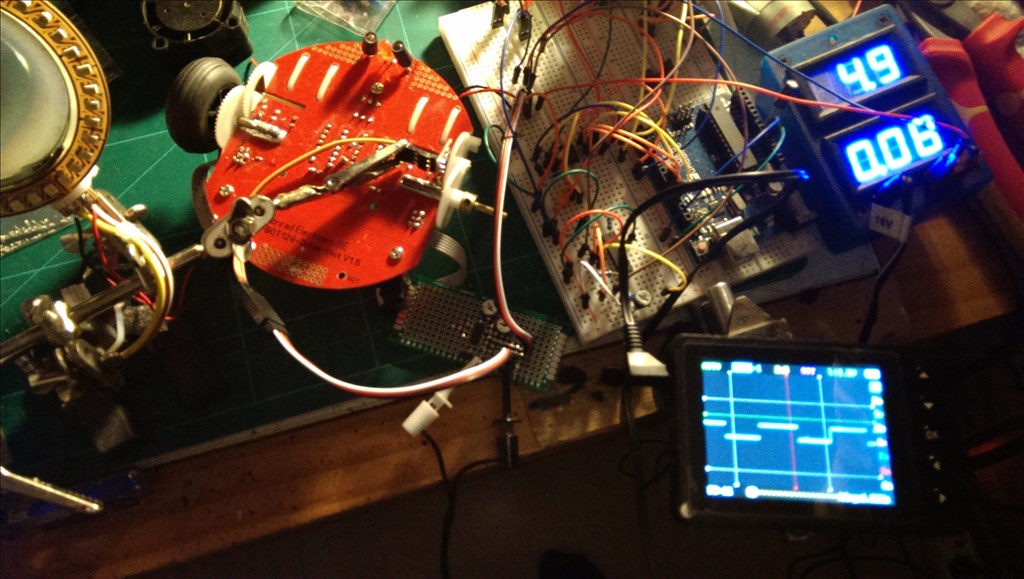

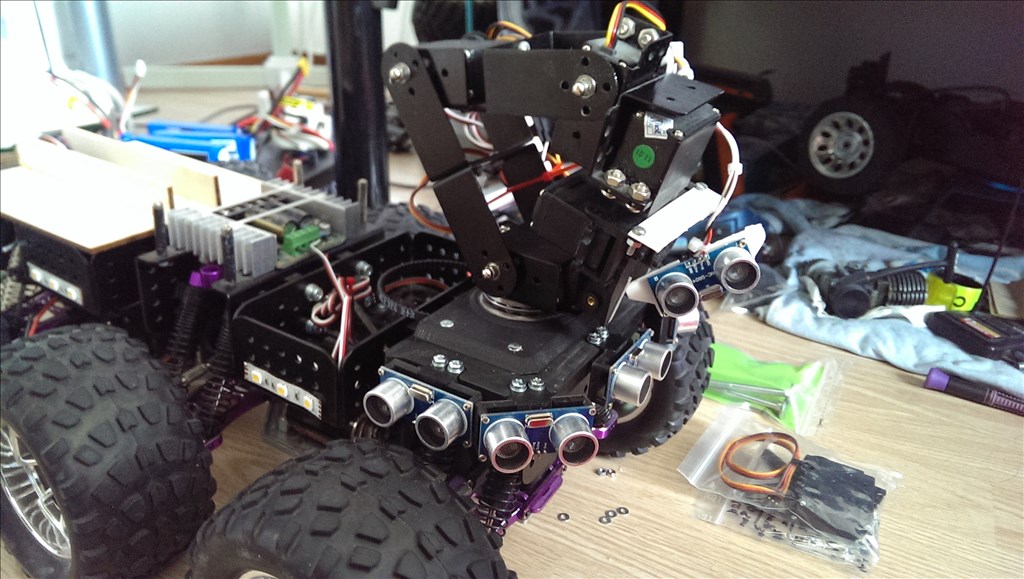

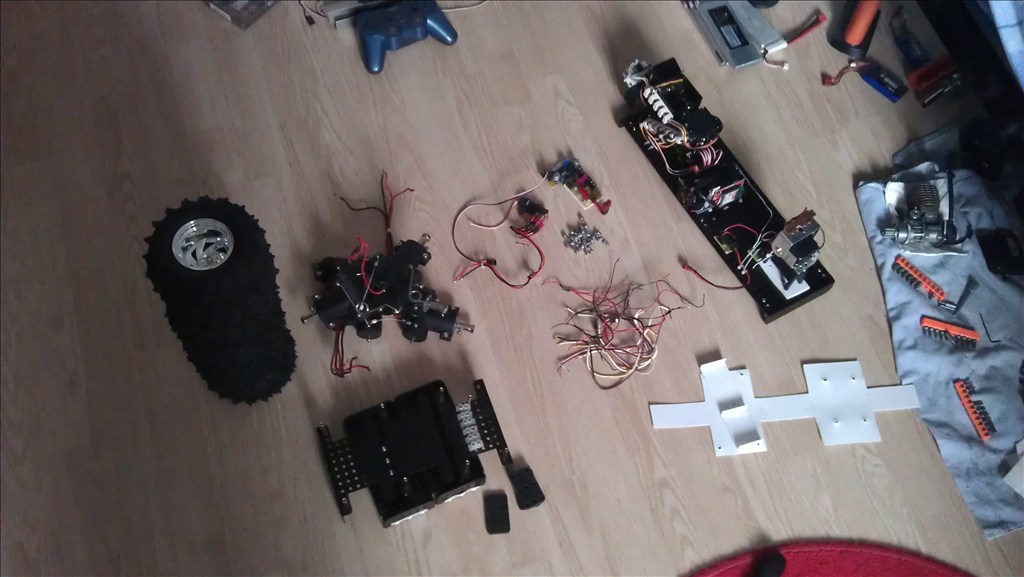

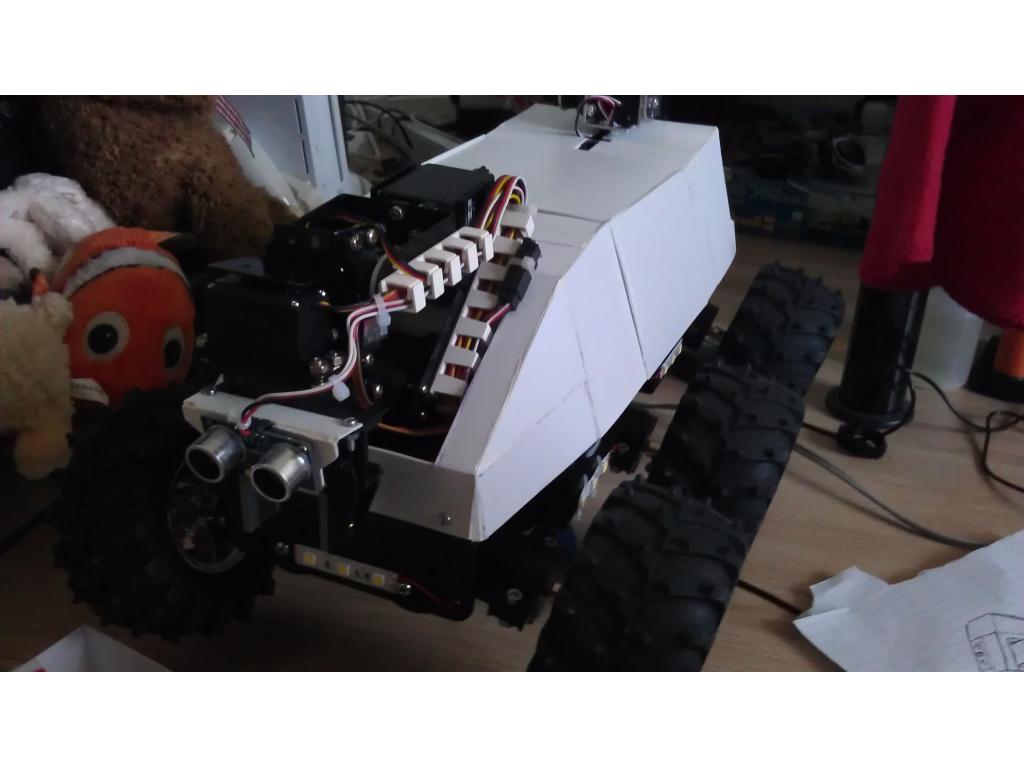

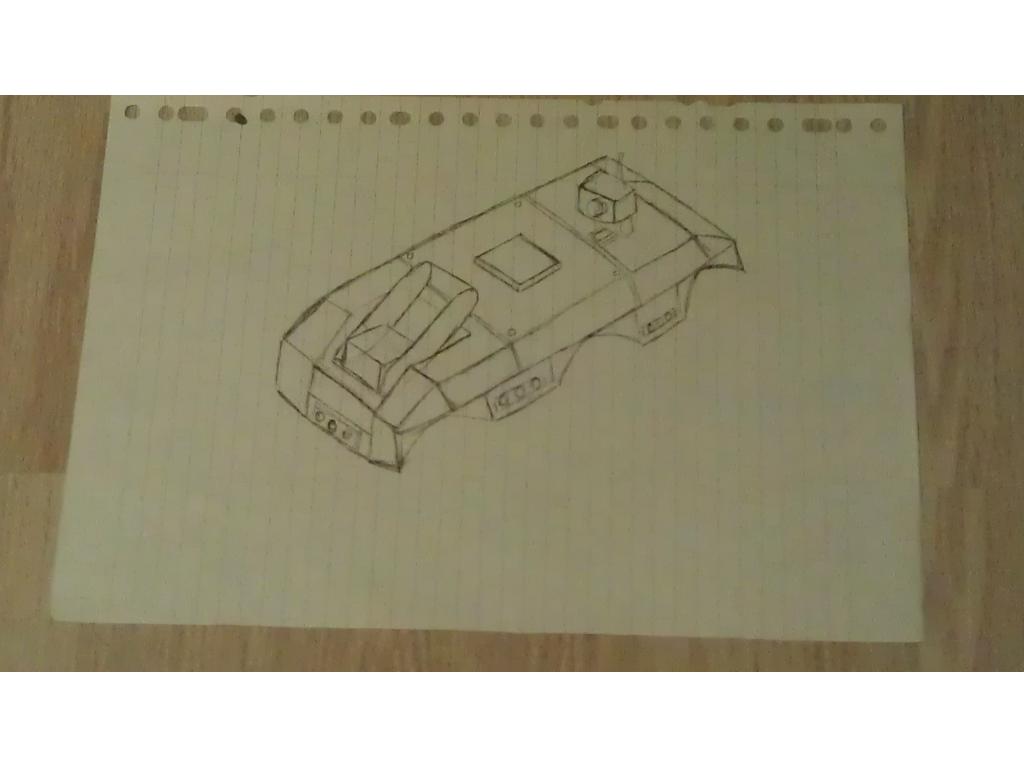

Hello fellow EZ-B'rs, As I finally discovery how to upload photos I thought it was time to share my robot with the world. It's called R.O.O.S.T.E.R which stands for: Remote Online Operating Scientific Testing Electronic Robot (took me about an hour to come up with that, but I like it).

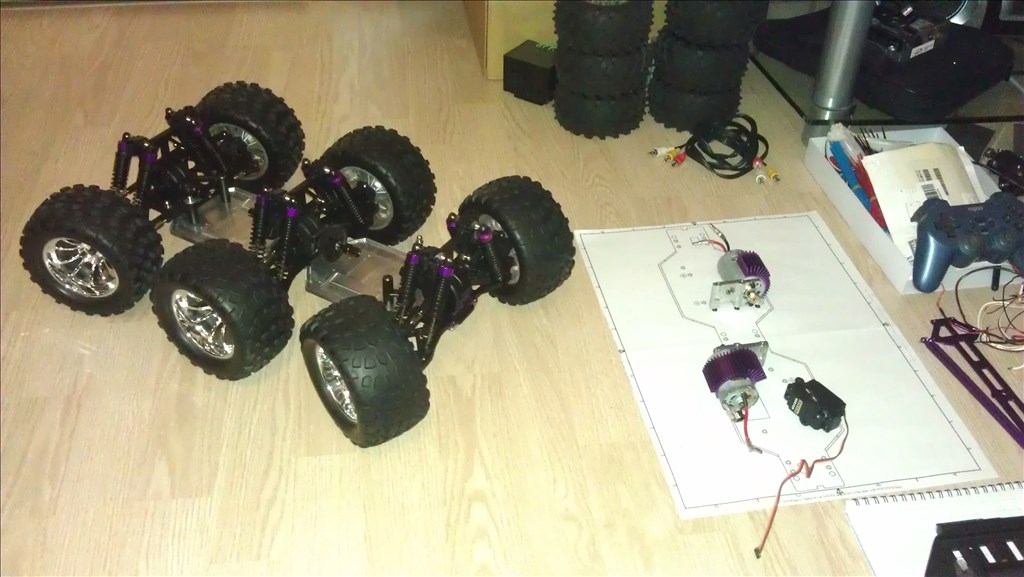

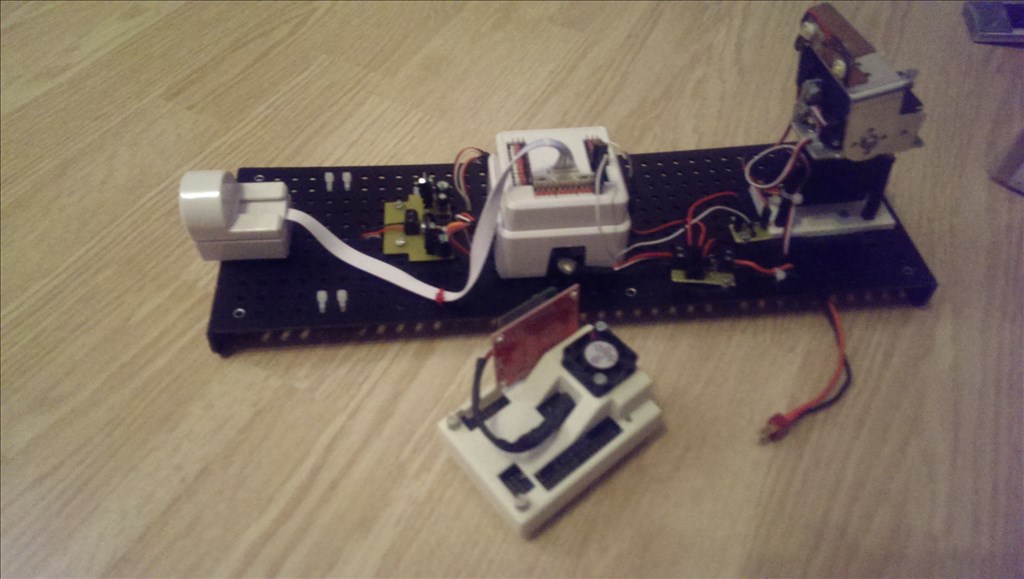

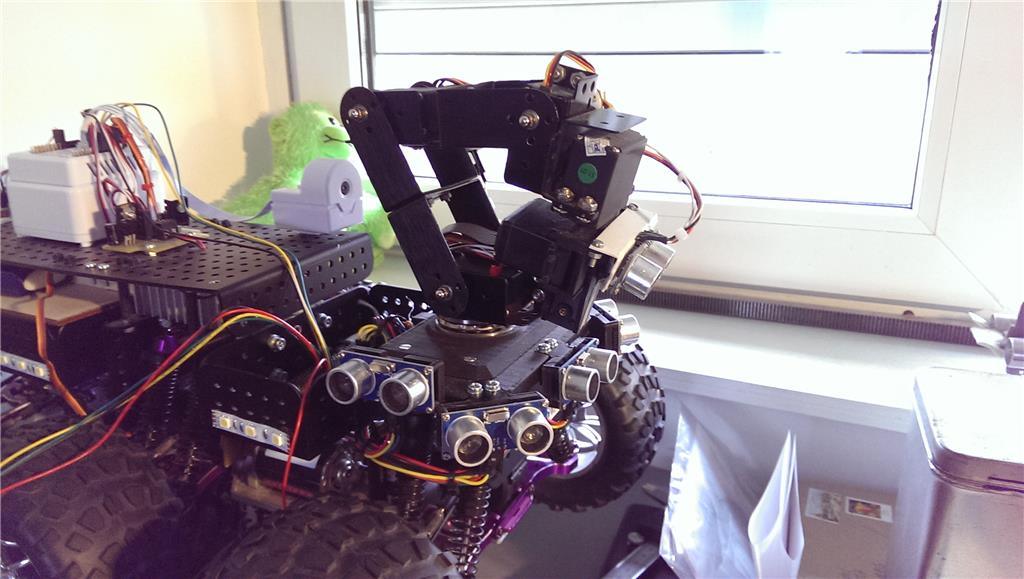

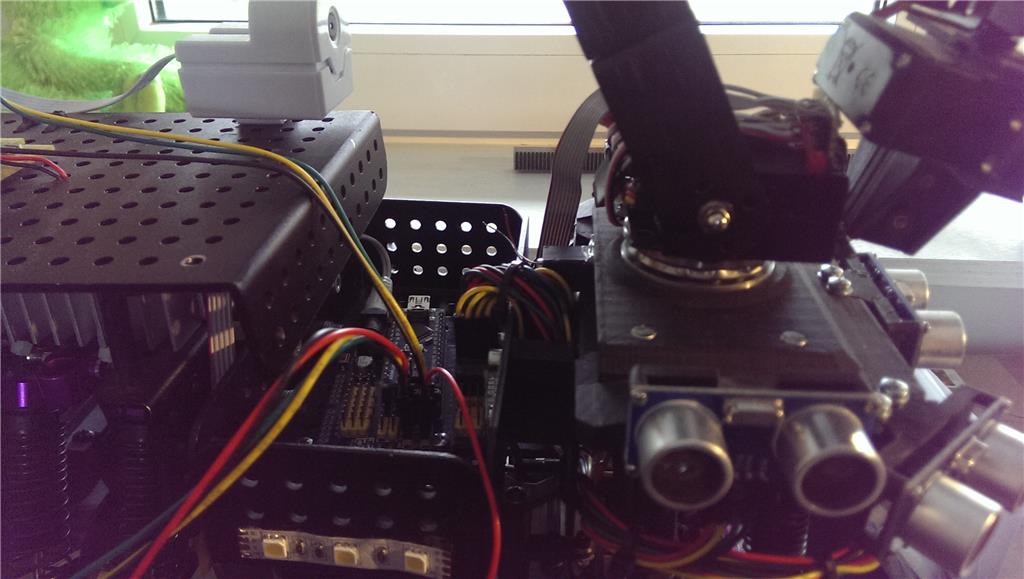

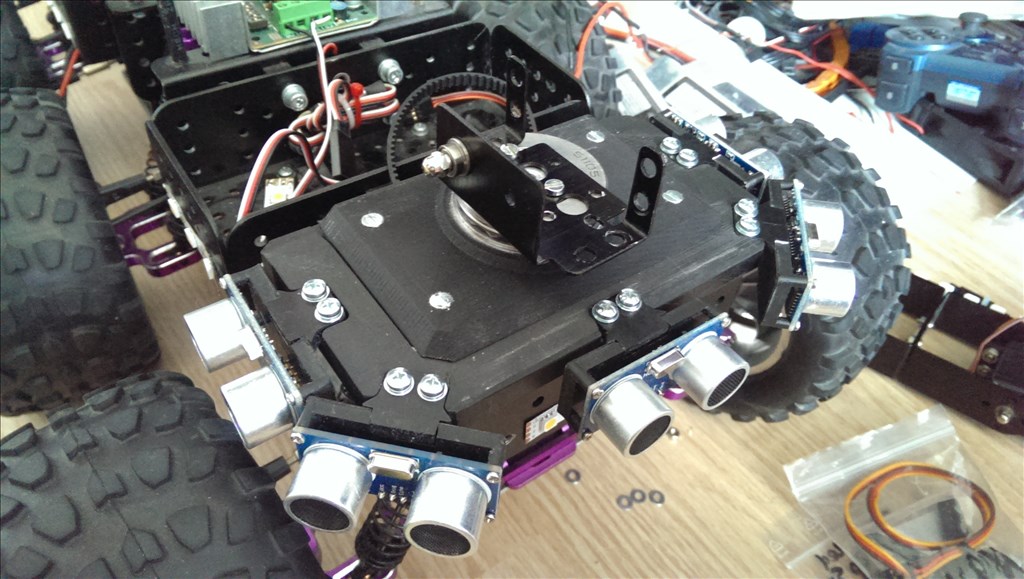

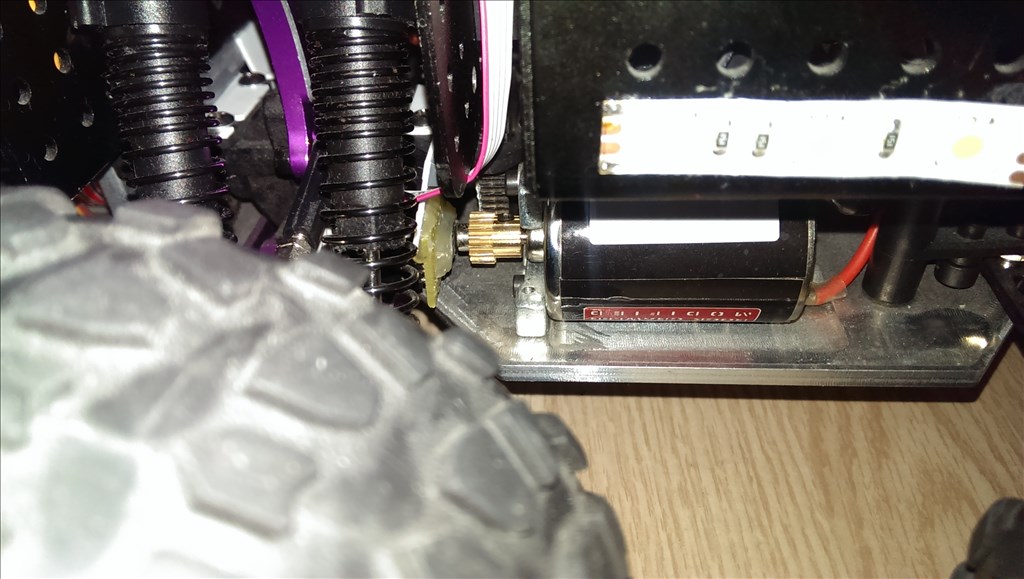

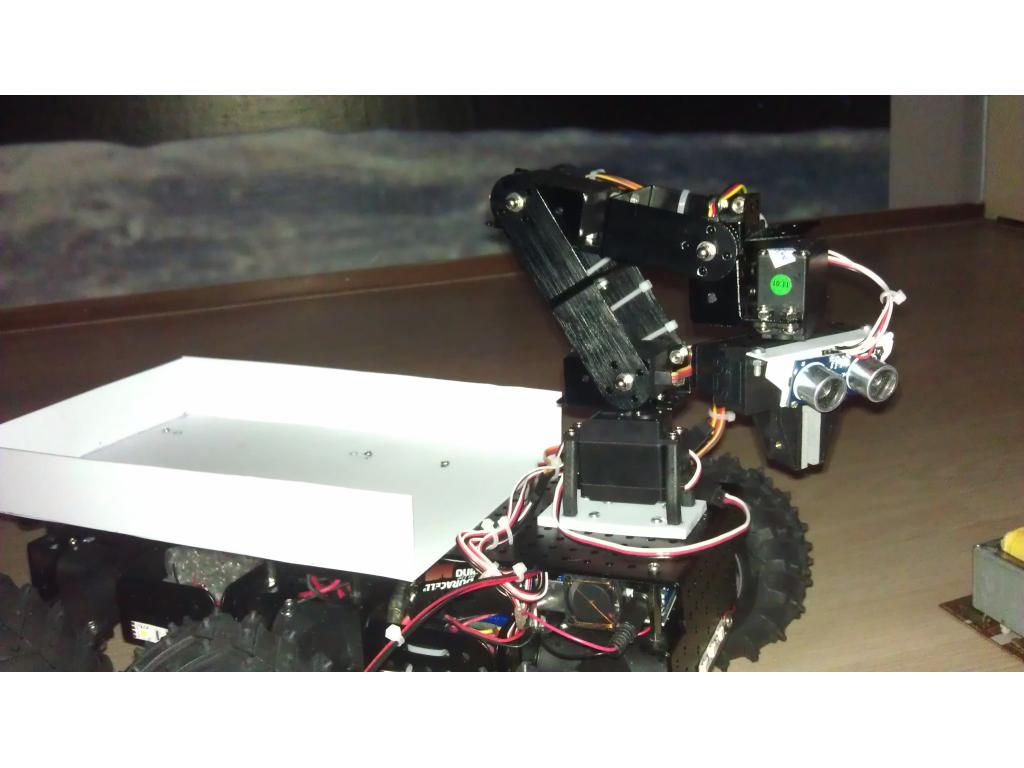

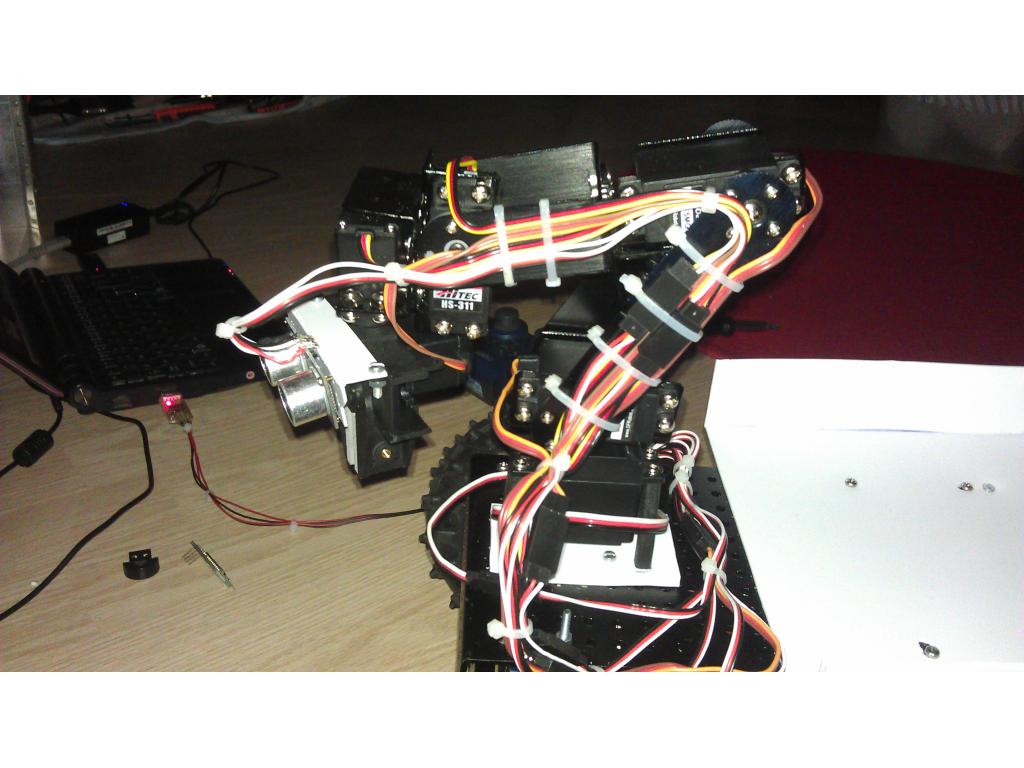

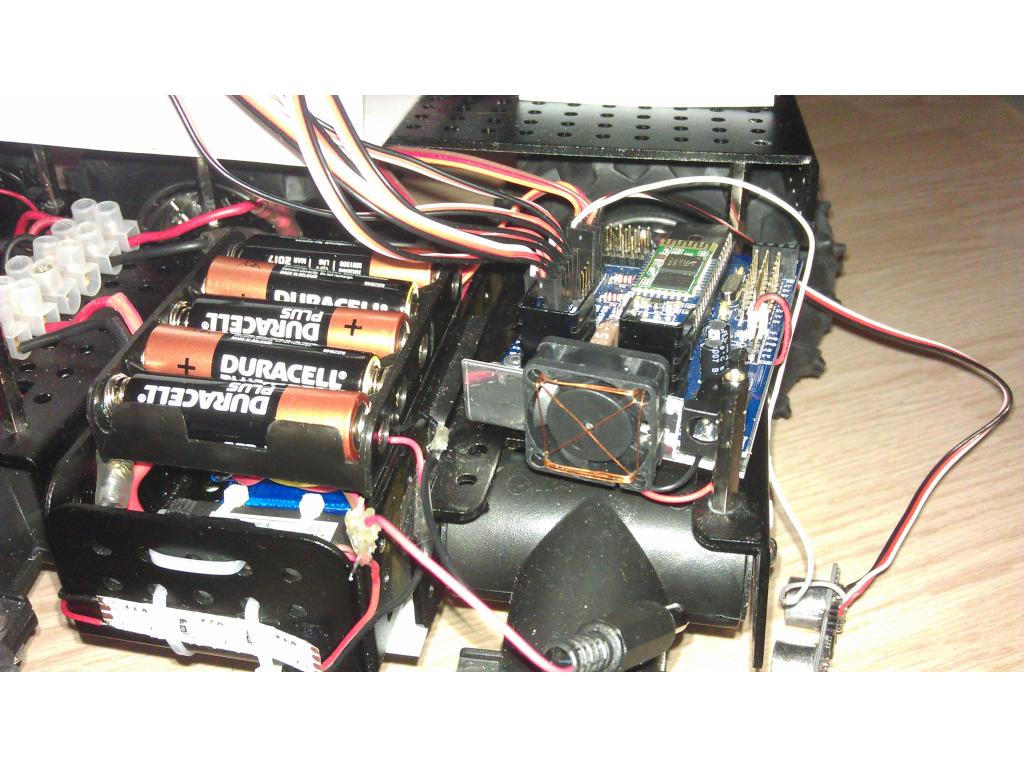

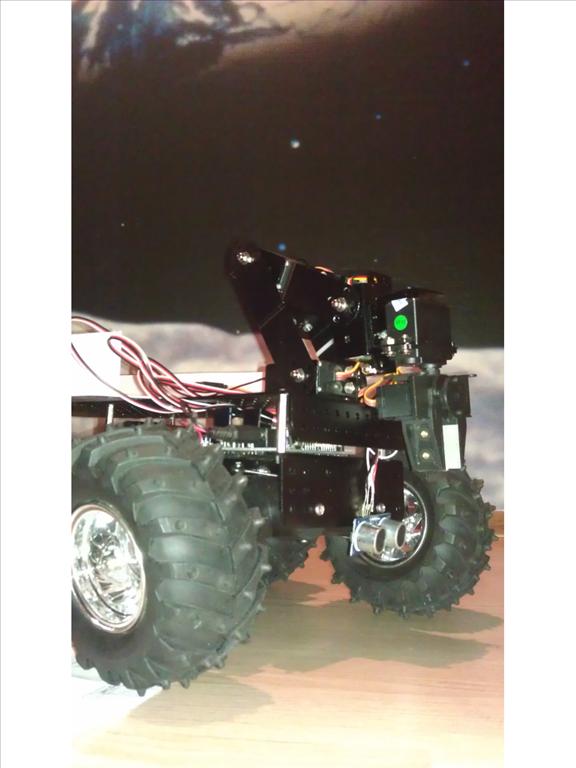

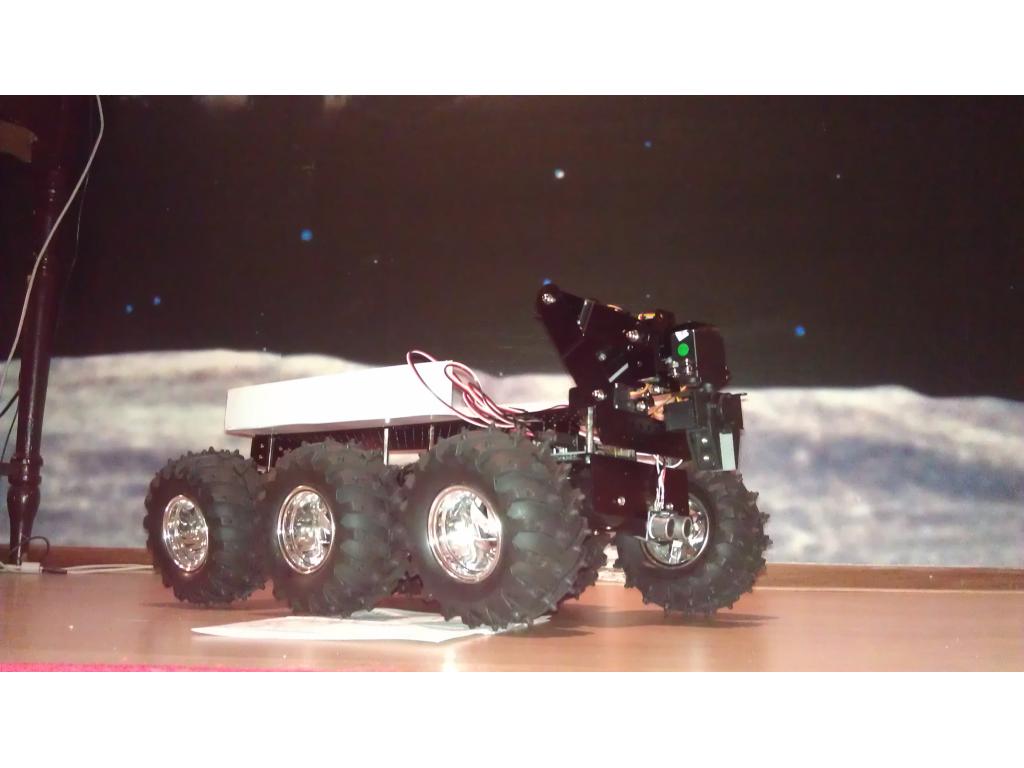

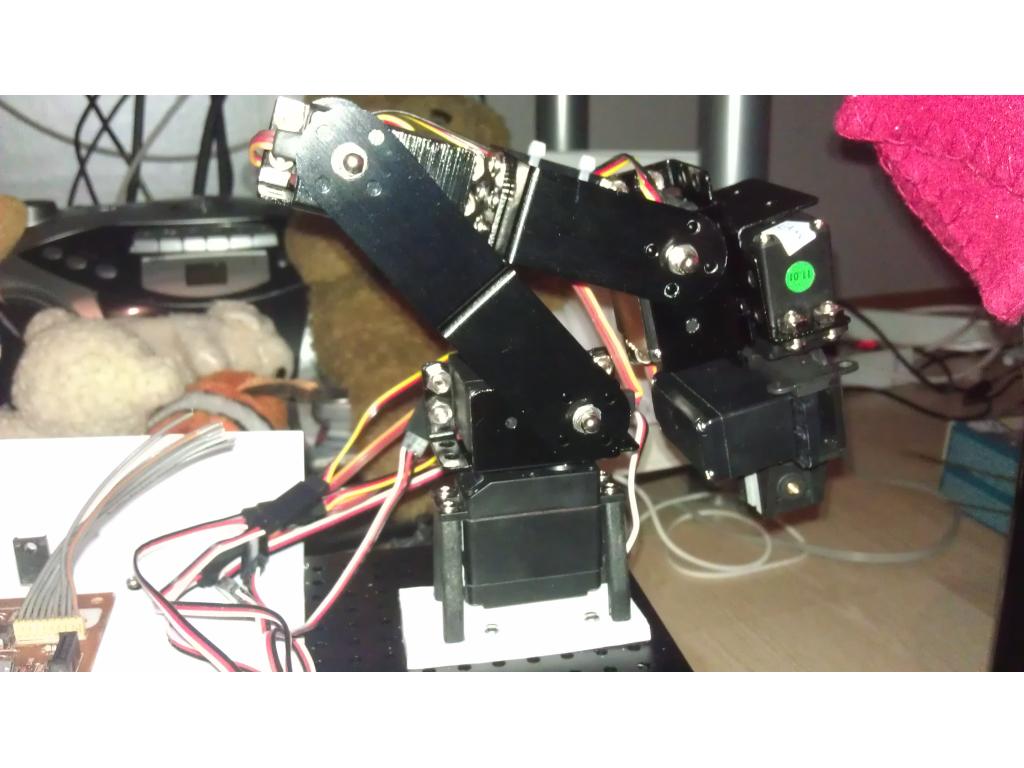

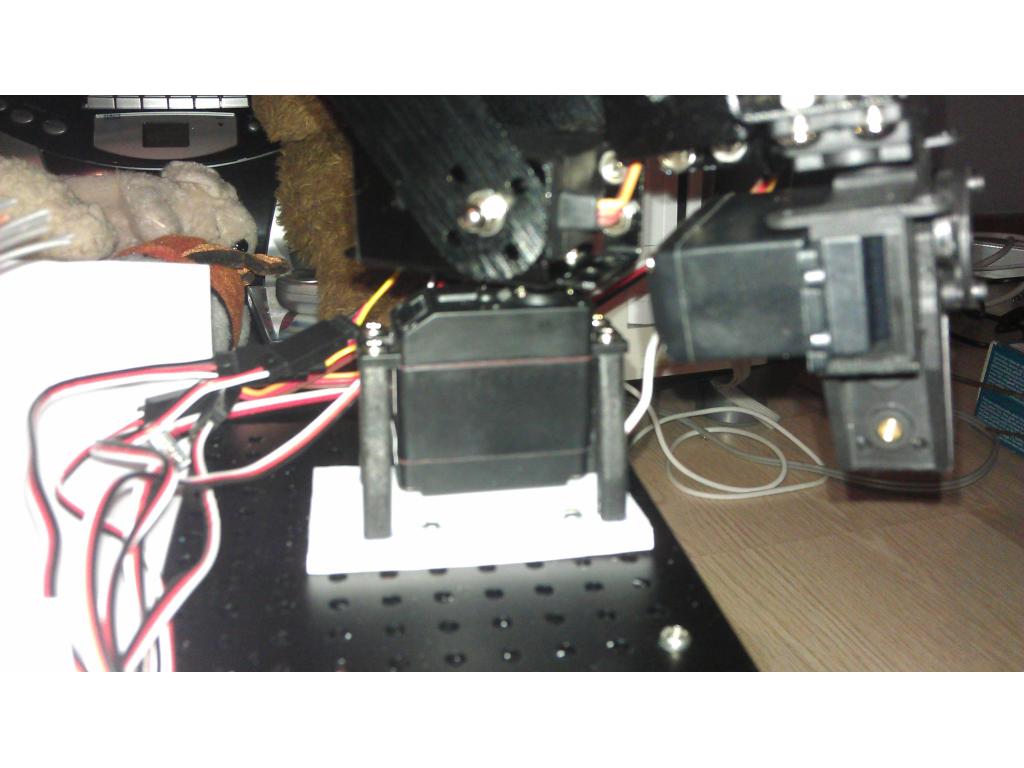

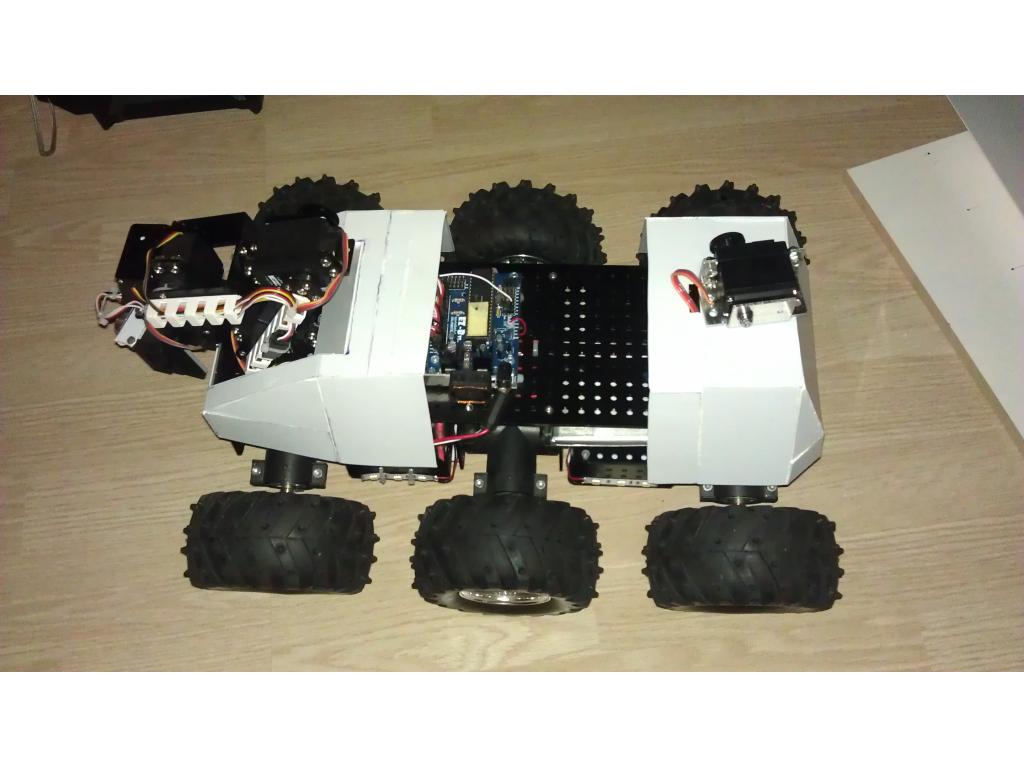

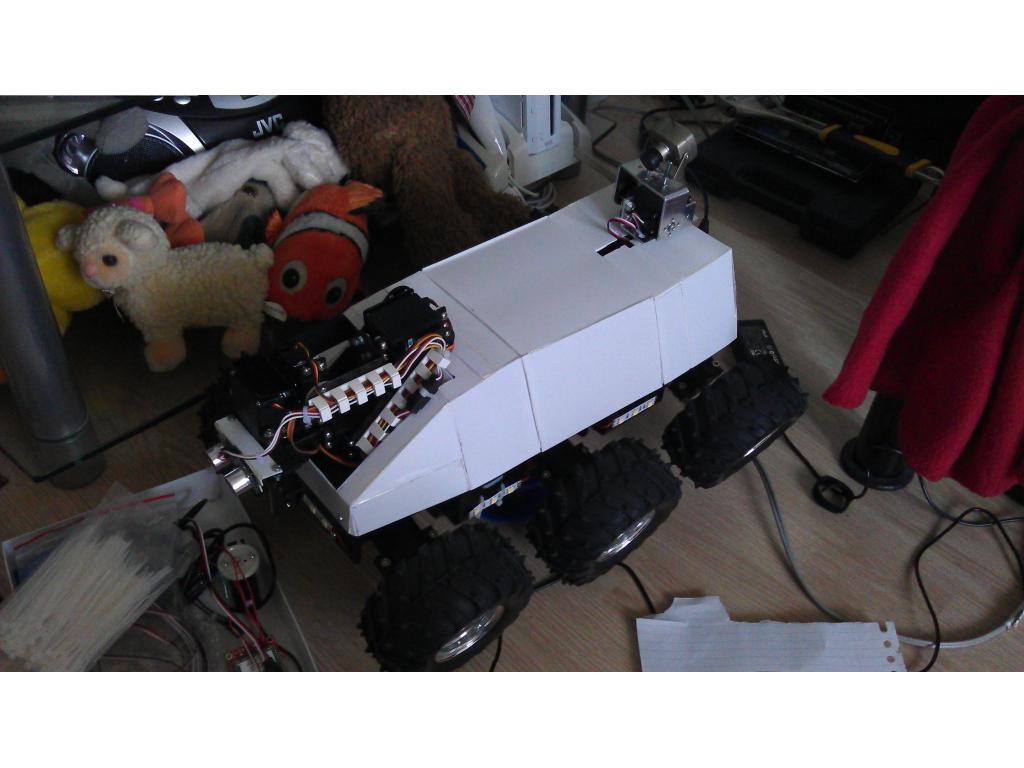

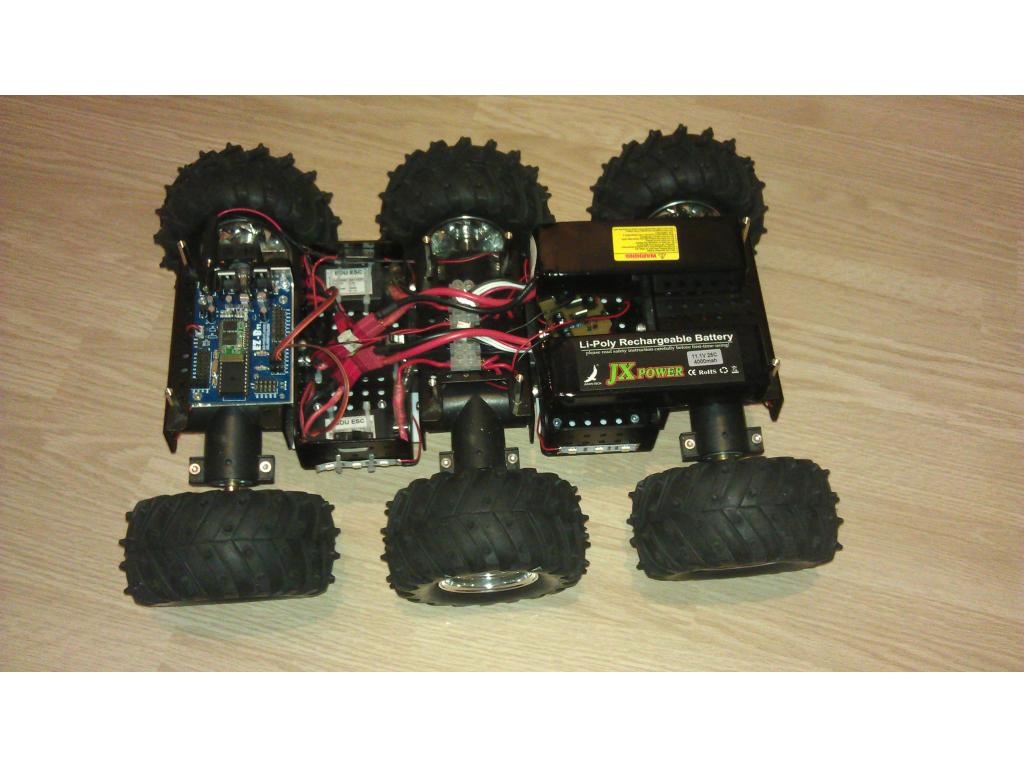

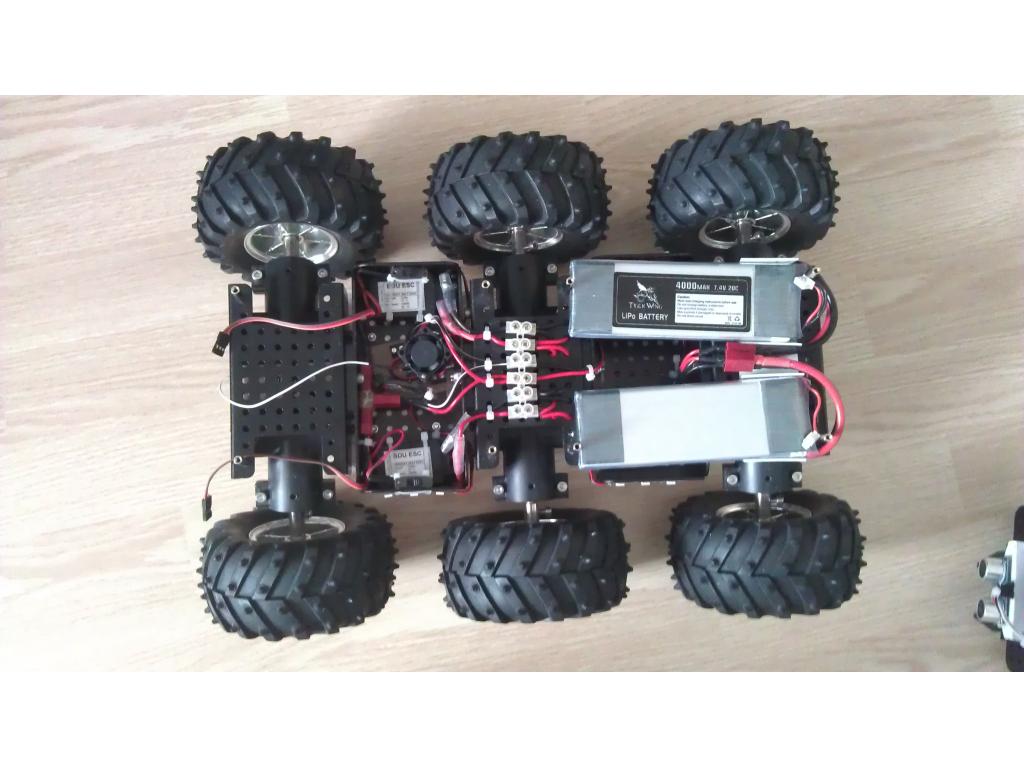

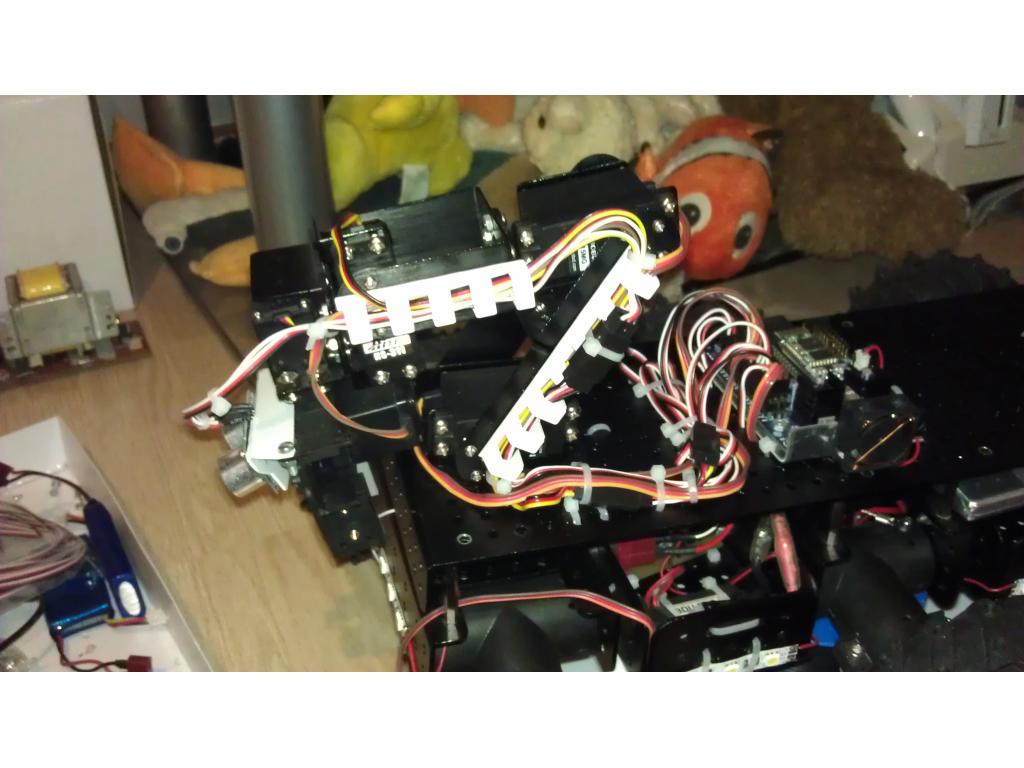

It's based on the 6 wheeled Dagu Wild Thumper kit. On top of that I added a 5 DOF robotic arm and a netbook.The specs:

- 6x 6v 6A motors

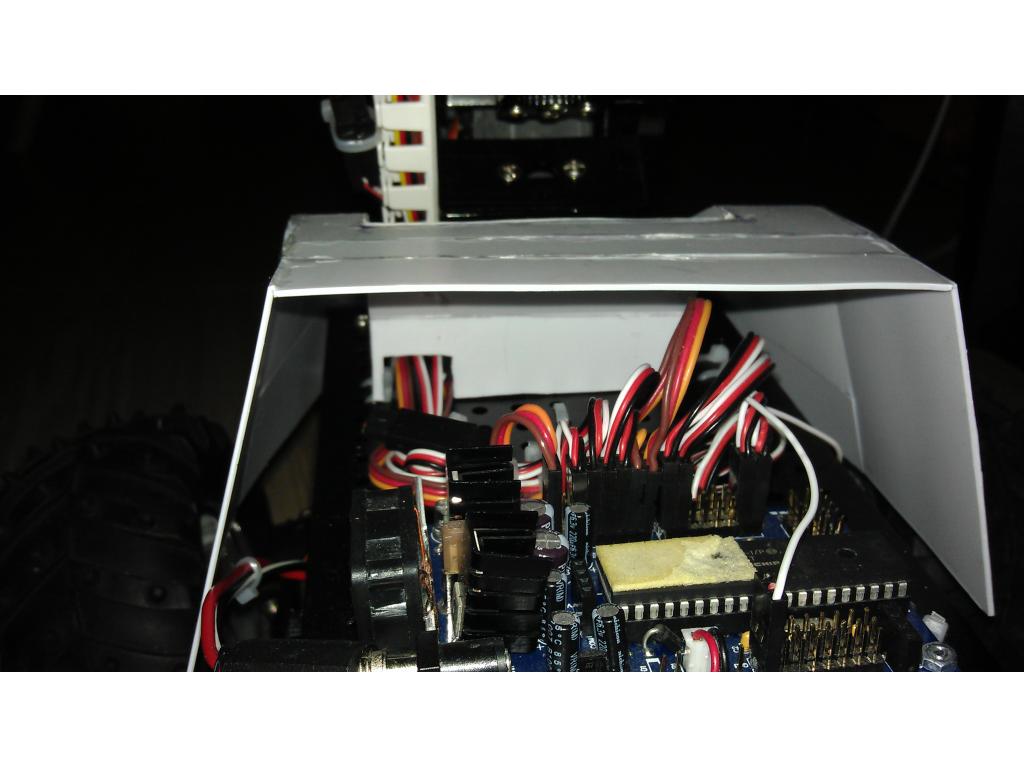

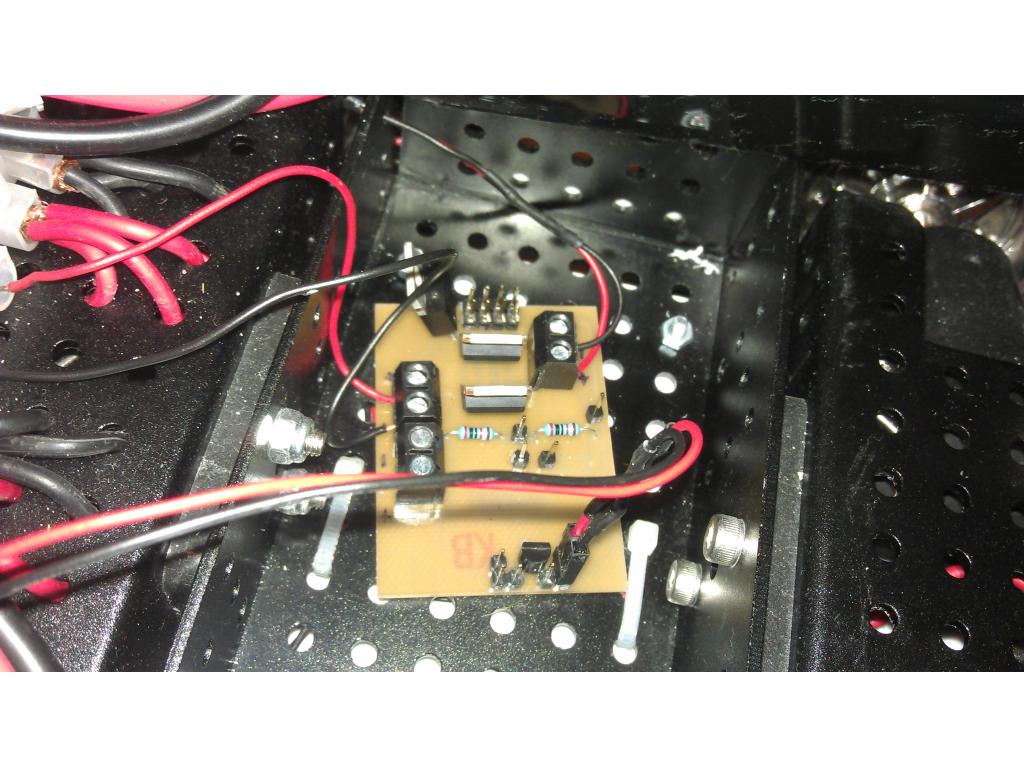

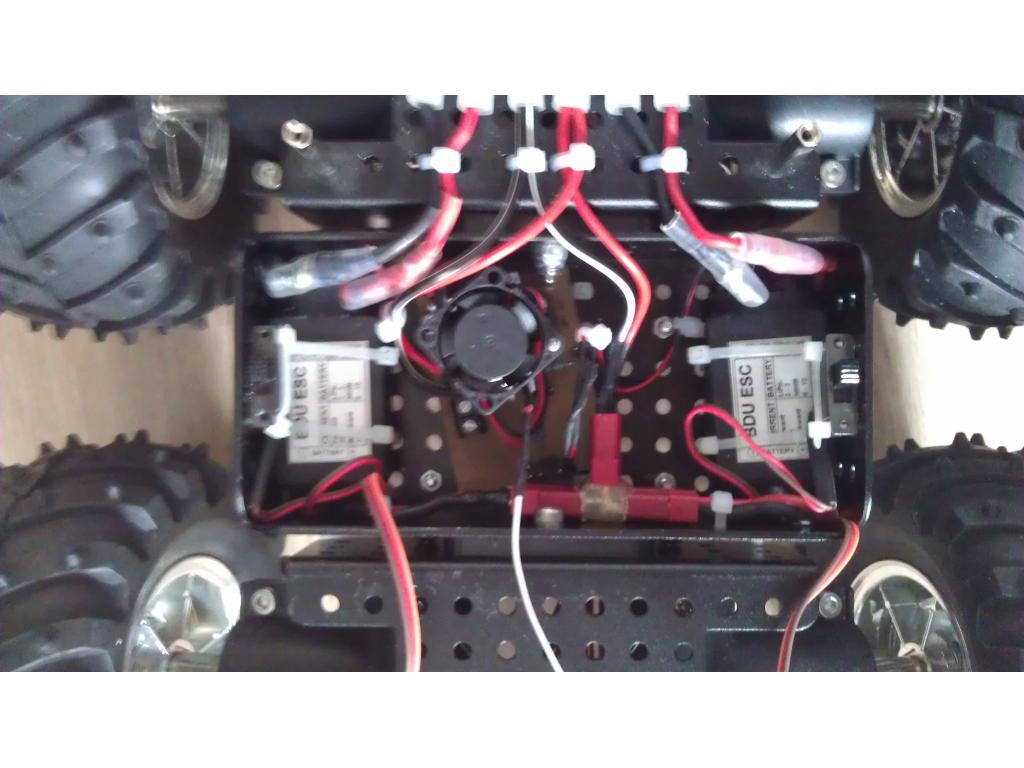

- 2x 20A Rc Car ESCs

- 2x Reddragon 2s 25c 1200mAh

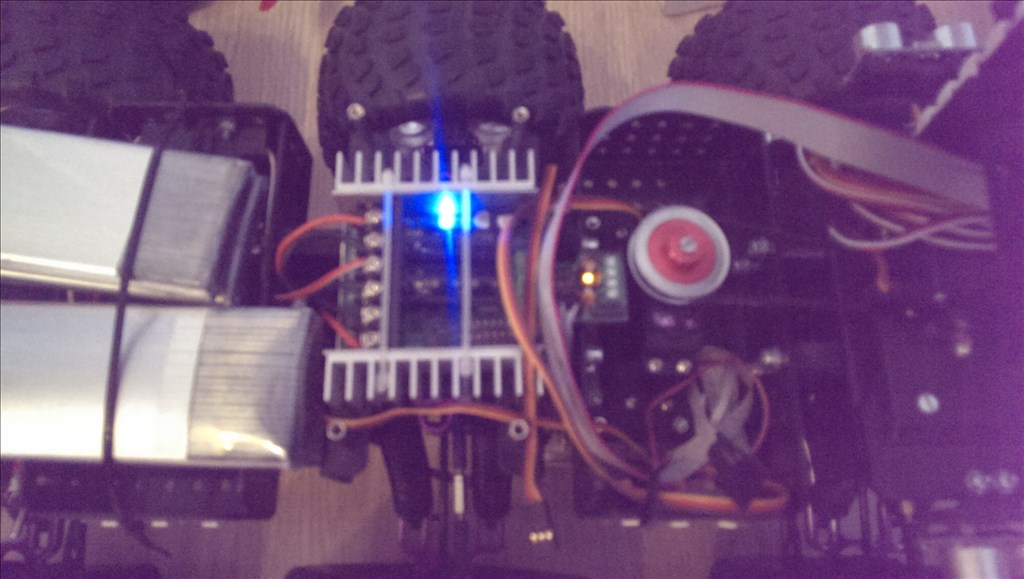

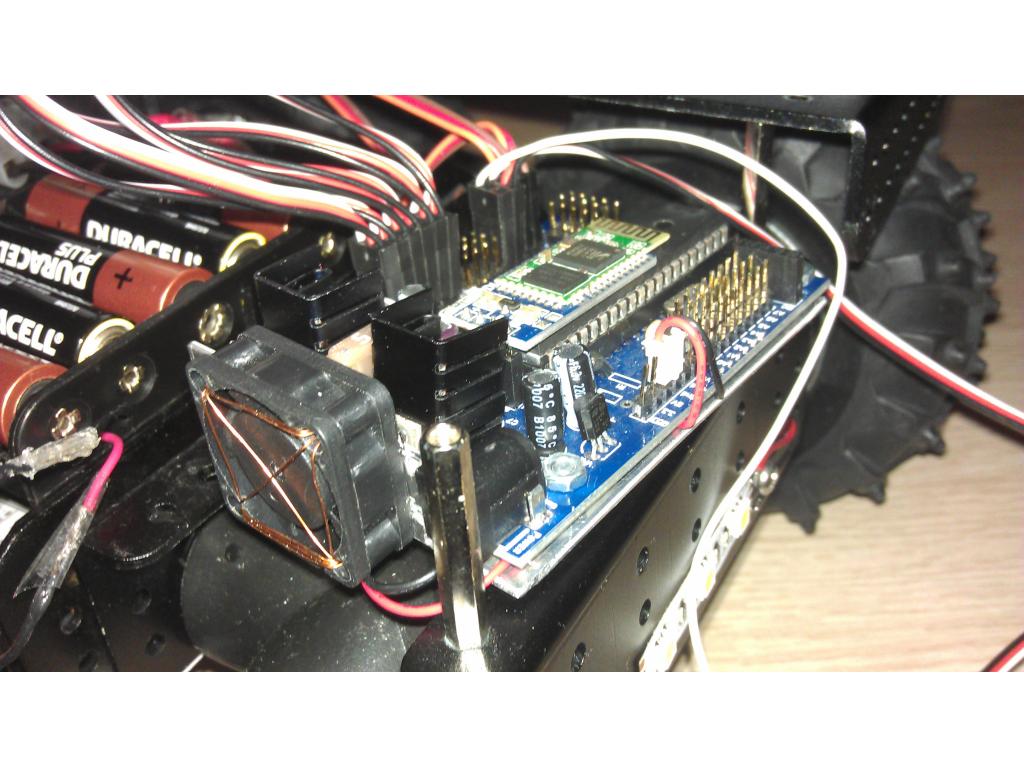

- Ofc the Ez- B

- Dfrobot 5dof robotic arm

- Asus Eee pc 900hd

- Ping sensor (well... I sort of broke it... It got stuck between the robot and the wall...)

Why I'm building it? Because I can, robots are Awsome, the EZ-B rules and I got tired of burning/shocking myself when I'm testing one of my "crazy" contraptions.

Up coming updates for robot:

- A rotationplatform for the arm.

- 2 gigantic lipo batteries.

- camera+ pan/tilt turret.

- Small rockets

- mini mini-gun

- Flamethrowler (a failed version of a liquid fueled rocket, but it's working if you call it something else)

- coilgun

- railgun

- Lots of other things I can come up with.

By budel0

— Last update

Other robots from Synthiam community

Tezsmith's My Robot Story

Synthiam ARC controls Revolution JD and Meccanoid, integrates computational algorithms, laptop/wifi and custom...

Steve's Elvis Gains An Extra Degree With Ez Robot Hdd....

Enhance 'Elvis Alive' WowWee robot: repair startup, add rotation pedestal with EZ-Robot lotiny controller and HDD servo...

Jstarne1's Ryobi 40V Robot Mower With 40V Trimmer Whiskers...

Back to building robots after moving to Chattanooga and starting a fiber optics technician role - resuming robotics...

@Ray Well I'm an engineering student, I call myself sort of a "Pro"(I have been able to draw everything I needed) with Autodesk Inventor or Solid Works, so if you need help let me know.

But when it comes to machining stuff I let that up to others, except things that can be made on the lathe, I can do that. But drilling holes is something thats just not meant to be done by me... I always endup sanding T.T

Latest update:

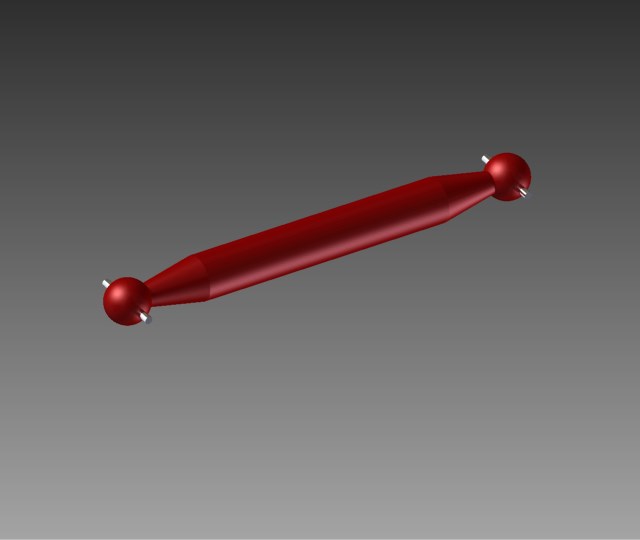

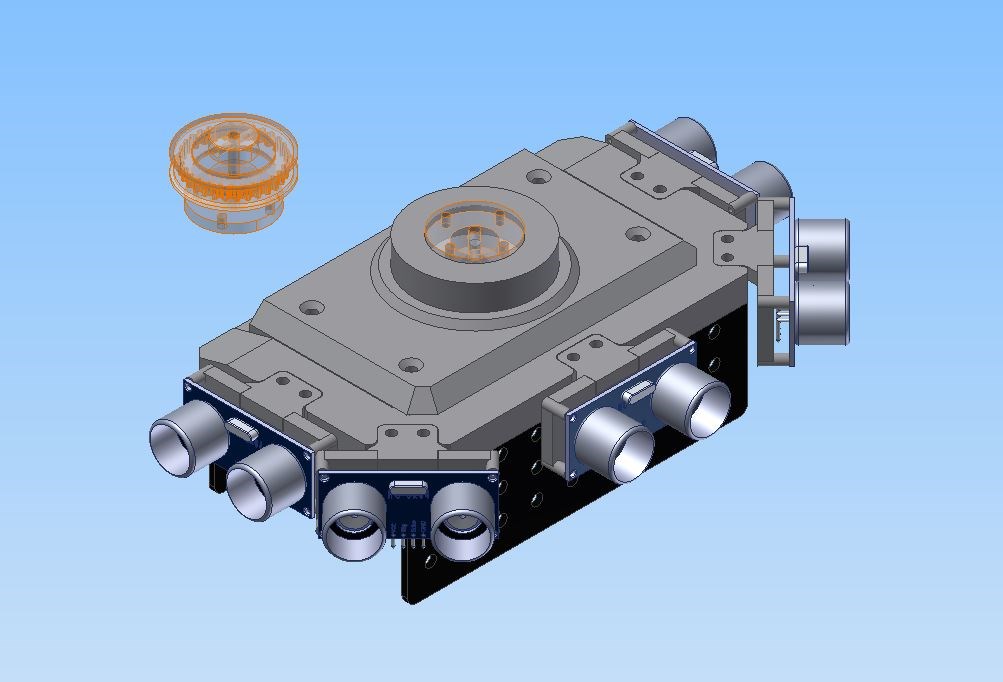

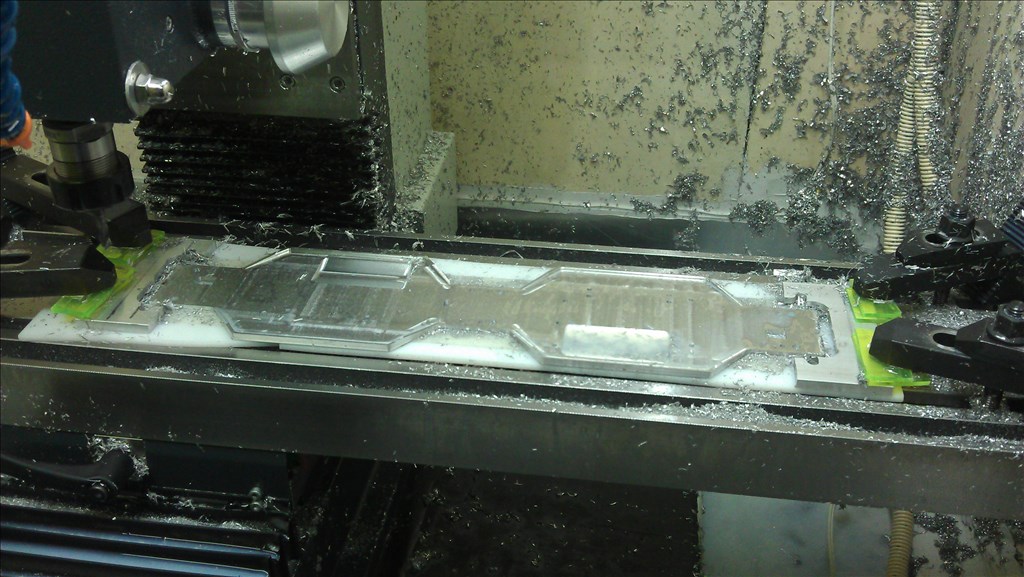

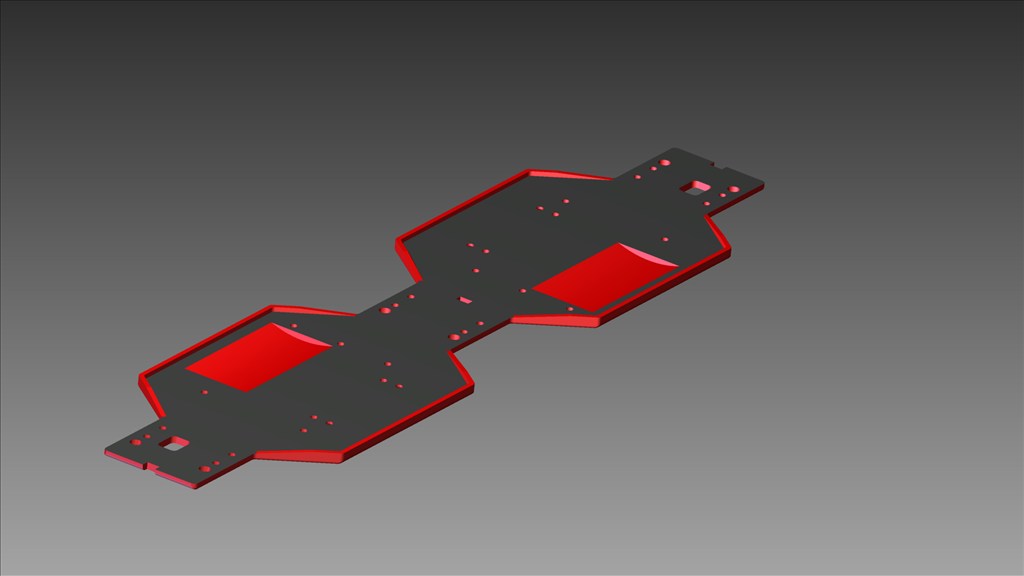

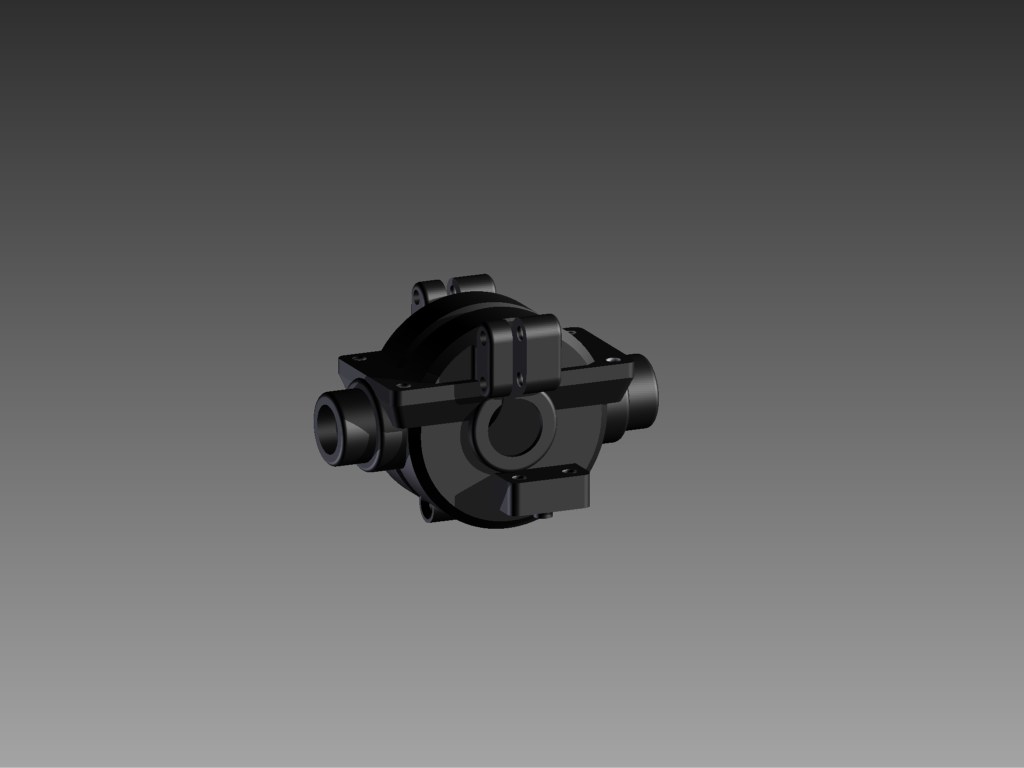

Finished up the design of the central differential. I reversed engineered it from the rear differential of one of the cars I bought for parts. I'm not sure yet how I'm going to make it, either CNC milling or 3D-printing.

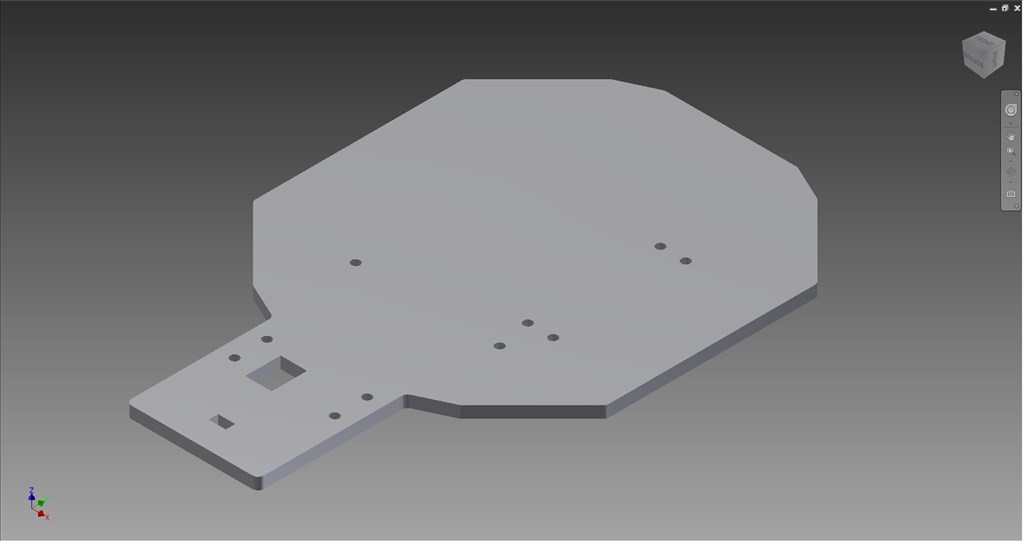

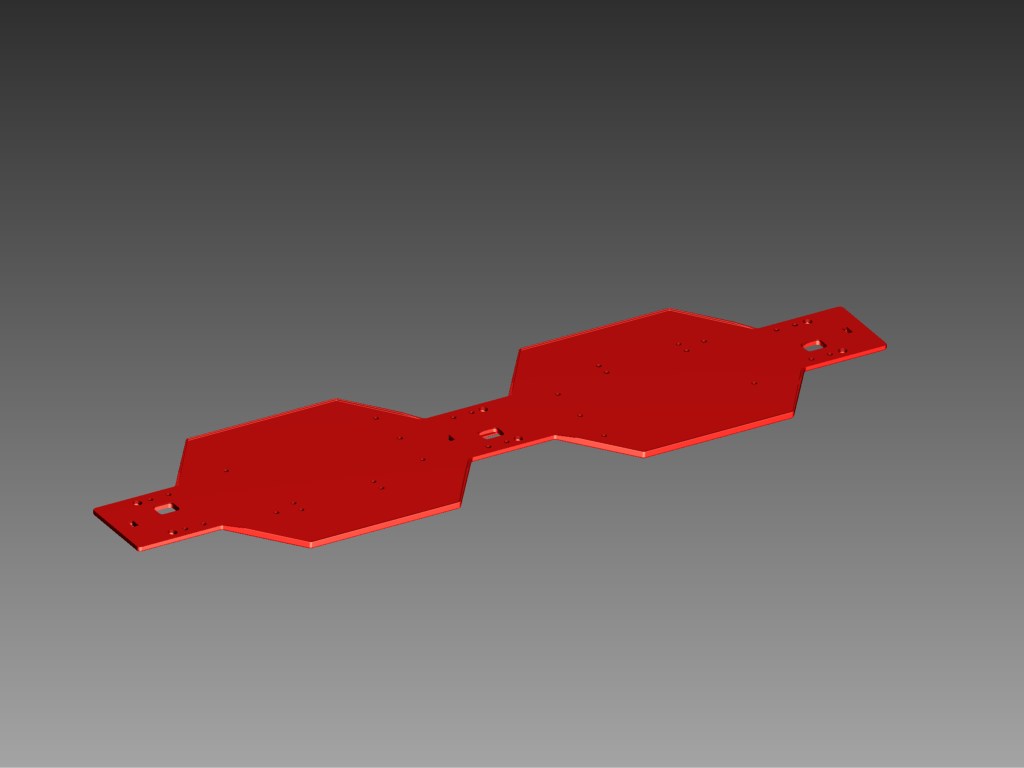

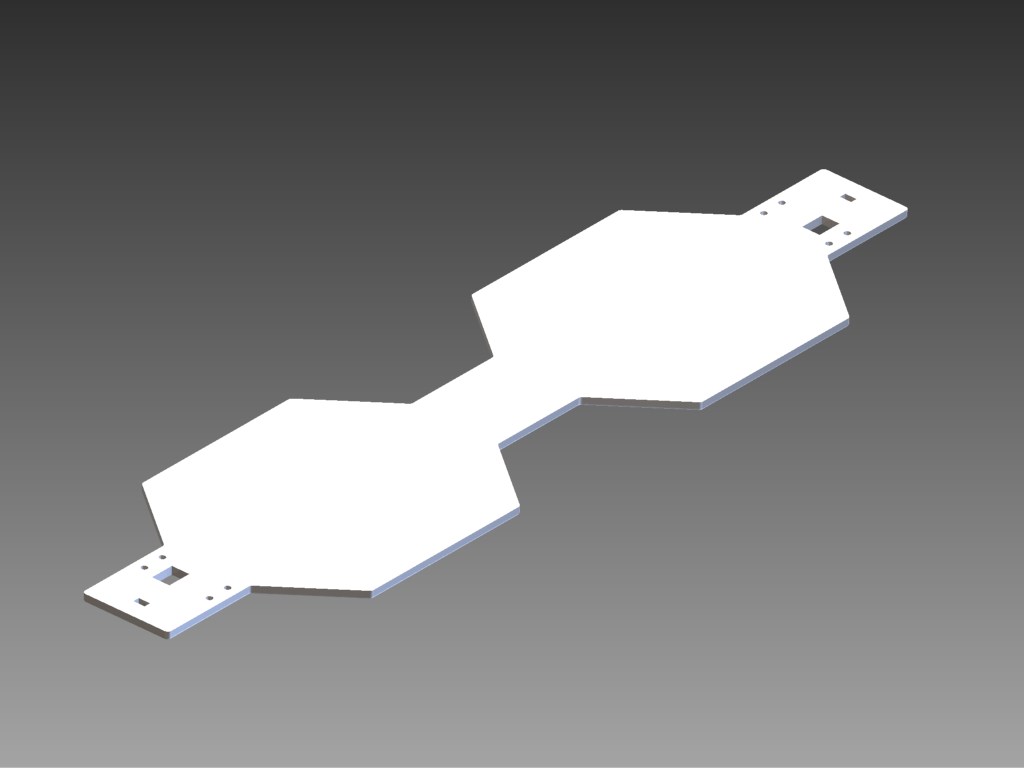

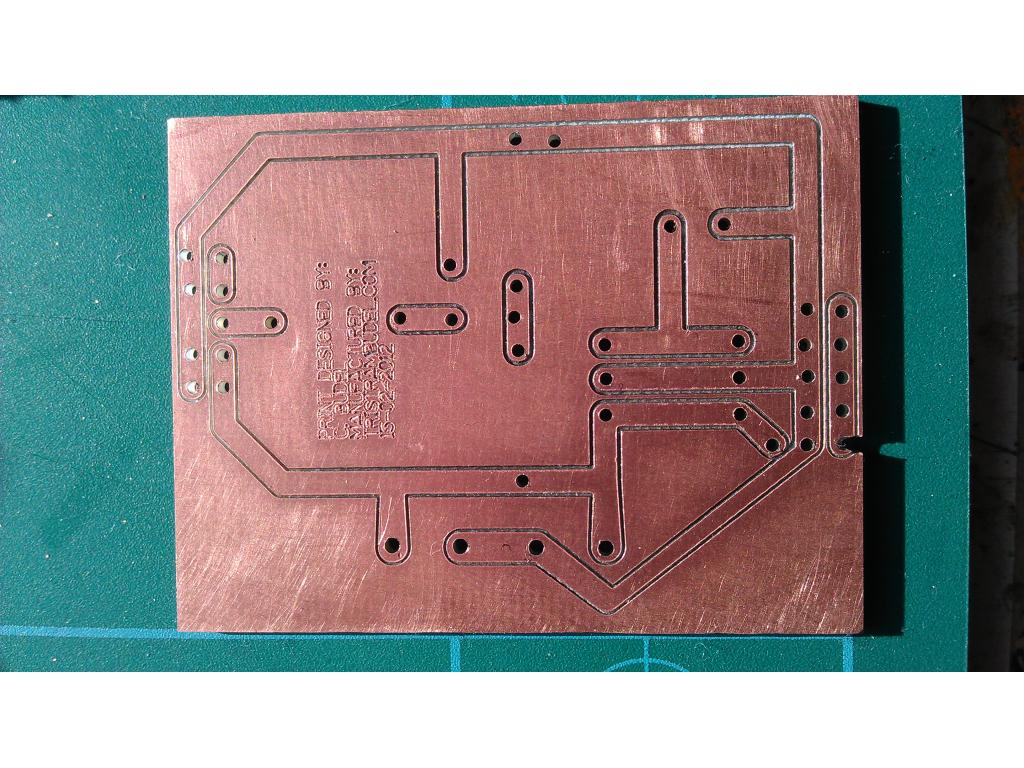

The design of the base plate is almost finished, still have to do a final check if all the holes match up with the existing parts.

To be continued.

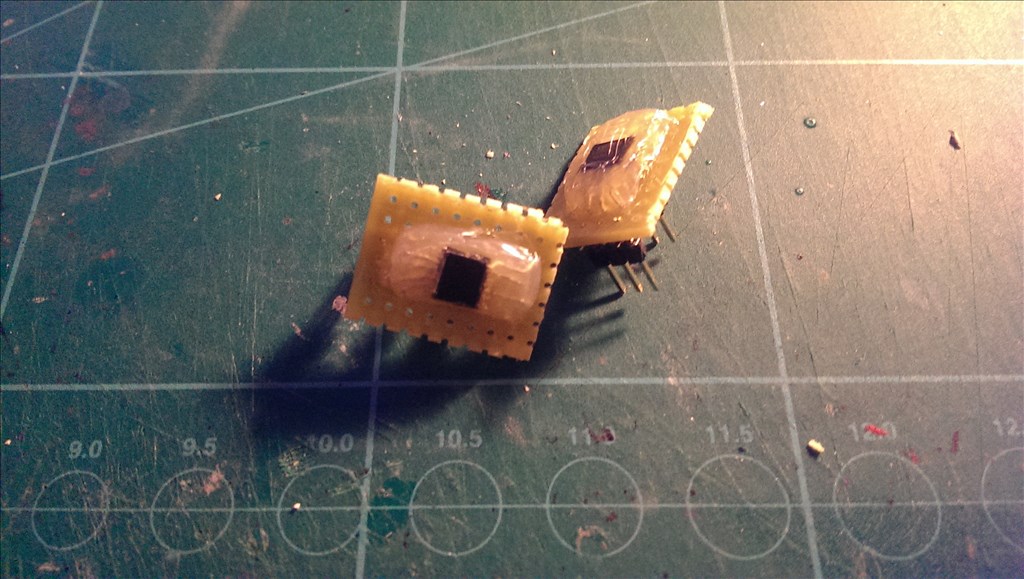

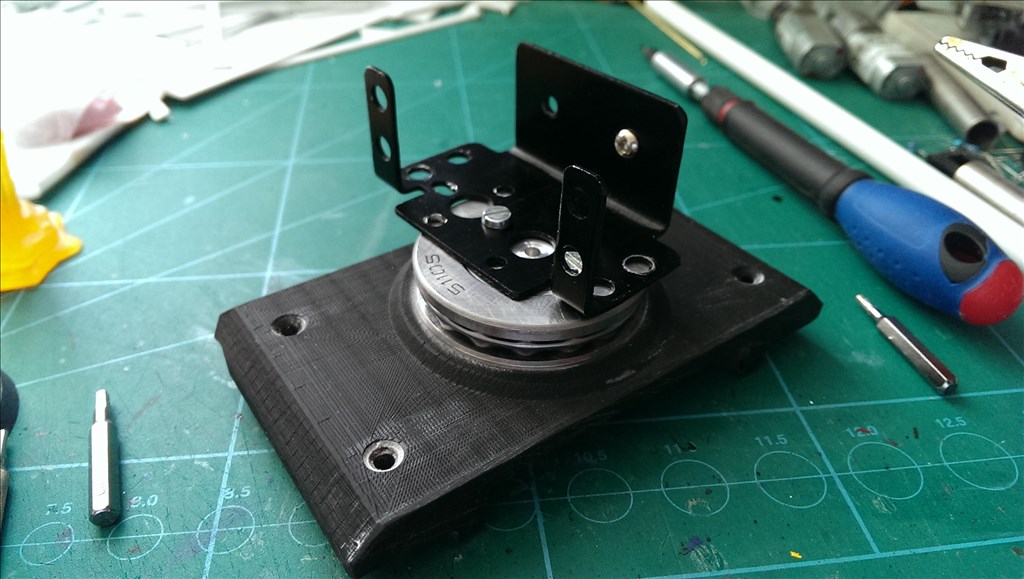

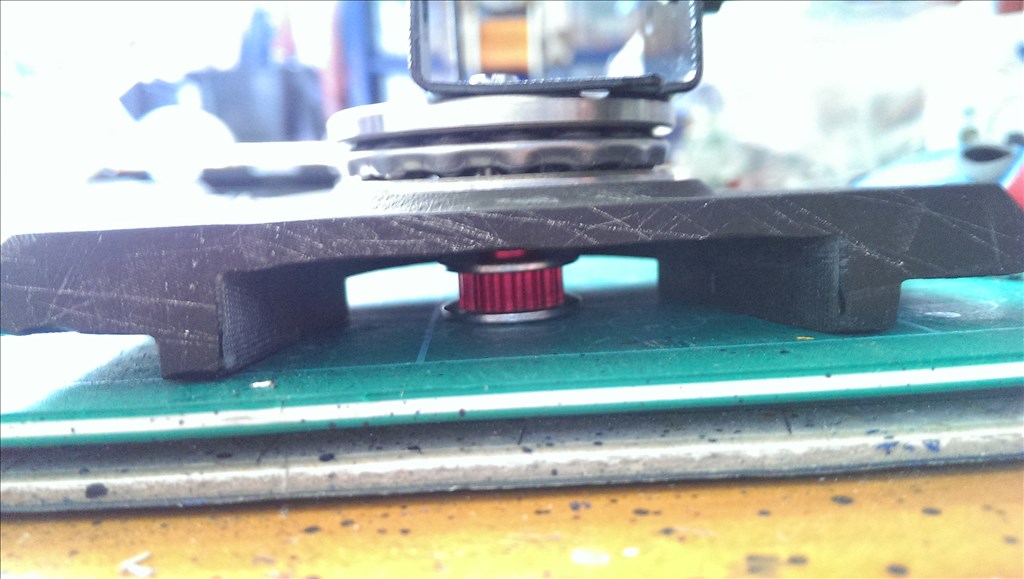

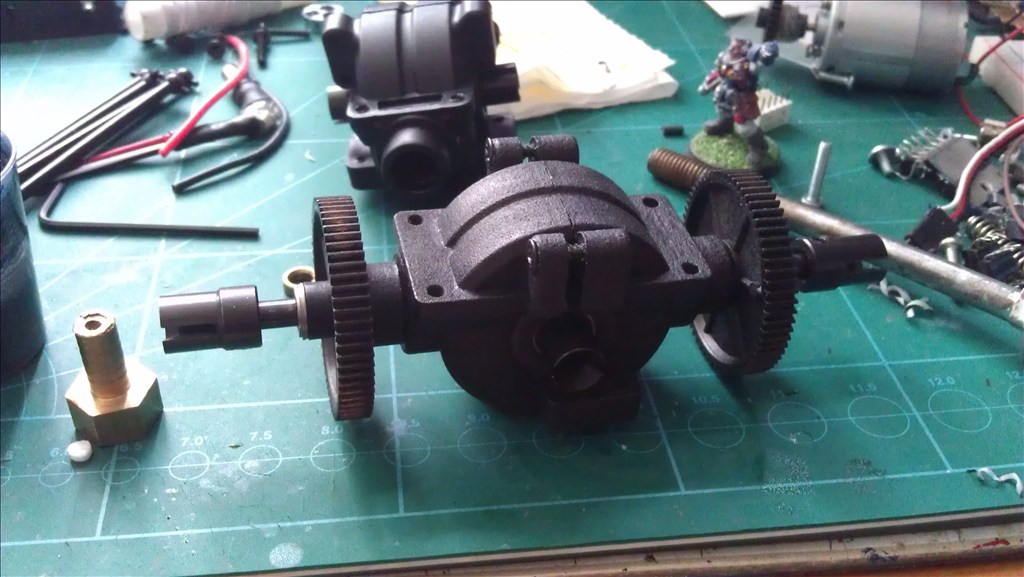

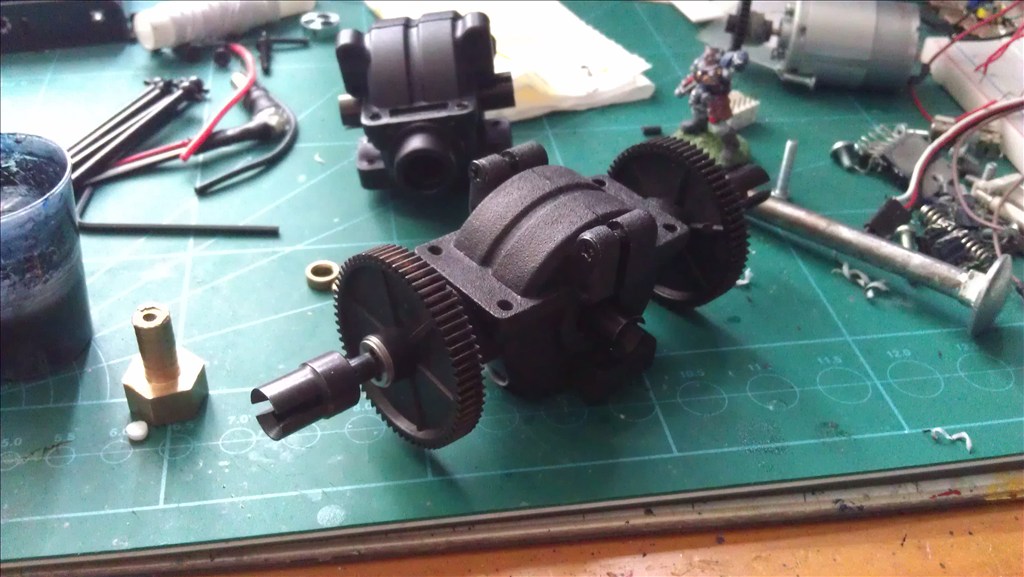

A small update on the project. Got my dual output differential housing from shapeways. I decided to 3D print it.

Only need to make a few adjustments to it, paint it and then it's finished. Once thats done I can finish the baseplate design and get it manufactured. After that Phase 1 is complete

Will be watching

Incredible, you could easily make a robot hand with this printer, I have seen some designs to download.

Are the parts that are 3d printed very strong? How did you design the differential? Did you just send them a part and they copied it?

@jstarne1 It should have a tensile strength of 48MPa / 6962Psi (48N/mm), it's made of laser sinthered nylon. But after I've painted it with an acrylic paint it should be stronger. Now its completly poreus. If I would fill it with water, it would slowly leak.

As for the differential itself, I designed it based on the existing differential. Started with a caliper in one hand and the existing differential(the black one) in the other and measured everything. Well actually I was designing and measuring at the same time, took about 3 hours to design. I usually design my parts in Autodesk Inventor or Solid Works, I used Inventor for the differential.

Once I checked all the dimensions I converted the file to an STL file and send it to ShapeWays. Note: always check the unit where you are converting your file to, I had a conversion problem and it ended up with a model 10x smaller (they couldn't print it) but everything worked out after a few e-mails and new converted parts. Got my parts in about 4 days, which is pretty quick, so I will order other things there aswell when I need them. They aren't to exspensive, you pay a standard startup fee and the rest of the price is the volume of the required material.

That's really cool. I should get solid works