Introducing Questor.

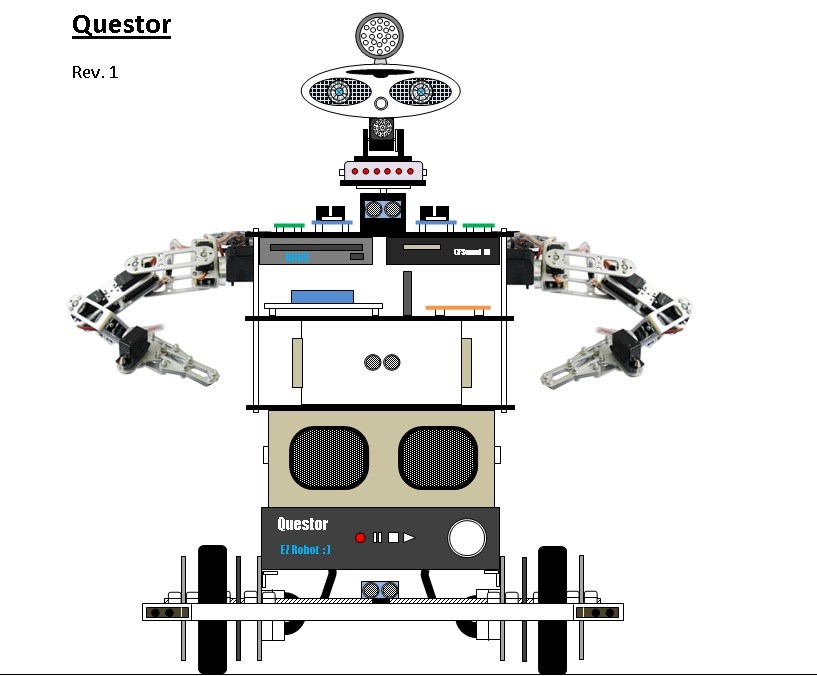

I put a hold on my large robot project Magnus awhile back due to budget and time constraints. I wanted to have a platform that was way smaller, easy to modify for testing purposes and small enough to roam around inside the house autonomously. Questor will serve as a test platform for systems that will eventually be placed in Magnus. Questor was not intended to be a cool looking robot platform, just functional and very basic in appearance. My main goal is for him to be autonomous with the option of me being able to take over remote control separately if needed. I would like for him to be able to automatically find and connect with his battery charger and to eventually have a good A.I.

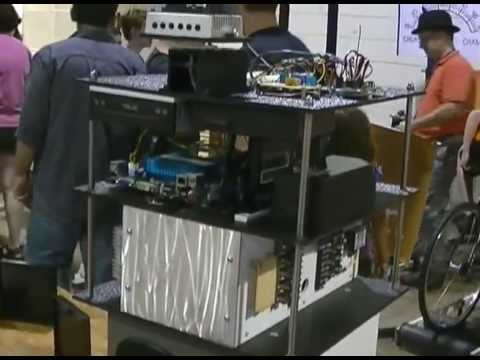

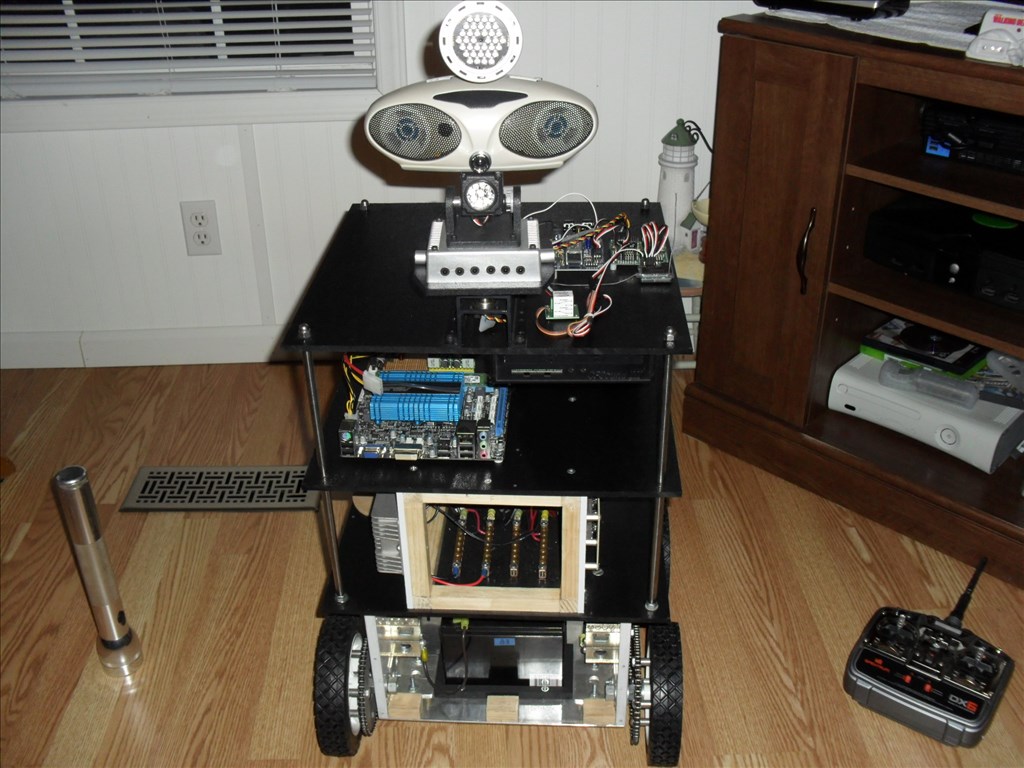

So here is a first look at him...

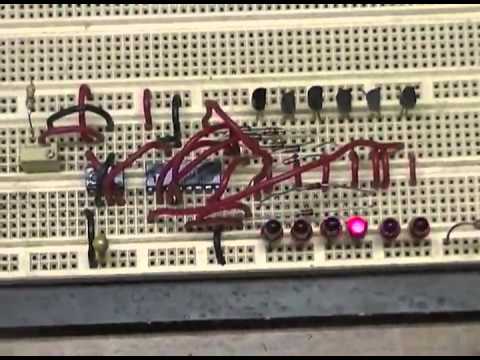

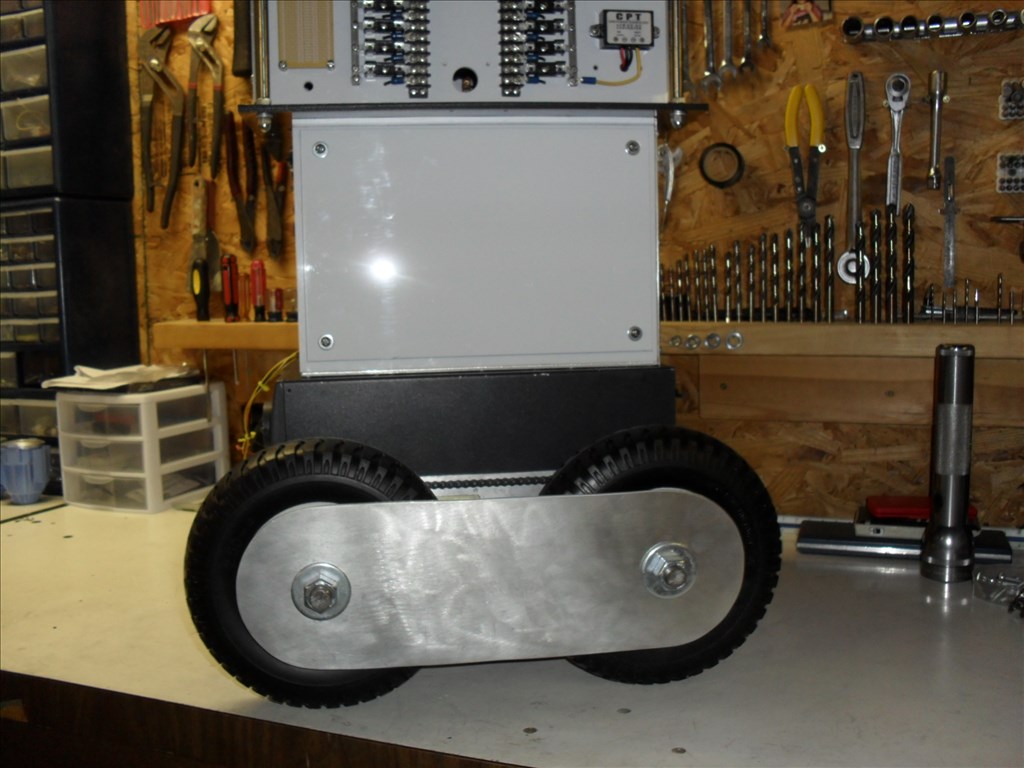

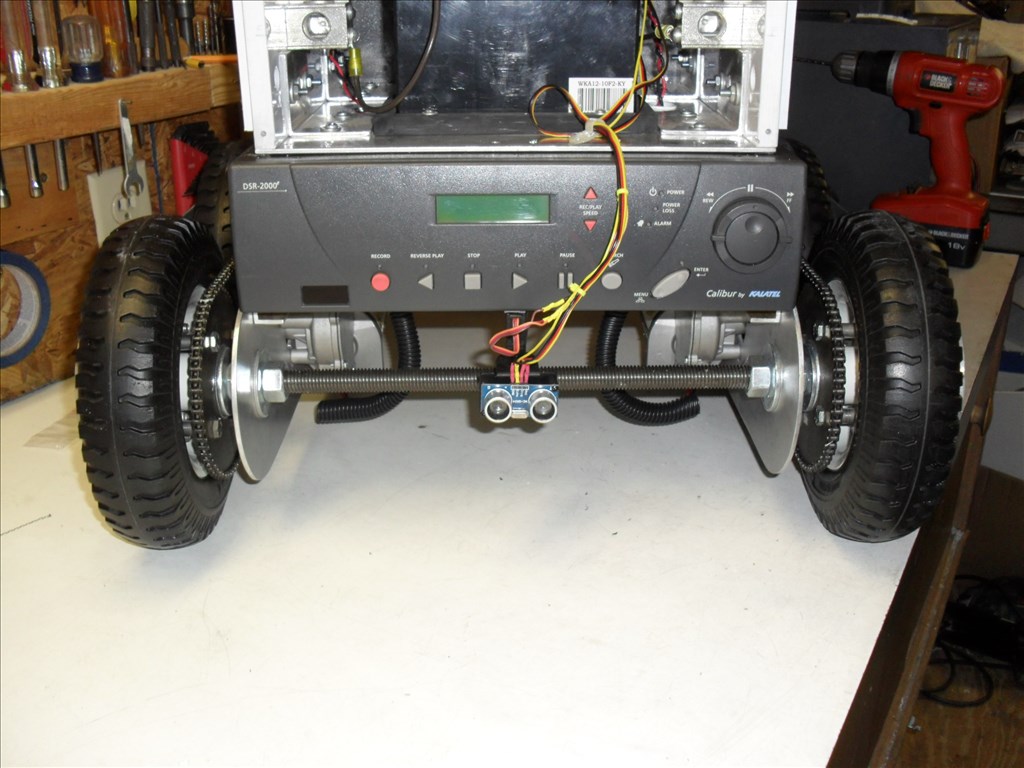

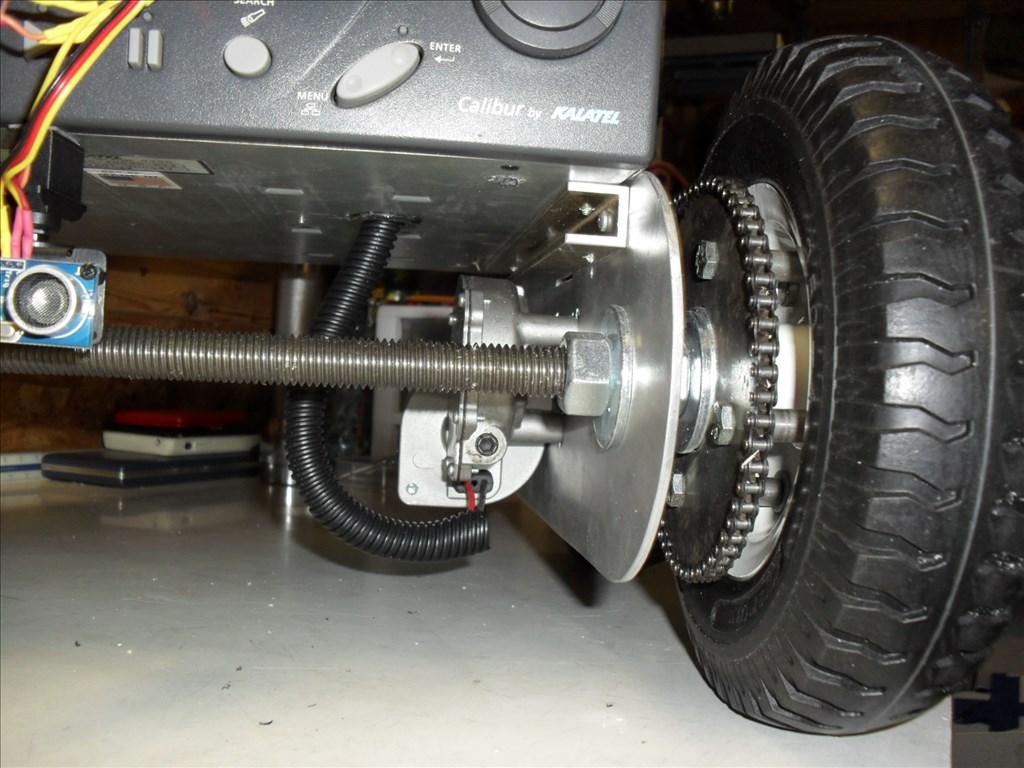

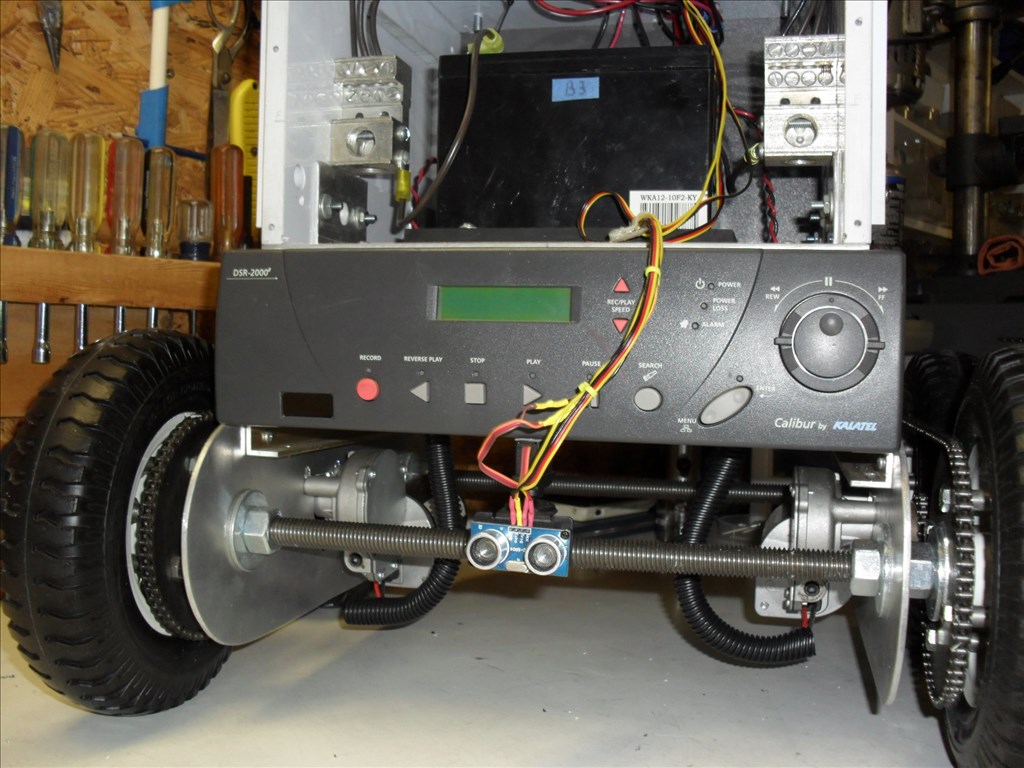

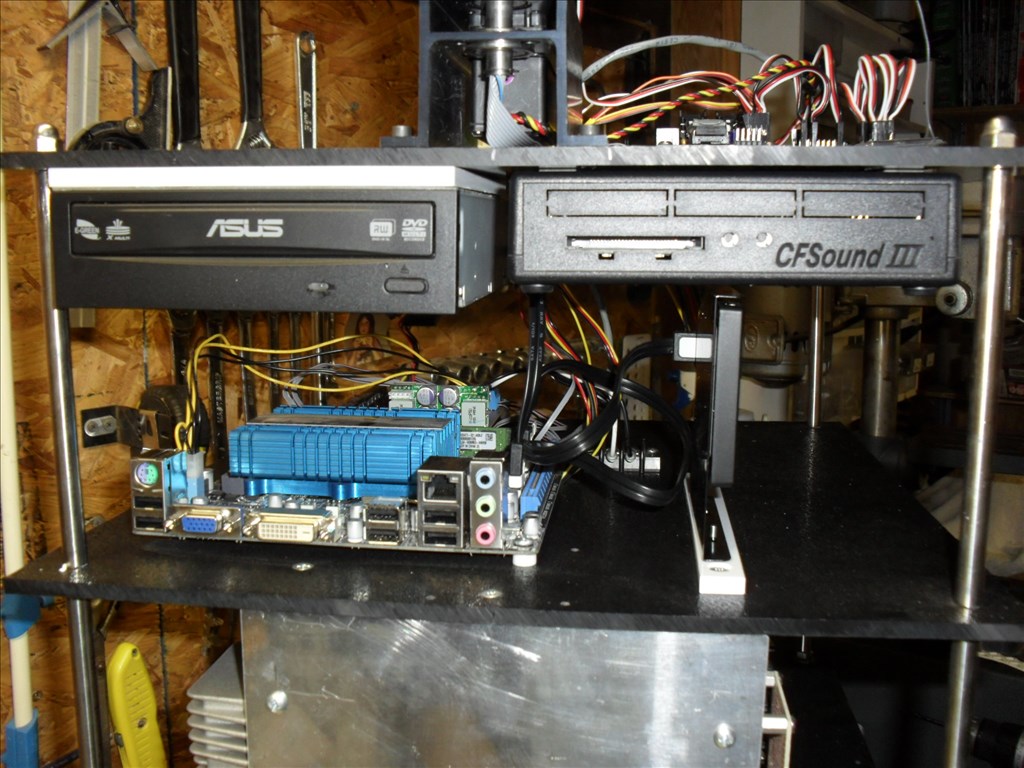

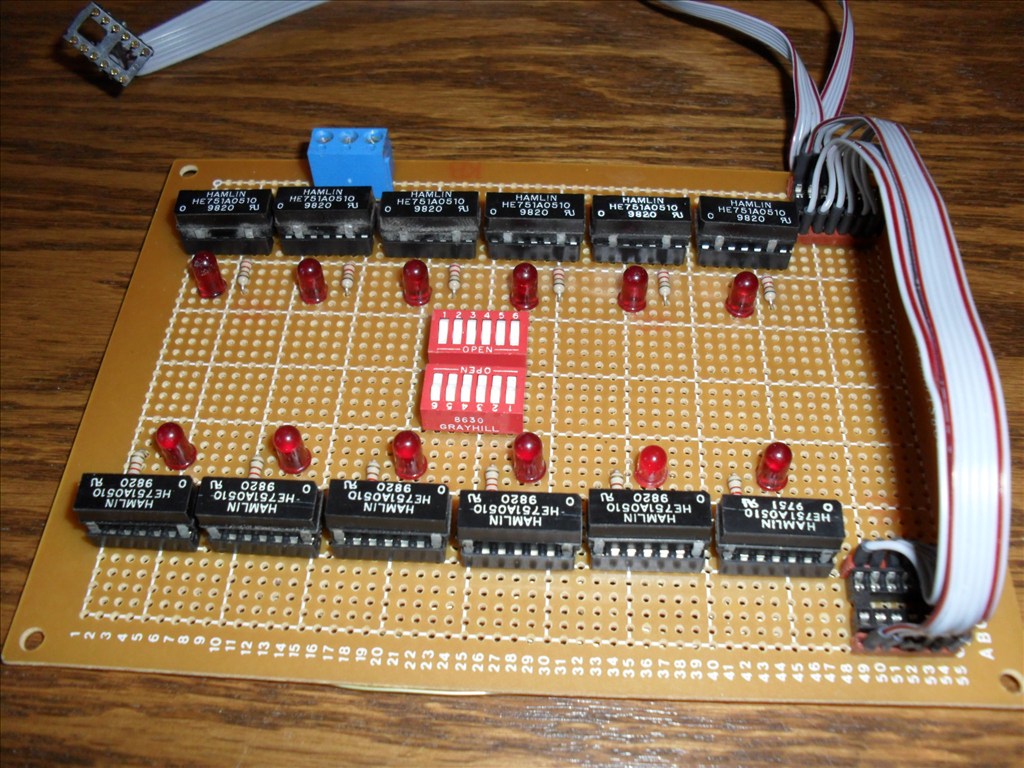

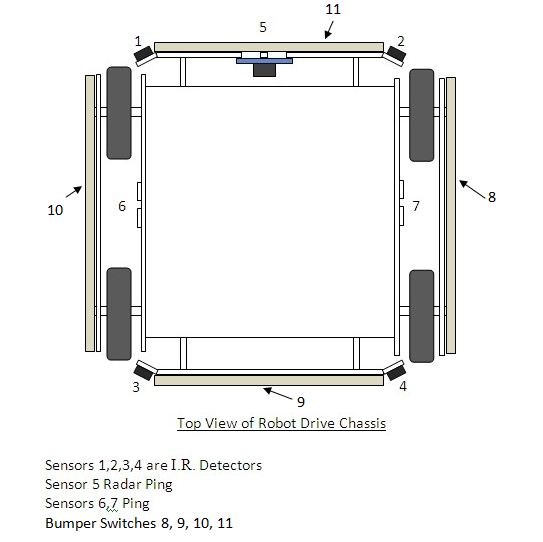

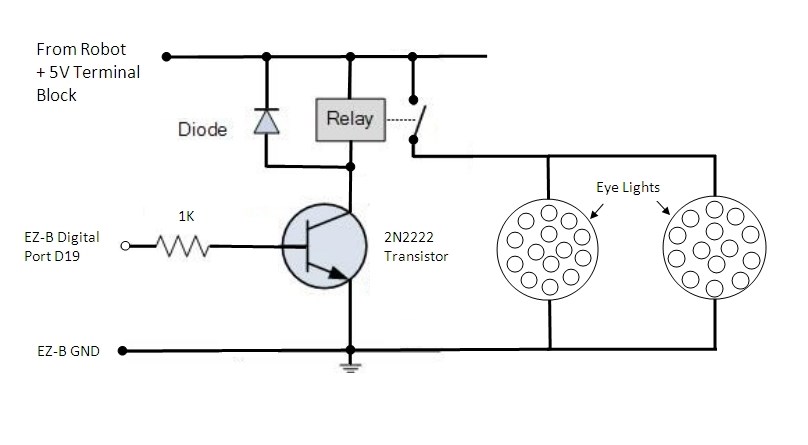

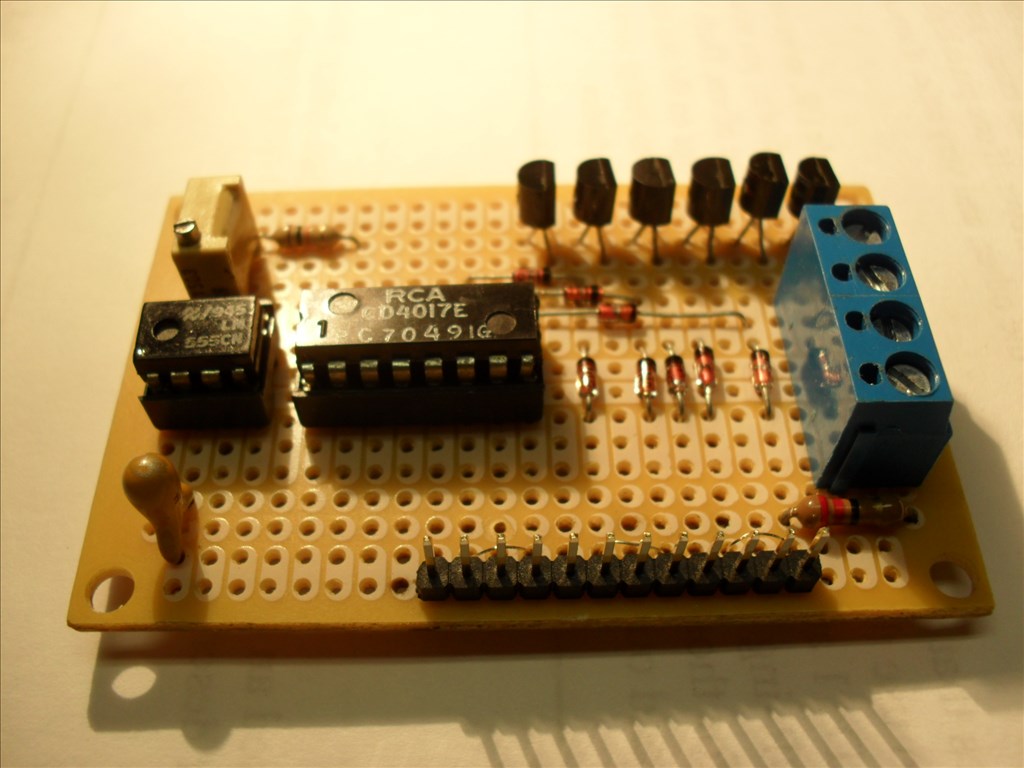

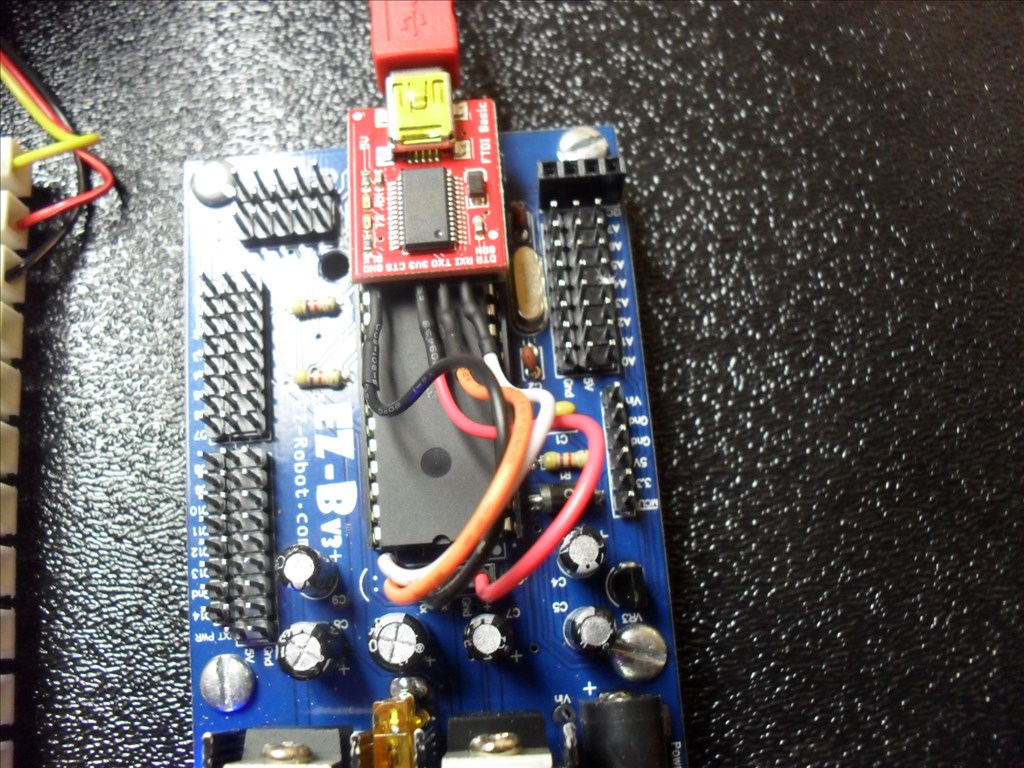

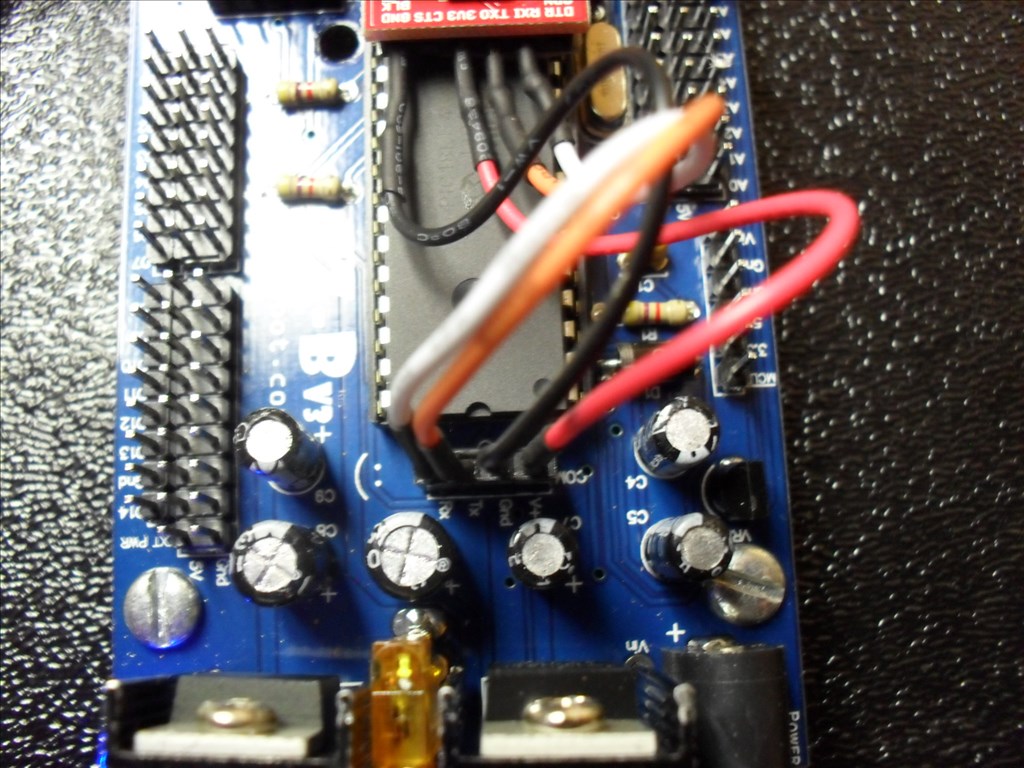

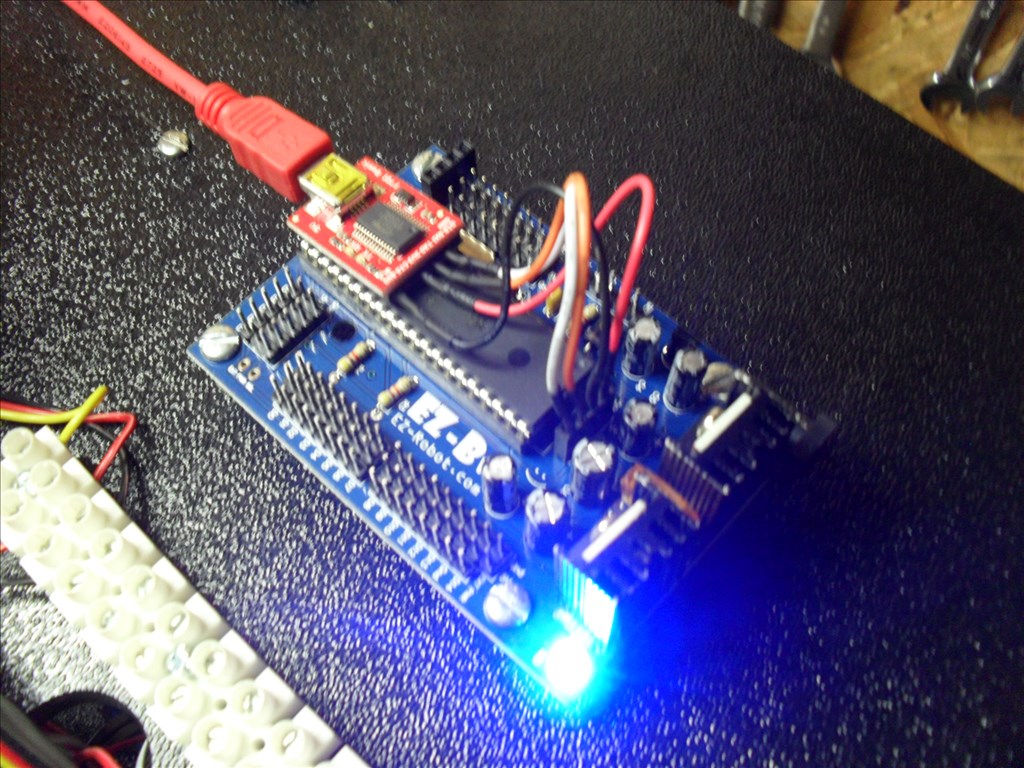

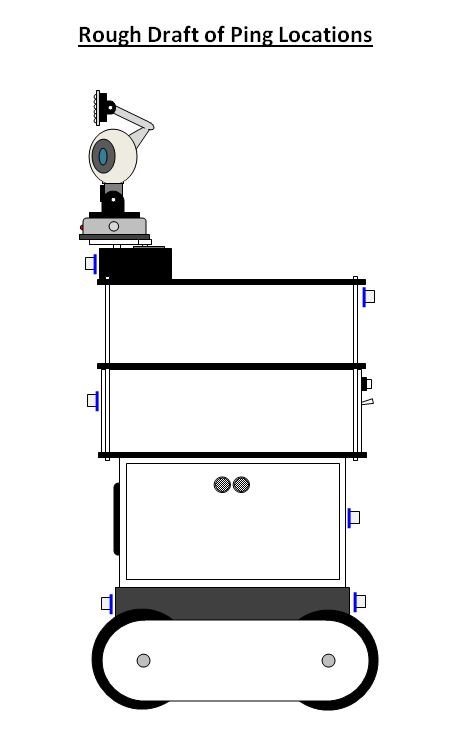

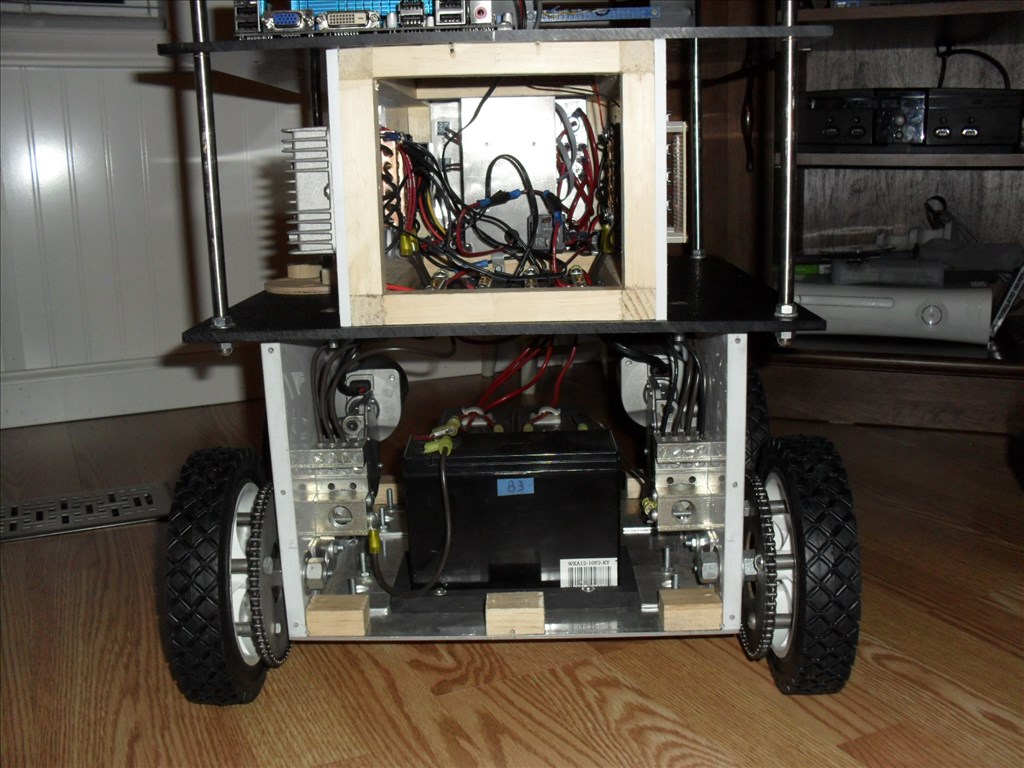

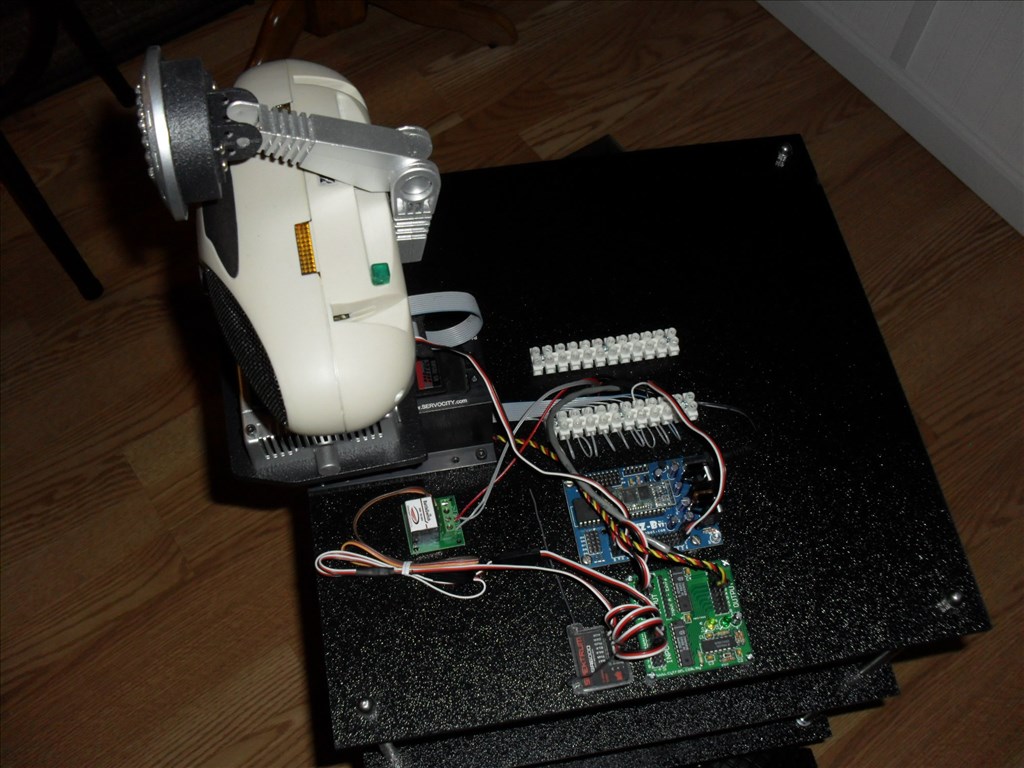

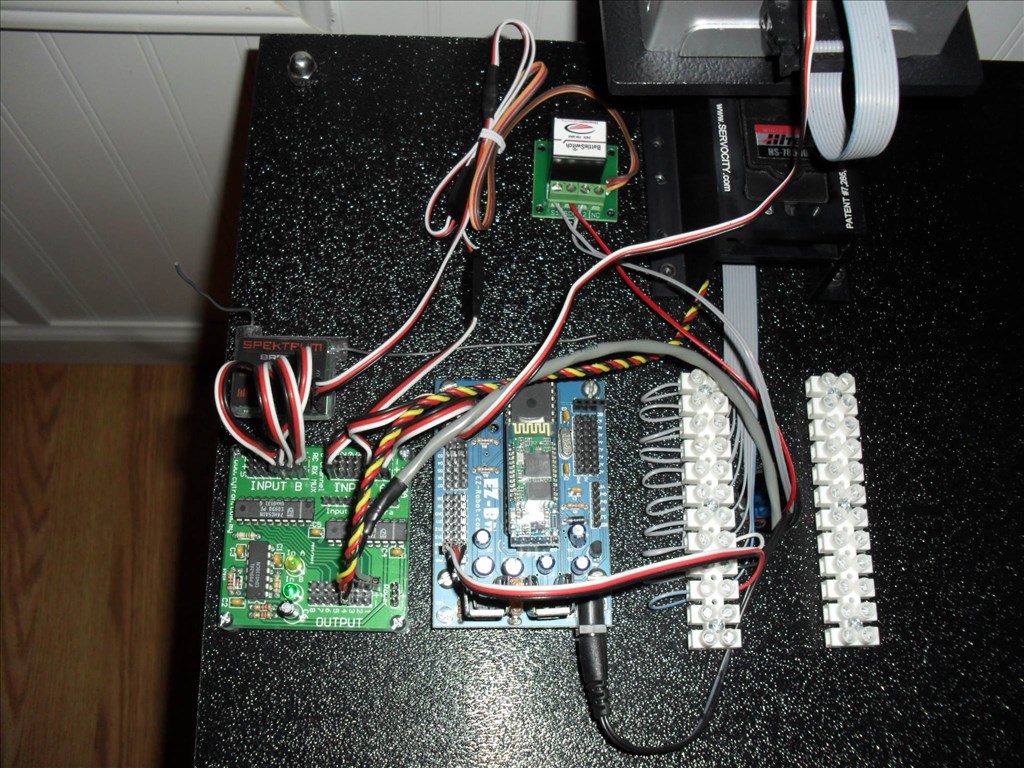

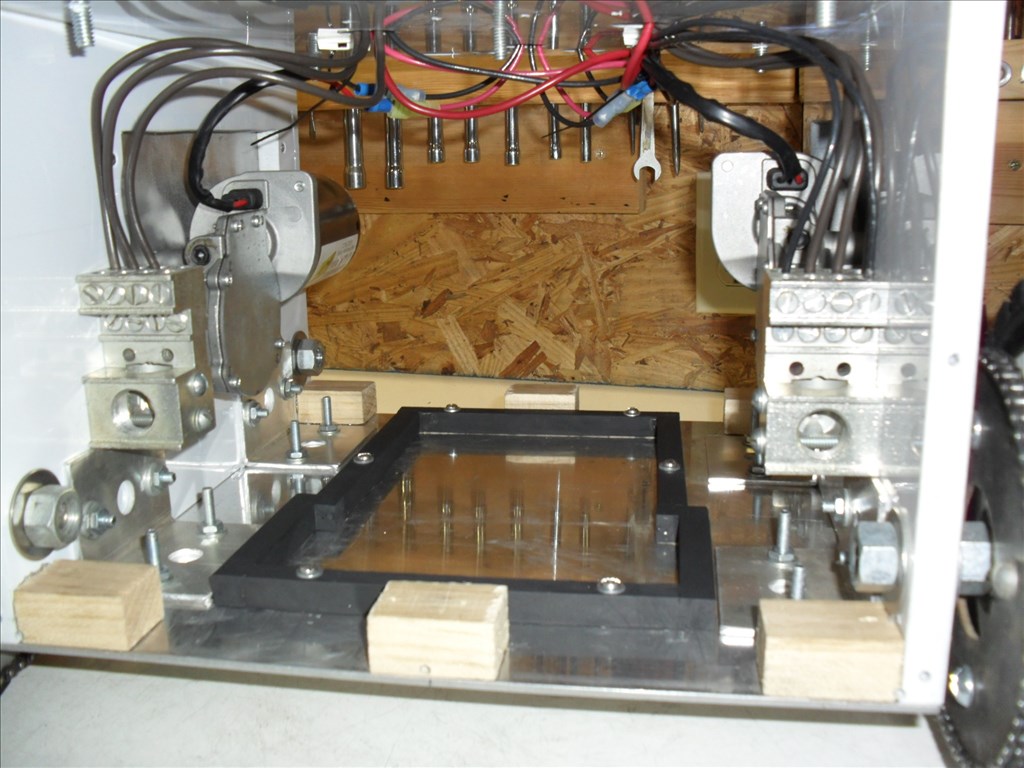

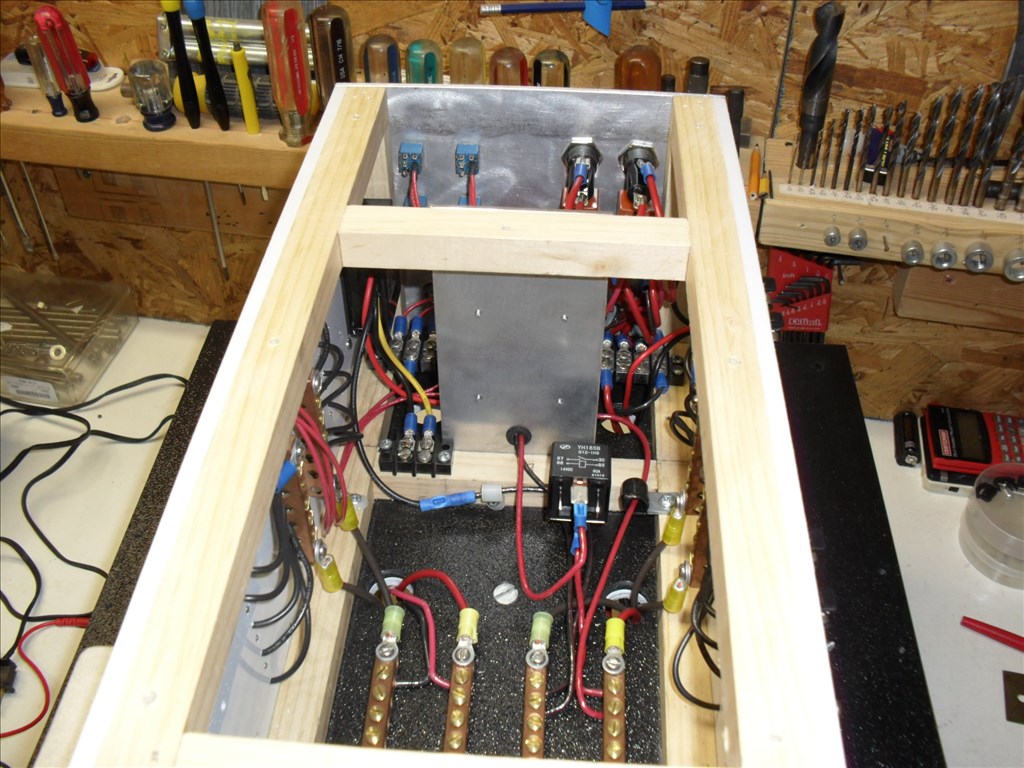

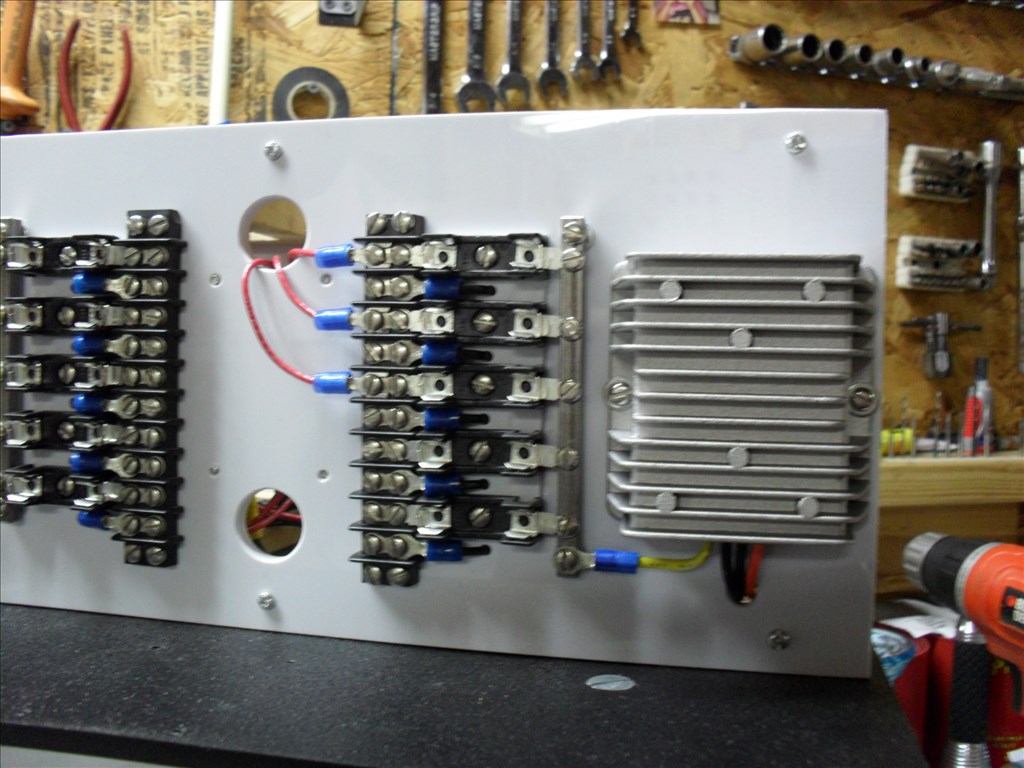

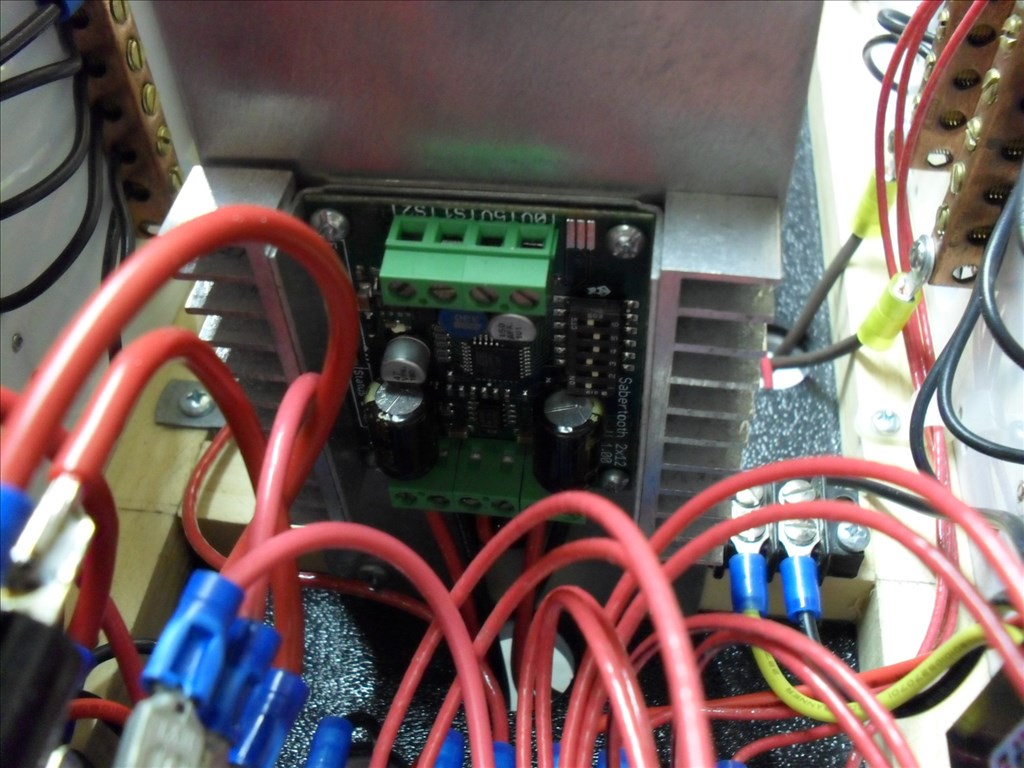

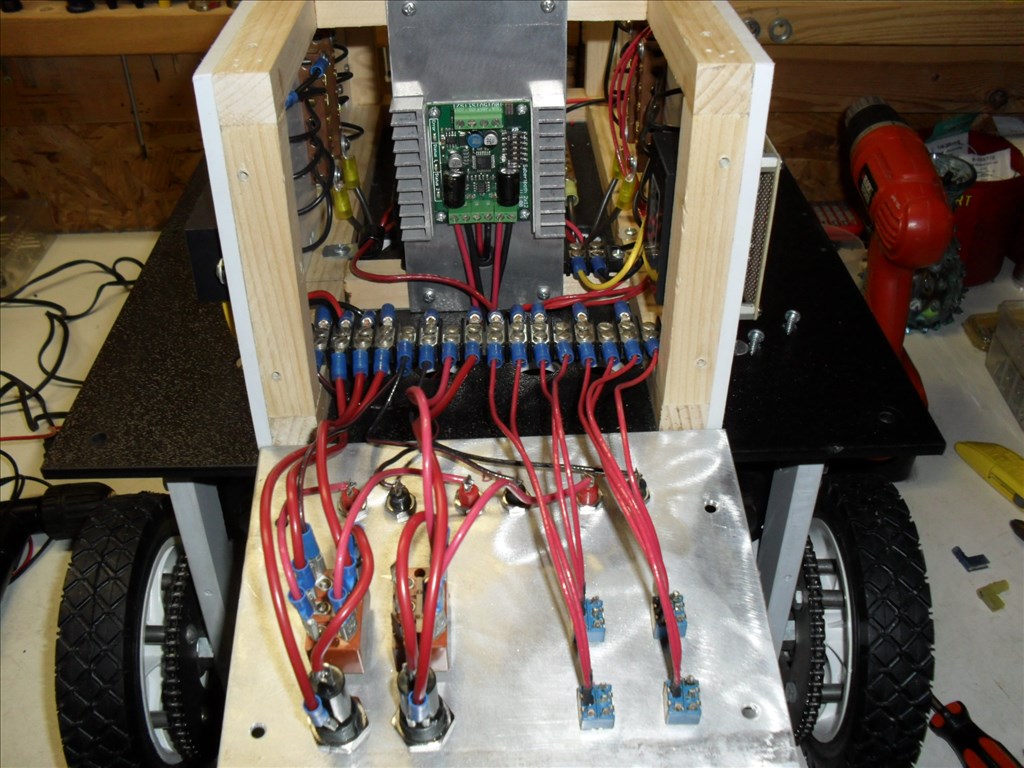

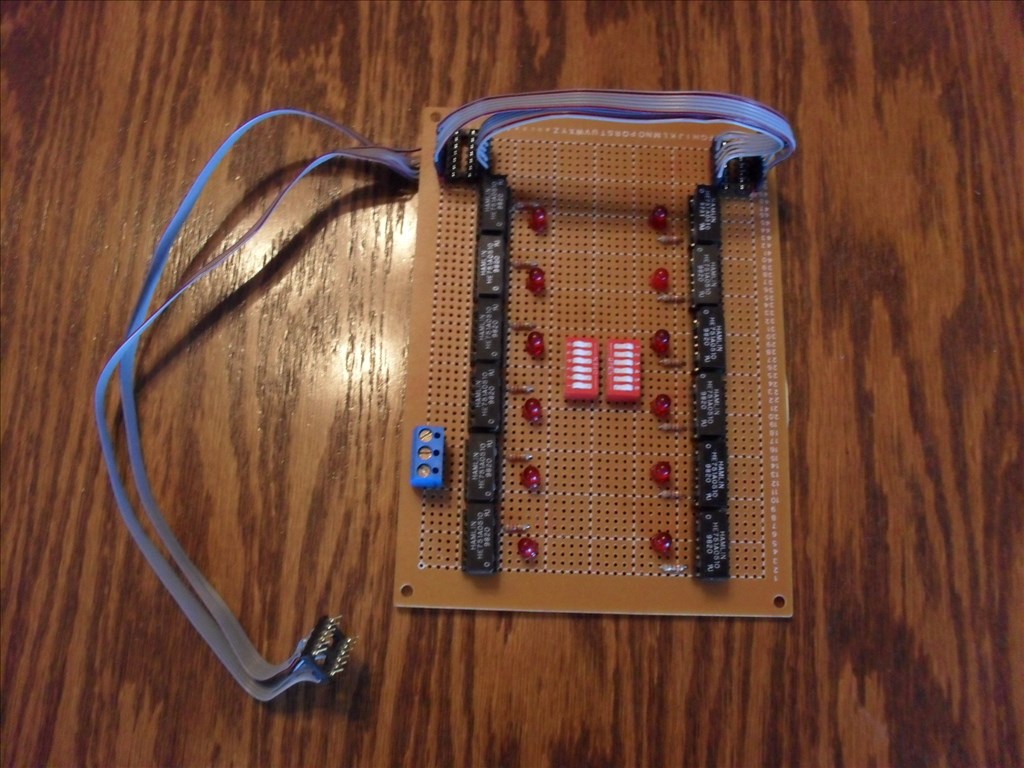

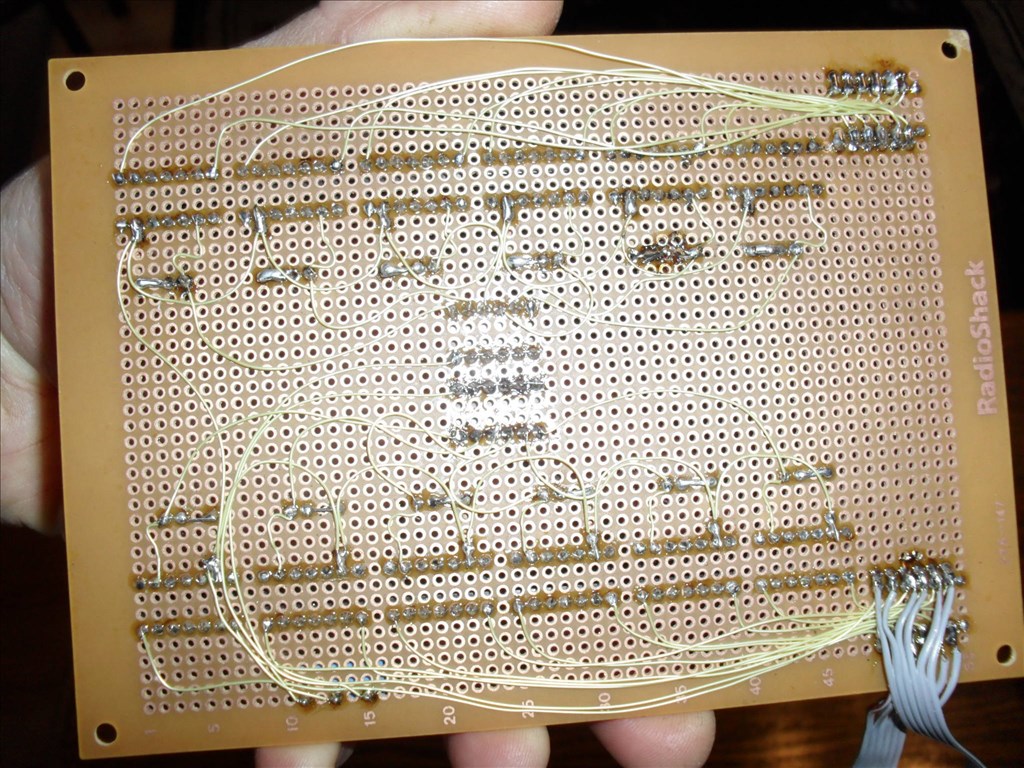

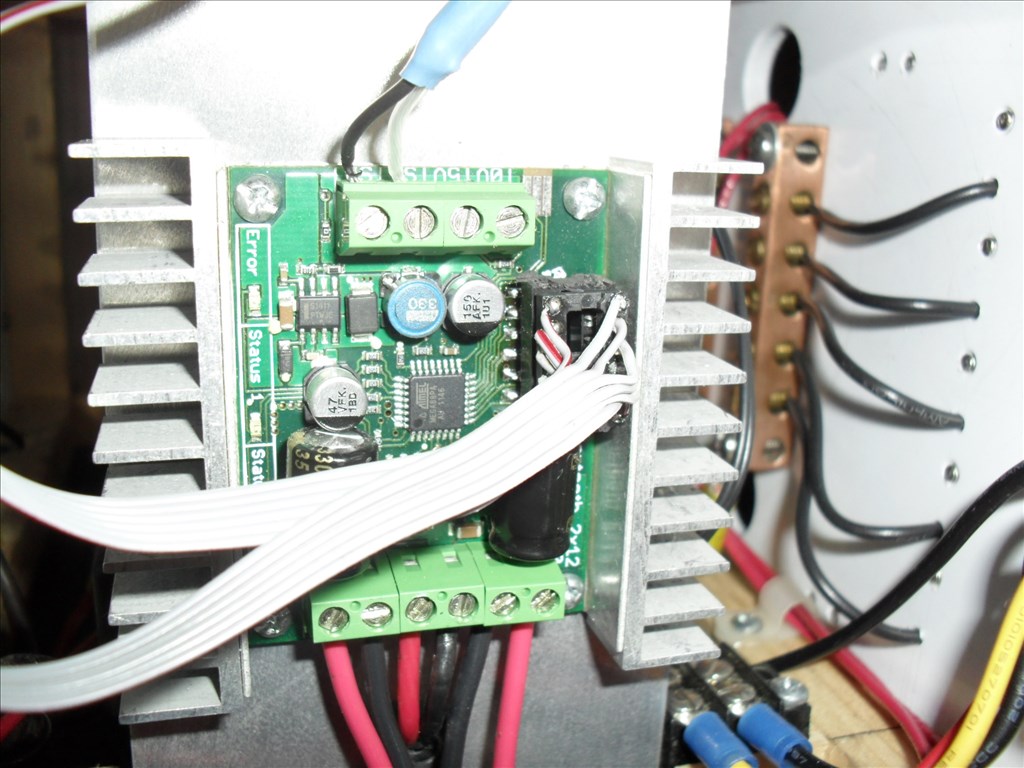

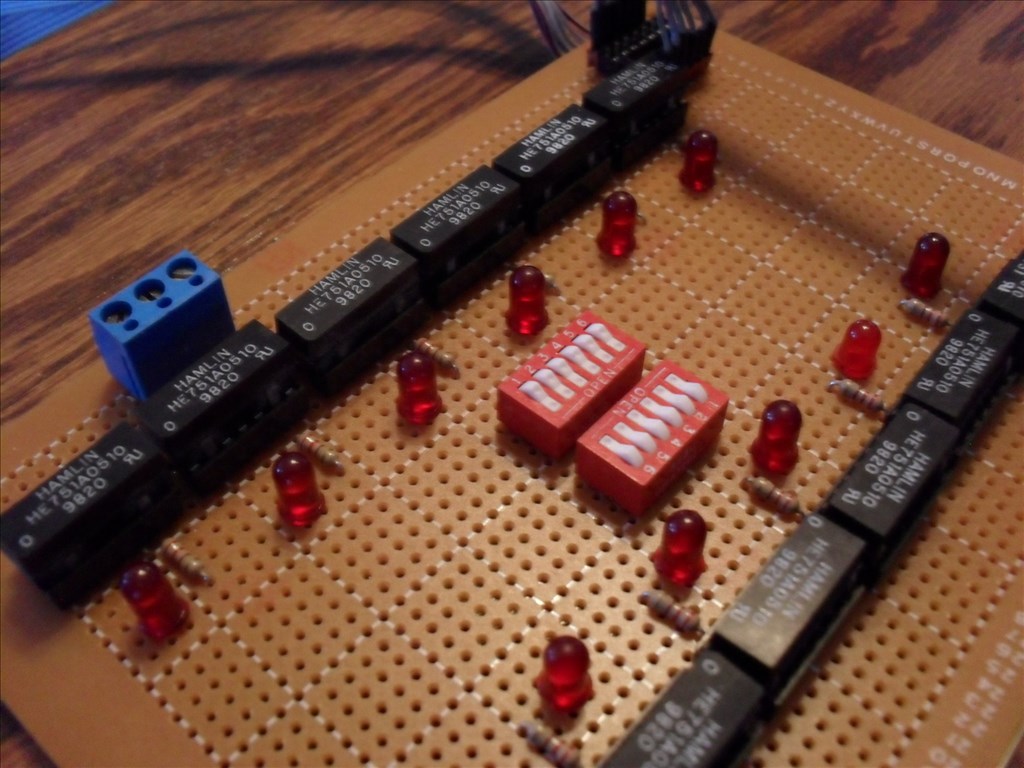

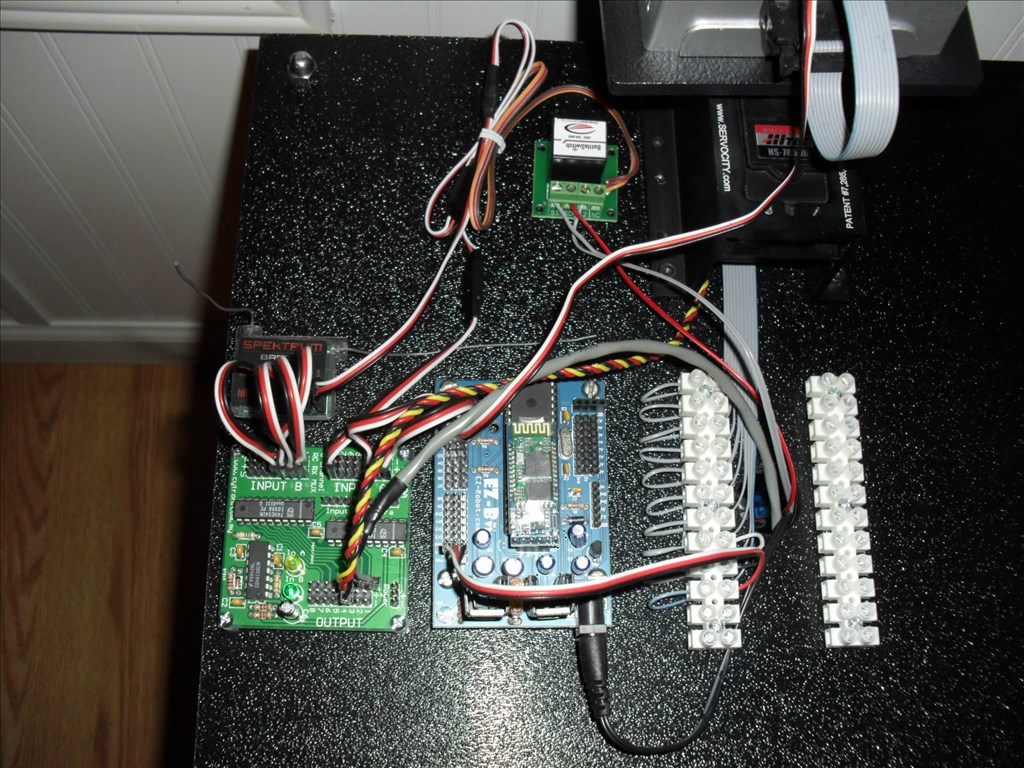

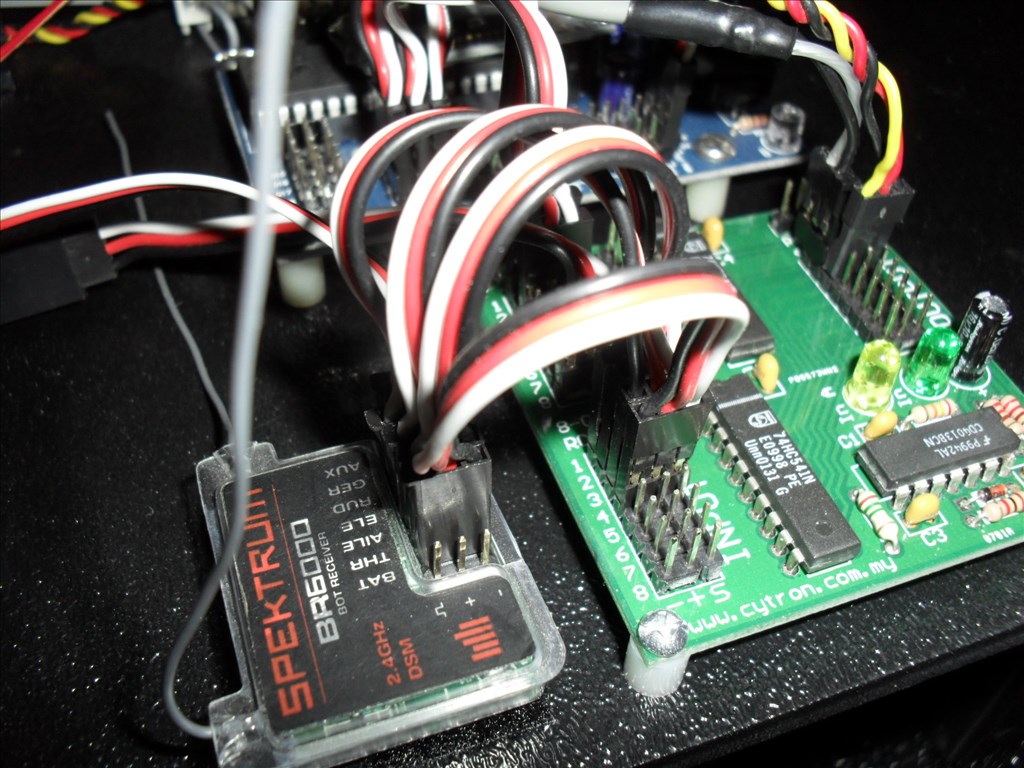

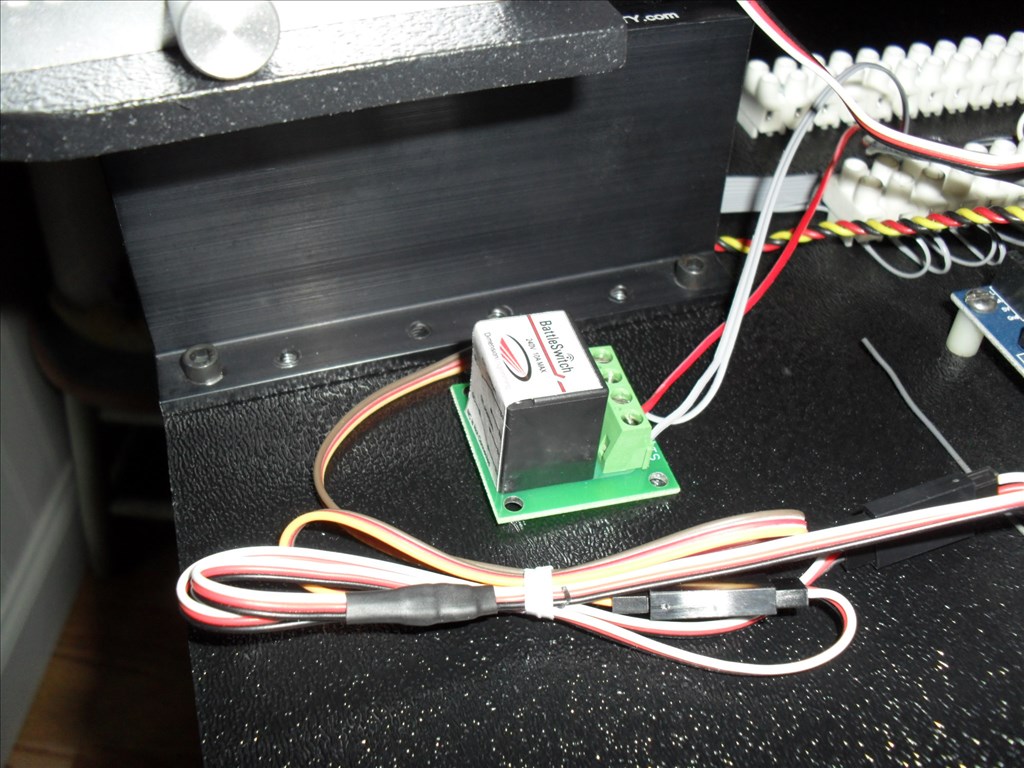

The head is made from a small boom box which I thought was neat because of the alien eye look. When illuminated they have a white border with blue eyes. His nose is the camera. Just below that is his voice lights made from an LED flashlight. I actually drilled a hole through the tilt servo case to pass the voice light wires through. The cluster of LEDs above his head are IR LEDs. Here you can see the EZ-B and the R/C Mux and Battle Switch. The LEDs on the silver box are for effect only. They will flash sequentially back and forth. View of the motors and battery compartment area. The power system deck.Weird....the pictures below [b]this line were not intended to be here in this first post. When I made the new post below, it saved the pictures in this post also. When I tried to go back and edit them out of this first post they don't show up on the thread so I can delete them. They belong in the post below....see details for the new wheels in the later post.[/b]

Other robots from Synthiam community

Jstarne1's 2013 Robo Ducki , Gift To Dj & The Ez Robot...

Tmesserschmidt's The Vision (Marvel) Robot Replica

Wow, he is a beauty! Great job dude.

This is a serious looking robot.

Wow! Questor is awesome! I love the look and the ease of access. Very clean and professional looking.

Awesome work dude! Where you been hiding this guy , not in a breadbox I'm sure. I like the industrial heavy duty feel. Surely you will bring him/her to makerfaire!?

That is awesome. BTW the name Questor has a special place in my heart so maybe I'm a little bias.

rgordon, Your project is an excellent work. All of the different layers and features are well built. If that is your test platform, I can,t wait to see the final product! Steve S

Good Job! It is Tight!

Thanks for all the nice comments! I got the name from Gene Roddenberry's movie The Questor Tapes.