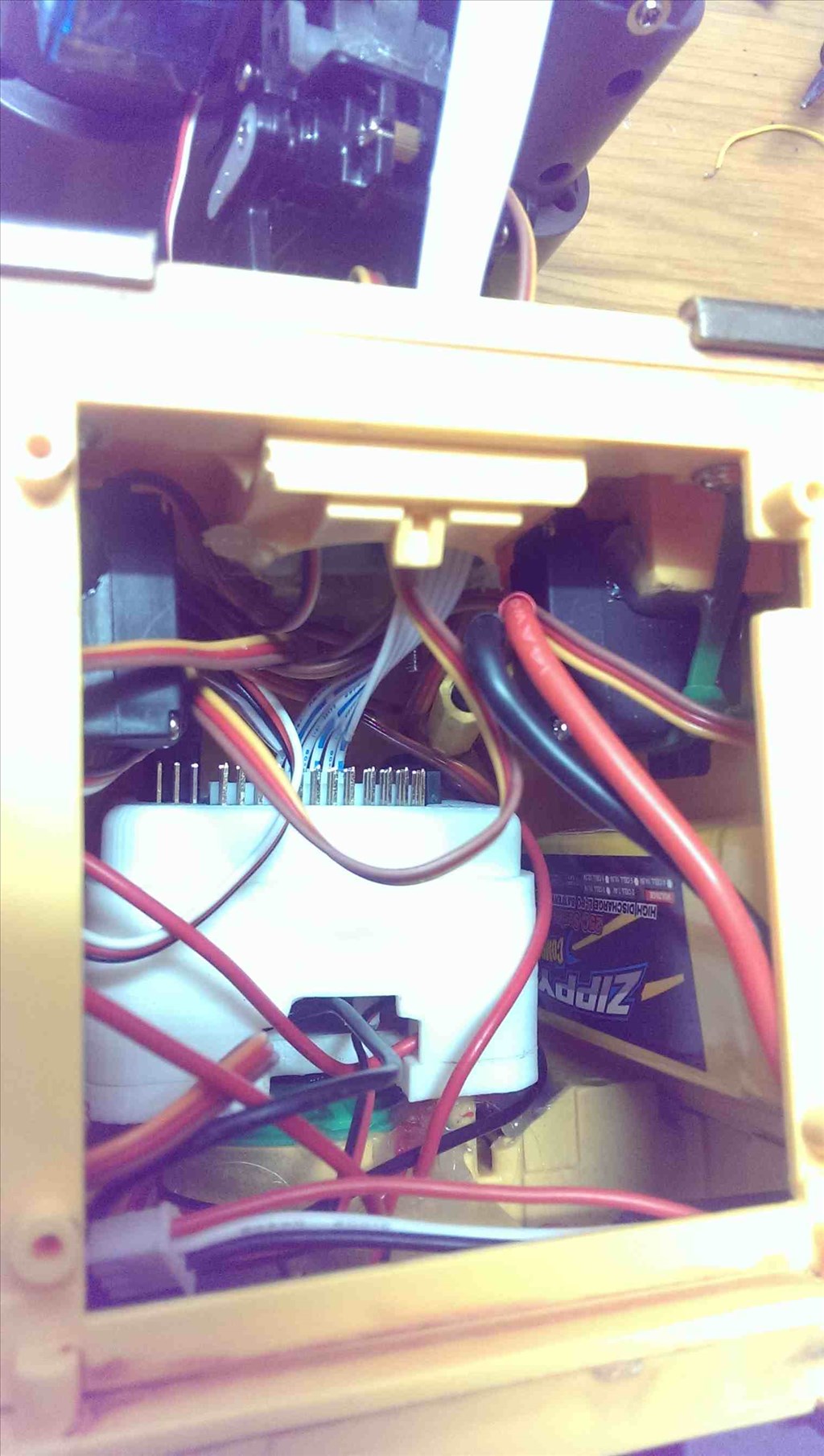

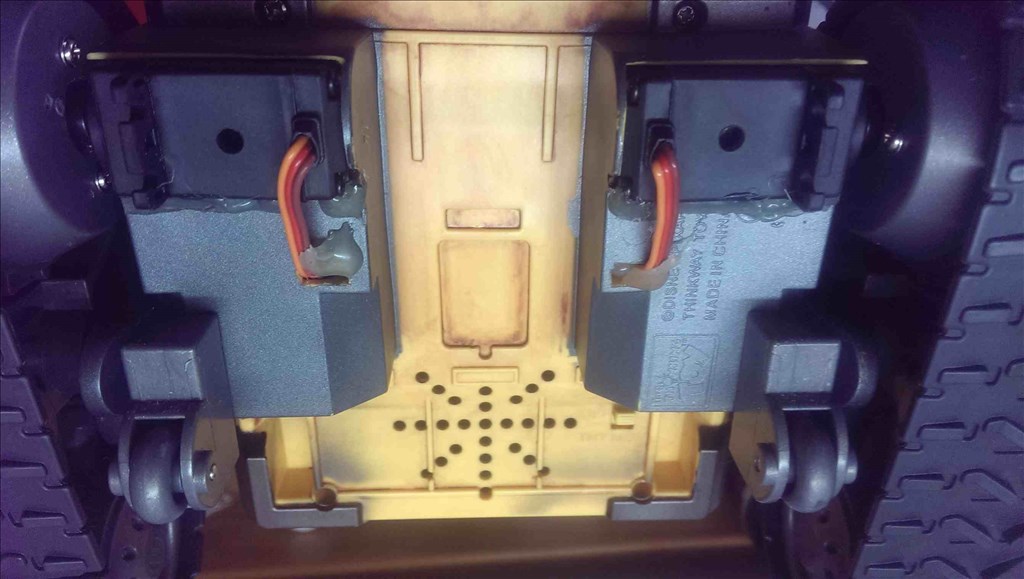

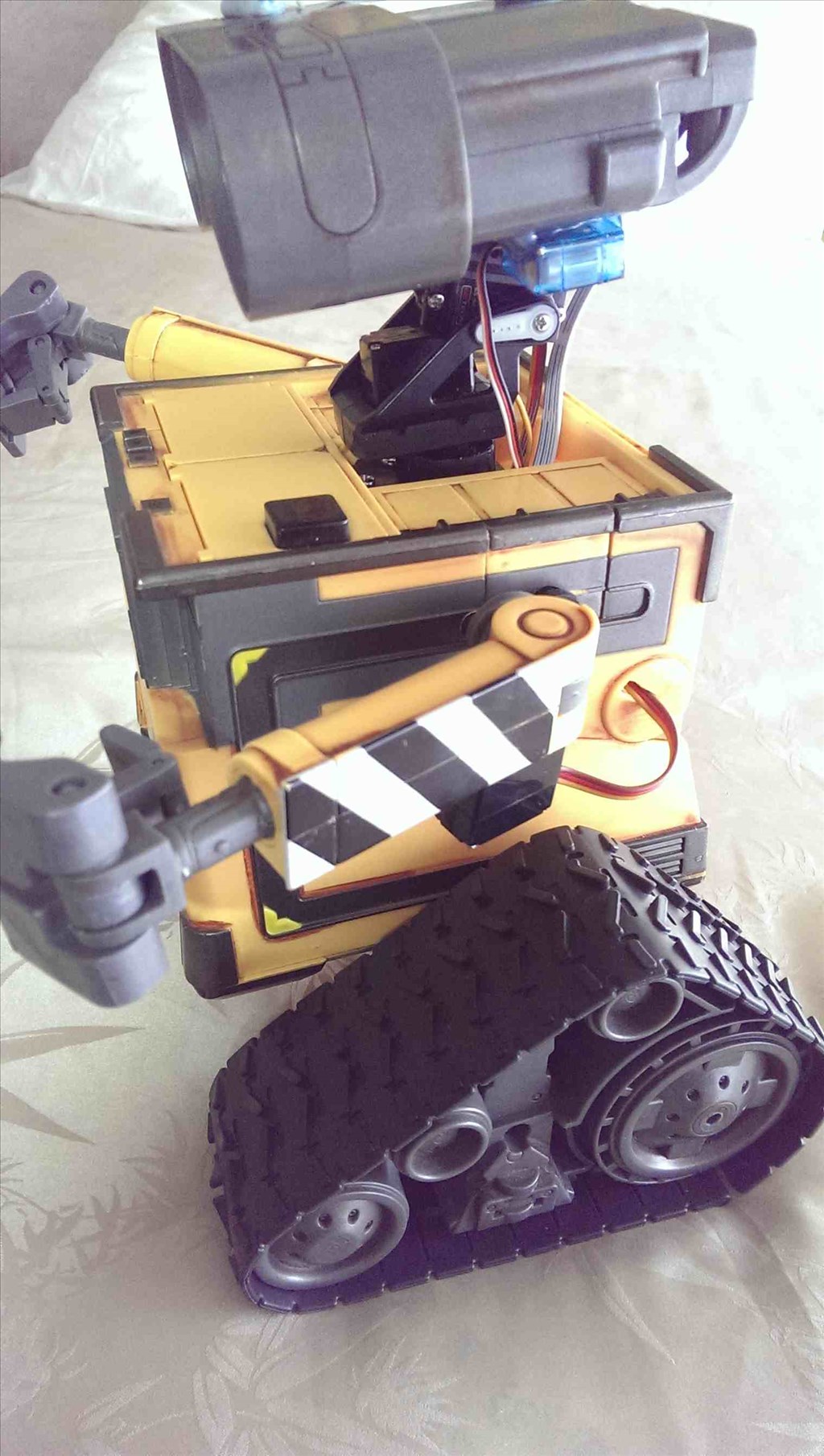

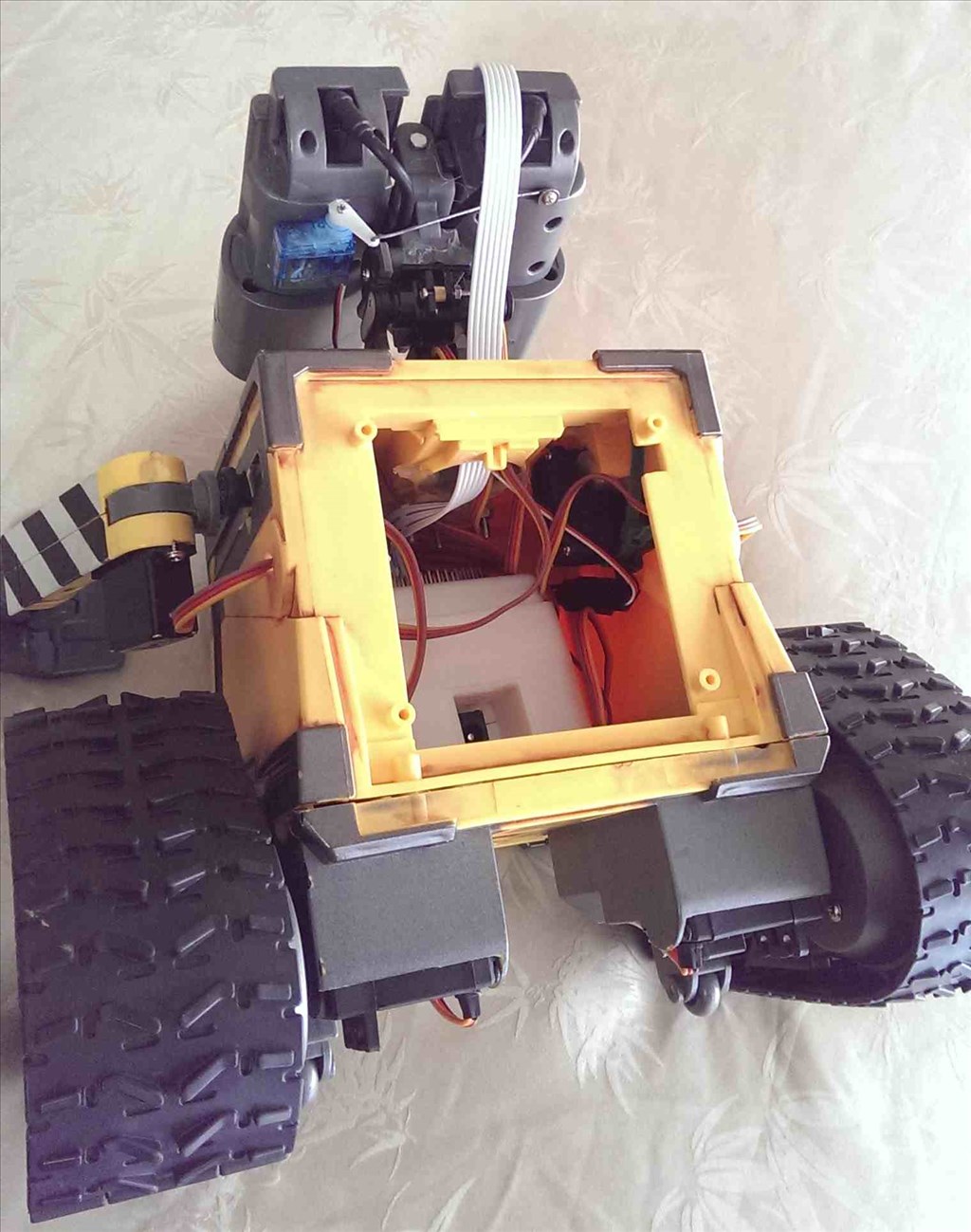

After receiving the Ez-B V4 development kit I was able to advance the build of my Wall-E with the insertion of the supplied continuous rotation servos and attachment of the the two tracks to the body. I'd spent a few months earlier gutting Wall-E and fitting servos for head rotation & tilt, eye twitch and two-way arm movement. I took a shortcut with the head movement by using a tilt/pan servo assembly that I got off ebay - https://www.ebay.com.au/itm/PTZ-Pan-Tilt-Camera-Platform-Anti-Vibration-Camera-Mount-RC-1-2G-2-4G-5-8G-FPV-/161176233437?pt=AU_Toys_Hobbies_Radio_Controlled_Vehicles&hash=item2586da25dd

Once I attached the tracks I could not wait any longer and connected all servos to the Ez-B and powered it up with a 4 x AA power pack to bring Wall-E to life!. I was greeted with the now very familiar "my battery is low" greeting but eventually got around that after connecting Ez Builder via WiFi.

I've been toying with Wall-E & the Ez-B for over a week now, with some success but also faced many frustrating problems. The main ones I think are being caused by power supply. The Ez-B goes into Birko mode for no reason, moving servos to extreme positions & even reversing them. I also get Unhandled Exceptions in the software with a reference to a non-existent D:/directory. This could be Windows 8? I will elaborate more after further testing and list somewhere.

My first aim is to replicate some DJ's Wall-E by studying and adapting scripts from the Legacy Wall-E robots. This will take some time as I'm new to Ez-Builder. I've had success with auto positioning, voice recognition, simple start up scripts and even some face tracking using the camera blue-tacked to the top of Wall-E's head! I've also been able to use the mobile Interface on my Android phone.

I'm having problems slowing down the servos. The worst are the continuous rotation servos supplied in the Development Kit. Their speed is not adjustable by the ARC software, so Wall-E spins his tracks and travels at virtual "break neck" speed making him pretty unmanageable. It's also almost impossible to smooth out the movement of Wall-E's other servos via the software, It's either full speed or very jerky movements.

There are quirks in the software which I would like to list somewhere without getting flamed by the Elite in this forum. One example is the Voice Type. All 3 voices installed in my version of windows get listed in the Speech Settings Panel but the Voice type can't be changed from 'Hazel" even if changed by Windows, ARC insists on using "Hazel"

The Ez-B speaker is very muted inside the Wall-E body. I might try to re-connect the original speaker, although Its ohm rating is not displayed on the case

So, overall, I'm pretty happy and satisfied with the Ez-B V4 and the ARC software. I'm surprised how far I've come in a week of tinkering. If I can do it, anyone can!

Other robots from Synthiam community

Toymaker's Losing Louie (Drone 3 From The Movie Silent...

Steve's Marcus The Expressive Android

Amen

Please see me PS above I added after you replied. It's important.

Thanks Dave

Some further progress on my Wall-E build:-

@d.cochran as reported on another thread I have connected the Ez-B directly to the original speaker that came with the Wall-E. Not sure if it is 8 Ohm but it sounds the same as a bigger 8 Ohm speaker I had lying around. It's a massive volume improvement on the small speaker built into the Ez-B, which I believe is muffled by the power base that comes with the Ez-B and even further muffled inside the Wall-E body. Unfortunately it also enhances the static noise I get when turning on the Ez-B Camera (also discussed elsewhere)

I also trimmed down the body of the Ez-B power base, shaving about 15mm from the height (see attached pic) and wired it to a switch in the base of Wall-E I have retained the base (with it's fuse) because I found the micro deans connector system a bit too "delicate" for Wall-E. After wiring the battery with a micro deans connector and plugging into the base of the Ez-B (which is a bad location for it to be), I found that slight movement would disturb the connection and reset the Ez-B. I concluded that the micro deans connector needs a firm, stable retention system, hence the power base that Ez-Robot supplies!

I might do away with the micro deans system by direct wiring like Dave Schulpius has done. This will give me more room inside Wall-E

@Jeremie, regarding trying to slow down the continuous servos installed in my Wall-E, I played around with the servo Movement Control panel for ages, getting inconsistent results and crazy directional movement for Wall-E. I eventually saw he was no longer tracking straight. Upon investigation (using some bluetak one each track) I found one of the tracks was moving faster than the other. There was also the dreaded grinding sound when I manually turned one of the tracks Sounds like the gears inside the servo are not engaging, ie. they're stuffed

Looks like Wall-E needs a sensor to stop the tracks turning when he falls so that he does not destroy his servos!

Are the continuous servos supplied by Ez-Robot in the Development kit metal or plastic geared? Could I swap the gears out of one of the 180 degree servos? Or should I just get some new ones?

Sounds like the gears inside the servo are not engaging, ie. they're stuffed

Looks like Wall-E needs a sensor to stop the tracks turning when he falls so that he does not destroy his servos!

Are the continuous servos supplied by Ez-Robot in the Development kit metal or plastic geared? Could I swap the gears out of one of the 180 degree servos? Or should I just get some new ones?

Hi @Tony1952

I have used the Modified servo Movement Panel several times to trim down the speed of the servos. Remember that since your servos are spinning opposite directions in order to move your robot forward you will need a minimum value of lets say 70 on one side and a max value of 110 on the other.

If your robot is not tracking straight you can do one of two things:

Adjust the values in the Movement Panel to have different offset values (ie: Max 95 (89 +6) on one side and min 75 (89 - 14) on the other) away from the center (stop) value (89).

Use a phillips screwdriver to manually fine adjust one of the potentiometers on a servo (which is accessible from the exterior of the servo where you can see a small hole on the side of the servo)

The continuous rotation servos in the development kit are plastic geared and you may be able to find some suitable replacements from other servos (or at a hobby shop) but I can't give you any guarantees.

In addition to using (what Jeremie said) the modified servo panel to match servo speeds, if your CR servo is indeed "stuffed" as you say... can't you just grab another (or two) from eBay and replace it?

@Jeremie thanks very much for the detailed tips on the Modified servo Movement Panel and also the individual servo adjustment on the servos. I saw those holes in the bottom of the servos and wondered what they were for! I suspected some form of adjustment but was reluctant to touch What I find odd about the "stuffed" servo is that the attached track can almost be turned freely by hand (ie not feel attached to the servo) but when powered the servo can still turn the track at about 75% the speed of the other one. This of course does not allow Wall-E to track straight and also any adjustment to the Movement Panel causes odd results

@Richard R please understand that I come from an era when you tried to fix things rather than discard and buy new. Would you believe I still straighten and keep bent nails just like my grandfather taught me when i "assisted" him in his garage. That's why I was wondering if I could exchange any damaged gears with those another servo. Once I remove the ton of hot glue holding the servo in place, I open it up and check out what happened. Having said that, I have already ordered two high torque metal geared replacements, which hopefully will do the job

After 2 AM! are you two working night shifts or suffering from insomnia?!