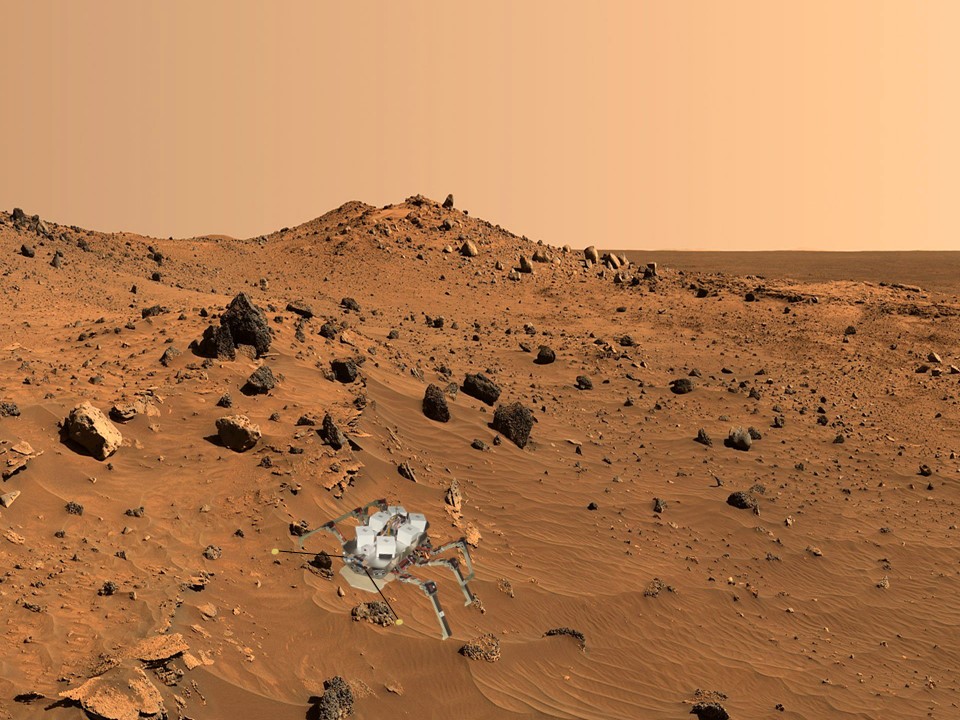

Hi guys, this is the first introducing part of a series, describing an autonomously operating hexapod with about 1 m width (my "large insect"). Idea behind this project: From early childhood on I wanted to build a kind of "mechanical turtle" or similar, being able to "survive" in the garden from spring to fall and doing whatever it would be programmed for, recharging its battery, seeking for shelter in case of rain, etc. Decades later (meanwhile a retired physicist, phd after 30+ yrs. in the space business) it was really time to realise this dream, meanwhile based on modern state-of-the-art electronics and software. Then, a colleague suggested to acquire an EZ-B V4-2 as the core element for such an undertaking and from thereon things picked up speed quite rapidly. As mentioned above, goal is the realisation of a quite large autonomous hexapod. The figure below is illustrating the general shape of this robot as well as the nomenclature for the legs (1, 2, , 6) and the servos (1.1, 1.2, , 6.3), respectively.

The base plate is made from 10 mm plywood and the legs from 20 mm x 20 mm pine wood. servo base blocks: 20 mm pine wood. A further light weighted plate (2nd floor) will be added later for accommodation of a scanning lidar, etc.. The hexapod’s legs are moved by 18 servos (Longrunner B07K68MK3Y:

In order to suppress unwanted rapid servo motions during EZ-B initialising, a switchable power distributor was added for each side (servos 1.1 through 3.3 and servos 4.1 through 6.3, respectively). These units are served by a central 2S2P LiPo battery (10.000 mAh) and are protected by individual fuses and are galvanically connected to the EZ-B.

Only the signal pin of each servo is directly connected to the EZ-B. servo Vcc and GND are both fed by these power distributors. Result: During EZ-B initialisation all servos are switched off - to be activated via toggle switches as required. Of course, all servos need to be positioned adequately beforehand. Currently, the hexapod is looking like this (together with his silent friend).

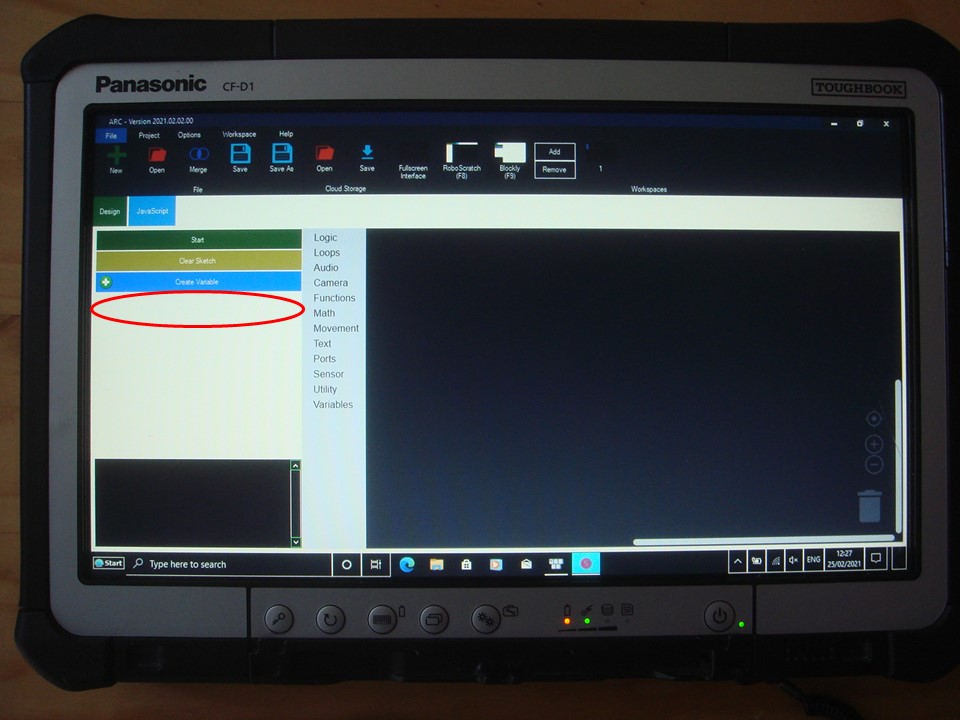

Programming was done in Synthiam BLOCKLY; surprisingly, the final version was completed within two days only !

Upcoming activities: First steps in the garden (Forward direction). Then: Backward, Turns, Sideways.

So long, that’s it for today,

Cheers

Volker

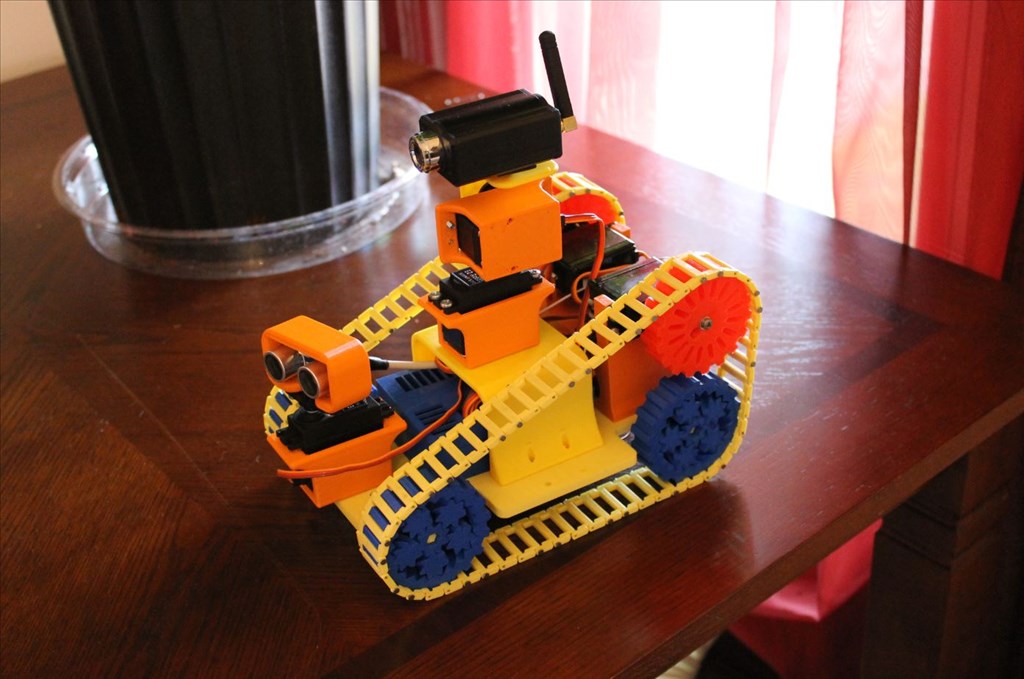

Other robots from Synthiam community

Halbinath's Traxbot - My First Robot

Tony1952's My Wall-E Powered By Ez-B V4

Not sure there is a lot of value in buying multiple EZ-B (Kind of expensive when you pay shipping etc) if you just adding ports a $4 ESP32 works well. For your set up you could just use 3 or 4 ESPs and also the audio "I have successfully connected to your network" will magically go away as well.

That actually gets me thinking. I wonder if you could make a fully redundant Highly Availabile robot. With your design any servo could fail and it could still limp along ok and if you had 2 controllers running the servo's and 2 running the sensors and monitoring each other so if one fails the other one takes over and 2 Lipo's and 2 banks of sensors and ...

I don't think there is a lot of people building highly available robots without a single point of failure. hmmm

It’s the wiring that sucks for using the arduino products. But the esp is so affordable. It took me a long time to get their tcp stack to work with arc. It’s got a bunch of problems natively .... but you get what you pay for

the ezb firmware for it works pretty good though. Check it here: https://synthiam.com/Support/Hardware/DOIT-Esp32-DevKit-v1

Looking at Klaatu build photos he puts separate header blocks for all his servos so I get the feeling wiring for him would be immaculate. (Where as I would have a hundred wires all the same colour, held together with solder and some duct tape)

Hi Nink,

if you have a closer look at my video (sorry for its miserable quality) you may see, that it actually can limp along (front left servo had wrong address at that day). This leg was only moving up and down; nothing more. It was marching quite good; just a remarkable drift to the left .

.

https://www.desmos.com/calculator/rpnk0wnpvj?lang=de

Just wanted to share this over here too...

Wow, that looks great, thanks Mickey ! !

Would be interesting to find out, whether it is also calculating servo force as a function of torque, arm length and angle.

During my work on the insect I found out that this can be quite critical, because load is distributed on just three feet during walking.

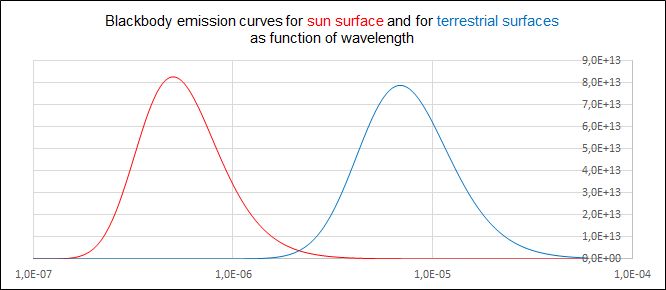

17 kp*cm torque (for my servos) sounds pretty good - in the beginning - but with some 20 cm effective arm length (vertical projection), only 0,85 kp are remaining. With three feet on the ground just 2,6 kp. The robot is now approaching this value: No weight reserves.

In a nutshell: Servos cannnot be too strong; is however is often limited by their price.

So true...there is a thread over here with the title "Servos For Robot Dog" you might want to suscribe to it. There are more and more available options for Brushless Motor Control, that might give you the amount of torgue and speed you are looking for!

If you would like to calculate the torque of any brushless motor, you can do so by calculating the torque constant from its KV value...

https://www.fxsolver.com/solve/

So my Tarot S 4108 should have a torque constant of 0.02512 Nm/A

Also you can calculate the revolutions per volt applied... The Tarot S 4108 has 380 rpm/volt or 39.79(rad/sec)/volt There is an online converter for this! https://lucidar.me/en/unit-converter/rad-per-second-to-revolution-per-minute/

I am using a 1:40 gearbox on top of that BLDC motor... So with the gearbox is working I will need to measure the amps the motor draws under load, but lets consider 2.5Amps... 0.029 * 2.5 = 0.0628Nm

By multiplying a gear ratio of 40, the ideal torque on the output is 0.0628*40 = 2.512Nm

This will give you a good starting point when choosing a motor which will be offering enough torque for your specific setup!

...I had asked in another thread this exact question, about your set up, torque etc, but all the answers are here! Good info!