Step 9. Wire and cable.

Love it or hate it, wire and cables are an important aspect for any electrical system. Most electrical devices will use wire at some point in their makeup. Whether it's a mass of wire connecting different components together, a couple of wires connecting battery terminals to a circuit board, or a completely wire free device that needs to be recharged that will use a mains power charger.

When building an electrical system, you will need to work out the power requirements for devices or peripherals used, such as the servos or DC motors that have been previously mentioned. Using an inadequate wire gauge connected to a DC motor for example, can cause the motor to not operate properly, and the wire can heat up excessively.

The difference between wire and cable is a simple one to remember.

A single or multiple metal wire strands that conduct electricity (normally copper or aluminum), make a wire.

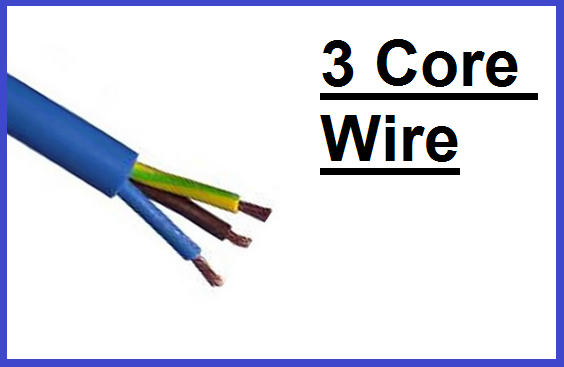

A cable, is made up of multiple wires.

Take a three core cable for example. This is made up of three wires (cores) which are usually "Earth or Ground", "Live or Positive", and "Neutral or Negative" wires.

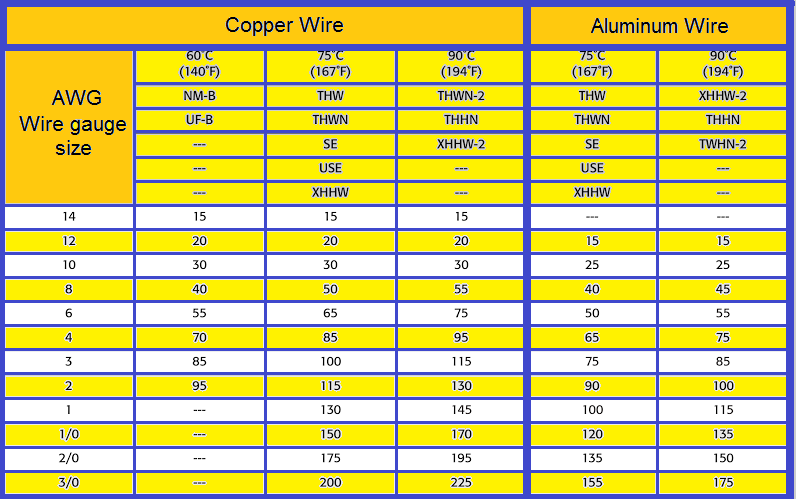

Wire comes in different thicknesses which is referred to as "Gauge". This is measured in millimeters and gauged in "SWG" (British Standatd wire gauge, and "AWG" American wire gauge). Understanding this is important. When it comes to the actual wire sizes, AWG and SWG are not equivalent in size. In general, an SWG wire would be bigger than an AWG wire of the same gauge. AWG is more widely used nowadays, although SWG measurements are used in some industries. So when working out your wire gauges, it's worth taking this in to consideration. Gauge measurements work out as a thin wire will be a high gauge number, and a thick wire will have a low gauge number. Much like the "waterwheel" analogy used to explain the flow of amps, the larger water pipe can deliver more current/amps, and the same is usually true for thicker wire.

Below is a wire gauge table that gives the maximum amp rating for different wire gauges...

CAUTION:

Pushing or drawing a higher amp rate than the wire is rated for, will cause the wire to heat up and possible melt the plastic, rubber, or silicone covering. This can cause short circuits and possibly burst in to flames.

The quality of wire varies as well, so make sure you get a good quality wire.

Thanks for this info. Still not sure why everything says it will handle 20plus servos because power wise, they cant. also a 20amp fuse will probably to blow before ez-b blows. this would be great in the specs!!

Thanks again

Scott

I'm not an expert, but there is common sense too.

Not all servos are equal: there are small torque and high torque servos, there are cheap servos (bad electronics, counterfeiter etc) and good servos (good engineering) and smart servos (with micro-controller e.g. Dynamixel with temperature, load, torque control).

Servos/motors have different current rates e.g. idle, torque stall, peak, inrush.

Some setups don't accommodate the Inrush/Peak current. Inrush Current is commonly used to describe the current that is required to energize an AC powered device when first applying voltage and power to it. If you have all your servos moving at same time you have a Inrush current during a brief period.

Some batteries have high discharges rates for example a lipo battery with 1000 mAh and a C=20 can handle 20 amps, but a niMH (AA) can't handle 20 Amps so the battery plays an important role.

And last not all fuses are equal there are quick-acting and time-lag (slow) a slow fuse can handle as much as 10 times the current for a brief period before blowing up...

Without knowing all details we can't make assumptions.

I recommend using EZ-Robot HDD digital servos for prototyping you product development, because they're the highest efficiency that you'll find. PTP is correct, in that your post may be assuming a specific servo experience, which is impossible to generalize. The EZ-B can provide power to entire InMoov large servo configurations. Even the EZ-Robot JD humanoid uses an EZ-B v4 and has 14 hdd servos and powers off a single 7.4v battery. This conversation of power requires explicit details of the hardware selected for your product development - as it cannot be generalized.

If you have questions regarding the EZ-B v4 manufactured by EZ-Robot, then you can visit their website at www.ez-robot.com to contact them directly. Otherwise, the opensource hardware and software for the EZ-B v4 design is available in the Synthian GitHub link at the footer of this website. Lastly, there's a number of supported hardware platforms for ARC in the Getting Started link on this website. Many options to ensure you experience positive results with your product development.