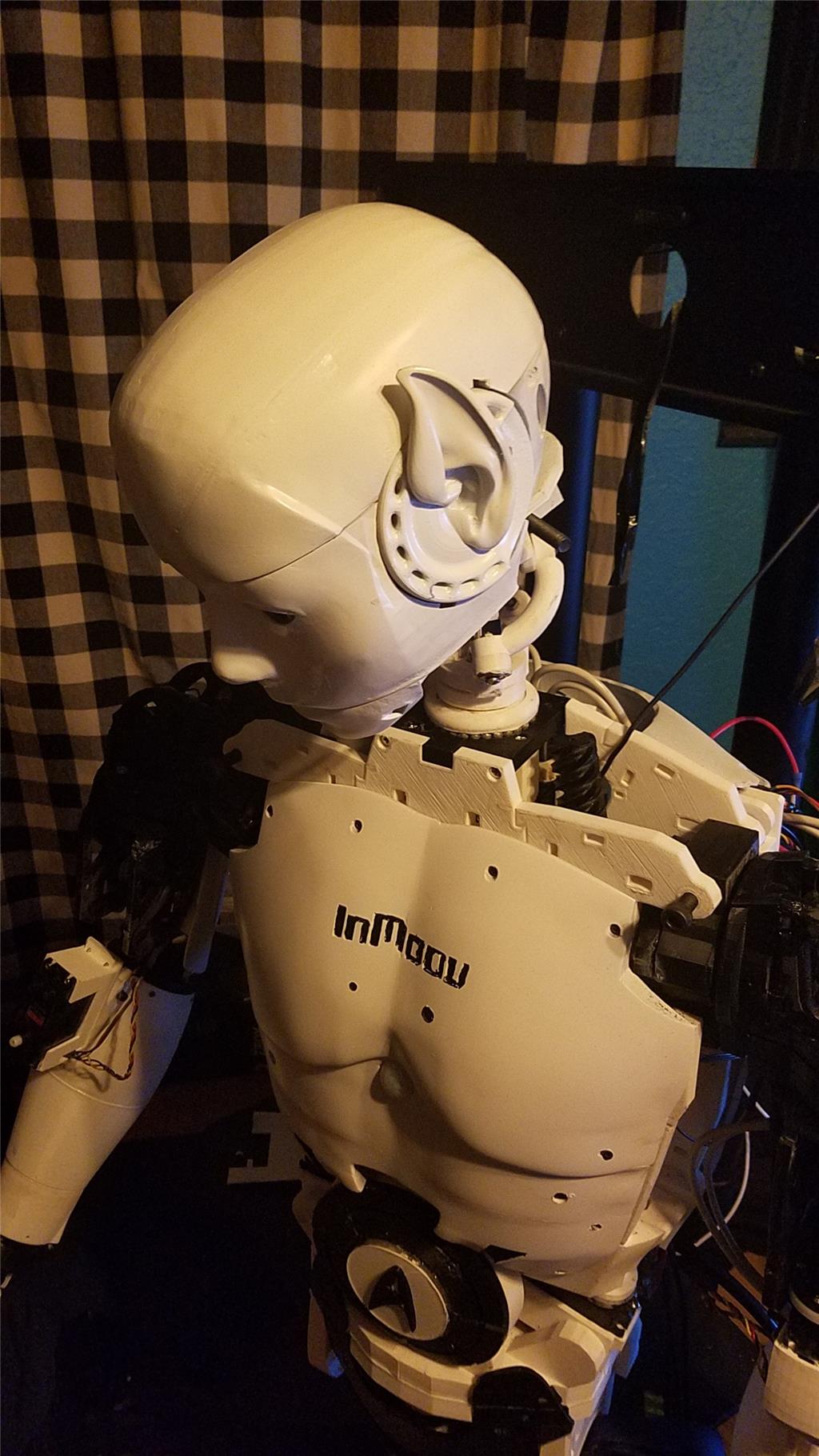

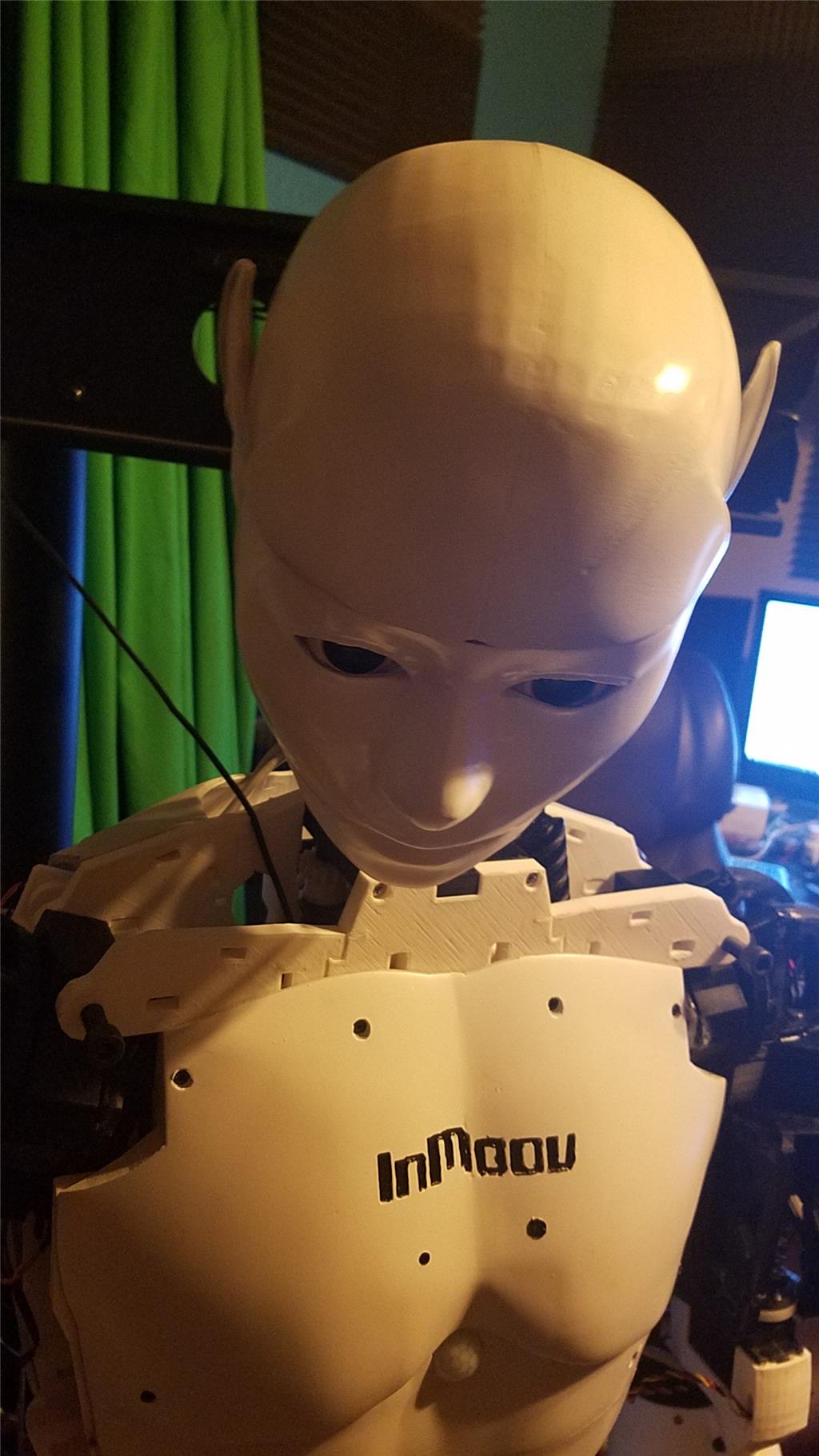

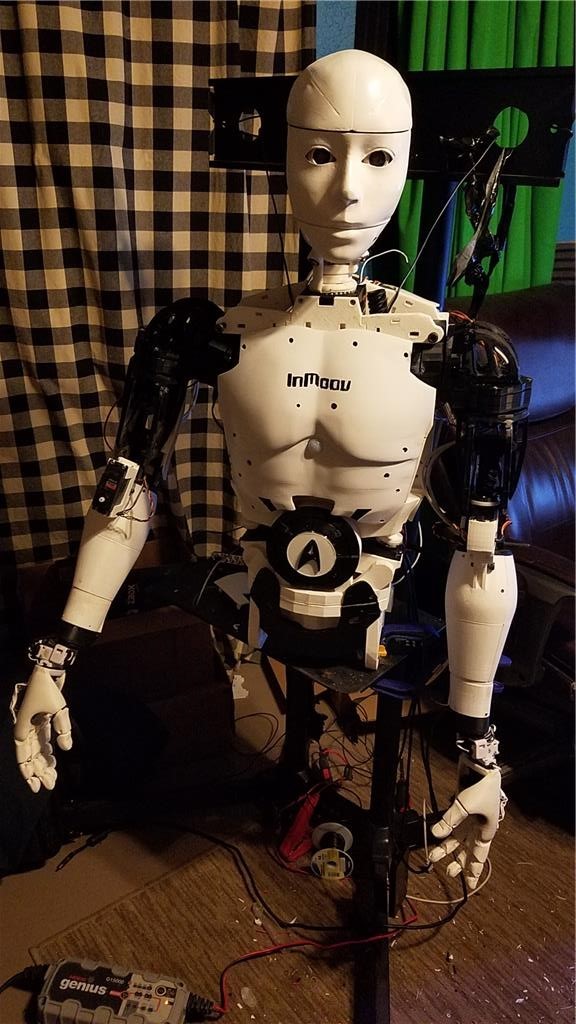

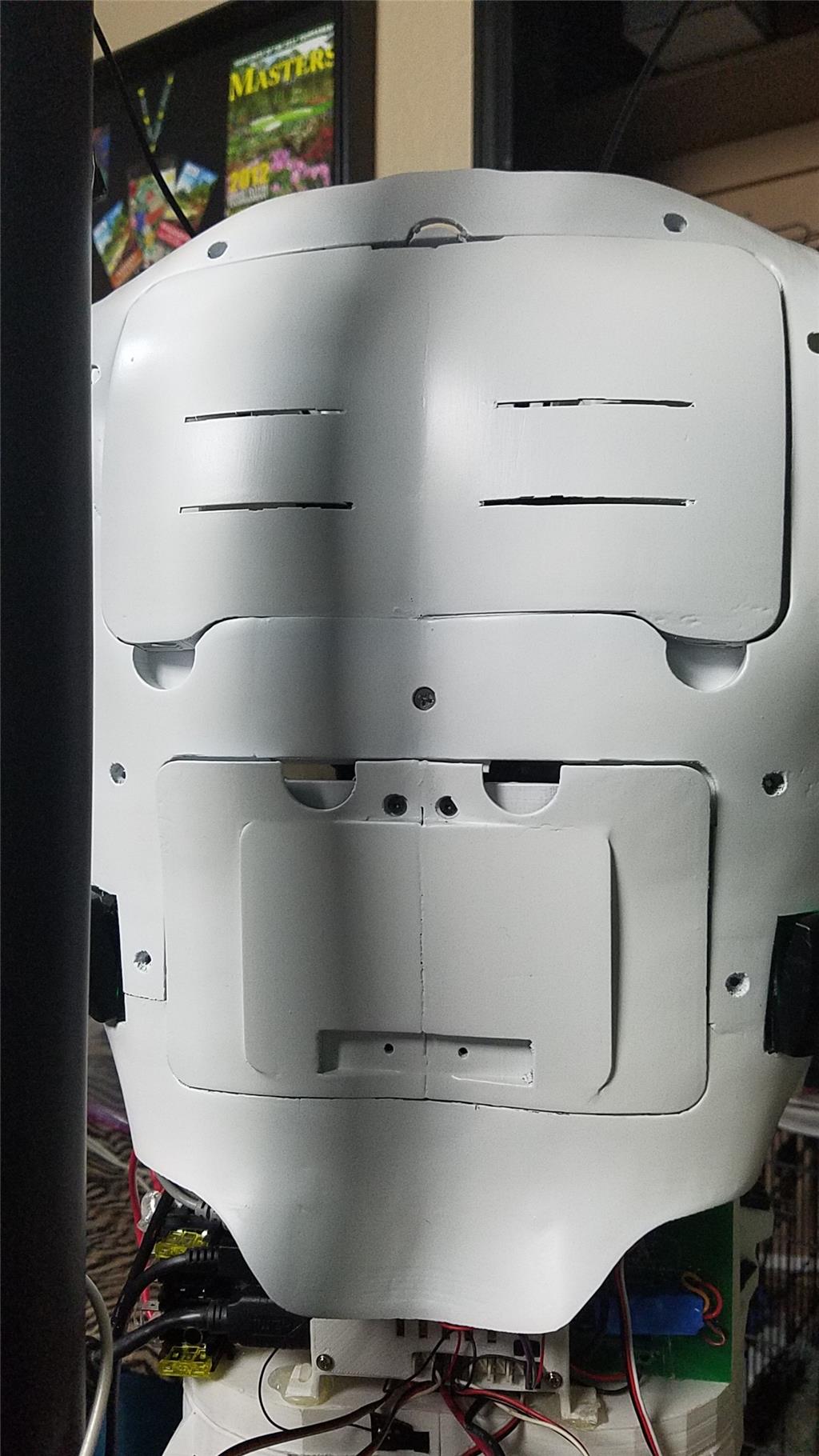

I have decided to start my InMoov project. I think I will call him Spock out of respect to Leonard Nimoy who passed away on the day that I started this project.

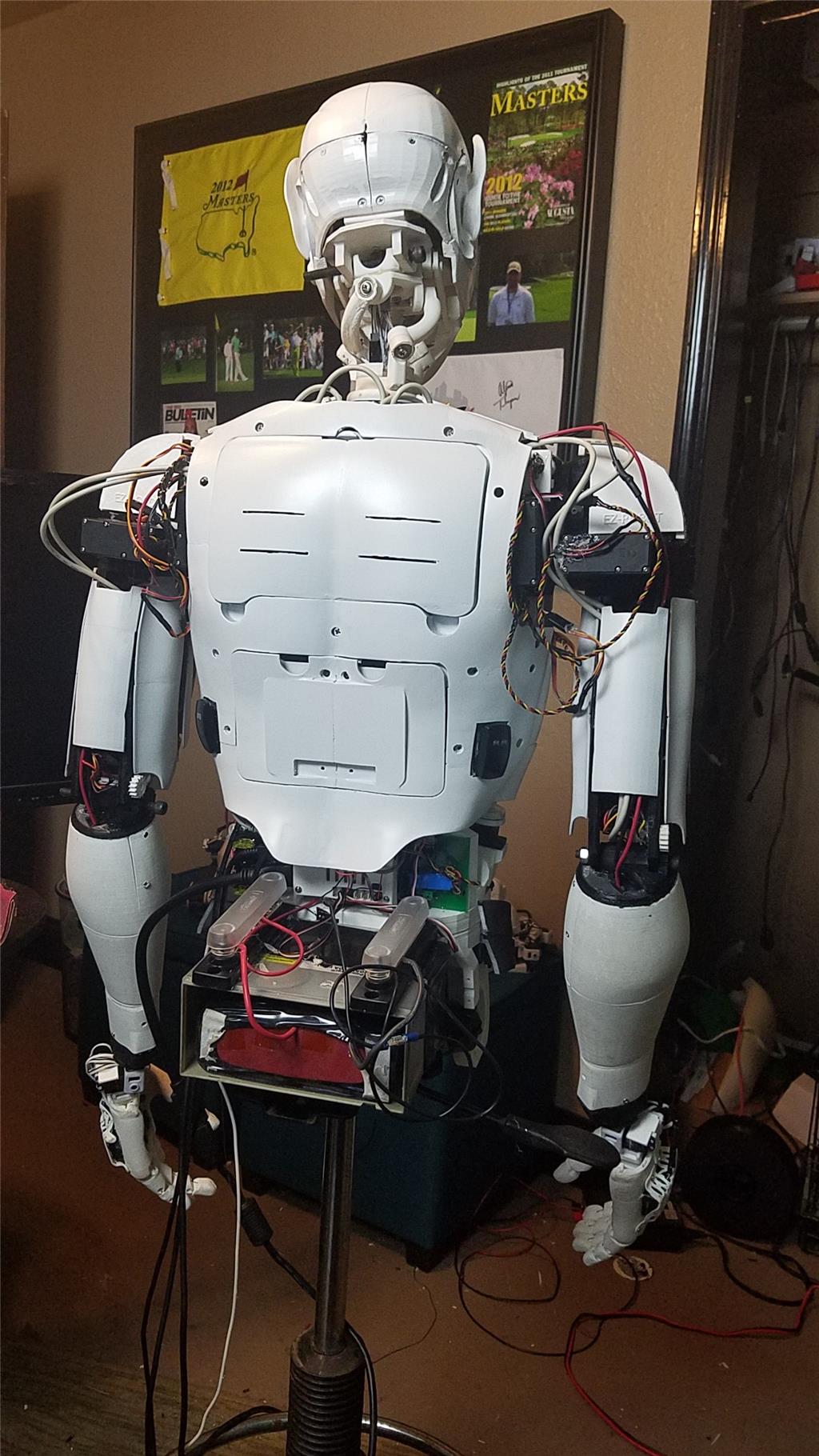

I am editing this post so as not to confuse people with the current configuration. I continue to update this post with the latest photos. If you are reading this for the first time, don't be confused. There have been a lot of changes to the InMoov over the past couple of years including starting over.

https://synthiam.com/Community/Questions/7398&page=21 Post 203 starts the rebuild of the InMoov.

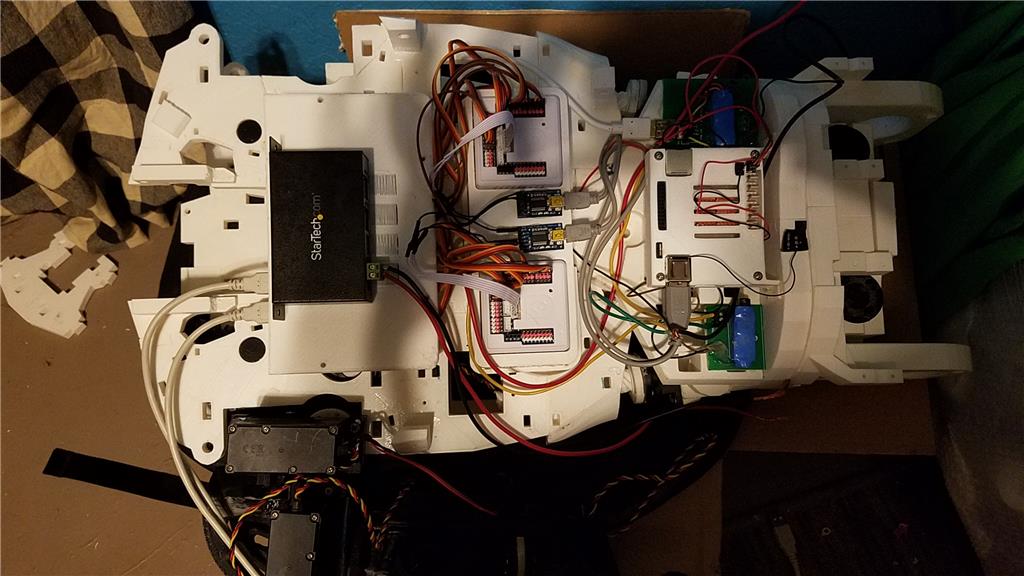

I have decided to use an onboard computer. I chose the Latte Panda due to it having an onboard arduino Leonardo and also because it uses little power.

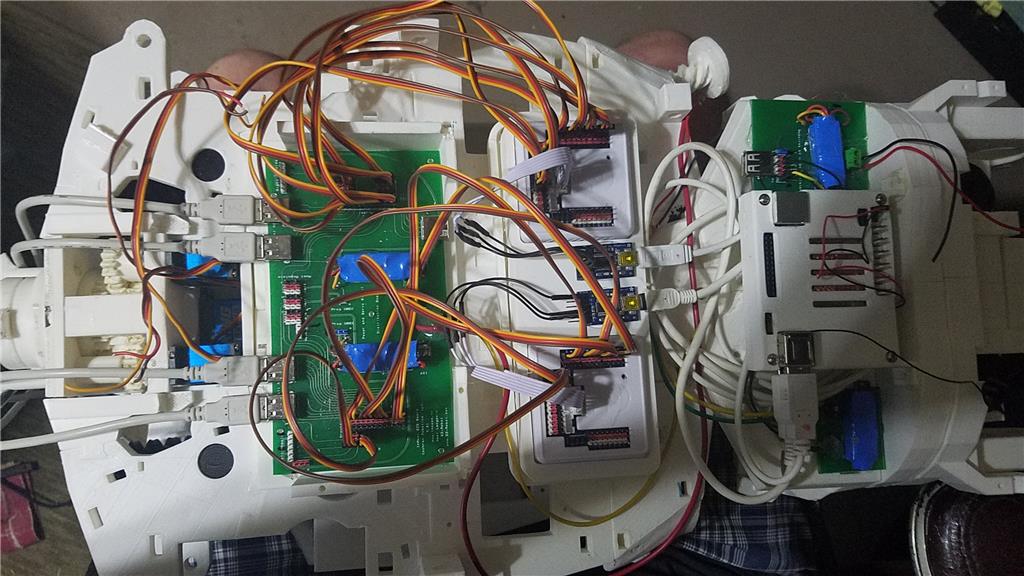

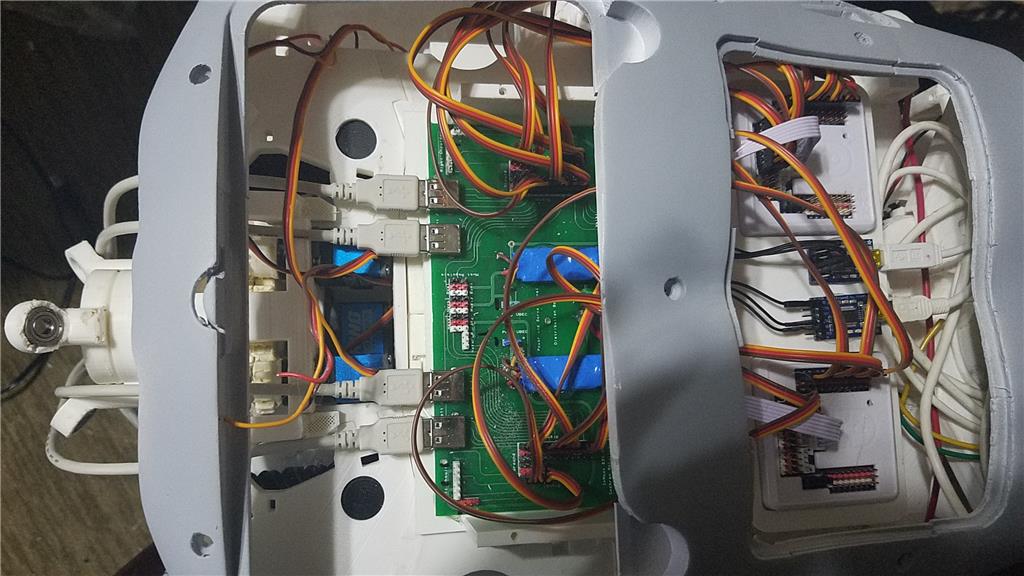

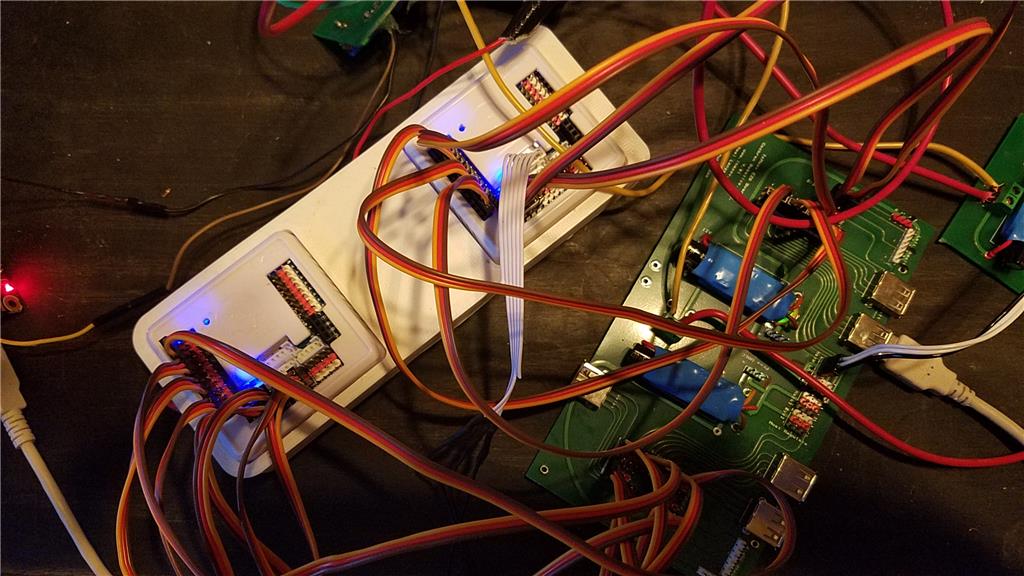

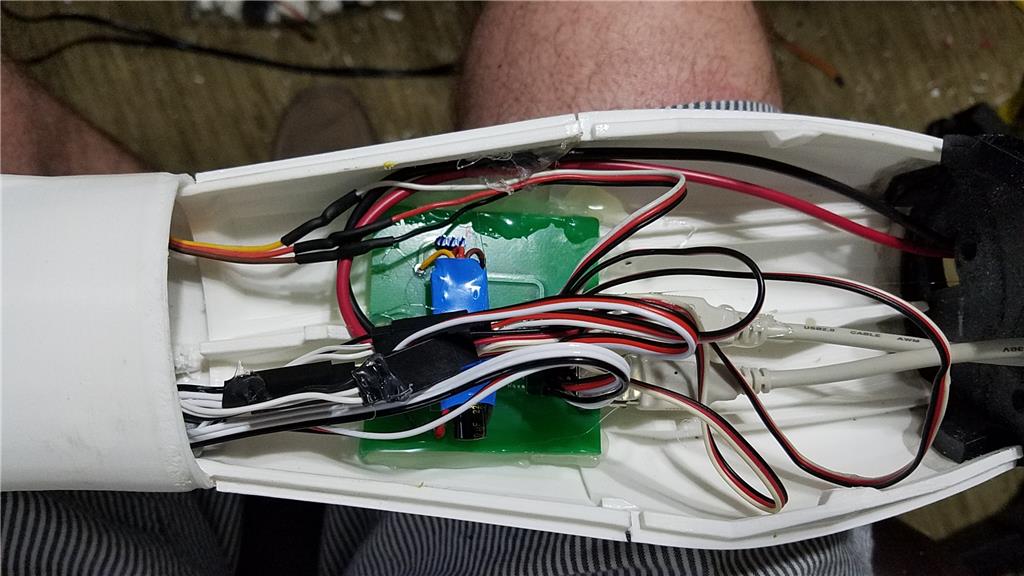

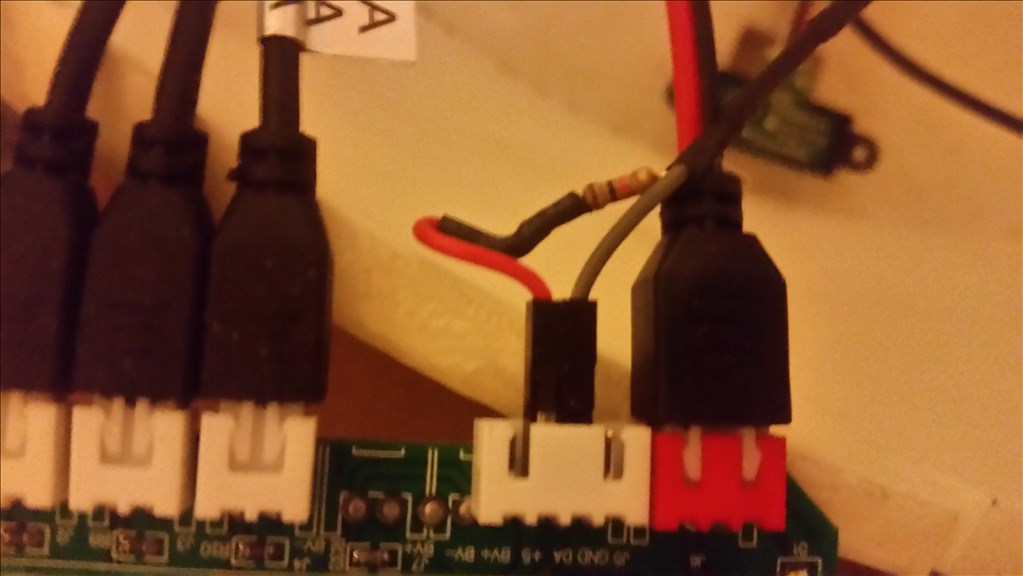

I used 2 EZ-B controllers connected via the camera port to Adafruit FTDI friend boards. This allows the Latte Panda to have a non-wifi dependent connection to the EZ-B's. I use a powered USB hub connected to the USB3 port on the Latte Panda to attach other items.

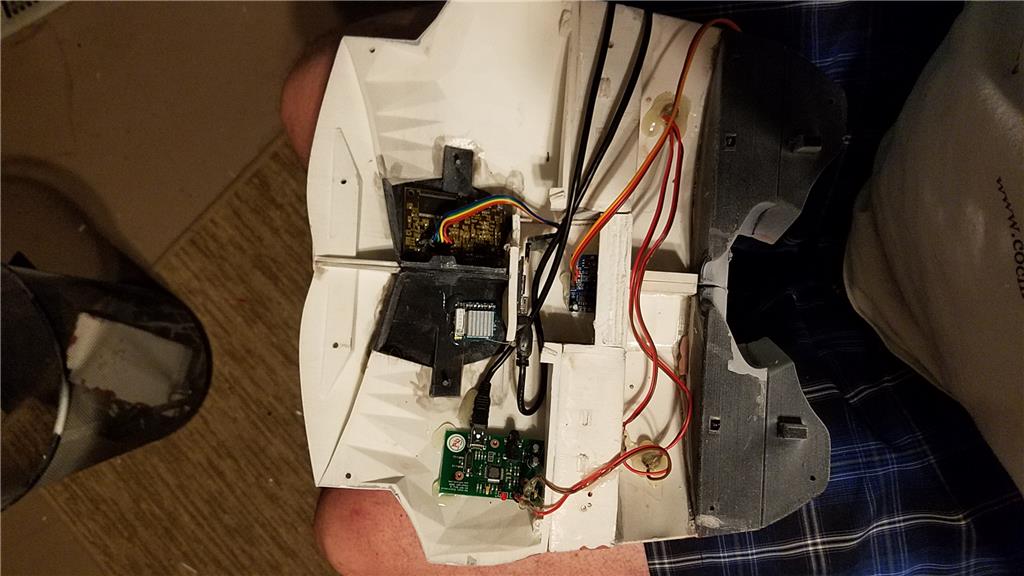

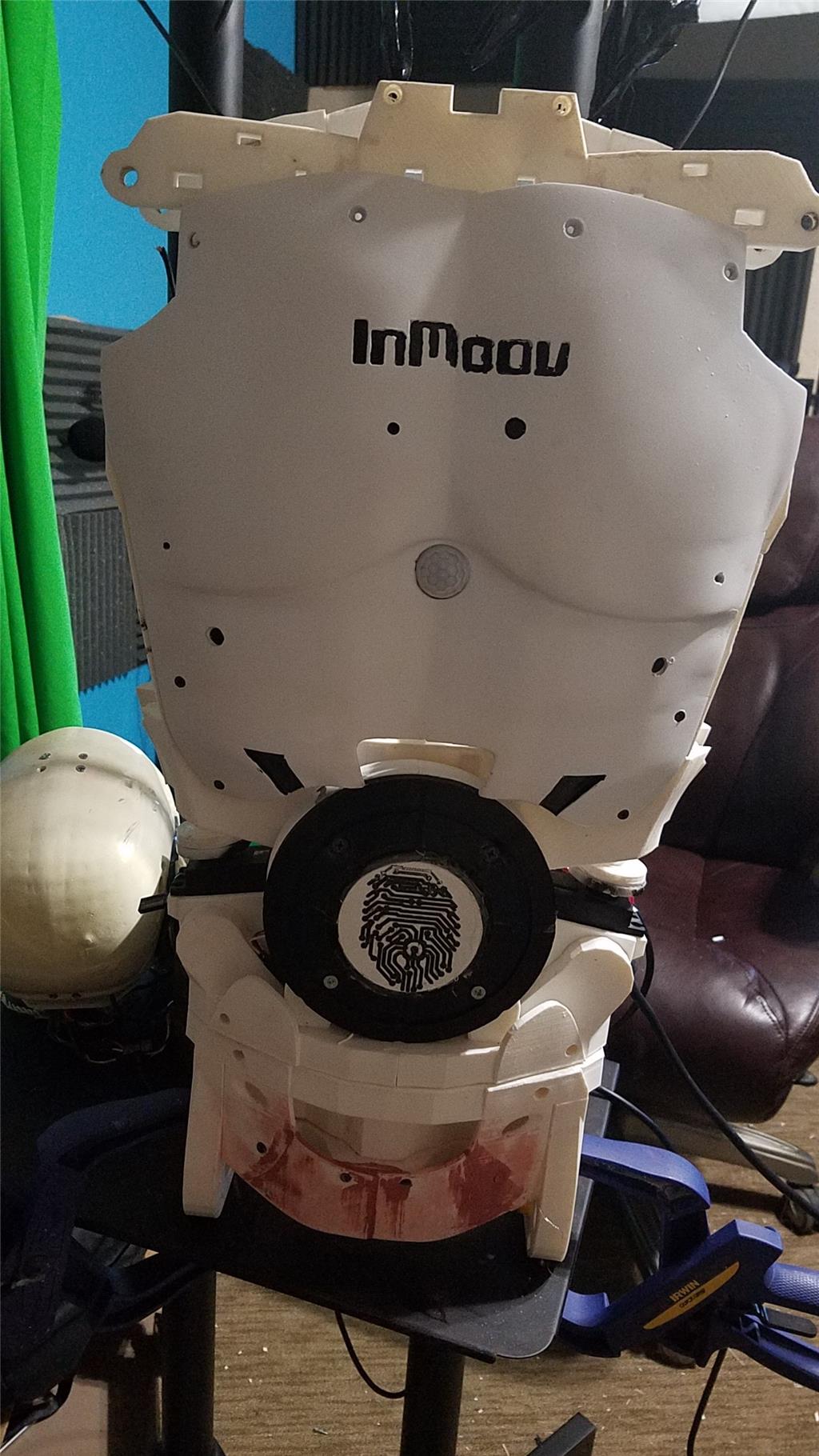

The Omron HVC-P is used to identify people, emotions, human bodies, hands, age and gender. It is attached to the Latte Panda via an FTDI friend which is then connected to the powered USB hub. It is mounted in the chest of the InMoov. I also use a 3 element microphone which is a MXL AC-404 microphone. It is disassembled and the board and microphone elements are mounted in the chest of the InMoov. This mic board is connected to the Latte Panda via a usb cable which is attached to the powered USB hub. There is a USB camera in the eye of the InMoov which is connected to the Latte Panda via the powered USB hub.

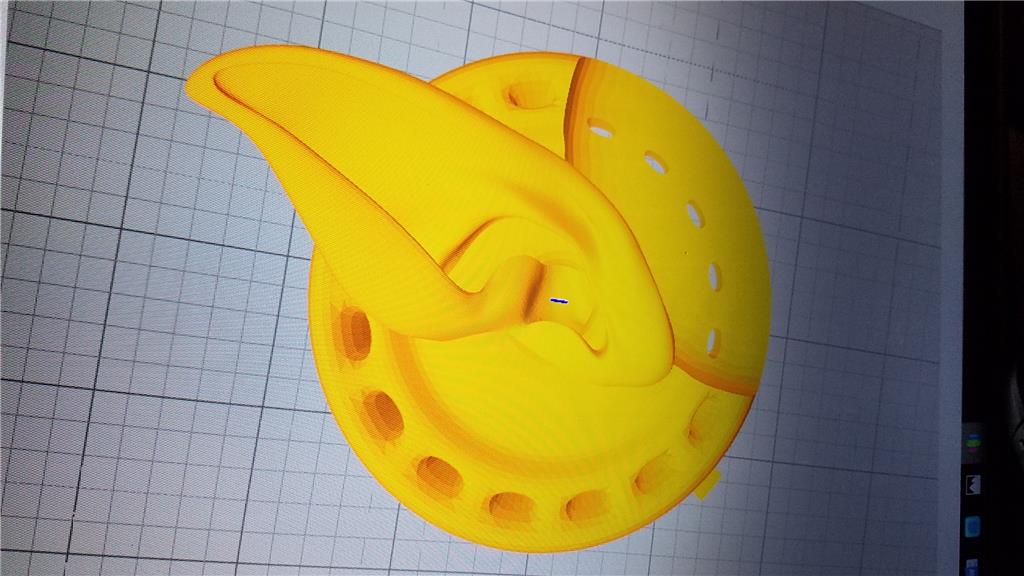

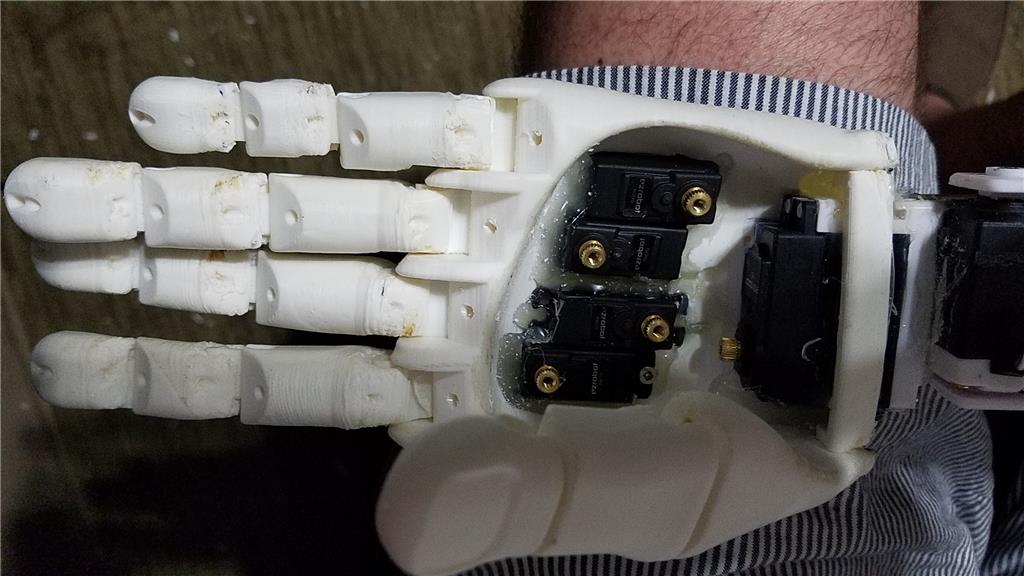

I chose to use the Flexy hand with the InMoov. The design is far more rugged than the original hand and works very well. There are 4 EZ-Robot Micro Servos in the palm of each hand which controls the main fingers. The thumb is controlled by an EZ-Robot HD servo. The wrist waves and uses an EZ-Robot HD servo to do this motion. I use the standard Rotational wrist.

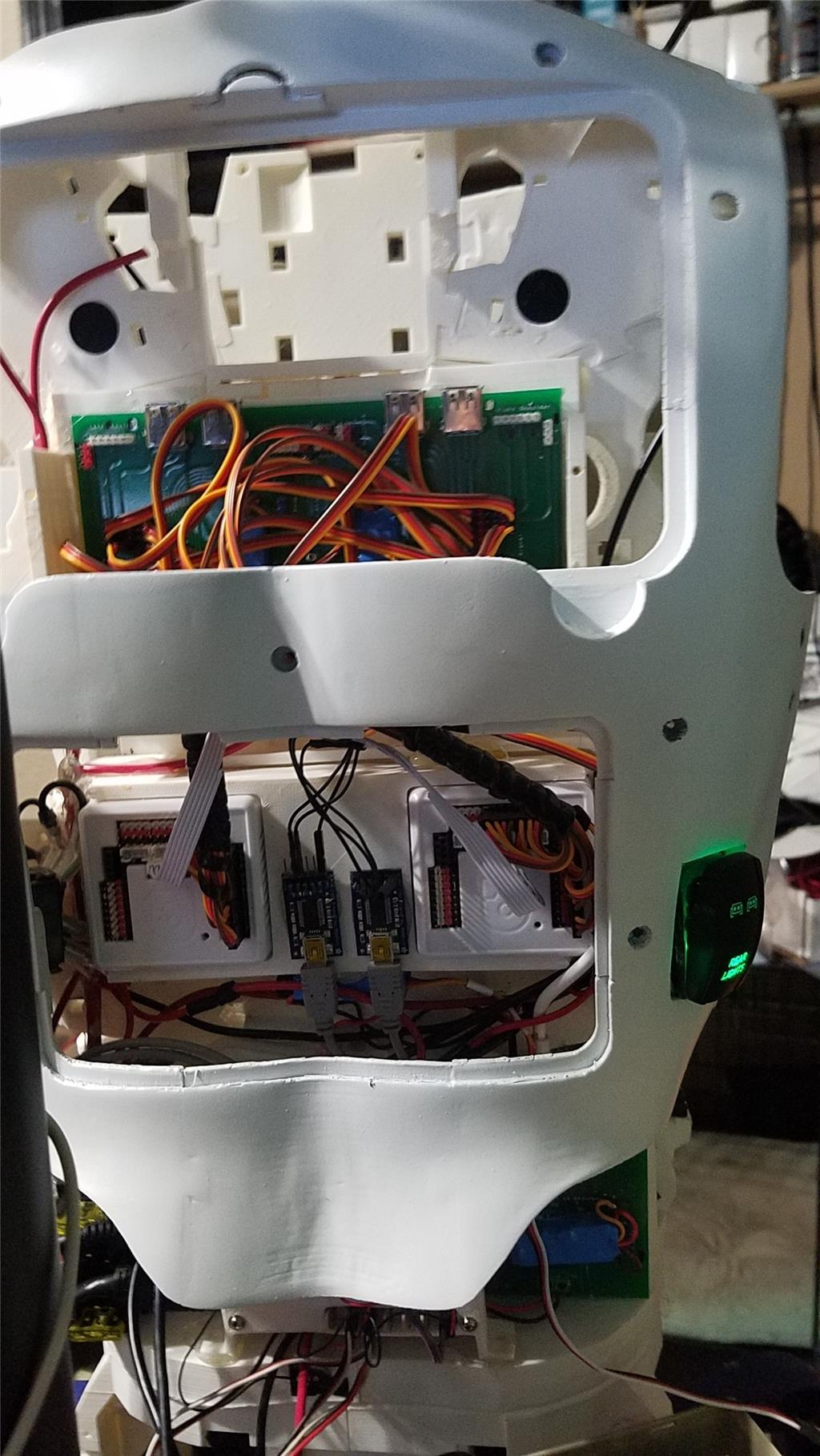

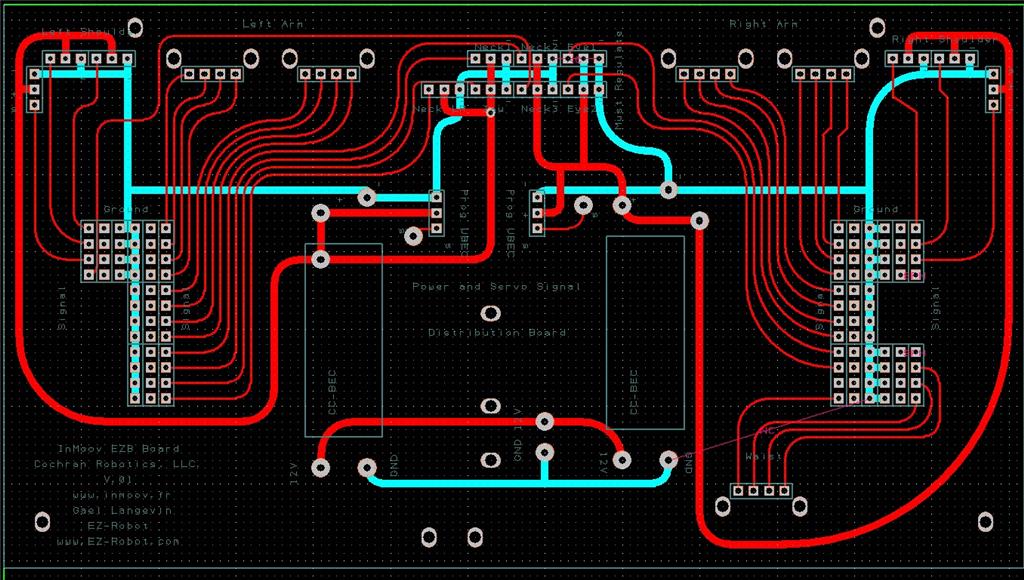

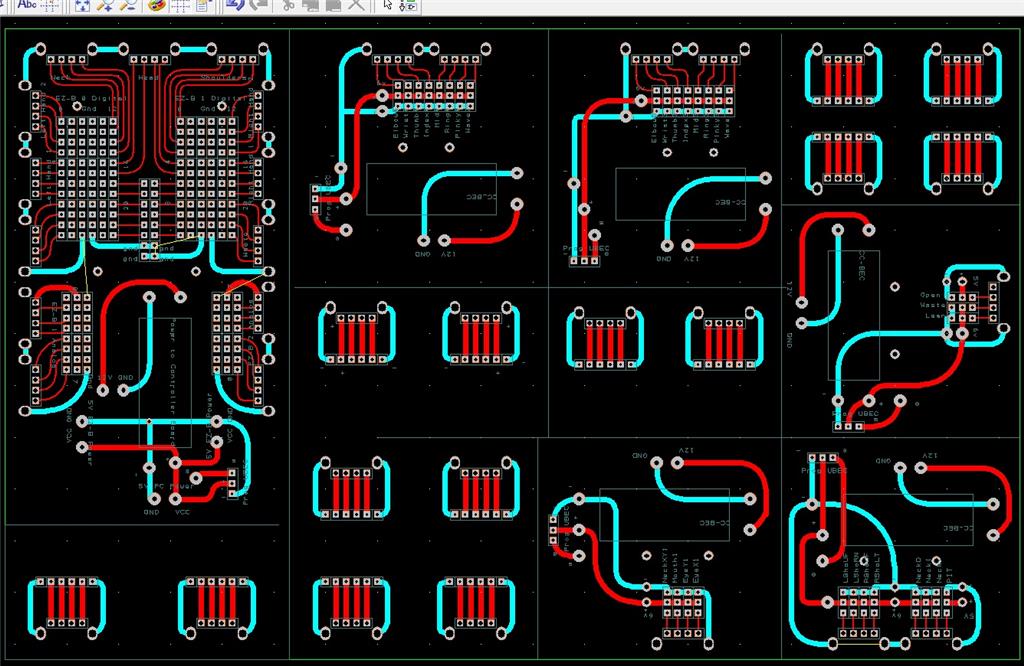

I have castle BEC's for power in the following locations set to the following voltages. Forearm's - 6.2 V - Controls fingers, wrist and elbows Custom power distribution board (2) set to 6.2 V controlling head, neck and Shoulder servos. EZ-B's - set to 6.1 V - it is mounted in the controller mounting plate and connects to the EZ-B fused power boards from a power base. Latte Panda - Set to 5.1 V and is mounted to the EZ-B controller mounting plate. Waist - set to 6.2 V and is mounted in the lower right side of the back. This provides power to the lean and pivot waist motors..

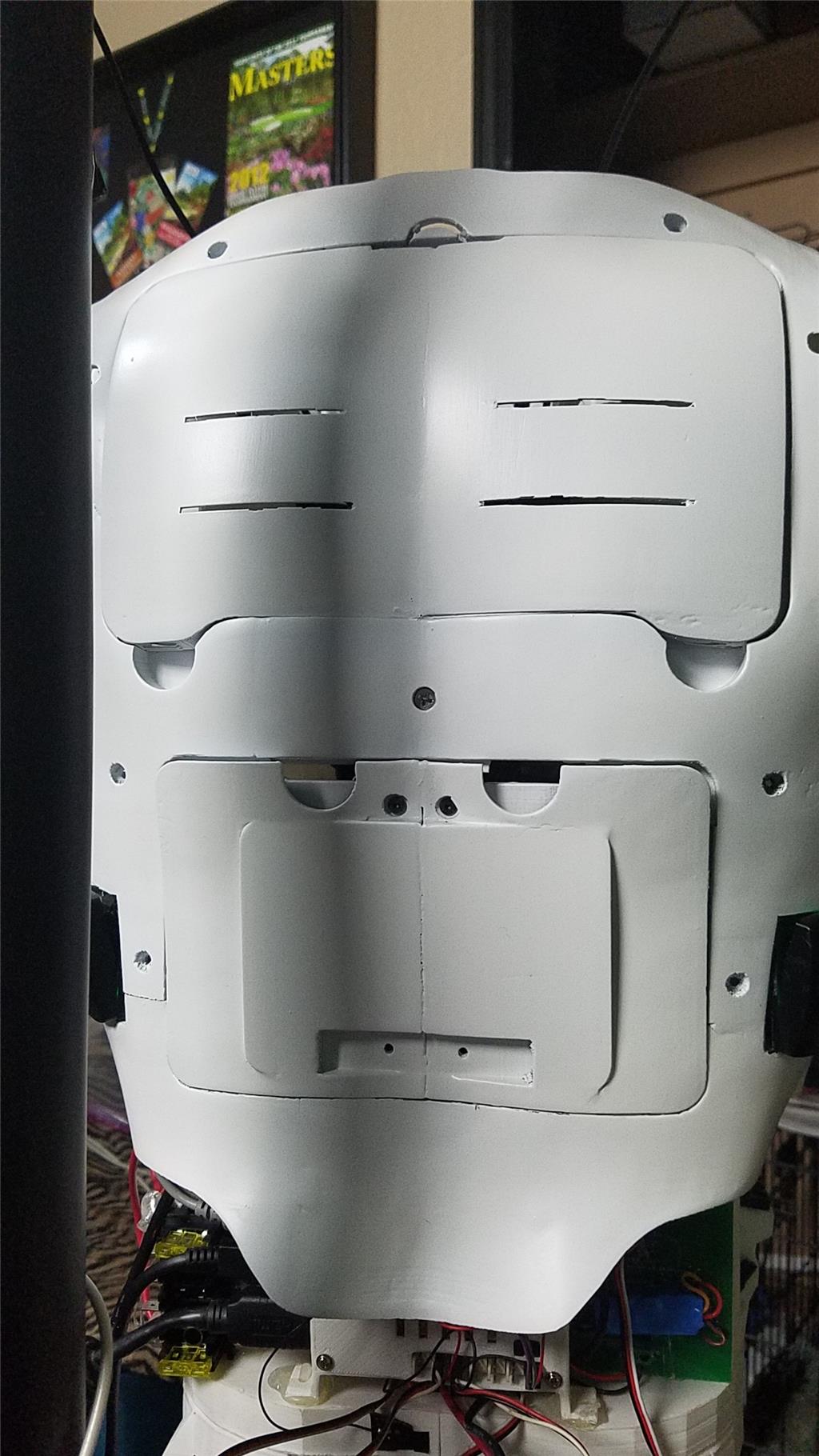

There are some custom power and signal distribution boards. These are in the forearms, lower back and in the upper back. The upper back or main board connects to these distribution points via USB cables to provide signal to the other boards for servos. The main board also has servo connector pins that are for the neck, head and shoulders. This allows the power to be distributed between multiple BEC's and also allows the servo signal cables to be shorter and more protected via the USB cables.

For power I use a LiFePo4 battery that is rated at 30 amps. It has the balanced charging circuit built into the battery and also has a low voltage shutoff built into the battery. This protects the battery and allows the battery to be charged with standard car chargers.

I put switches on the back on the InMoov which are rated at 20 amps at 12 volts. These are rocker switches that allow the user to pretty much slap the switch to turn it off. There are two of these switches. The servos for the elbows and fingers are on one switch. The latte panda, neck, shoulders, EZ-B's, waist motors and some lighting is on the other switch.

I also added a fuse block. This allows 20 amp fuses to be put in line to help protect things. The switches above drive the fuses for each of of the motors listed in that section.

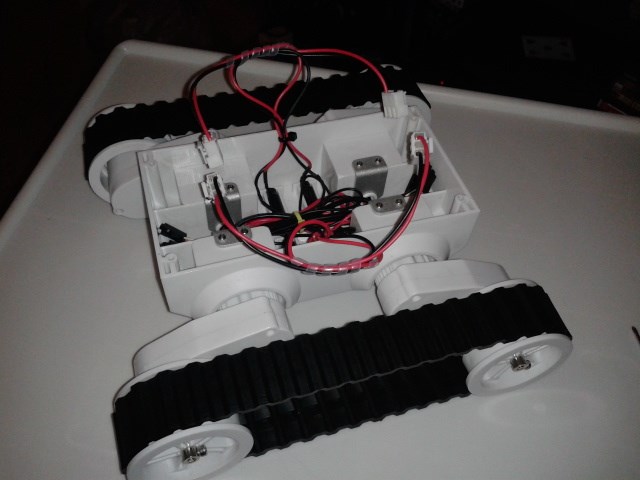

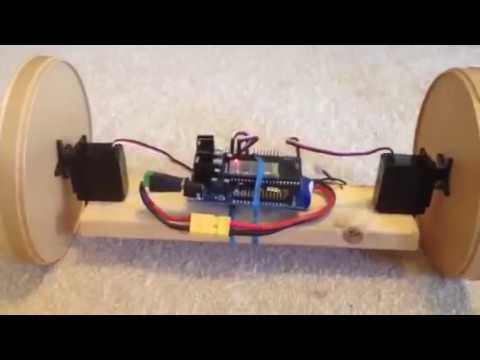

Other robots from Synthiam community

Billderwent's Boris V2

Steve's Rolling Bot Ez Robot Experiment

-636348381130562972.jpg)

-636348716348649435.jpg)

Thanks guys. Dave, I agree. It's easier in a way I guess. 0 in head, 1 in chest, 2 right arm, 3 left arm and 4 base. The more complicated part (I think) is that it pretty much eliminates the possibility of using the Auto Position control. Other than that. It won't be bad. In a way, it makes identifying what I am doing in scripts easier. D0 for thumb, d1 index, so on with two of the v4's. Very few servos on the other controllers. Knowing or remembering what port goes to what becomes much easier.

Each arm including fingers / wrist / elbow / 3 servos for shoulder, total 10

Each arm will have 2 cables. One individual power cable going to power supply One HDMI cable ( 20 available connections) Connected to EZB at the back One EZB controler should be enough to drive 2 arms

Still there are 10 extra connections on each arm available for sensors or other

The inspiration comes from Markus in Youtube

HDMI connection in Inmoov

I was looking at using the HDMI cables but realized that if I could fit a v4 in the arm, this would eliminate the need for the hdmi cable. I love what he has done, but want to take it one step further . I will probably use the hdmi breakout device he has used. I plan on running one power cable down the arm to a block in the arm. From there I would split the cables on the servos out to power them from the block along with powering the V4 that is in the arm from the block. I would take all of the servo signal cables and run them to the digital signal pins on the v4 that is in the arm. This would take the number of wires that are passing through the shoulder down to 2 (one positive and one negative power). This would be easier to hide in the shoulder.

. I will probably use the hdmi breakout device he has used. I plan on running one power cable down the arm to a block in the arm. From there I would split the cables on the servos out to power them from the block along with powering the V4 that is in the arm from the block. I would take all of the servo signal cables and run them to the digital signal pins on the v4 that is in the arm. This would take the number of wires that are passing through the shoulder down to 2 (one positive and one negative power). This would be easier to hide in the shoulder.

The other option is for me just to power these 10 servos off of the v4. The only issue that I have with that is that the large servos especially could draw quite a few amps on startup.

I had the extra V4's laying here and thought that if I used them for this project, I could reduce the length of the wires which has its benefits in multiple areas. I am trying to see if there is room in the upper arm to house the V4 and the wires that would need to go to it. I realize that this will add some weight but really this is small if placed high enough in the shoulder. I would probably use the run of hdmi cable to pass through the elbow and provide power and signal to the hand servos and the rotational wrist servo.

This solution would make the inmoov more modular. I would also put a power connection at the shoulder so that the arm could be removed as one unit and tested as one unit. I would do the same with all of the other body parts making the inmoov effectively 5 separate robots working together through ARC, which can use up to 5 EZ-B's in the same project.

All of this does depend on if I can find a location to house the V4. If I need to, I will remove it from its case. The V4's have been modified to not use the mini deens connection for power.

this one might be better for my use.

I am thinking about adding 5 arduino mini's to this project, 1 for each EZ-B. I would use these to do things like control neopixel rings or strips for some cool lighting in different areas. I would also use the ones in the arms to add touch sensors to the fingers or hands of the InMoov. I don't have a lot of experience programming on Arduino but there is no time like the present to learn, right?

David, If I can do basic programming on arduinos you will excel at it... It is basically C++ and their is a ton of example code all over the internet and within the Arduino IDE itself...

Is there a difference in mini's? I find quite a difference is prices. Trying to figure out what the differences are. The only real arduino experience I have is from the controller on my 3d printer. That really doesn't count...

Here's a Arduino URL that may give you some additional info about the choices available.