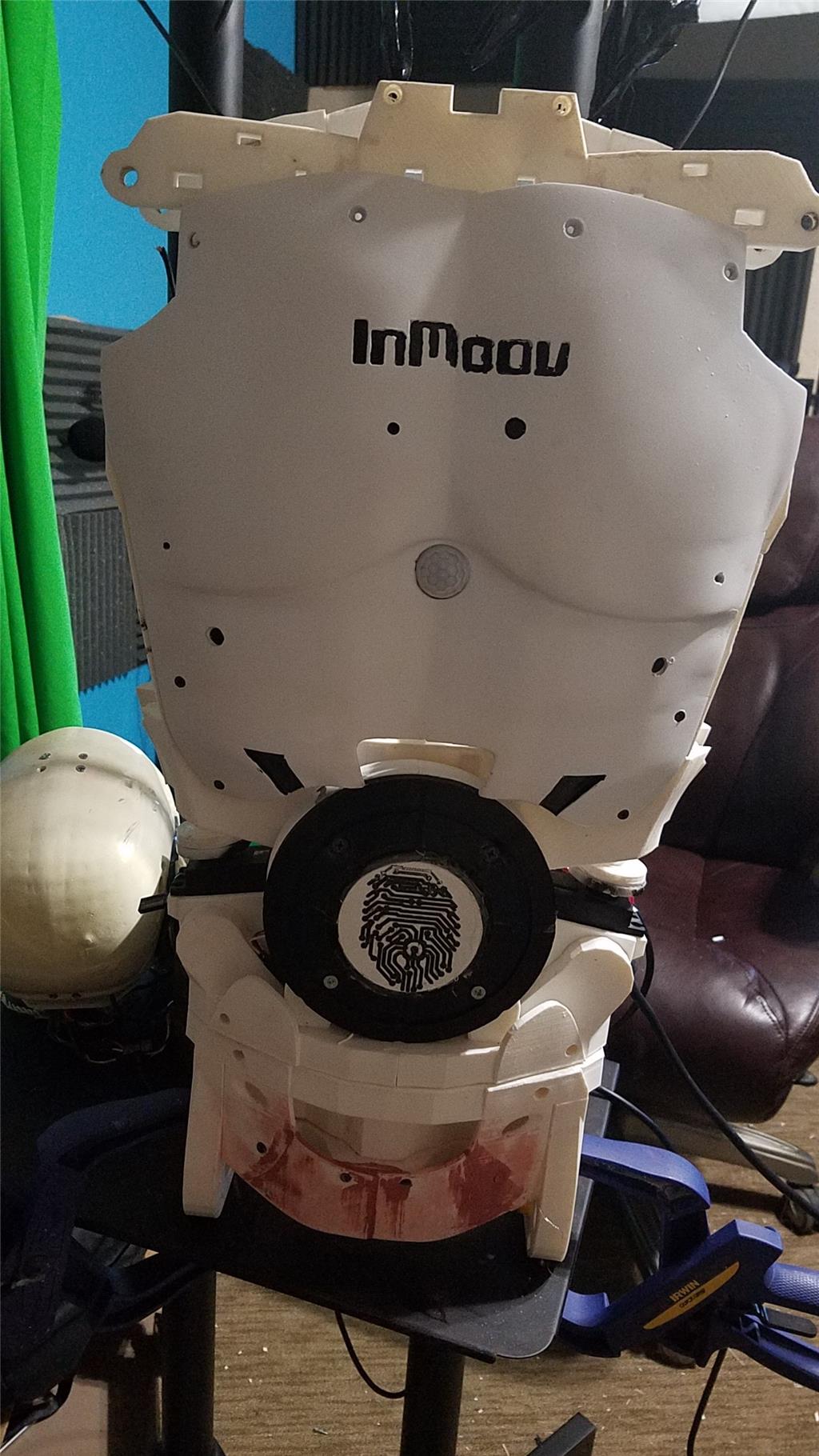

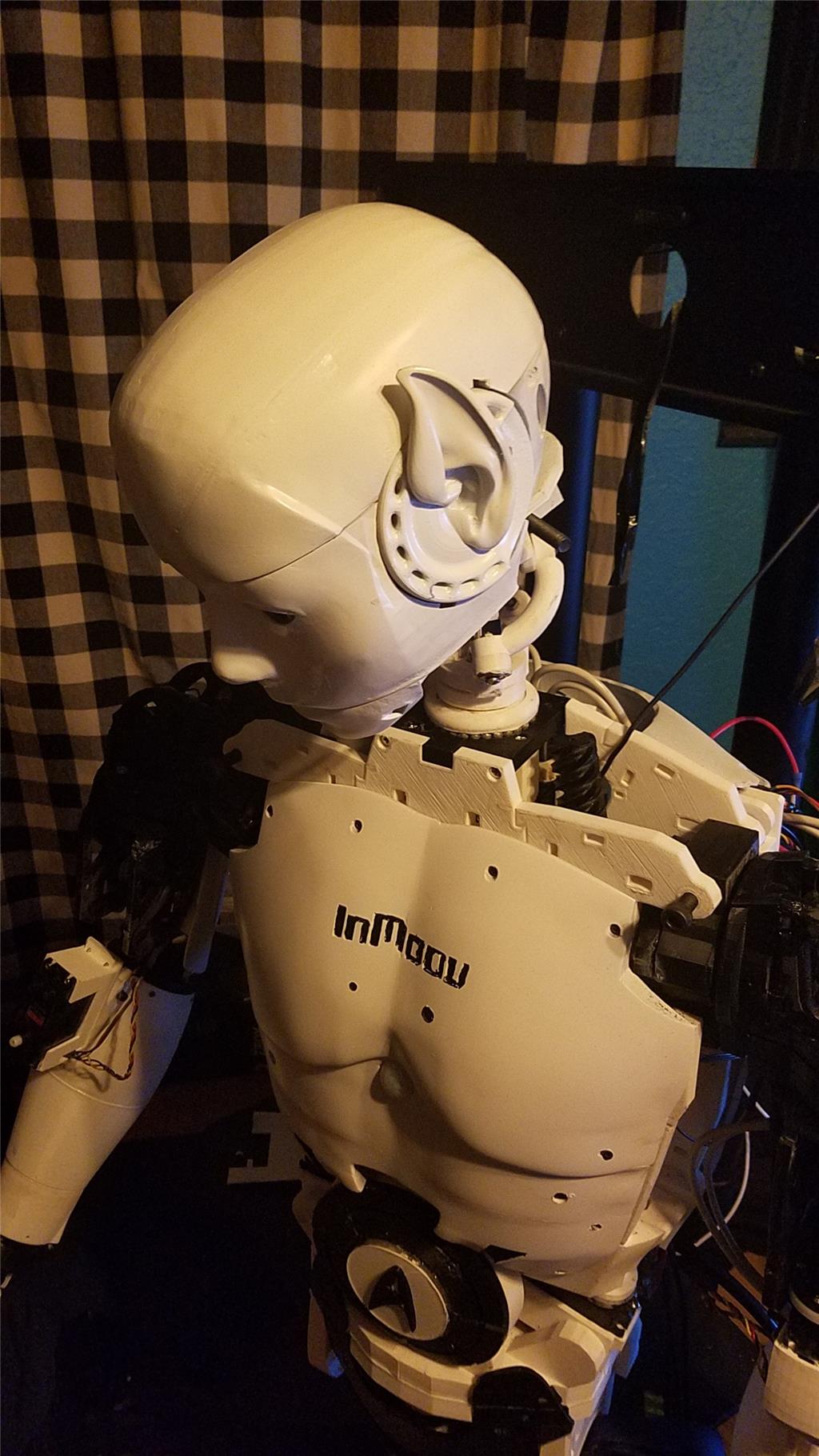

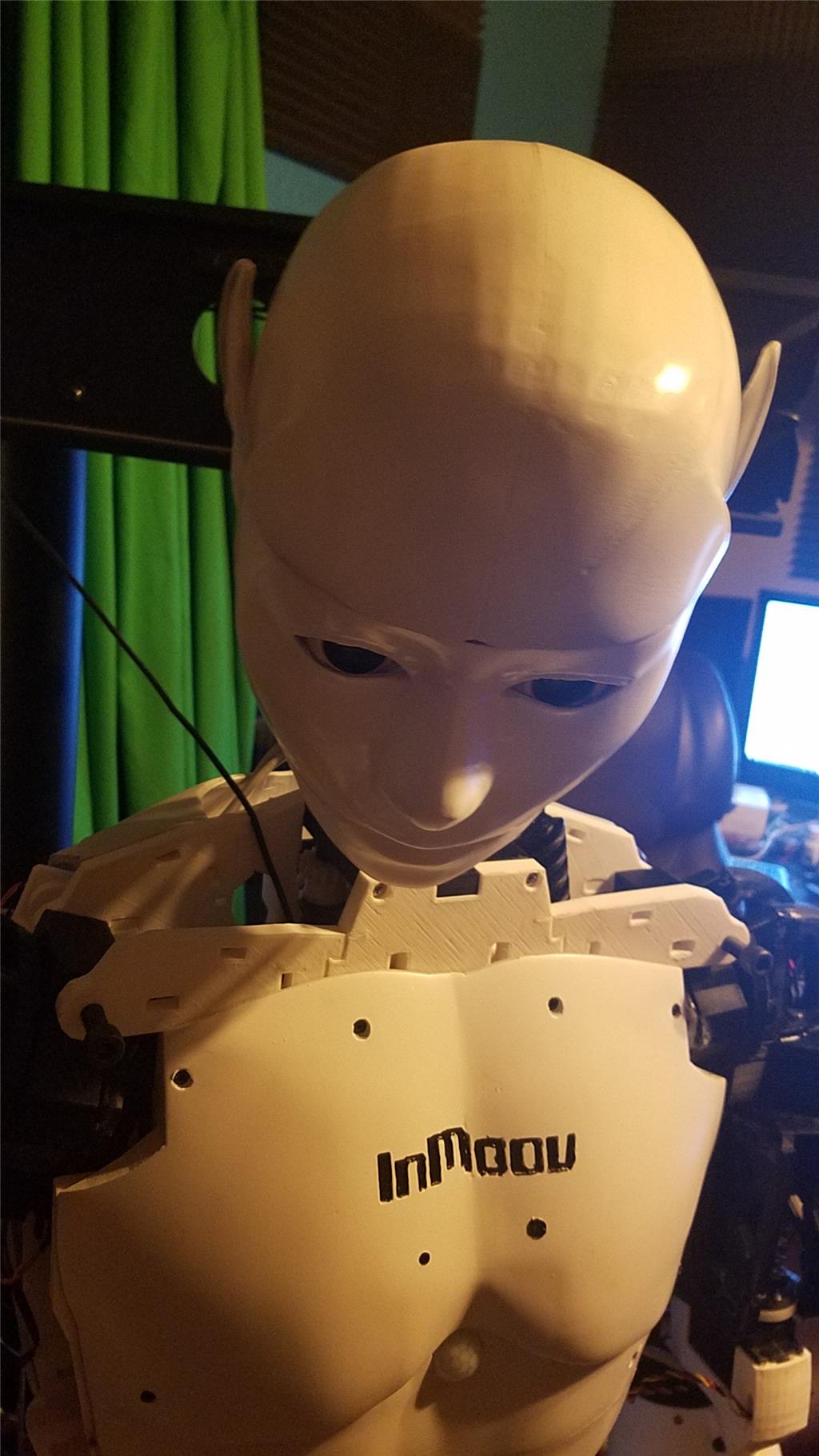

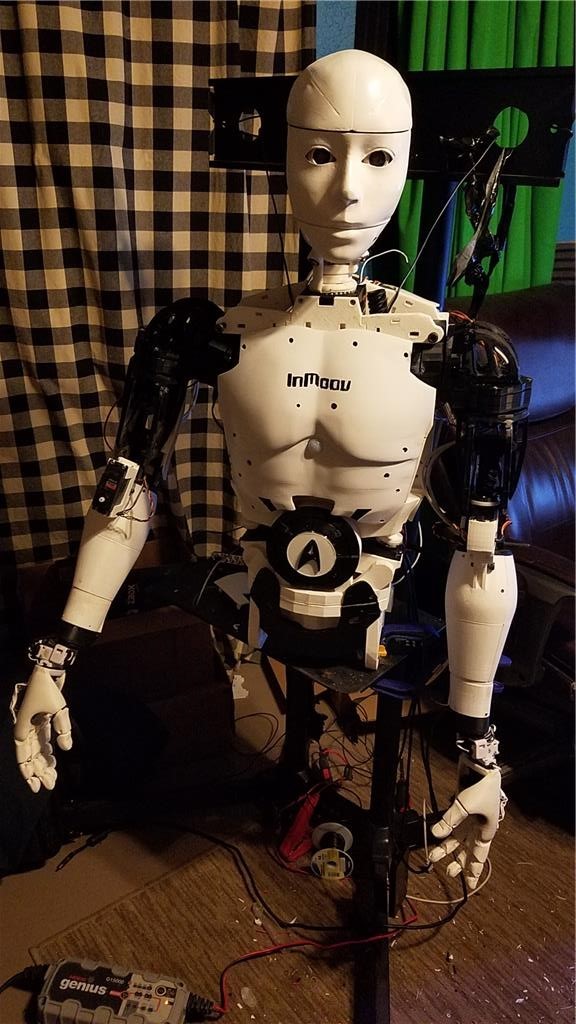

I have decided to start my InMoov project. I think I will call him Spock out of respect to Leonard Nimoy who passed away on the day that I started this project.

I am editing this post so as not to confuse people with the current configuration. I continue to update this post with the latest photos. If you are reading this for the first time, don't be confused. There have been a lot of changes to the InMoov over the past couple of years including starting over.

https://synthiam.com/Community/Questions/7398&page=21 Post 203 starts the rebuild of the InMoov.

I have decided to use an onboard computer. I chose the Latte Panda due to it having an onboard arduino Leonardo and also because it uses little power.

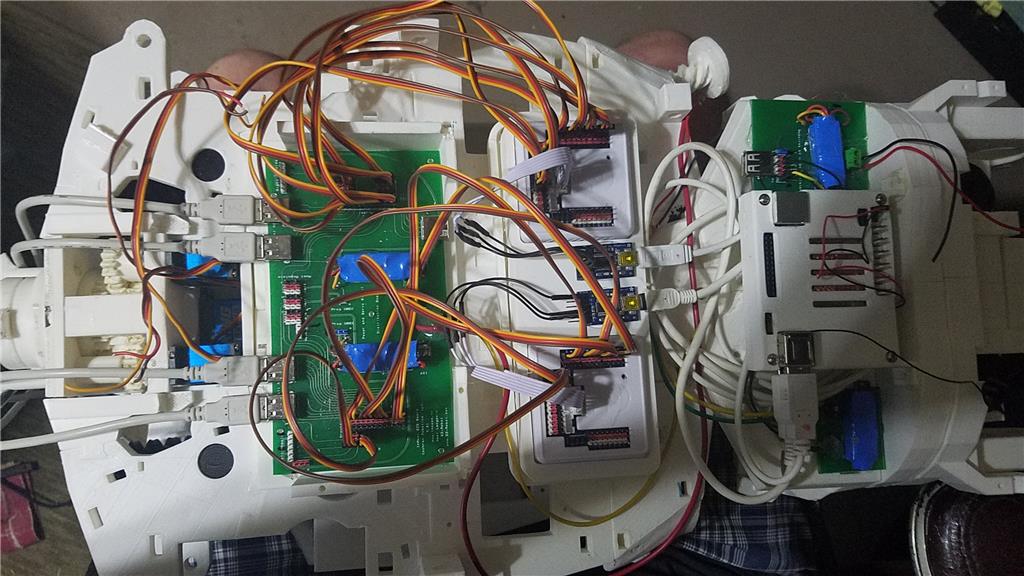

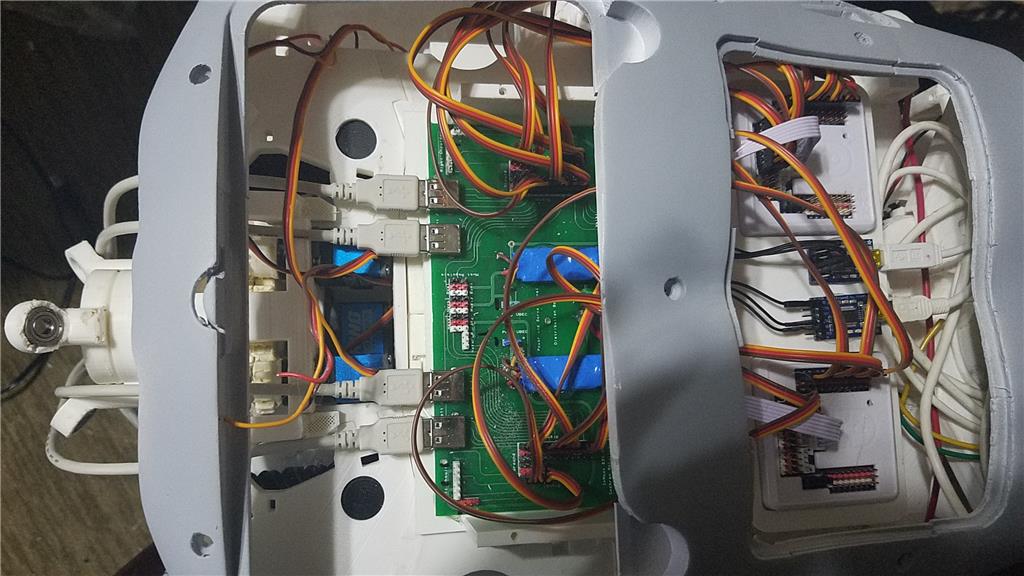

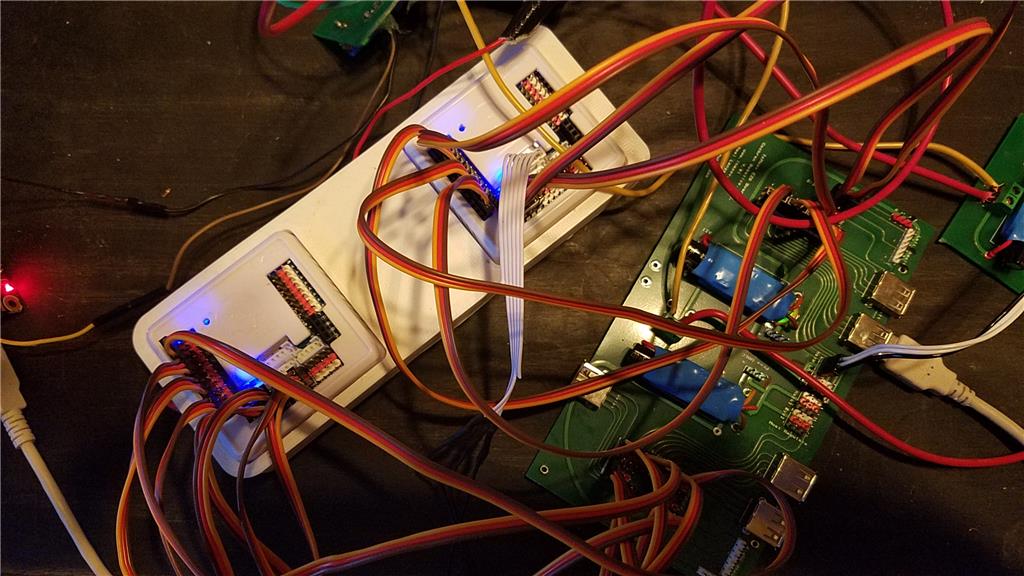

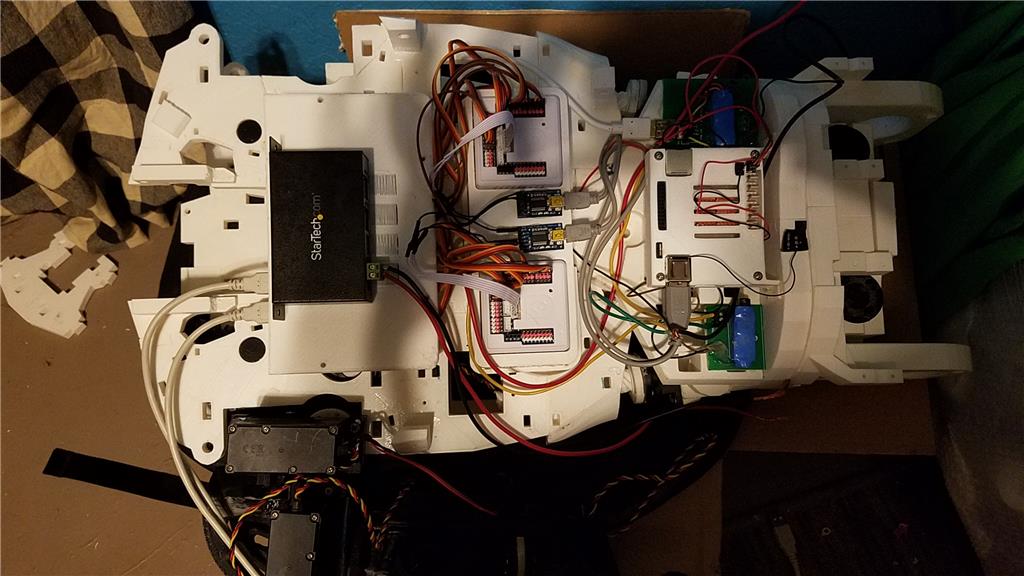

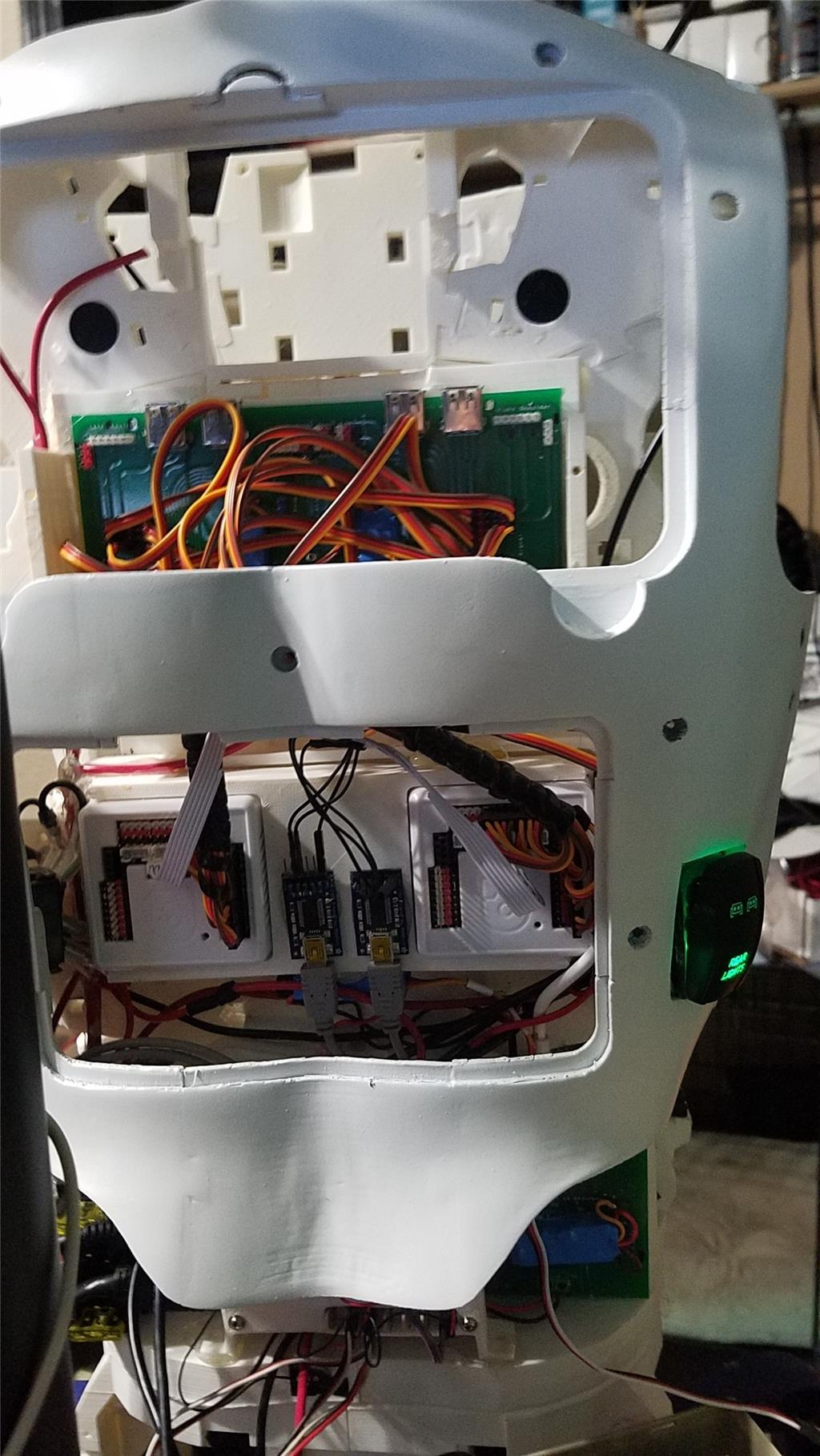

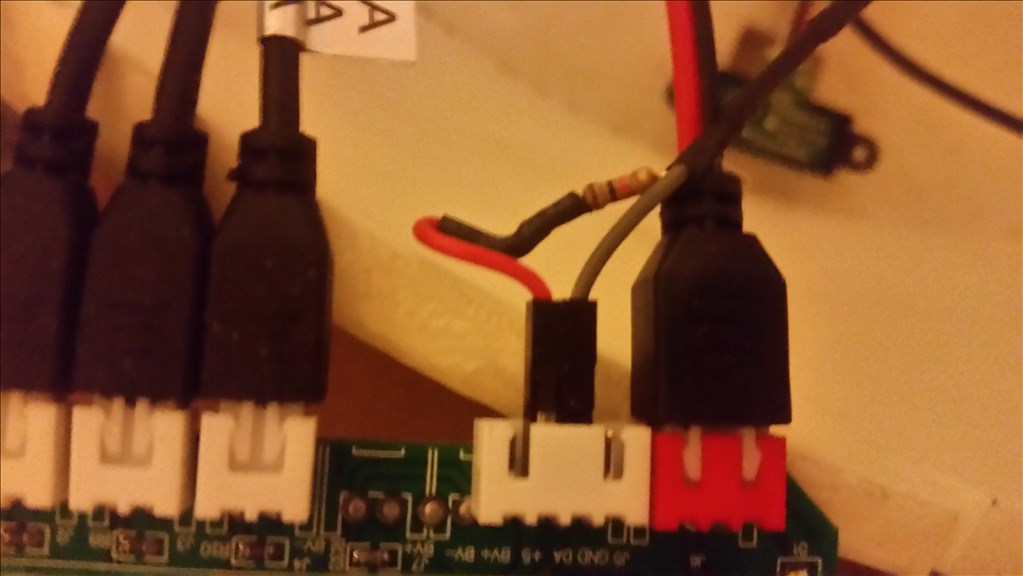

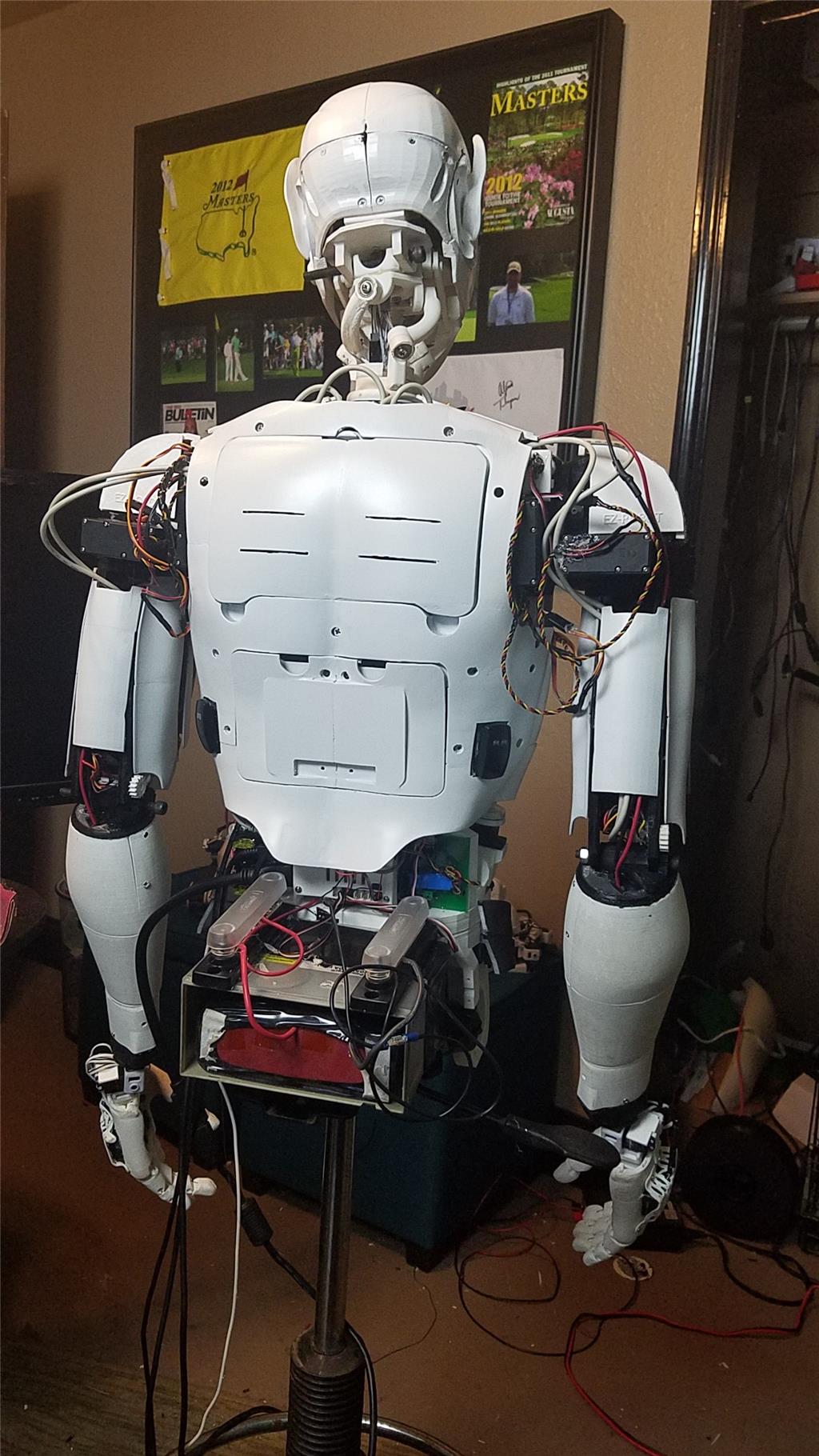

I used 2 EZ-B controllers connected via the camera port to Adafruit FTDI friend boards. This allows the Latte Panda to have a non-wifi dependent connection to the EZ-B's. I use a powered USB hub connected to the USB3 port on the Latte Panda to attach other items.

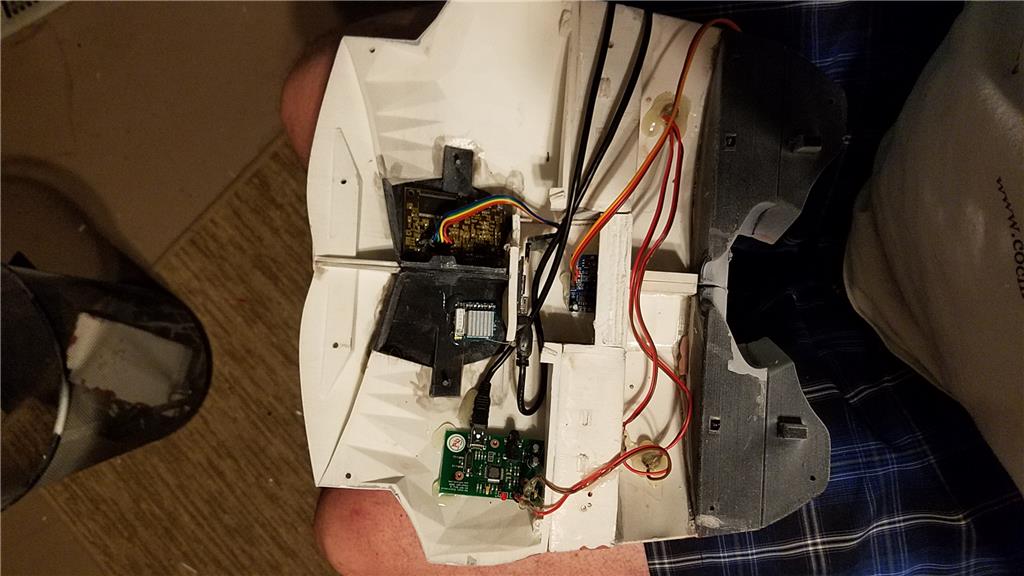

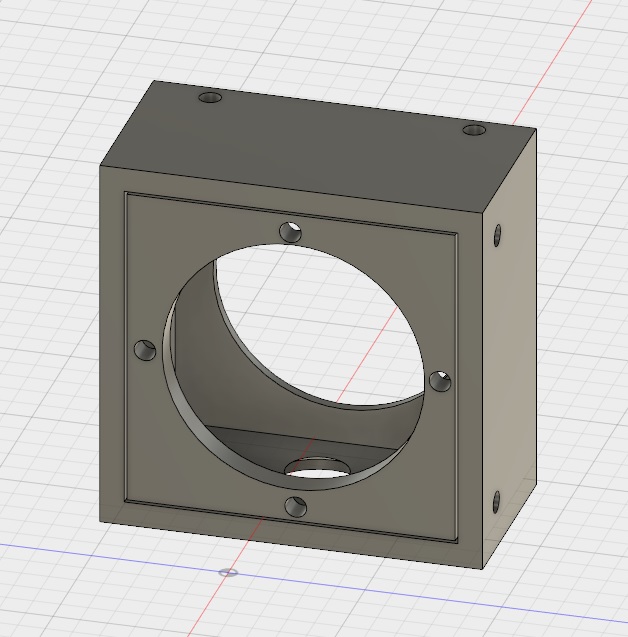

The Omron HVC-P is used to identify people, emotions, human bodies, hands, age and gender. It is attached to the Latte Panda via an FTDI friend which is then connected to the powered USB hub. It is mounted in the chest of the InMoov. I also use a 3 element microphone which is a MXL AC-404 microphone. It is disassembled and the board and microphone elements are mounted in the chest of the InMoov. This mic board is connected to the Latte Panda via a usb cable which is attached to the powered USB hub. There is a USB camera in the eye of the InMoov which is connected to the Latte Panda via the powered USB hub.

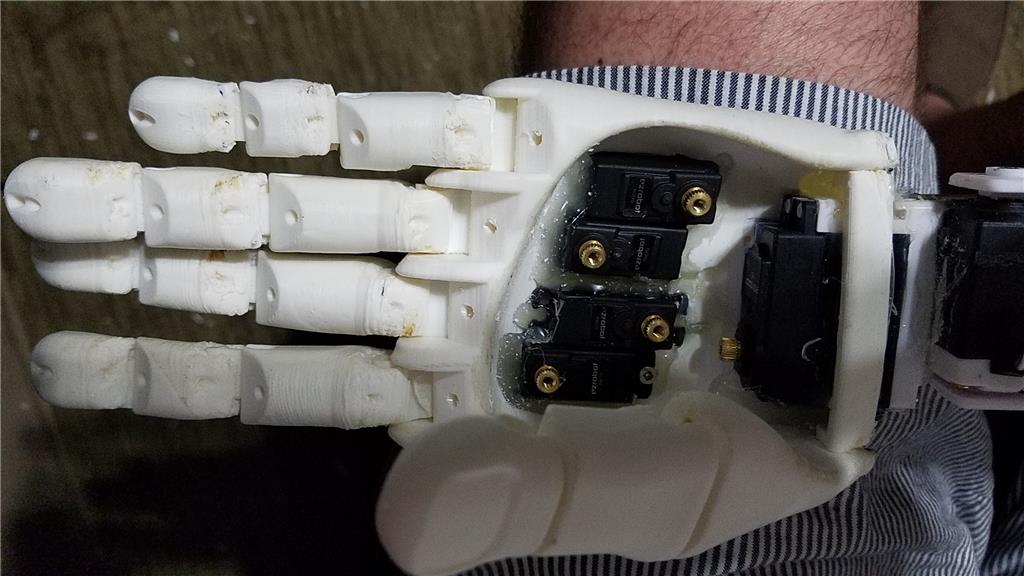

I chose to use the Flexy hand with the InMoov. The design is far more rugged than the original hand and works very well. There are 4 EZ-Robot Micro Servos in the palm of each hand which controls the main fingers. The thumb is controlled by an EZ-Robot HD servo. The wrist waves and uses an EZ-Robot HD servo to do this motion. I use the standard Rotational wrist.

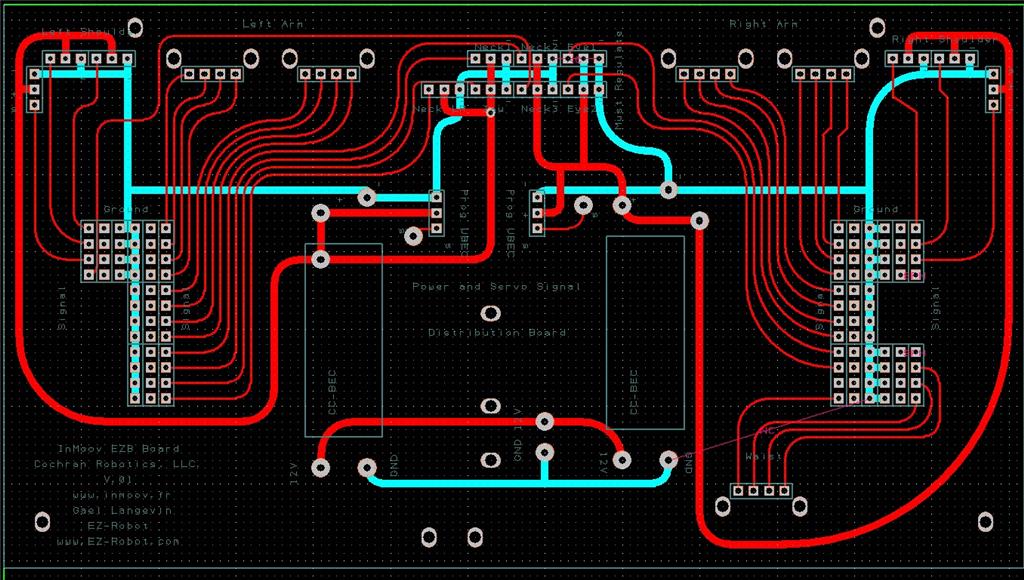

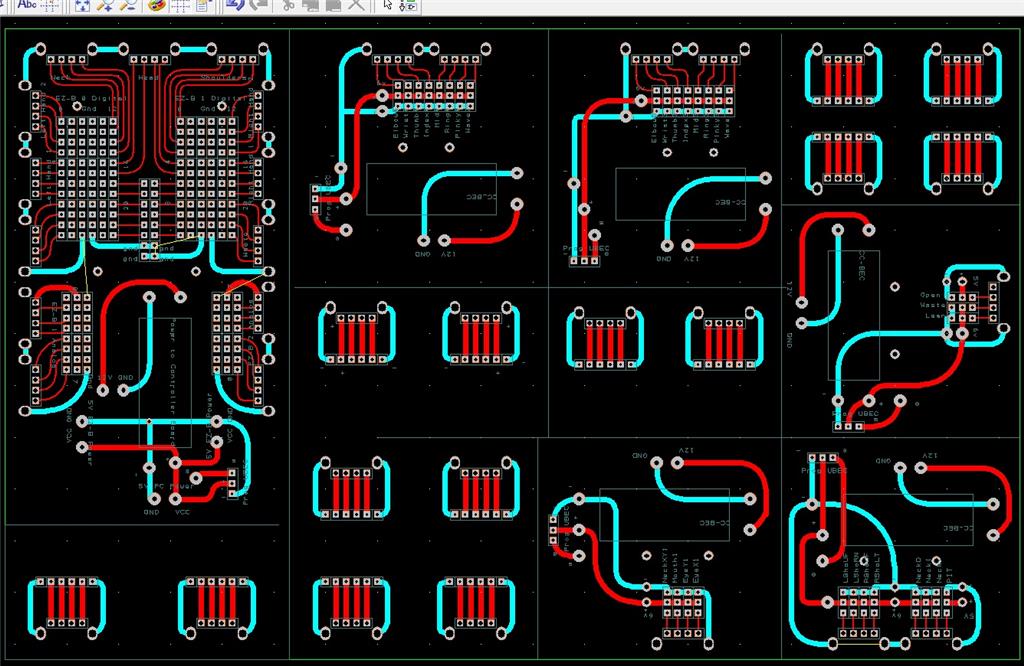

I have castle BEC's for power in the following locations set to the following voltages. Forearm's - 6.2 V - Controls fingers, wrist and elbows Custom power distribution board (2) set to 6.2 V controlling head, neck and Shoulder servos. EZ-B's - set to 6.1 V - it is mounted in the controller mounting plate and connects to the EZ-B fused power boards from a power base. Latte Panda - Set to 5.1 V and is mounted to the EZ-B controller mounting plate. Waist - set to 6.2 V and is mounted in the lower right side of the back. This provides power to the lean and pivot waist motors..

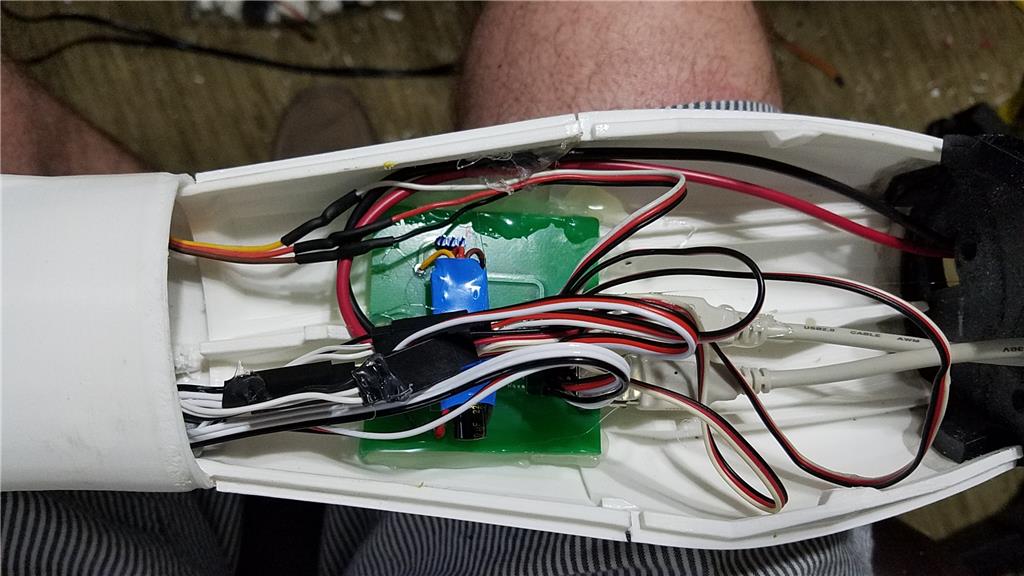

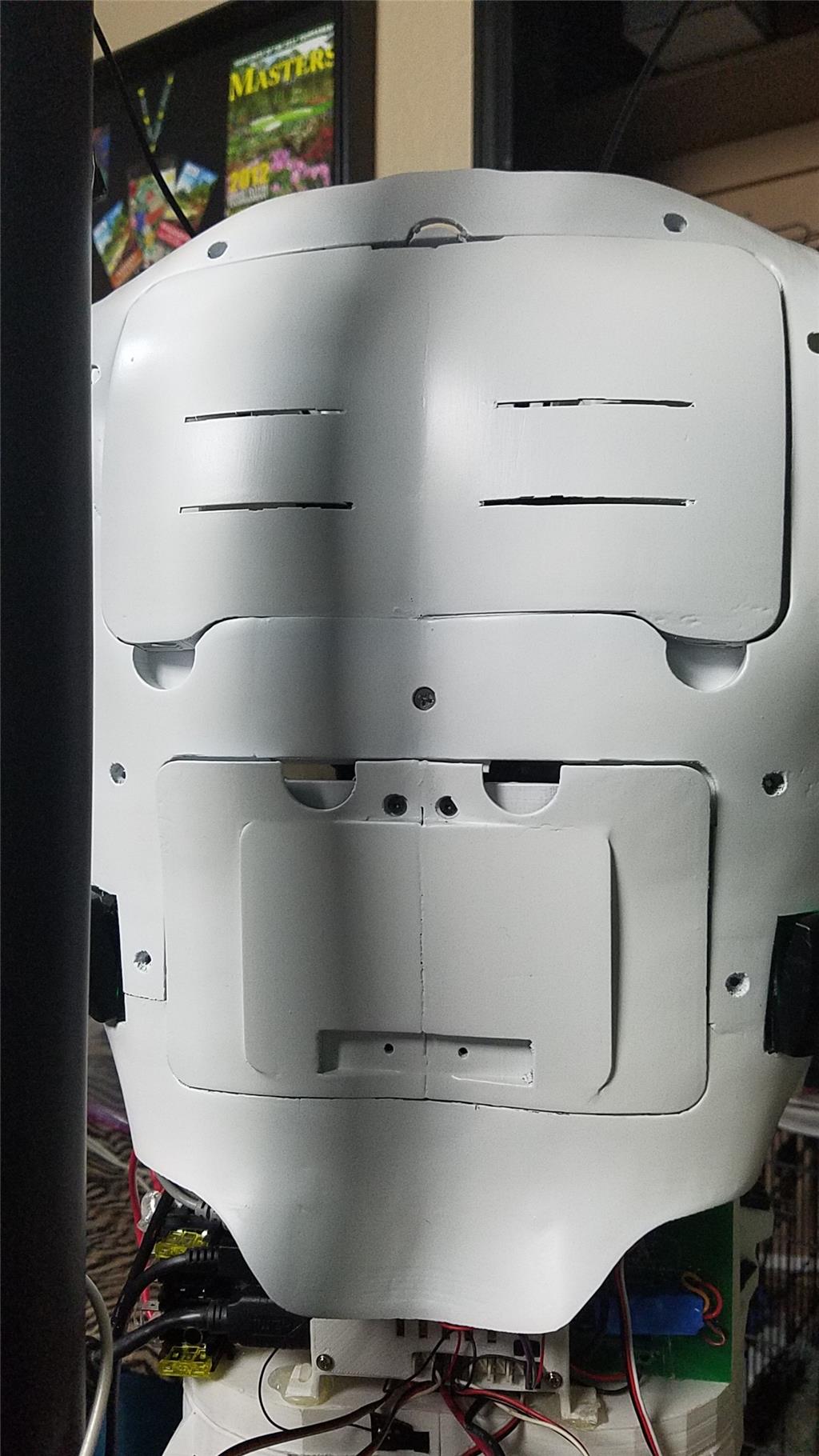

There are some custom power and signal distribution boards. These are in the forearms, lower back and in the upper back. The upper back or main board connects to these distribution points via USB cables to provide signal to the other boards for servos. The main board also has servo connector pins that are for the neck, head and shoulders. This allows the power to be distributed between multiple BEC's and also allows the servo signal cables to be shorter and more protected via the USB cables.

For power I use a LiFePo4 battery that is rated at 30 amps. It has the balanced charging circuit built into the battery and also has a low voltage shutoff built into the battery. This protects the battery and allows the battery to be charged with standard car chargers.

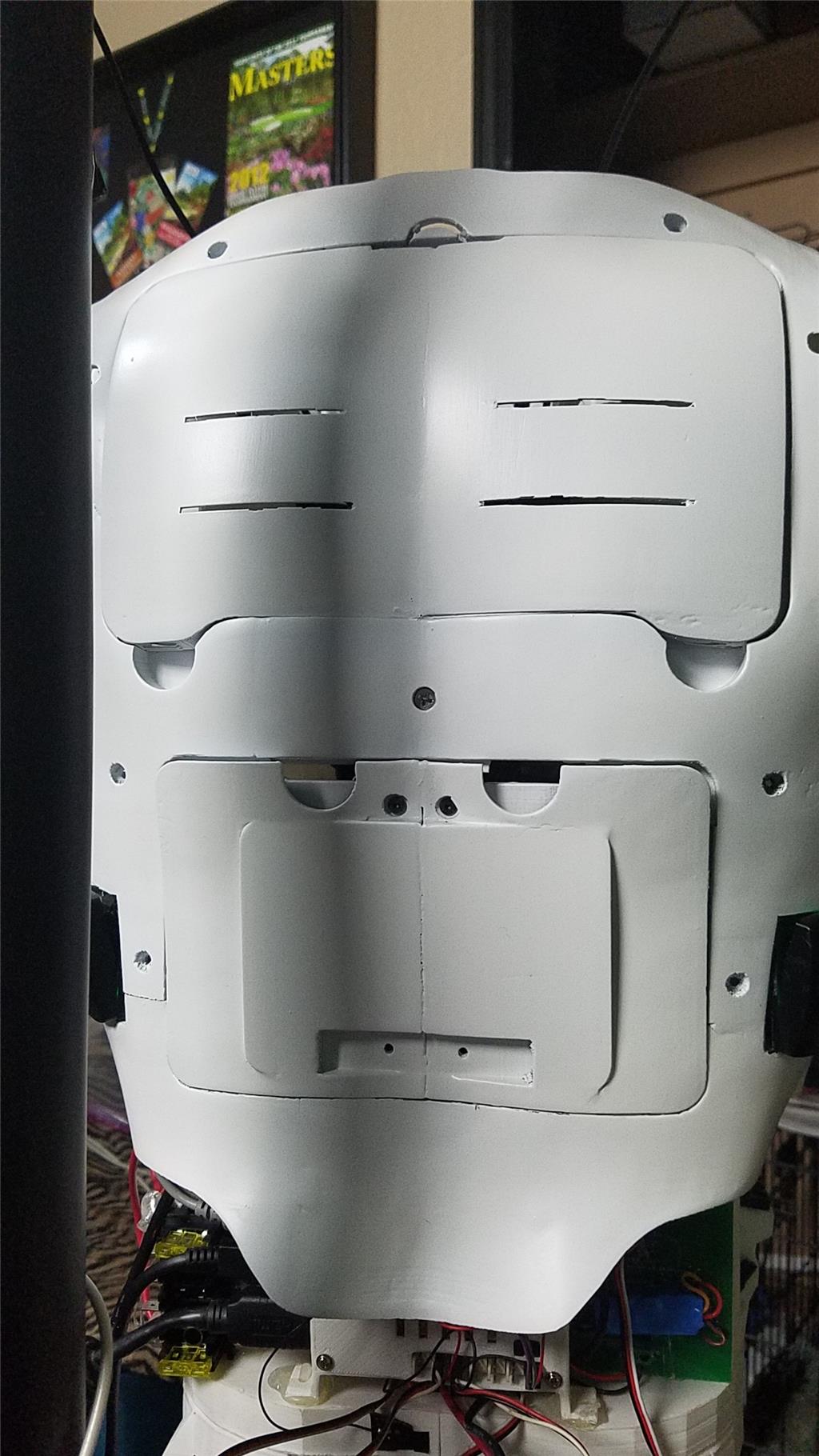

I put switches on the back on the InMoov which are rated at 20 amps at 12 volts. These are rocker switches that allow the user to pretty much slap the switch to turn it off. There are two of these switches. The servos for the elbows and fingers are on one switch. The latte panda, neck, shoulders, EZ-B's, waist motors and some lighting is on the other switch.

I also added a fuse block. This allows 20 amp fuses to be put in line to help protect things. The switches above drive the fuses for each of of the motors listed in that section.

Other robots from Synthiam community

Ezang's Some Examples From The Past Of Glyphs, Glyphs With...

Rb550f's Ez Robot Attacknid 6Lr

-636348381130562972.jpg)

-636348716348649435.jpg)

A 7 inch table probably would have no issue fitting these parts. It would also be easy to adjust the size of these parts to fit other sizes.

@David, one word WOW. You have done an outstanding job and very thorough on thinking things out. Gives me the itch to start something like this.

Can you share the .stl files with the rest of us?

Also, how much did it cost to get everything printed?

Was there a mixture of abs, pla and nylon?

For small computers I have used 3 of the iView's. Hard to beat them for the price and they run a very long time on a 5VDC battery pack.

The stl files were given to me by a friend in Russia in return for making EZ-AI work with MyRobotLab. I still need to finish that piece for him but also need to check with him before making them publicly available.

The printing was done by Merne on this forum in exchange for getting EZ-AI up an running on his computer. He printed all of the parts in PLA. The cost I had was shipping of $85.00.

The pc I went with was because this robot will contain my primary database for EZ-AI. My other robots will run off of this database. I opted for more power so that the database would perform well. It is a power hungry solution but one that allows everything on my network to work great.

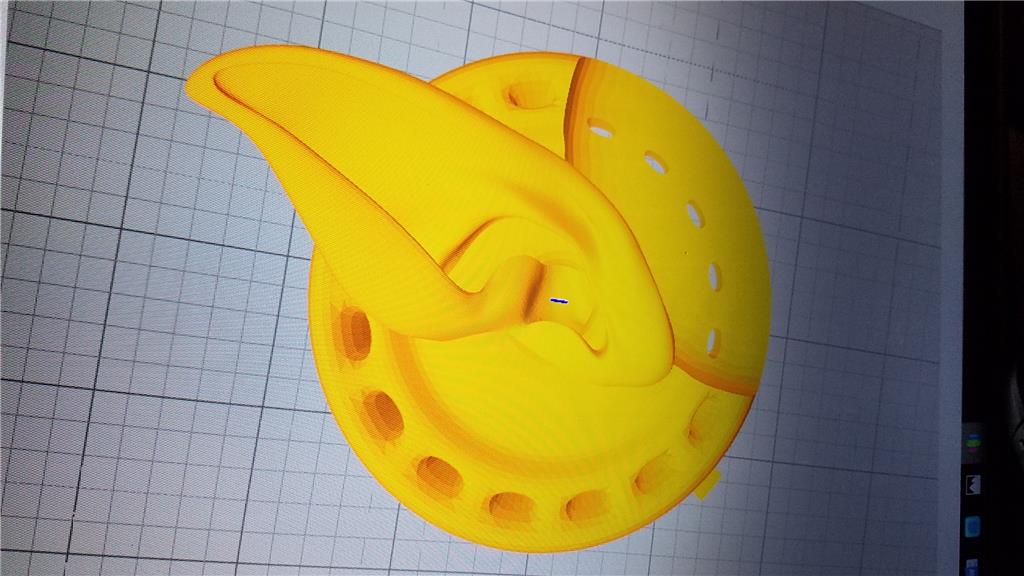

As far as an inmoov build goes, it is fun and frustrating at times. It shows your the flaws in 3d printing very well. Every part so far takes sanding and modification to fit correctly. I have the torso, shoulders and bicep structure about 90% complete at this point. Superglue is your friend and you will use a lot of it. It makes you appreciate the injection molding process.

I would do it again at this point. I also will be buying a 3d printer but will be opting for the most precise one I can afford. MERNE'S solidoodle will get the job done for sure and I thank him for printing this for me. A more precise printer would be my choice when I go to purchase one.

@69developer Not to mention the chest pieces are no good to you anyway without all the other inMoov STLs.... The whole inMoov project (and all the stl downloads) can be found here... inMoov project

Where David has the 7" screen, I was possibly going to put a Dell 8" Venue. So I was hoping to start with something and just modify it a little bit. I have all the inMoov stl files downloaded but very few printed yet. Between helping my kids with ball season and letting them learn on the Roli and JD and me working on a mobile robot platform that uses mostly Phidgets, don't even know why I started thinking inMoov...... confused

I haven't heard back from Alex yet. When I do, I will be happy to share the STL files on my website and update this link. I just want to make sure he is okay with it first.

Understand completely, and thanks!

I think I am going to put a 7" iView Win 8.1 Touch screen there instead of my Dell. It only has 1GB RAM is the bad thing but for what I am going to be using it for, it should work out ok.

I have the stomach and chest built but I don't see parts to tie these two together. If anyone can point me to these parts, I would really appreciate it. The instructions get really poor when you get to the stomach.

Edit - found the parts. These are gonna be fun to get in place...