Hi all,

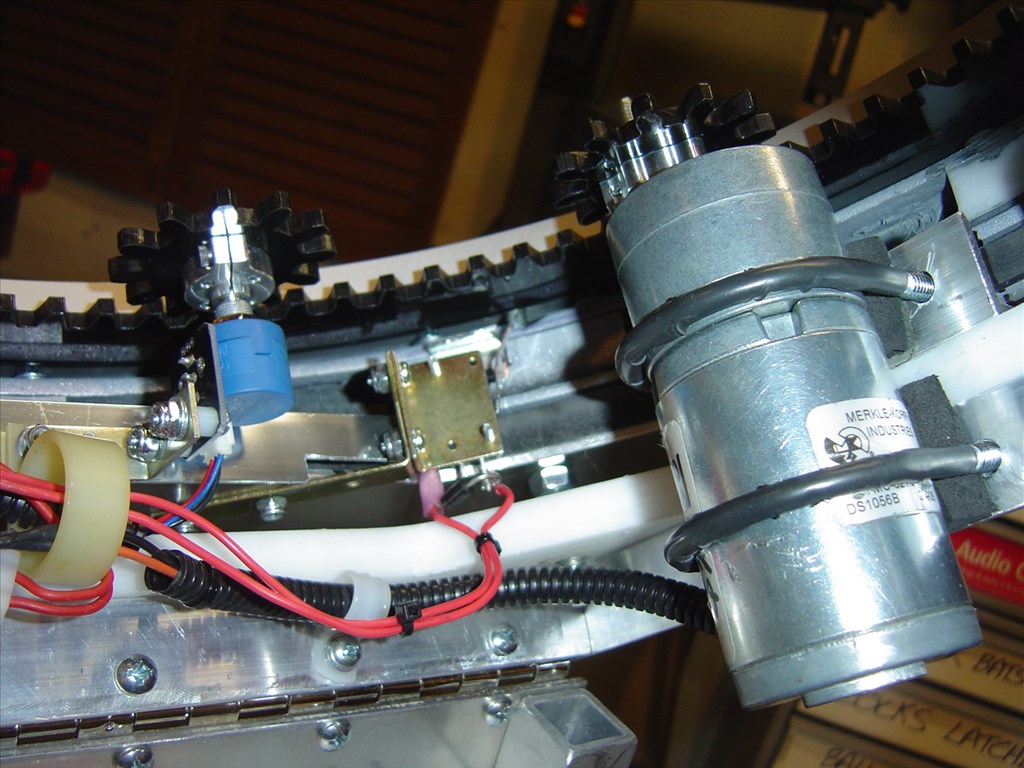

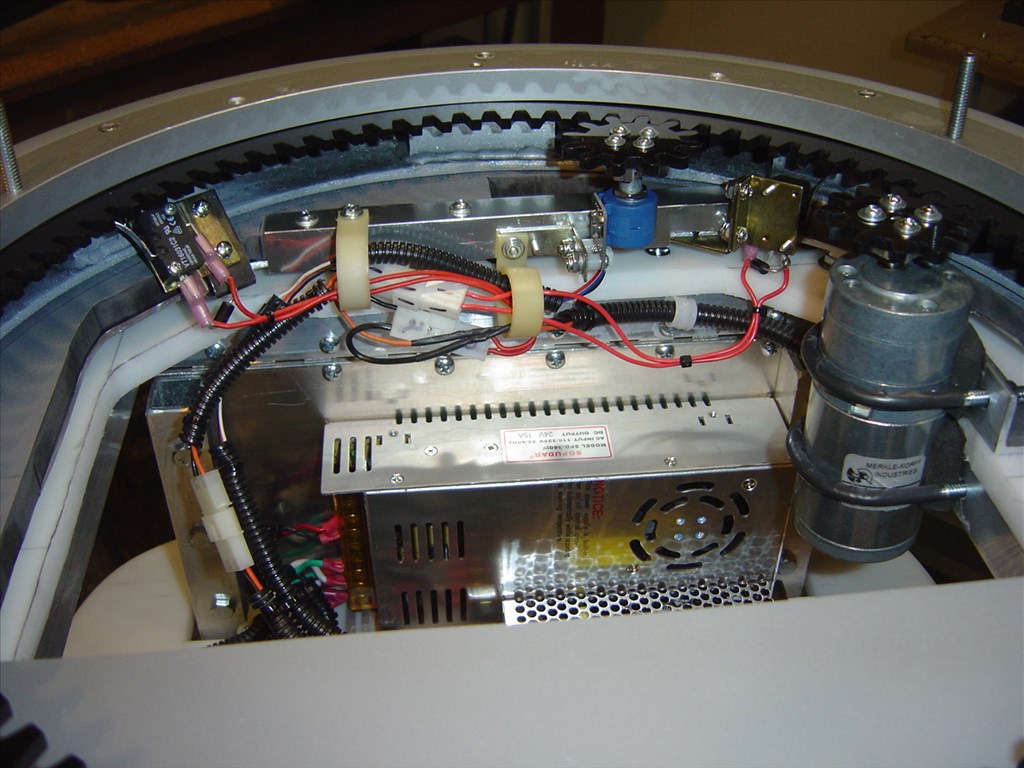

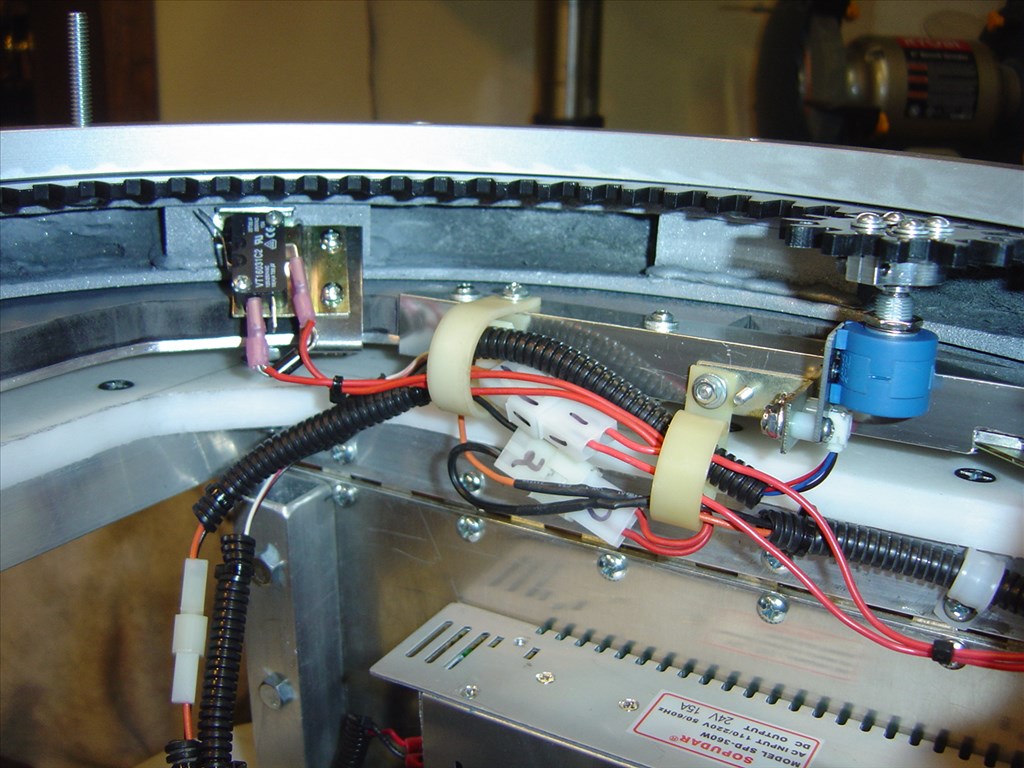

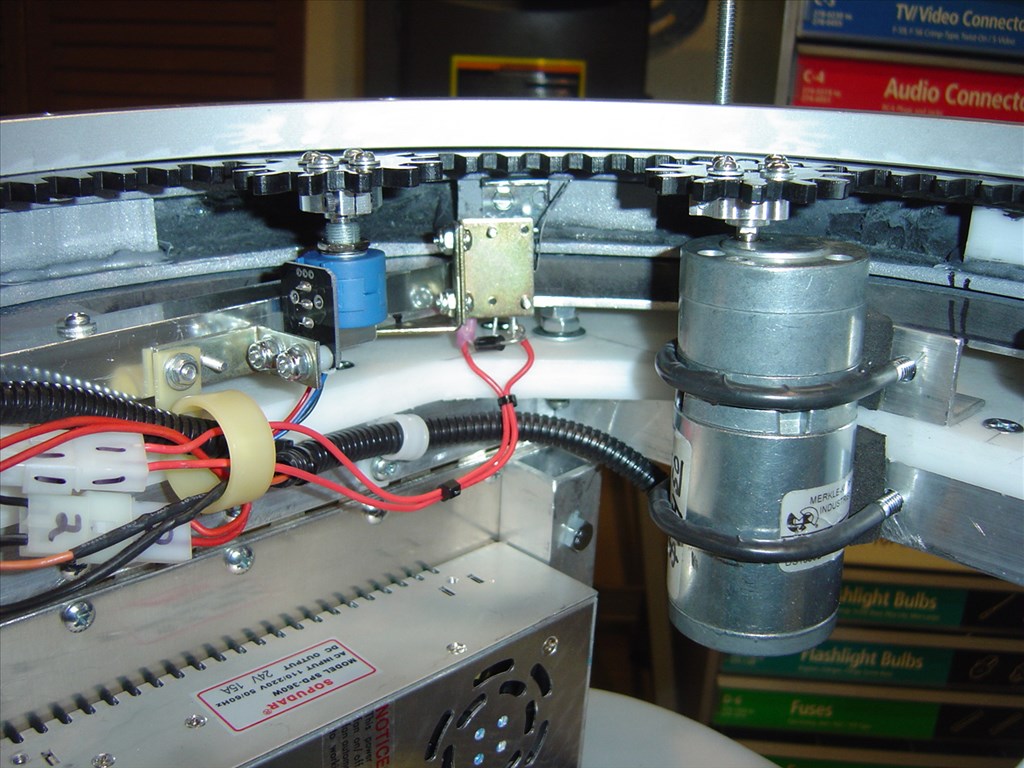

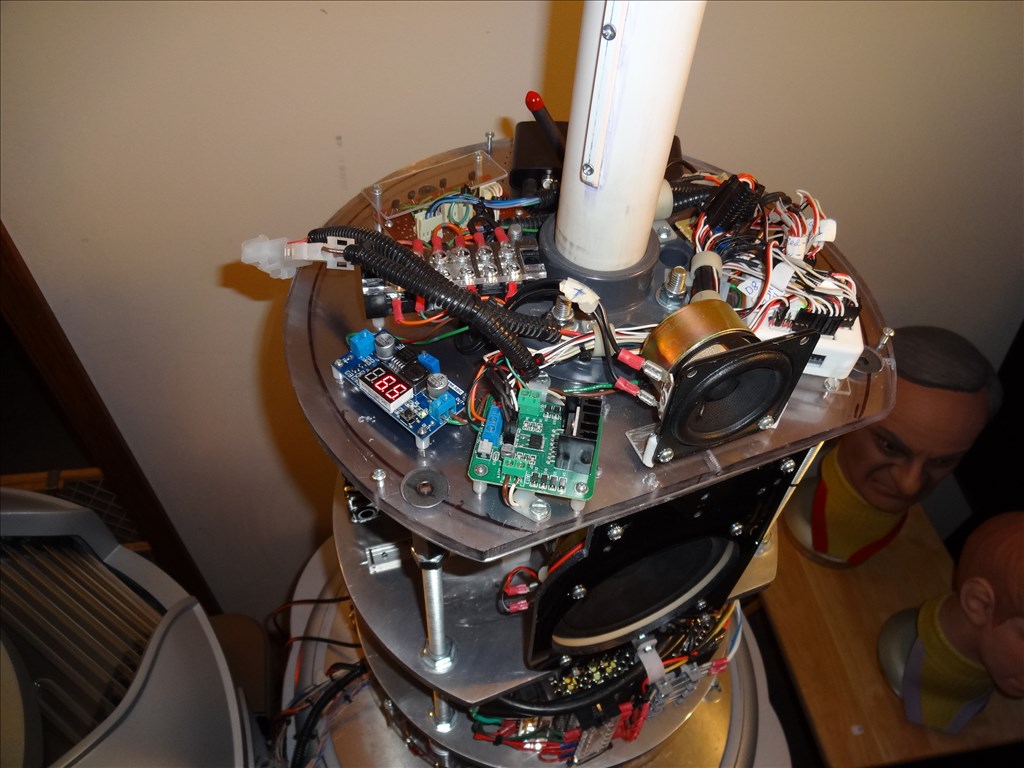

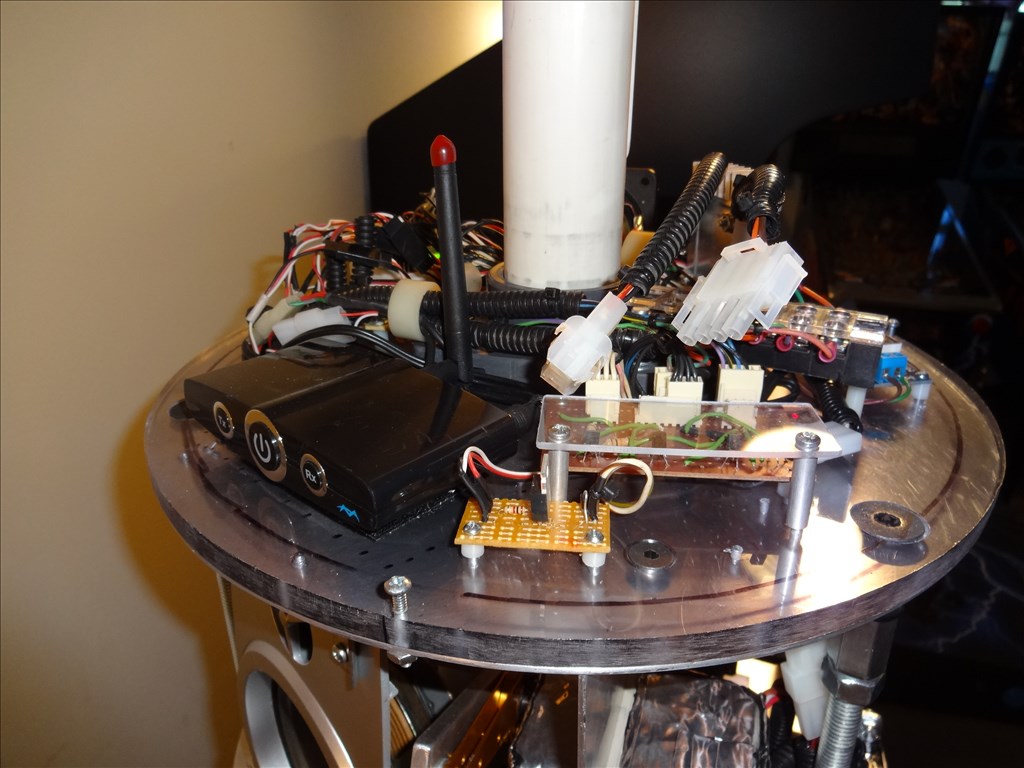

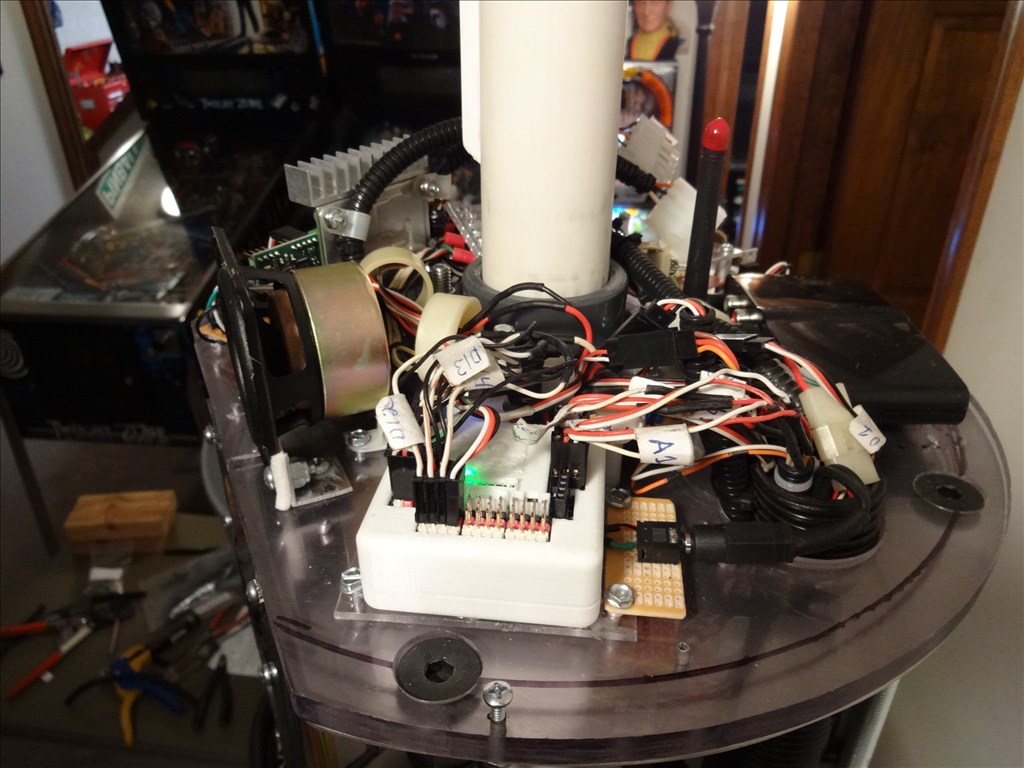

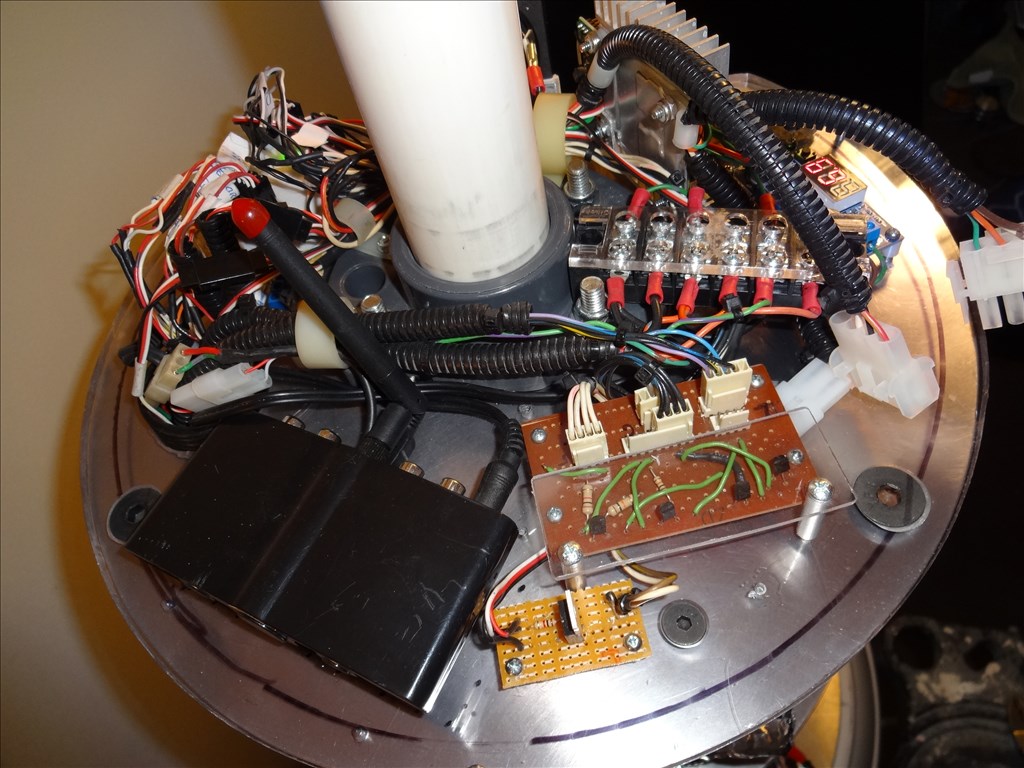

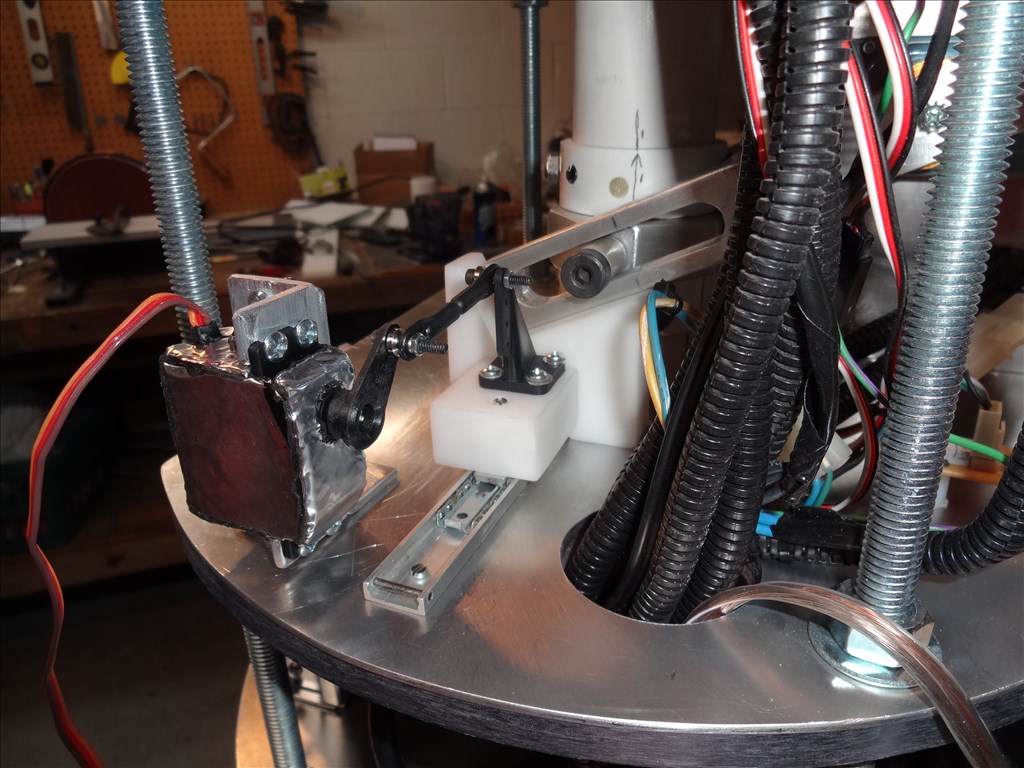

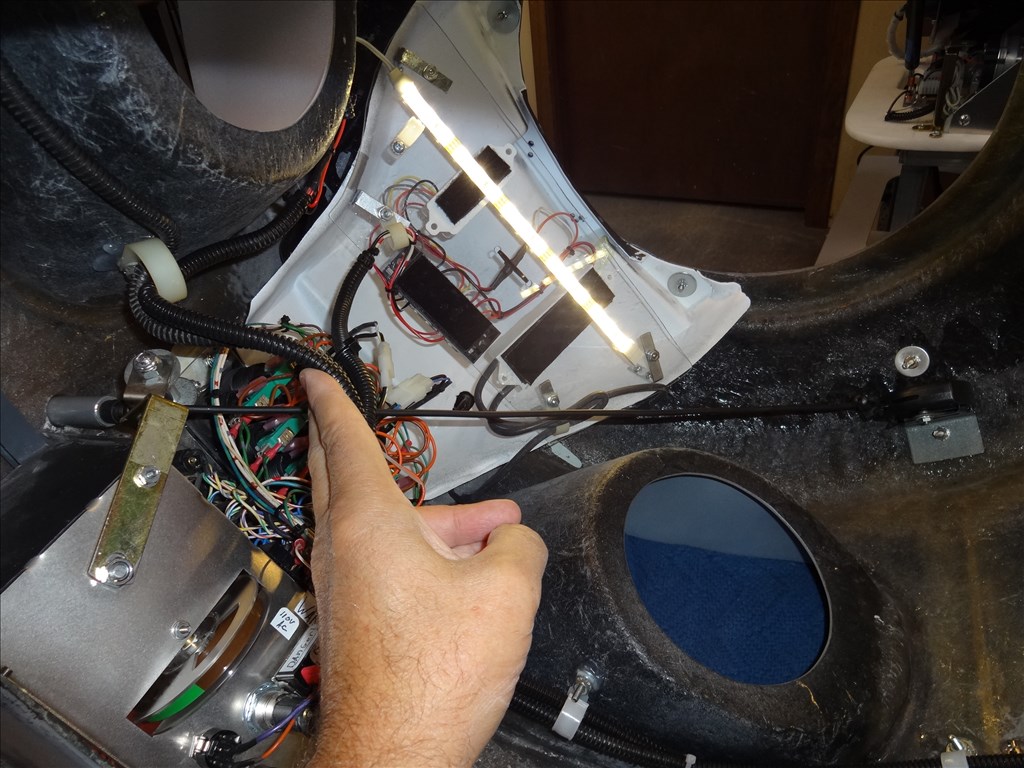

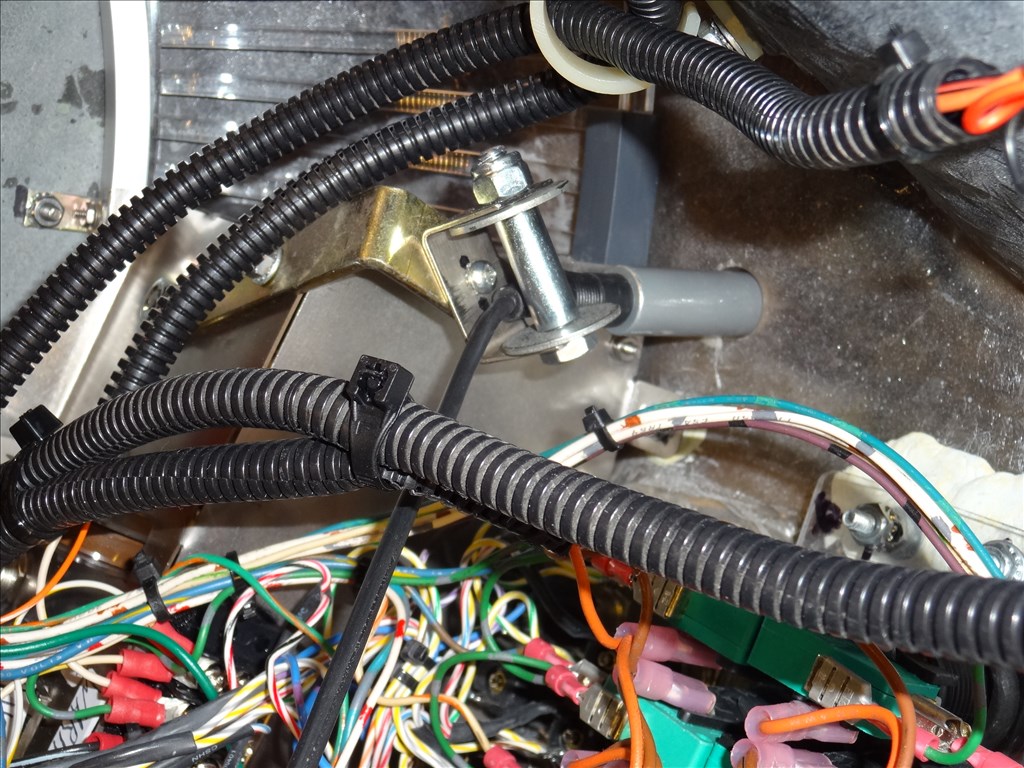

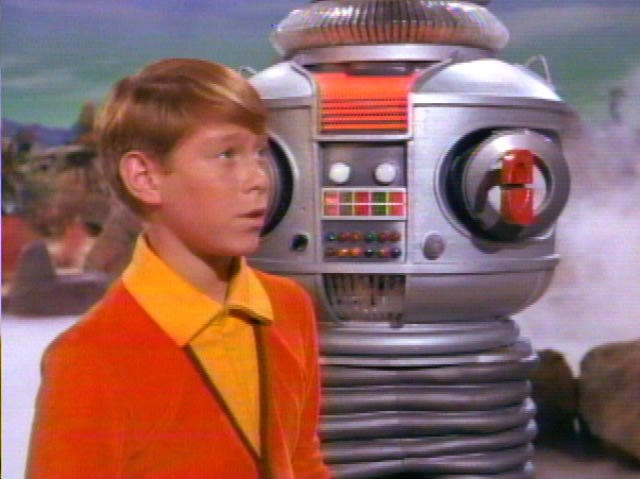

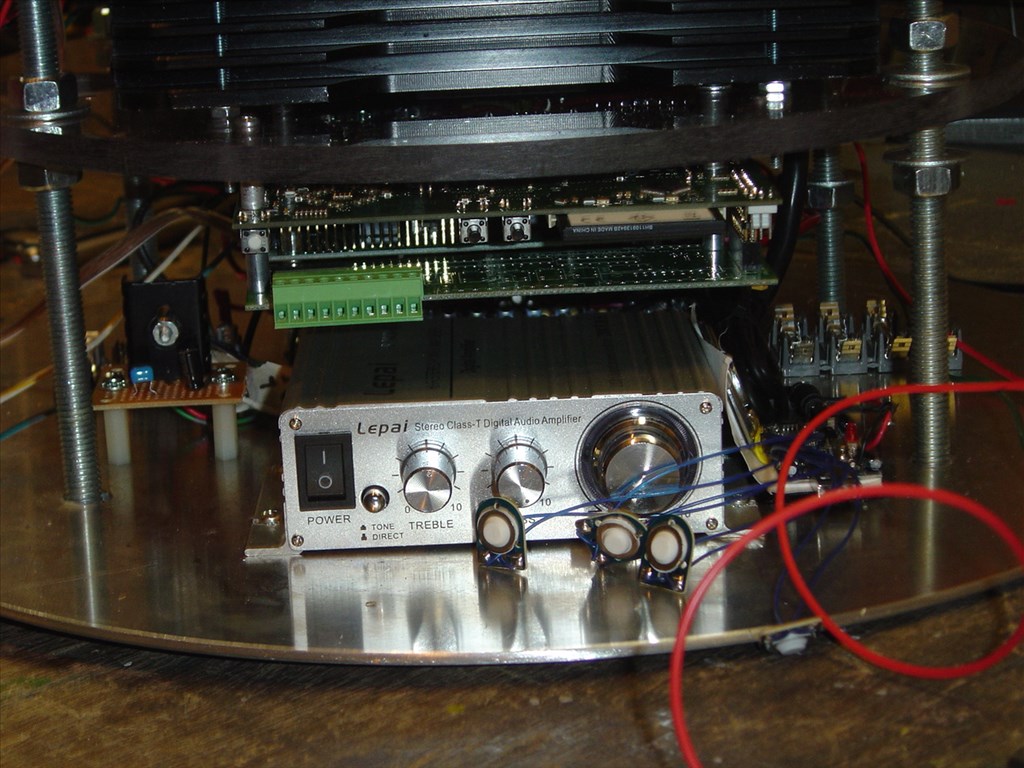

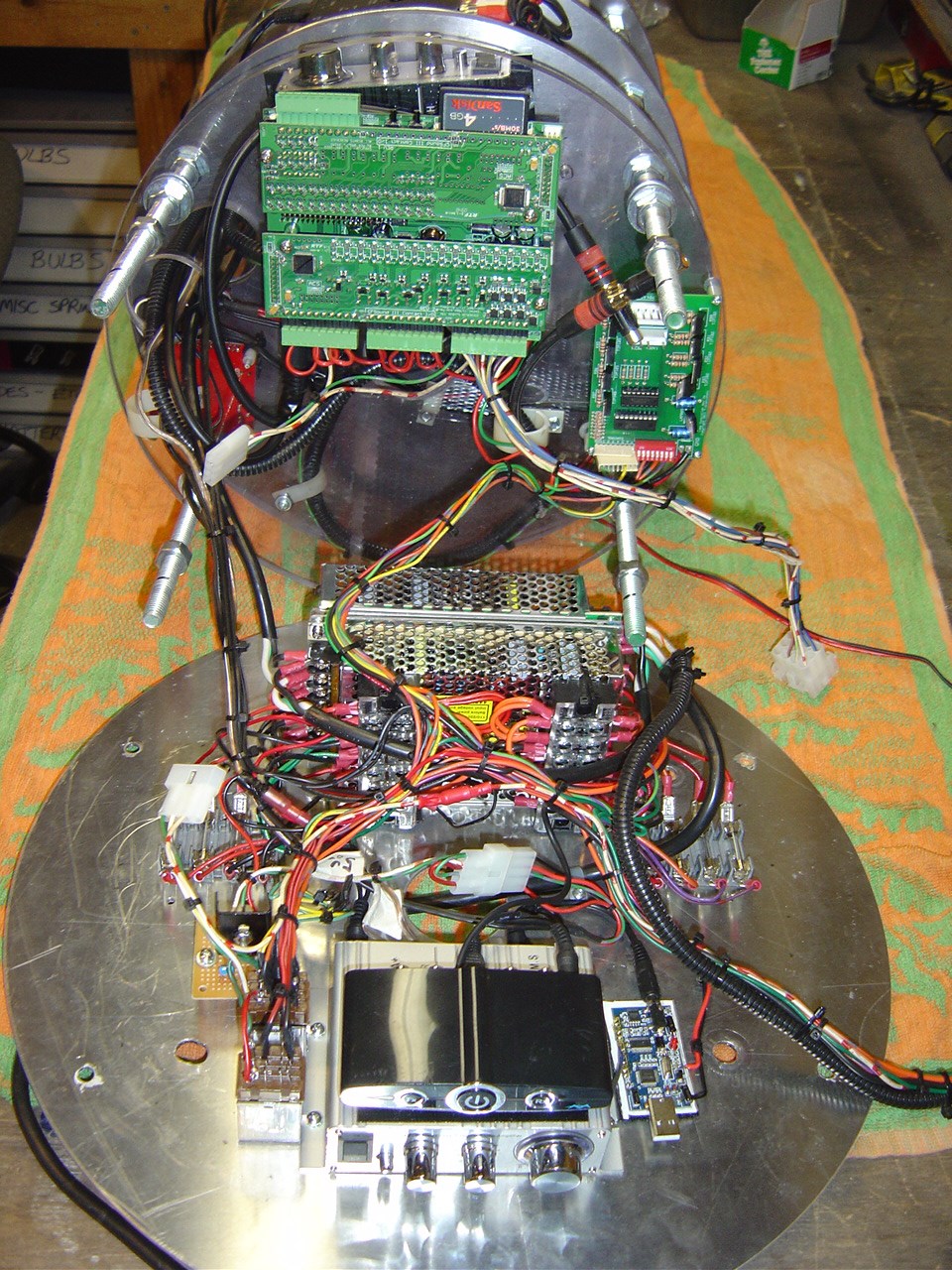

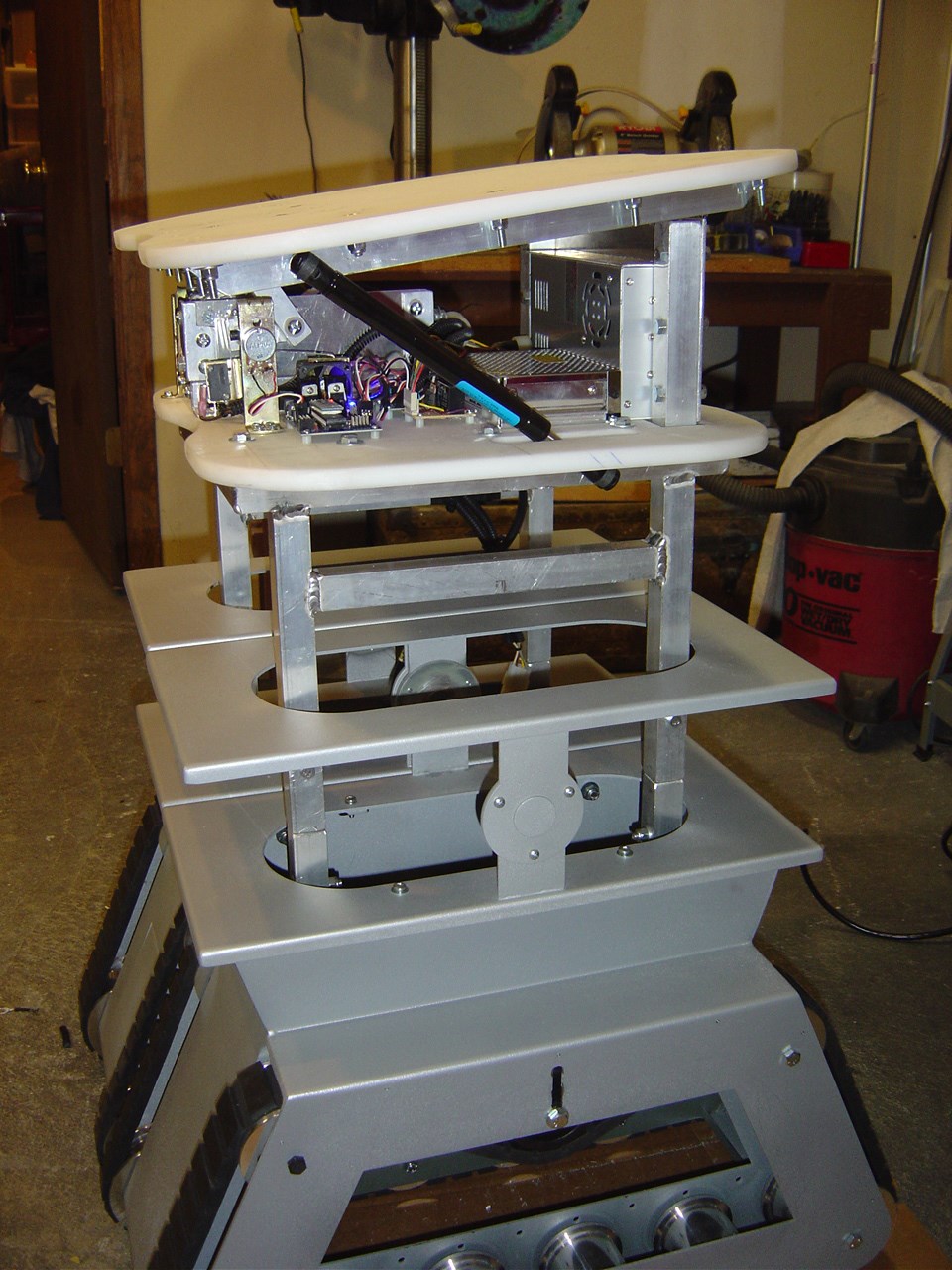

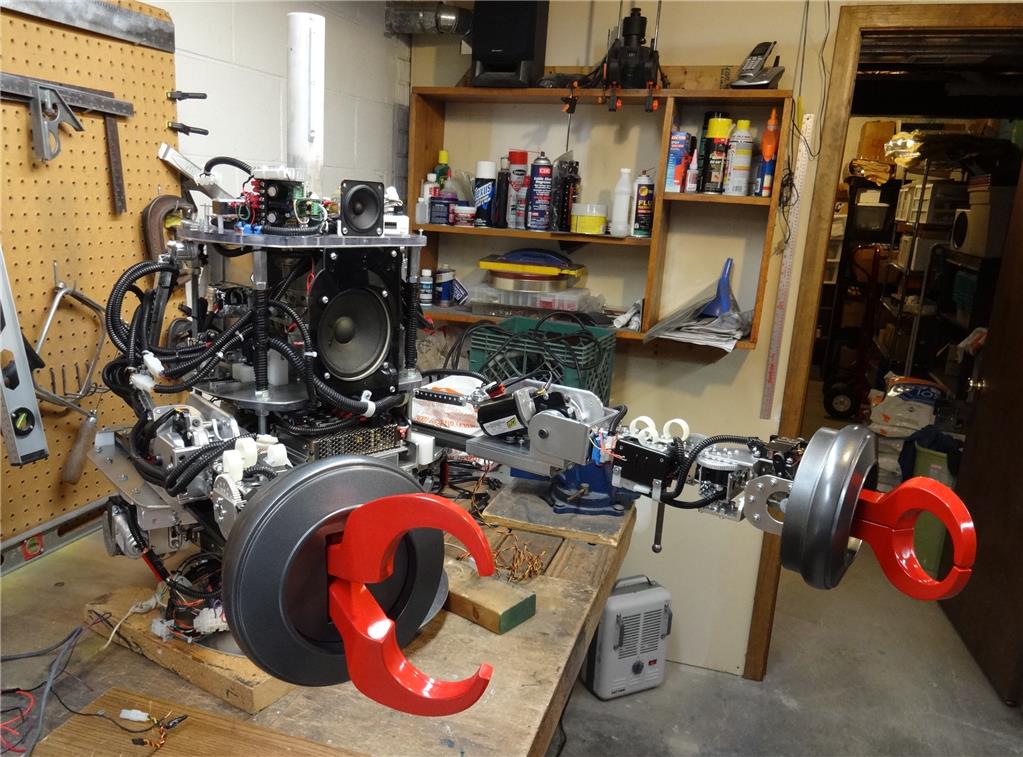

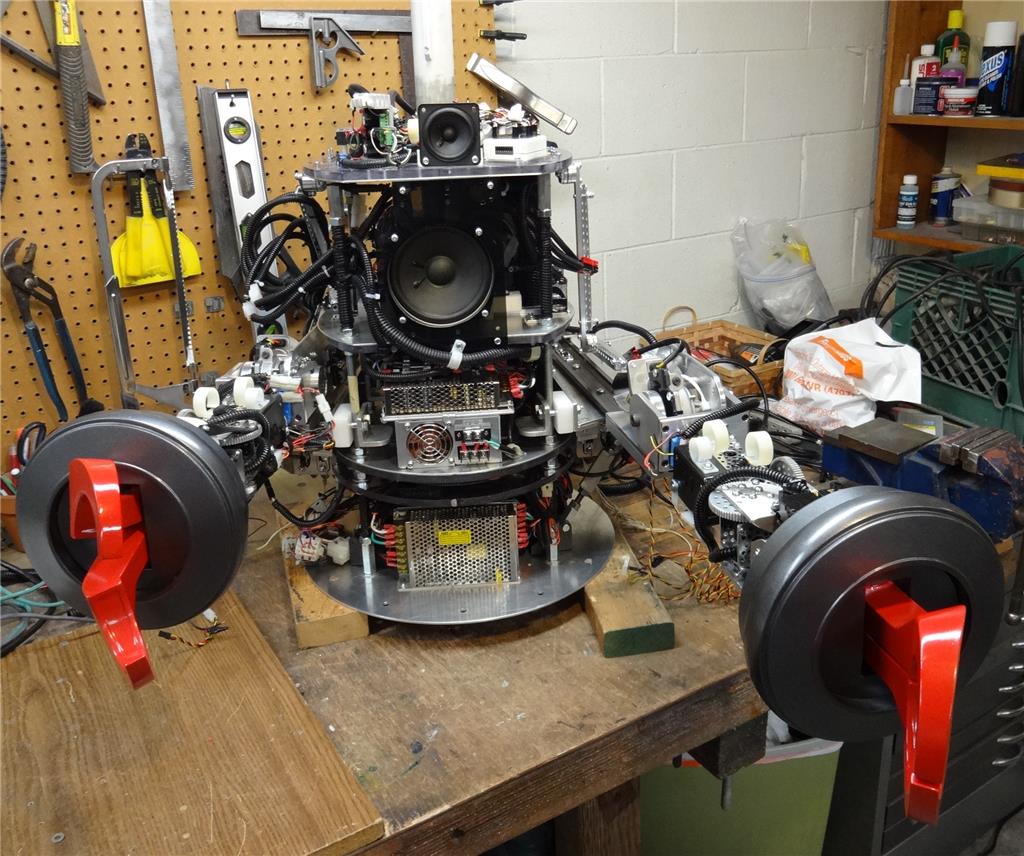

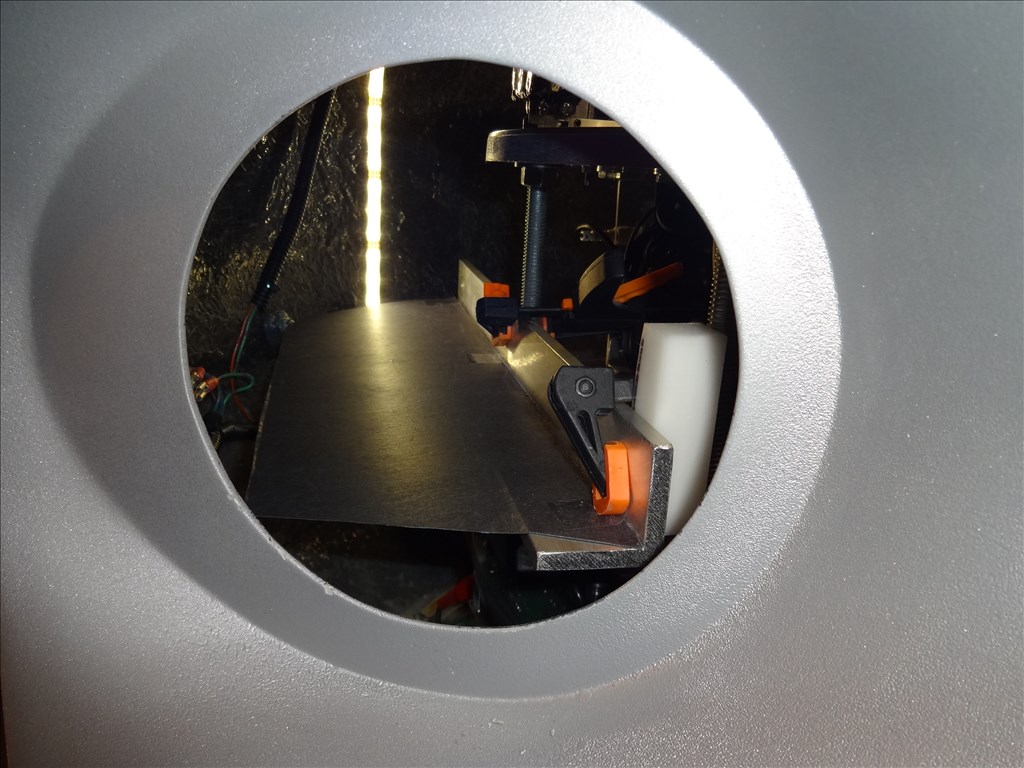

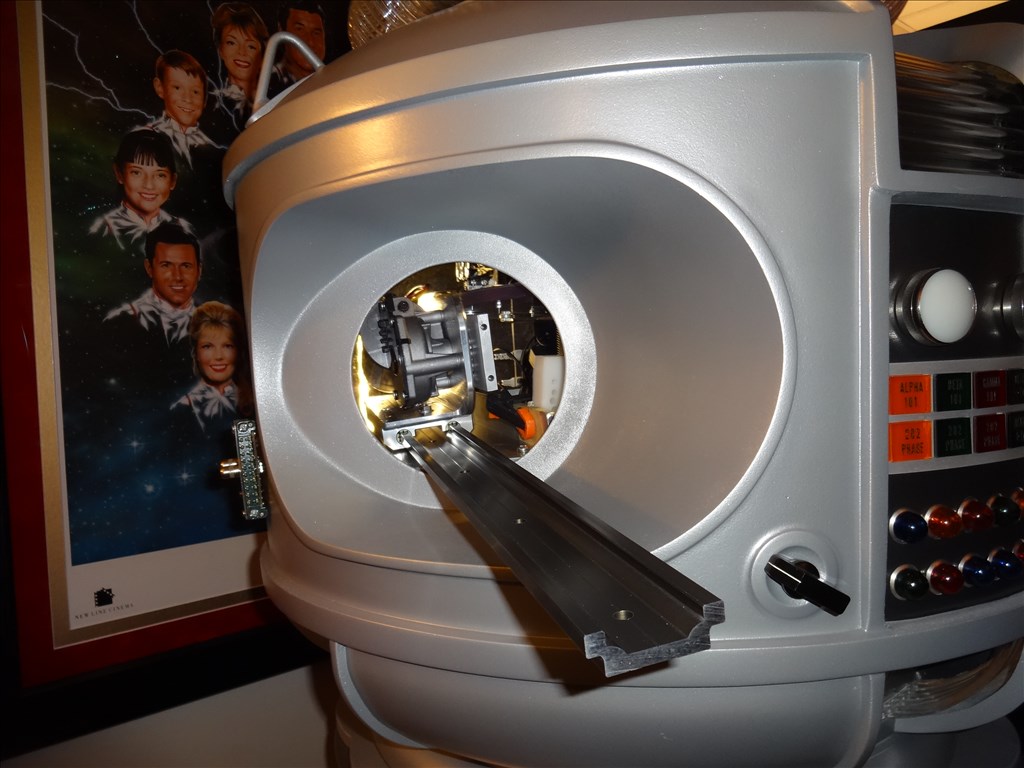

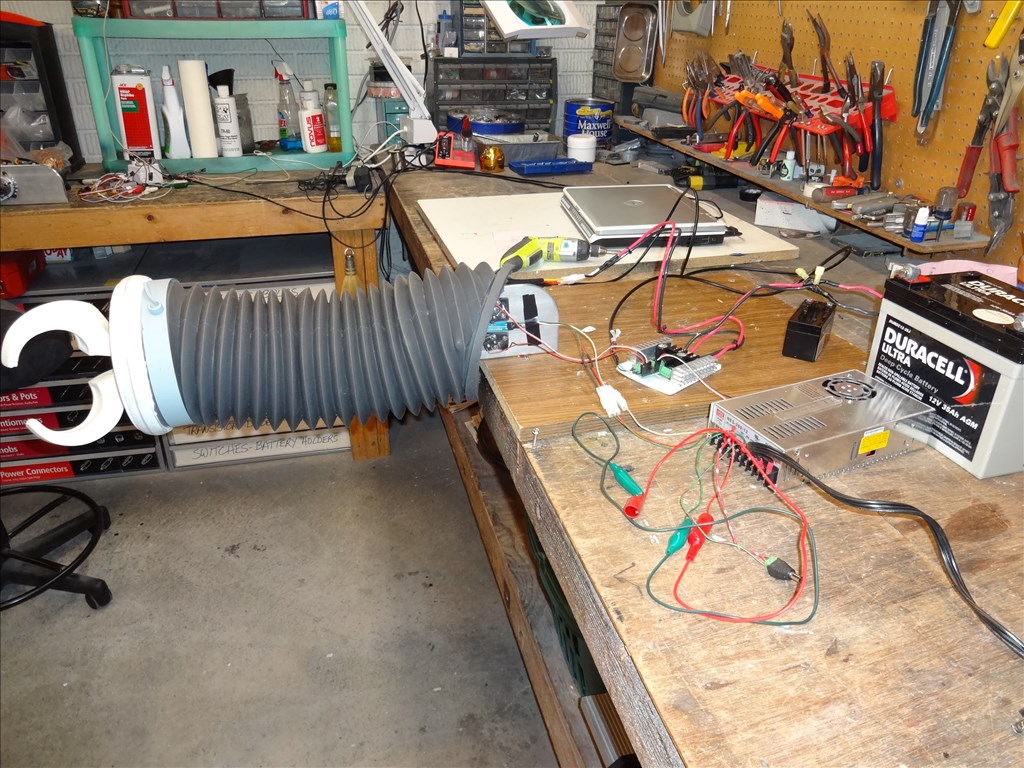

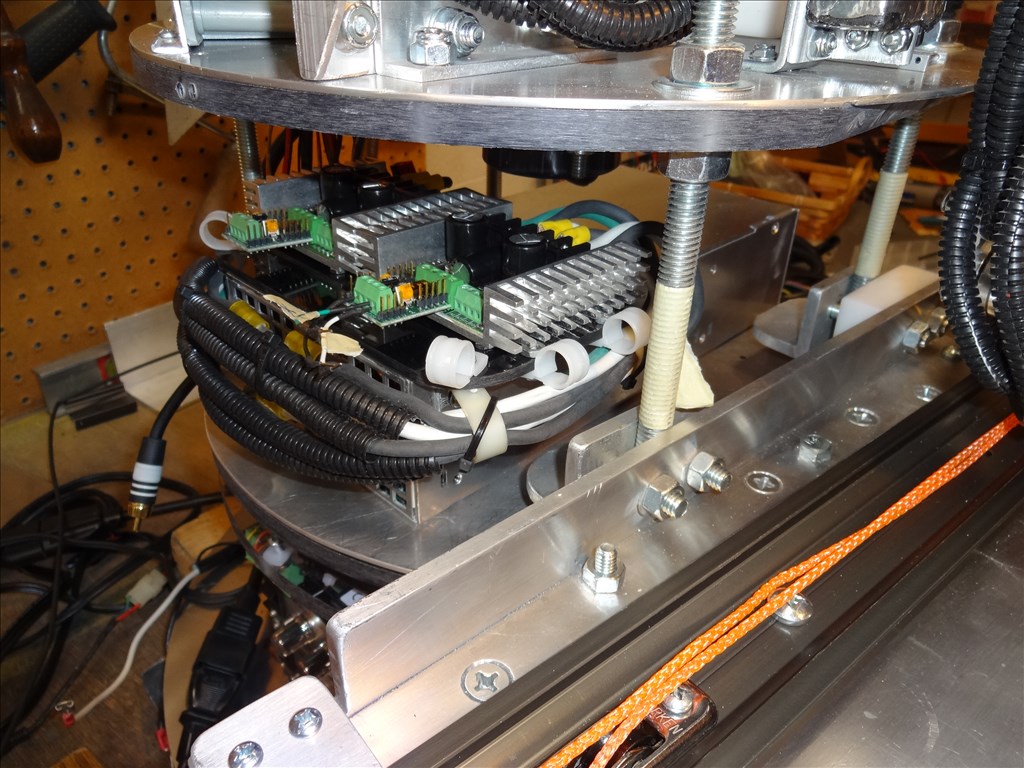

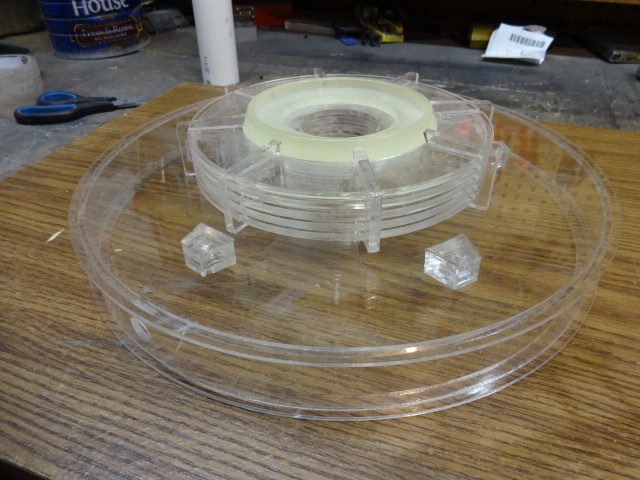

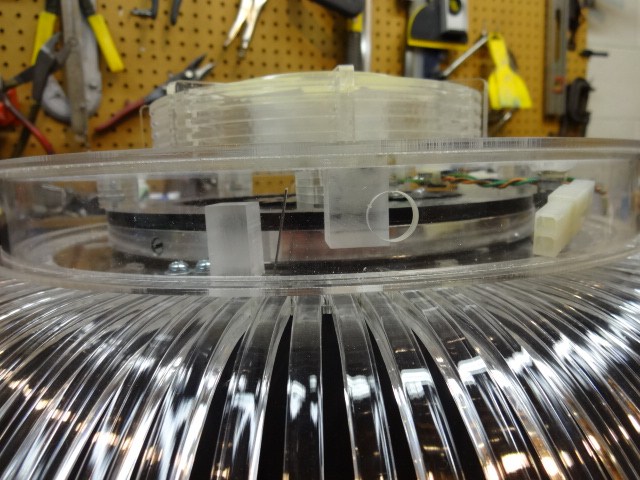

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

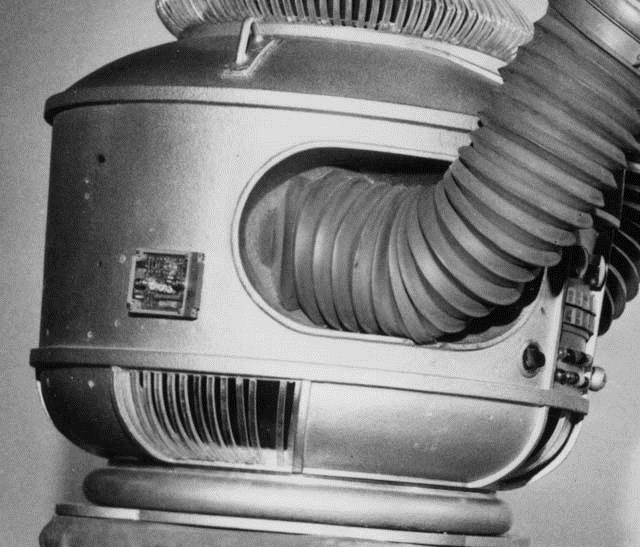

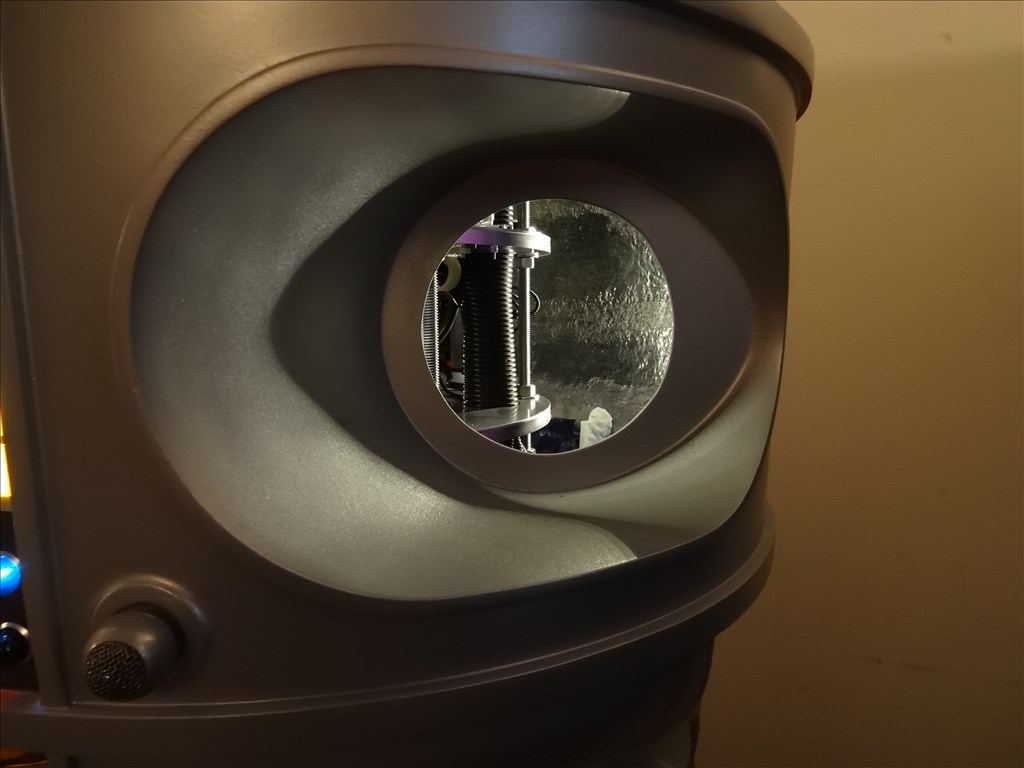

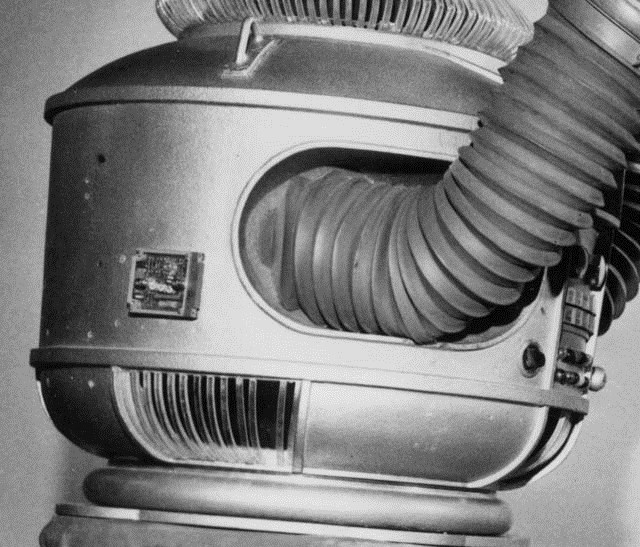

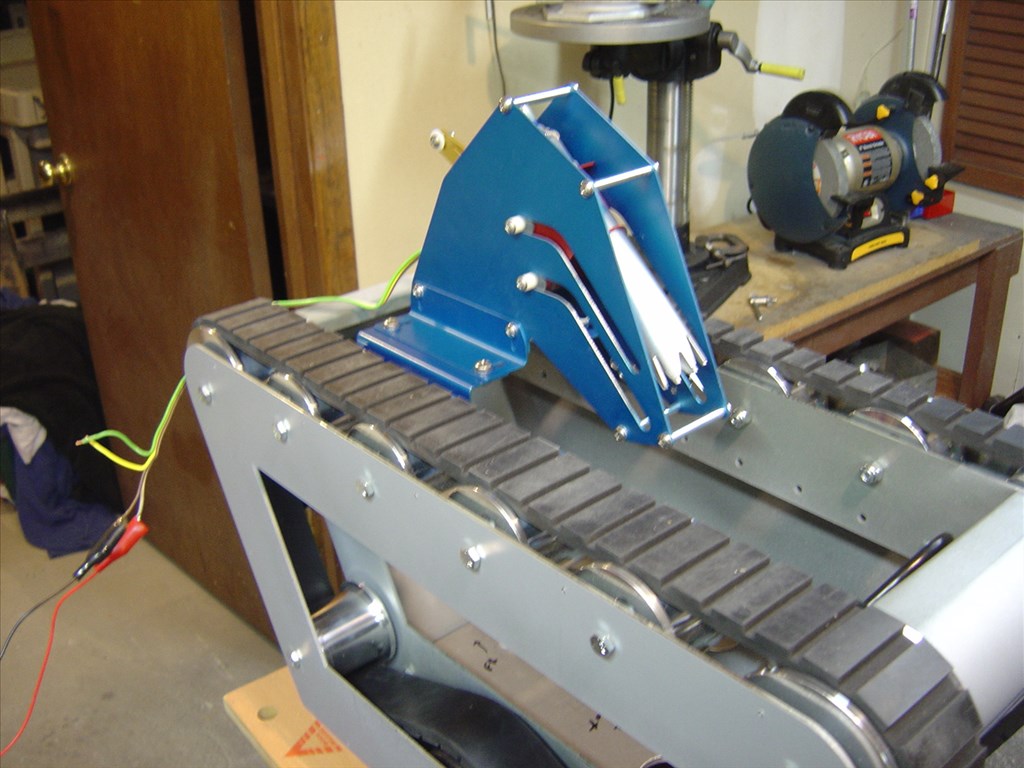

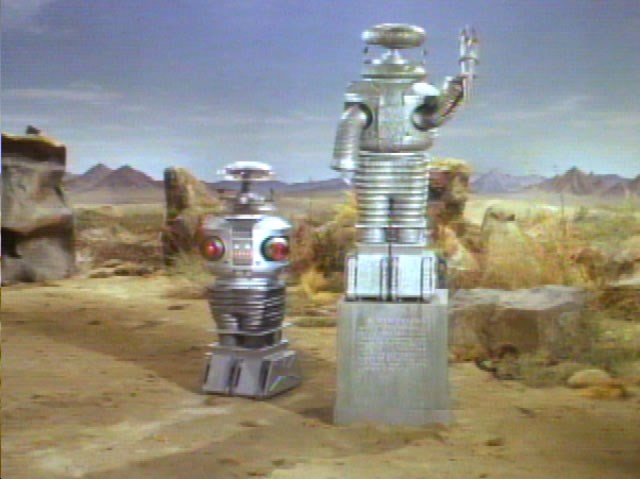

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

Rb550f's Jo Robosapien Project

Ezang's My New And Improved Talk Servo

-635353562186322812.png)

Thanks Tony. That means a lot coming from the "Master builder and inventor".

Actually that's Skye peeking through the claw. She seems to have been the one of the two sisters that has attached herself to me. She's always hanging around me and watching what I'm up to. Funny how dogs will do that. They seem to choose you and not the other way around.

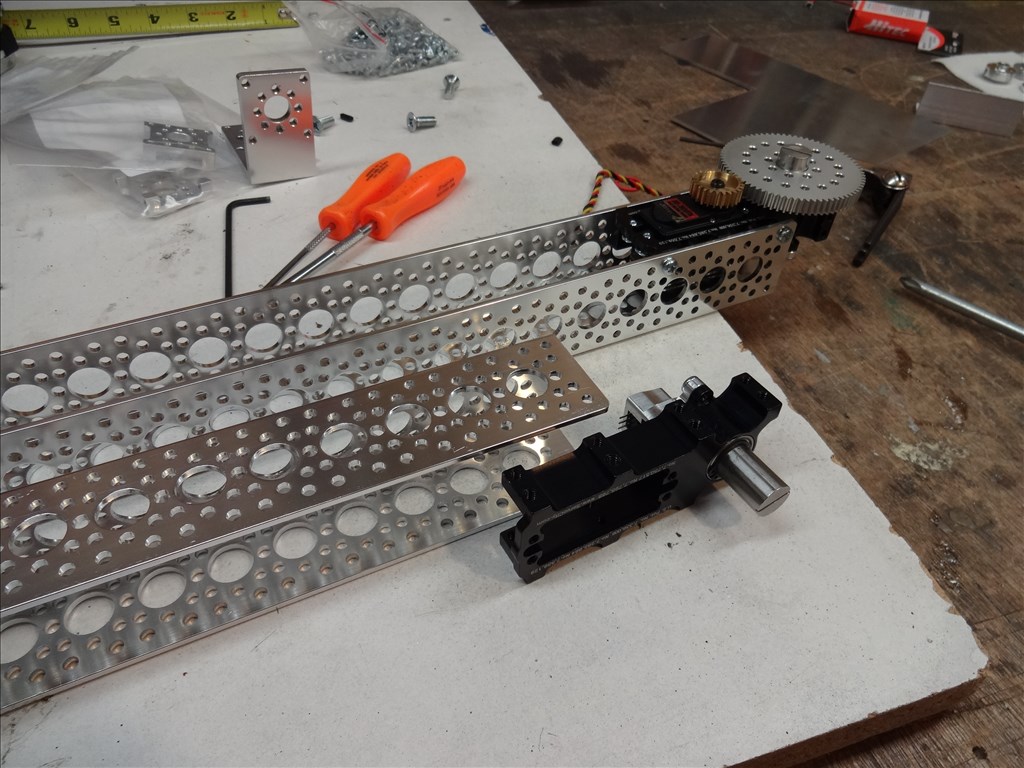

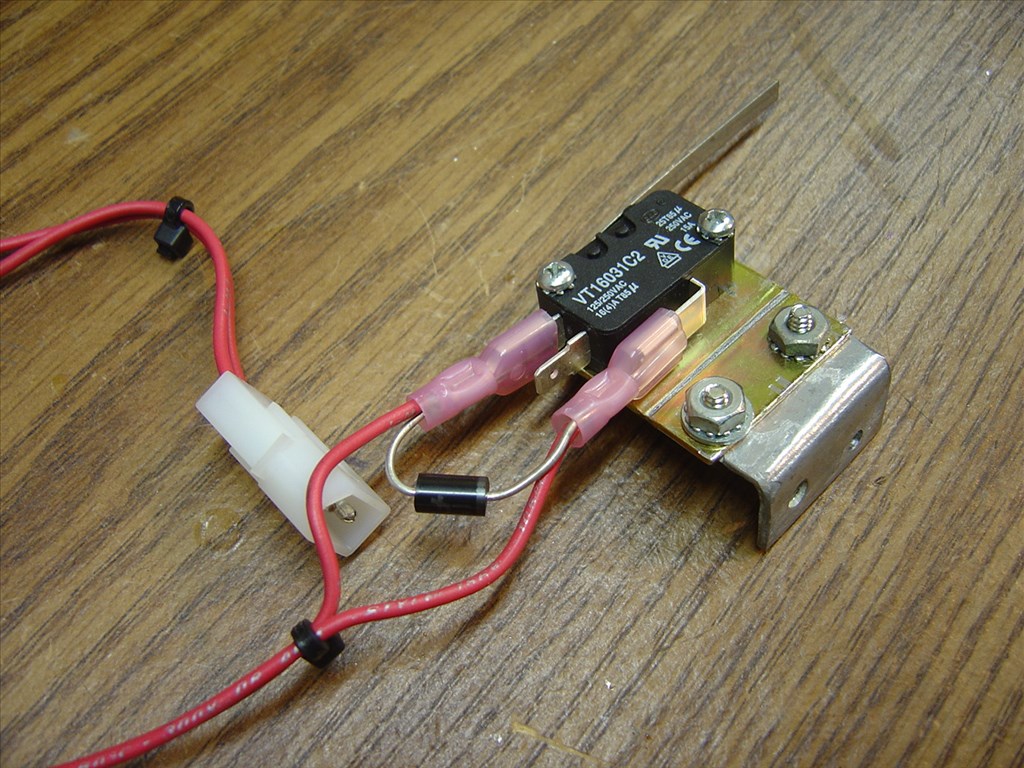

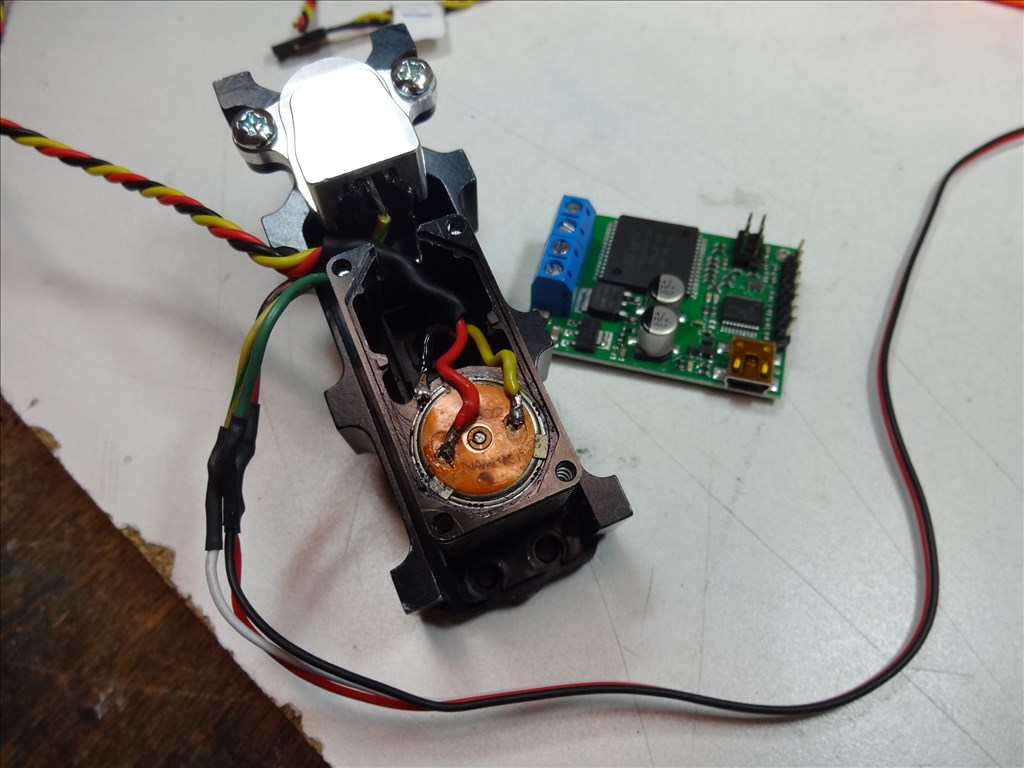

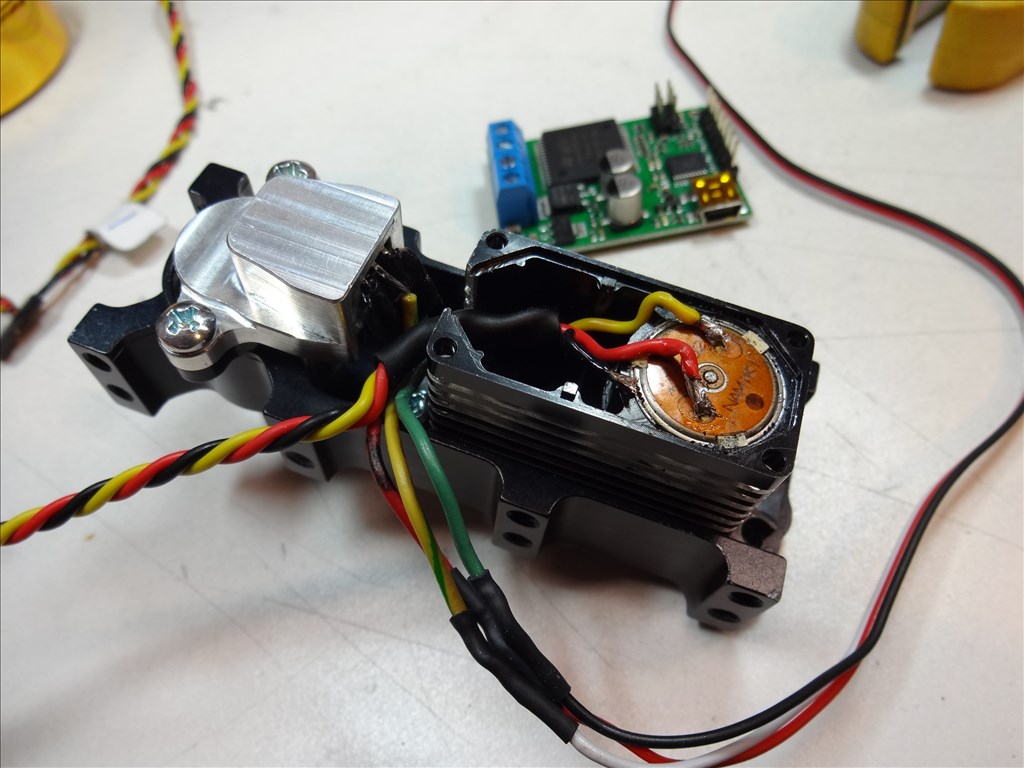

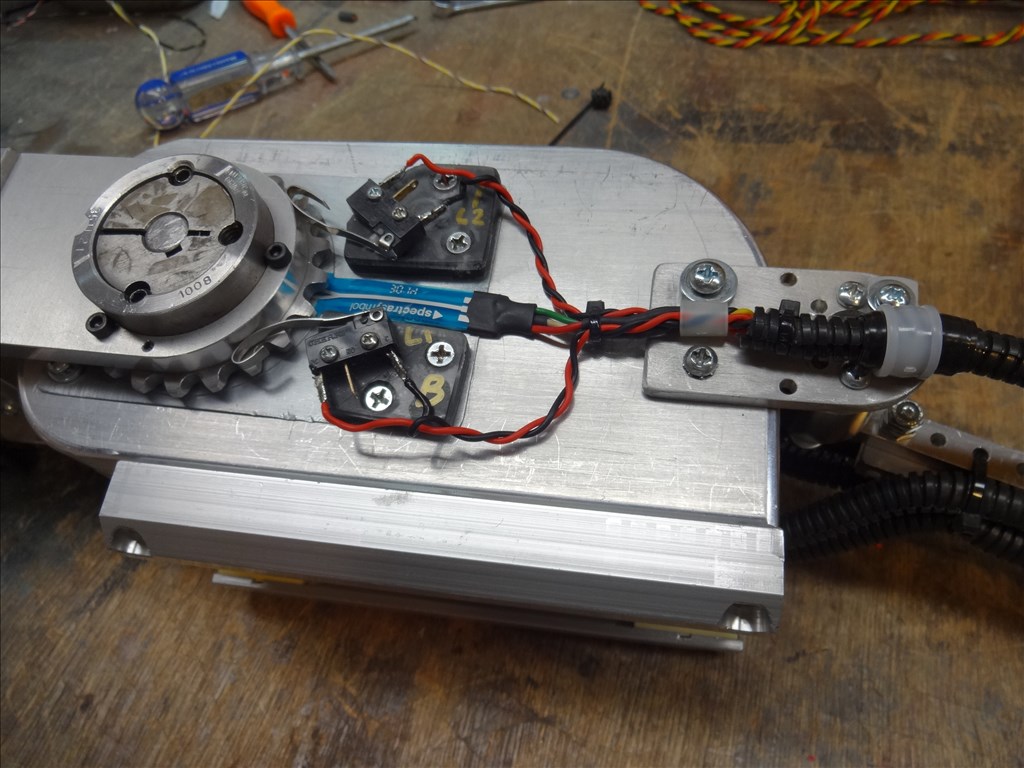

Here's an update. I've been working on finding a stronger servo for the wrist back and forth swing. The HS-645MG just didnt seem to be quite strong enough when the arm was raised in the up position and it needed to lift all the weight of the claw section. I've ended up using the Power HD 1501MG instead.

Here's a post I made on another thread that tells about the process I had to go through:

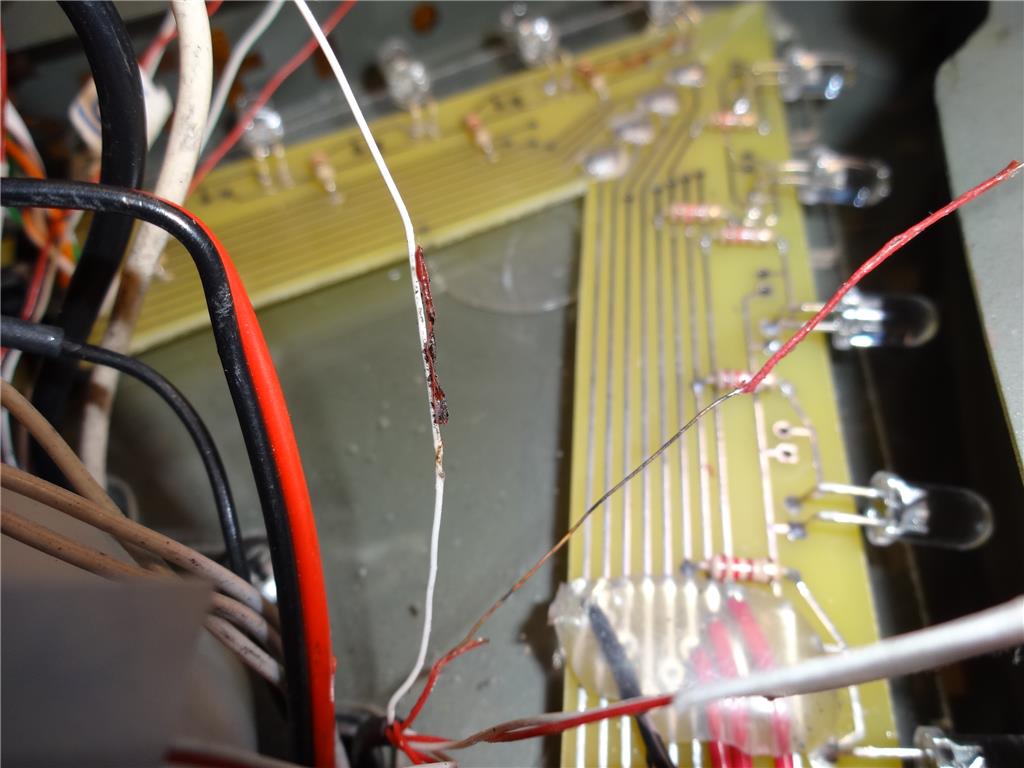

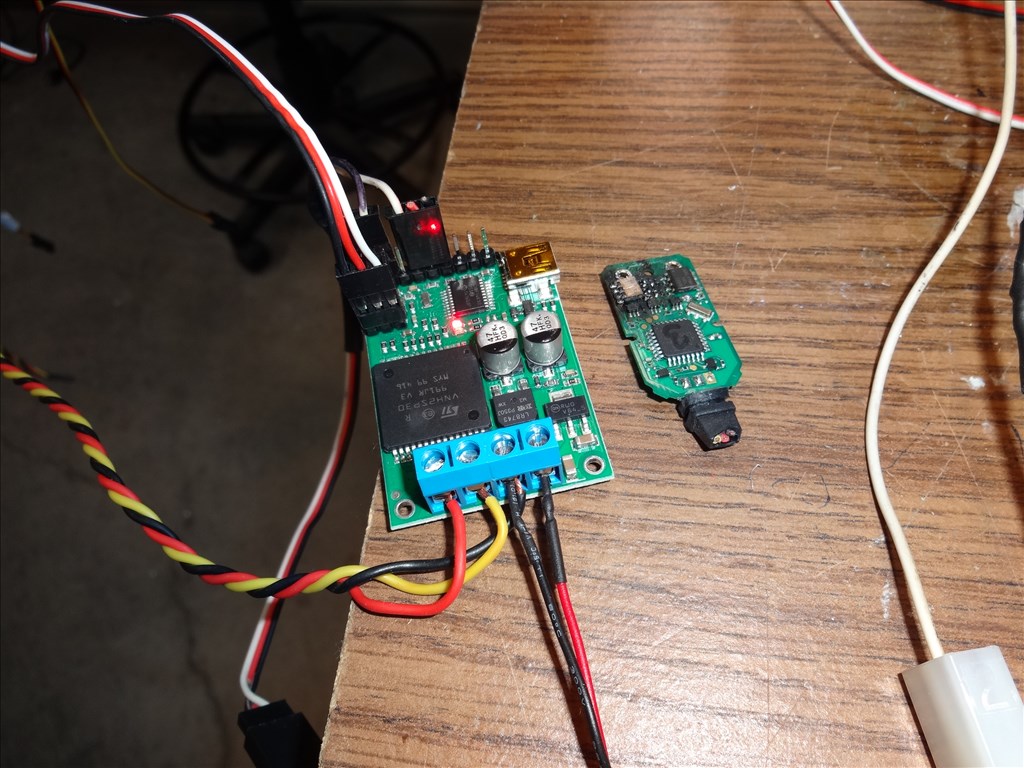

I ended up buying two more of these Power HD 1501MG and I'm glad I did. The first one I posted about here did have a bad pot. After replacement of the pot the servo didn't have the shutter anymore but the pot I used couldn't be re-installed into the servo where I needed it. Relocating it on the joint is not an option. So I decided to get two more of these because I really liked the torque they put out, they fit where I need them and they are smooth.

The position hold feature when the servo is released may or may not be a good thing for me. I haven't worked that through yet but it doesn't seem to heat up when sitting and released. I also haven't placed an amp meter on it to see what the draw is when as it sits idle. The spec sheet says it draws 5ma when stopped and idle. Another worry I have with this feature is longevity. Will the servo sitting and released but holding position shorten it's life span? I wont know this till time wears on.

My last concern with the 1501MG is quality. As I said above I bought two more of these. The cost was $16 USD on Amazon or $20 from Pololu. I ought from Amazon. Not a lot for such a strong and smooth servo. However the first one had the bad pot (Reviews have stated that others have had this same problem). Then the second 1501MG I installed froze up after just a few swings back and forth with hardly any load on it. When I took it apart I got the motor to work again but only in one direction. Then the board flamed out after a few seconds of running. However, now I have the third 1501MG installed and it seems to be holding up with no problems. Not sure why I had to go through two servos before I found a good one. I did buy from Amazon and suspect they were returns that were reshipped to me. This has happened to me several times when buying from amazon. Perhaps if I buy directly from Pololu I would get newer and vetted Power HD 1501's with no problems.

Anyway, I'm going to stick with this servo for the time being as it does exactly what I want. At 6 V: 0.14 sec/60degrees, 240 oz-in (17 kg-cm), 60 g it's a monster.

@Mcsdaver, The spec sheet says it is only rated to to 6 vdc. I guess you could run it at 7.4 v but given my concerns of quality I'd be afraid to push it up to that voltage. The extra voltage may not hurt it but the extra torque may put too much stress on the circuit board. However you never know till you try and go too far. Here's a link to this spec sheet:

Here's a link to this spec sheet:

Power HD HD-1501MG Datasheet

If your looking for a way to to drop the voltage from 7.4 down to 6 or lower I found a great little Bec 10A 6S Switching Regulator by Castle Creations. It's super small (only about 1 inch x 1/2 inch), programmable output voltage (With an extra unit you have to buy), runs cool and will handle up to 10 amps draw. Here's the specs:

www.amazon.com/gp/product/B000MXAR12/ref=oh_aui_detailpage_o05_s00?ie=UTF8&psc=1

Dave - I did a little hunting around. Looks like "Value Hobby" has them for $12.50 www.valuehobby.com/power-hd-1501mg.html# with a $3.99 flat rate ship per order.

Thanks Buddy. Your the man, uh, I mean the Pig.

Oh I want that arm for my B9 PLEASE help I can pay you LOL Let me know

Hi Chris,

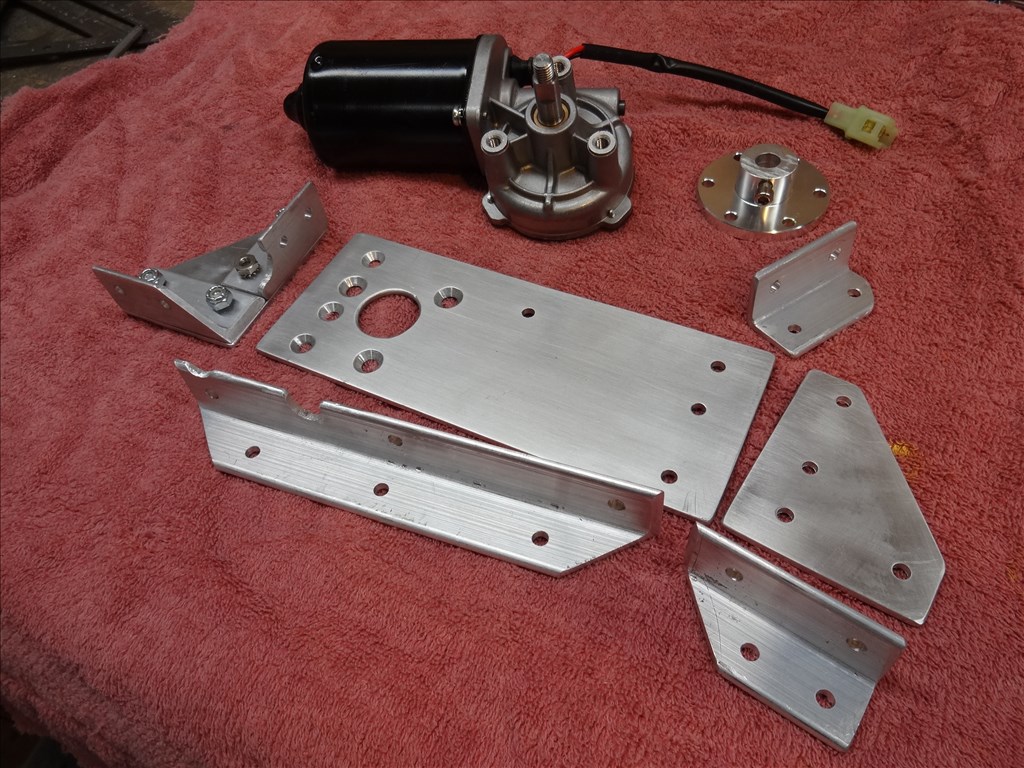

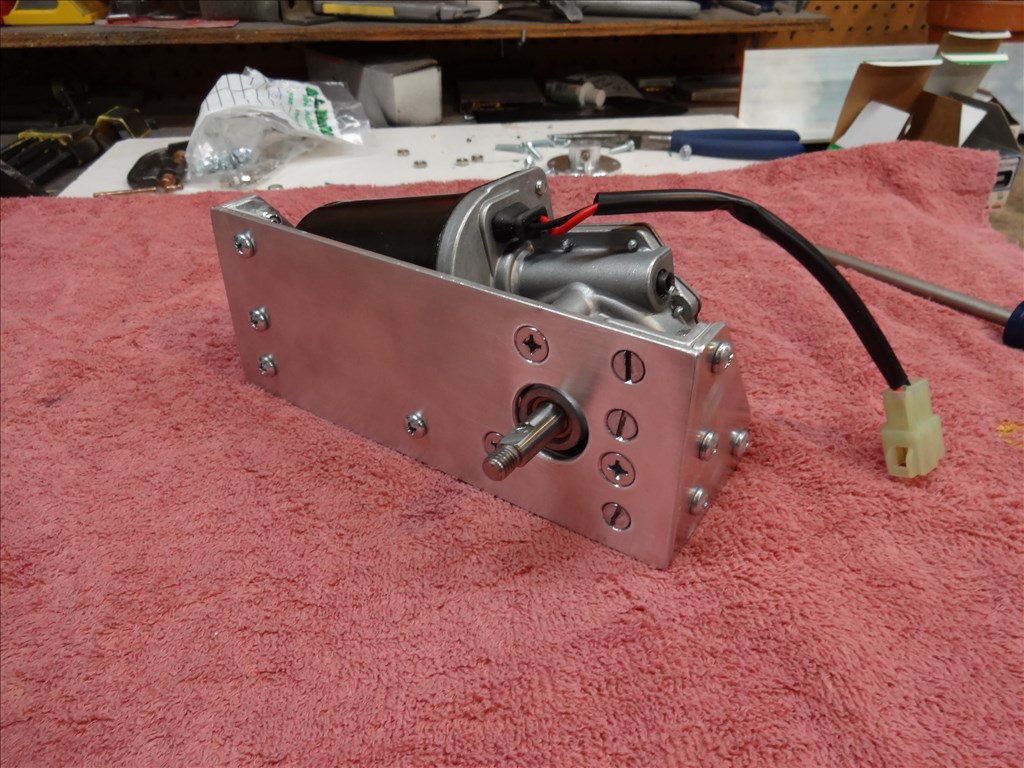

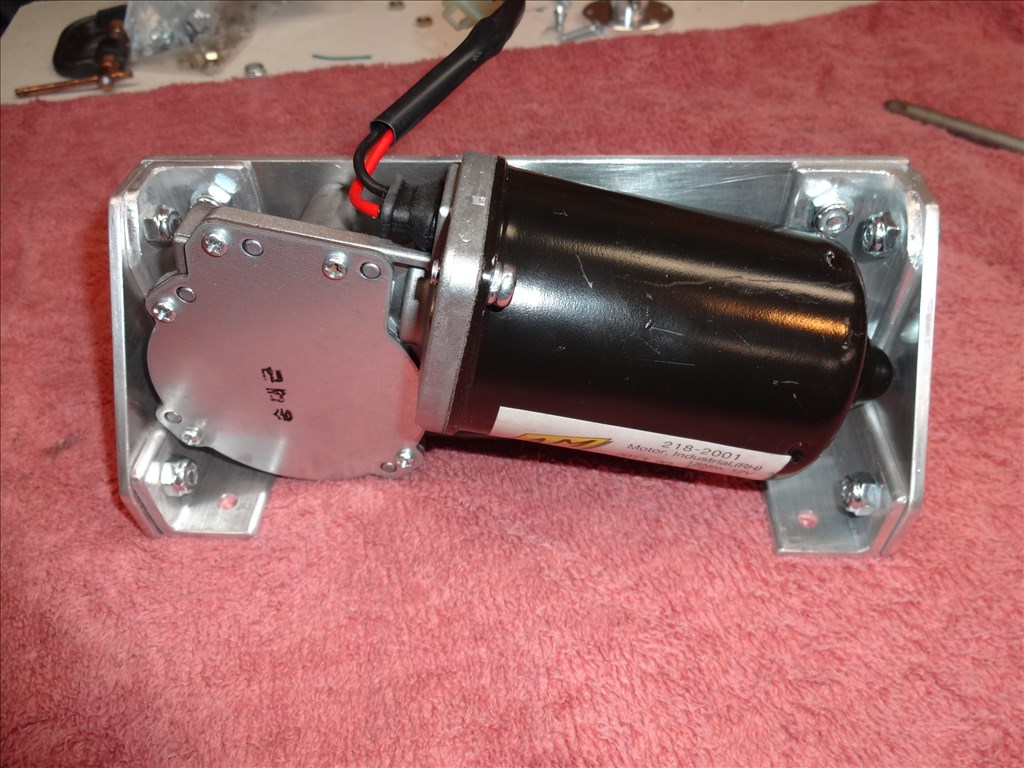

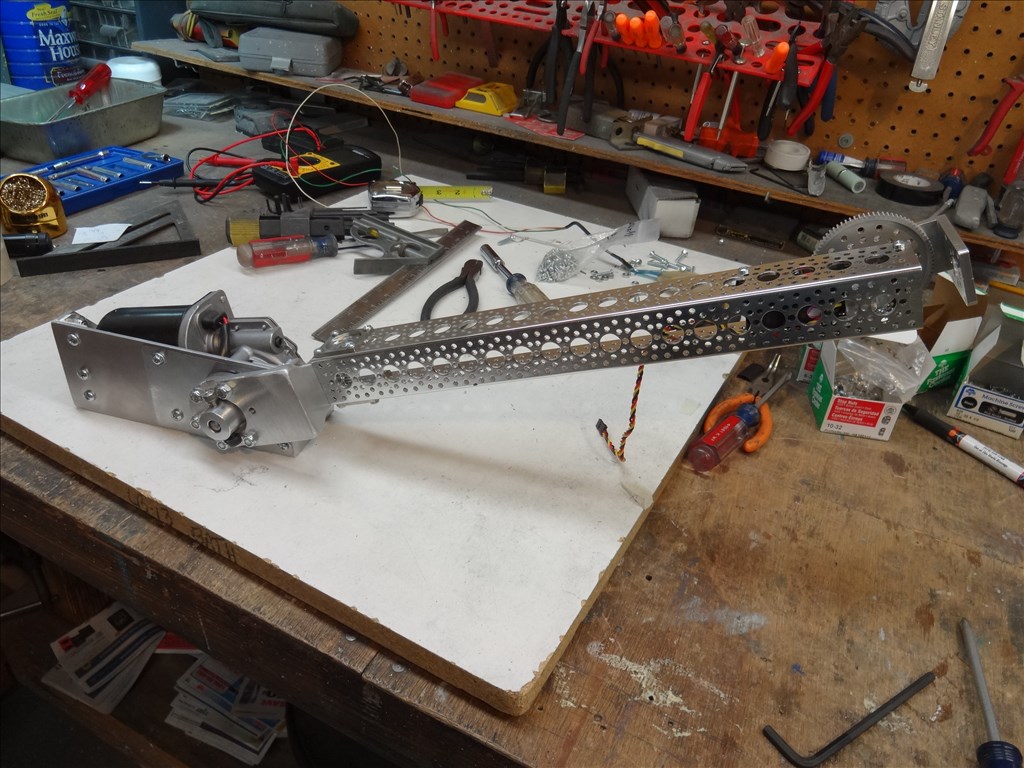

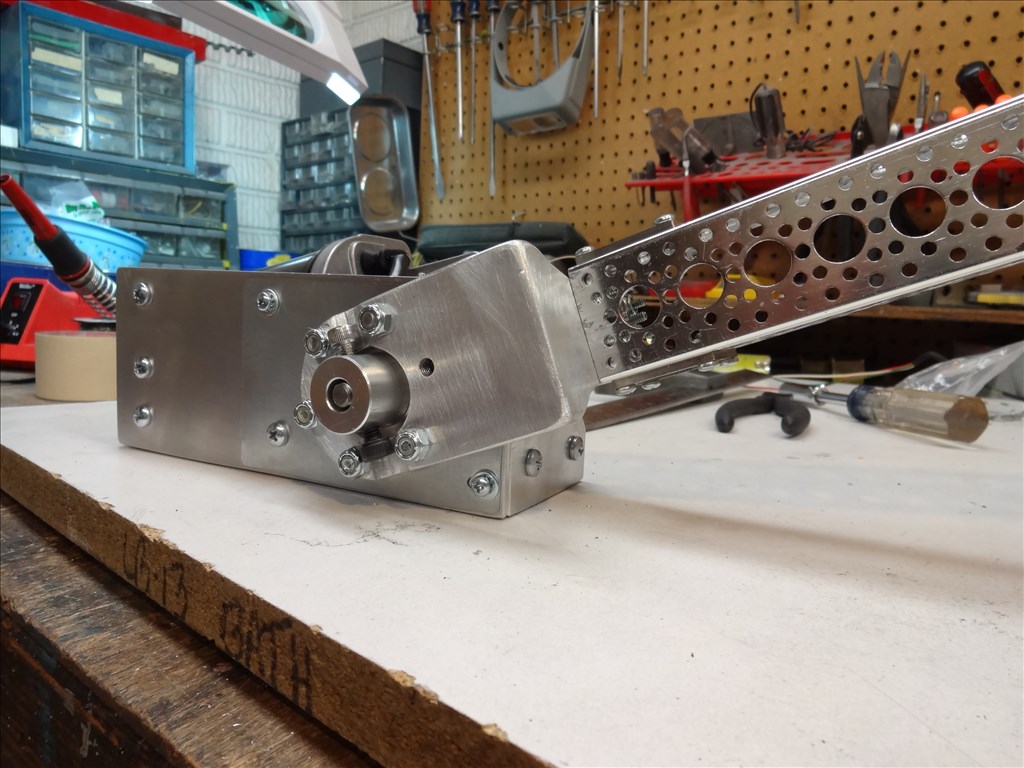

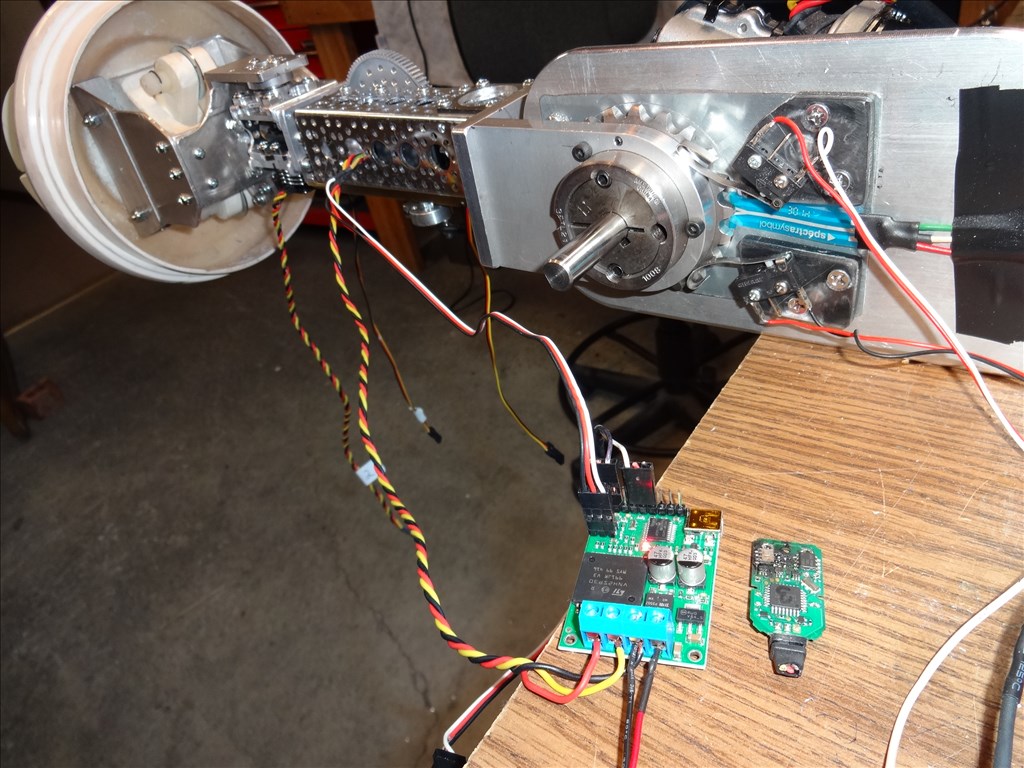

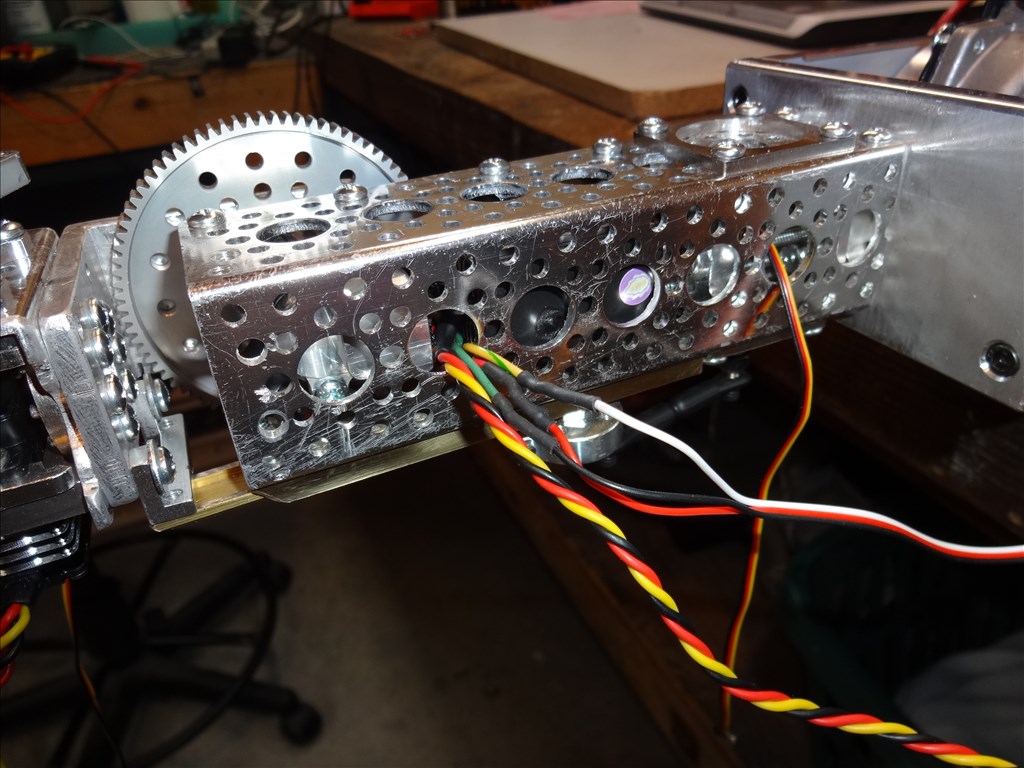

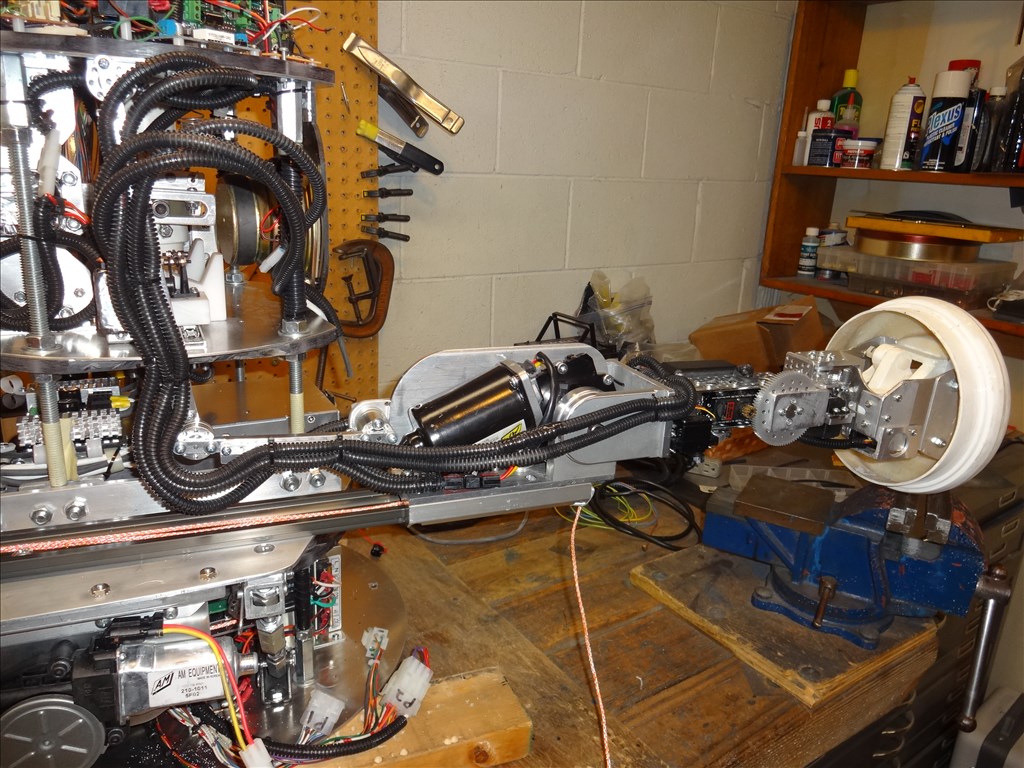

Thanks for the interest and wanting my design on your B9. I have had many, many B9 builders say they want me to start offering these arms as a vendor for the B9 Builders Club. I gotta say that I'm not real thrilled doing that. I'm surely going to at least offer the design and material list to people wanting to try to reproduce this arm. I may also at some point offer to do a run on the machined DC motor mount with the elbow joint. That's the one thing that really makes this design work and be able to lift this very heavy arm.

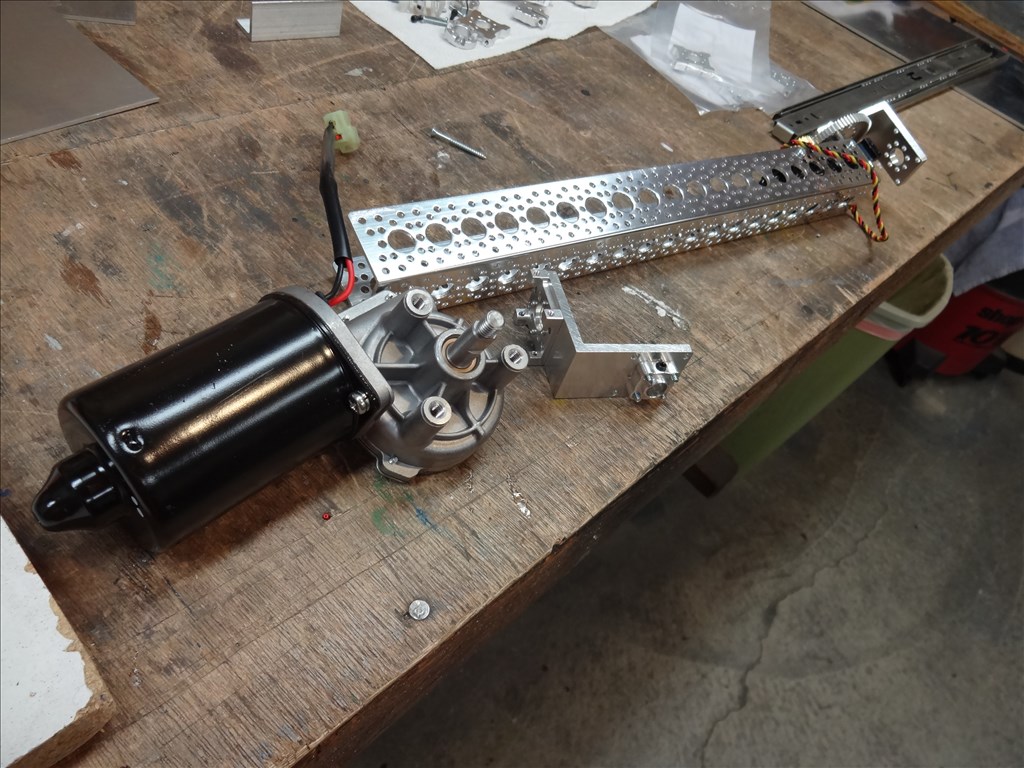

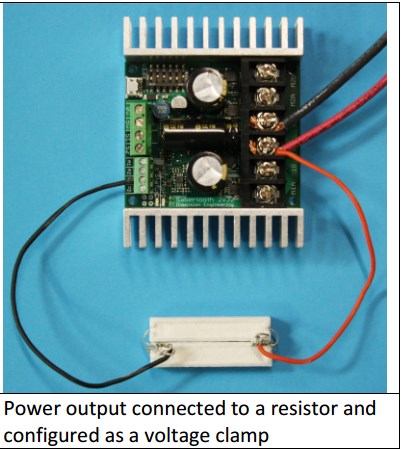

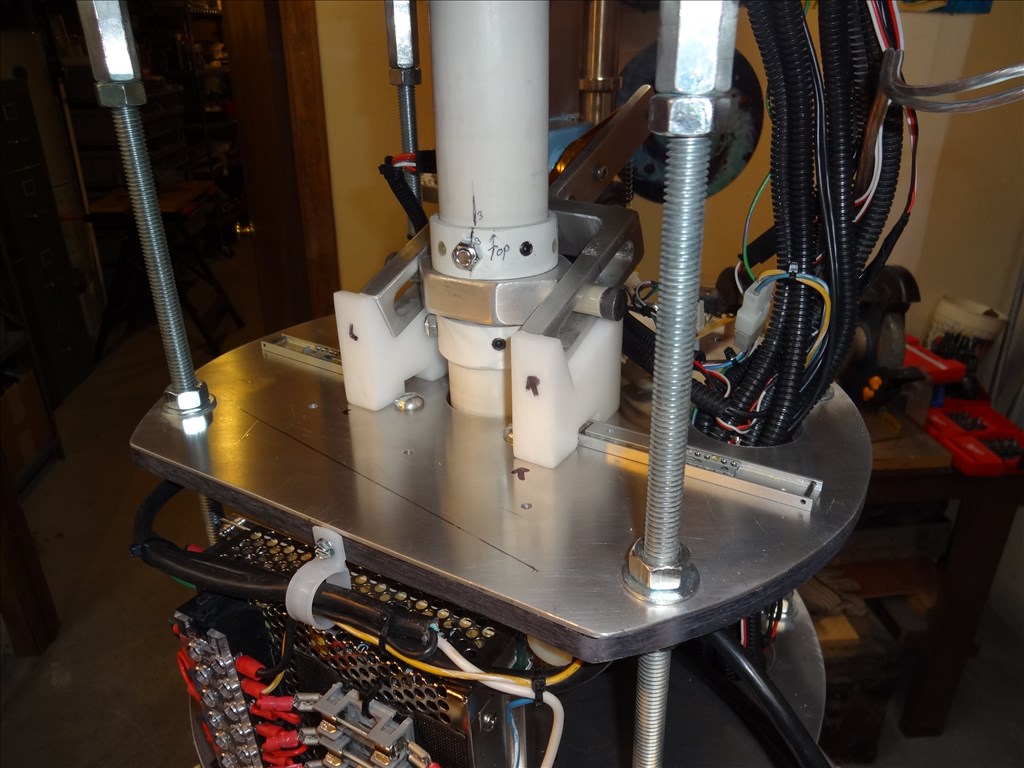

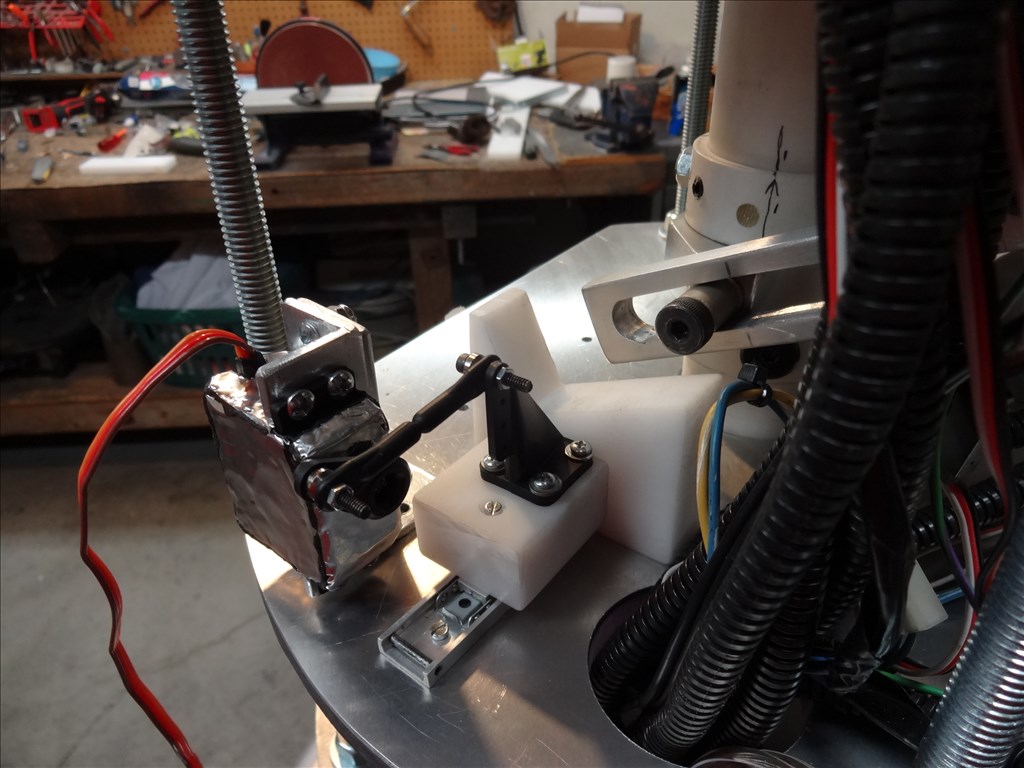

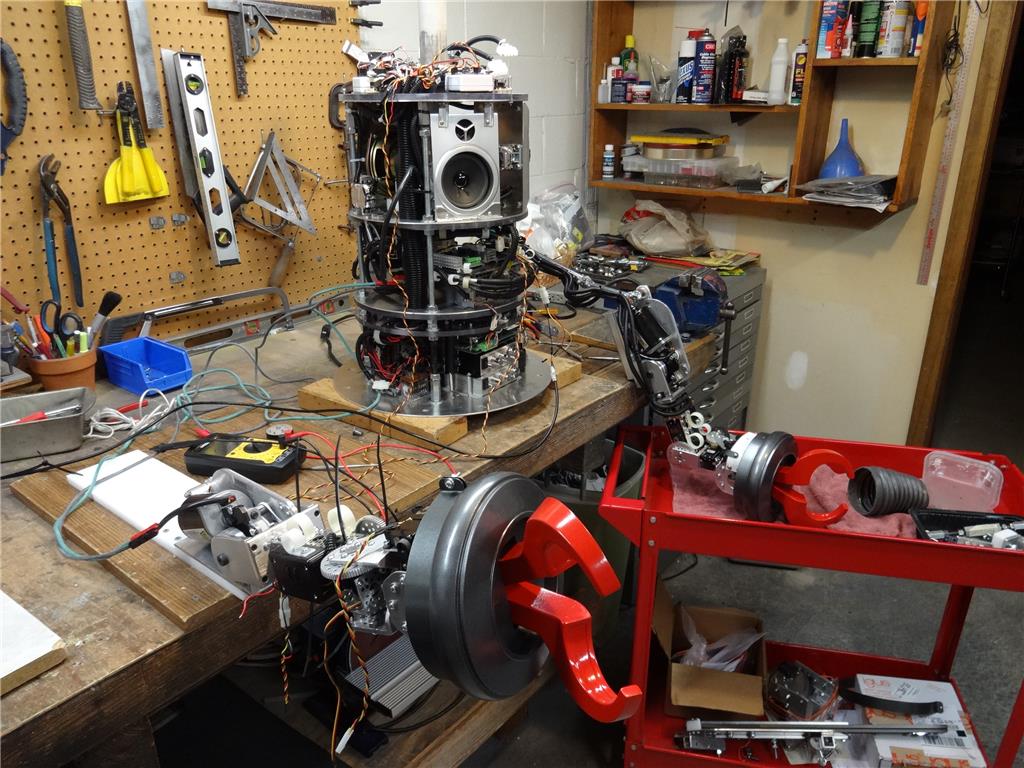

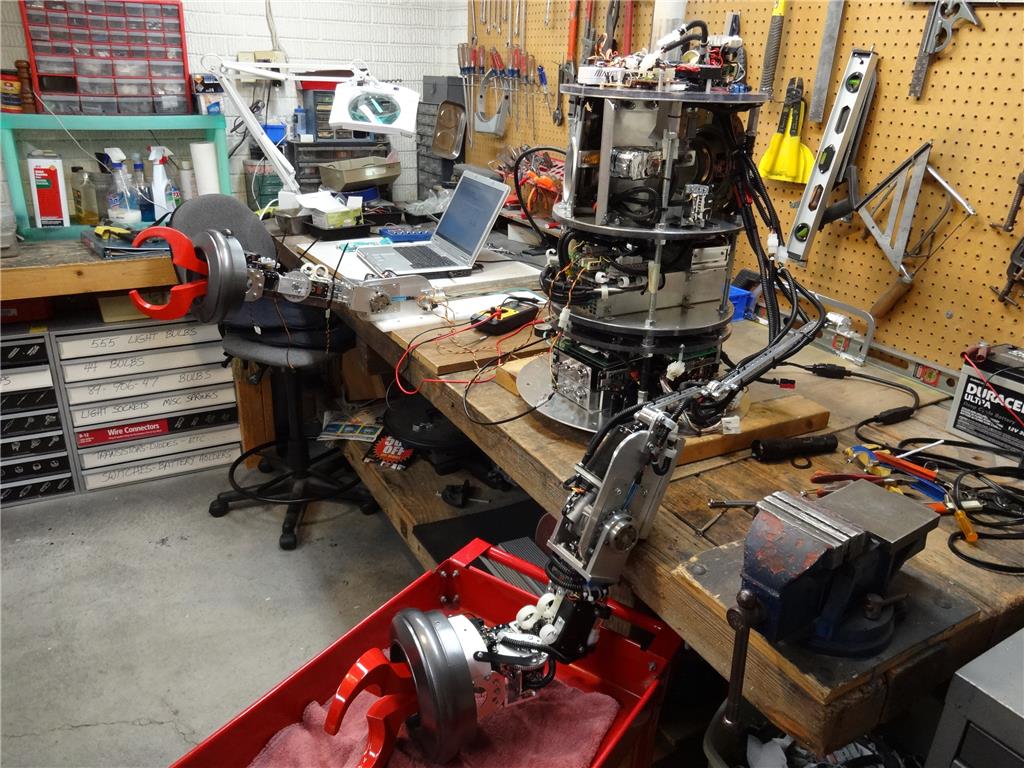

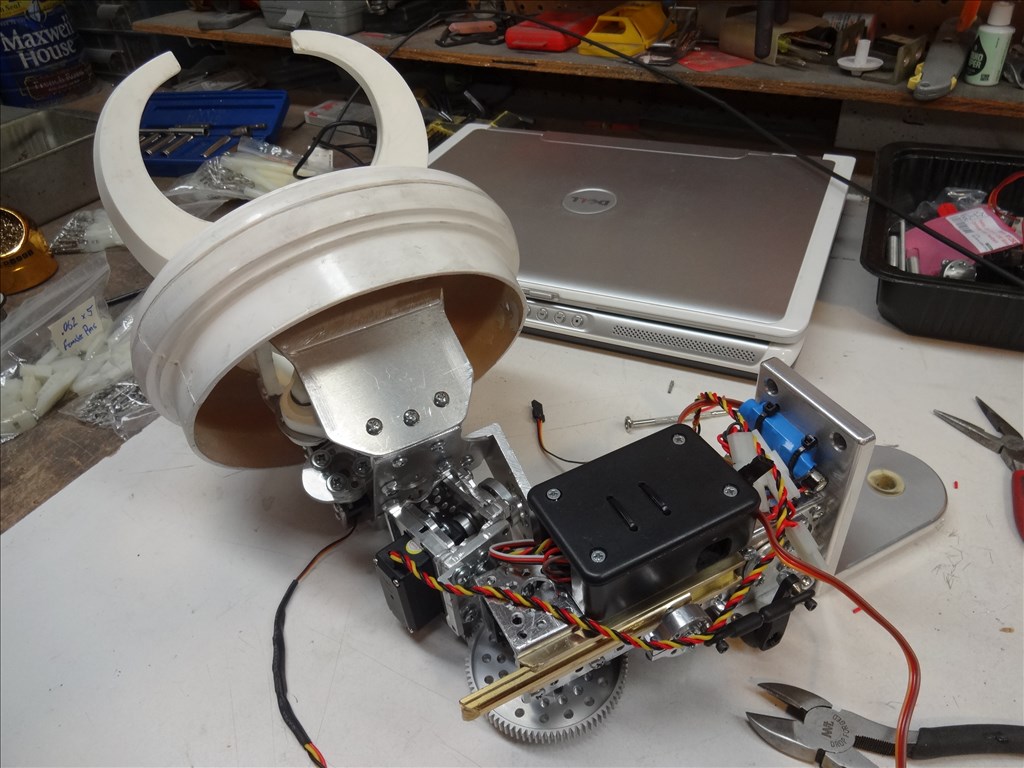

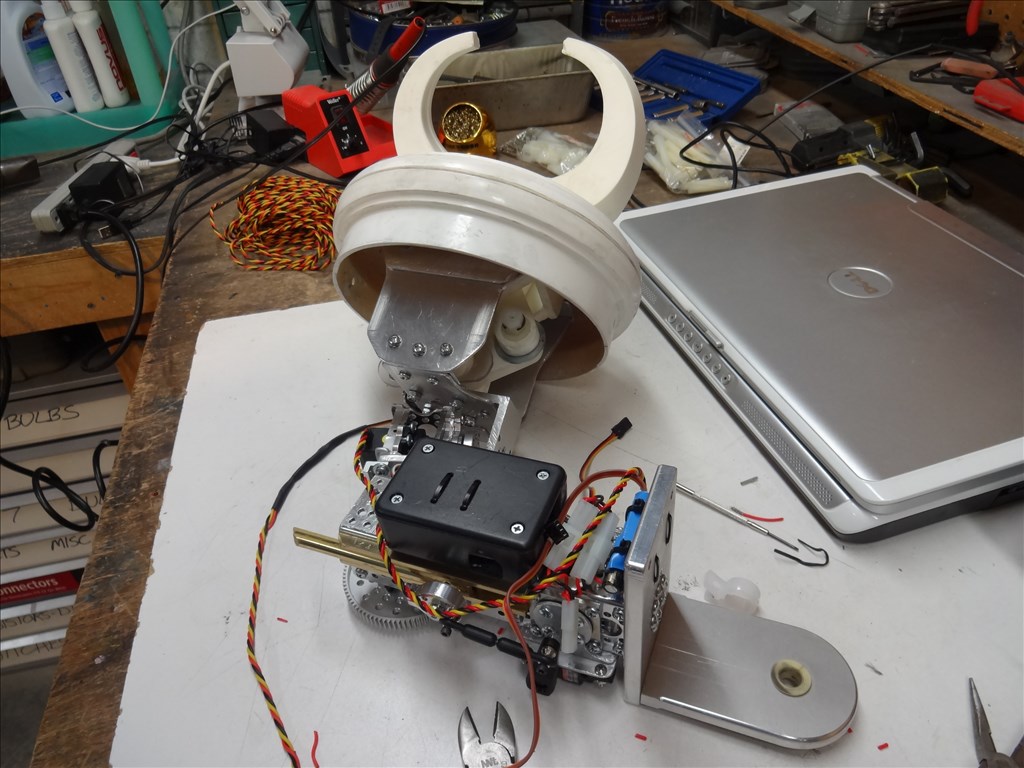

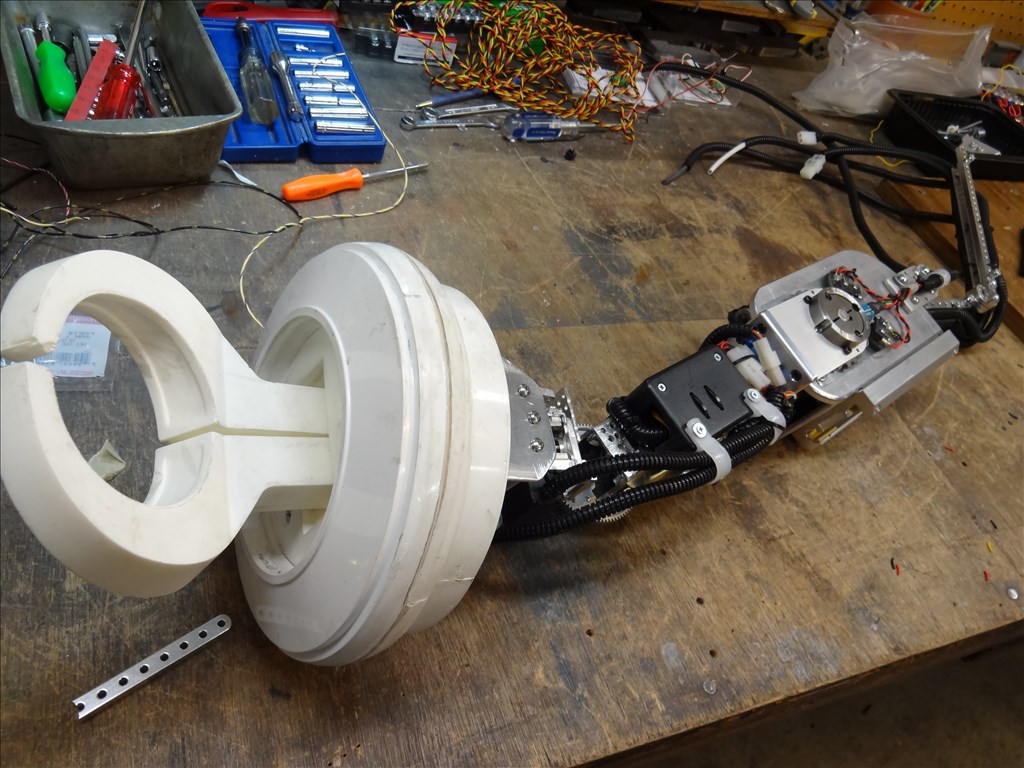

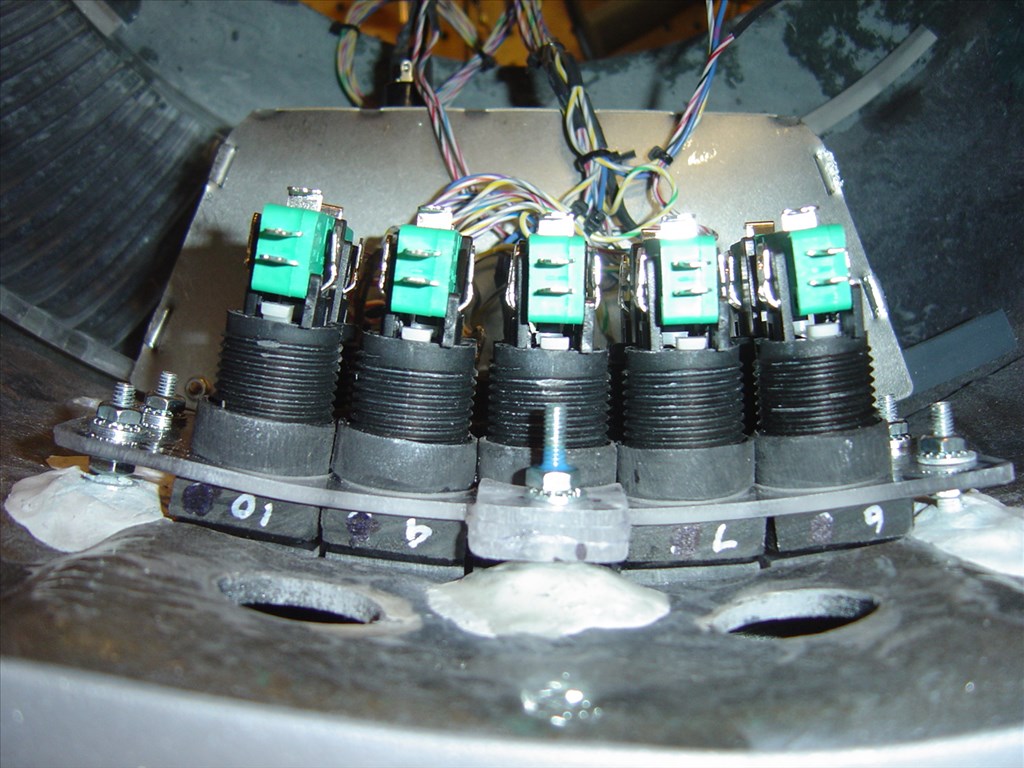

There is a lot of custom work needed to be done to stock parts and tweaking to programs running the two motor controllers. After a year of prototyping and 4 months of work adjusting the final arm I think I'm finally to the point of installing it on the robot.

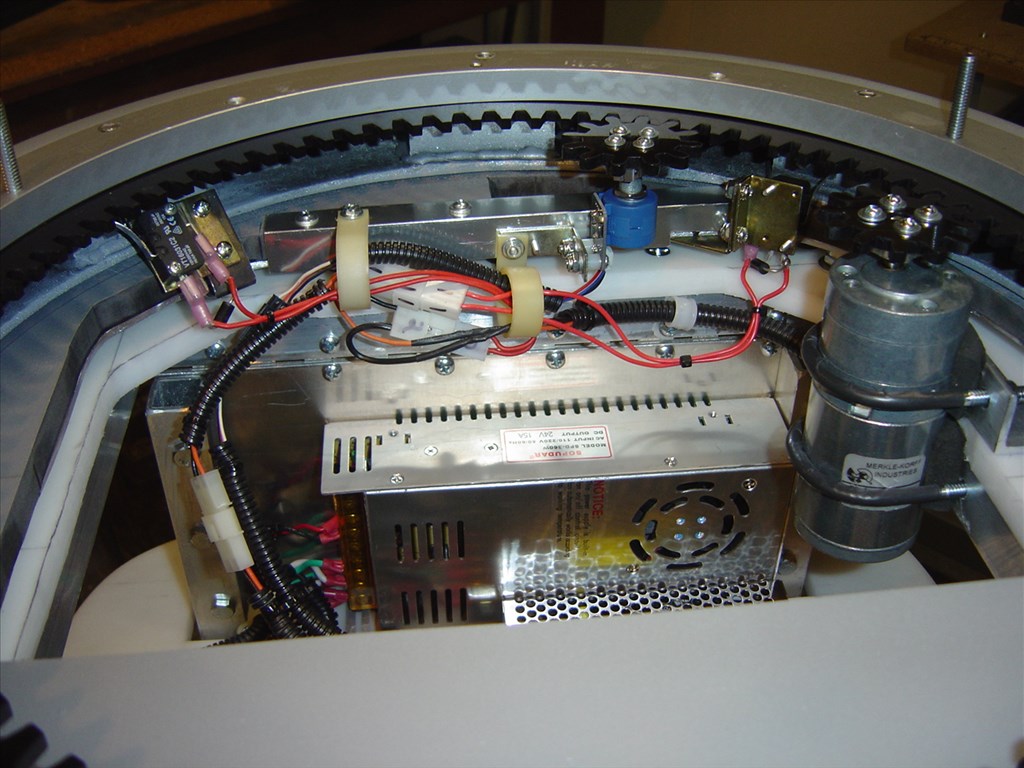

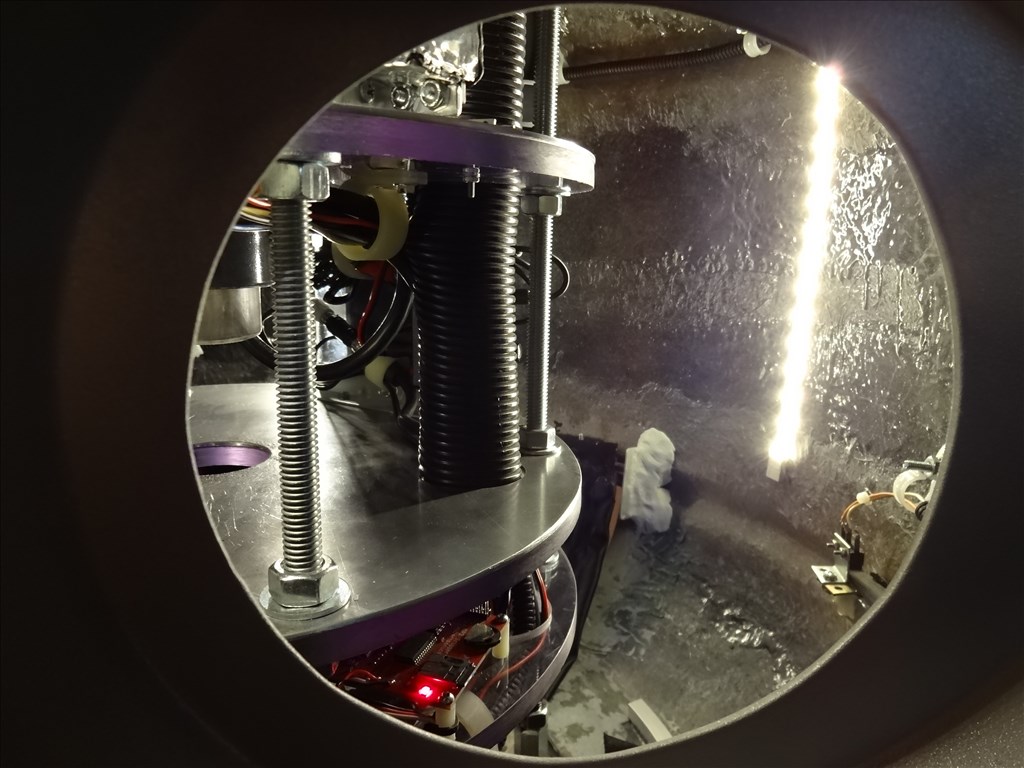

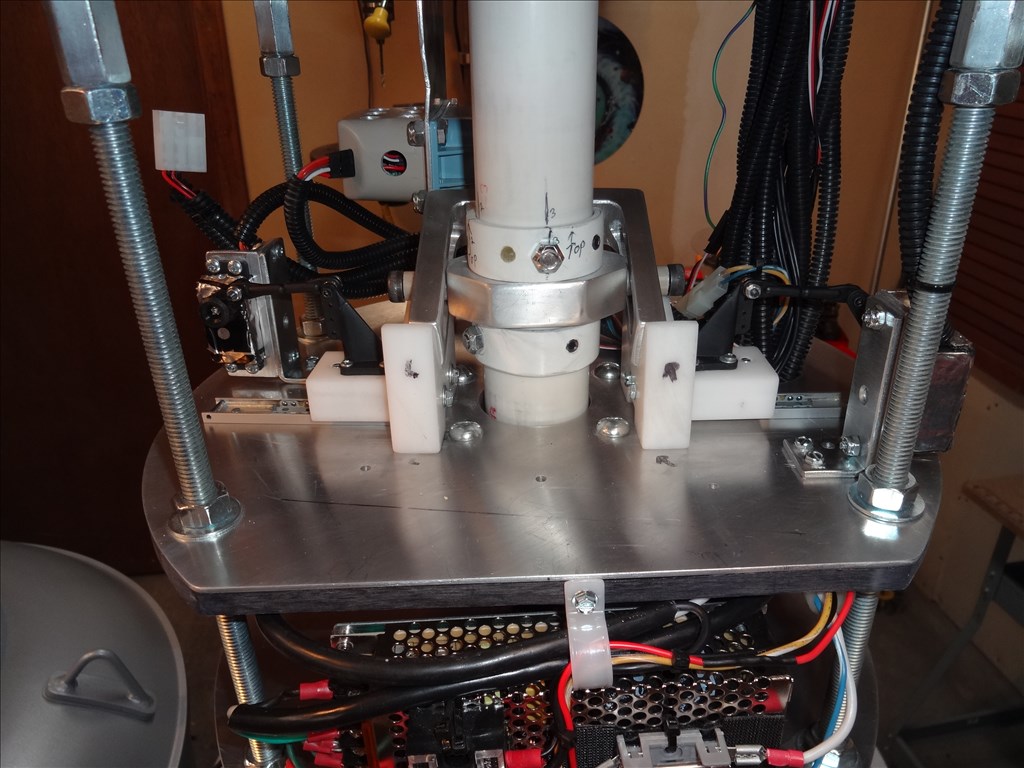

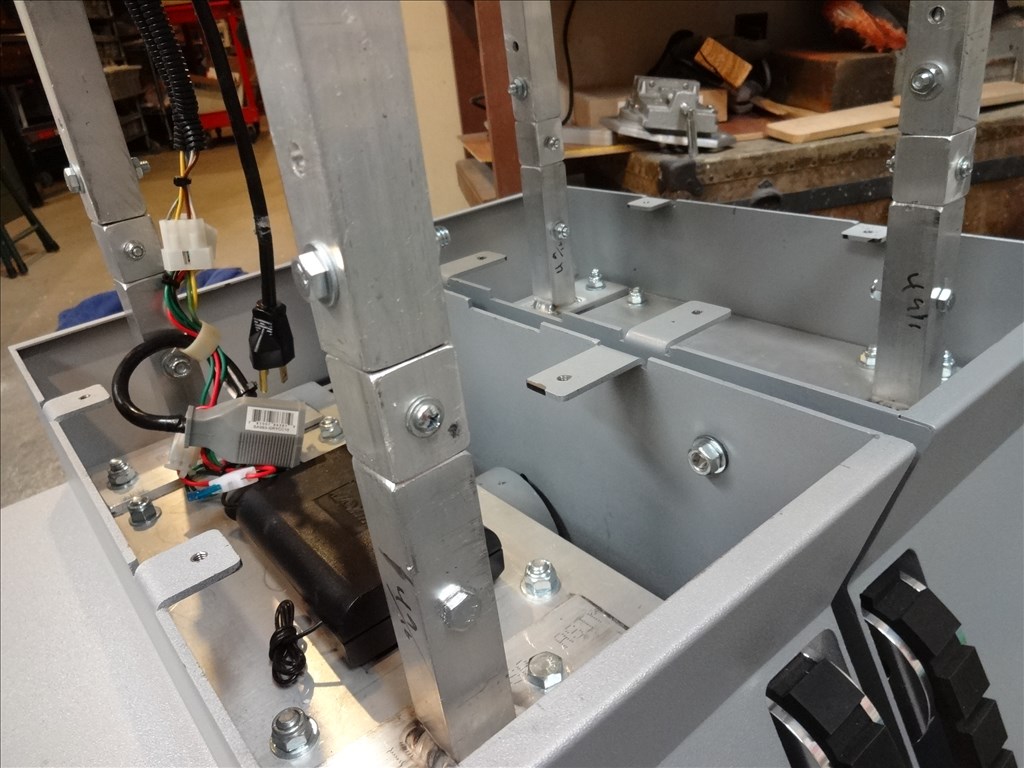

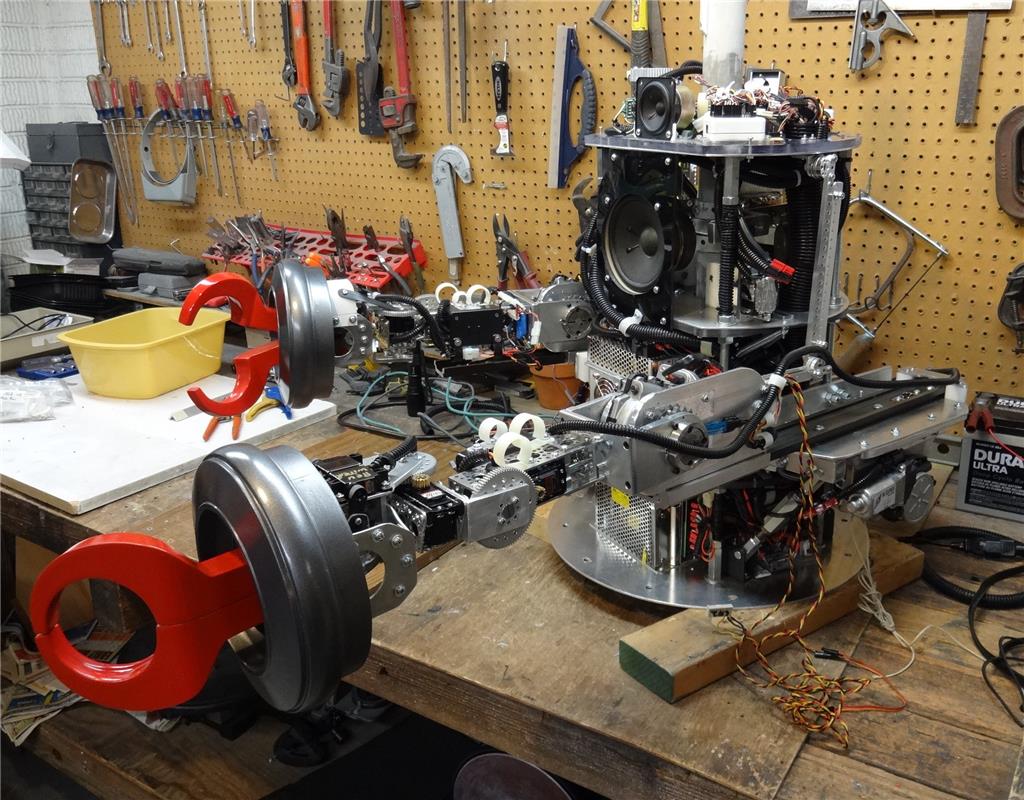

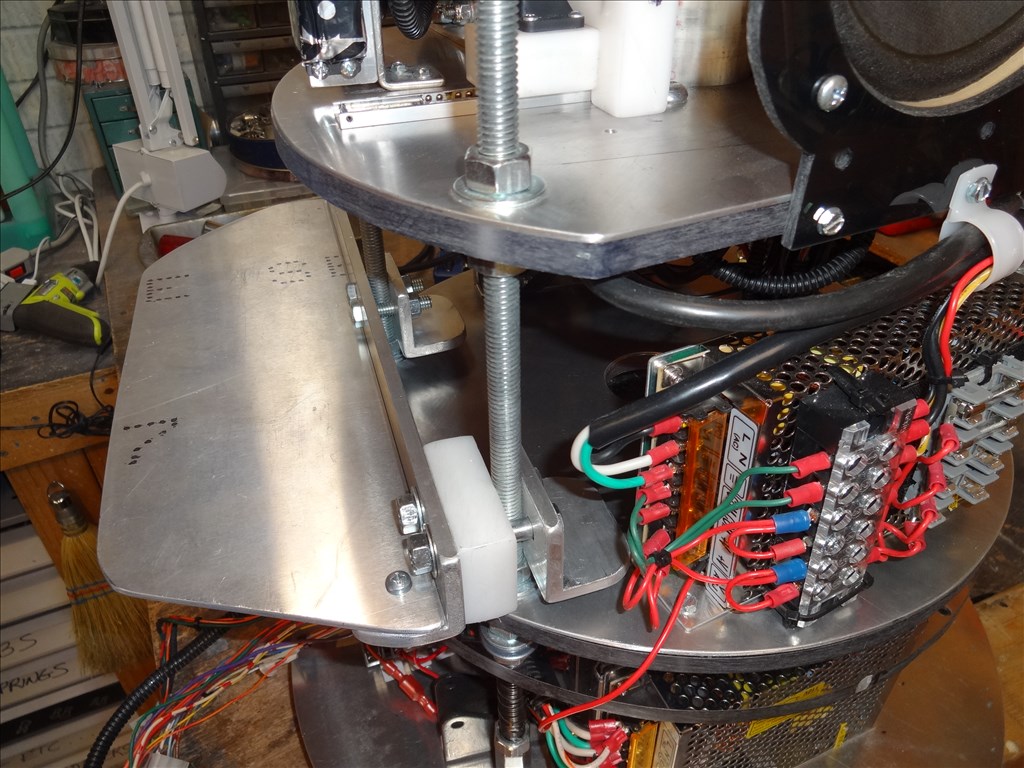

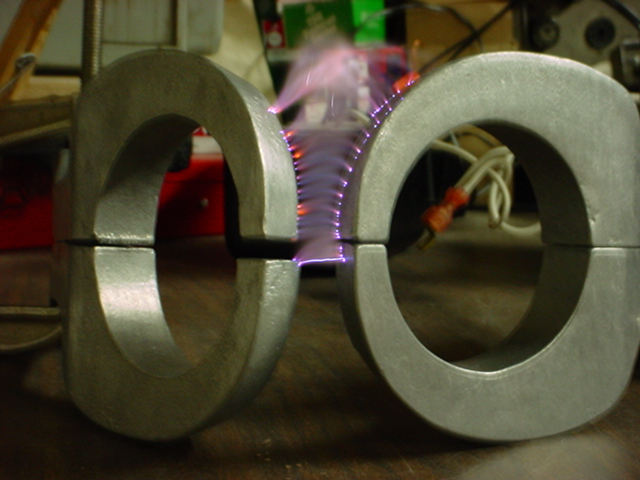

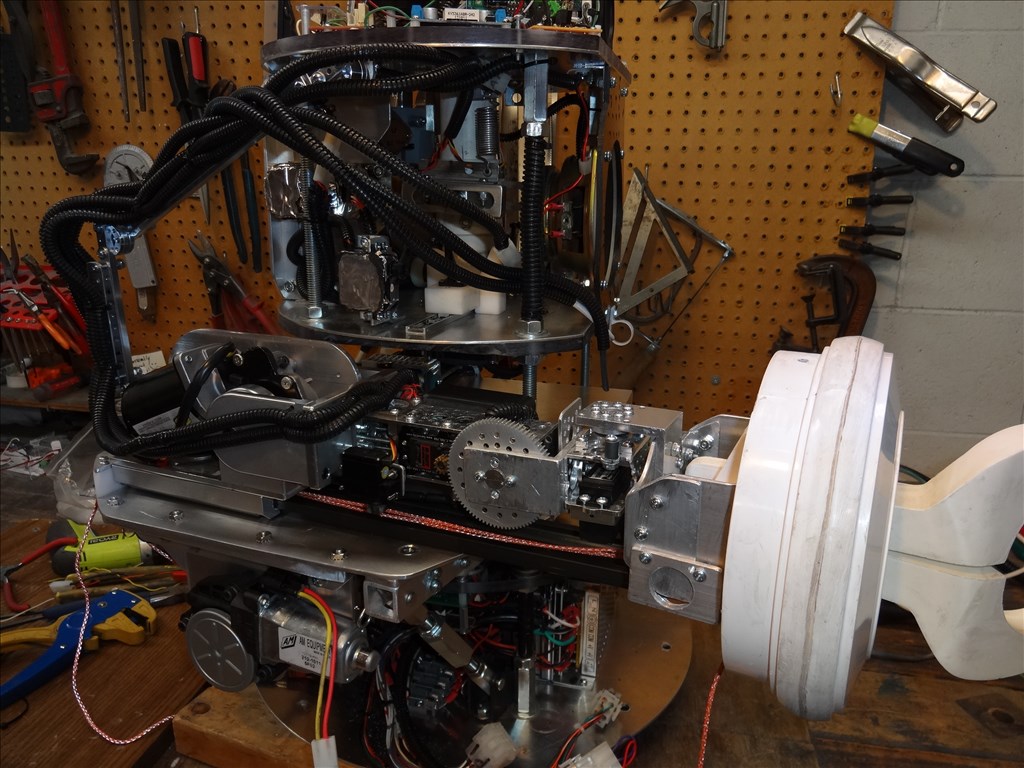

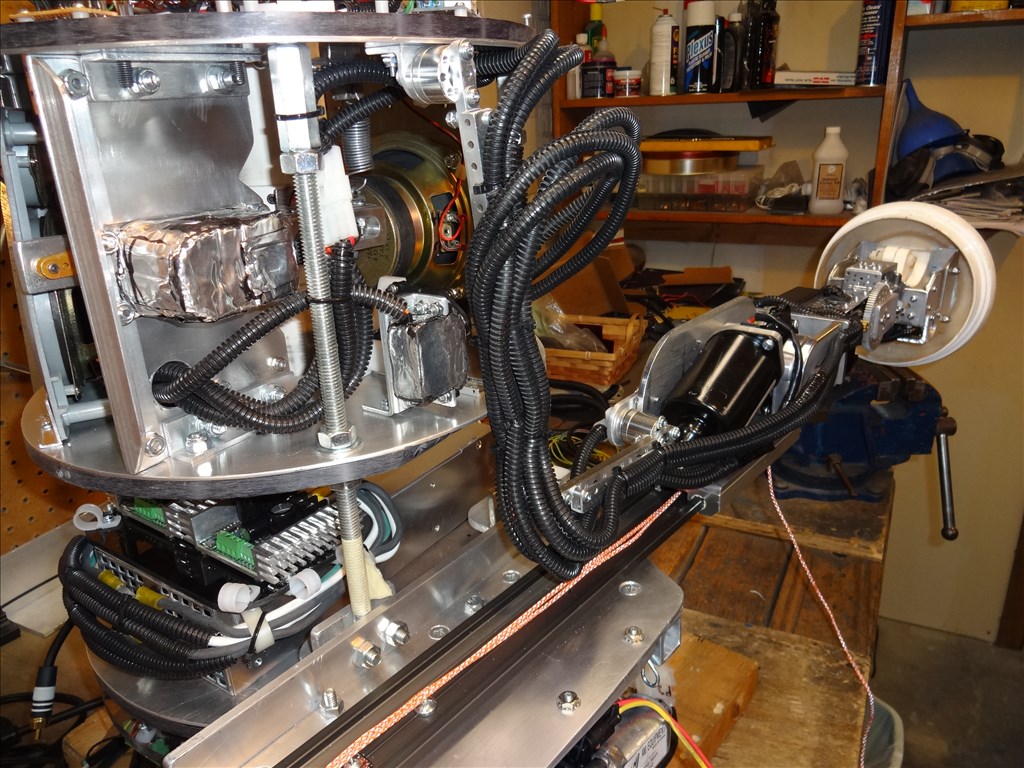

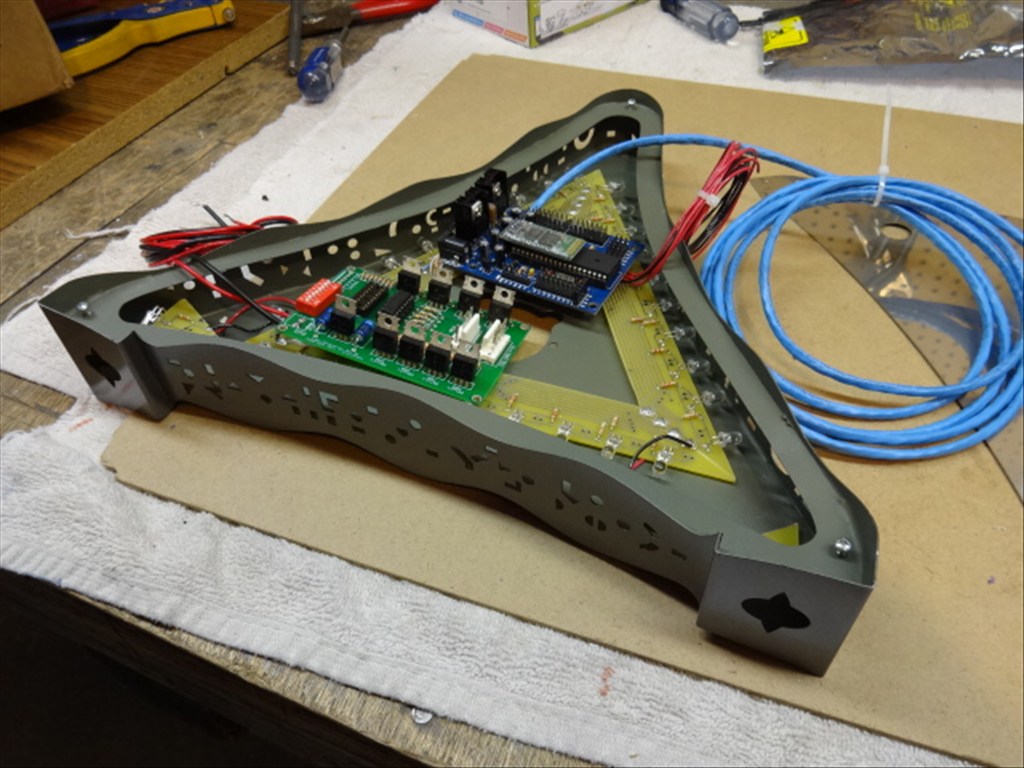

All that and I still need to invent a way to get my liner slides to move this system in and out of the torso. I really don't want to sell or suggest to anyone an unproven product. Last thing I need is to have people spent a thousand USD or more on something that does not work. Also, this design my not be for every B9. With the arms extended and waving around your point of gravity will be way forward and you risk the danger of him tipping over or even breaking off at the waist. eek. These arms MUST be attached to a central skeleton that will support the weight and and distribute the load and stress throughout the support structure. Your structure needs to look something like this and be connected from top to bottom with a heavy and low point of gravity:

Good luck, have fun and stay tuned.

Your B9 is amazing and I hope his arms do everything you want them to do. Your B9 is a real robot and I look forward to videos showing him off. If only I had the time, money and a place to build one, I could have a B9. All I have is a 2 ft tall B9 that I will get running around someday.

Thanks my friend! That means a lot.

The little robots are a lot of work and just as impressive. I'd like to do one some day.