Now I have the EZ-B kit and the Hearoid it's time to start my Showcase thread.

I still haven't decided on a name for him yet, all suggestions are welcome.

I won this robot on ebay weeks ago, for the past 2 weeks he has been waiting for me to collect him...

Today was the day, a road trip to pick him up and bring him back to his new home...

In his new home (with Omnibot and Wall-e in the background totally unaware they are next in line to be opened up)

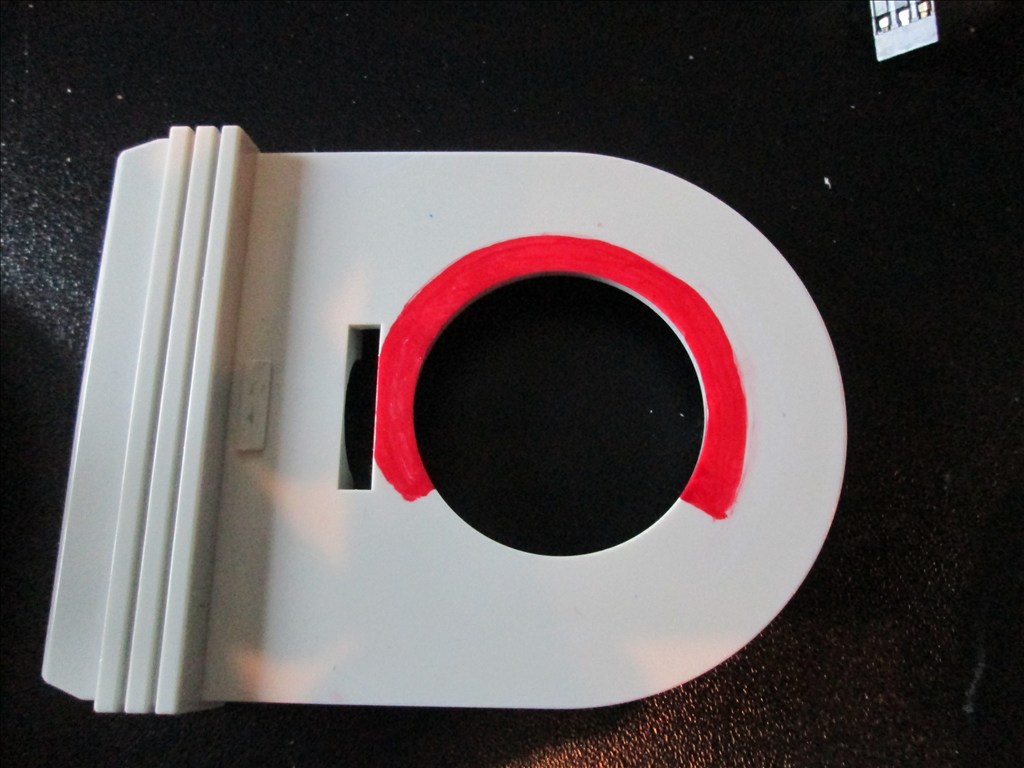

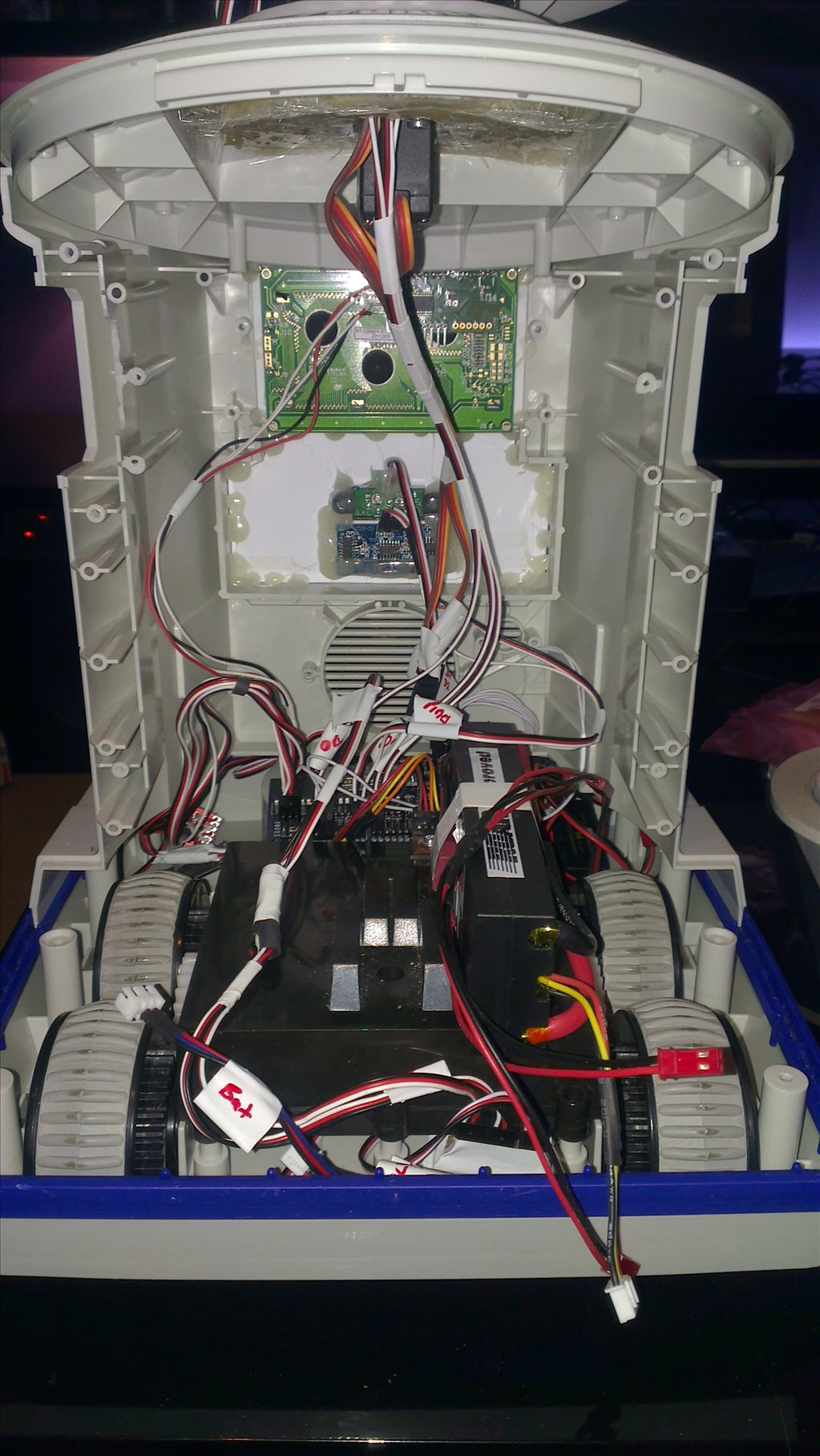

It wasn't long before this happened...

Now waiting to go in the dishwasher to get nice and clean.

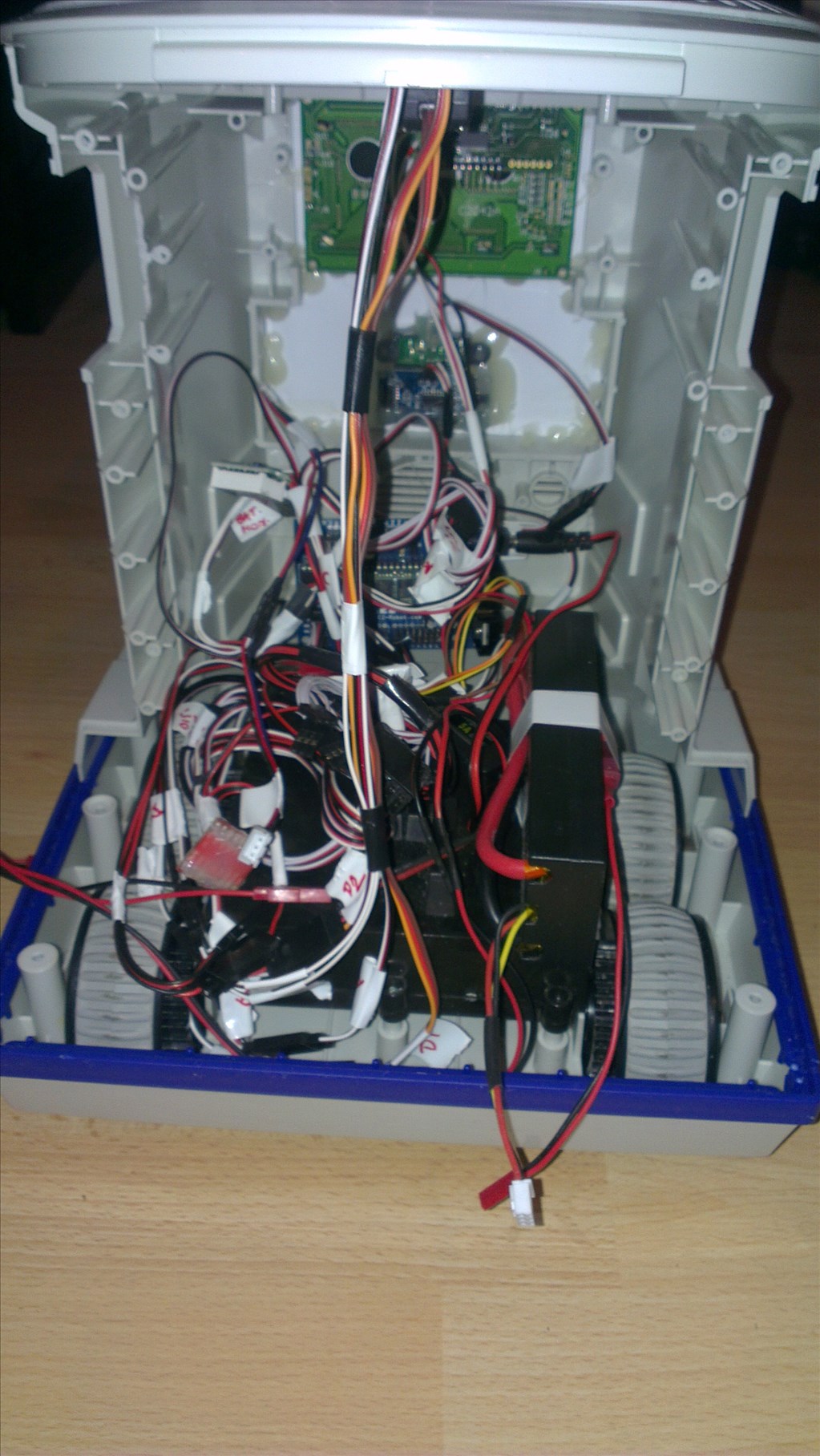

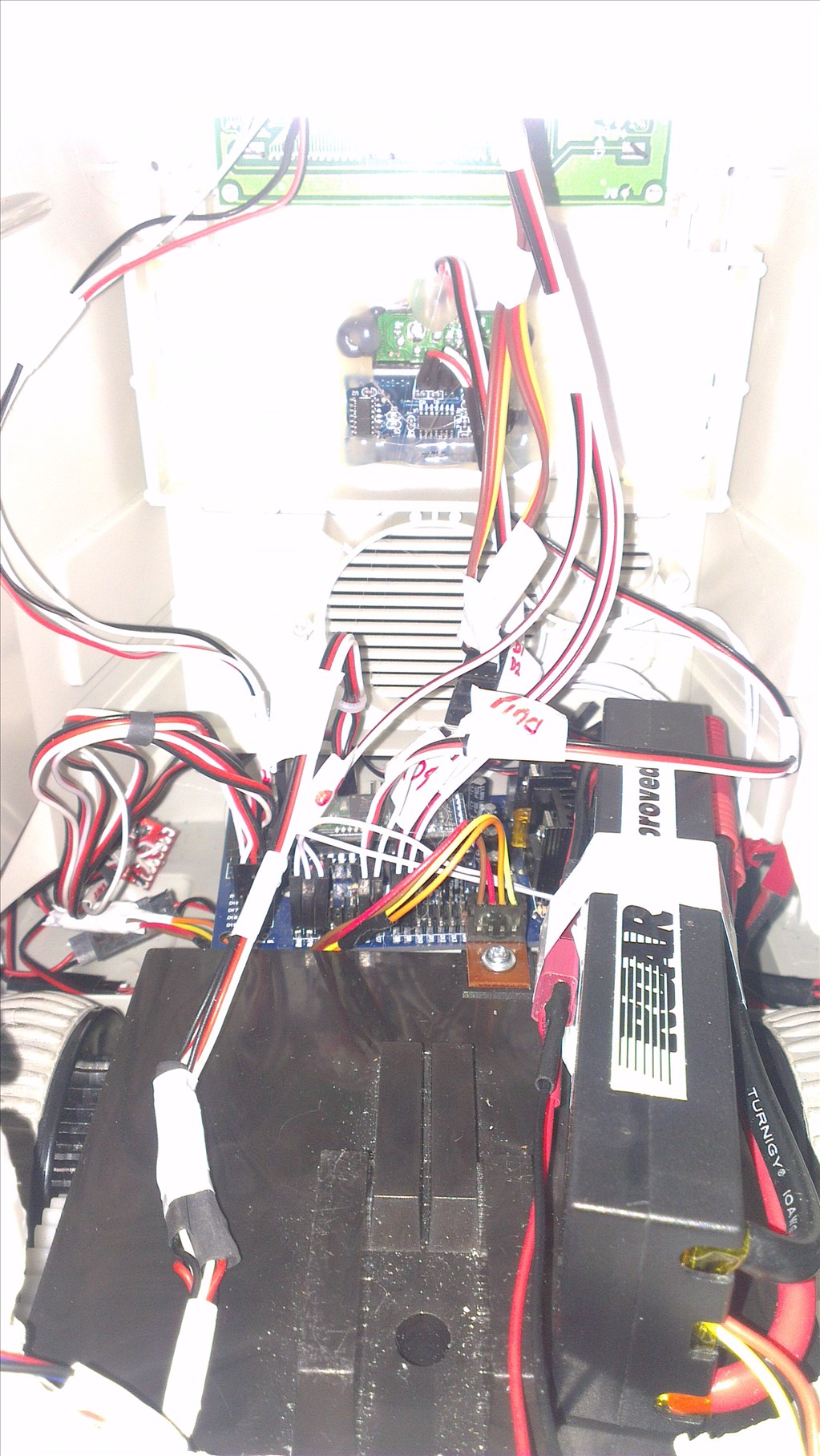

The plan is to make him autonomous, running 24/7 (except for when he knows to go charge himself up) but will also be adding in the various image tracking options.

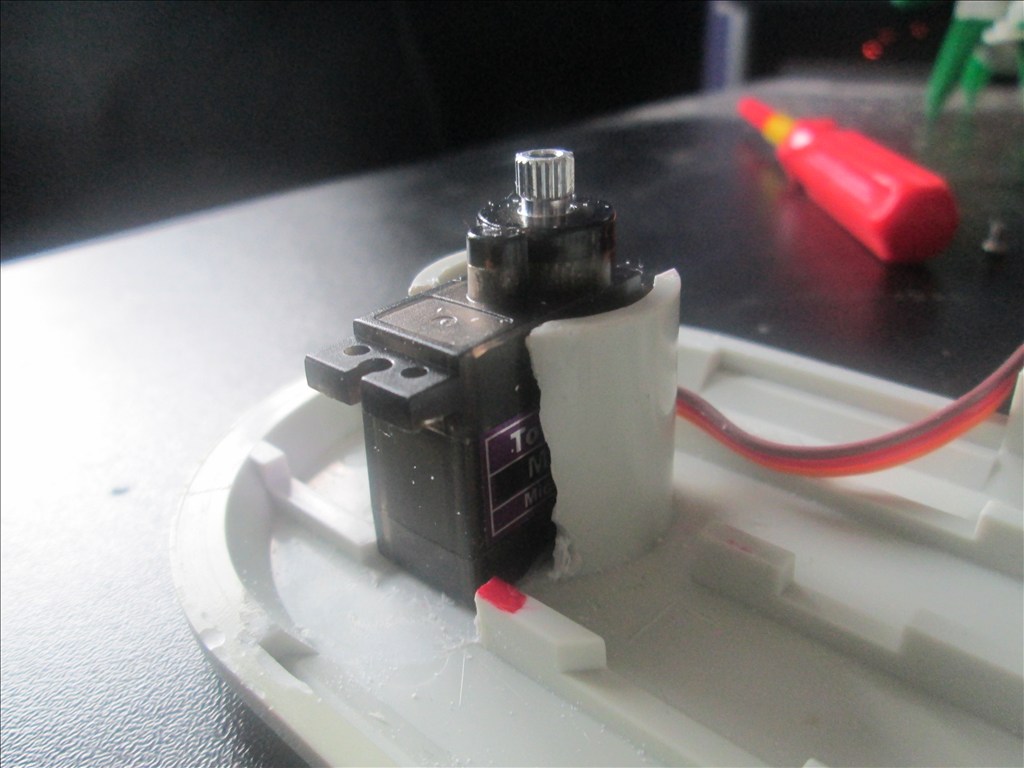

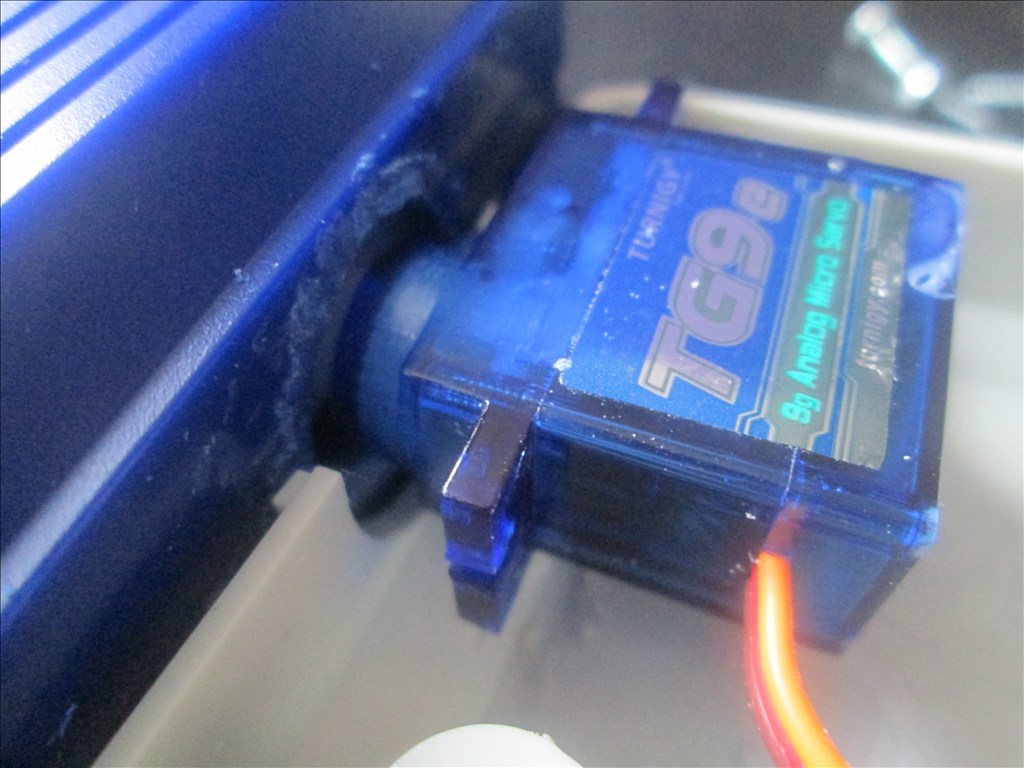

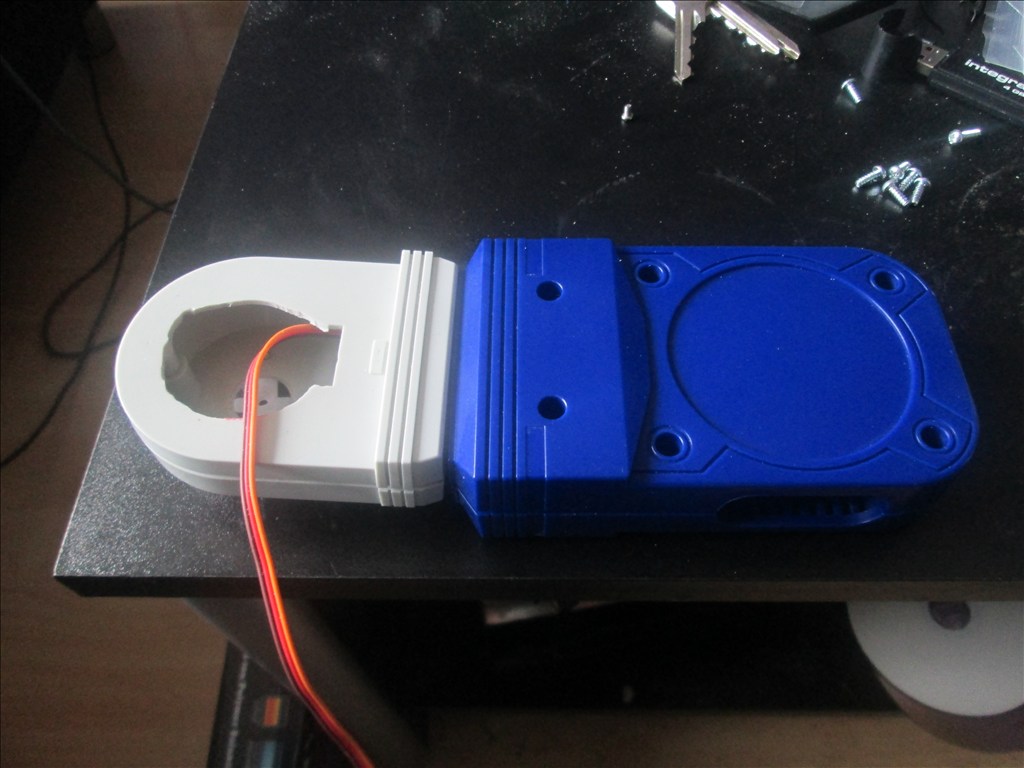

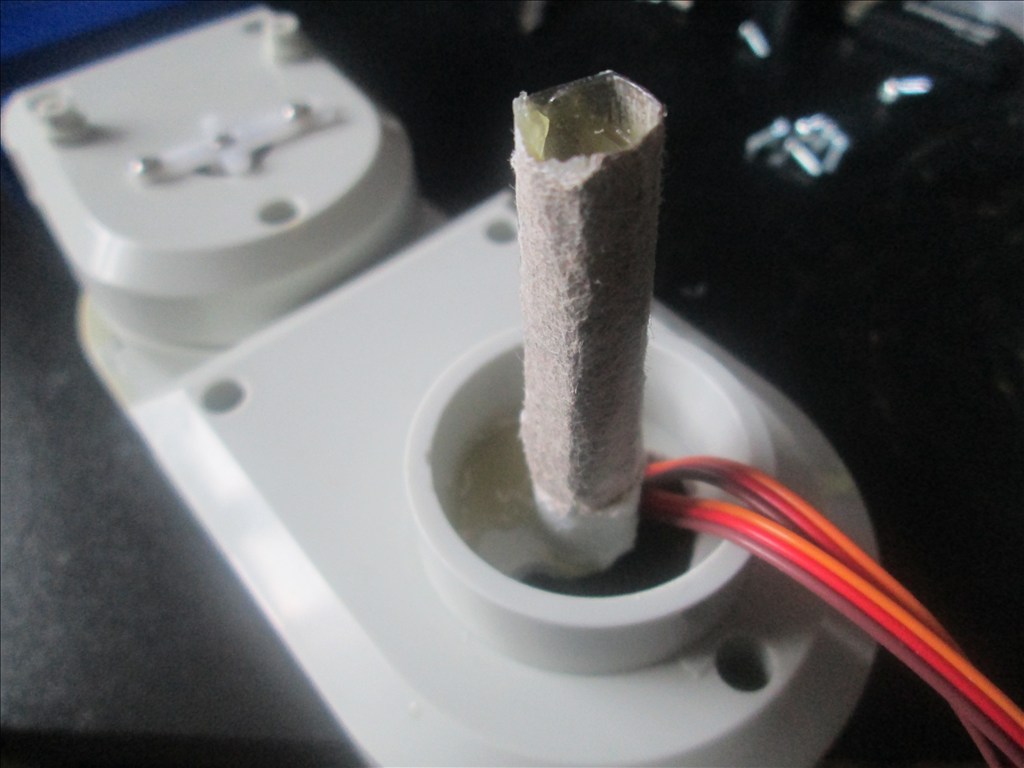

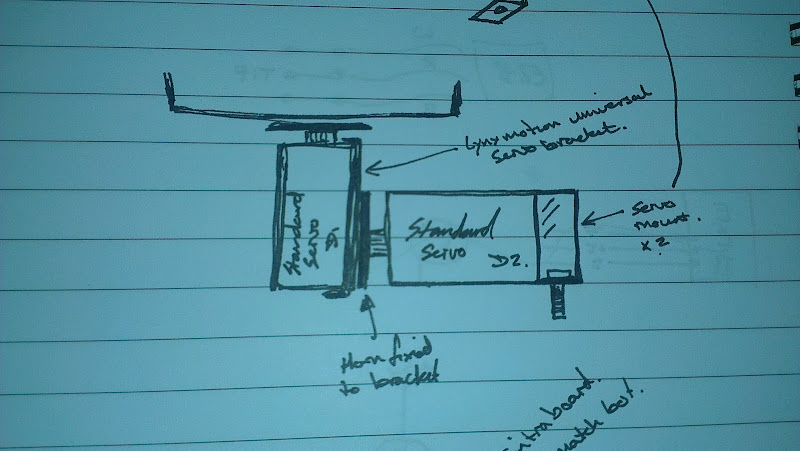

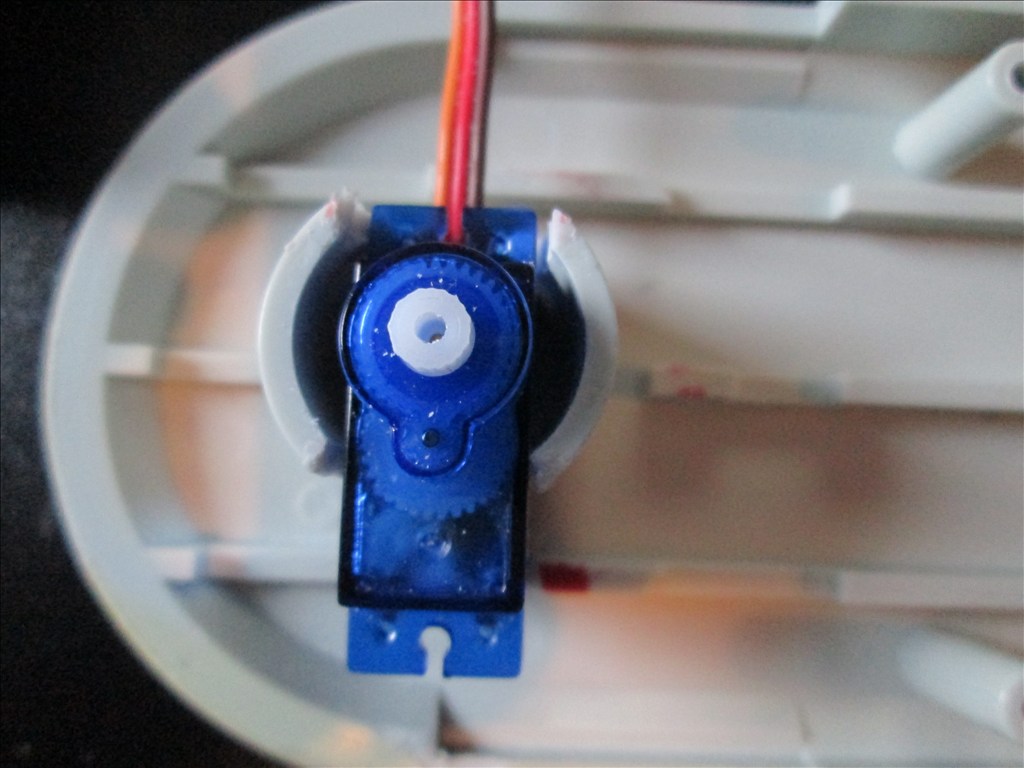

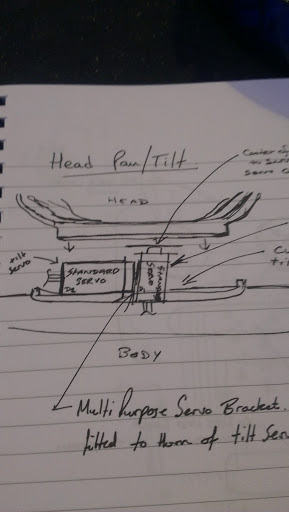

The only other slight modifications to be made to him are to convert the head to tilt & pan which will involve having to give him a small neck.

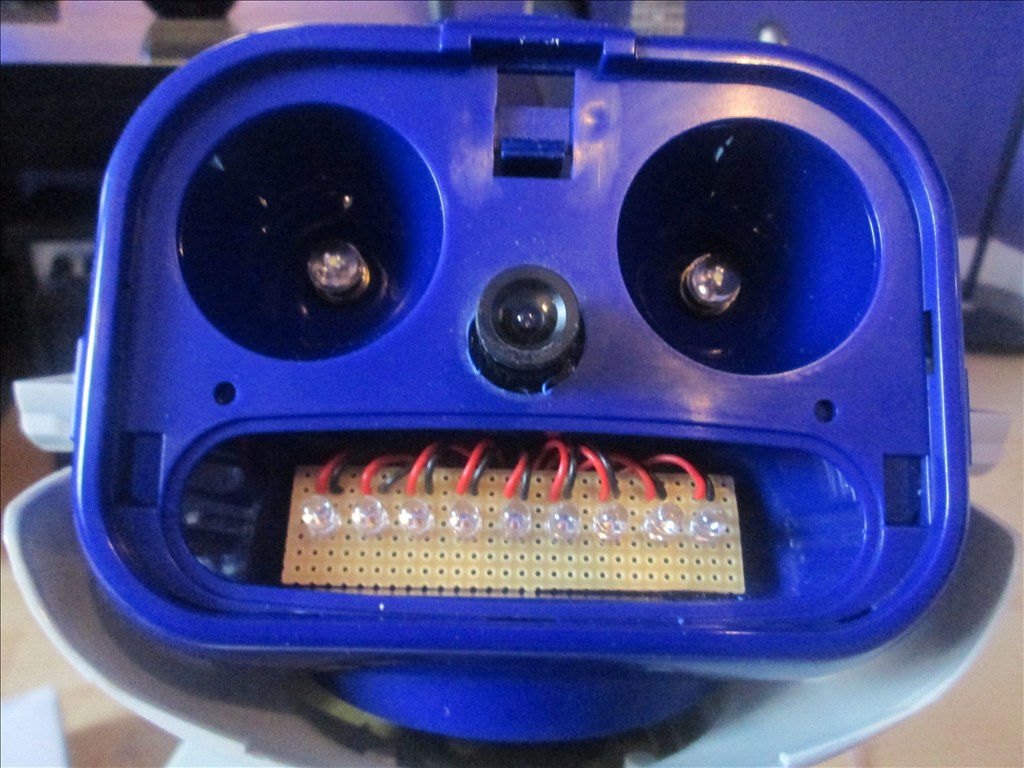

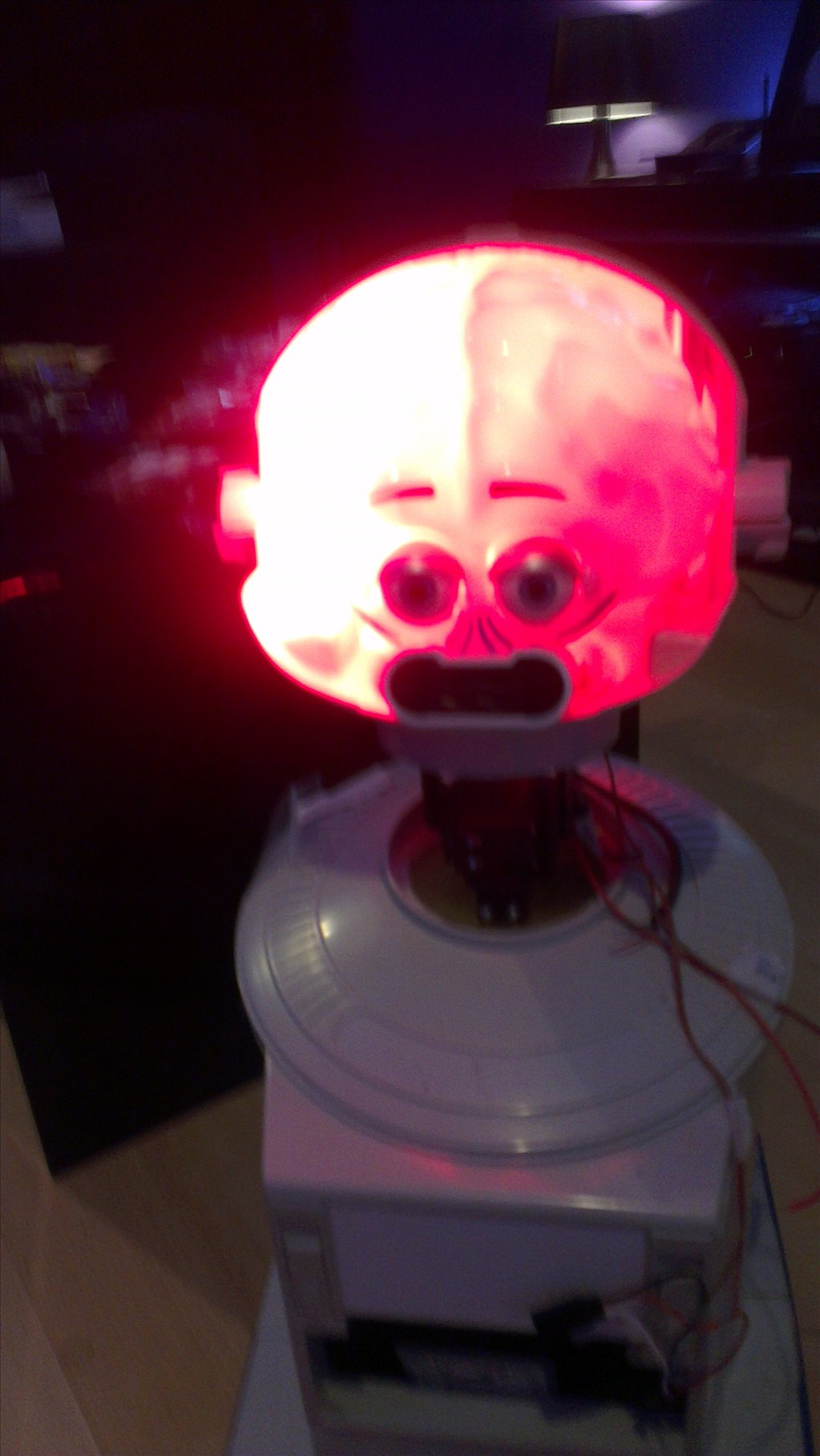

The head will include the camera. I haven't yet decided to fit it in one of his eyes or to make it his nose. The issue to overcome with this is the blue tint on the bubble head. The mouth will have a light or some lights in which flicker when he speaks.

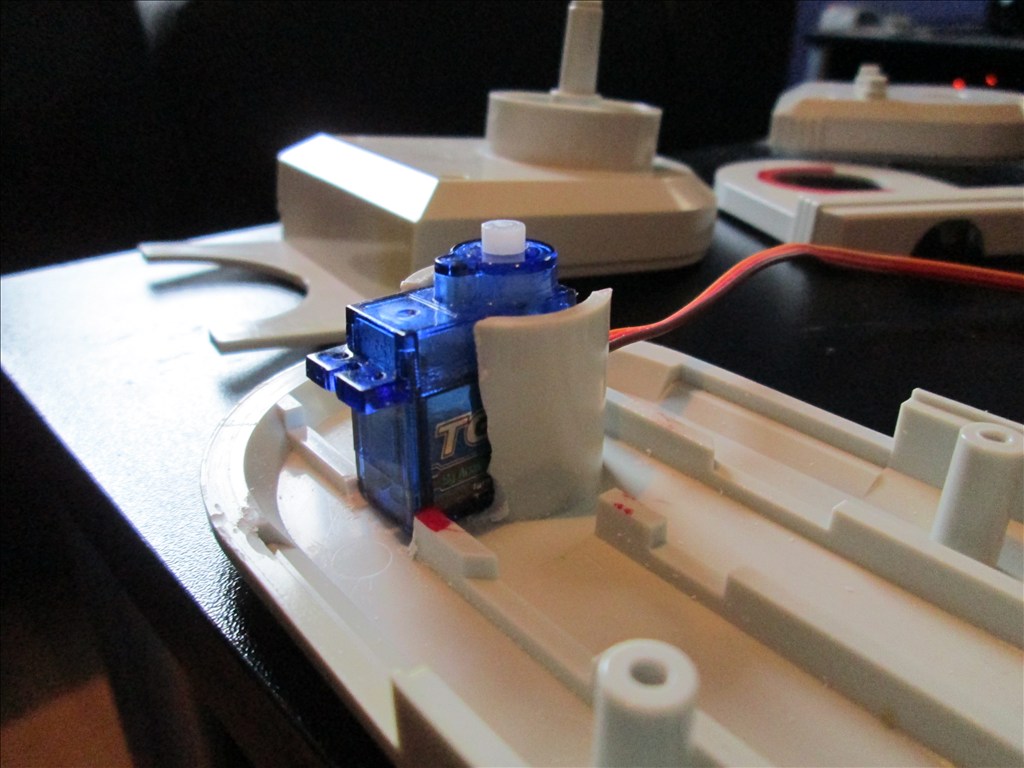

The arms will be given some life with servos at the shoulder joints and the elbows provided I can get them to fit in there nicely.

Ultrasonic sensor will be in his chest, probably on a servo to give a wider view.

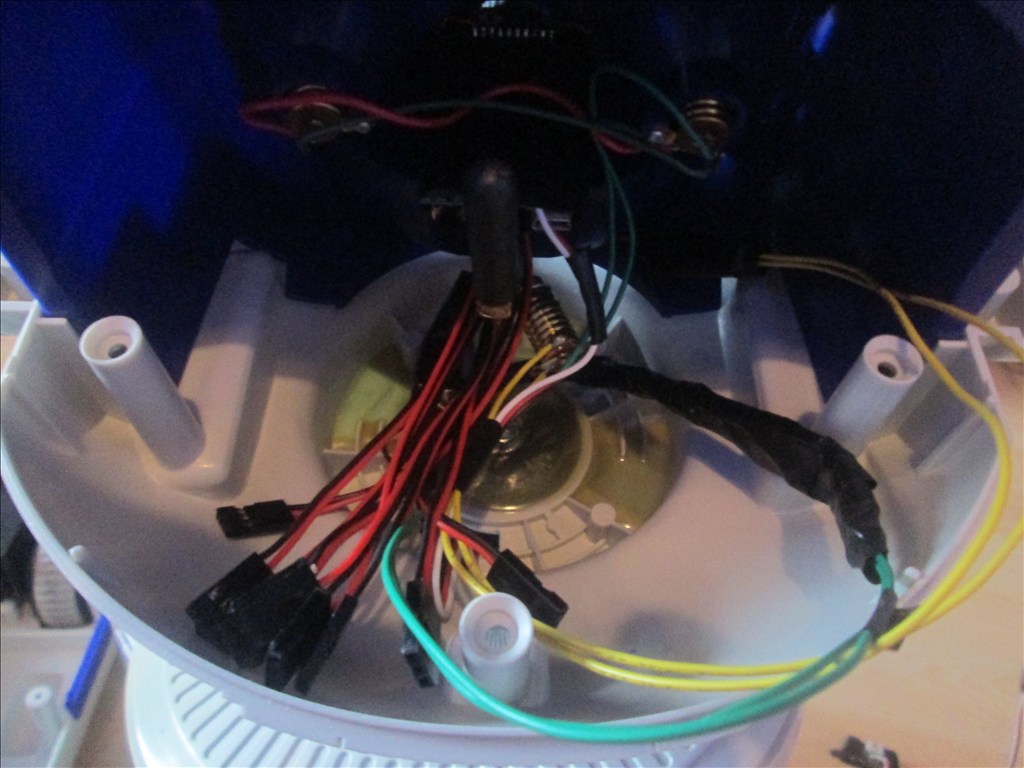

Original drive wheels and gearbox seem to be in very good shape so will plan to reuse those and just replace the existing motors for the modified servos if they can manage the task.

Speaker and microphone will be in the original positions - if it's not broke why fix it?

Not too big a project but enough to give me a test, help me learn and bring an old robot back to life.

Other robots from Synthiam community

DJ's Darth Vader Humanoid Robot

Cem's Ziggy The Hexapod

@irobot58 I'm sure DJ has implemented functions in EZ-Script to round off the values to 2 decimal places, I just need to read the manual

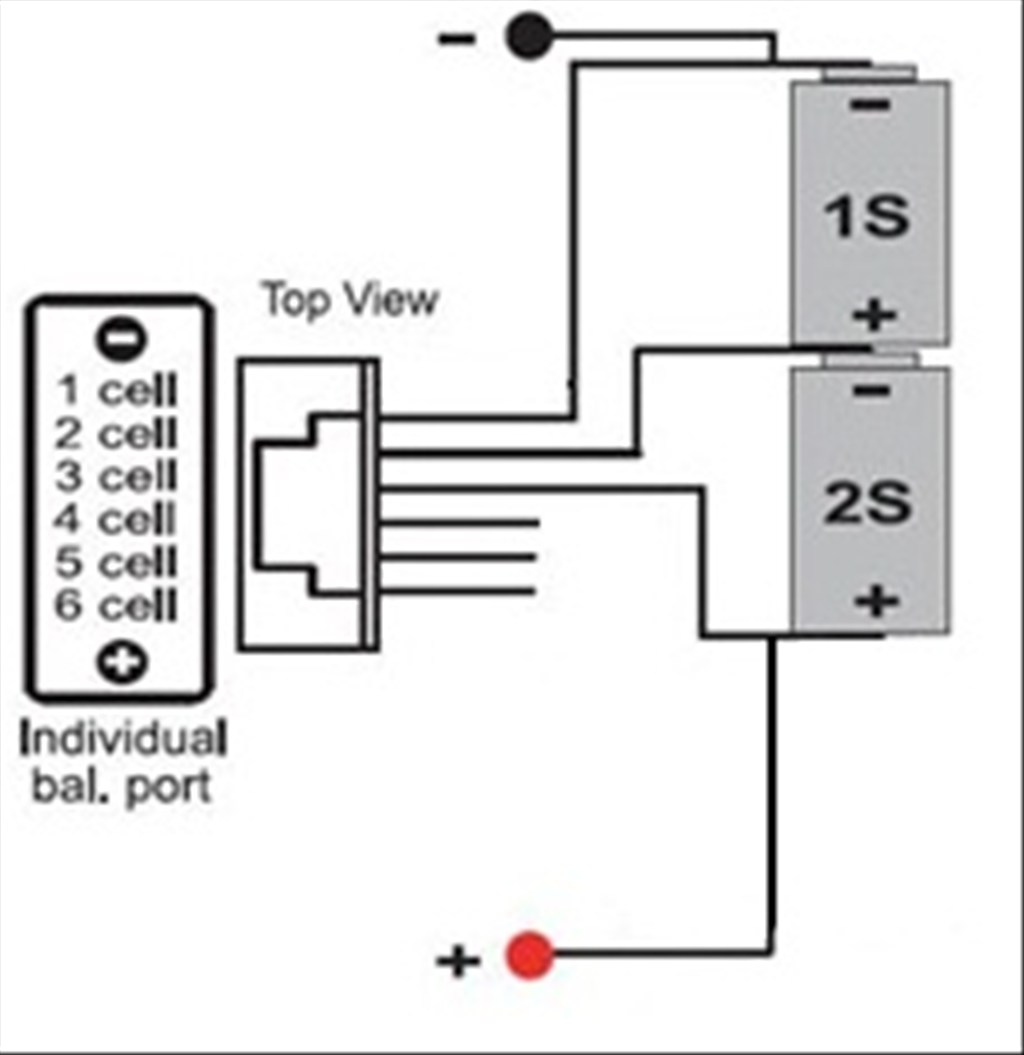

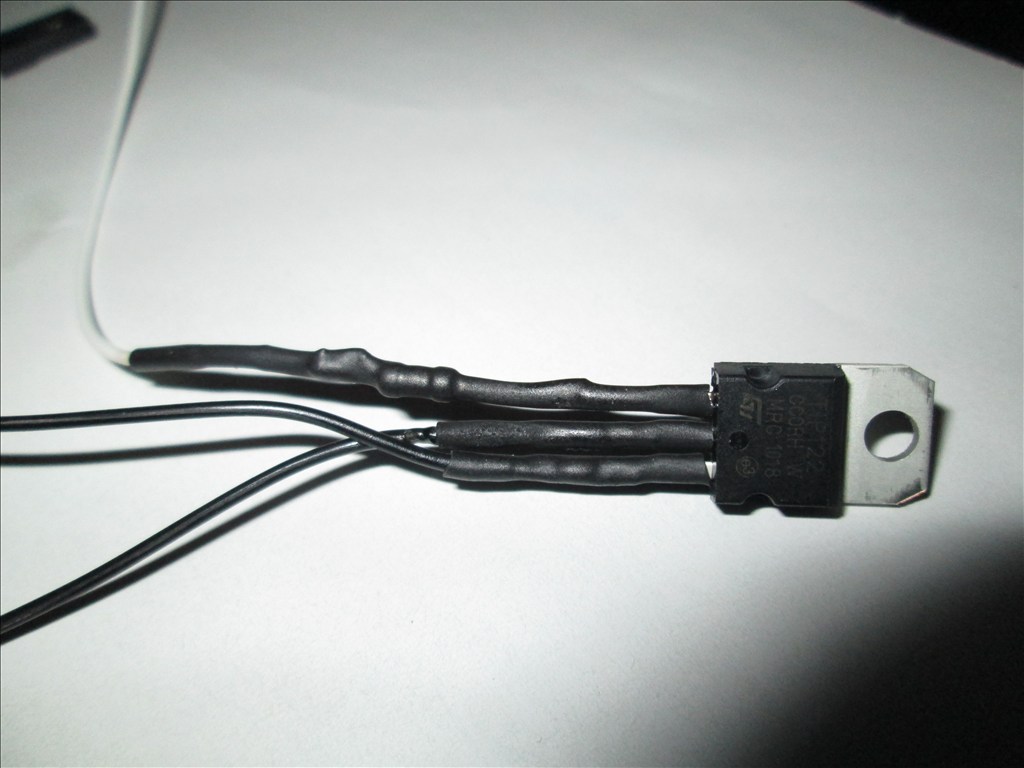

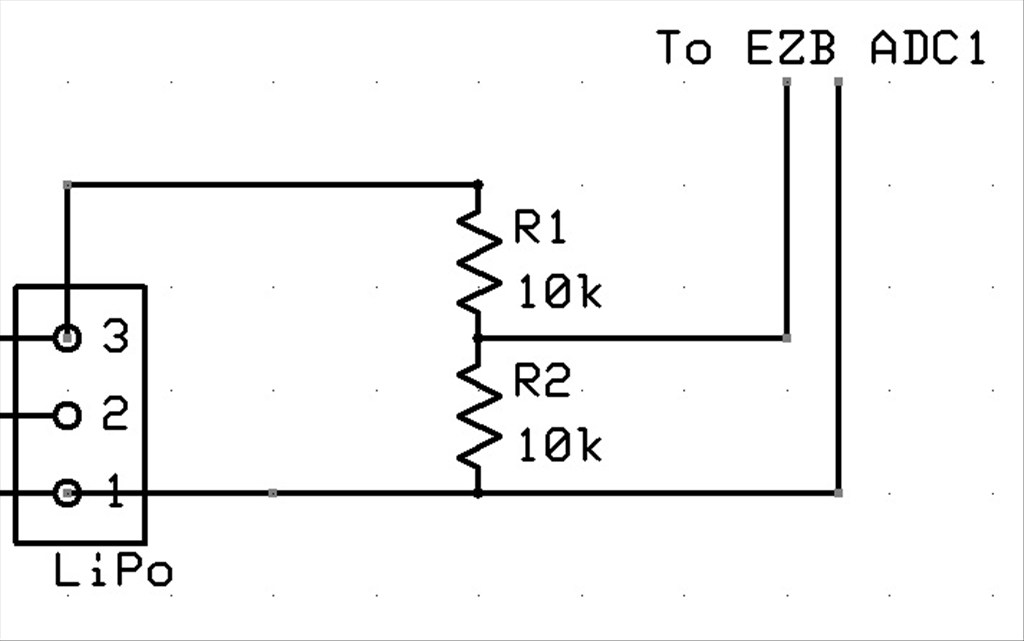

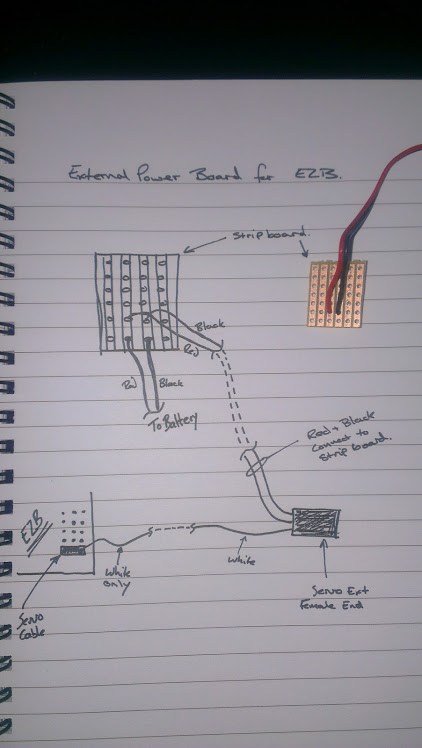

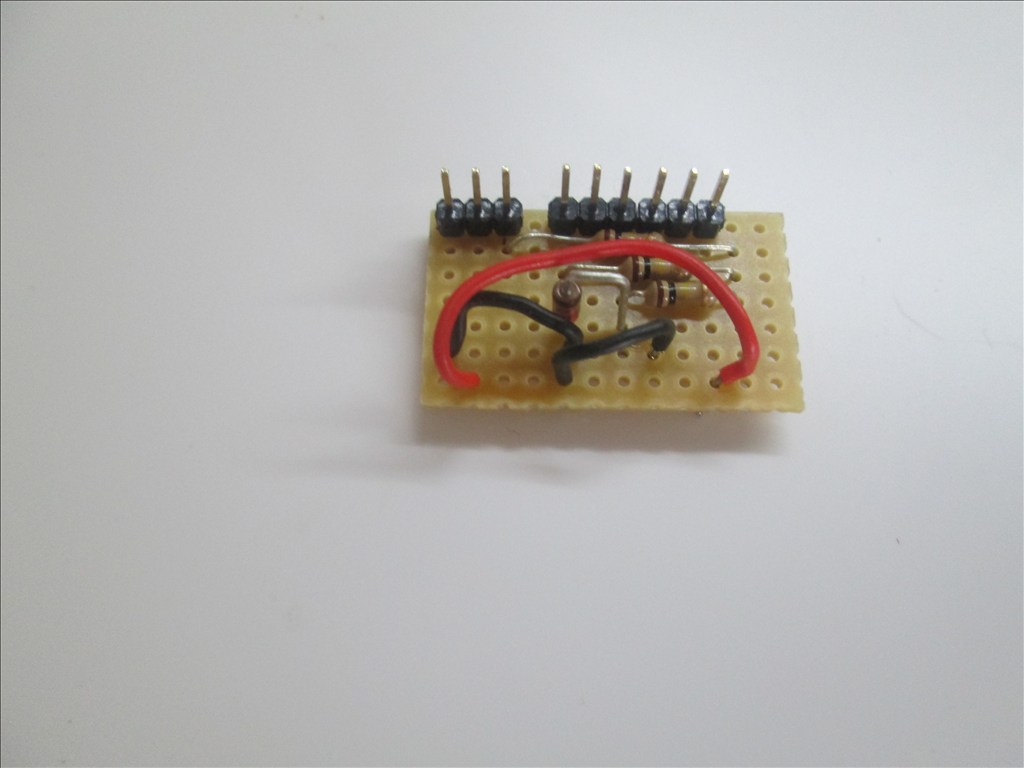

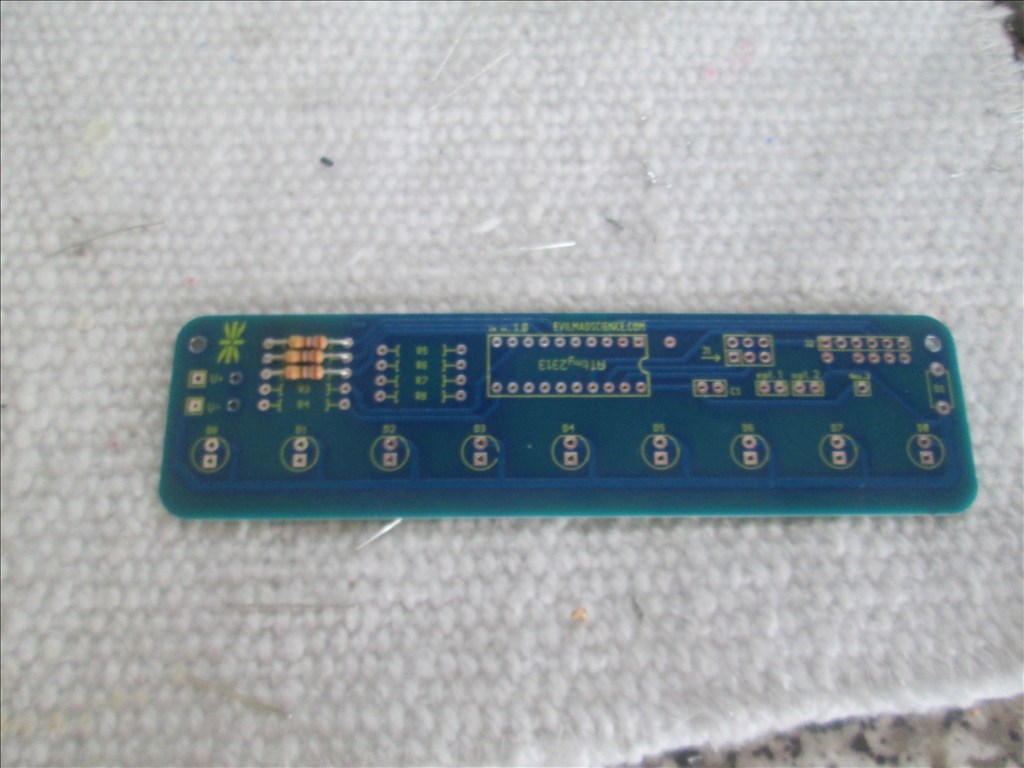

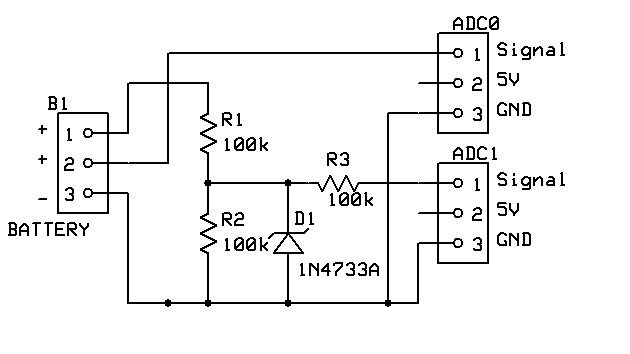

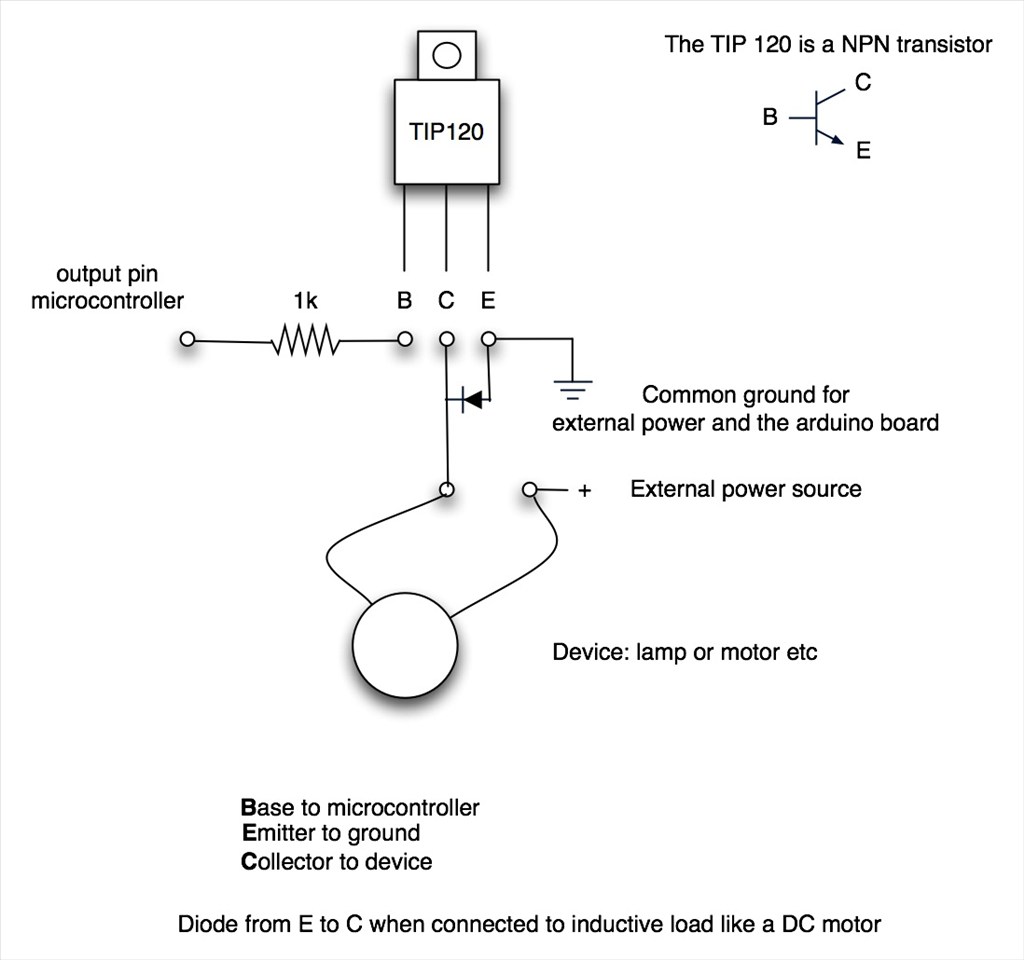

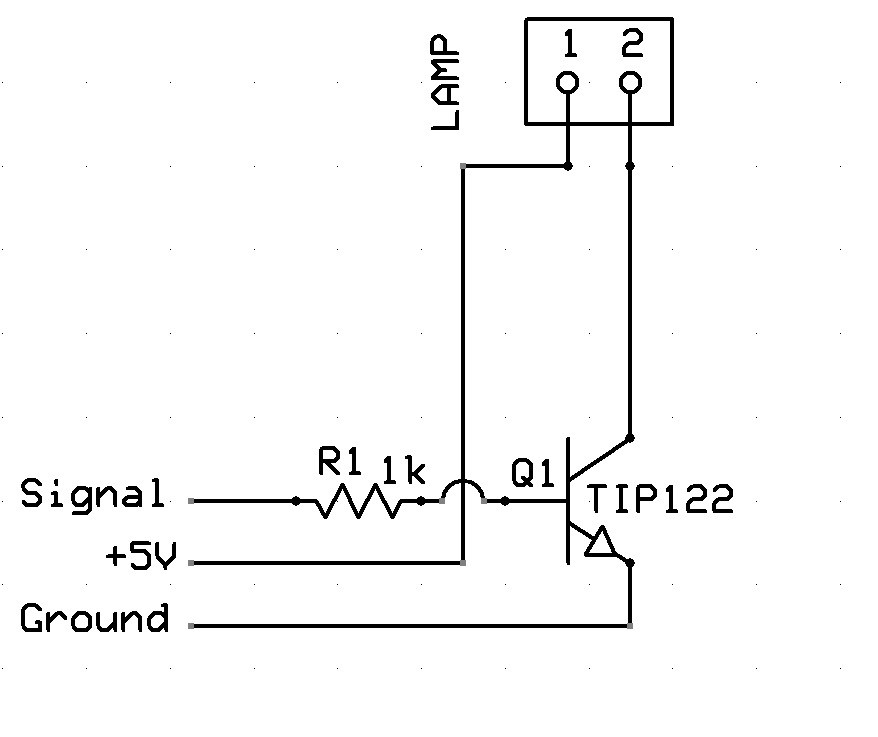

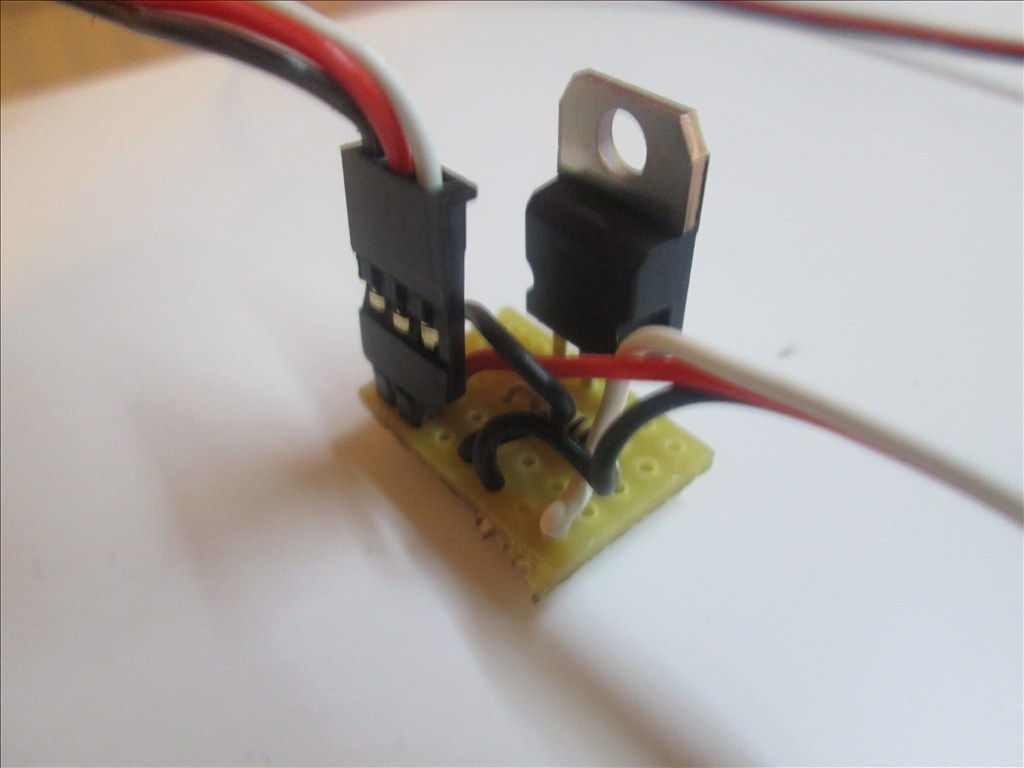

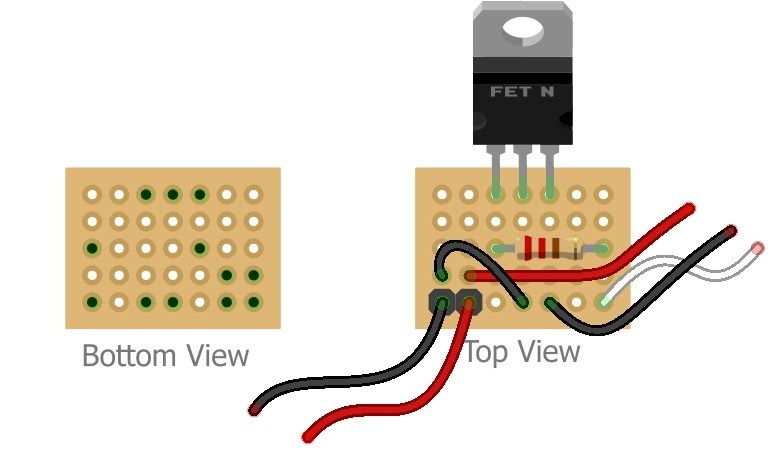

you still need voltage dividers,but only one is needed ,way i do it is on your circuit i would use 3 resistors and using only one analog port and would be able to read all 3 voltages using only one porT.

I guess most guys only look at 3 1/2 digits accuracy ,with me i look at about 8 1/2 digits just some thing i i am use to doing. SINCE i have made test equipment of to 24 bits and more robots i guess dont need it since only the A-D is 10 bits ,

BUT how i design my robots ,voltage or current or temperature and more

on resistors for the divider you dont want to go too high,mostly noise ,but 200k total may work

ALSO if you notice i look at noise in the system ,it can cause problems like random resets and more so i use whats called SPG (single point ground ) or wire i try to keep short and twisted oon keeping wire short you save some current ,longer the wire on power you add more resistance where if you do ohms law and wire gauge resistance you will see power loss might not be good at programming but more of a expert in this field

I don't see the benefits of having the voltage monitored over one ADC port, I have 8 ports and only use 1 of them (possibly 2) leaving 7 (or 6) for battery monitor.

There is a reason why I will be rounding it to 2 decimal places, so it looks right on the LCD display. It's an 8x2 and 2 decimal places like "C1 0.00v" takes up 1 row.

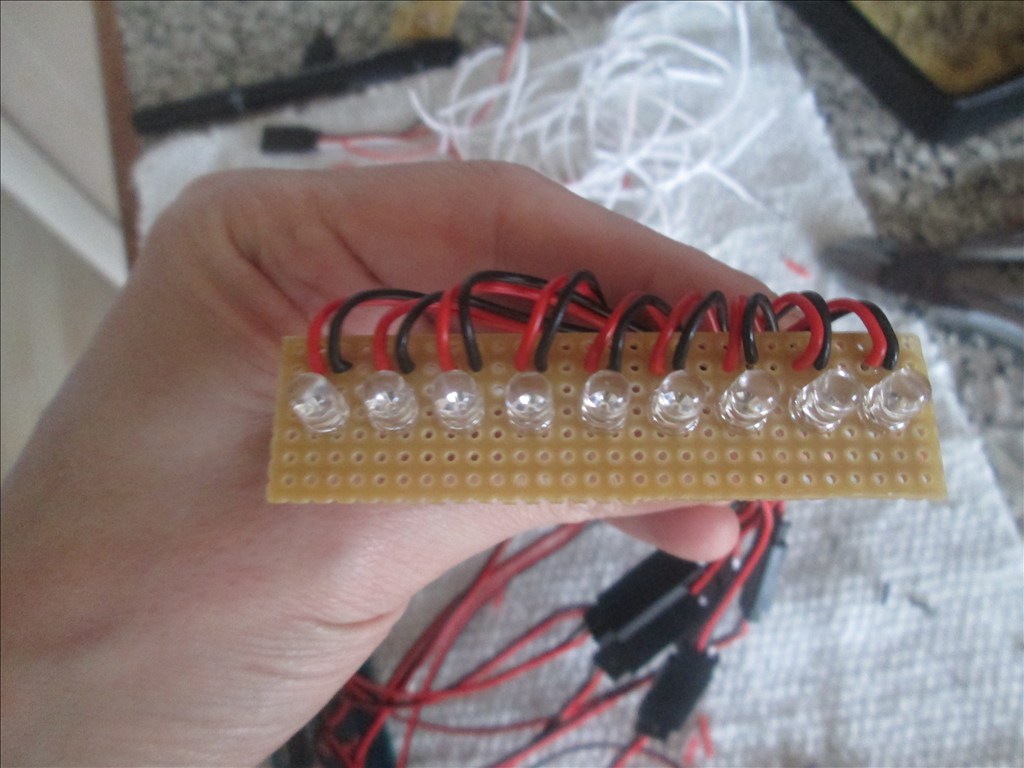

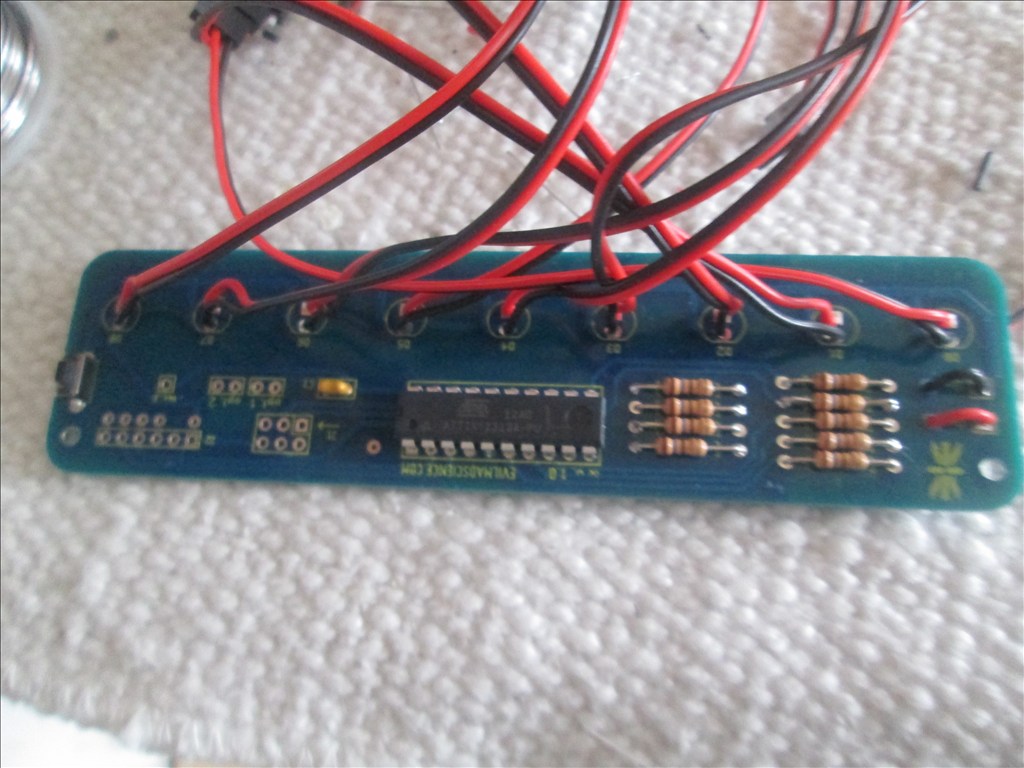

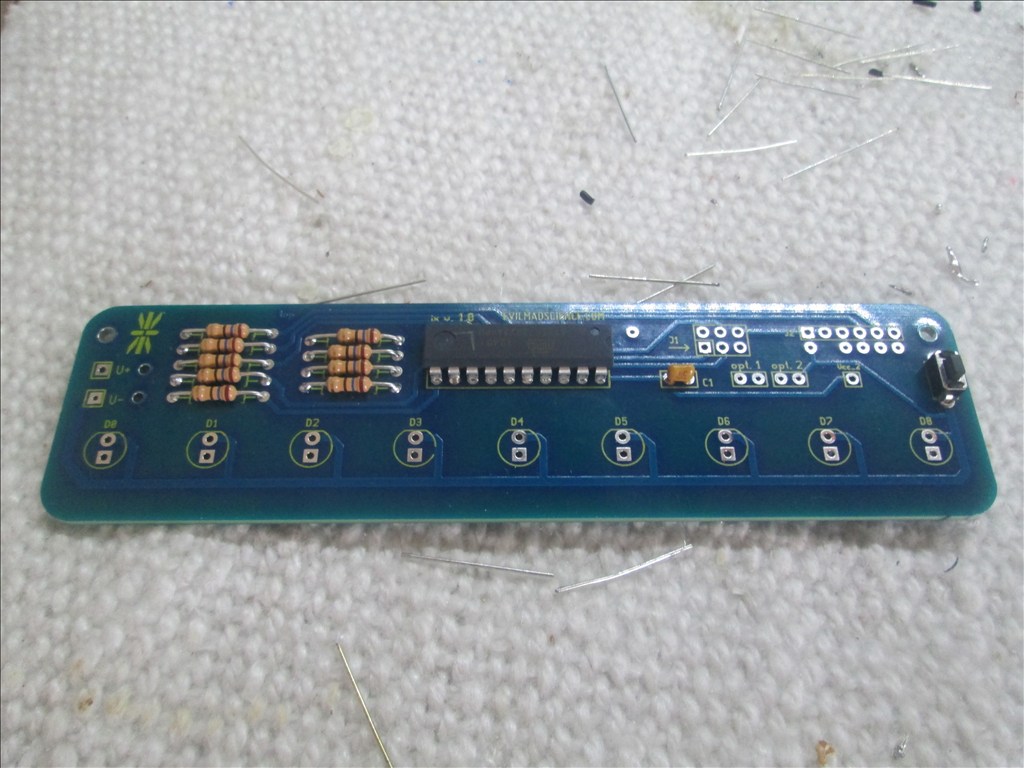

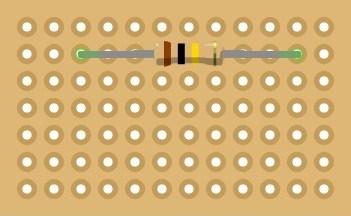

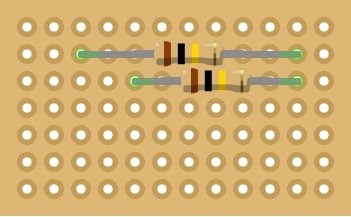

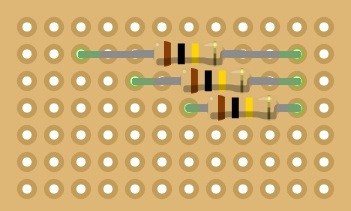

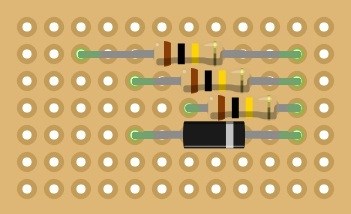

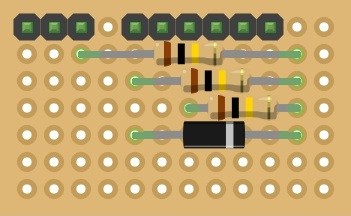

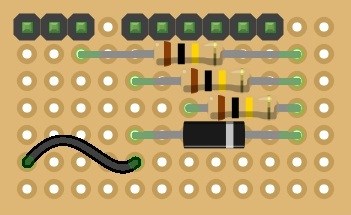

Now stocked up on resistors of all kinds of values as I know I will need them on future projects. So I will be trying the divider with a couple of 100k resistors, might try a third 100k on the signal wire to reduce current draw too.

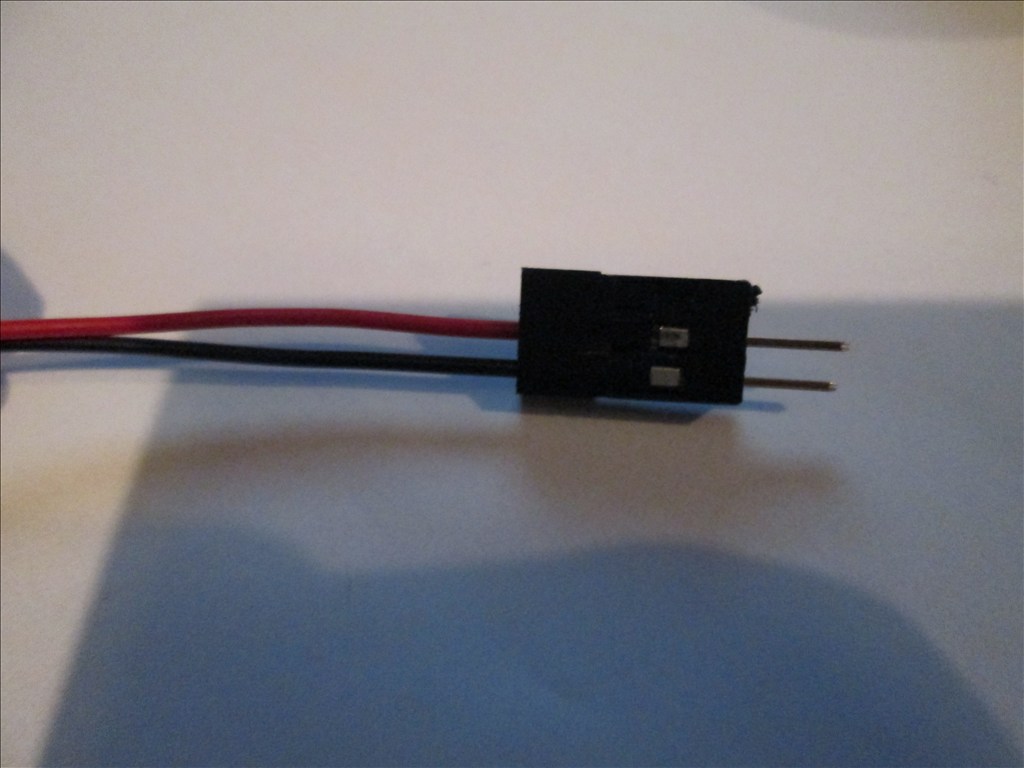

Also threw in a couple more IR distance sensors for the front corners of the base, so that'll make 3 IR (2 in base, 1 in chest next to Ping) and use up 3 ADC ports, but that still leaves me with 5 for battery monitoring, 2 already used, 2 for possible future extra battery and one spare.

Should all be with me tomorrow afternoon, then I can avoid doing the arms for a while longer as I'm still not happy with how they turned out (although is the only part of the build I'm unhappy with).

Hey Rich, take a look at how Josh Starnes did his arms on his omni 2000. After I saw that I wish I had done it with my omnibot (my servo stcks out at the elbow and is not very flattering - but it works great!).

I'll take a look.

The problem with mine is the buzz from the servos when they are fixed in position so it is to do with the weight and servos. As they are the highest torque mini servos I could find and running with 6v I can't go better.

Plus they are a little floppy at the moment as I didn't want to fix the servos in too permanently until after painting but I may have to so I can strengthen the arms...

It's something I need to do a lot of thinking about and always knew I would.

The other issue is rotating the claw hand. Other than the fact I fixed the wrong hand on the wrong side (not a problem, it works), the open/close mech for the hand goes in to part of the hand assembly that I cut off of the other side to make way for the servo and horn. It's either lose the open/close or lose the rotation. Tempted to rob a hand from the omnibot I picked up as a donor for parts but he is good condition and works so it is a shame to ruin him for a hand...

My main challenge was to make the elbow move without a servo showing and I managed that, I just need motivation to get going on it again.

On my omni I replaced the original opening claw with a metal one and was able to keep rotation claw

But I have buzzing issues too. I think it is a problem if there is a load on the servo and it requires some voltage to maintain position. A little shock (like from an RC car) might work to help support the arm so it requires no voltage at a resting position. THat is the idea I am toying with.

Yeah I've thought of some kind of spring to help against the effects of gravity, I may also remove as much plastic from the inside of the arms as possible to reduce weight as much as possible (plus all the hot glue in the hand that was used as a temporary measure but ended up being permanent), I know it wont be much but it will all help.

I saw your claw, that was an idea also but goes against my whole idea of keeping it as close to original as possible. I did also have a few ideas of some hands, like the toy robot grabber hands with the mechanical handle that pulls a wire to close the hand, I saw one wired up with servos and impressive is an understatement (I may have seen it here?..)