Project:

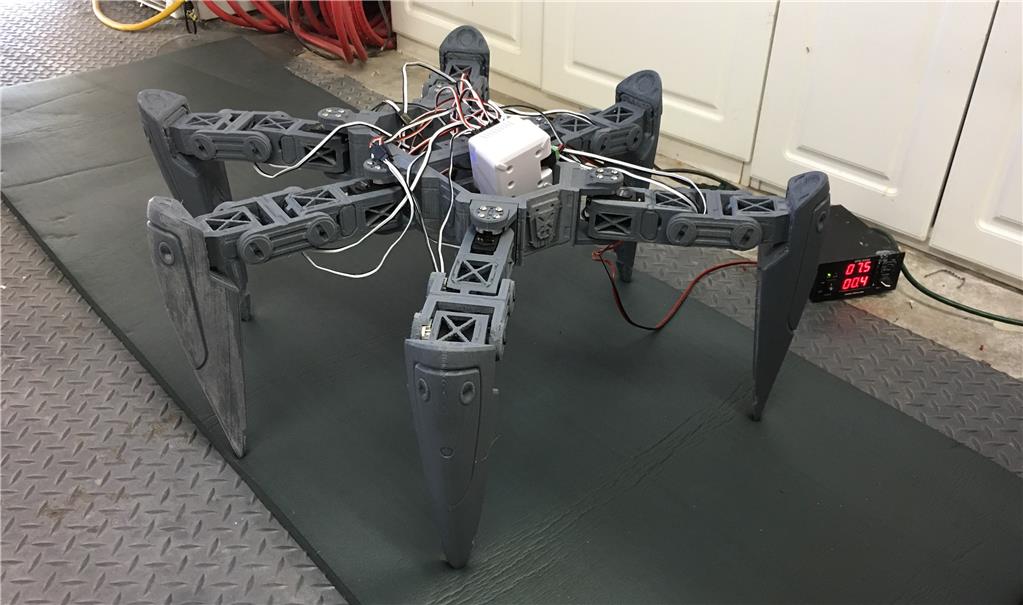

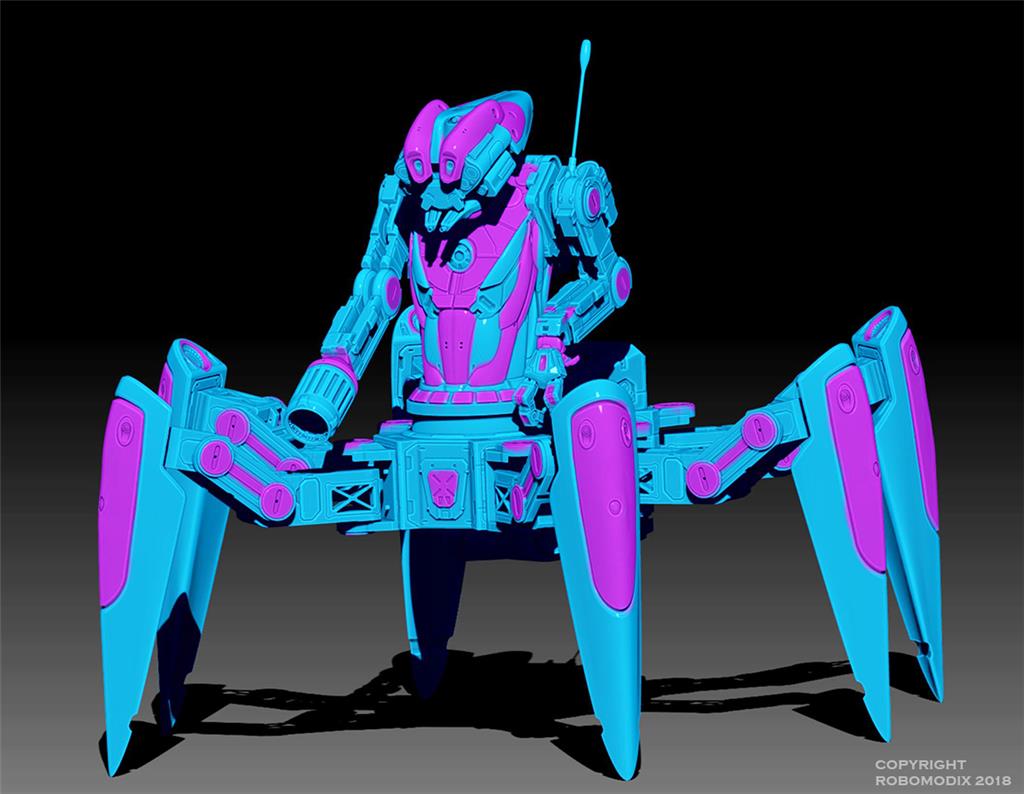

By request, my 6 year old son wanted me to design and build him a Hexapod. So I started to whip up some designs in Zbrush and together we decided what he would look like. "Main thing he has to have dad, is an arm cannon!" So we got that. Then I thought it would be cool to have a robot kinda part of or riding the hexapod. So kinda a centaur bug/robot thingy.

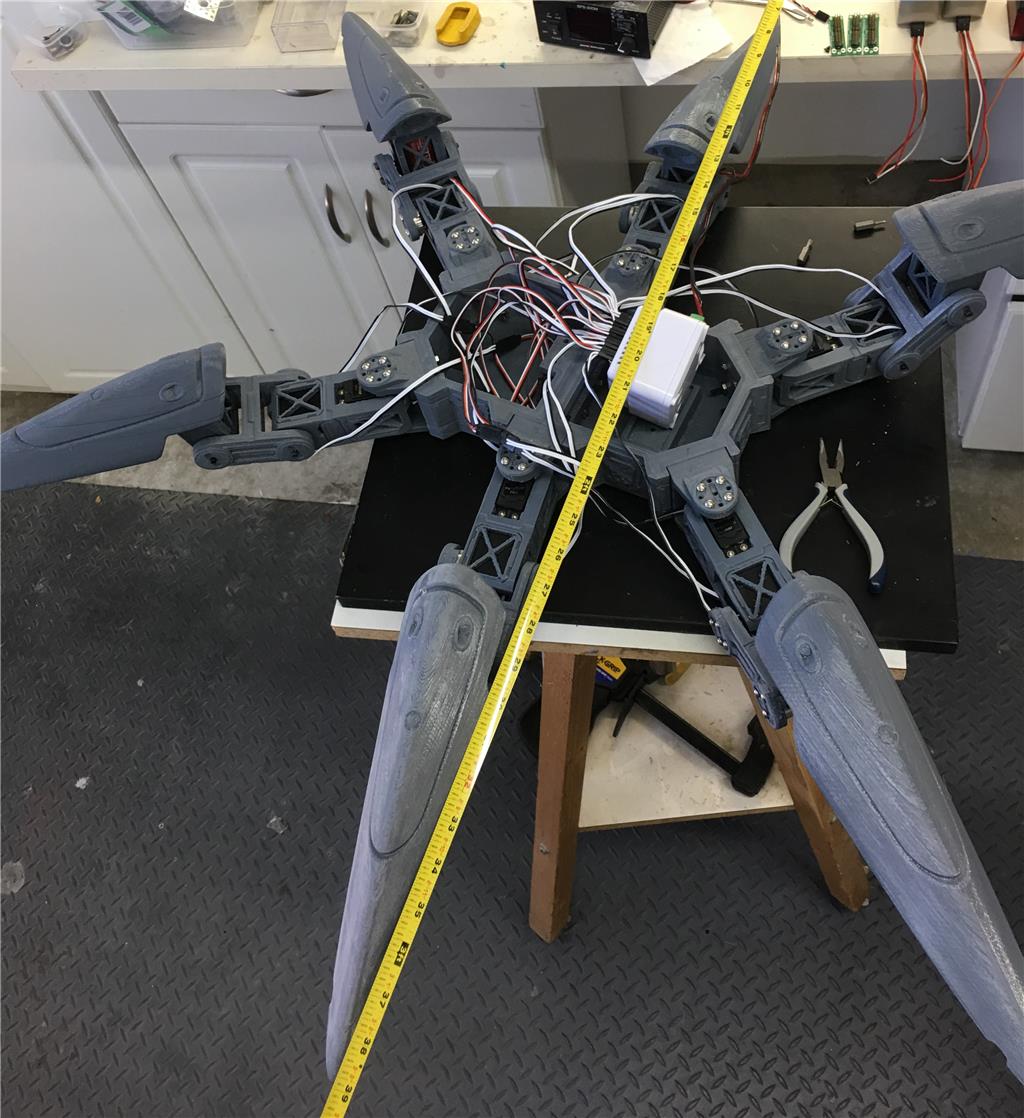

First thing I had do was figure out was how big would be too big? There are alot of reasons why not to go too big, which I ignored. So from an engineering stand point, "will it walk?" is the big question. At first I thought it would be about 5 pounds, then it went to10 pounds and now it might be around 12 pounds...so again time will tell. Maybe it walks once or 2 feet then crumbles!

I sourced out the materials and batteries. Knowing this was going to be a 23 servo design, I wanted a good battery and and chose a 7600 mah lipo. Maybe it will run for 15 min underload... again untested, time will tell.

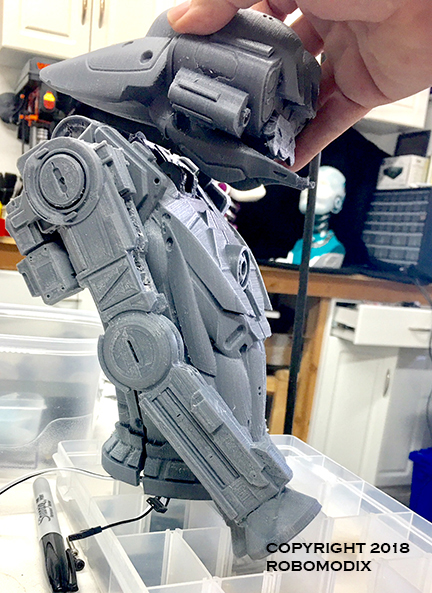

Finally I chose PETG for the print material, due to its strength. Two weeks of printing on 3 printers 24/7. There ended up being 53 individual parts.

The Motions include 18 axis for the legs, waist forward/back tilt, waist rotate, cannon arm up and down, head up and down and rotate. 23 axis in total. The body is comprised of EZ Robots micro servos and the legs and tilt are the HDD servos also from EZ.

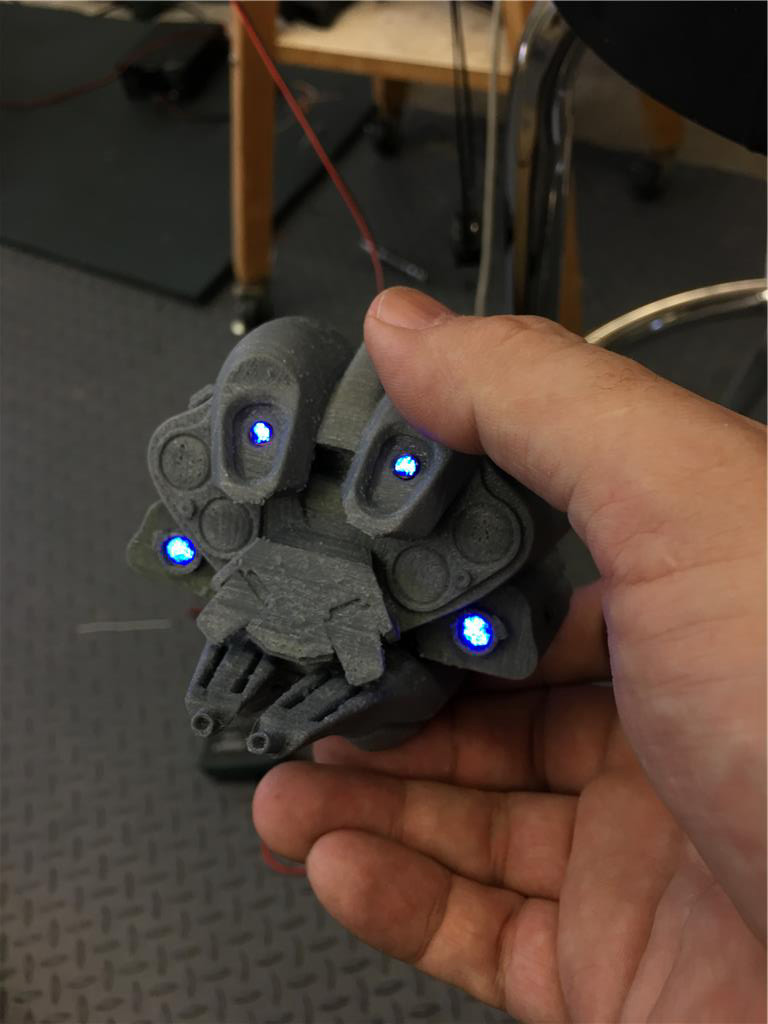

There will be an EZB inside and camera in his chest. A Bluetooth amplified speaker system onboard will allow us to play TONS of robot sounds from BlueZone.

I will updated this project as I finish goals, but if he doesn't walk due to weight or burning out servos due to stress, I will most likely abandon this build, as the next logical step would be to move up to dynamixels, but that would require $5000 worth of servos. A bit much for a toy!

So lets get started!

Here is a final design in zbrush and keyshot

Then came the modeled parts each one 3d Printed.

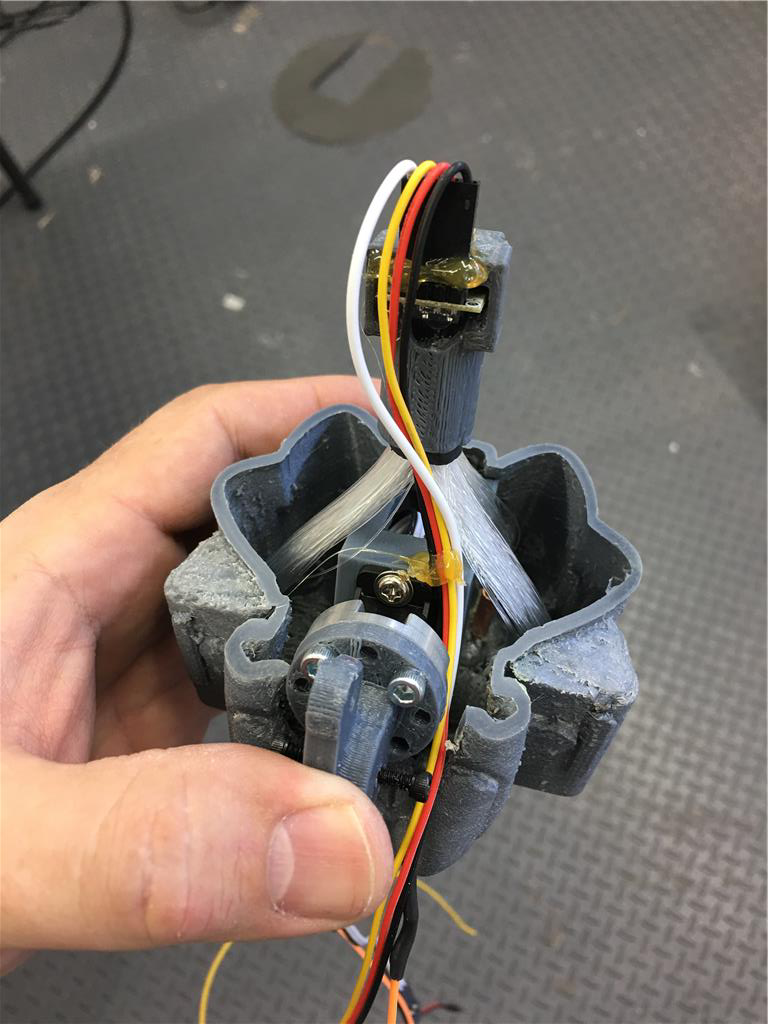

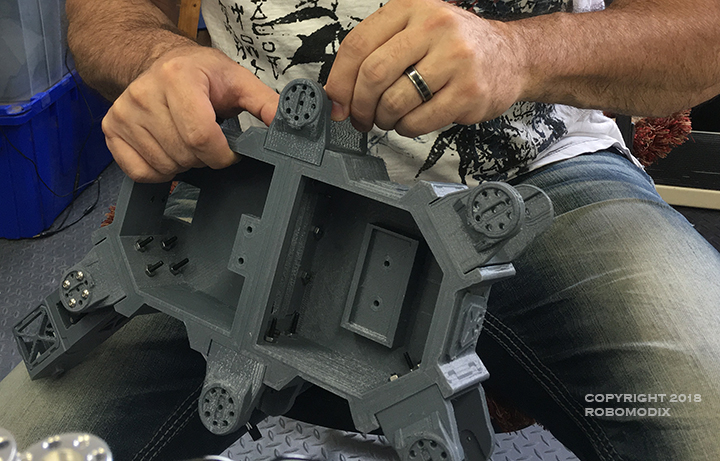

Here I've started adding the axis to the body

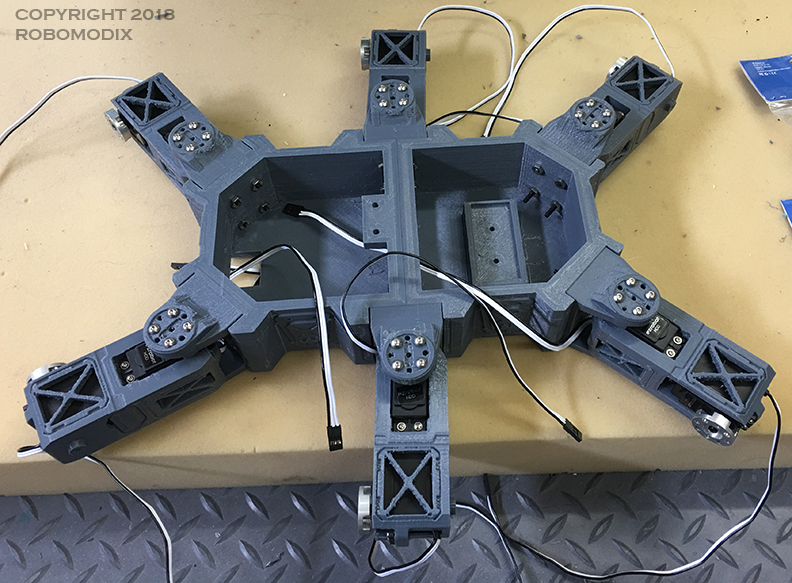

Here I continue on with assembling the main chassis

I could only assemble one side of the legs as I am waiting on some servos and screws to arrive.

And here is my first sloppy attempt at testing motion with autopoistion:

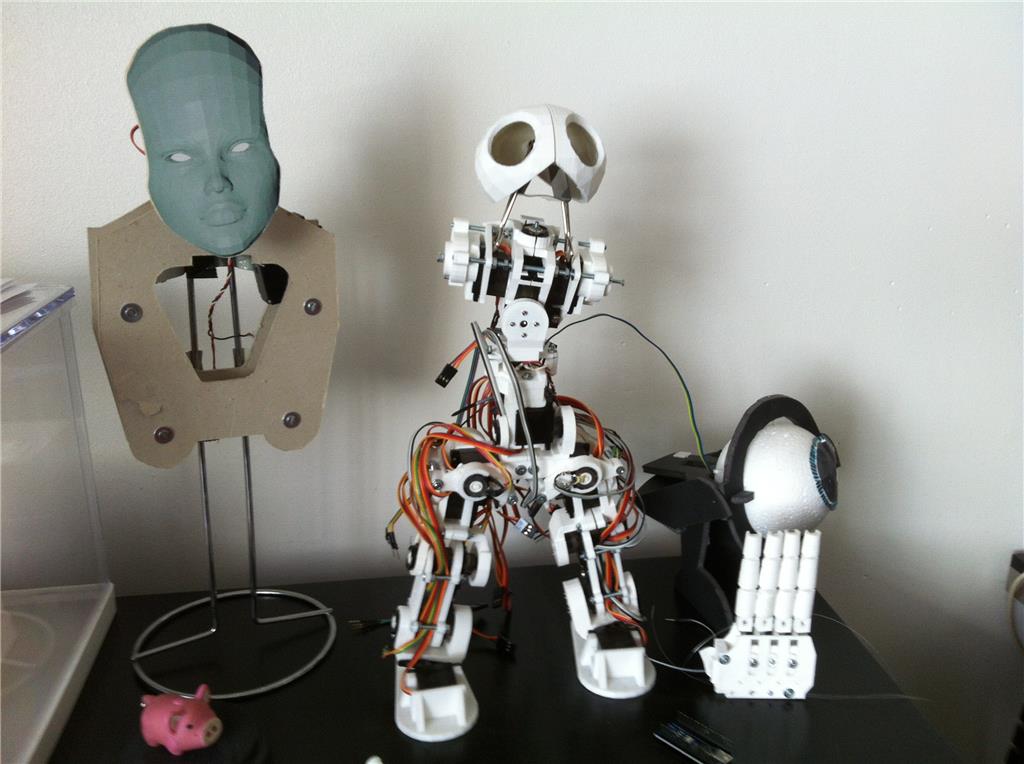

Other robots from Synthiam community

Ezang's Mr. Conehead Monster

Buratino's Basilio

Epic is the perfect word! eek

Ya, Grandpas of our generation had different ideas of who wore and played with makeup. Did your's ever get to see the success you've gained with your talent? I bet he would now understand and be proud.

He did live to see me make it to Hollywood. Both my dad and gramps were both very proud and did their best to see the films I worked on.

Not quite walking yet. Maybe for awhile. I'm pretty sure that I will need to do some modifications to lighten the load on the upper body, if he is to walk. That may include reprinting the torso with thinner walls and less infill. I also may modify the arm design making them one whole arm as opposed to the two separate parts. This will give me one single wall and lighten the weight.

As I had suspected the micro servo is struggling to rotate the body with its weight ( the body is too small to place a standard servo inside). I've ordered another micro servo with higher torque (6 kg/cm). Combined with lessening the load should stop the shimmy of the body that can be seen in the video.

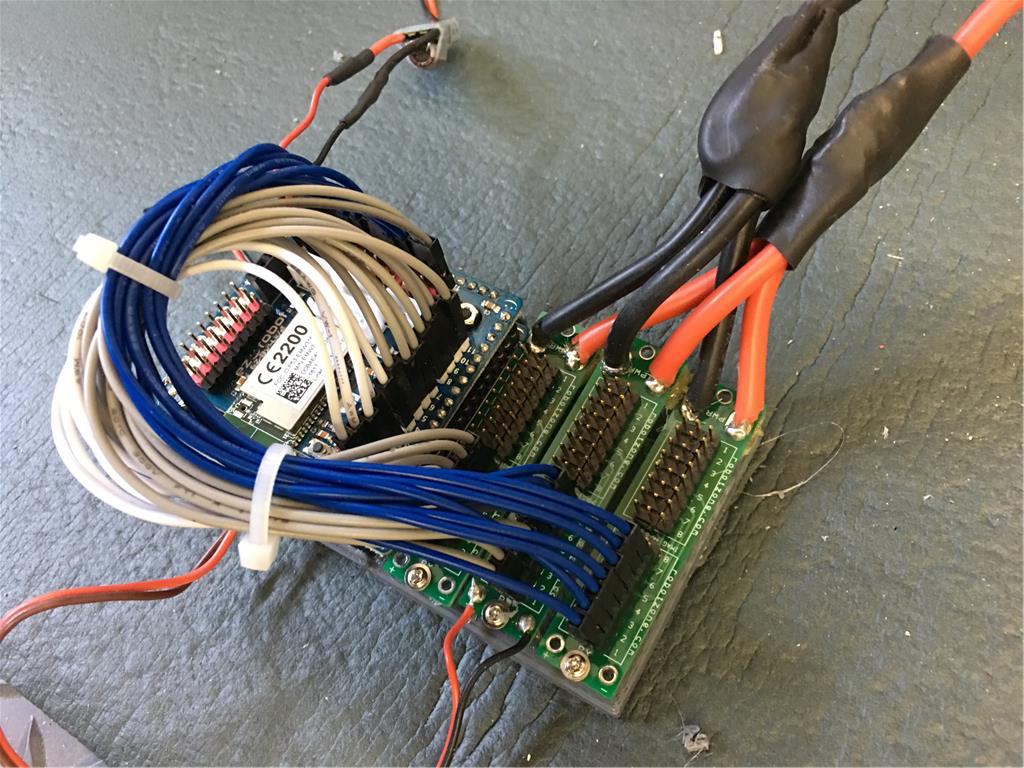

I also worked on a solution for wire management, as seen here in a test.

Ahh, a setback. That sucks. Hopefully the stronger servo will help. I'm sure you want to reprint as a last resort. tired

Very nice wire management!

Such is the way, for prototyping.

I've managed to move some things around in the inside of the body (digitally designing that is) and I'm going to get a full sized servo in there. That will resolve the jitters. But still thinking about reprinting the body shell and arms to reduce the weight. That will take some time...so prolly taking a break for a week while they print.

Sweet wire management!

Gar looks like he a a tad too much Saurian brandy... but still impressive as hell!

Hehehe, yes! The great thing about 3d printing the parts is just a redesign and then waiting for the parts to print. I love the star trek replicator process. Just wish there was "rapid" , in rapid prototyping. LOL! And I'm one printer down...so that is slowing things down.

And now my son might be changing his mind about the cannon arm....

stress stress stress

I think the cannon arm is a great idea! I hope he goes back to liking it!