This project has evolved some , the basic rundown is I'm modding two Omnibots , one a regular the other a larger 2000 model. I will have two ezb kits , rad base idea was thrown out because of so much noise but could go back on the table if the omnibot drivetrain is too weak to pull it.

By jstarne1

— Last update

Other robots from Synthiam community

Doombot's Archetype Finally Complete

Archetype droid using EZbits and an EZ-B: expandable design, currently on a 2A regulator with supercap fix; battery...

Mgodsell1973's Hexxy - My First Walker

Hexapod walker build with 18 servos, hand-cut parts and calf/foot photos, DIY EZ-Robot Revolution progress and assembly...

Zxen's Robomannequin

Eve - share your impressions and feedback so far.

cE9s4PsOgeBQIORwjd5!~~60_1-634818020230156250.jpg)

BO)Lupuc4g~~60_35-634706297915000000.jpg)

LupbT6!~~60_35-634706298769375000.jpg)

C5j!~~60_35-634655044863125000.jpg)

C5j!~~60_35-634659603510781250.jpg)

C5j!~~60_35-634651704046230469.jpg)

Ok I went ahead and made the slot taller. Once it is painted I will use black Spandex as sort of a.streachy grommet so you cannot just see straight into the base.

It can point down more and it looks like I see about 10 inches in.front of each corner.

Very cool Josh and great idea for the flexible grommet.

might work to the spandex,but i am looking at a more easy idea,i thoght of something like rubber but mine looking at clear thin plexglass attached to sonar and IR,first it does two things it keeps dust out when going back and forth and add a clear plastic lens to the IR from dusting getting on it to make its simple clear acrylic film cut bigger then the opening in your omnibot and a hole cut out for sonar,need to make each longer as the sonar goes from one to another and still cover up the hole on the omnibot

also another idea for all IR sensors to add acrylic thin sheet and have it molded inthe omnibot,some i see are facing down,dust will get on them alot

look at the roomba design and neato XV-11 both have that for DUST PROTECTION

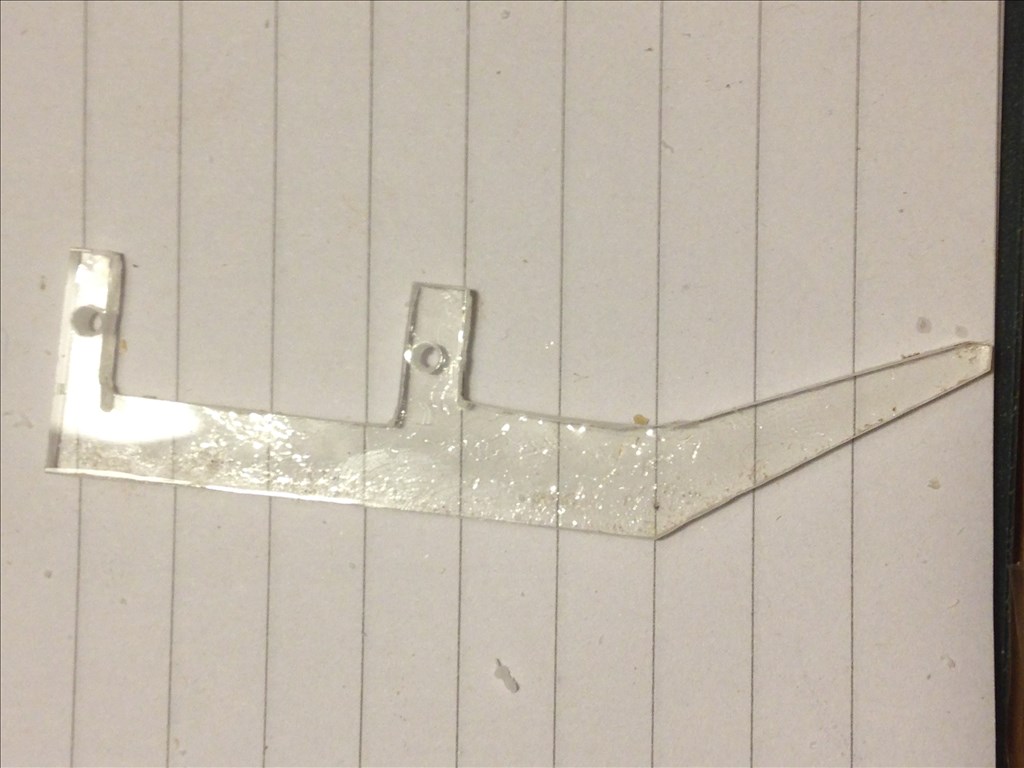

Ok now that I modified the gearbox I need to get this little guy lubed up. Also I am extending the back of the base to have room for the gearbox. This will be fun lol. I do also need to make a internal frame to support the weight of this 50 + pound robot. The axles will be directly adhered to both the base and sidewalls. The axles themselves.will serve.as a brace.

So what's the best lubricant to use? I've heard rumors that petroleum / oil can cause damage to.gears that.are.plastic. Like it breaks them down. Lithium grease?

Ok I taped off the open edges of the piece I cut out. I used two tubes of epoxy and it was not enough to finish. I have fiberglass resin but IM about to go to bed and didn't want to fill the house with fumes. Lol I will wait till tomorrow and even put in a later or two of fiberglass while IM at it to make sure I have not list structural strength by modding the backside of Jarvis base. Guys got a big butt now.

Not only did I push it back enough for the gearbox but there is nearly a inch clearance behind it. With this gap I could place sound deadening foam. I ofcourse have plans to cover it with 1 inch all the way around and that's ontop of dynamat! Hopefully batteries and motors controller will be here soon because I need to load the base down with 60 pounds test weight and run the base around to house to ensure everything works correctly.

Jarvis gots junk in da trunk!

A great lub for plastic gears is White Lithium grease. I use it in re-lubrication of Roomba brush decks after installing sealed ball bearings. You can find the grease in most Auto parts stores.