Hi Friends!. well I'm finally ready to put my full size R2 to roll... But I need a tip from you. What kind of H-Bridge or controller do I need (or can I use) to use with my ez-b ? I believe that the regular one will not be able to power this Scooter motors that i'm using.. am I wrong ?!

By tevans

— Last update

Other robots from Synthiam community

Ezang's New Creation - Mr. Roman

New Arduino creation Mr. Roman features moving eyes and mouth, with more enhancements coming.

Bhouston's My Inmoov Running On Synthiam

InMoov robot running on EZBv4 with 24 servos controlled successfully, demonstrating reliable single-board servo...

Louis's Quadrupedal Robot Xr4

Budget quadruped with 1.5mm carbon fiber/aluminum frame, 12 MG995 servos and EZ-B controller for omni-directional...

Sabertooth 2x12 is probably a good option. Without knowing the specs on the motors it is impossible to know though.

If you go the sabertooth route, and if your motors have encoders, I would also add a kangaroo.

I second what David said... A sabretooth is even easier to use than a cheap H bridge....

Thanks guys! Hey.. By the way, I'll be traveling to California for the next days (finally got my 12 days vacation ! ) Do you know some good store where I can buy robotic supplies ? Since is kink of hard to find it in Brazil, I'll use some time in my tripe to dig some stuff.... I'll be in LA and San Francisco ( and in the road between..) lol Thank for any hint!

@tevans i went with the sabertooth 2x25 for my R2 it is hybrid wood and aluminium and other scraps so its not very light... from the looks i have the same motors you have and the sabertooth does fine at 12v

Thanks @jayutmb! It seems the sabertooth is the choice of you expert guys! So I'll look for that to buy.. ??

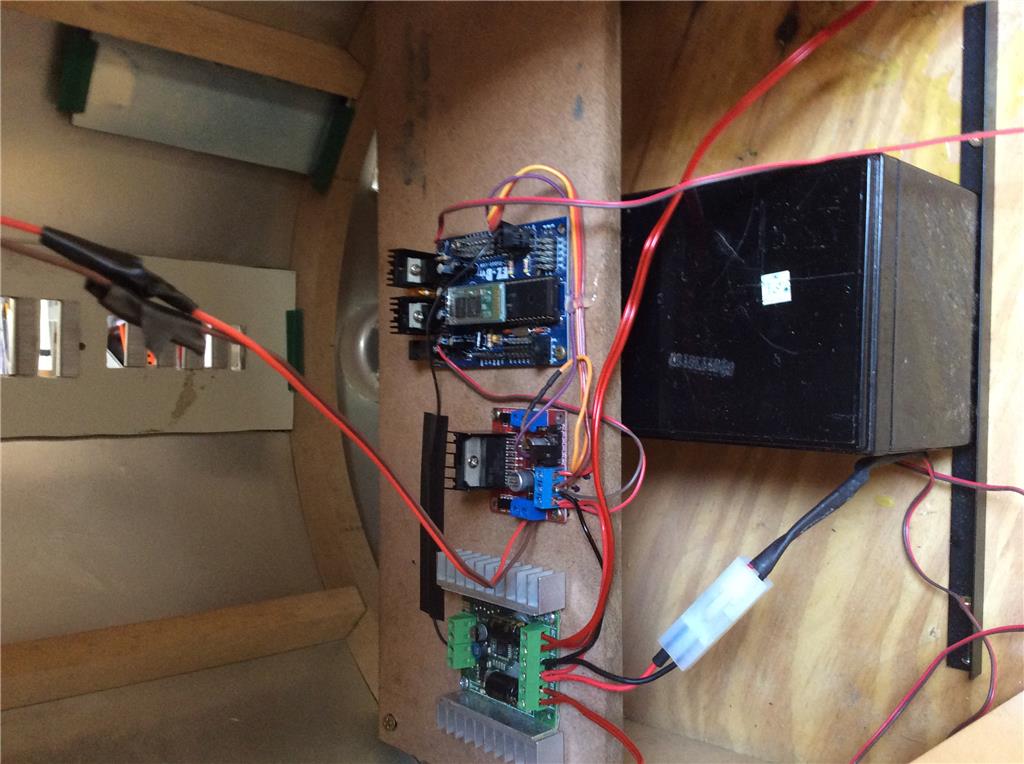

Hi friends! I took your advice and installed a saber tooth. It's great! It's working fine. Now... I installed anothe h-bridge do run the 12v motor that drives the dome. My question for you my genius friends is: how do I set position on this motor... Since it is not a servo... .? I'll post a phot of the sistem so you can have an idea..

You can use a potentiometer connected to one of the ezb's analog ports... A 5 or 10k pot should work fine... Connect it to the center of the dome (so that it rotates with the dome) and it should read the dome's position no problem....