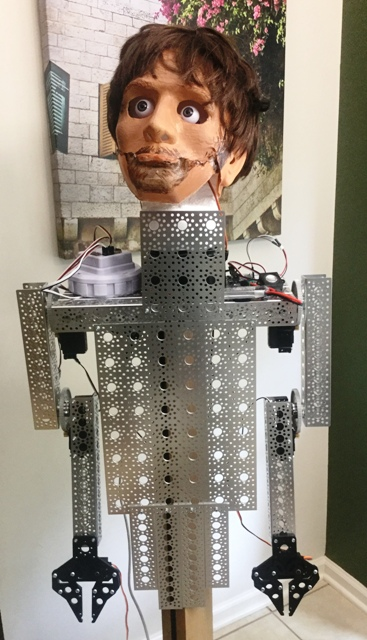

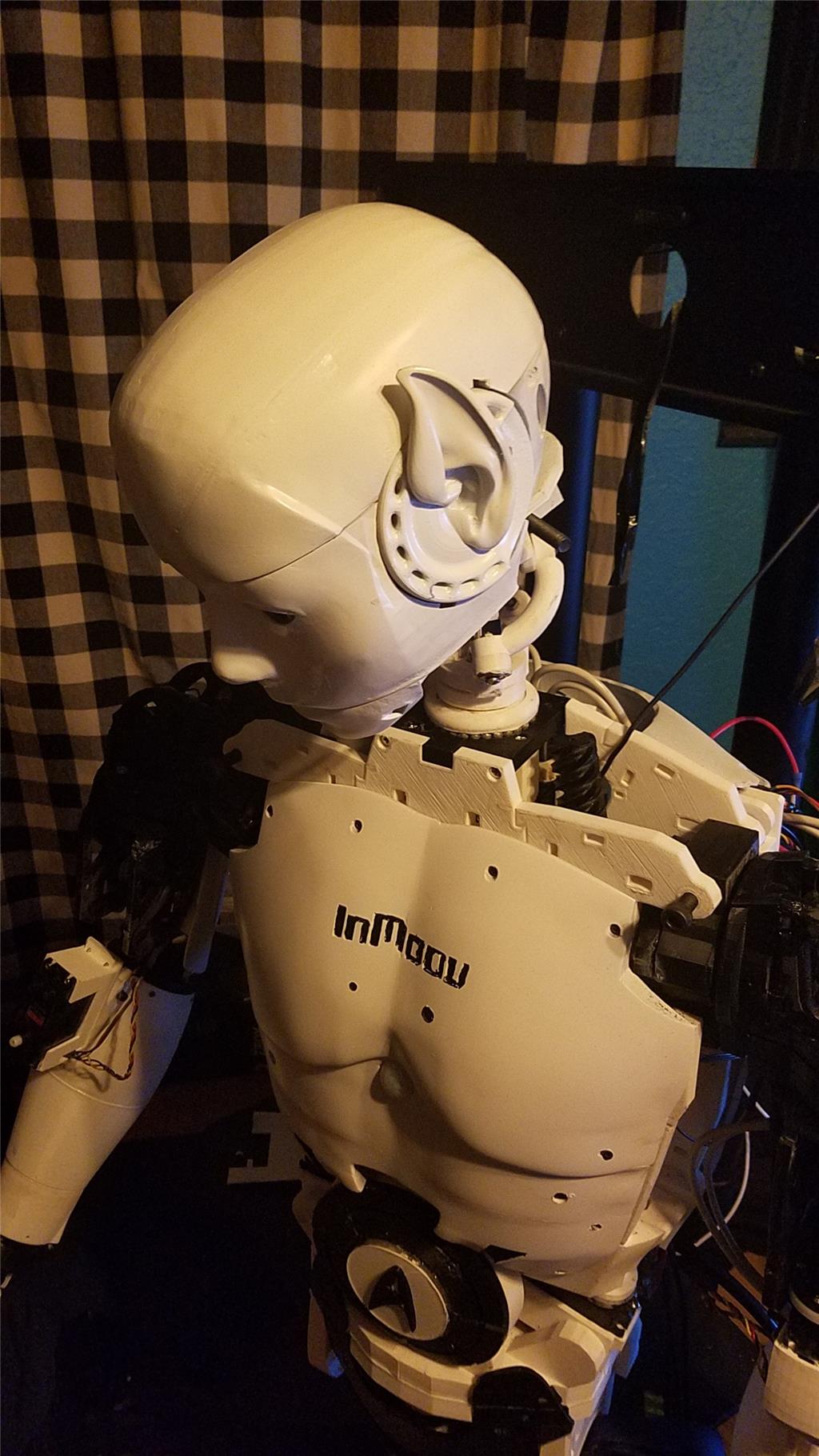

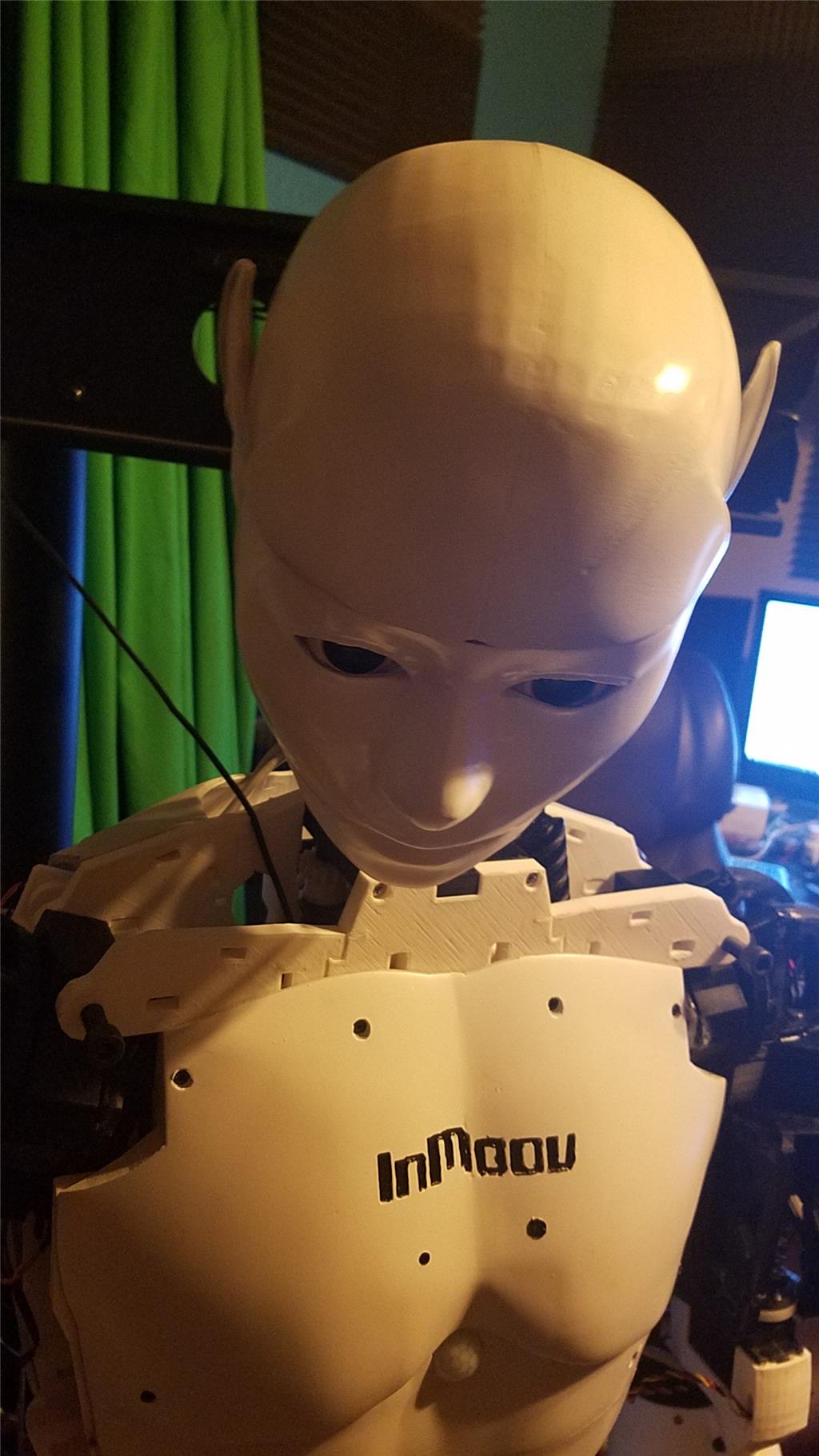

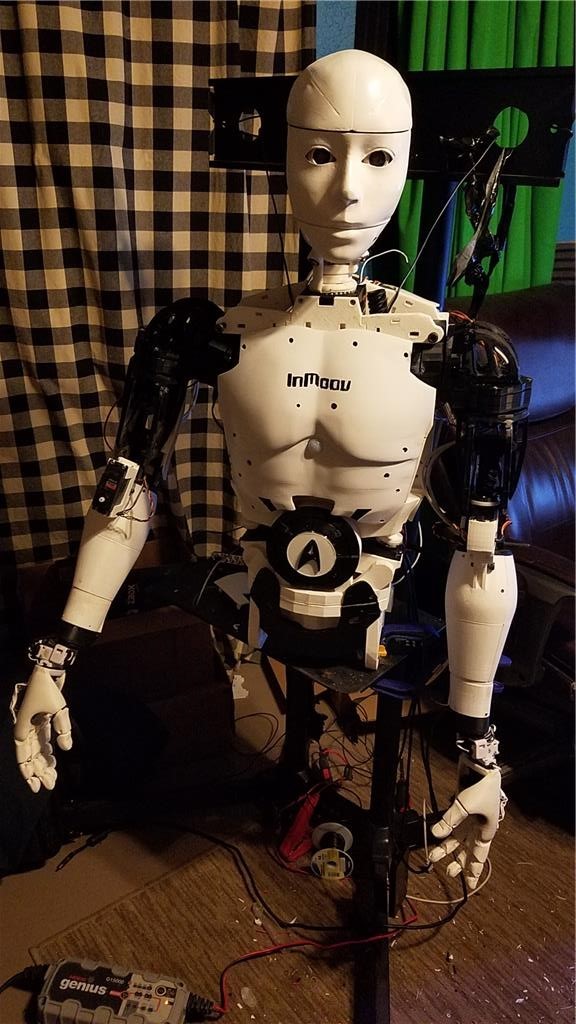

I have decided to start my InMoov project. I think I will call him Spock out of respect to Leonard Nimoy who passed away on the day that I started this project.

I am editing this post so as not to confuse people with the current configuration. I continue to update this post with the latest photos. If you are reading this for the first time, don't be confused. There have been a lot of changes to the InMoov over the past couple of years including starting over.

https://synthiam.com/Community/Questions/7398&page=21 Post 203 starts the rebuild of the InMoov.

I have decided to use an onboard computer. I chose the Latte Panda due to it having an onboard arduino Leonardo and also because it uses little power.

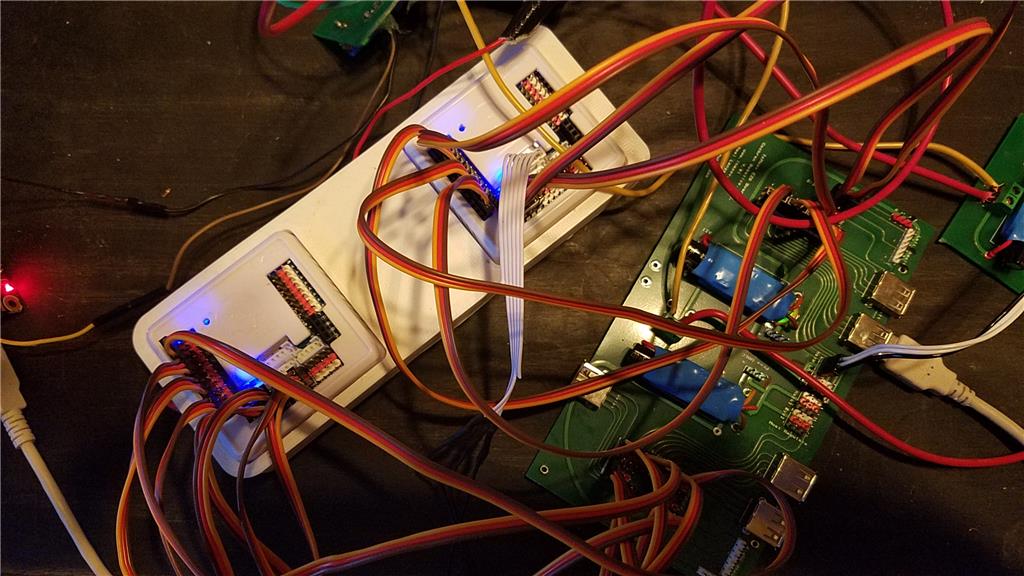

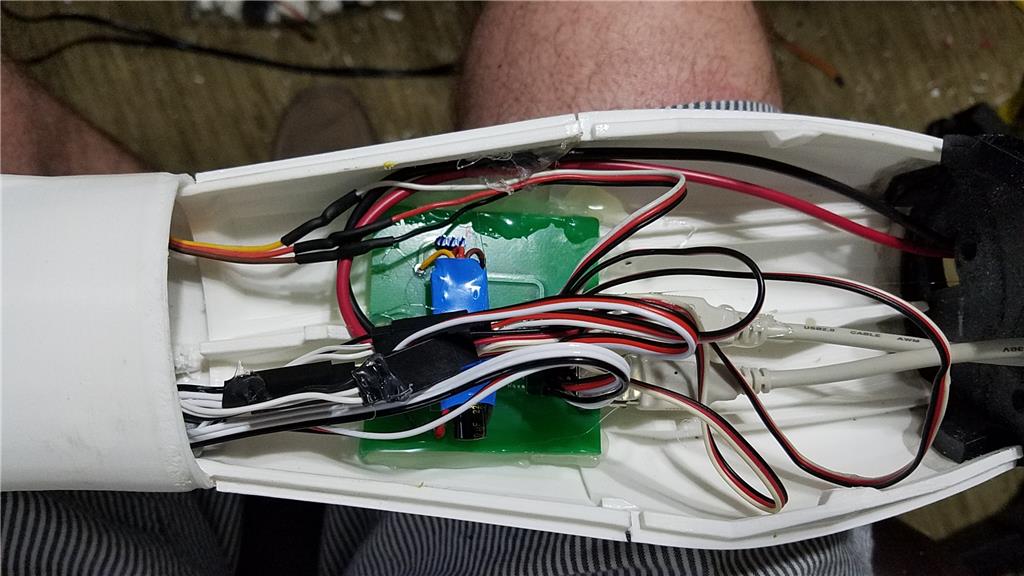

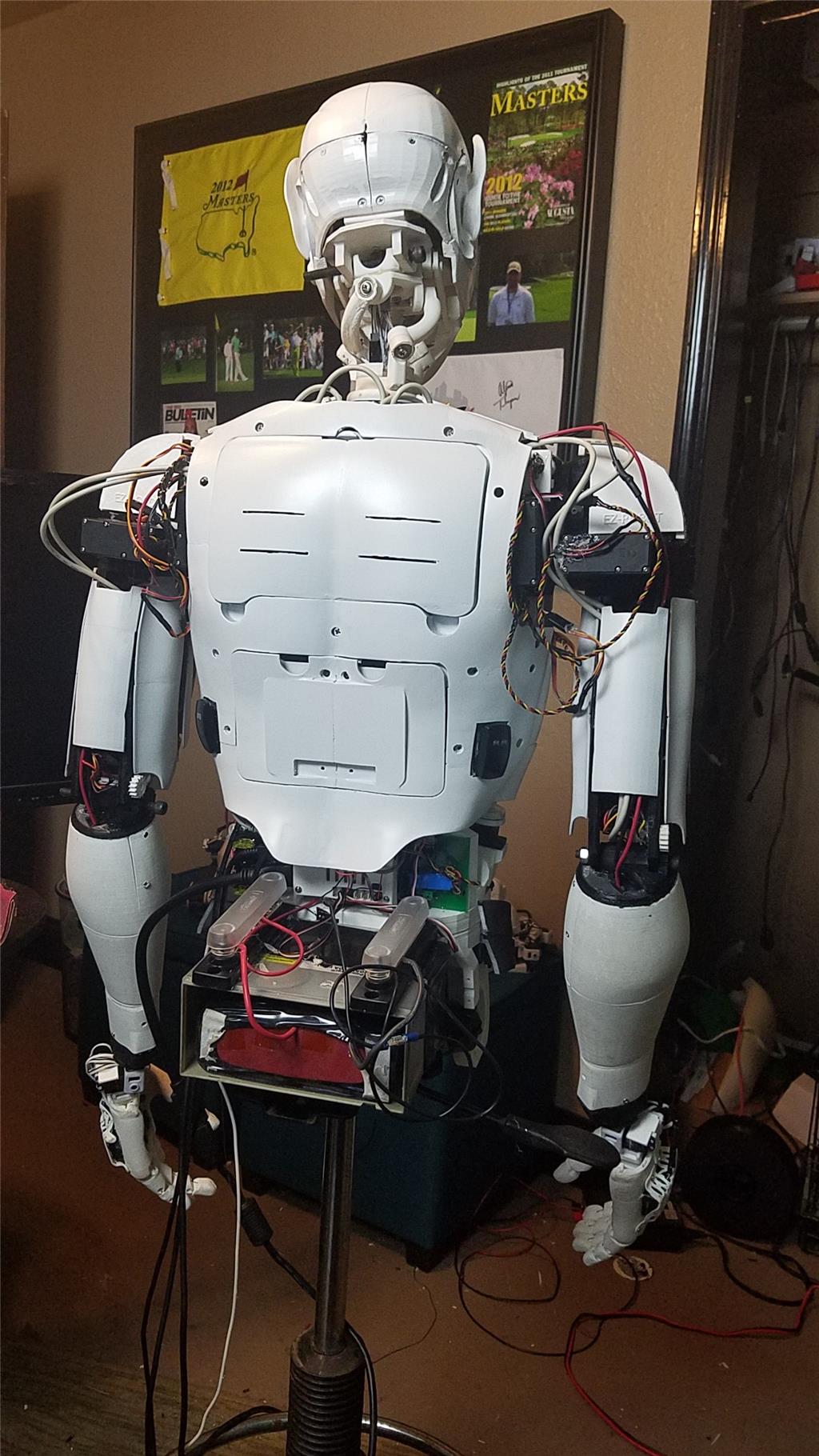

I used 2 EZ-B controllers connected via the camera port to Adafruit FTDI friend boards. This allows the Latte Panda to have a non-wifi dependent connection to the EZ-B's. I use a powered USB hub connected to the USB3 port on the Latte Panda to attach other items.

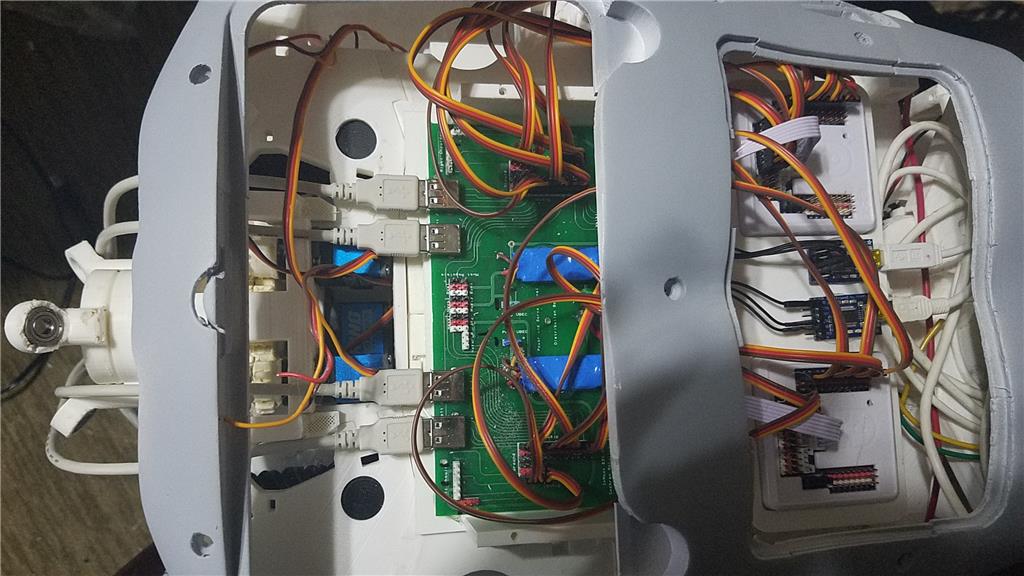

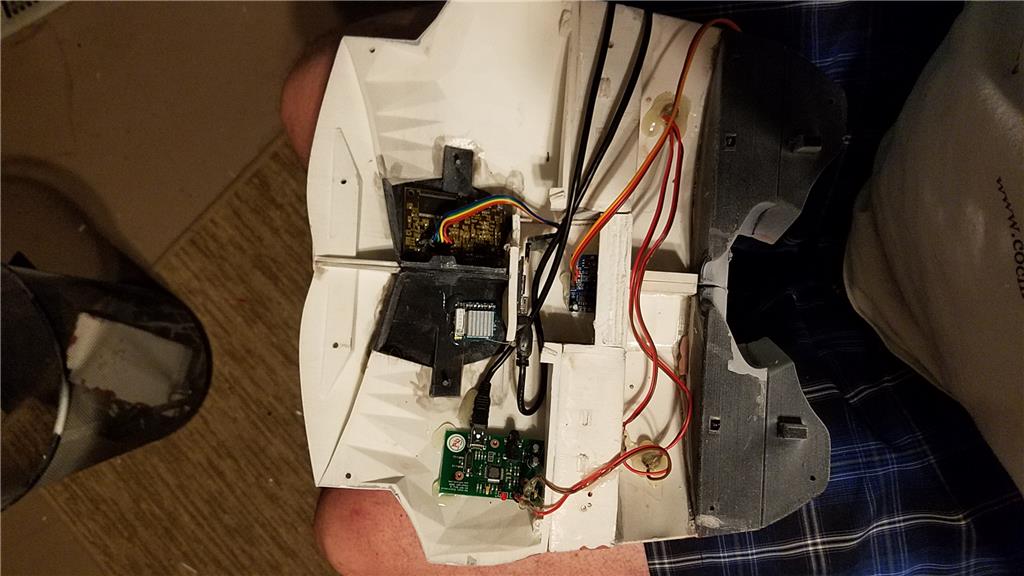

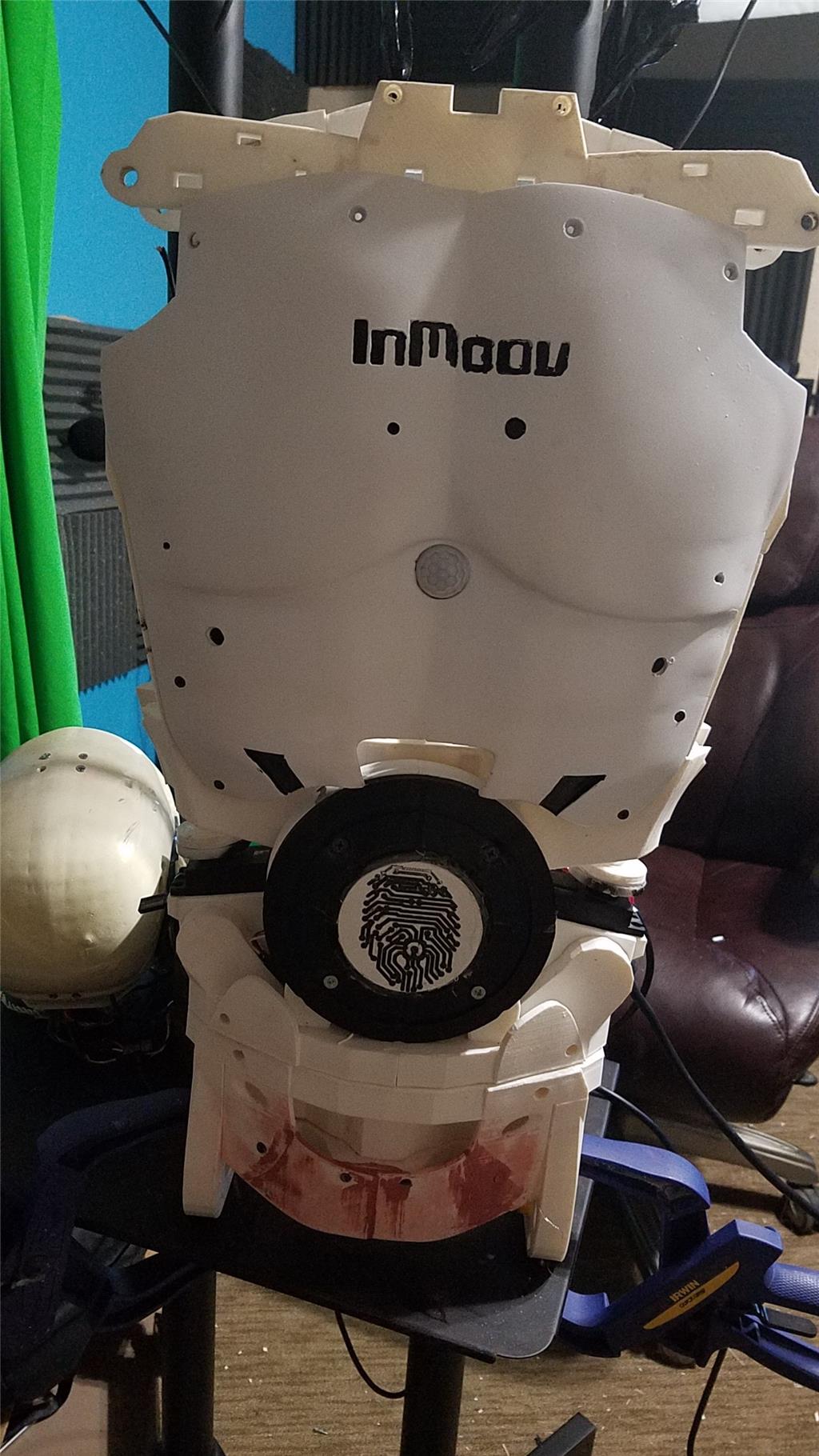

The Omron HVC-P is used to identify people, emotions, human bodies, hands, age and gender. It is attached to the Latte Panda via an FTDI friend which is then connected to the powered USB hub. It is mounted in the chest of the InMoov. I also use a 3 element microphone which is a MXL AC-404 microphone. It is disassembled and the board and microphone elements are mounted in the chest of the InMoov. This mic board is connected to the Latte Panda via a usb cable which is attached to the powered USB hub. There is a USB camera in the eye of the InMoov which is connected to the Latte Panda via the powered USB hub.

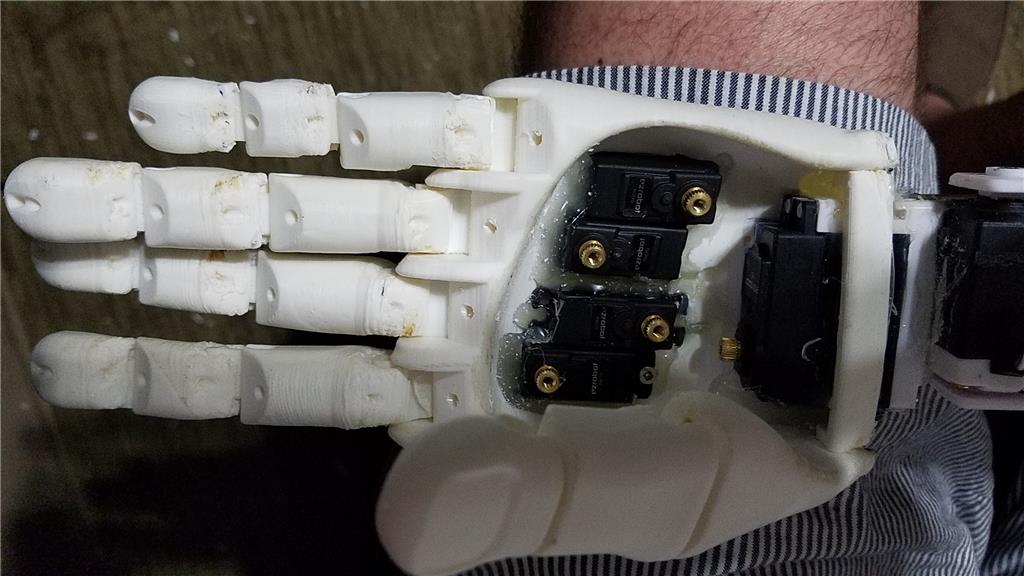

I chose to use the Flexy hand with the InMoov. The design is far more rugged than the original hand and works very well. There are 4 EZ-Robot Micro Servos in the palm of each hand which controls the main fingers. The thumb is controlled by an EZ-Robot HD servo. The wrist waves and uses an EZ-Robot HD servo to do this motion. I use the standard Rotational wrist.

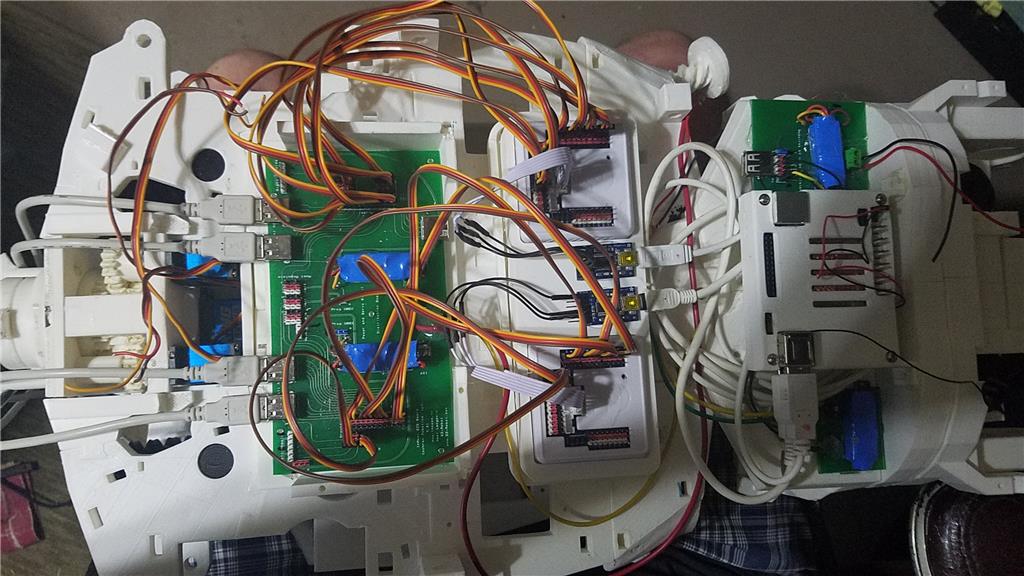

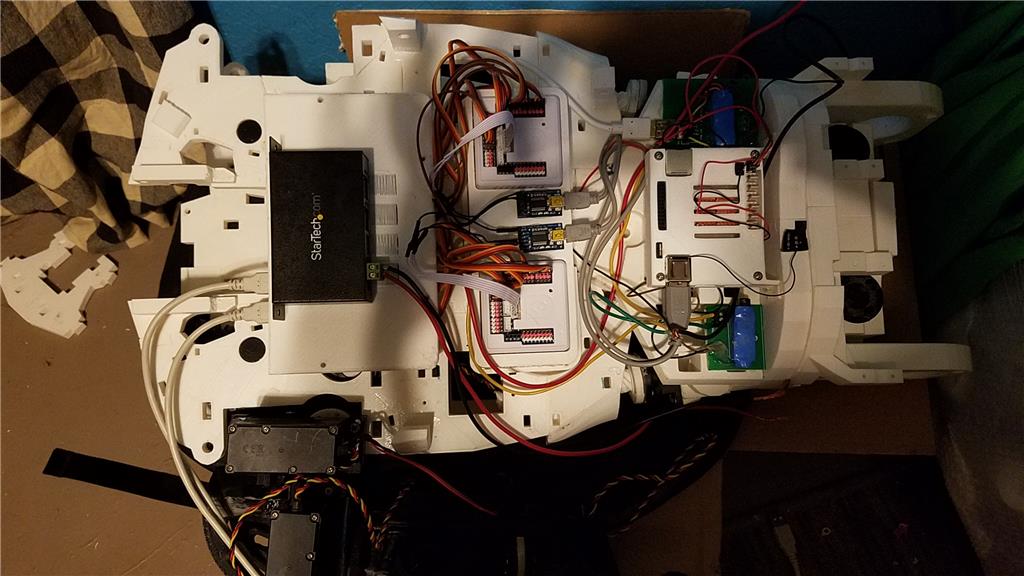

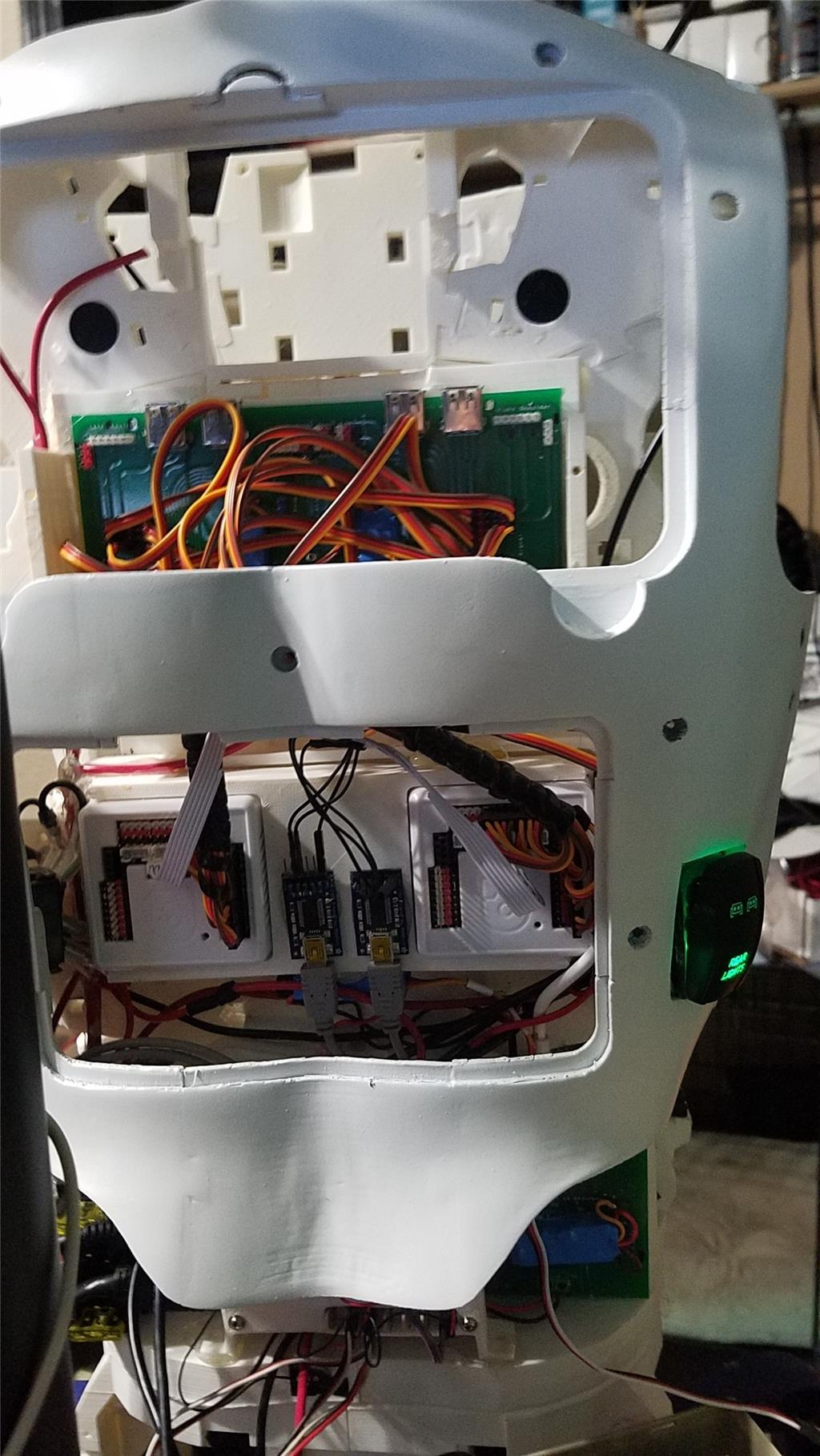

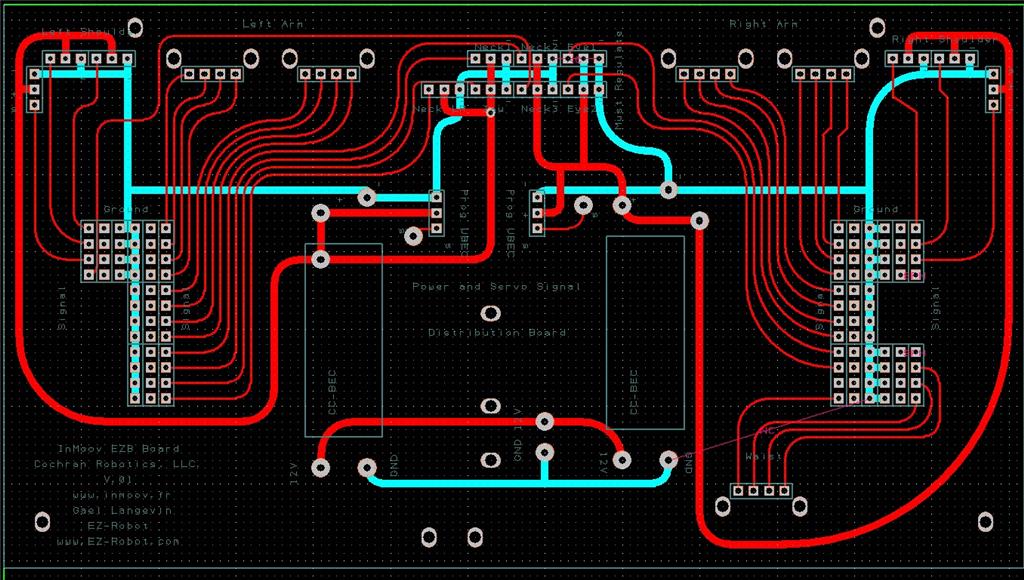

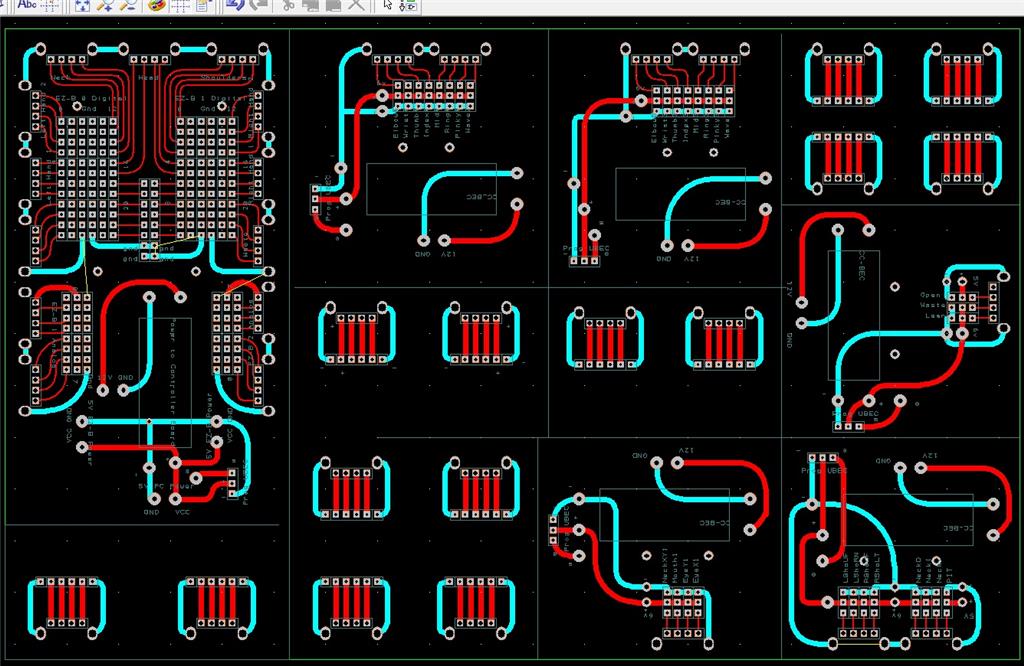

I have castle BEC's for power in the following locations set to the following voltages. Forearm's - 6.2 V - Controls fingers, wrist and elbows Custom power distribution board (2) set to 6.2 V controlling head, neck and Shoulder servos. EZ-B's - set to 6.1 V - it is mounted in the controller mounting plate and connects to the EZ-B fused power boards from a power base. Latte Panda - Set to 5.1 V and is mounted to the EZ-B controller mounting plate. Waist - set to 6.2 V and is mounted in the lower right side of the back. This provides power to the lean and pivot waist motors..

There are some custom power and signal distribution boards. These are in the forearms, lower back and in the upper back. The upper back or main board connects to these distribution points via USB cables to provide signal to the other boards for servos. The main board also has servo connector pins that are for the neck, head and shoulders. This allows the power to be distributed between multiple BEC's and also allows the servo signal cables to be shorter and more protected via the USB cables.

For power I use a LiFePo4 battery that is rated at 30 amps. It has the balanced charging circuit built into the battery and also has a low voltage shutoff built into the battery. This protects the battery and allows the battery to be charged with standard car chargers.

I put switches on the back on the InMoov which are rated at 20 amps at 12 volts. These are rocker switches that allow the user to pretty much slap the switch to turn it off. There are two of these switches. The servos for the elbows and fingers are on one switch. The latte panda, neck, shoulders, EZ-B's, waist motors and some lighting is on the other switch.

I also added a fuse block. This allows 20 amp fuses to be put in line to help protect things. The switches above drive the fuses for each of of the motors listed in that section.

Other robots from Synthiam community

Ezang's Roman The Robot

Fxrtst's Will Huff's Lost In Space B9 Robot Build

-636348381130562972.jpg)

-636348716348649435.jpg)

I'd love to poke around your robot and see your work 1st hand. It all sounds so professional and amazing.

Thanks Dave. I am using lessons learned from mistakes made with the Rafiki build. Hindsight is 20/20 but learning from it is the most important.

@proteusy just to let you know, I also am following David's progress on Rafiki. I currently have a full set of the 3D printed parts, and many mechanical and electronic components ready for Rafiki. As soon as my Antonn is running on a Latte Panda and has some more enhancements, I will begin the Rafiki shell assembly. I think David's lessons learned from his Imoov, applied to the Generation 3 Rafiki will be worth the wait.

Thanks Andy, hope you will poste your progress as you build. Regards.

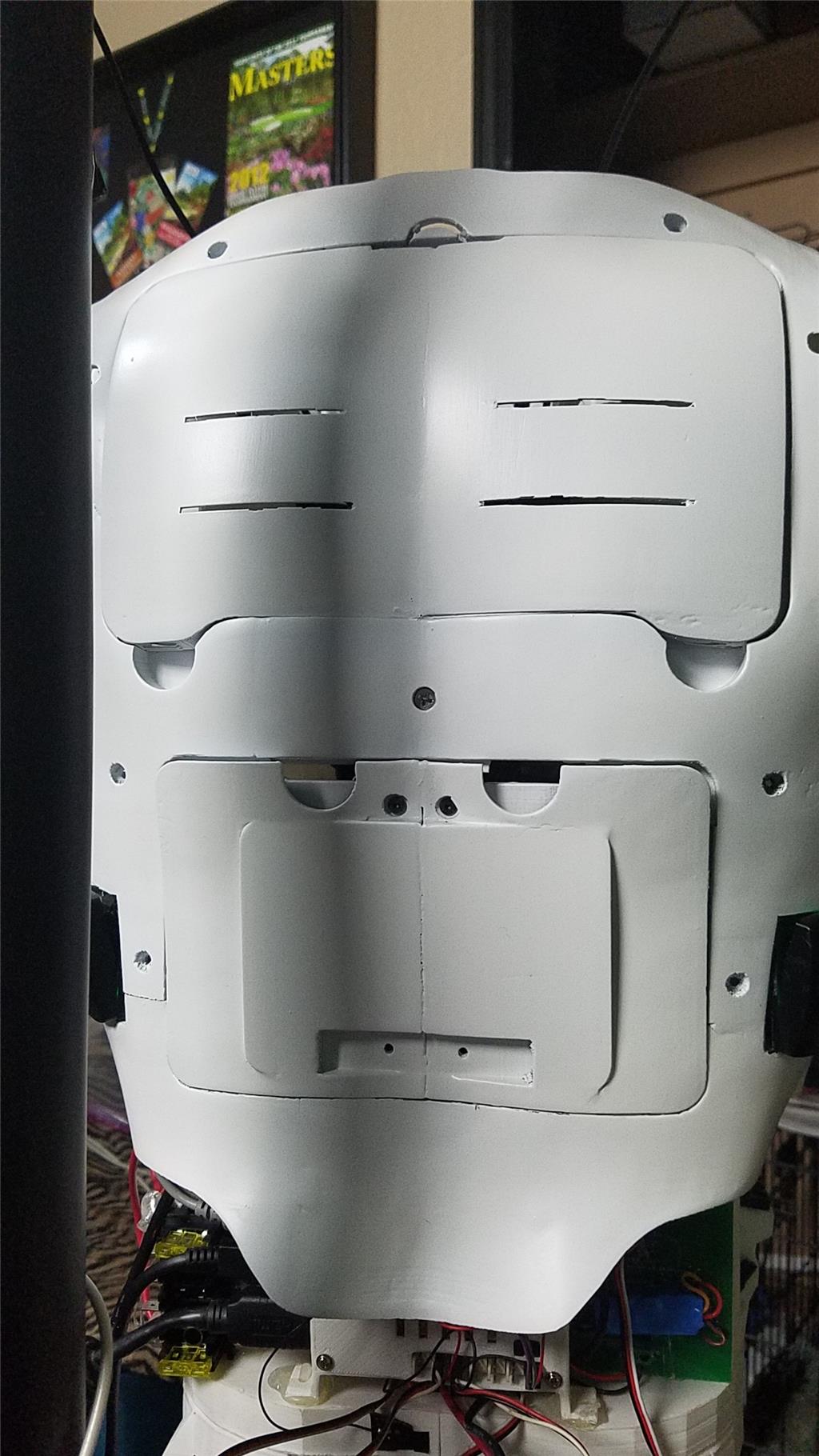

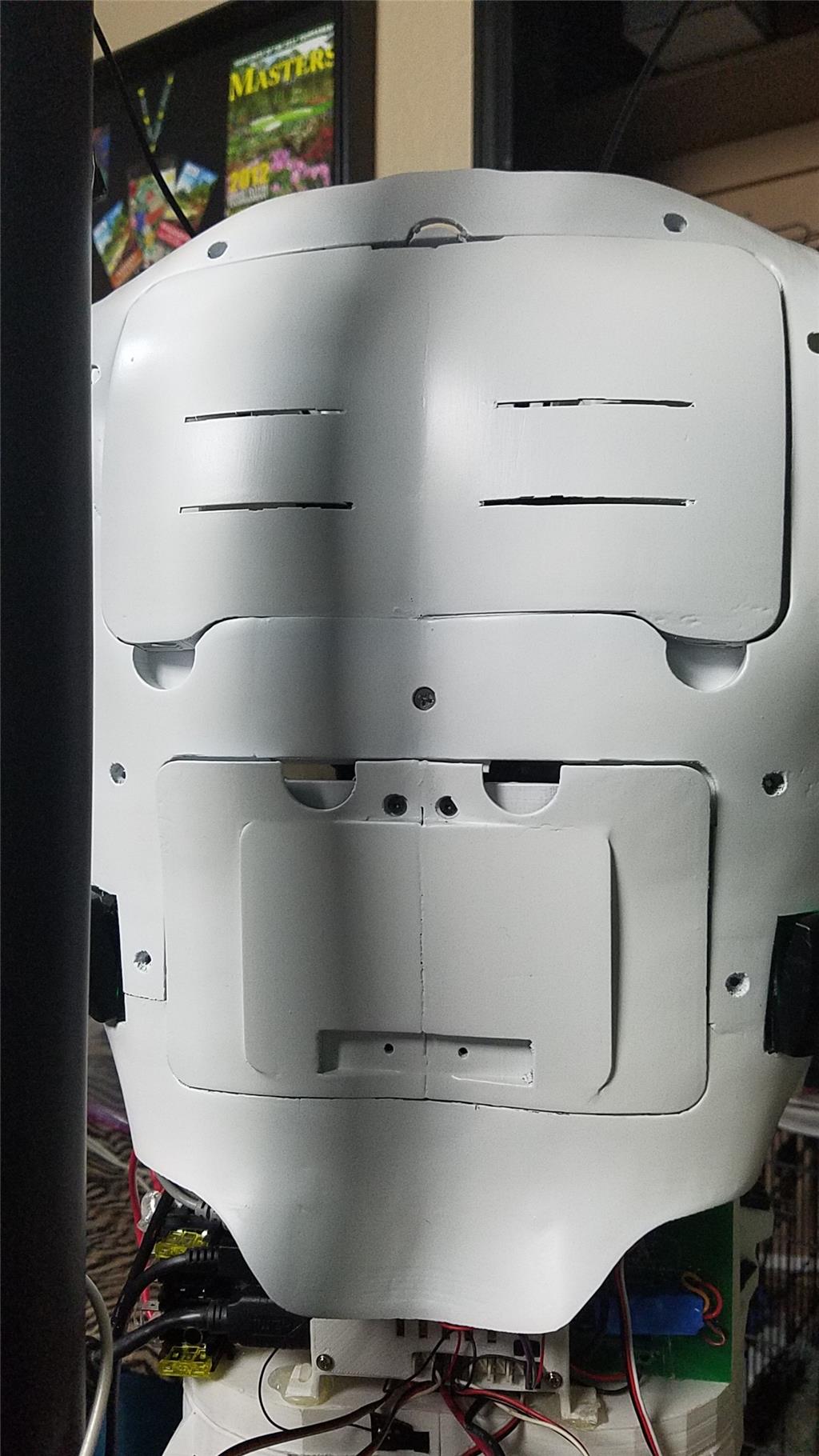

I have managed to find a little time this week to work on the InMoov. I have the chest sanded, filled put a coat of primer on it. I also sanded the back doors and back and have a coat of primer on them also.

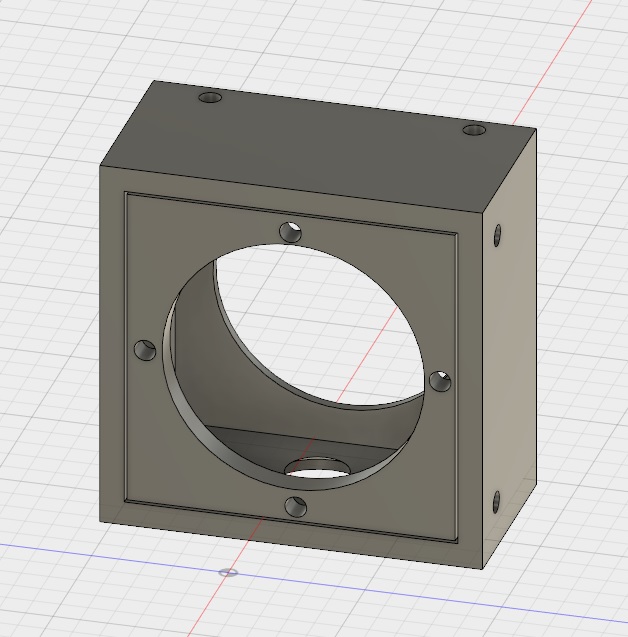

I designed and printed out the part that the EZ-B's will sit in and am trying to figure out how to get everything to fit in the space in the back. The EZ-B's sit inside of sockets (like what the Revolution robots have) and are powered through the normal power pins in the EZ-B. I used the power boards with the 20 amp fuses also and have the power for these concealed except for the BEC's power input wires.

I picked up the screws to complete the neck but haven't finished it yet.

Work has kept me pretty busy and there isn't any sign of letting up soon. I am off work on Friday but will be going away for the weekend so there wont be much building until I am back in town. I do plan on doing some tests with the boards that are remote and are connected via the usb cables next. Hopefully I will have time to do this before Friday.

I know, pictures...

I am starting to think you are a cruel tormentor for talking about all this cool stuff and not showing us pictures. I'm interested the back piece. I am at the point of wondering If I should glue mine together and fix it up as one piece. I don't plan on using the battery door opening

I'm interested the back piece. I am at the point of wondering If I should glue mine together and fix it up as one piece. I don't plan on using the battery door opening

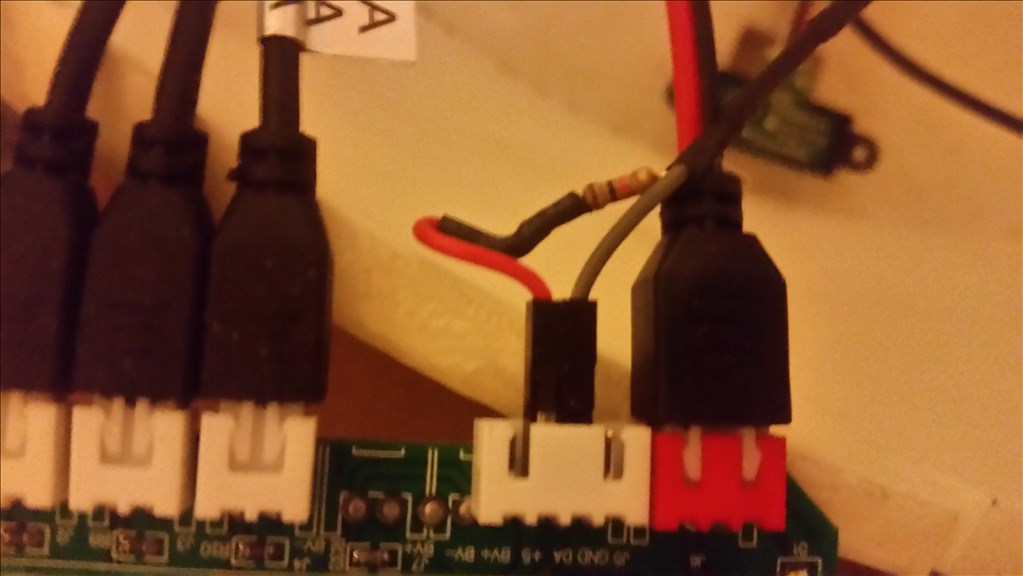

I got up at 4 am this morning to find some time to do the test of a servo connected via usb through the boards. I decided that I might as well do the test by hooking up all of the components that I will be using. The test was a success.

The image shows the battery, possitive and ground blocks, latte panda connected via serial, ez-b's in their holder, power and signal distribution boards and arm power/servo connection board connected via a usb cable and the servo. I was RDP'ed into the latte panda for this test.

This puts me at ease as this was a slight concern for me. It worked well.

Another test that I figured would work and helps to reduce wiring a lot.

Because ground is connected to all ground pins on the EZB and also on the distrubution board, I am able to just connect ground from each EZB on one pin to ground on one pin on each side of the distribution board and then the signal wires from each EZB to the distribution board. This greatly reduces the amount of wiring involved from 104 wires to 38 wires from the ezb's to the distribution board, which will make for a much cleaner (and less space consuming) install.