Hi all,

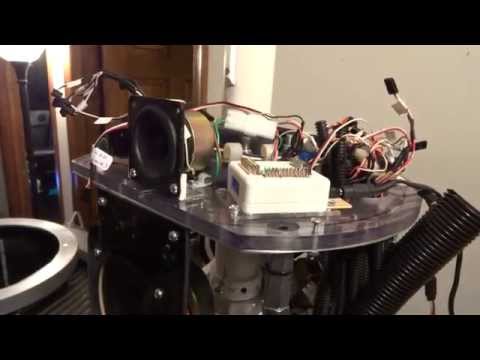

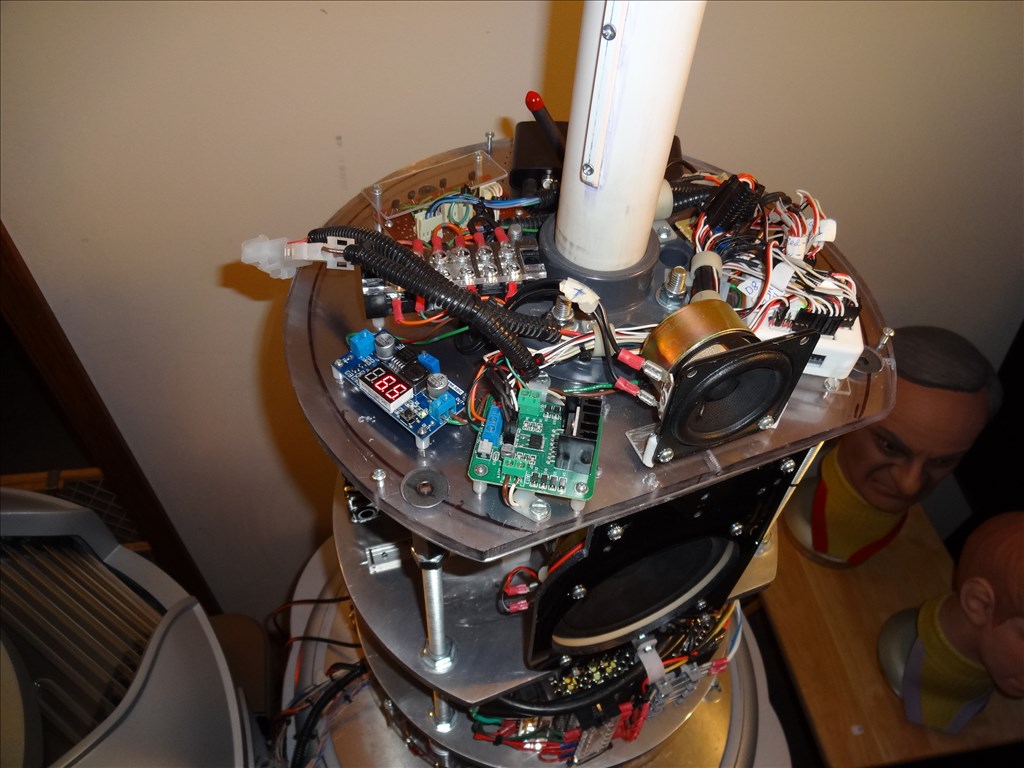

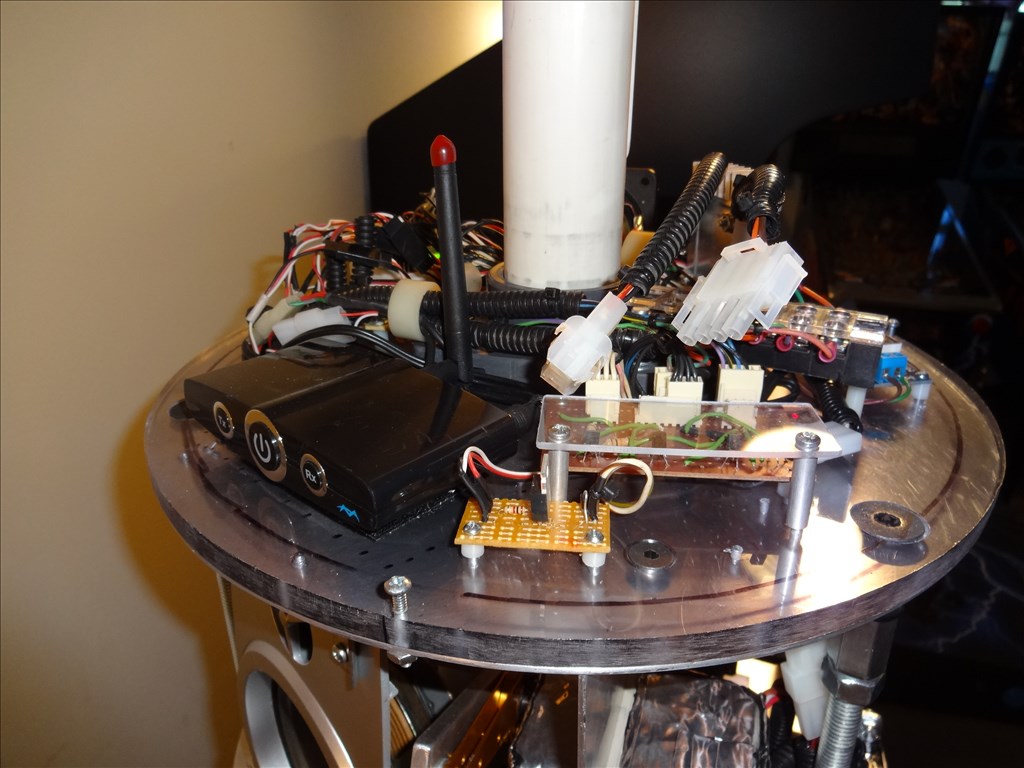

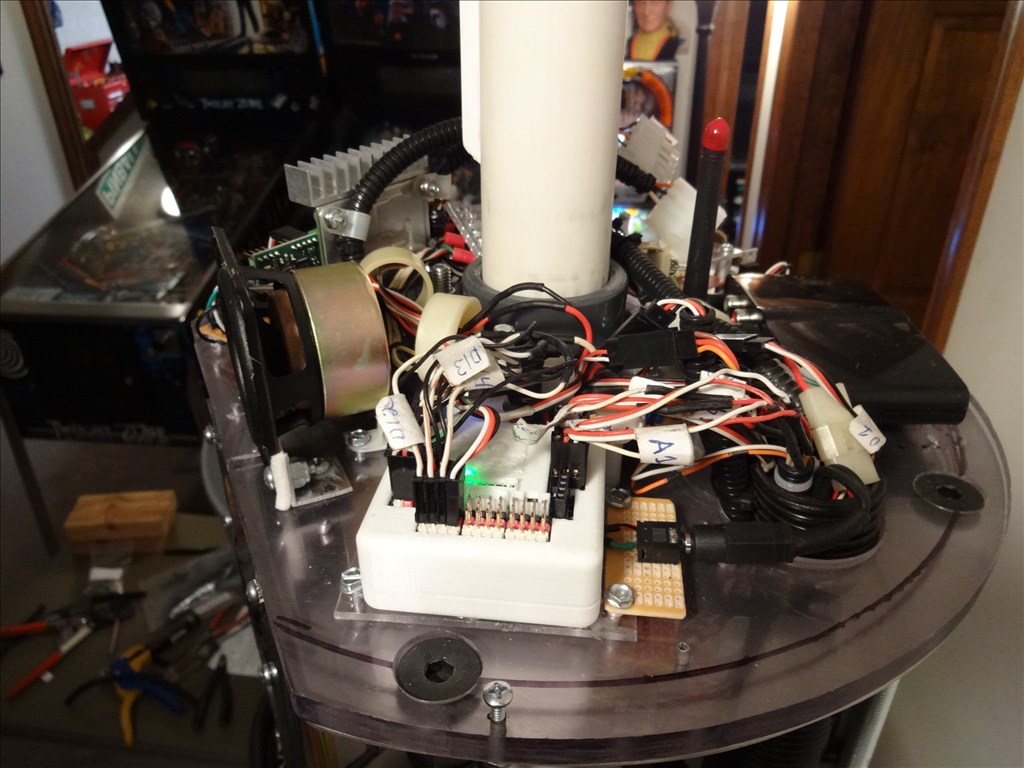

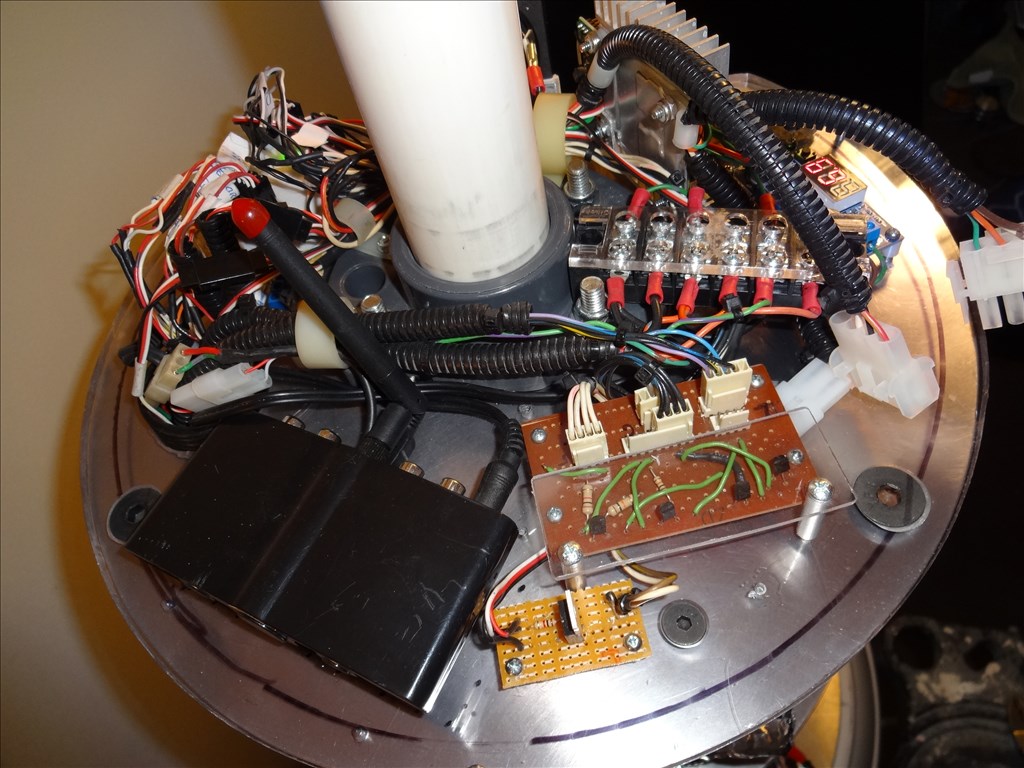

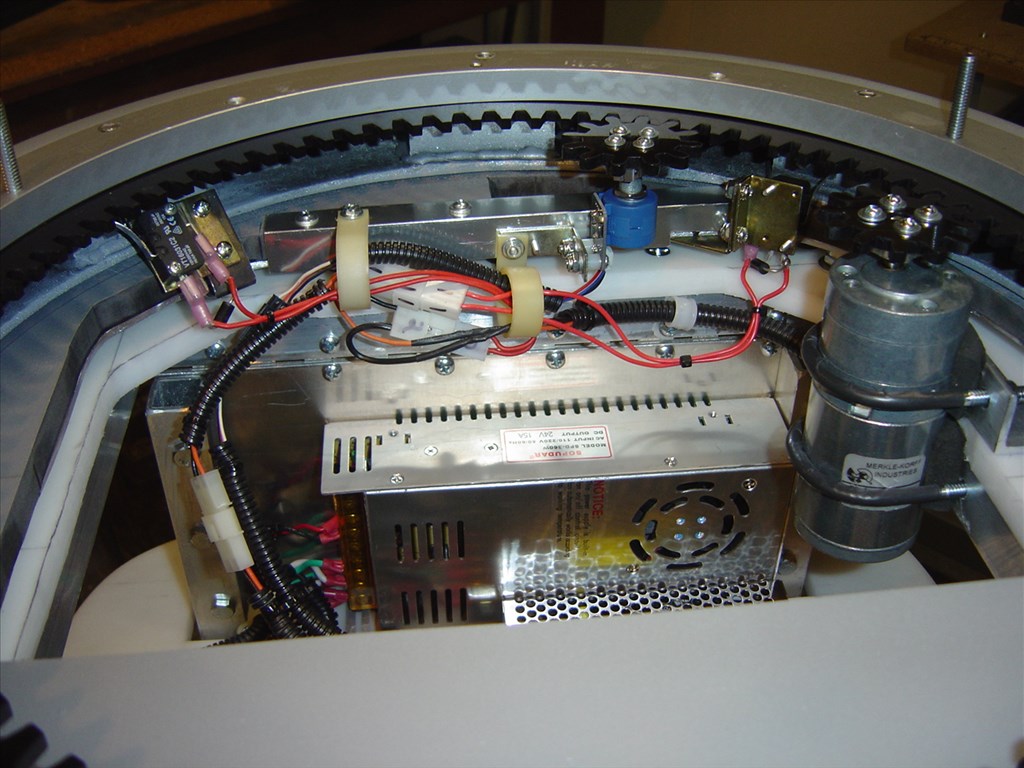

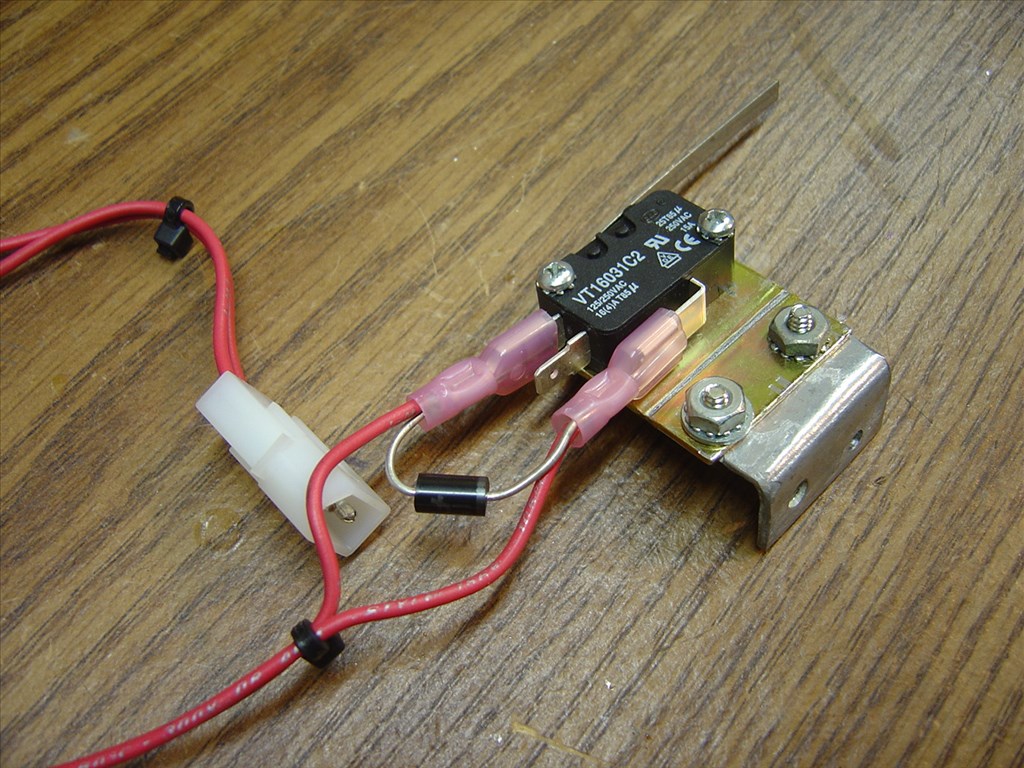

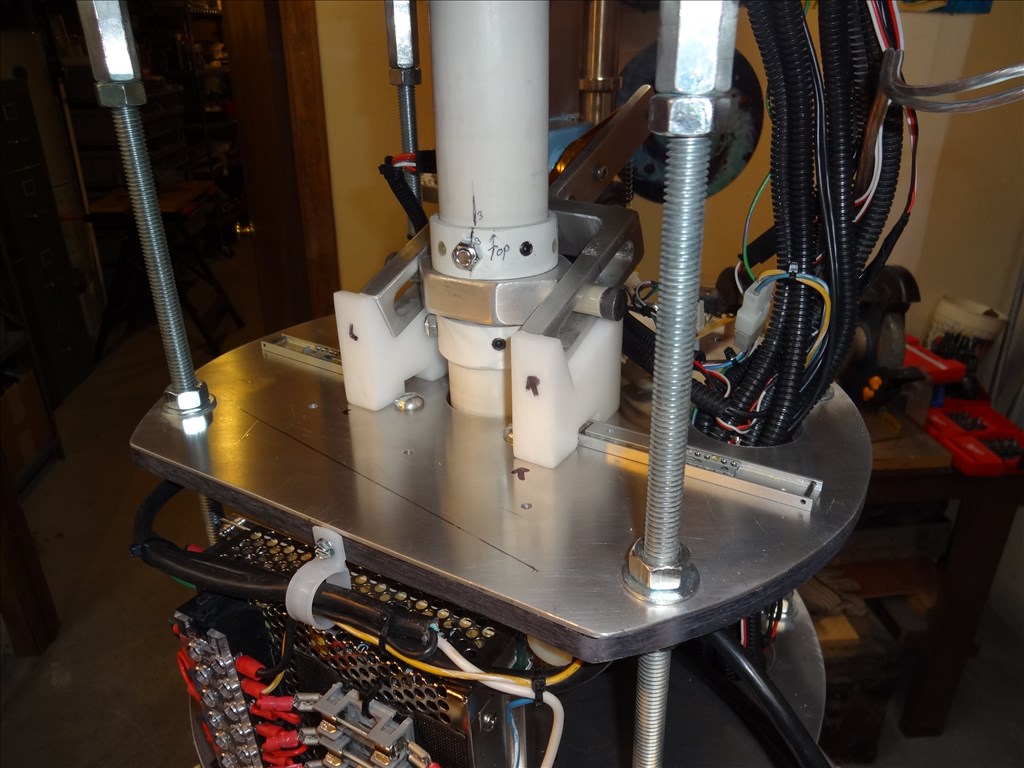

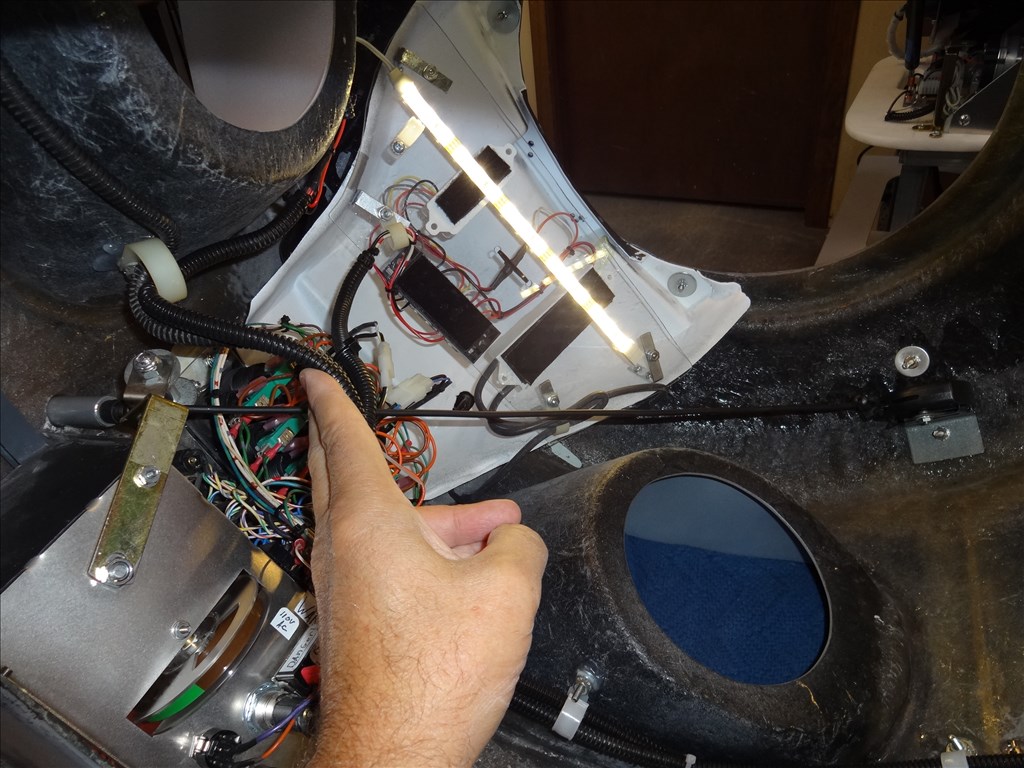

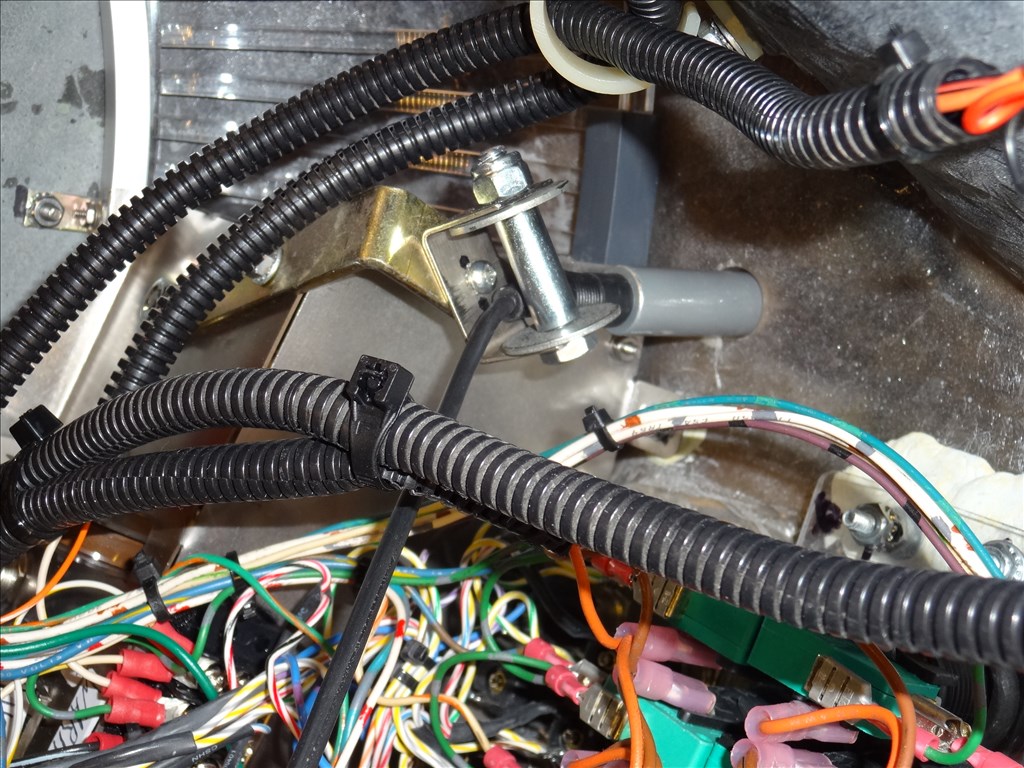

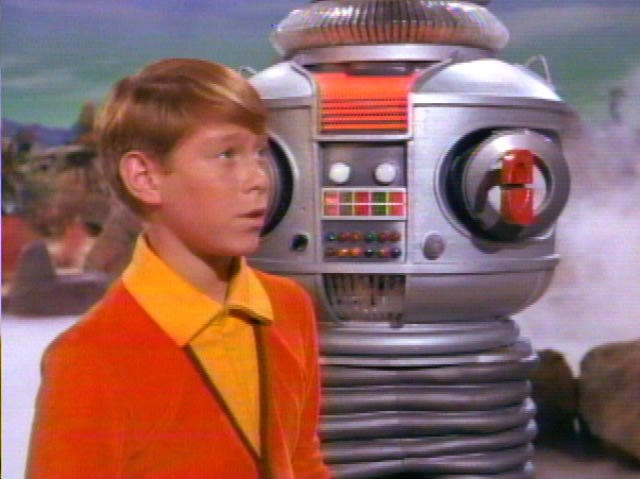

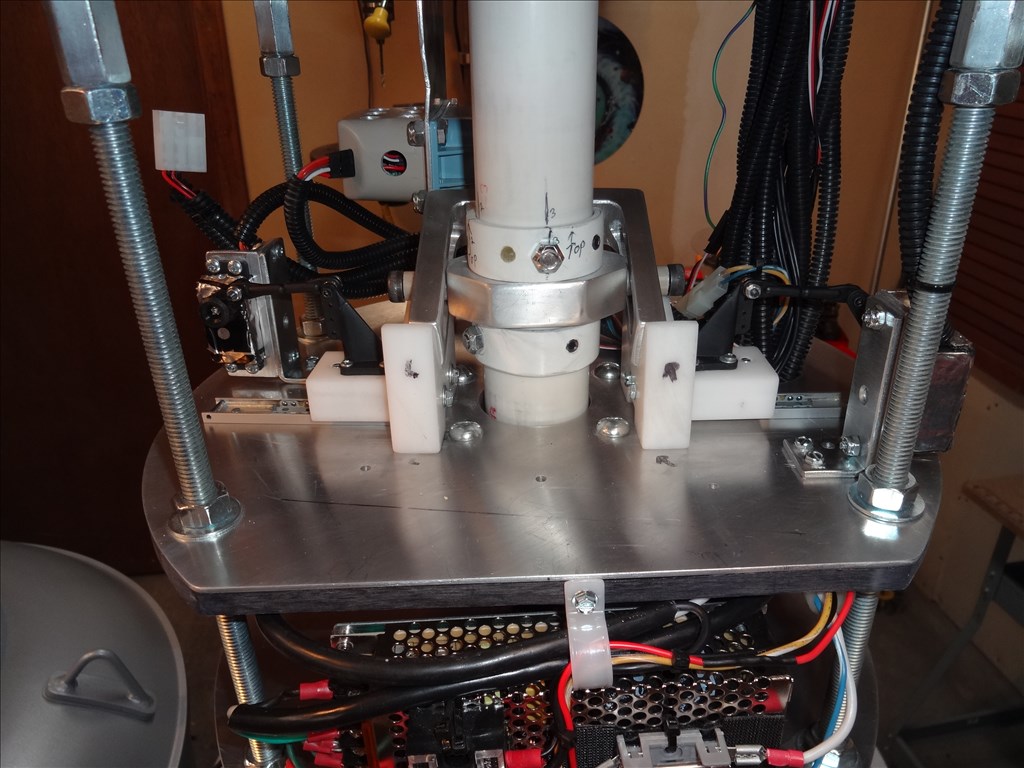

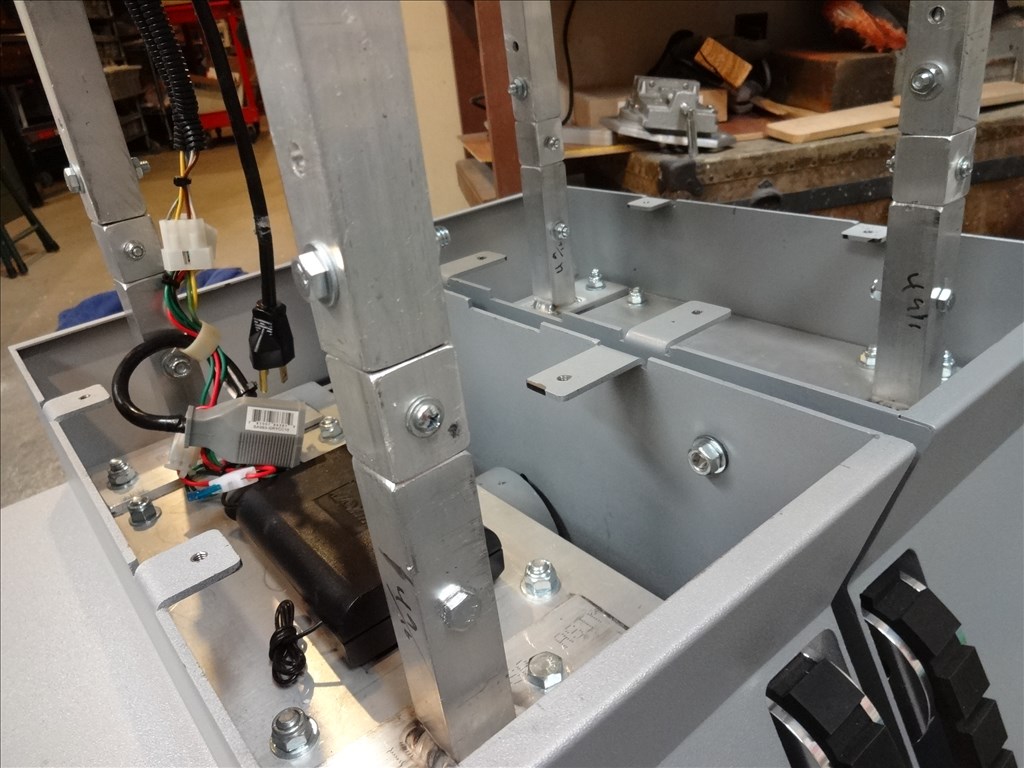

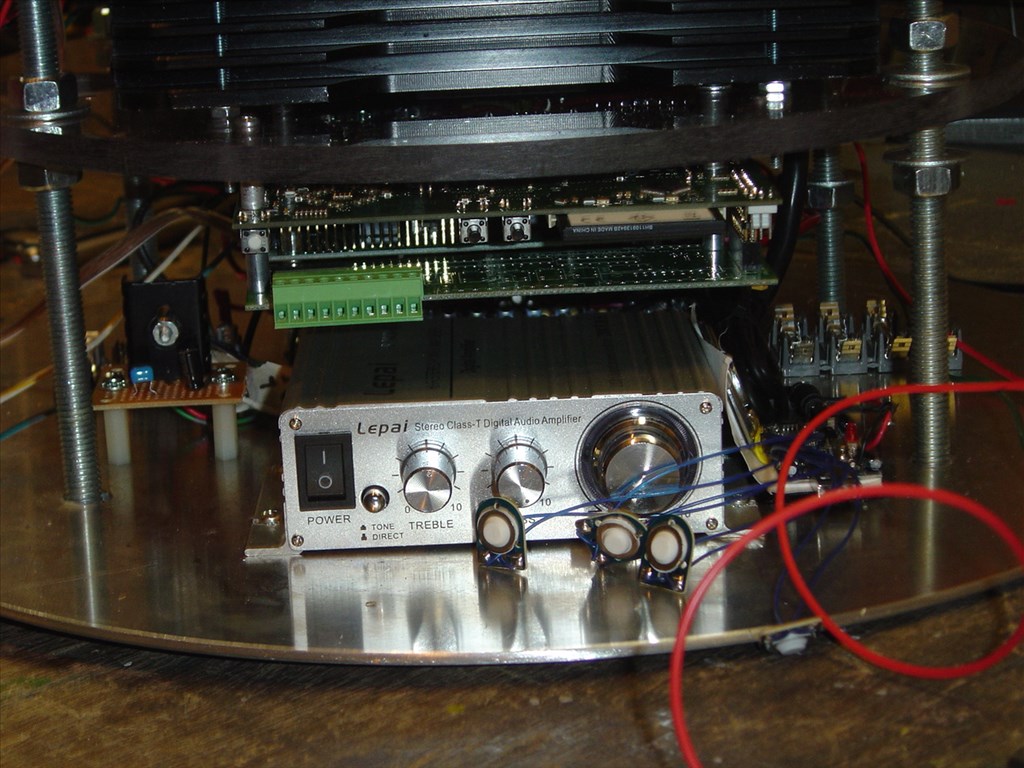

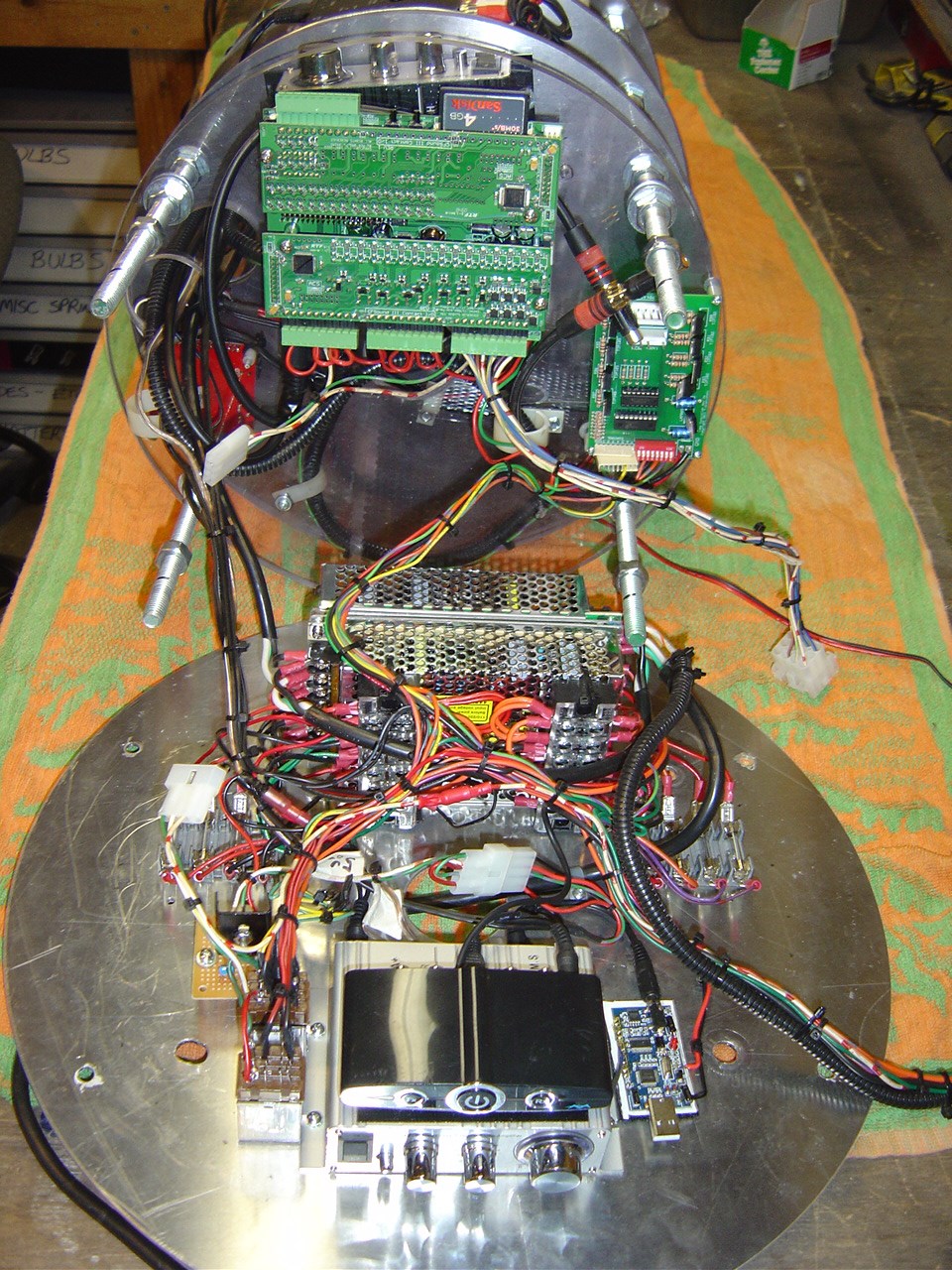

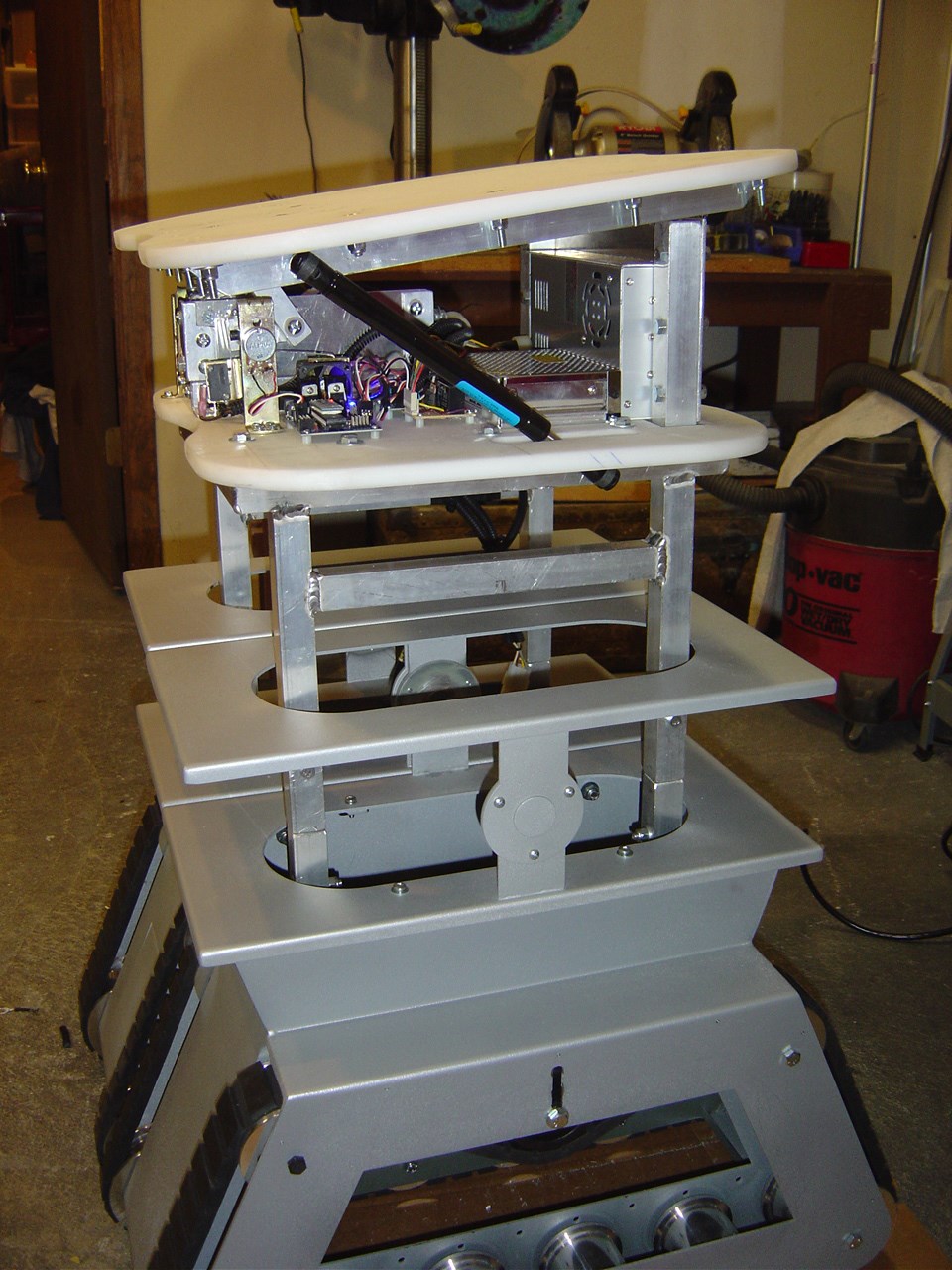

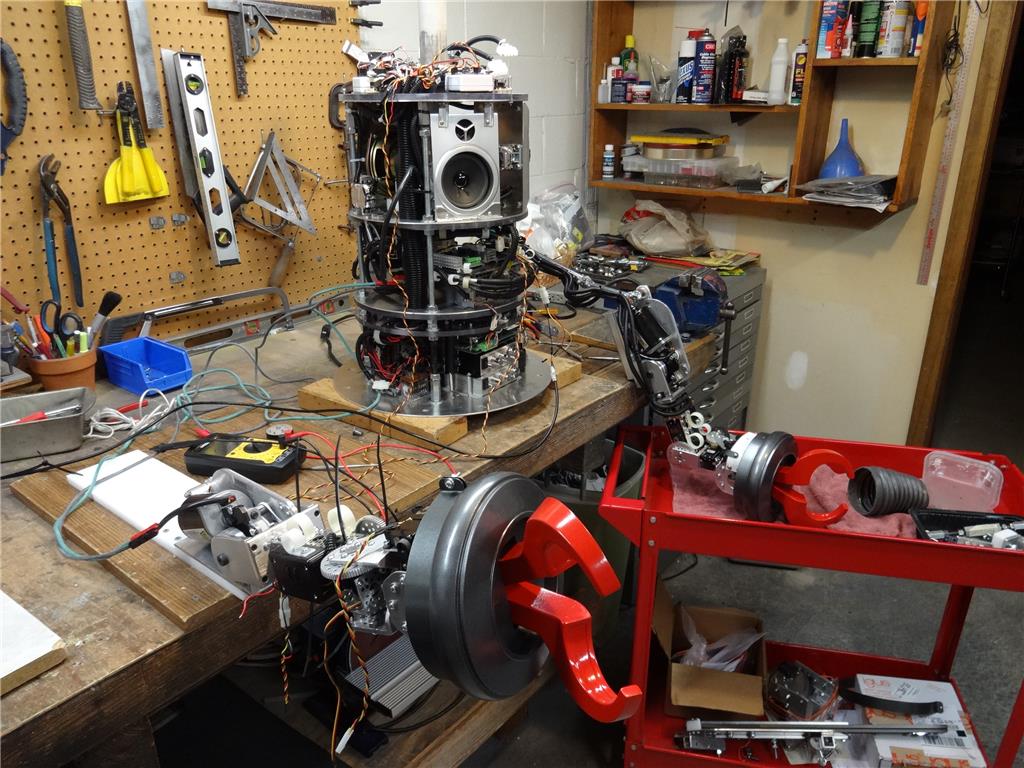

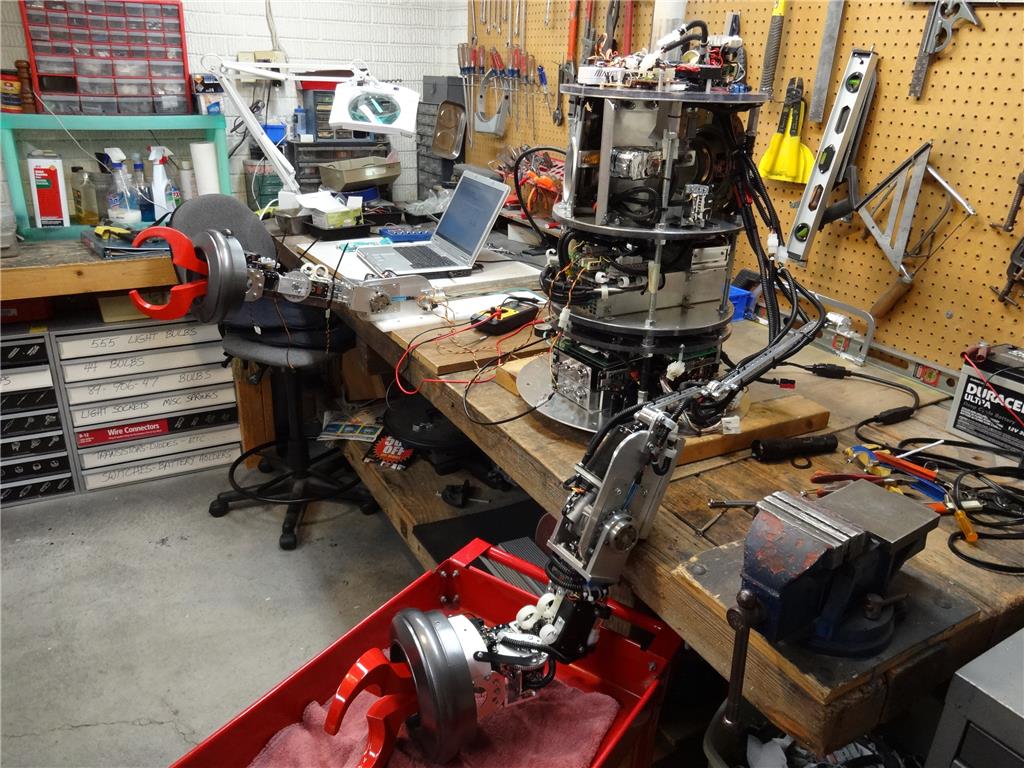

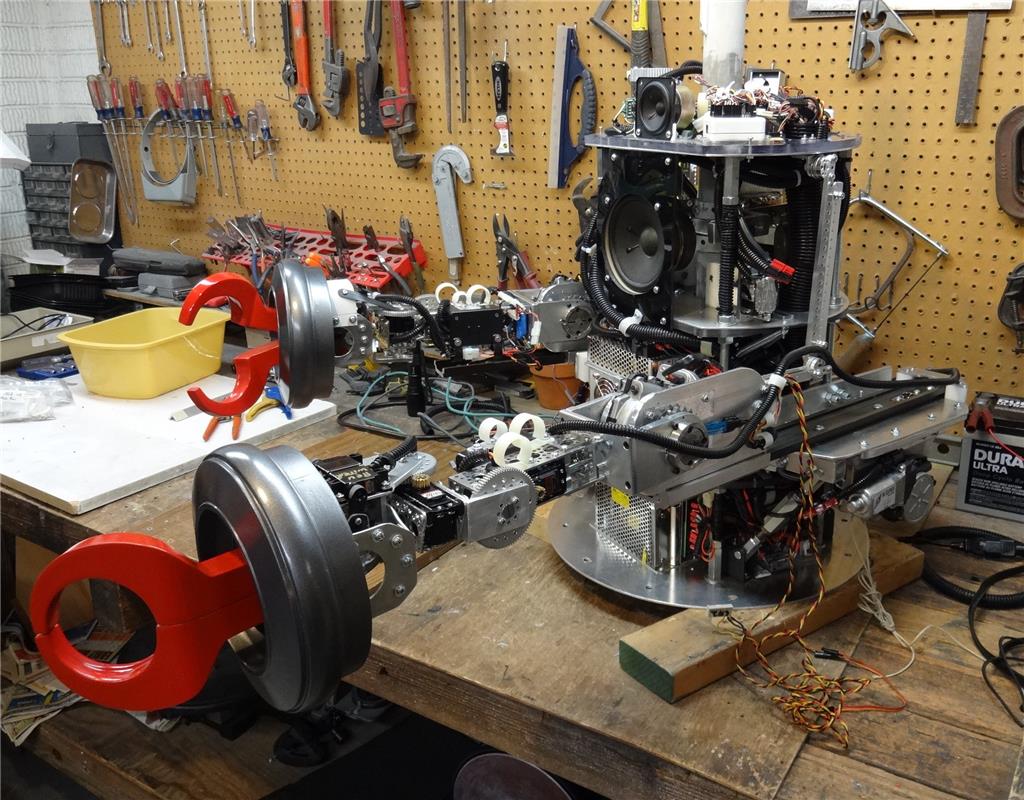

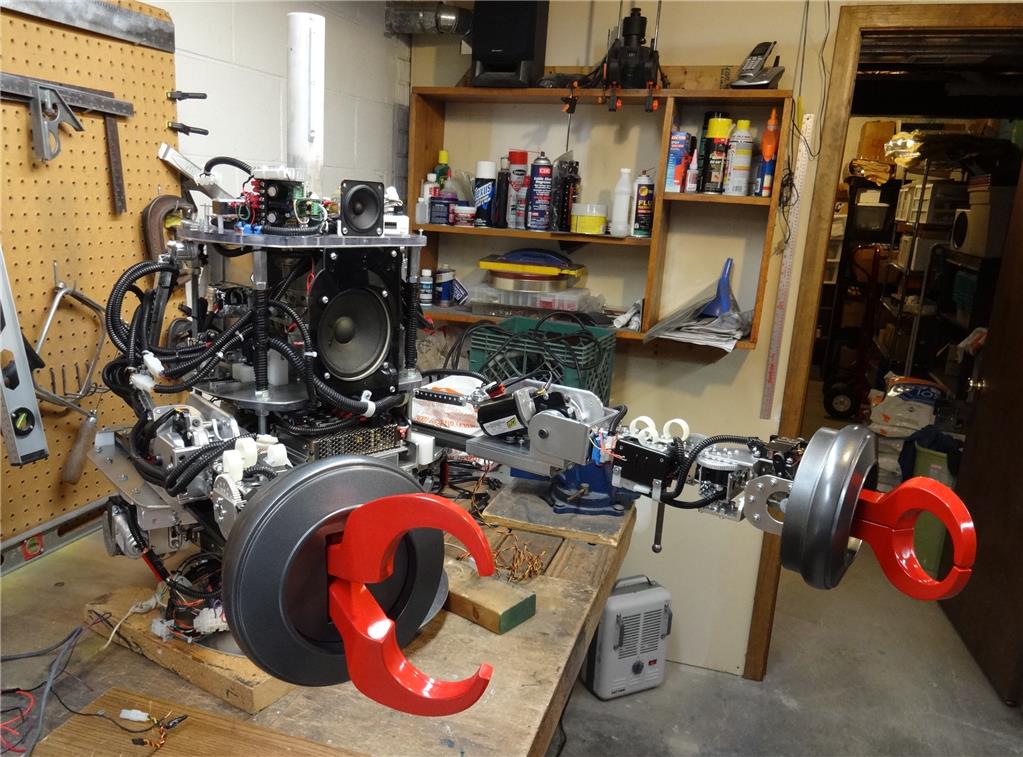

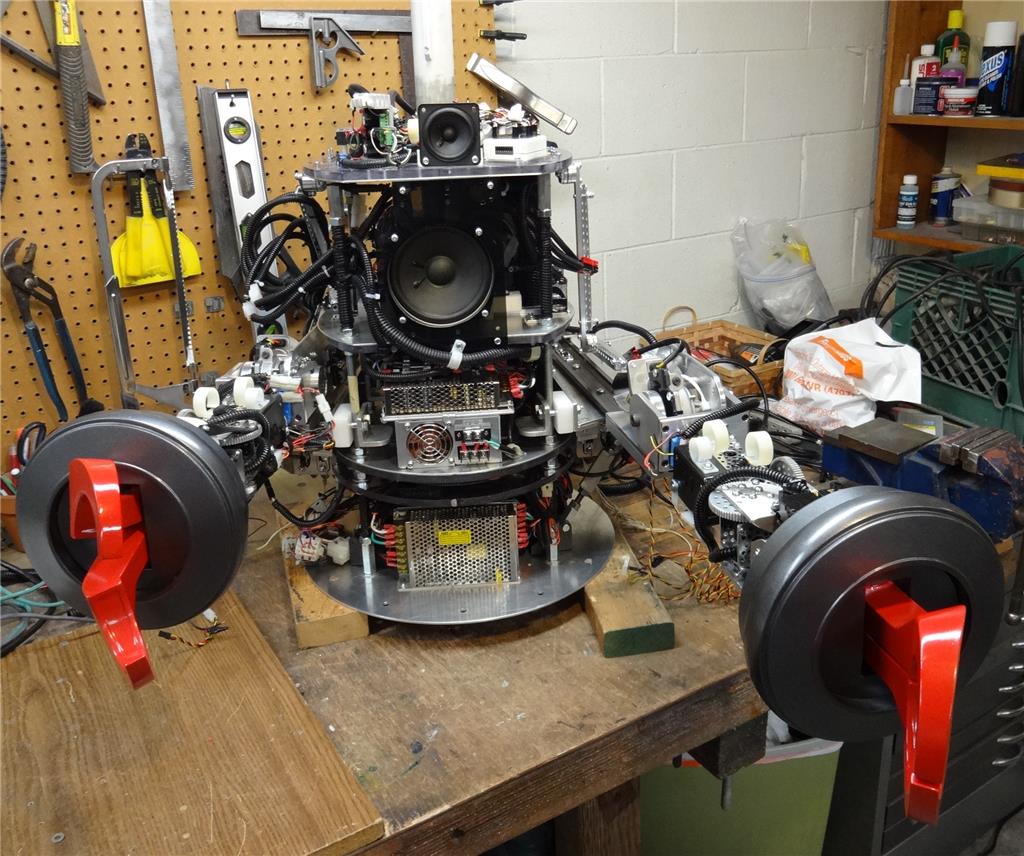

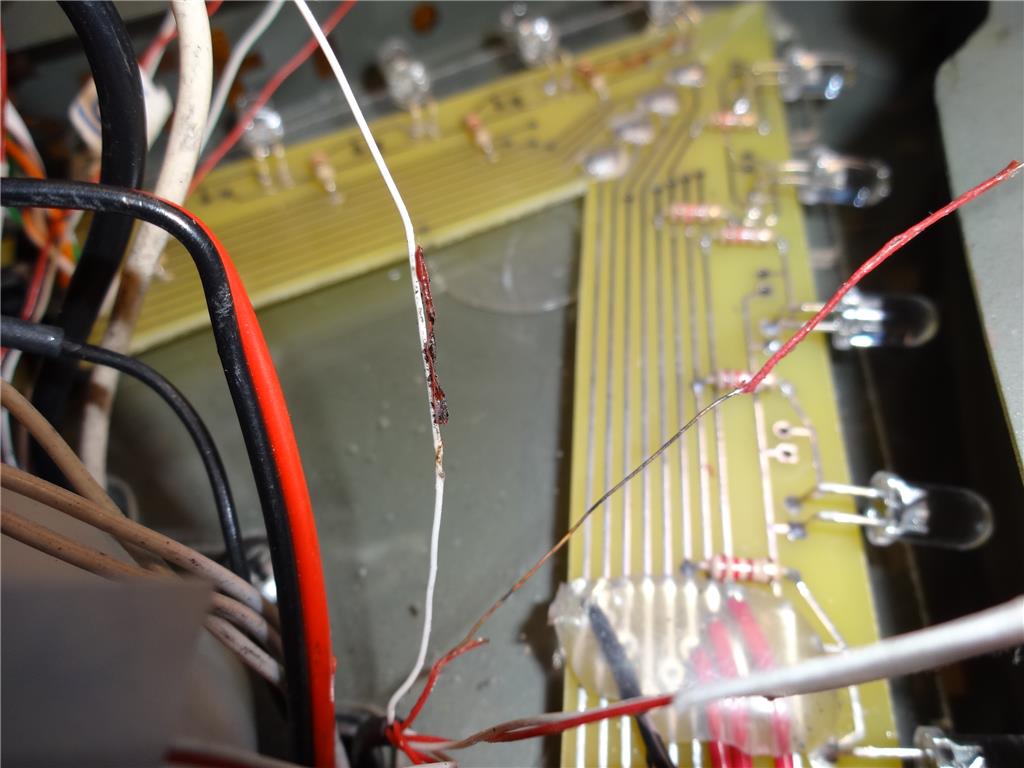

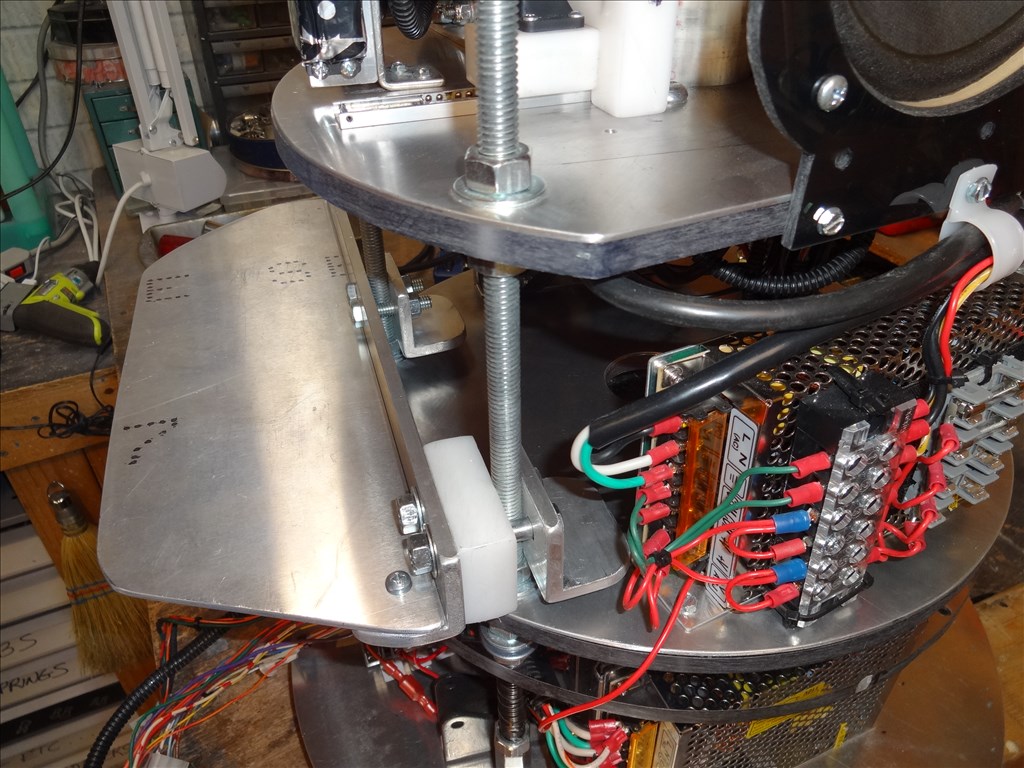

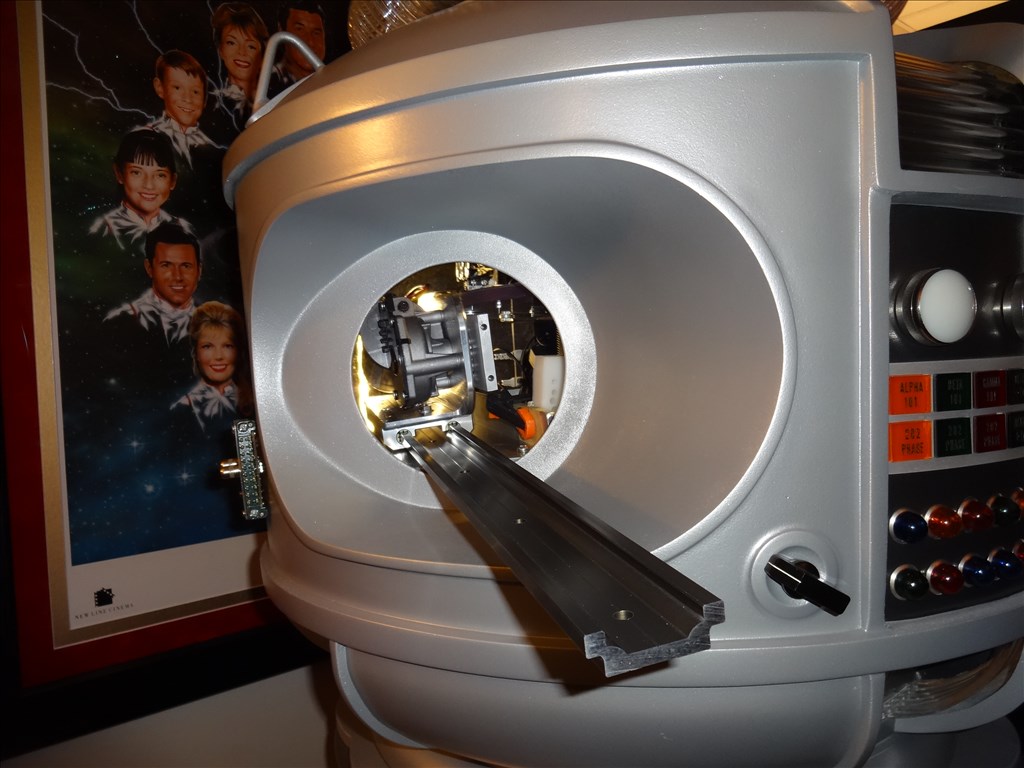

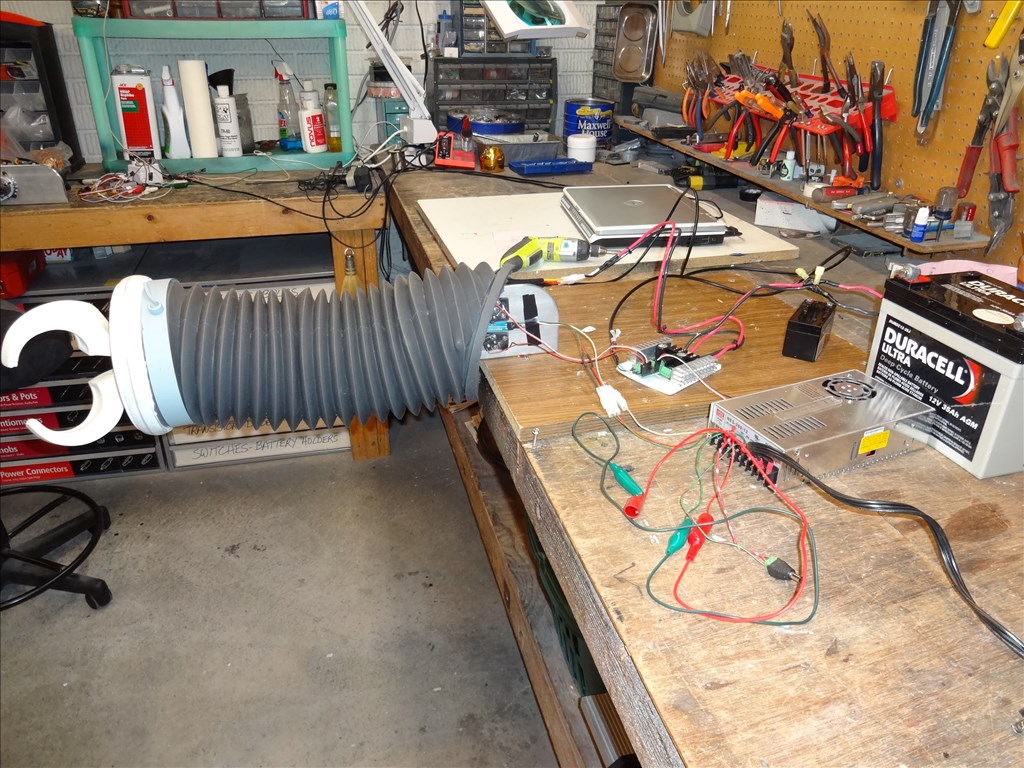

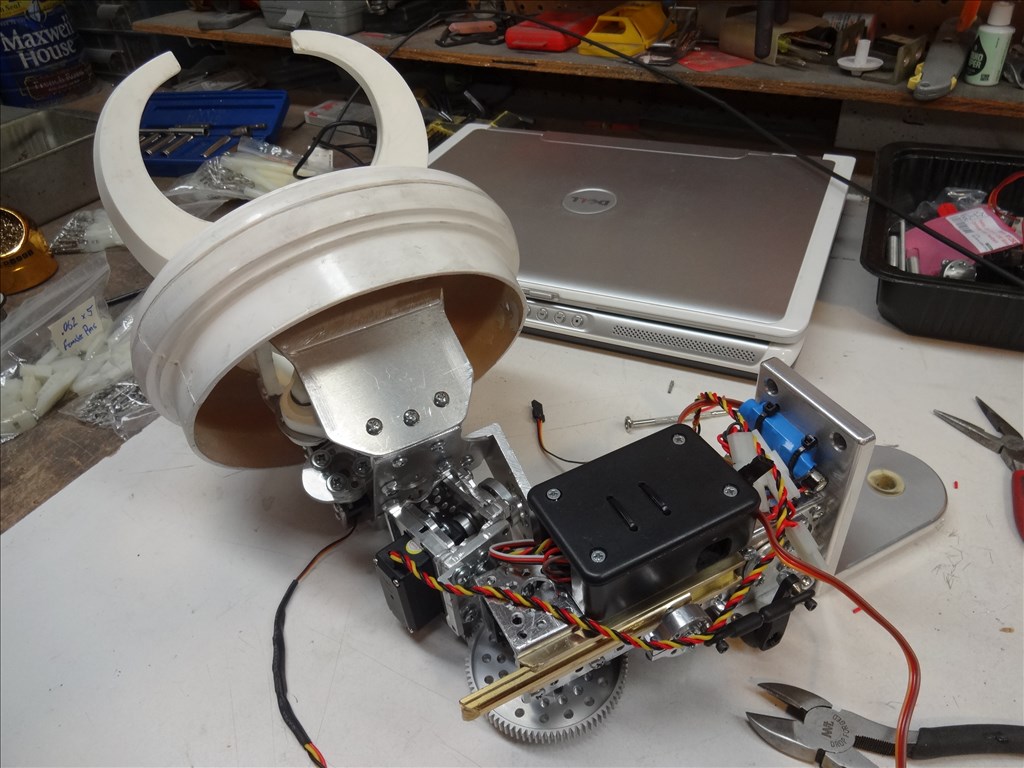

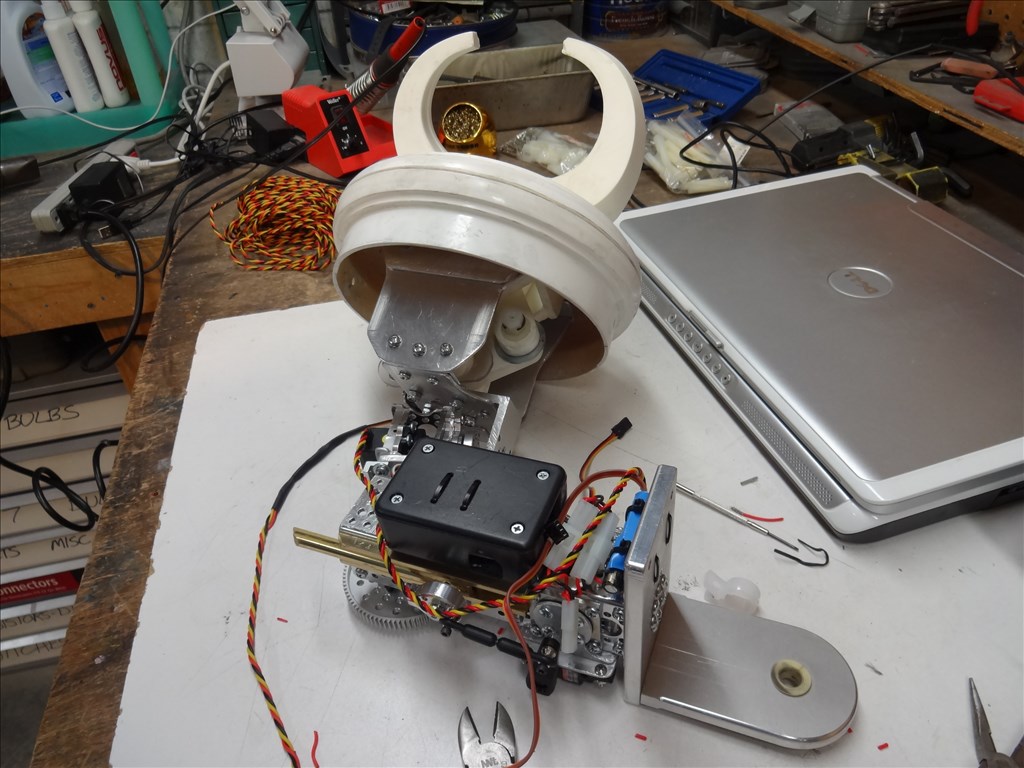

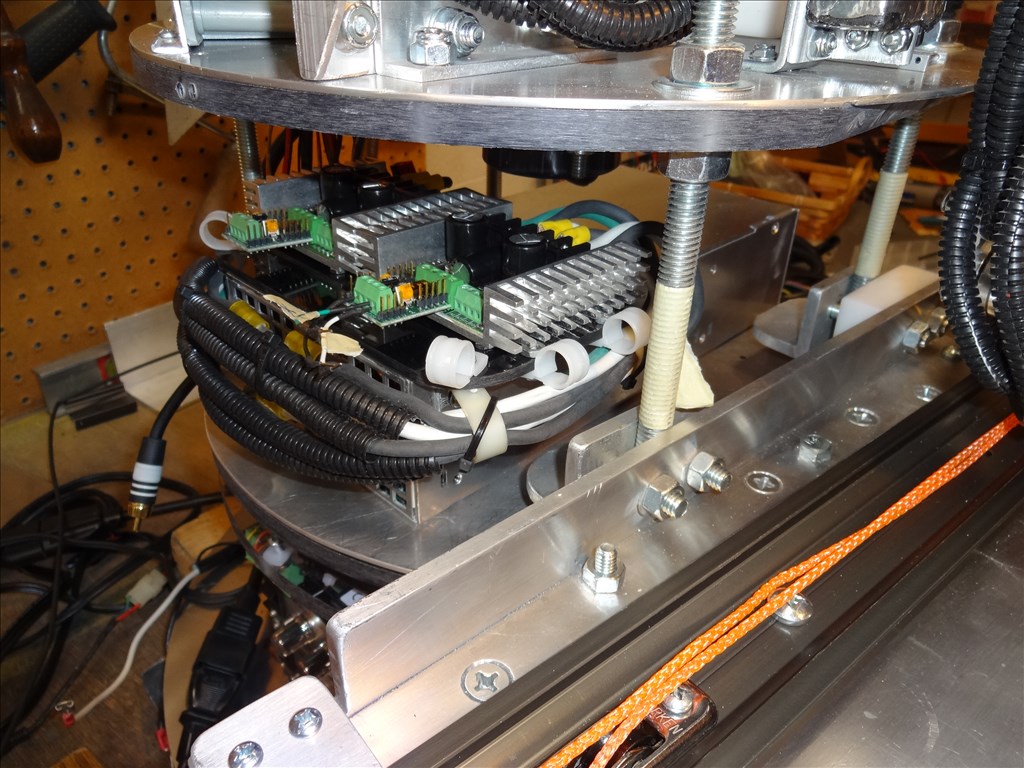

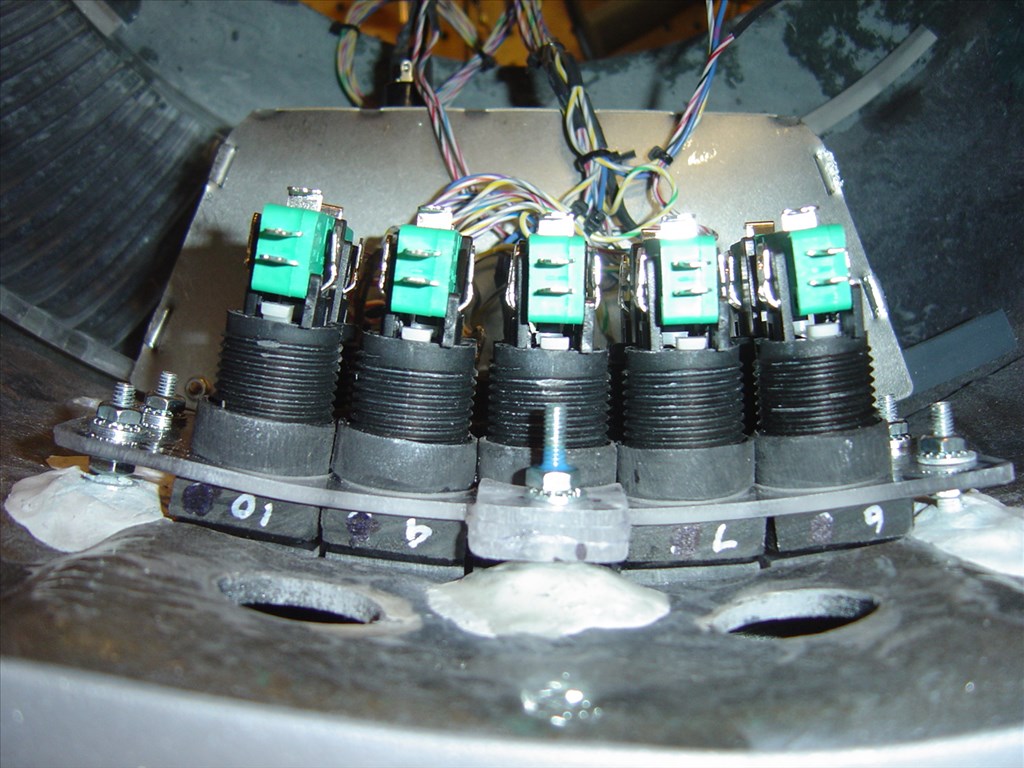

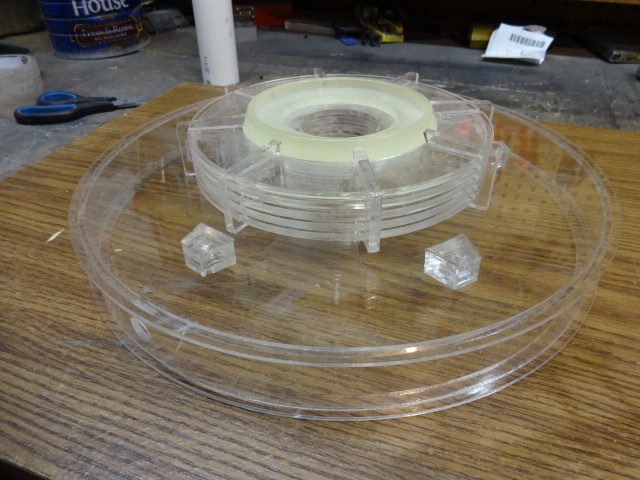

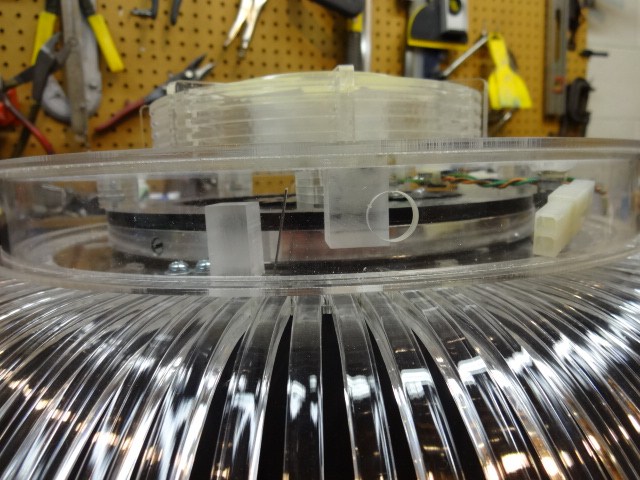

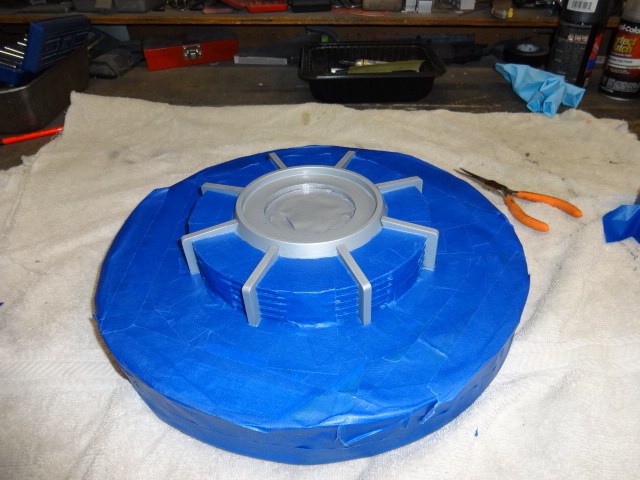

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

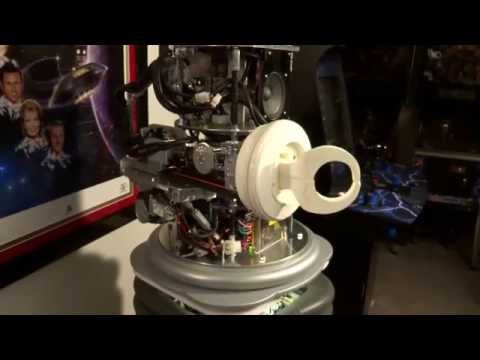

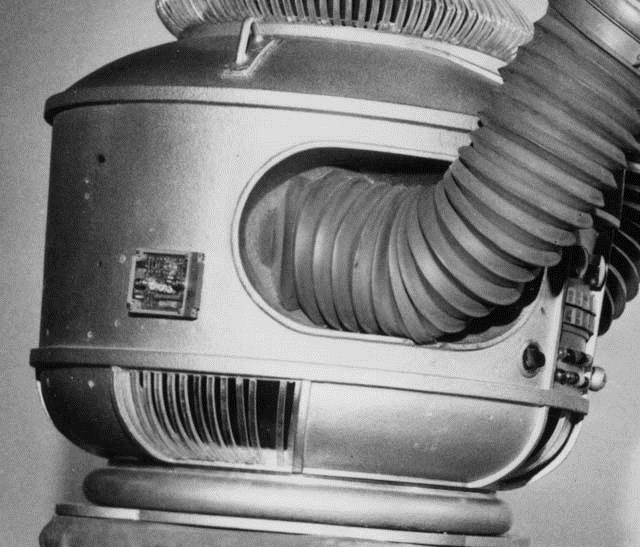

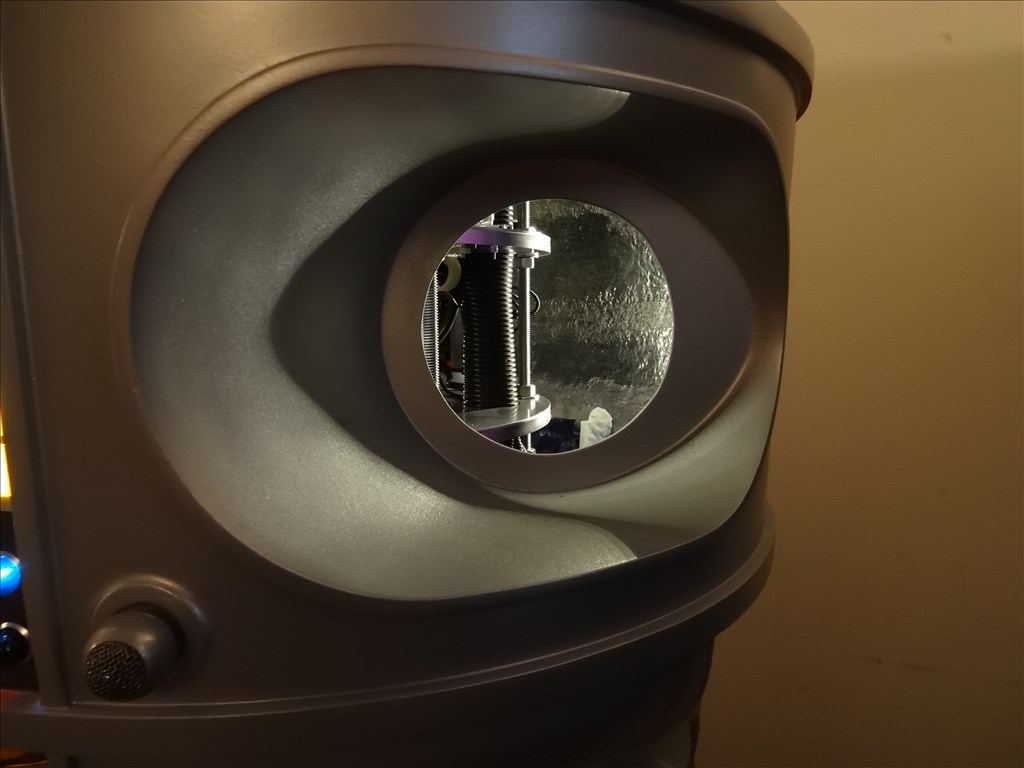

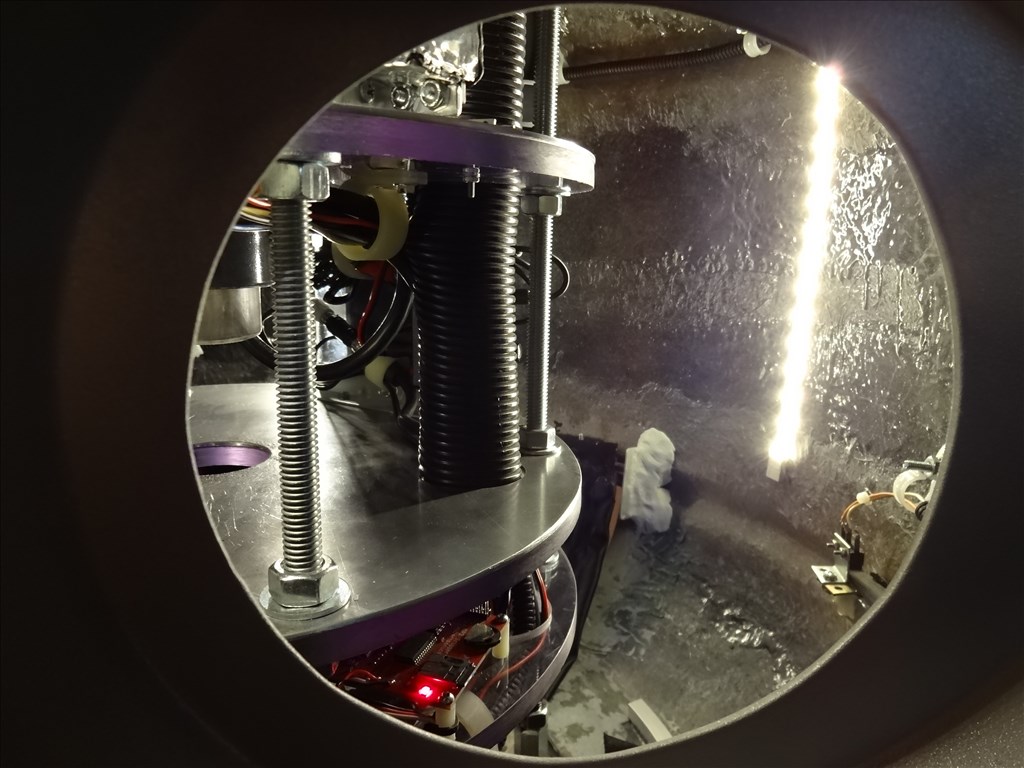

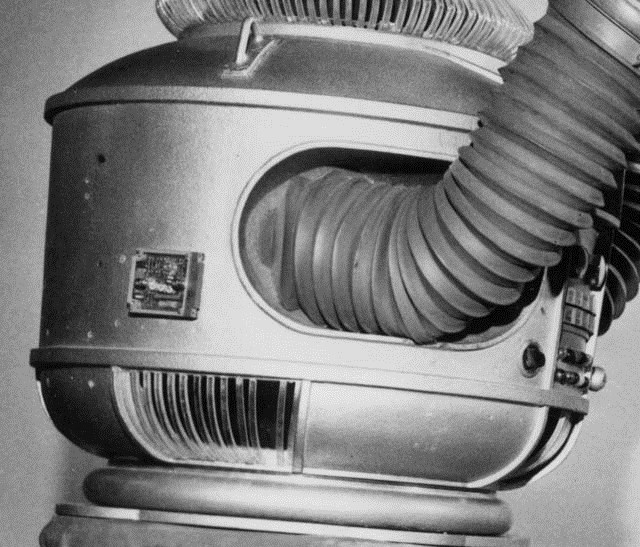

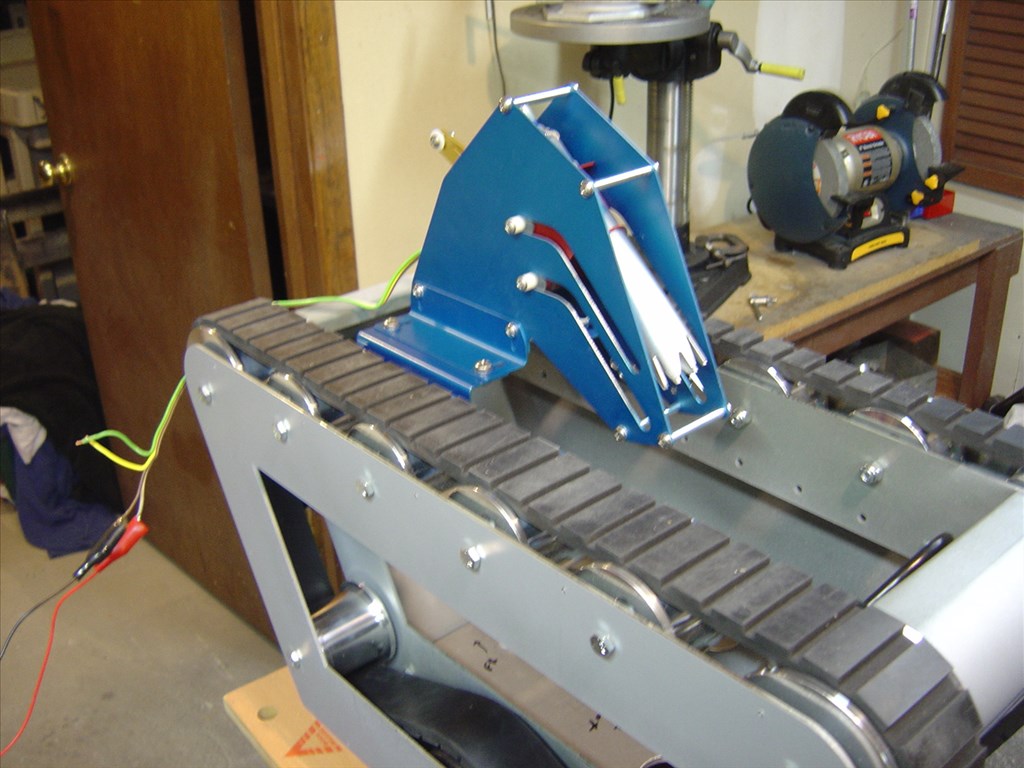

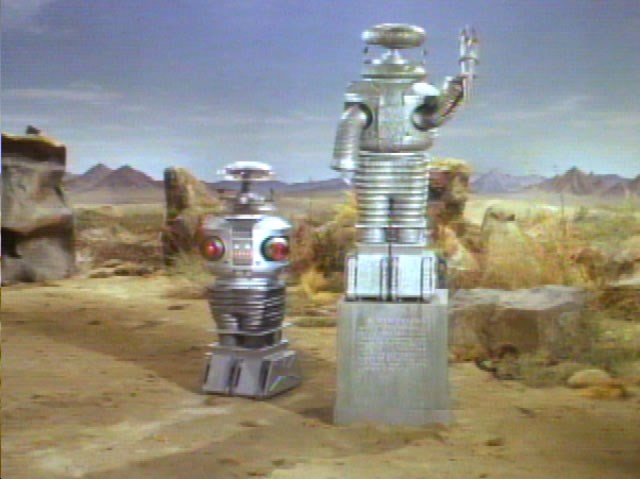

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

Bhouston's Inmoov Doing Math

Ezang's My First Video Of My Metal Arm Gripper Nov. 7, 2019

-635353562186322812.png)

Hi Dave, Rex

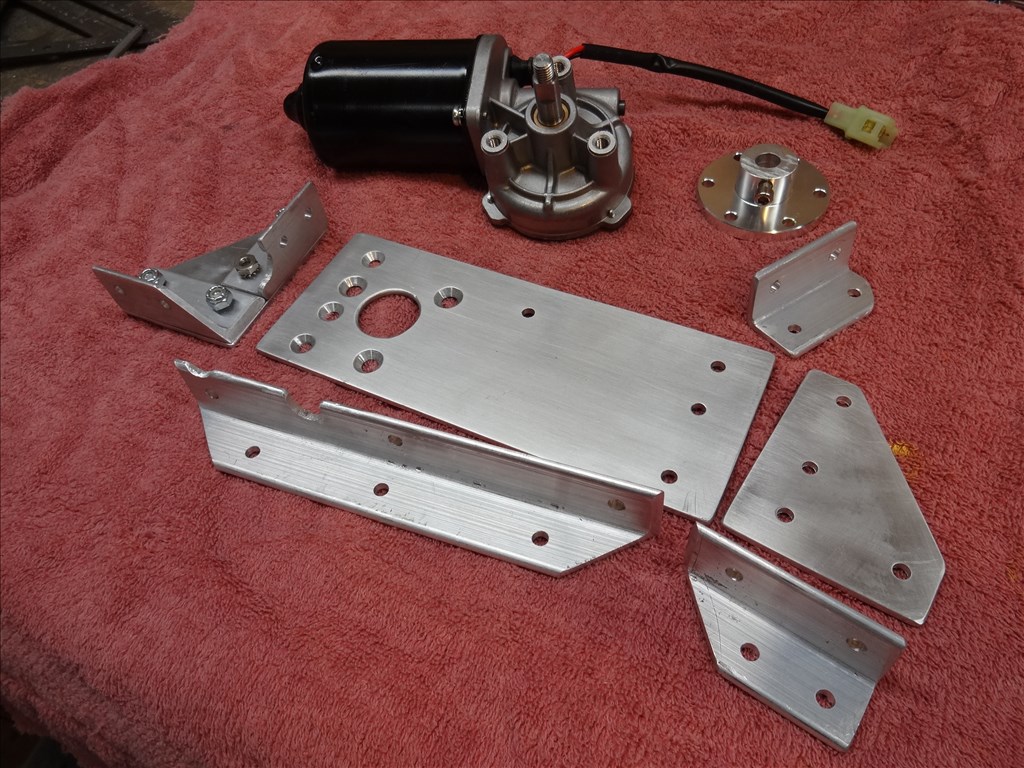

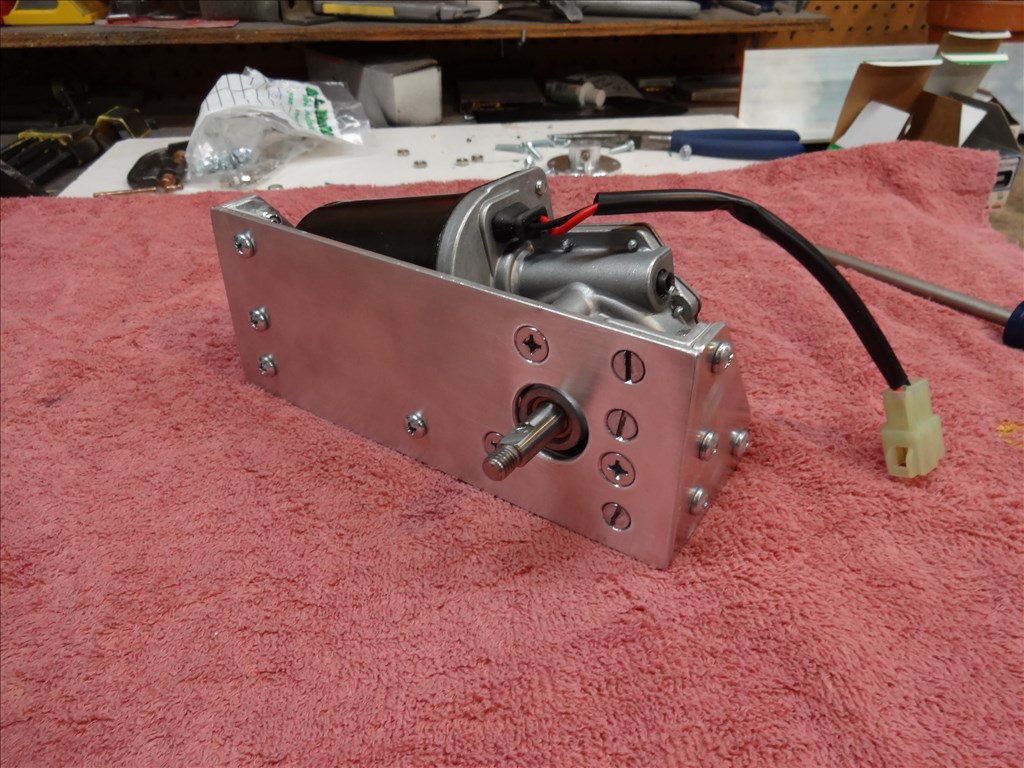

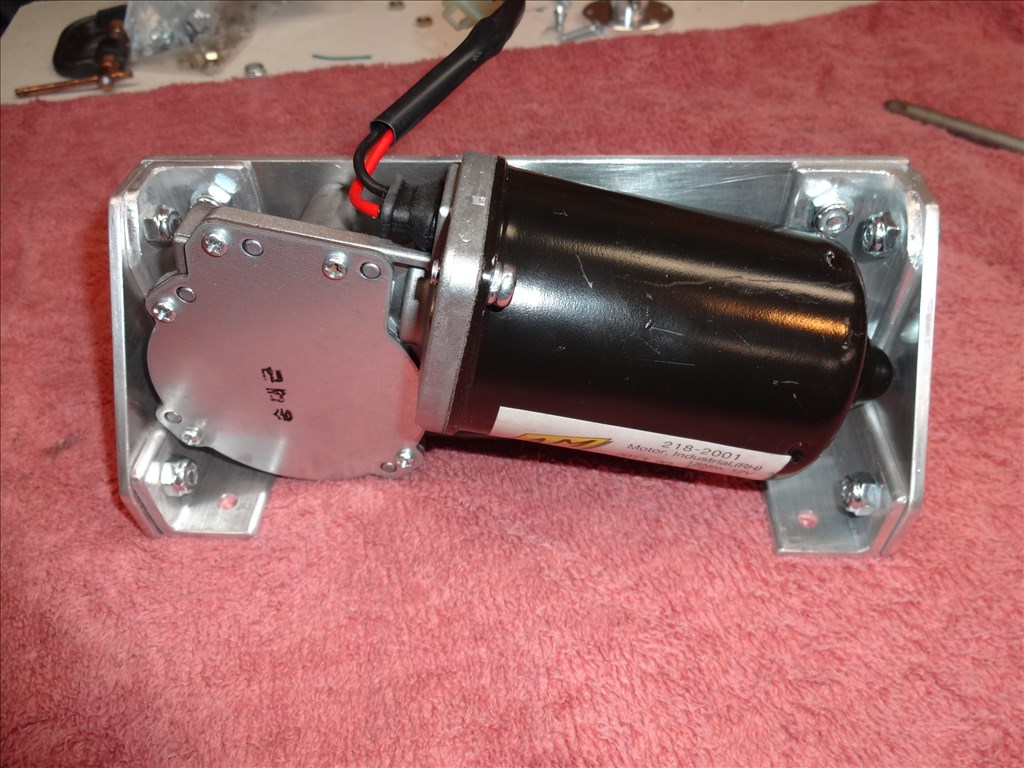

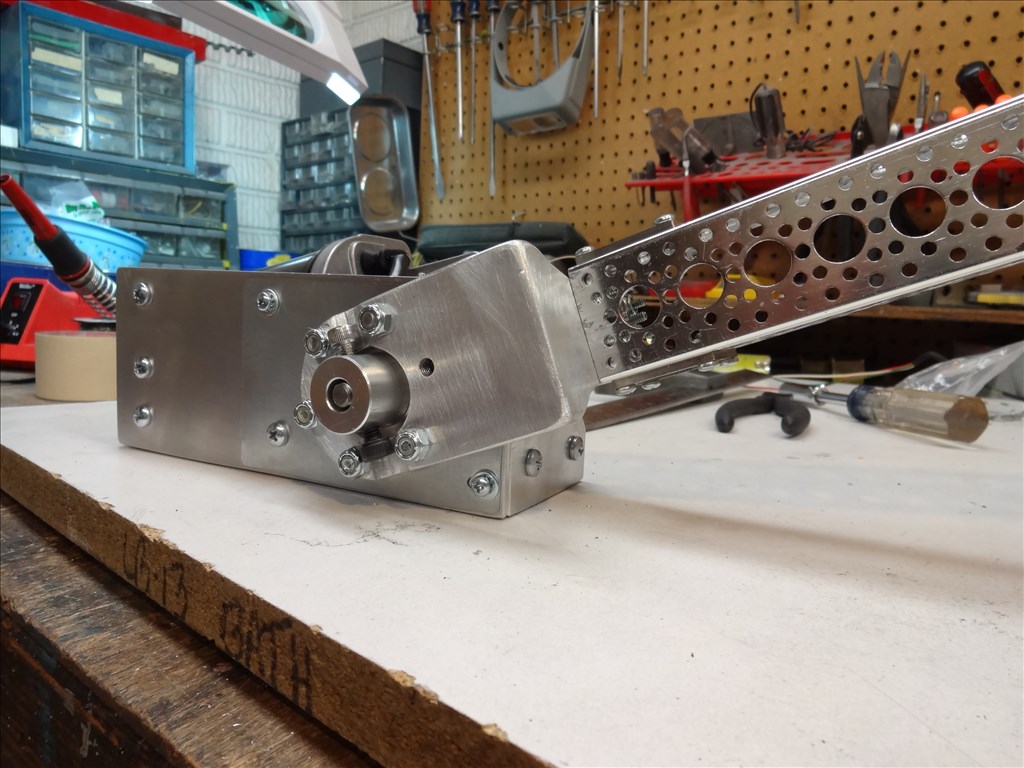

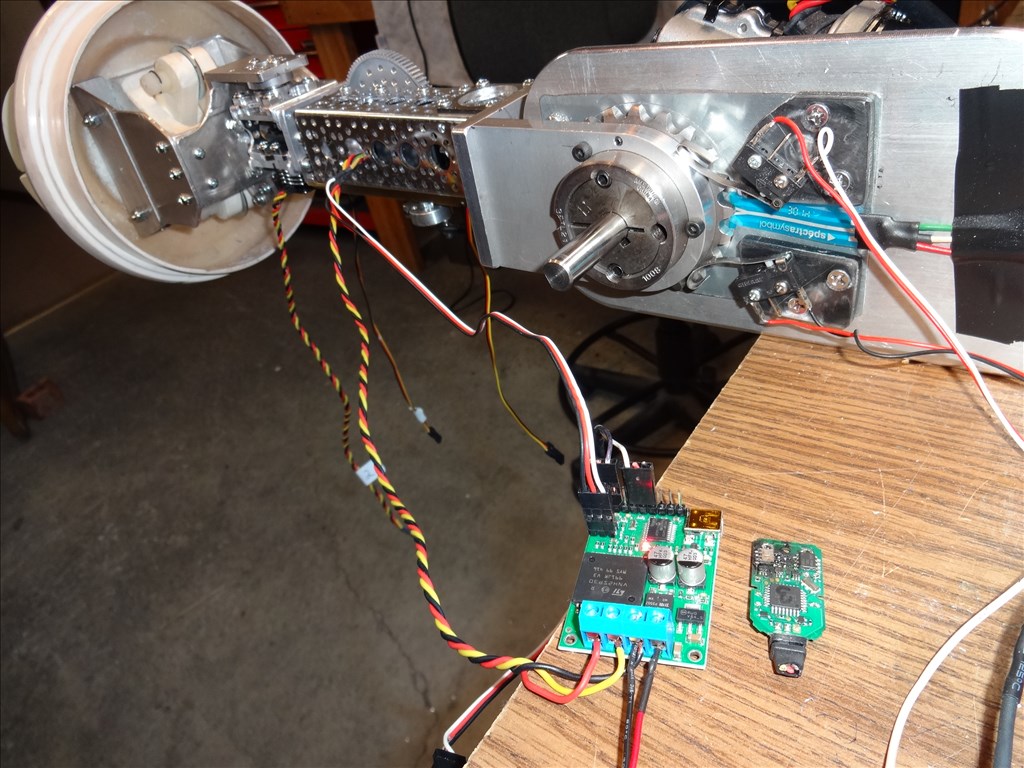

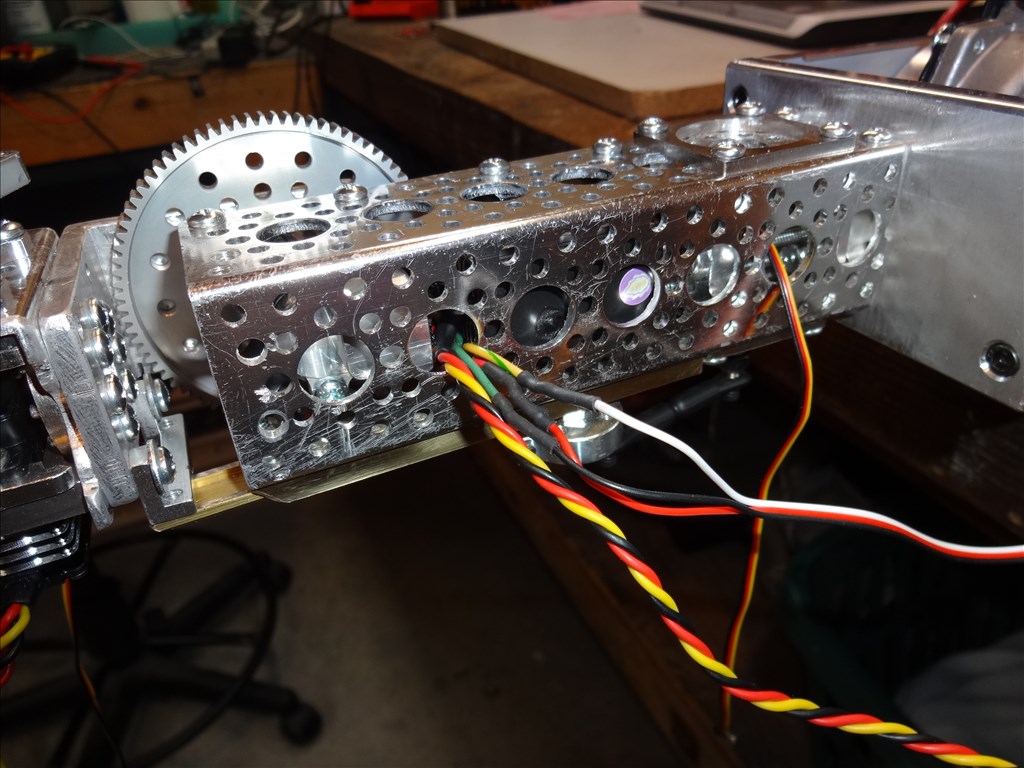

I think the motor drives that I sent you should make great arms for a B9 size robot if the motors can fit in the arms rubber boot material. You would need 2 coupled drive motor for the shoulder. These motor drive makes an amazing high torque, precision movement and very quiet arms, like you will see in the video below.

If the motors work out for your arm application, I could send you some more if you need them.

Tony

Hi Tony,

I do plan to try to use the motors you very kindly sent me. They seem like they are just what I need and watching your video I see they are close to the speed I would like to see. The best part is that it looks like they are strong and silent. They should also fit nicely into the arms I have.

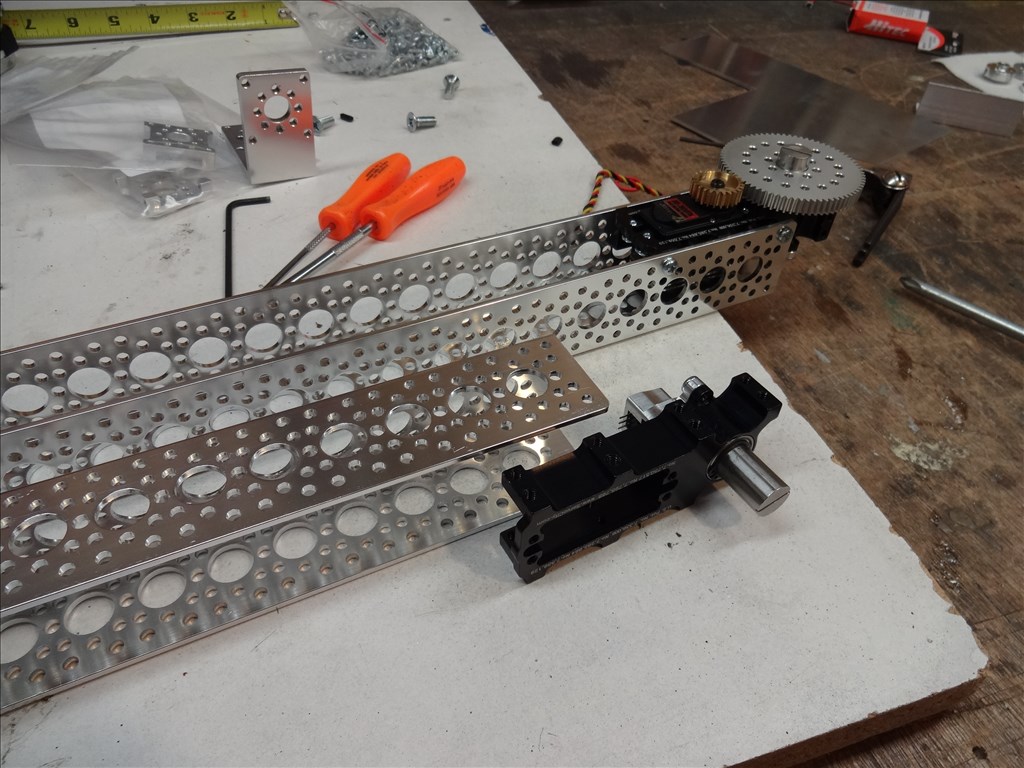

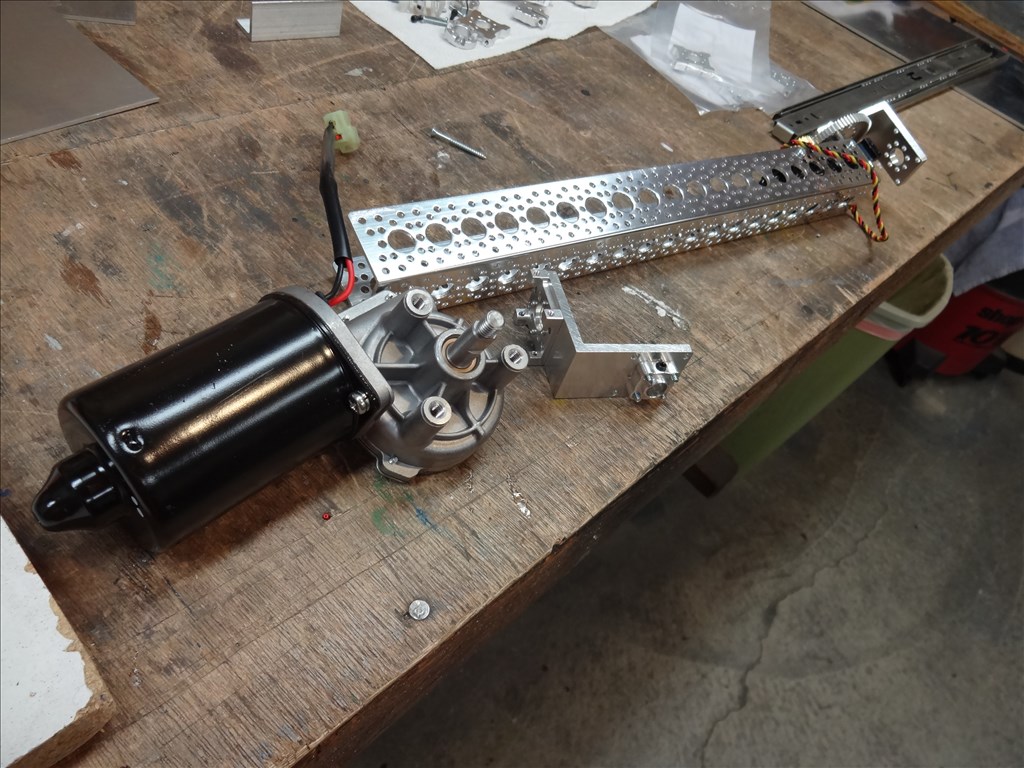

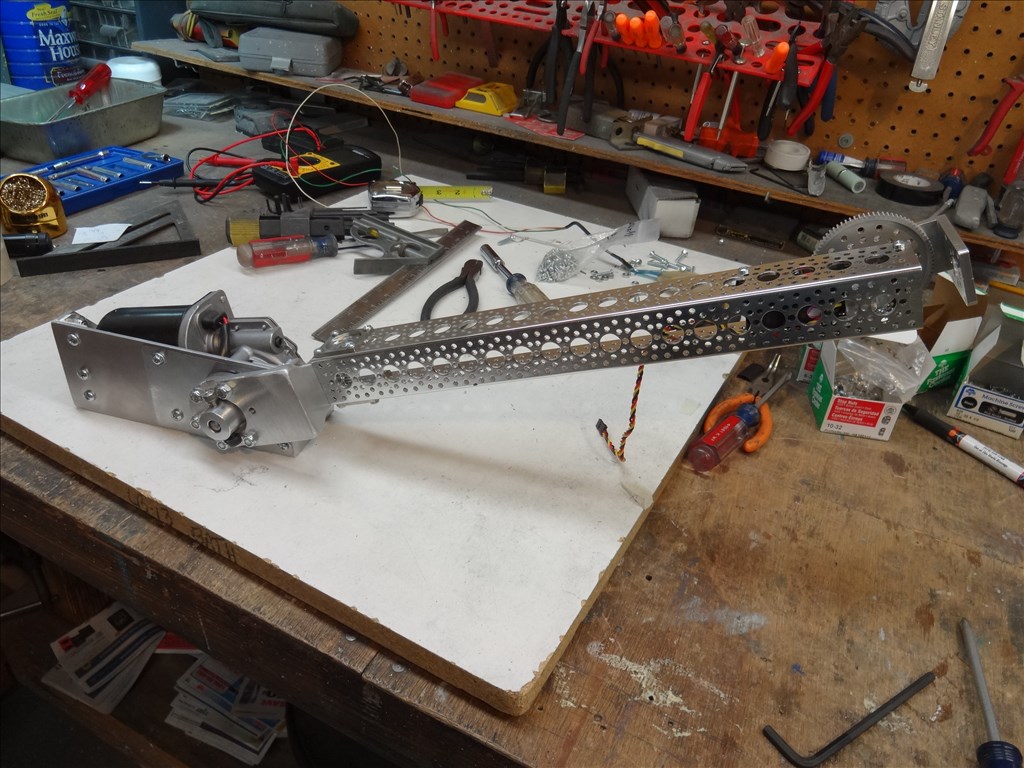

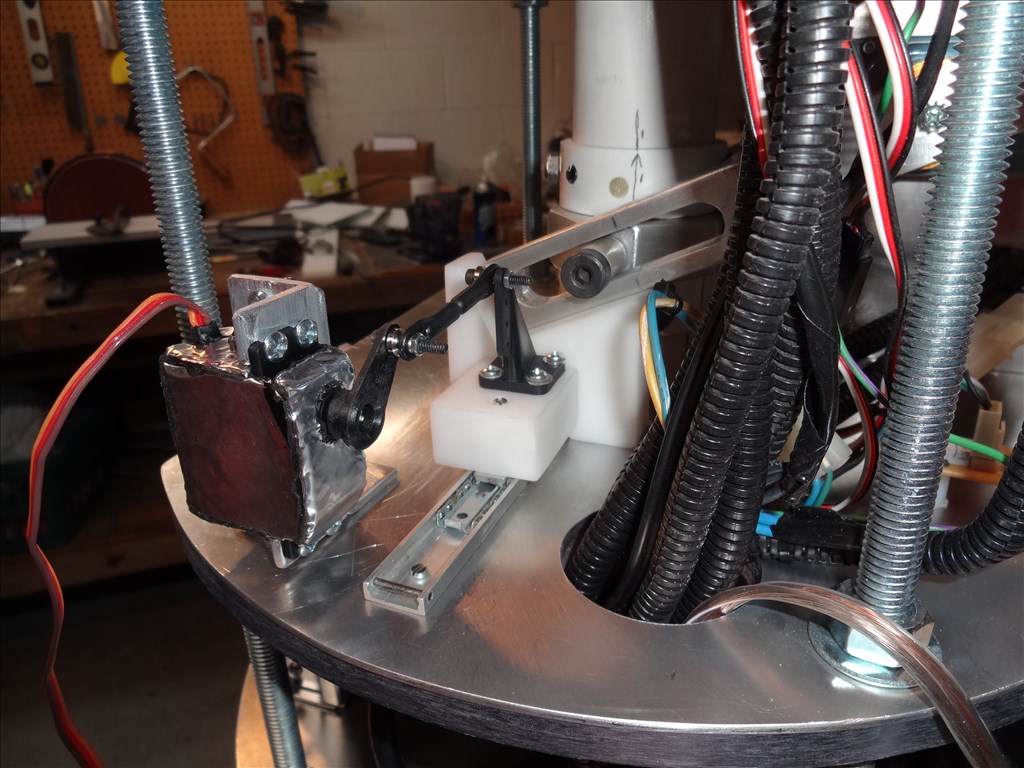

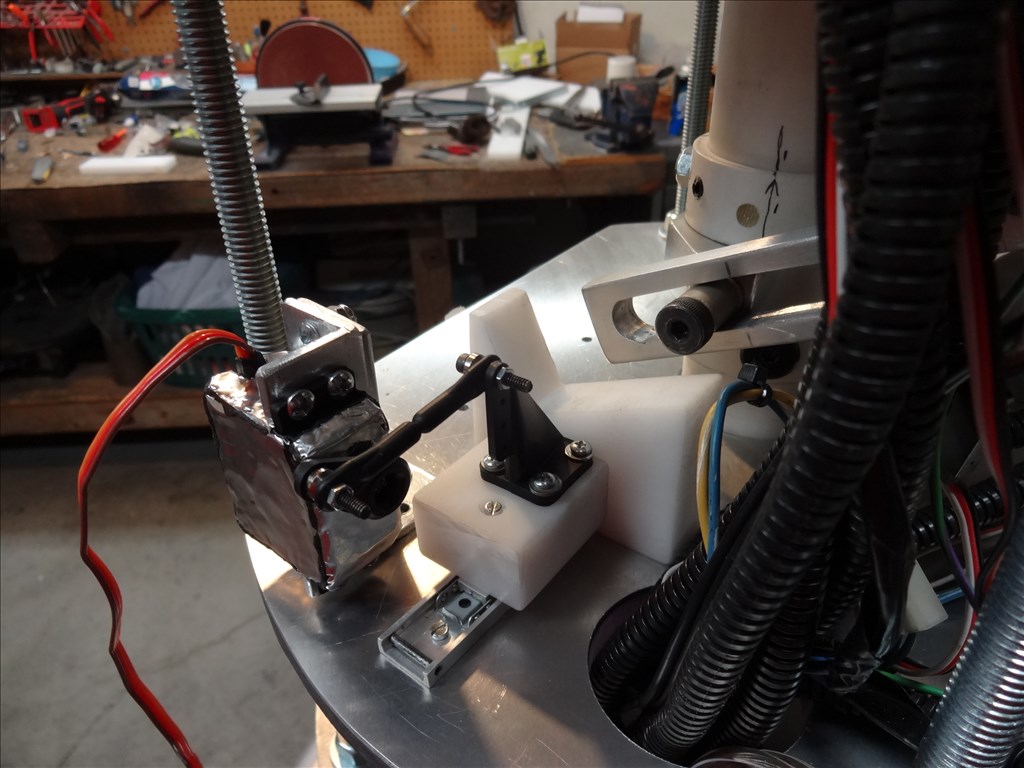

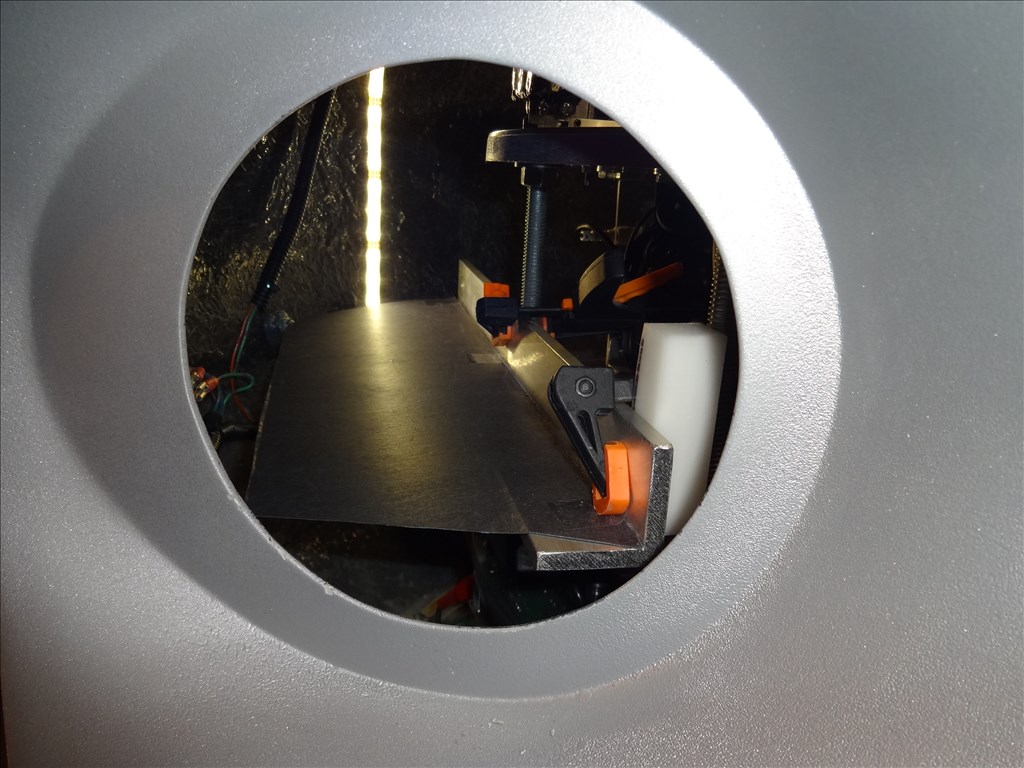

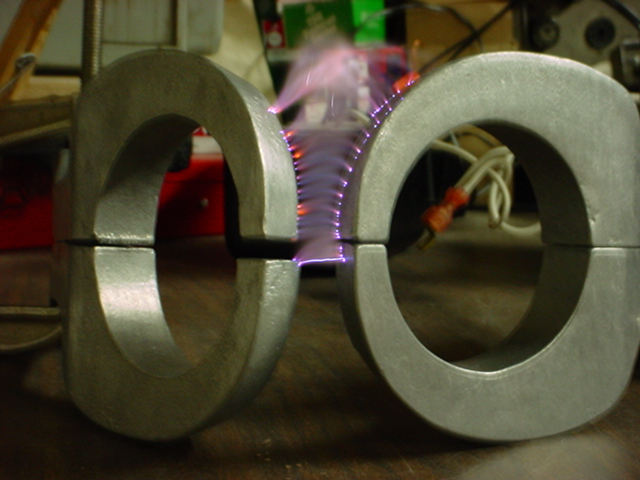

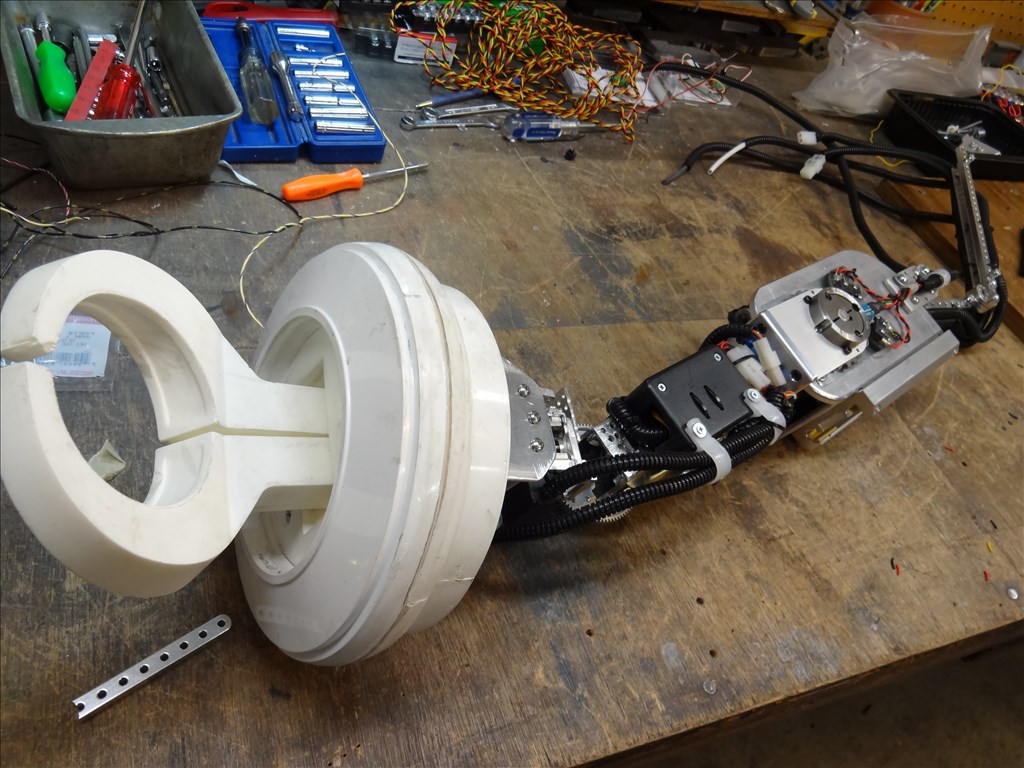

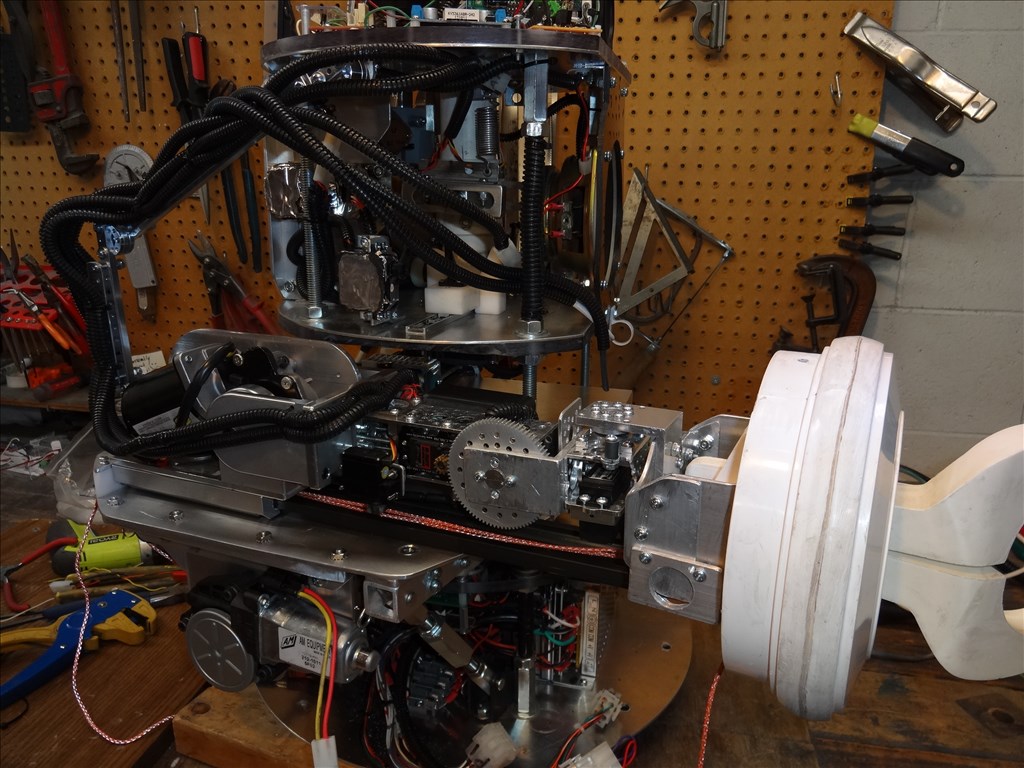

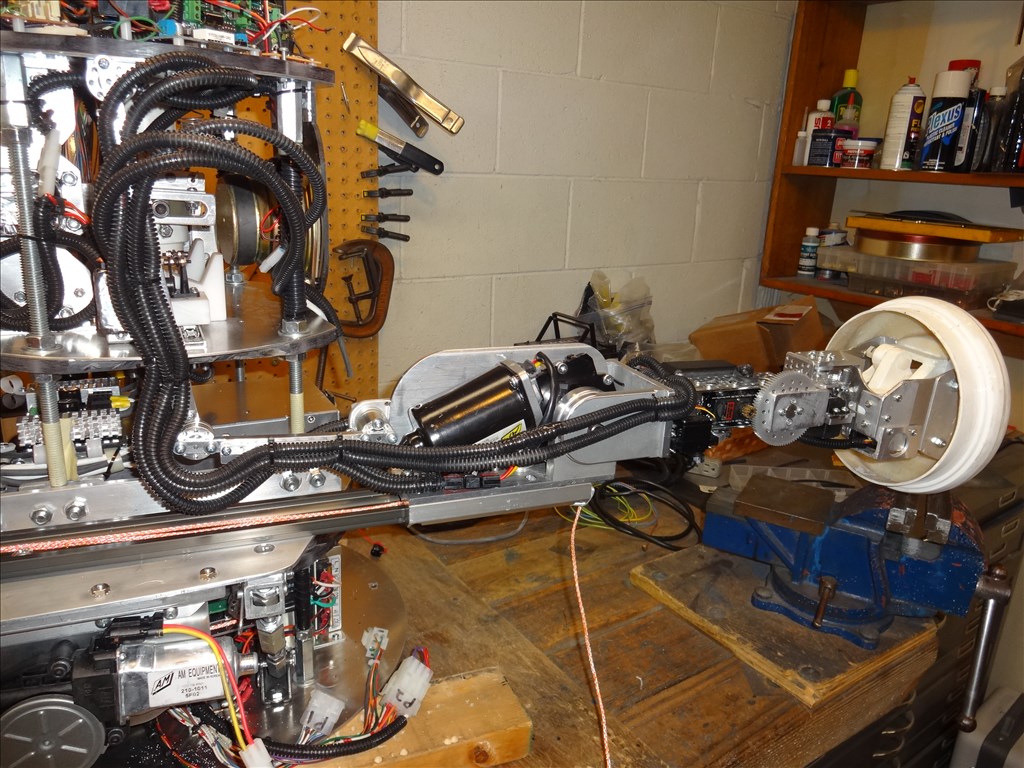

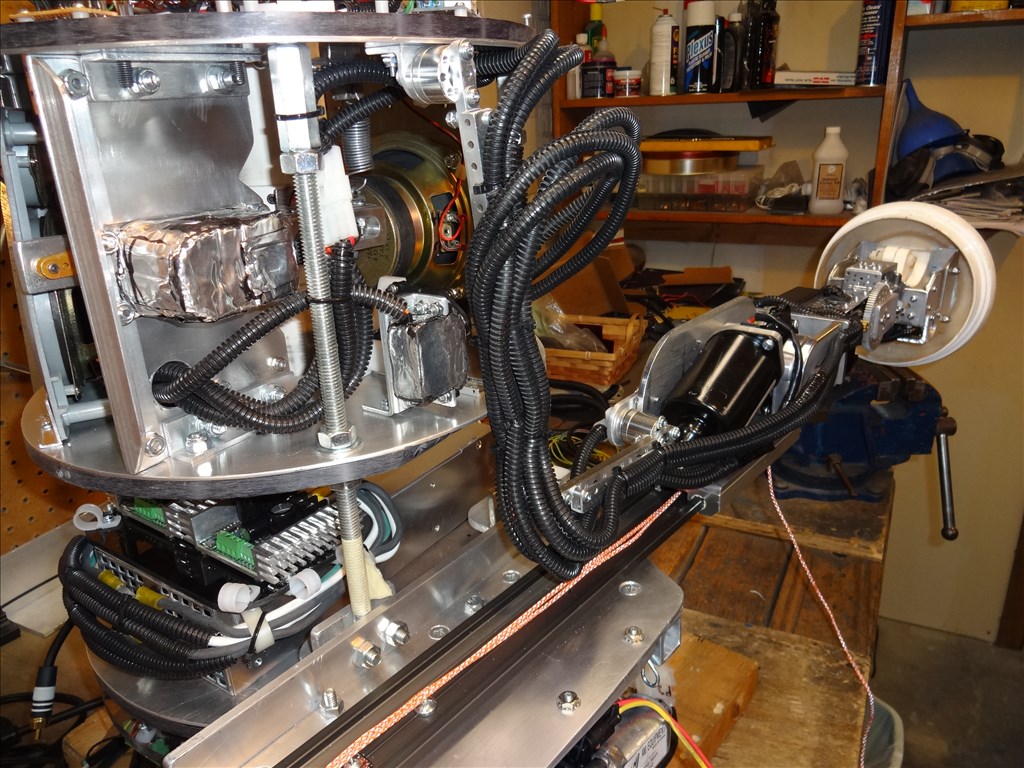

I just don't have the time these past couple months to do much wrench turning on the robot. What time I have had I've been gathering info and trying to come up with the best way to put this all together. What I have decided is that I really don't need a shoulder motor. From watching the old TV show and looking at pictures, the actor in the robot costume (Bob May) hardly raised the arms at where the shoulder may be considered to be (which would actually be inside the torso). The arms slid straight out and then would bend them up and down and wave back and forth about 6" out from the torso. However he also did bend at the wrist which is about 4" below the claws. If I follow this example I would need the arm assembly to slide straight out on a Linear Slide. Then on the end of the Linear Slide I would have an 4 way elbow joint that would end up about 5" out on full extension then another 4 way wrist joint about another 15" or so out just below the claw. Of course at the end of all this in the claw assembly I would have a micro servo to open and close the claw (and maybe another one to spin it back and forth). The claw assembly should be the easy part. In the end it would look something like from the outside:

Again as I stated before my only concern with the motors you sent is that they not be fast enough to satisfy my taste. Didn't you mention in the past a way you were able to get max speed out of these motors? The other thing is that ARC has support for relative servo positioning and servos seem like they would be easier to get natural arm movement with the 4 way joints. I like the silent strength of the motors you sent but my concern it I may not be able to get the natural movement using only the motors built in pots and EZB's ADC ports.

If you have any comments or ideas I'm all ears.

Thanks again for all your help and the time you've spent with me on this matter, Dave

Hi Dave

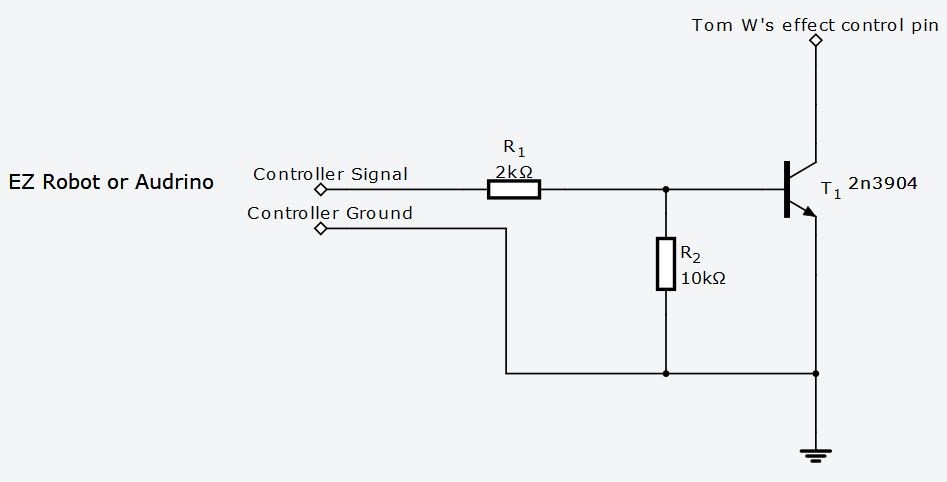

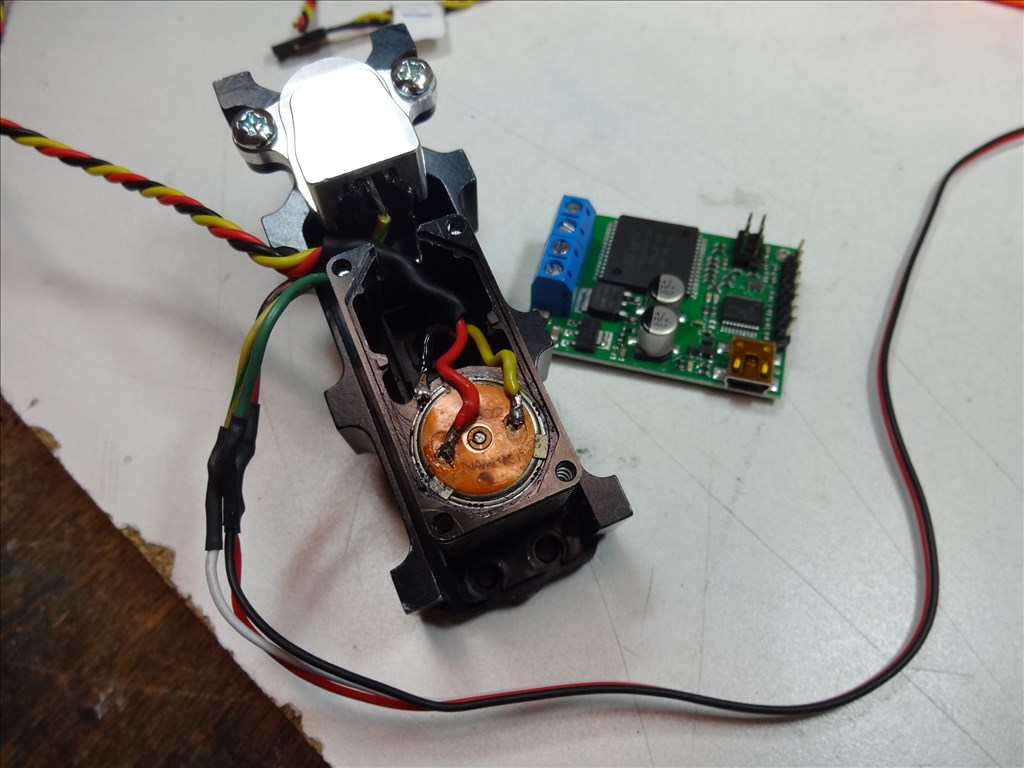

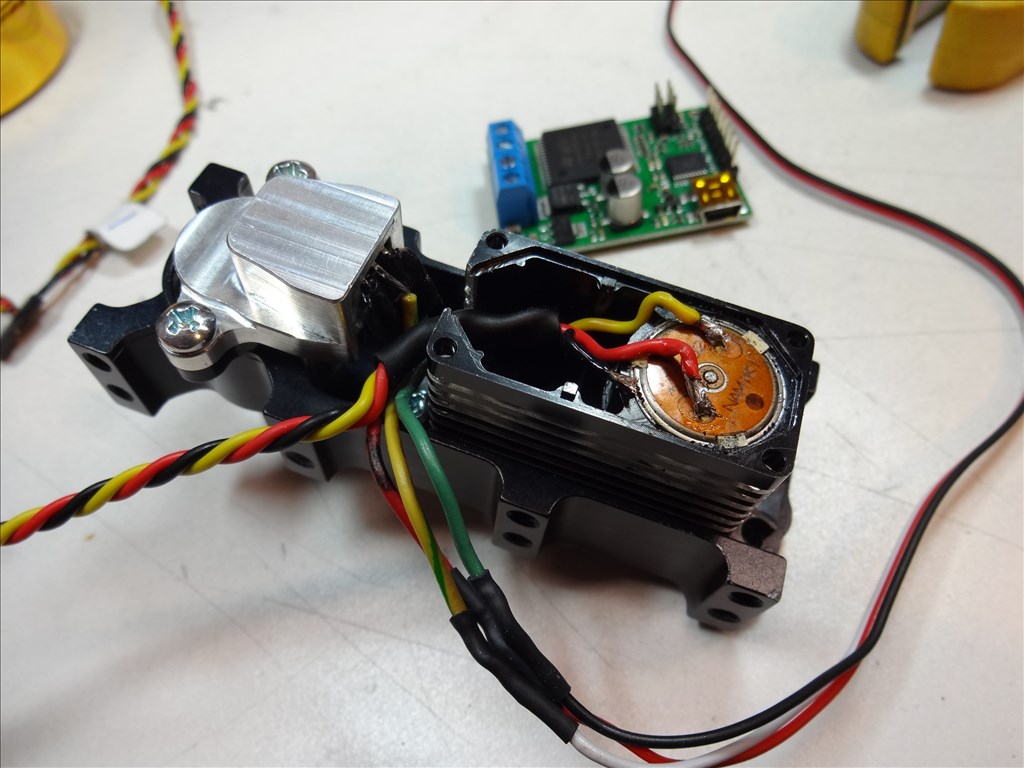

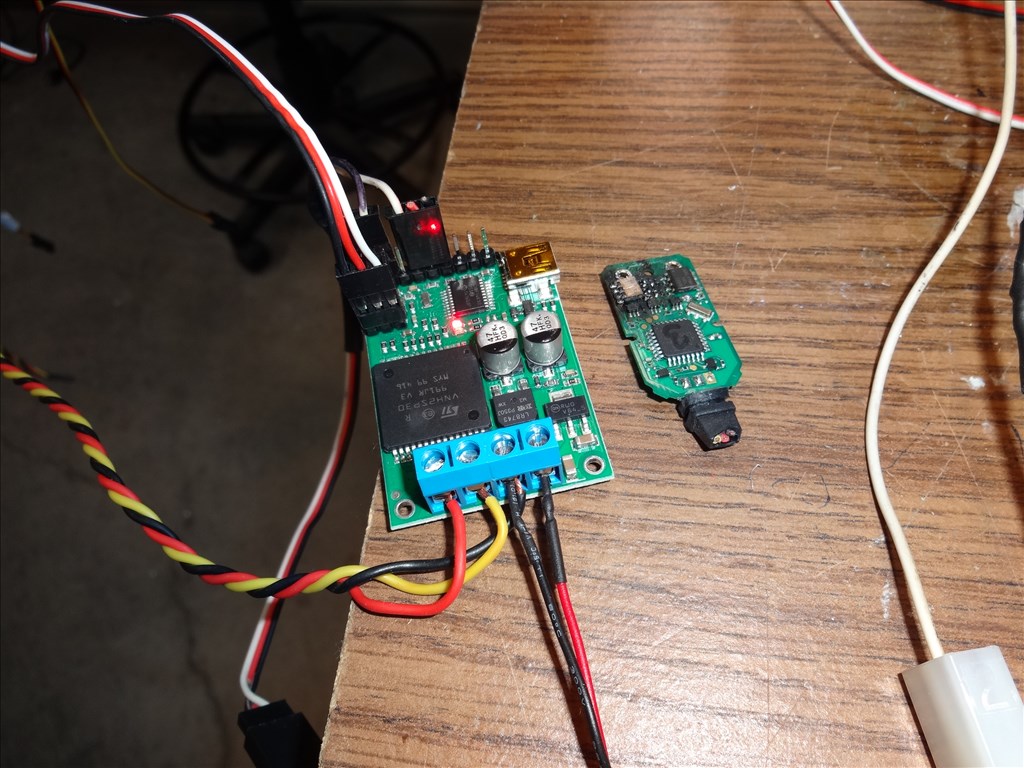

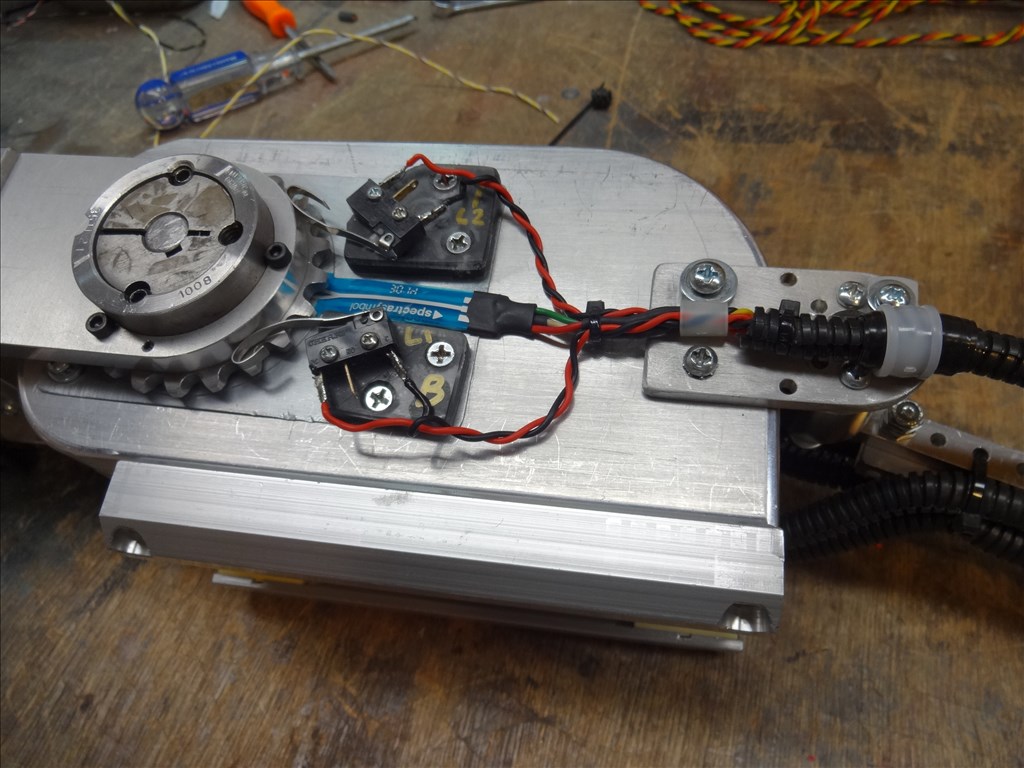

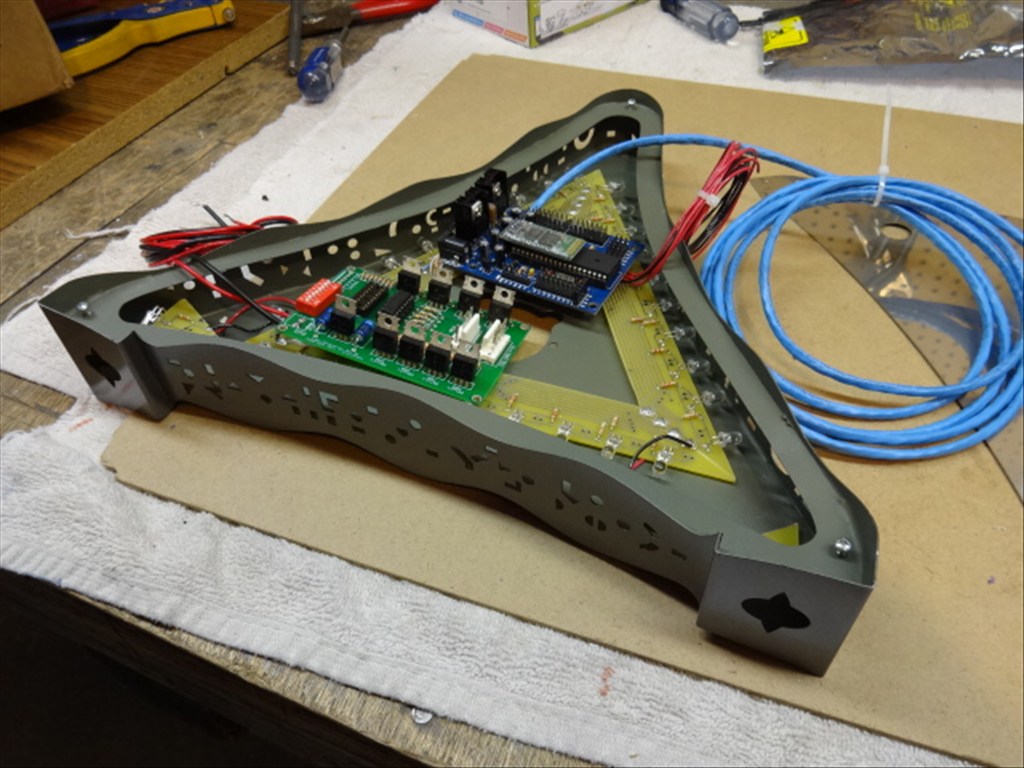

As you probably know I have produced the pre-production smart servo board for these motor drives.

But it is only a test production run (of 20 boards) so I do not have any spare yet, later when the production boards are made I will send you some, but that will be some months away. I take the shoulder motors up to 18volts (via a buck convertor) and get very good speeds.

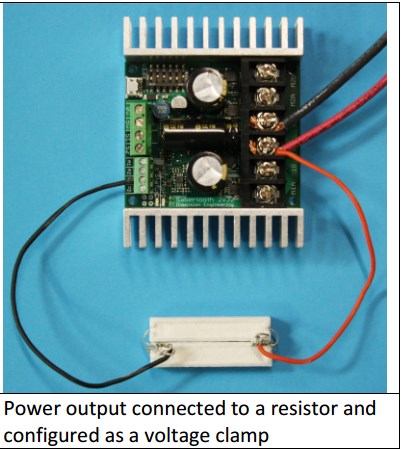

In the meantime Rex is going to use the kangaroo X2 board and this should work very well with these motor drives, these drive motors are quite amazing and only have peak currents of 500mA even at very high torque, so you will not need a high amperage motor controller (that the X2 plugs into), in fact because of the low current requirements of these motor drives a L298 H bridge happily powers them without the need of a heatsink as you can see on my controller board.

Both ways these motor drives will act as standard servos as far as the EZ-B is concerned, so it is exactly what you are looking for.

Tony

Oh ya, the kangaroo X2 board! With all that has been going around my home these past few months I had forgotten about that board. Thanks for reminding me. I will for sure use that with your motors.

Just to be clear, it looks like I'll need one Kangaroo x2 for each motor? Is this correct? EDIT: Da! X2 means it will control up to 2 motors. Looks like it mates up to h bridges that can control 2 motors.

Too bad your servo boards aren't ready yet. They seem to be the answer to all my needs. tired

I'll have to take you up on your offer of more motors. I'll need at least 4 for each arm and I only have 4 now. However let's wait a few weeks till I get my design firmed up.

Thanks once more Tony! Dave

Awesome perseverance Dave! Its hard to beat a human actor inside a robot shell! That's Hollywood for ya I know the goal is to emulate as close as possible to the TV B-9 and you will be successful!

I know the goal is to emulate as close as possible to the TV B-9 and you will be successful! imagine trying to create a robotic C3PO

imagine trying to create a robotic C3PO

Thanks irobot58! Your input means a lot. Imagine trying to create a robot C3PO would be something on the level of Disney would have to take on (or DJ).

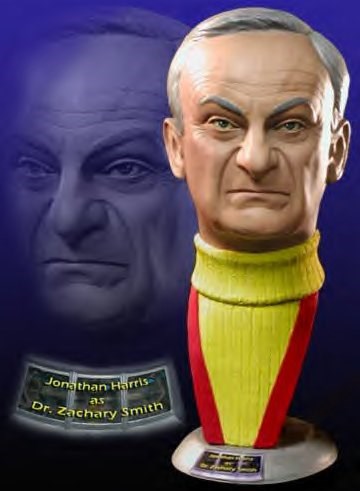

Your B9 will mimic the TV robot so well that people will think someone is in there. Who knows maybe some fans will want to use yours in some fan made movies. They will need someone who can play Dr. Smith well! I need to find time to work on my B9 (large RC toy B9) that I got from ebay. So much to do ! Funny irobot58 said something about C3PO, because I will be starting up my old C3PO project again soon. Now that my 3d printer is working well again I will make the needed STL files to print. My C3PO will be under 1/2 scale , but he will seem alive.

My Working C3PO Link

Thanks for the kind words mcsdaver. If at least he looks close to the TV robot I'll be happy.

Your link doesn't work. I'd love to see what your working on.