Hello all, I am getting back in the saddle making robots now that I am moved into my new home and settled into my new job as a technician maintaining the Fiber Optics network in Chattanooga TN.

IM BACK !

By jstarne1

— Last update

Other robots from Synthiam community

Doombot's Archetype Finally Complete

Archetype droid using EZbits and an EZ-B: expandable design, currently on a 2A regulator with supercap fix; battery...

Tfitzrandolph's Custom Robot Build Wobble Frog

Wobble Frog robot toy built with EZ-Robot IoTiny, LIPO and 270 servos, controlled via Synthiam ARC scripting to create...

Moviemaker's Bob And Marty

Photos of Bob, Marty, Leaf & MEL and Fred - quick snapshots uploaded to share and enjoy.

-635971125254815084.png)

-635971009768280111.jpg)

-636393423097260688.jpg)

-636337988865509663.jpg)

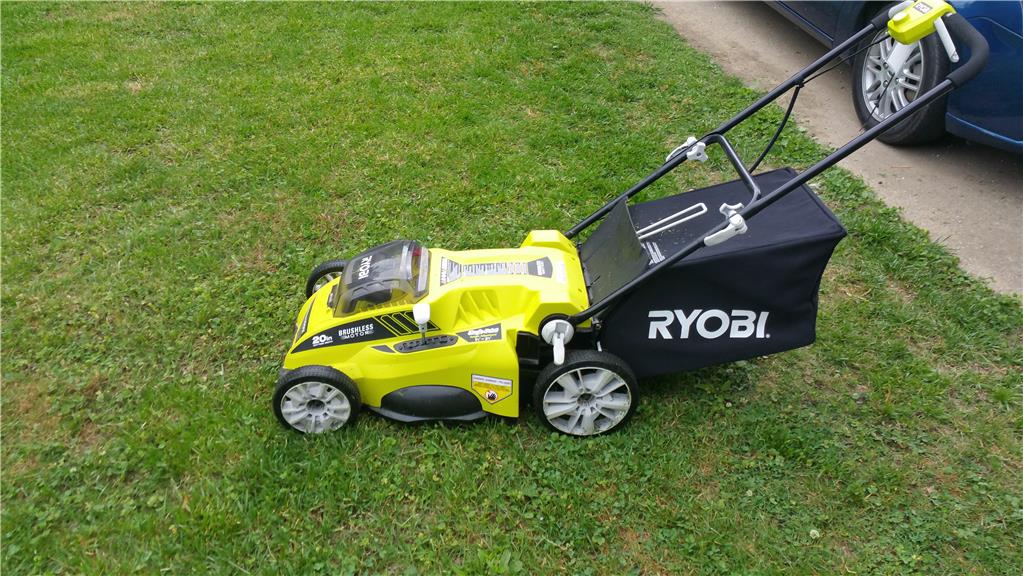

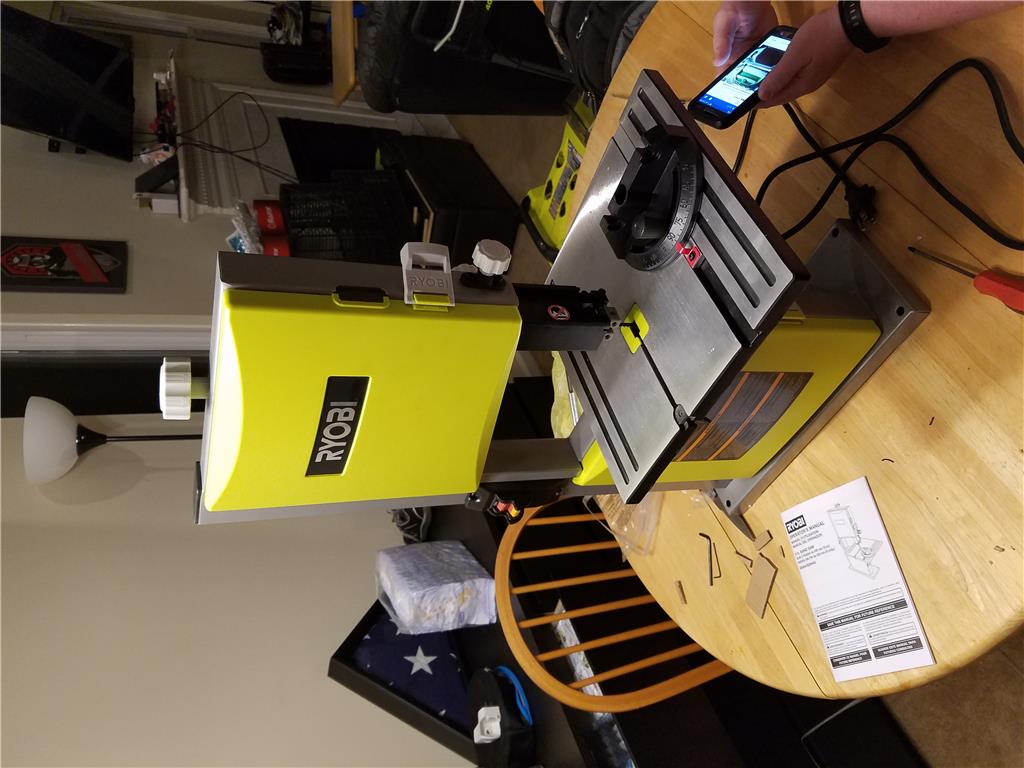

Man, That's a cool machine. cool Can't wait to see it eating some grass!

My girlfriends kids look over building , they are so interested! Especially the 2 yr old

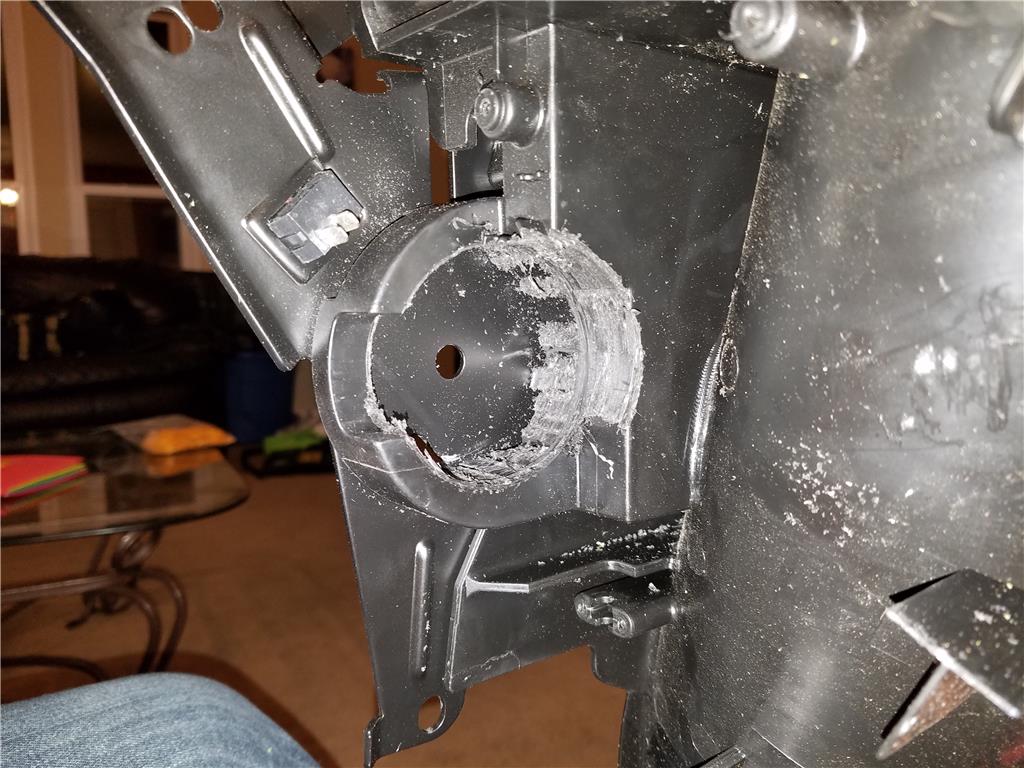

Yes he totally drilled a hole! , with me starting it and holding the drill ofcourse as he pulled the trigger

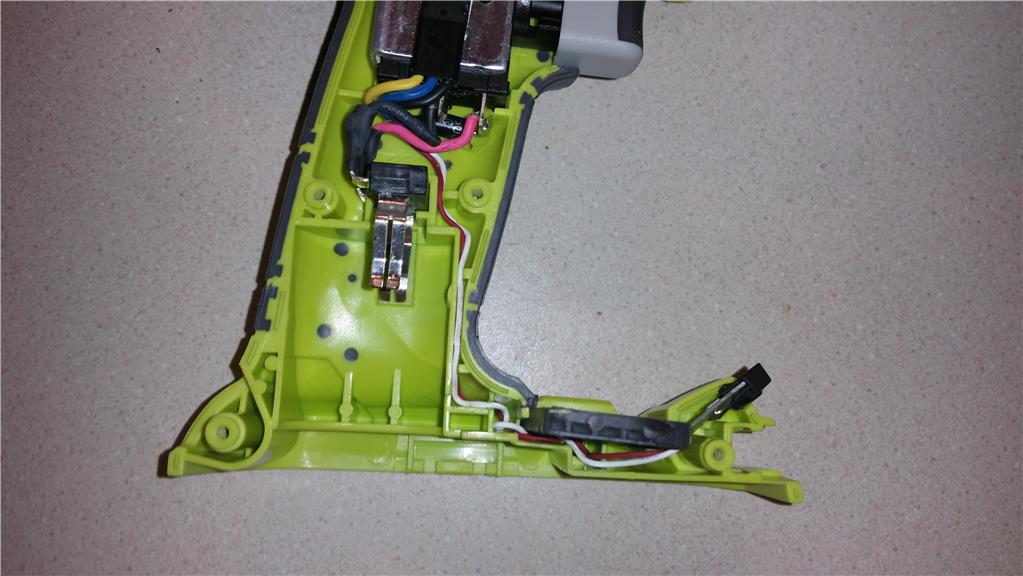

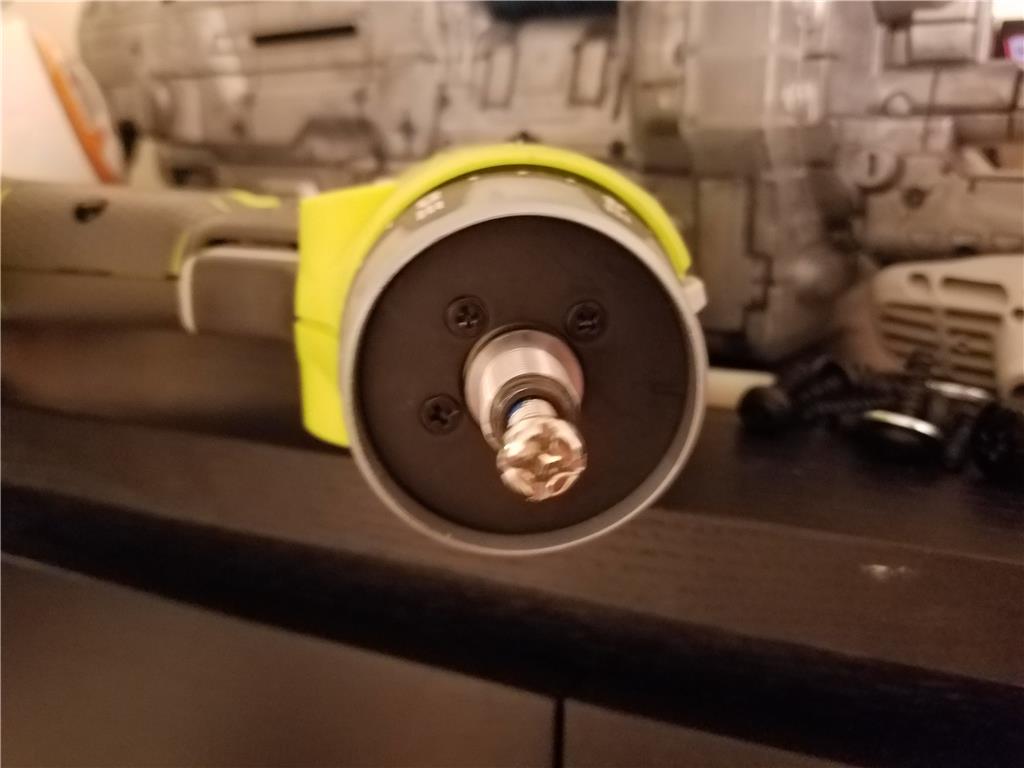

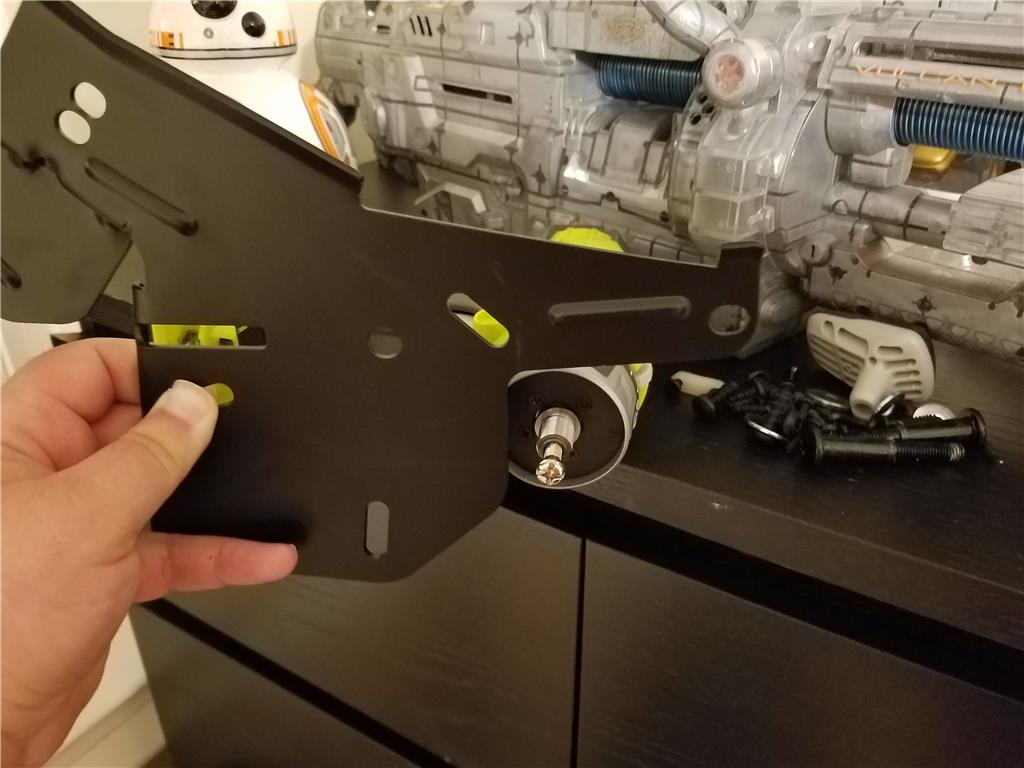

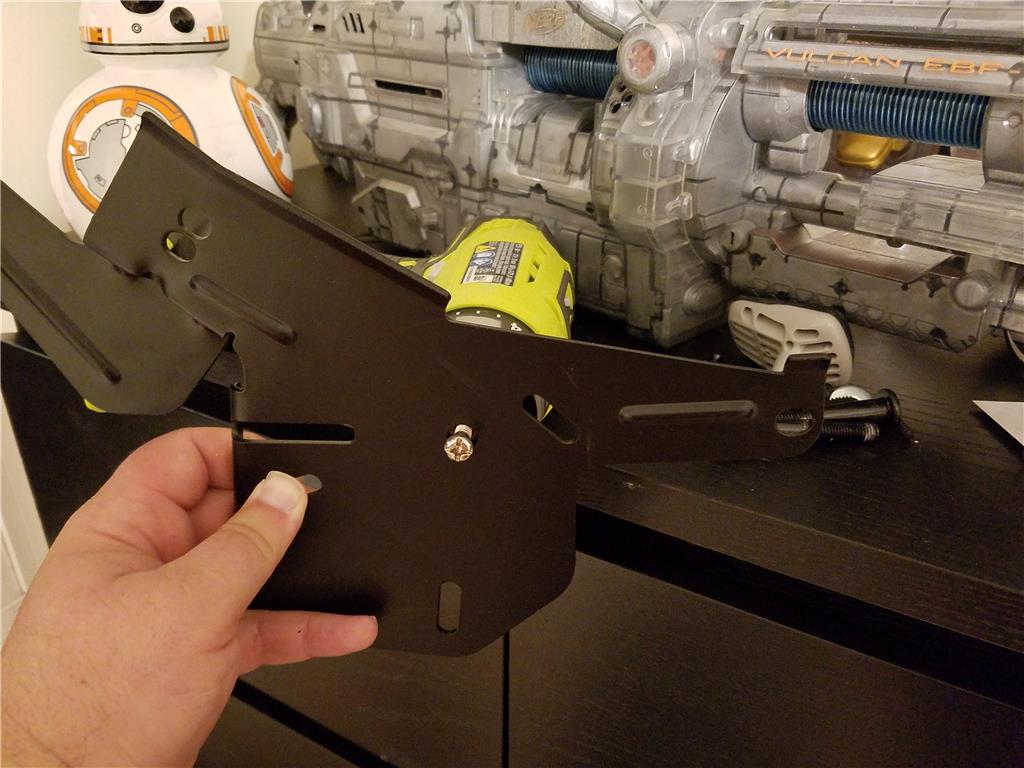

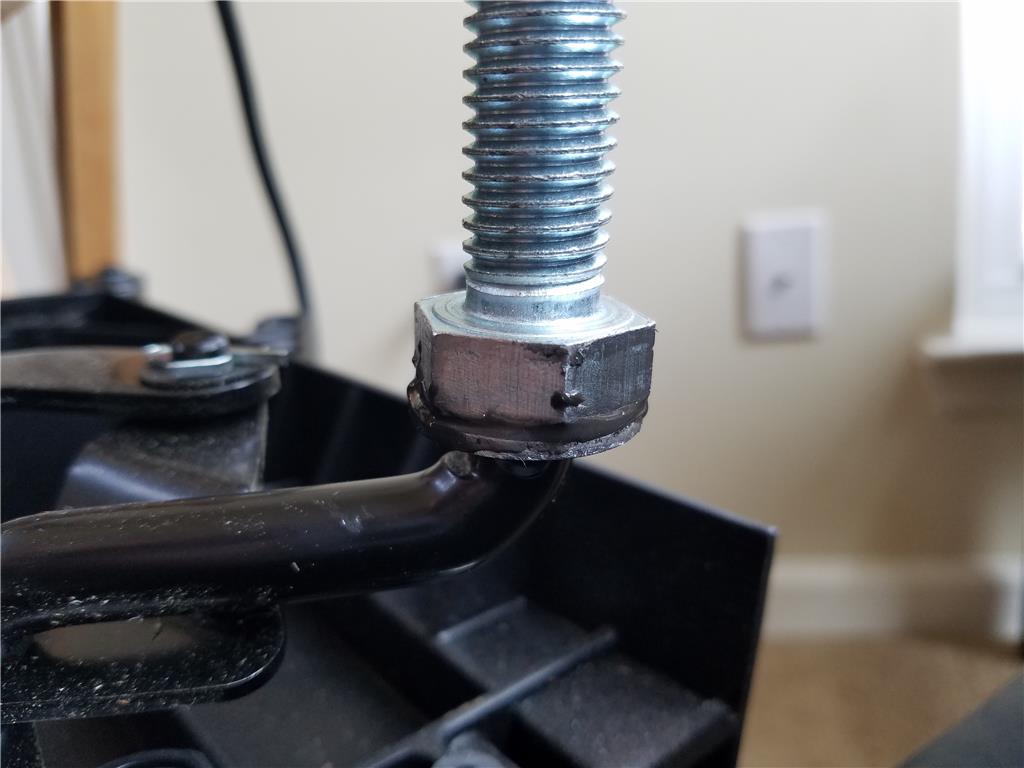

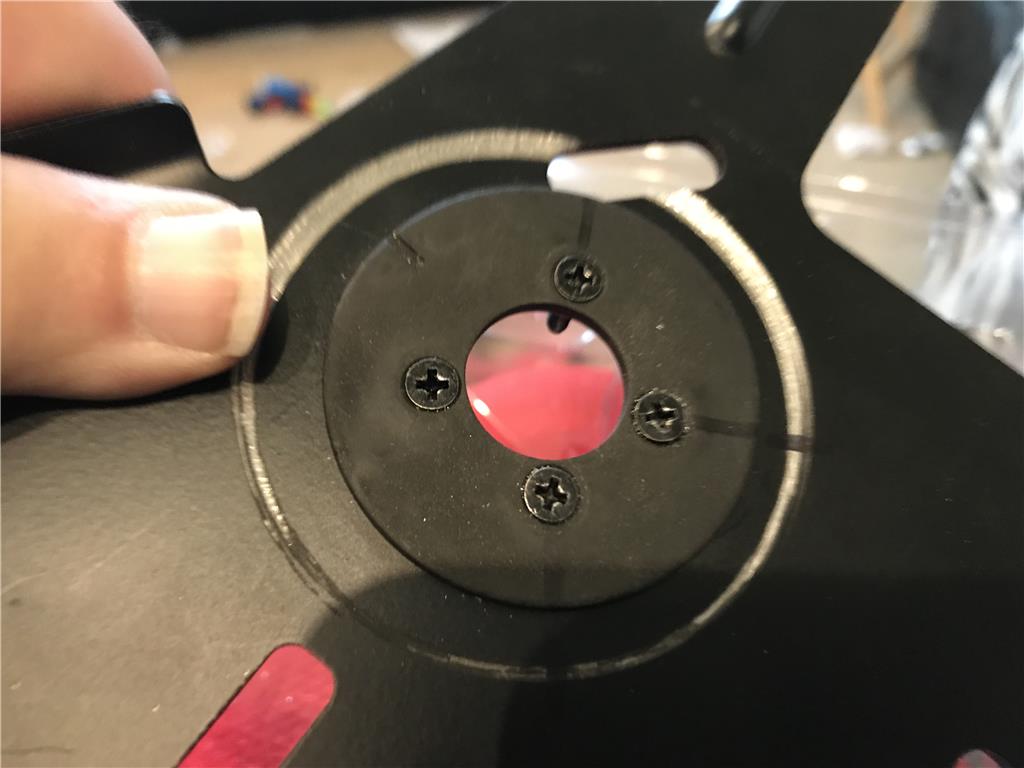

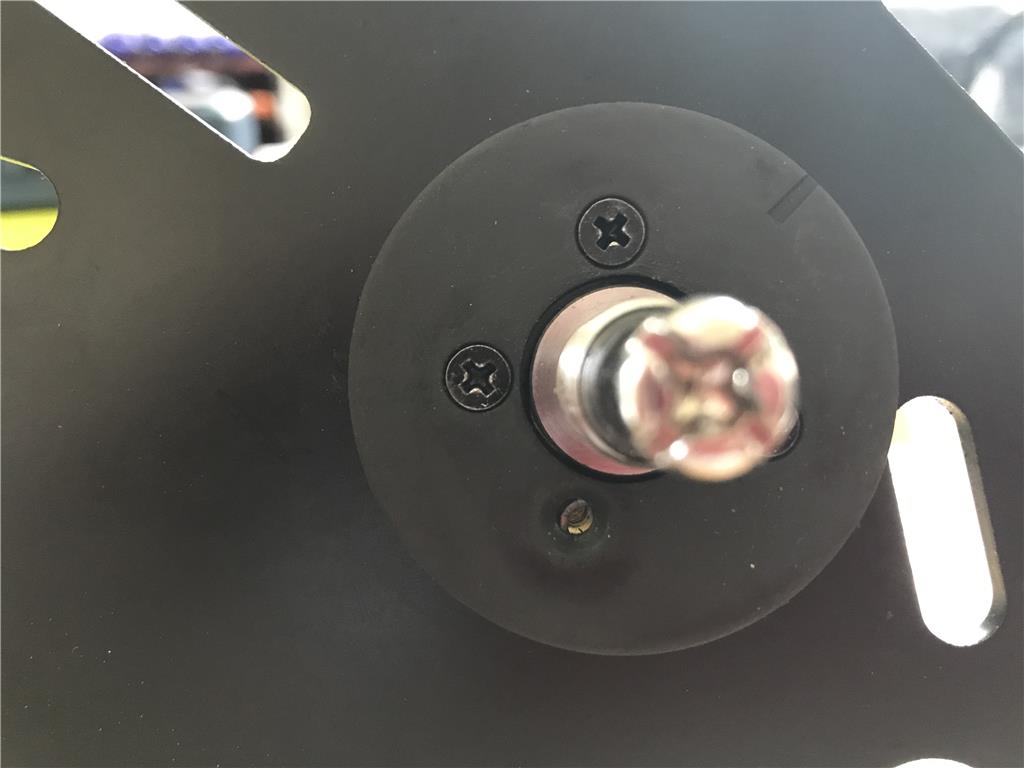

I decided the first half of the motor mounts could be bored through the frame , then run a large bolt through the drills motor casing that was originally intended to be the mount for the second handle grip. I believe I will improvise with pvc pipe to make a sort of cradle for the other half. I can use instamorph to make a glove molded fit to the motor and cut a couple slots to feed soothing like a hose clamp through that can be tightened down.

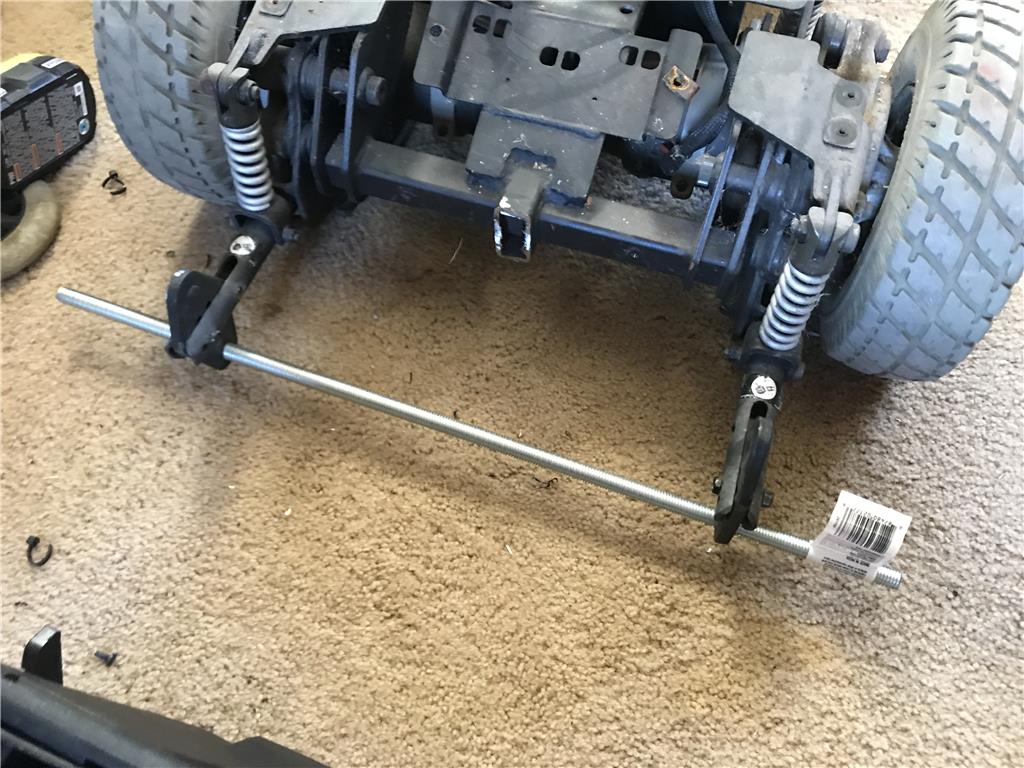

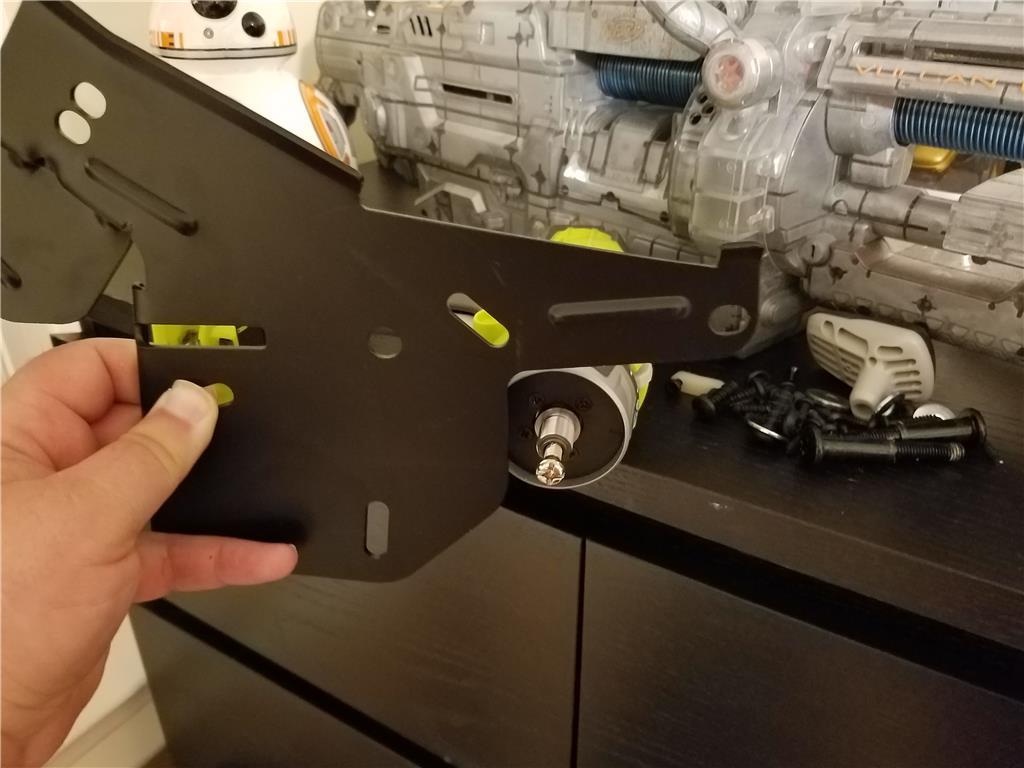

I believe I have decided on keeping the original handle mounts for the mower since they are all steel and have feet that make storing this project easier by standing it up on end like so...

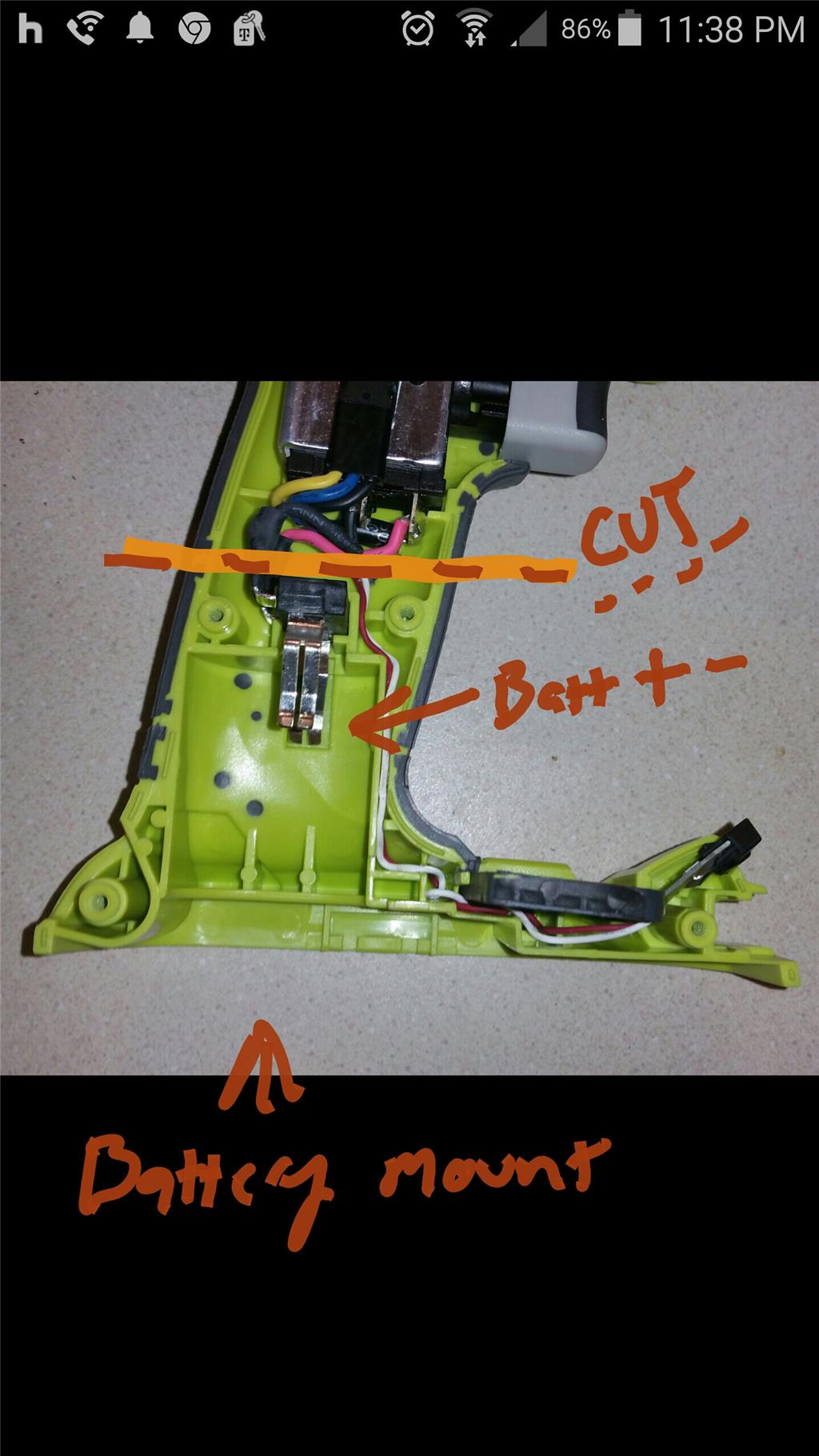

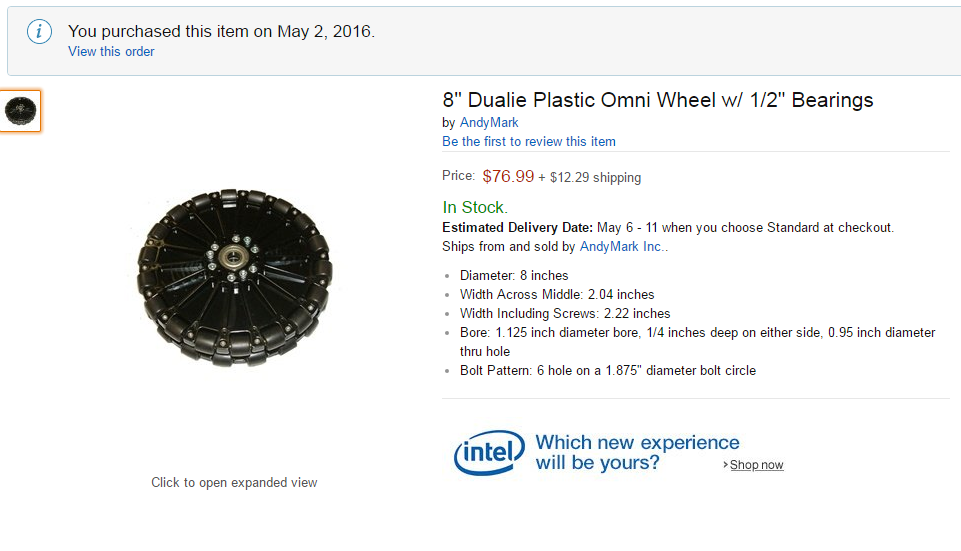

I am honestly still trying to figure out where I will mount the 1 or 2 18 volt drill battery connectors. There simply is not enough room in the battery area unless I compromise on having one 40 volt 5 amp hr battery instead of two , and also compromising on having only one 18 volt battery as well which the largest I can buy is 4AH.

Here are the two cut outs I just removed and a example battery pack. These are only 1.5 AH 18v , the 4AH is more than twice as thick, but the same footprint.

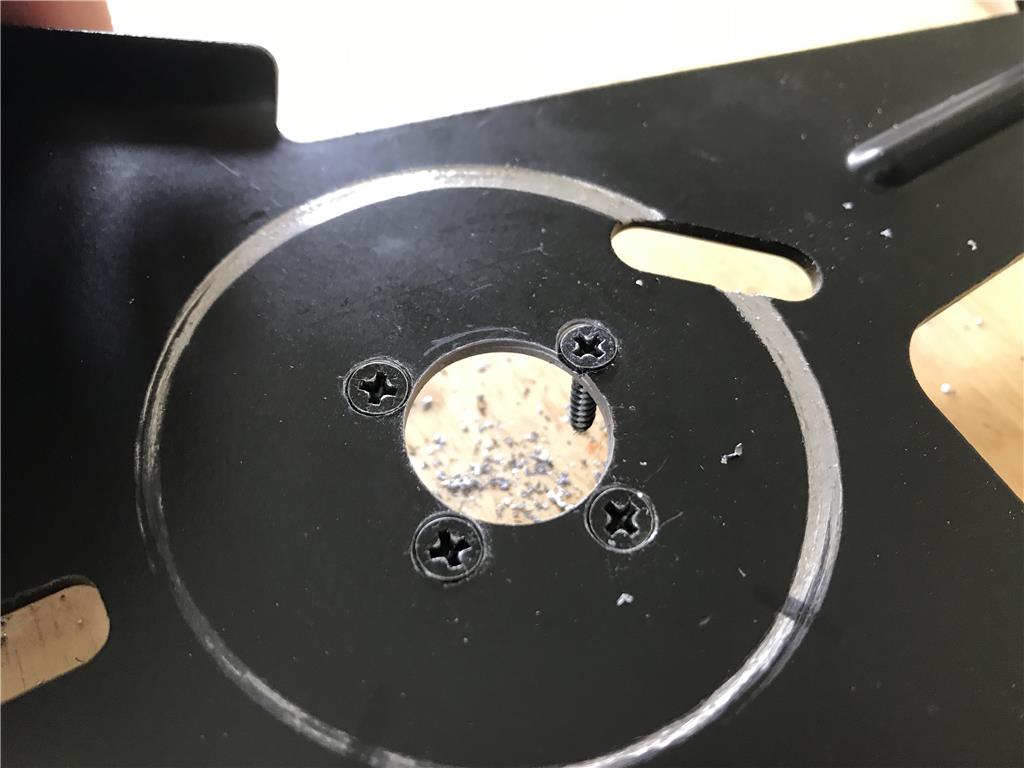

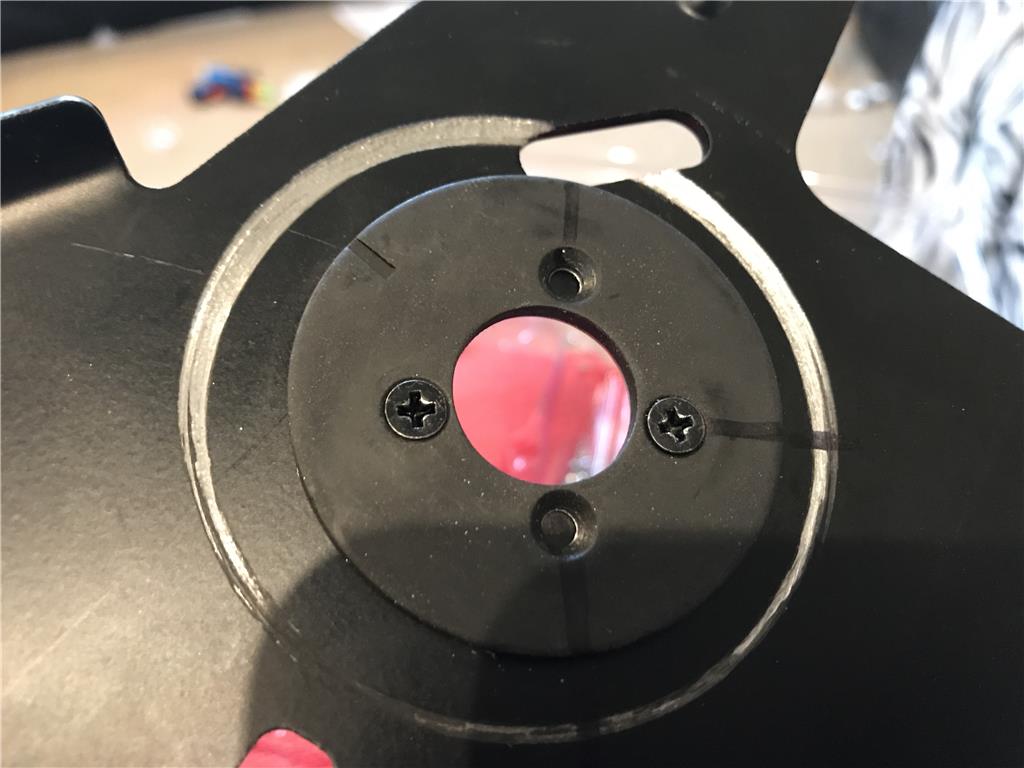

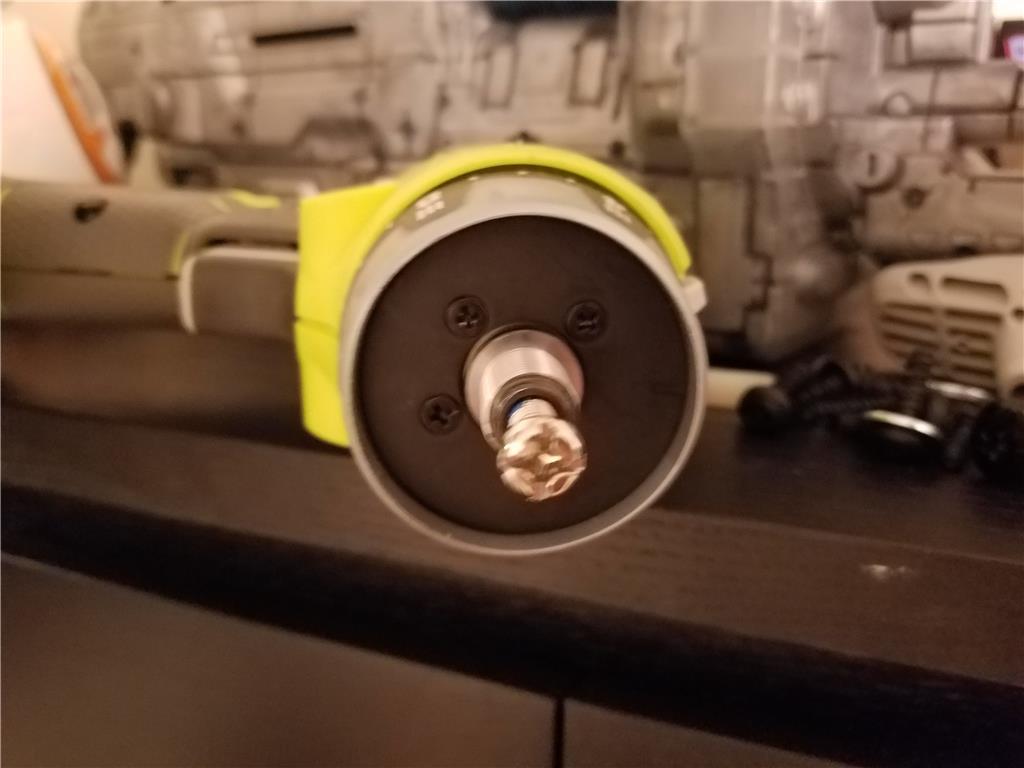

Ok so I started using pvc as a base for mounting the drill motors. I must use the casing because it holds the transmission and motor together. First I carefully cut out a 3 inch hole through the frame from one side to the other. Then I trimmed the grass outlet chute to clear the pvc pipe straight across. This way I really only need to mount each end of the tube.