Hello all, I am getting back in the saddle making robots now that I am moved into my new home and settled into my new job as a technician maintaining the Fiber Optics network in Chattanooga TN.

IM BACK !

By jstarne1

— Last update

Other robots from Synthiam community

DJ's Cookie Monster Robot

EZ-B Cookie Monster robot: auto-collision detection, timed head motion, remote-controlled arms, radar screen, DIY frame

Smarty's Halloween Synthiam - Annabell

Annabell Halloween EZ-Robot, a new spooky custom robot shared with EZ-Robot friends.

Cardboardhacker's Ez-Ollie

ez-Ollie: recreate Sphero Ollie with a simple low center-of-gravity build for stable rolling, easy forward drive and...

-635971125254815084.png)

-635971009768280111.jpg)

-636393423097260688.jpg)

-636337988865509663.jpg)

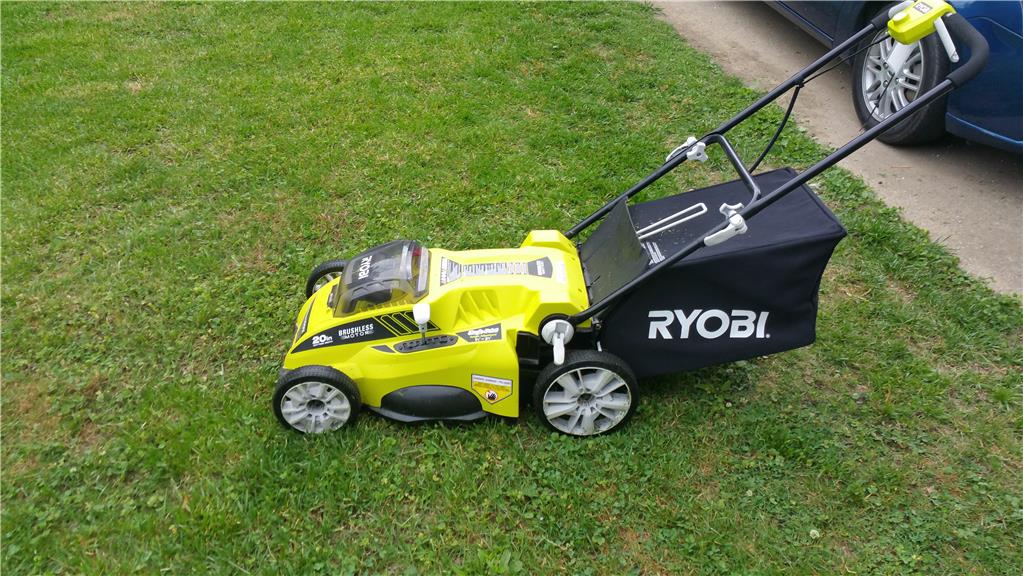

Ok so I am going to run over the general idea. I have been researching getting a robot mower and the options are sickly. They simply don't offer a full size electric robot mower for a reasonable price, at least for my pockets.

Welcome back. We missed your creativity!

Alan

Dito on what Alan just said. Welcome back. Your a creative genius and we need that around here.

Your back just in time for the new web site to launch in a few weeks and the new EZB release! These are happening times around here. Have you been peeking in and staying up to date or totally off in the real world this past year?

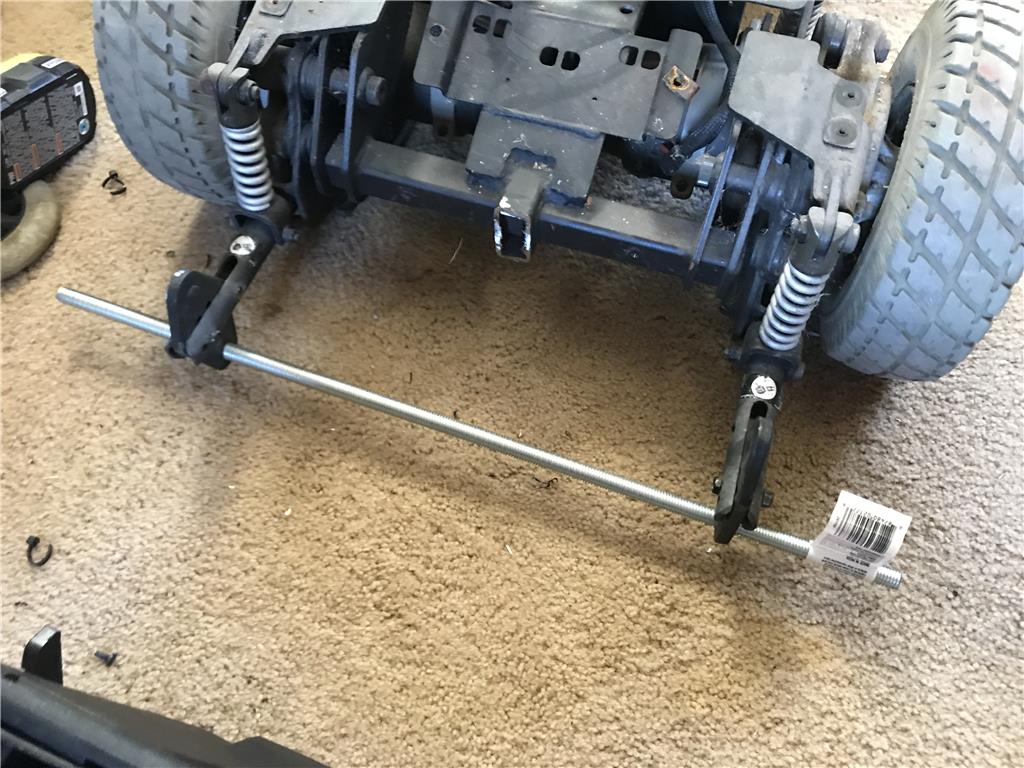

Good luck on the new project. Sounds very interesting. Are you building the platform from scratch or using your last Power Wheels car project to build this from?

Hey Guys ! I missed you! Yes I have been totally gone off the face of the earth lol. Once I started the new job it took some months to get oriented and settled in. It was basically like full time school. Anyways I haven't heard about the new ezb, and I haven't broken in my V4! wow. I applaud progress though!

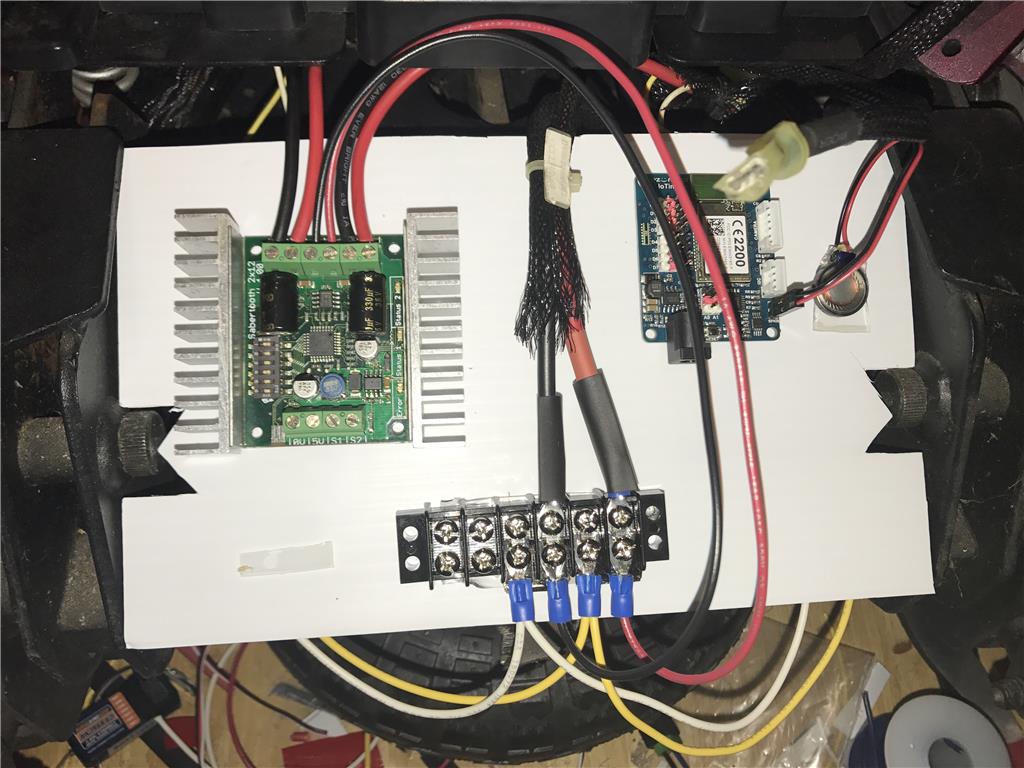

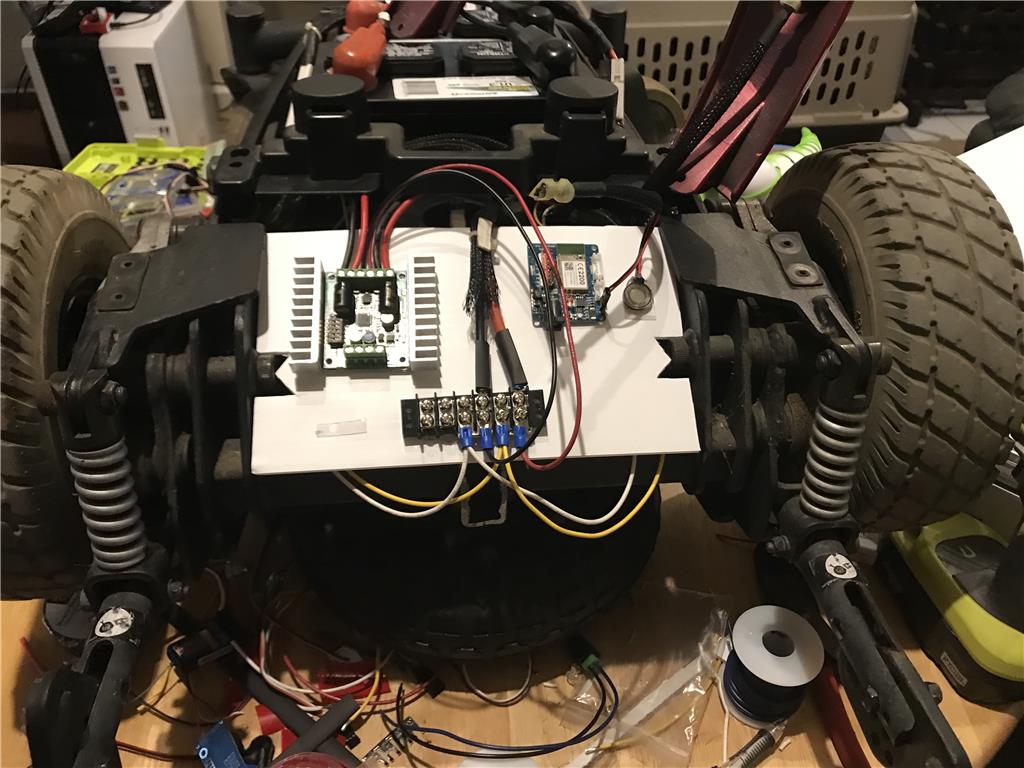

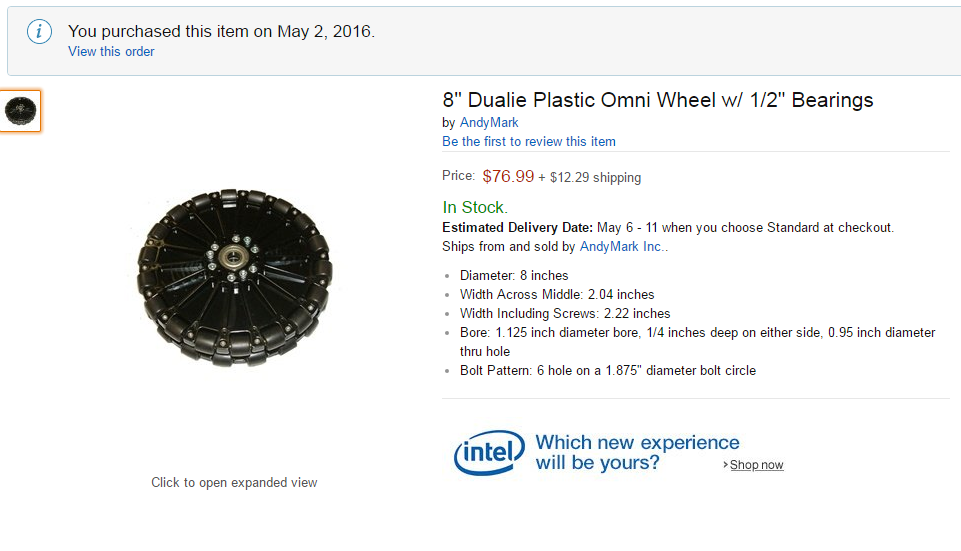

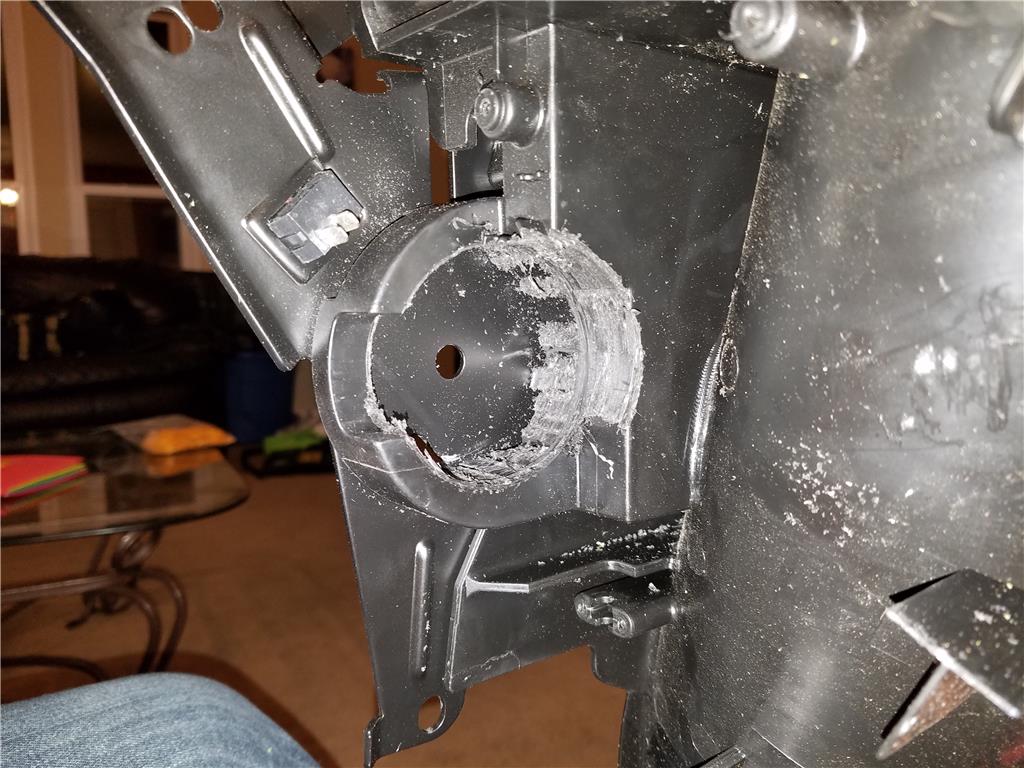

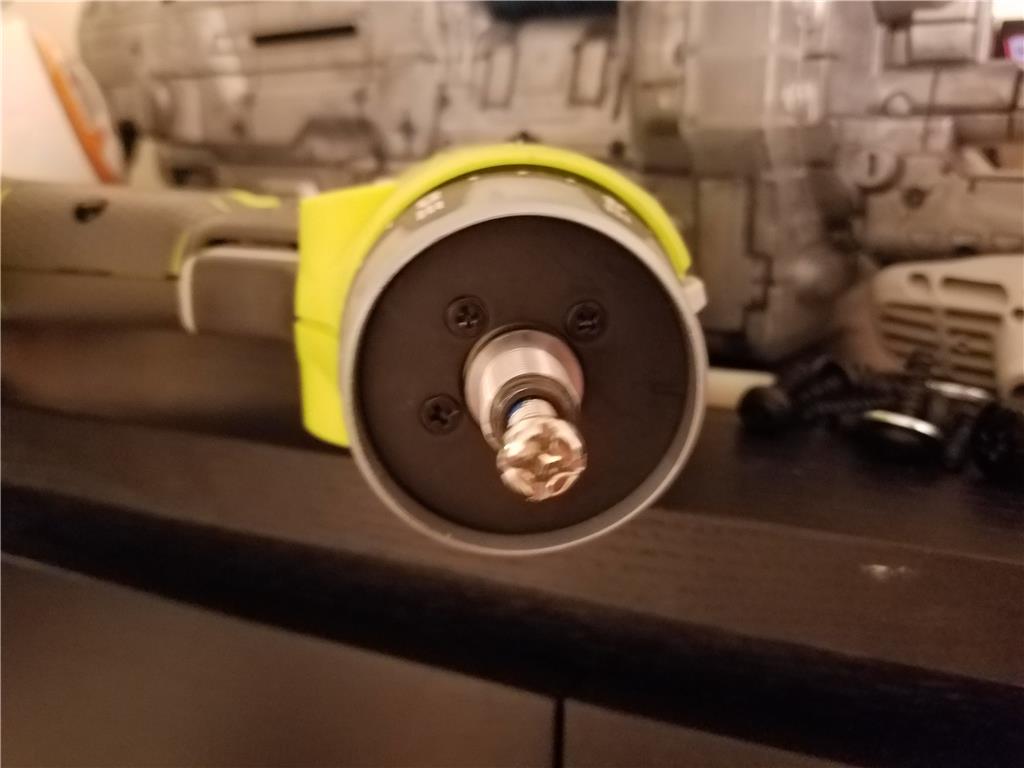

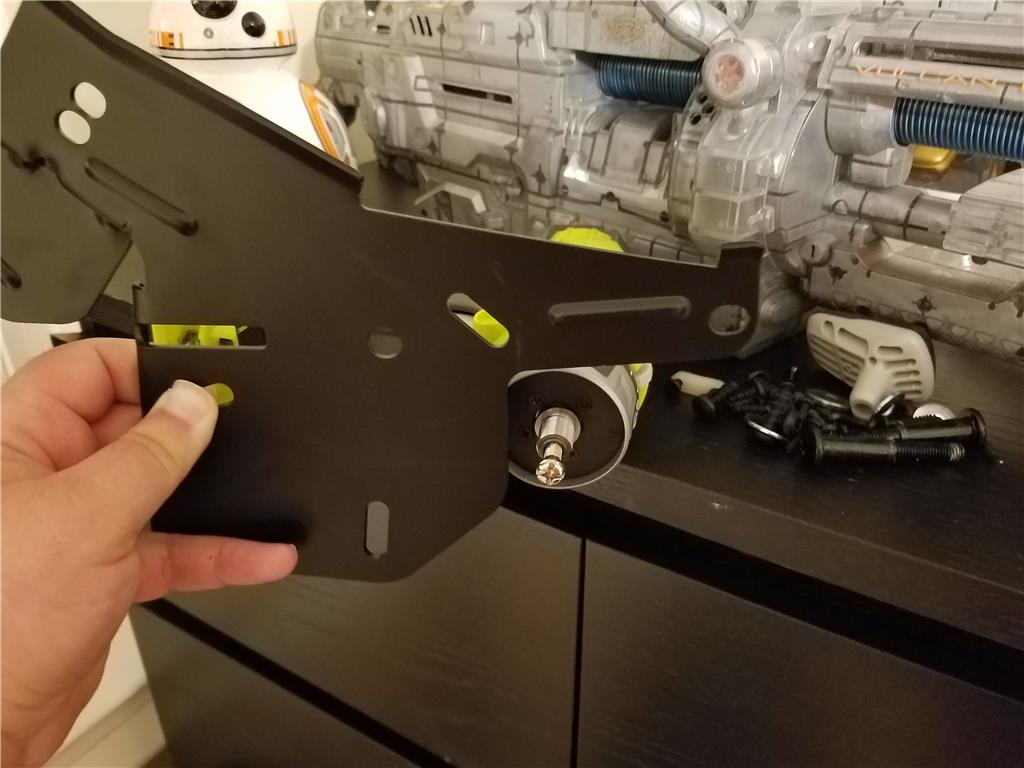

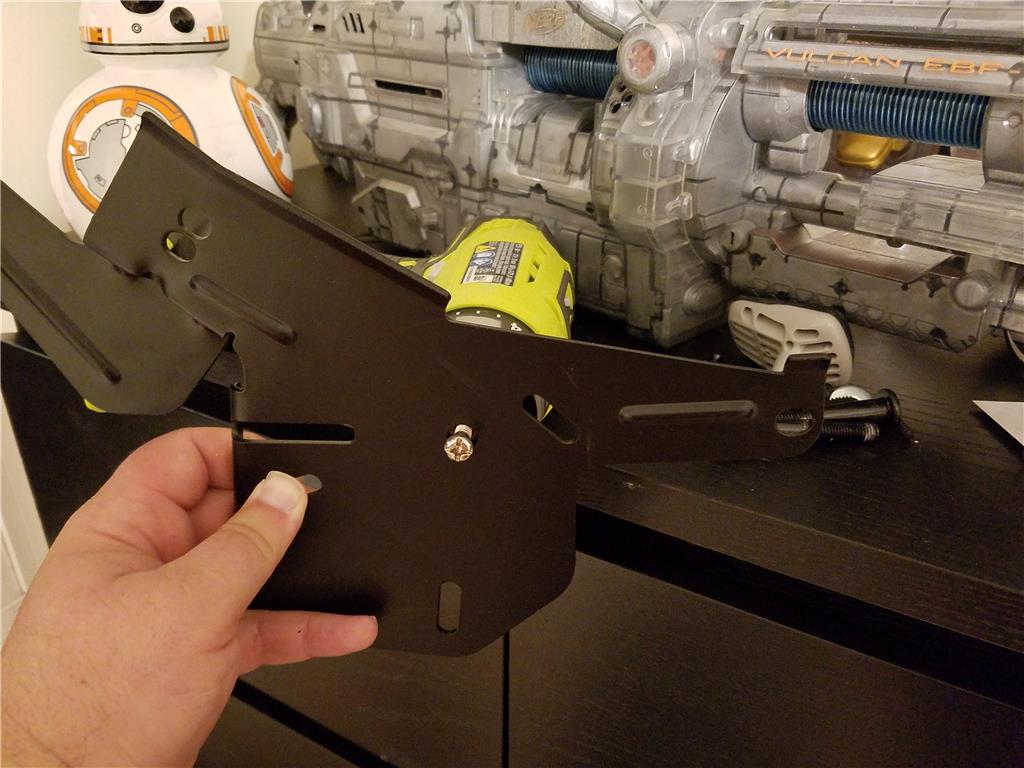

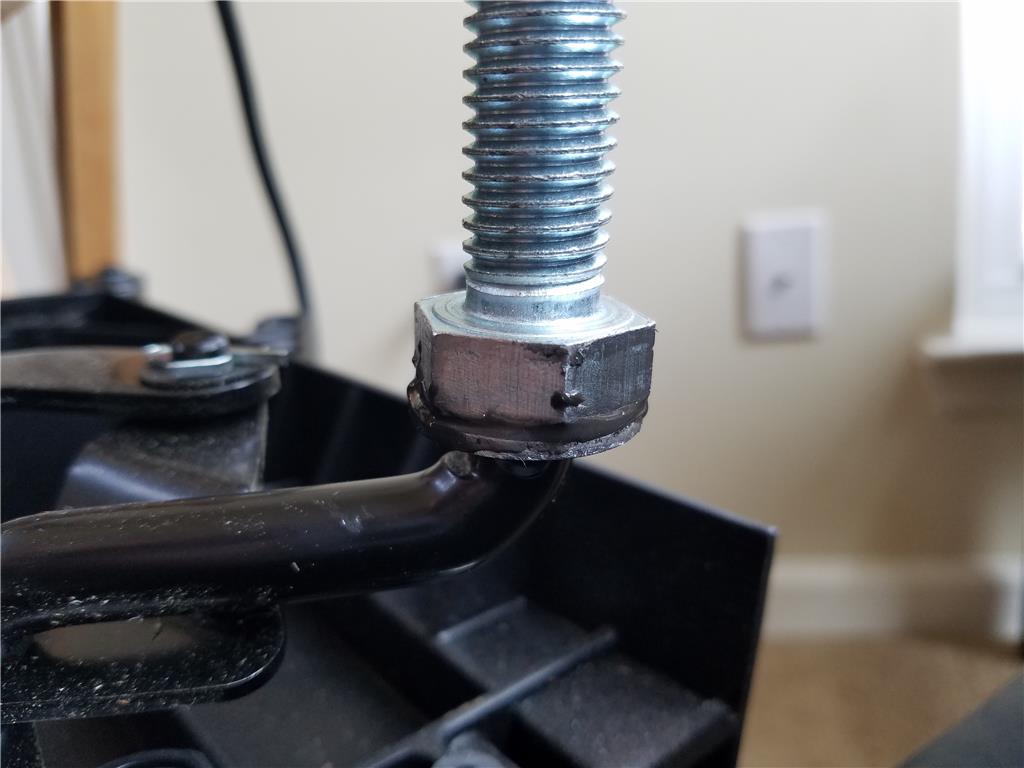

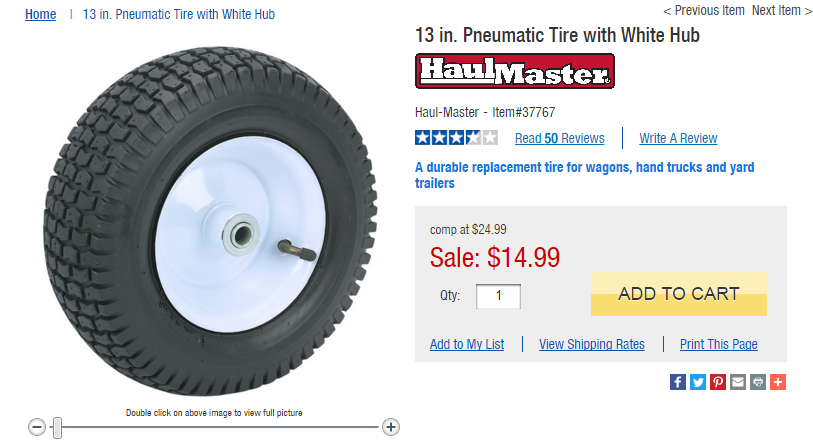

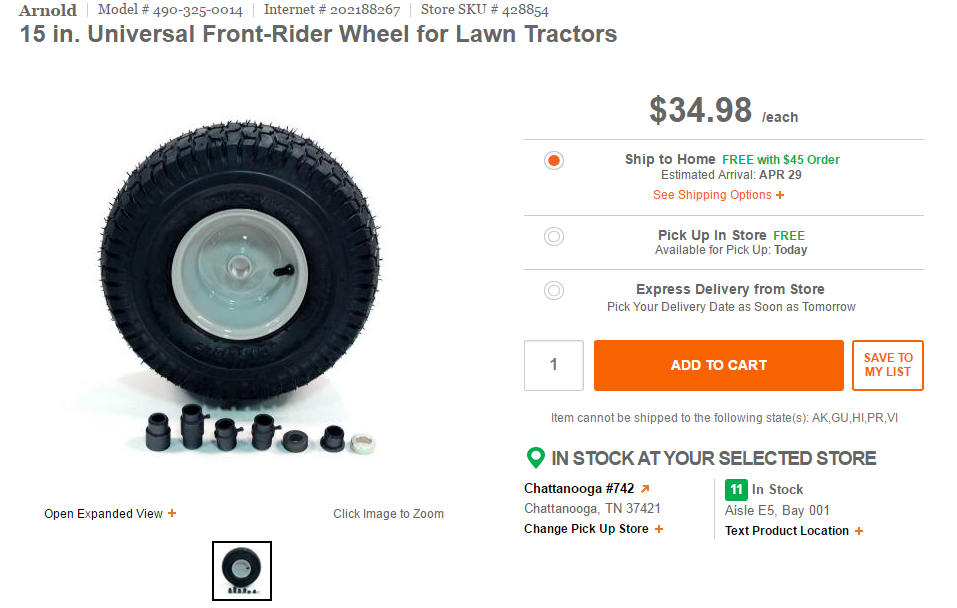

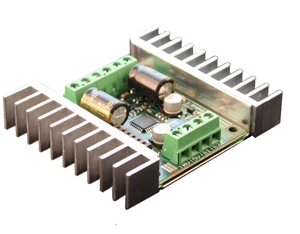

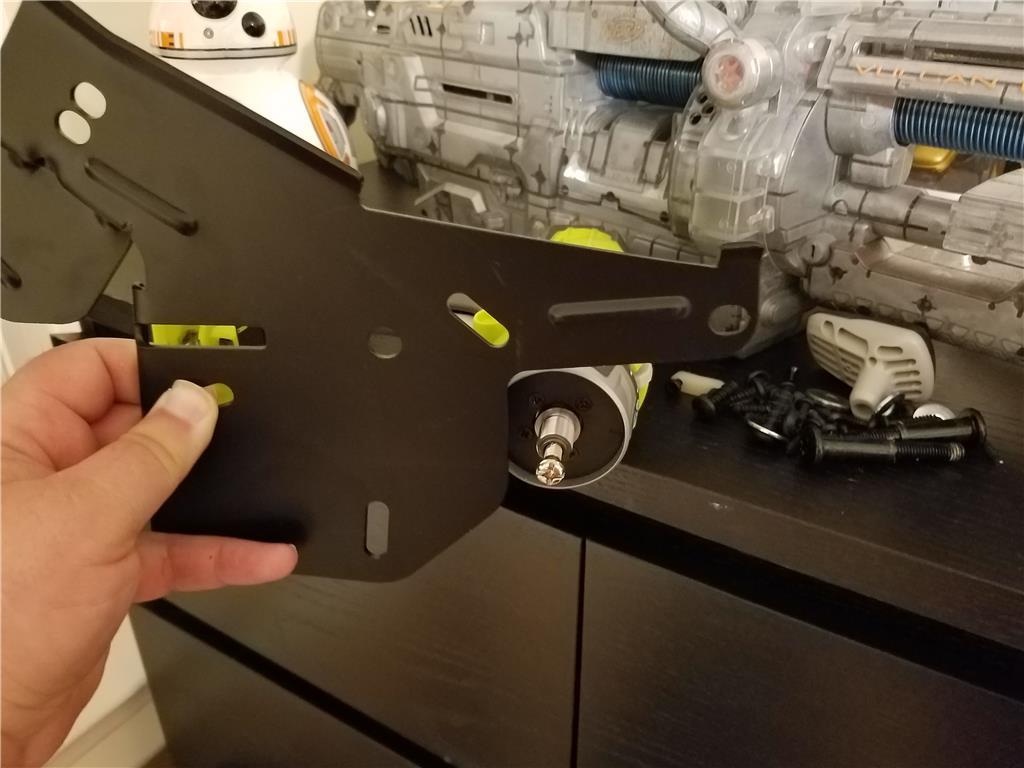

So As far as chassis , I am considering using some parts from the truck project, but they may be too big. I will use different wheels likely for more grip , caster wheels in the front, and a chain drive to turn the wheels. I want to do that so I can keep the height adjustment. It would be awesome if I could put a servo or something on the height adjustment as well , how cool would it be to have those stripes like on a gold course!

Yes, You Have Been Missed ! Welcome back. Looking forward to you new endeavor.

Your project will cause much interest at my house. My 1/2 acre would be just the right size test site for this project.

Ron R

About time that you've returned

This is going to be a fun build to watch

Ok so here's the items I have on the way as we speak that will arrive either Monday or Tuesday.

Ok so list of stuff on the way so far..

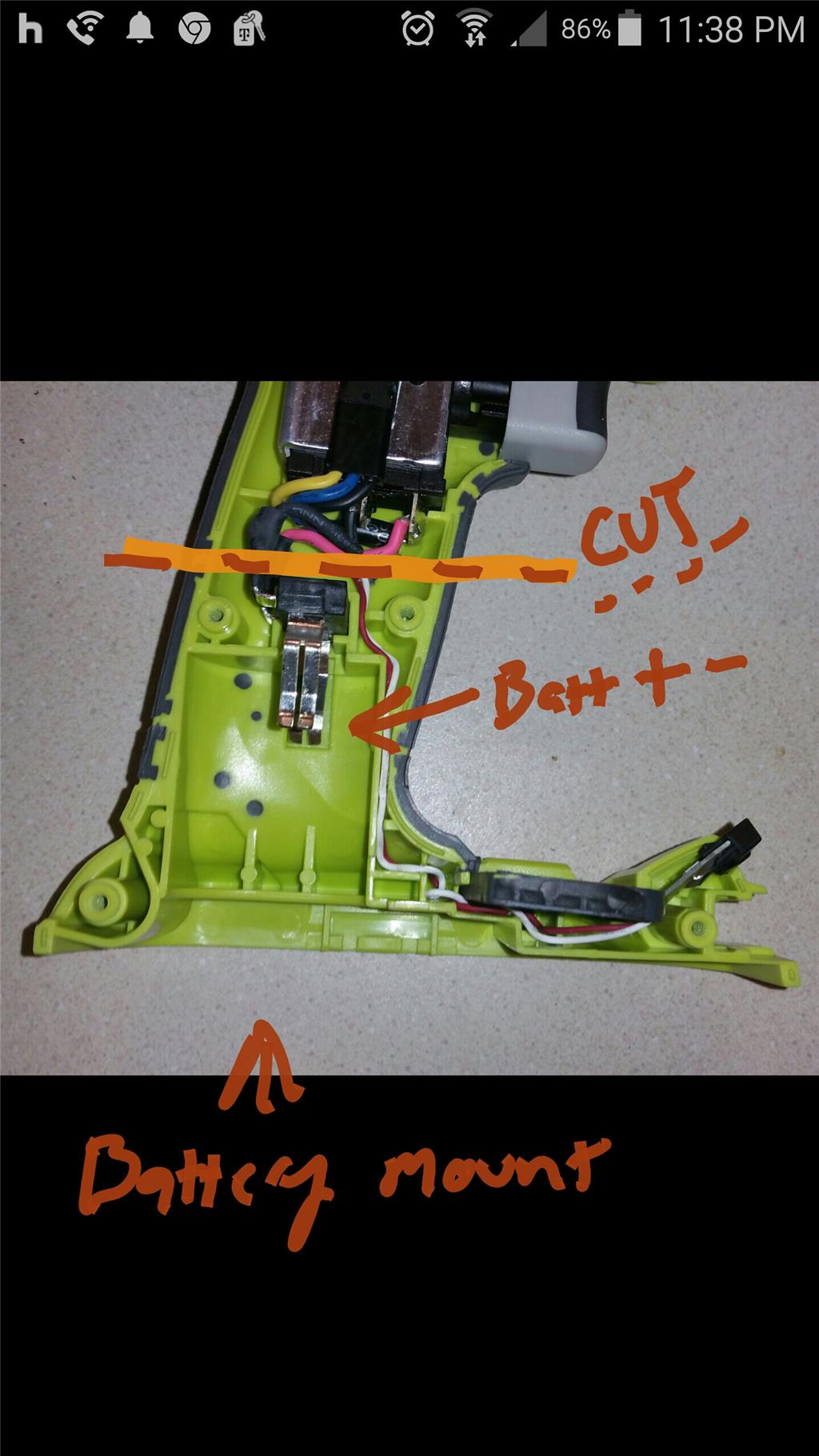

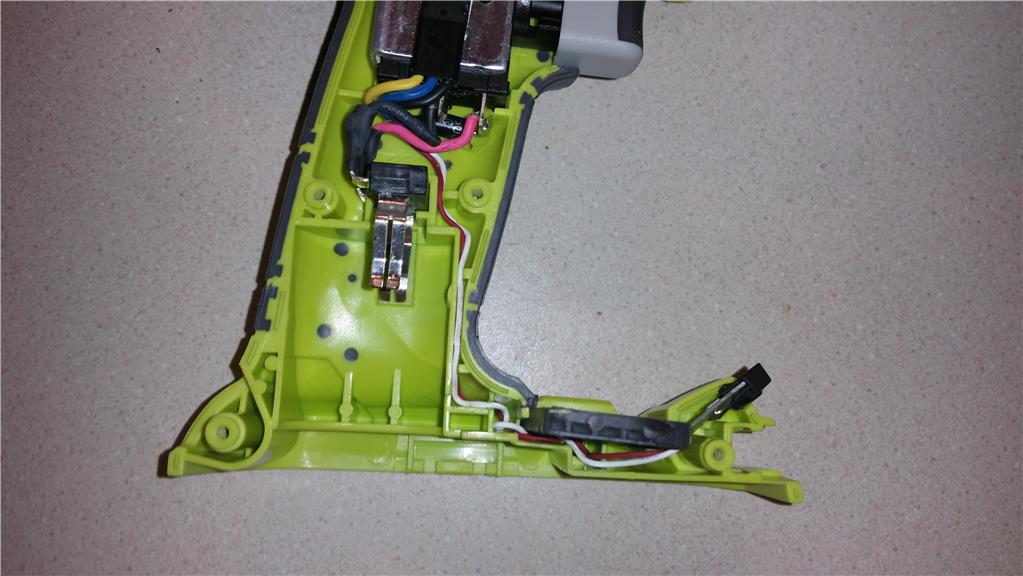

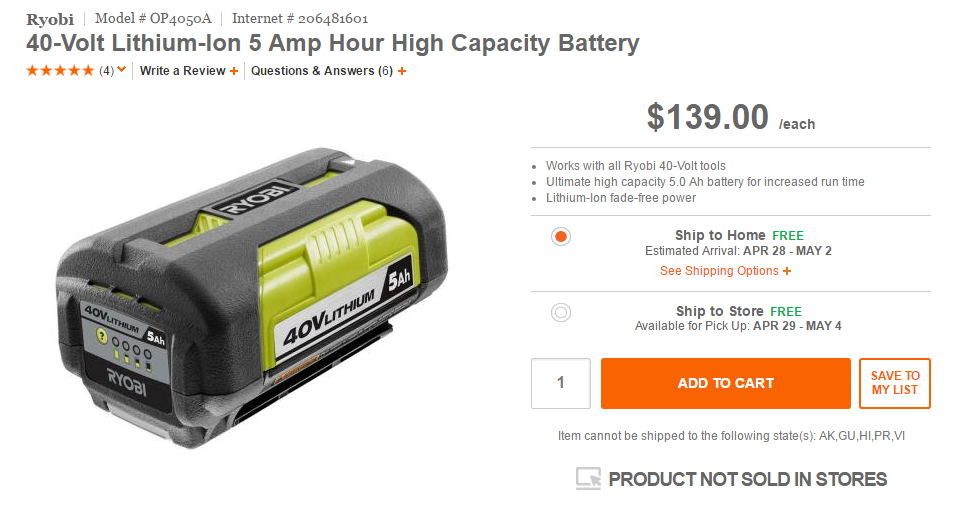

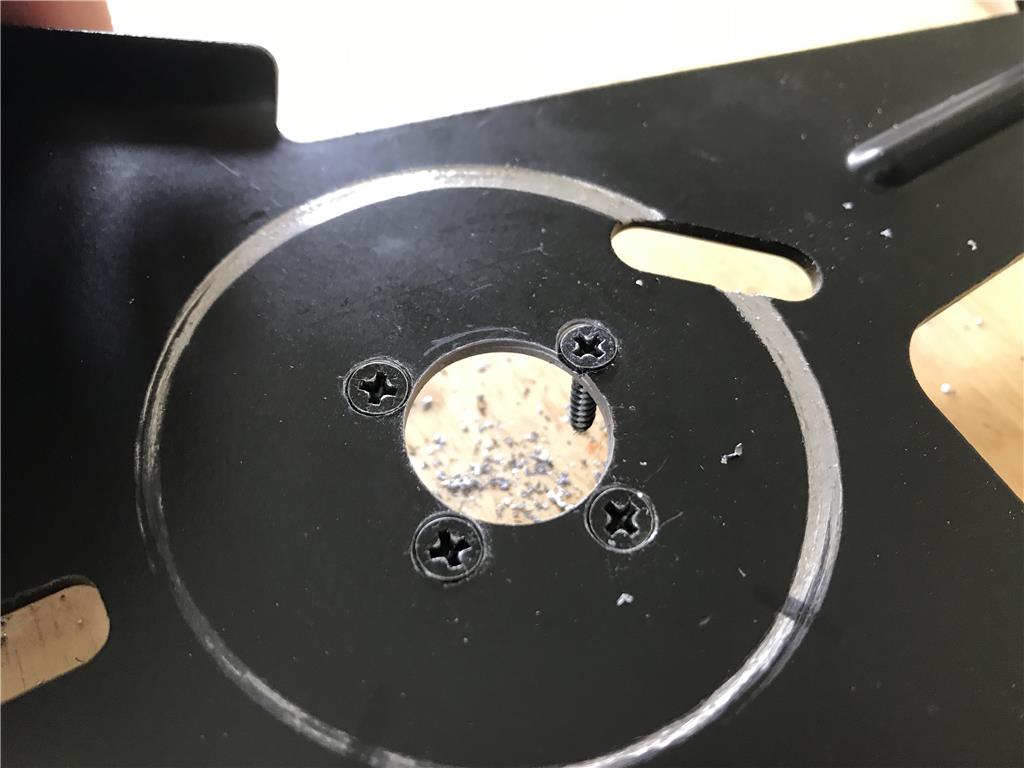

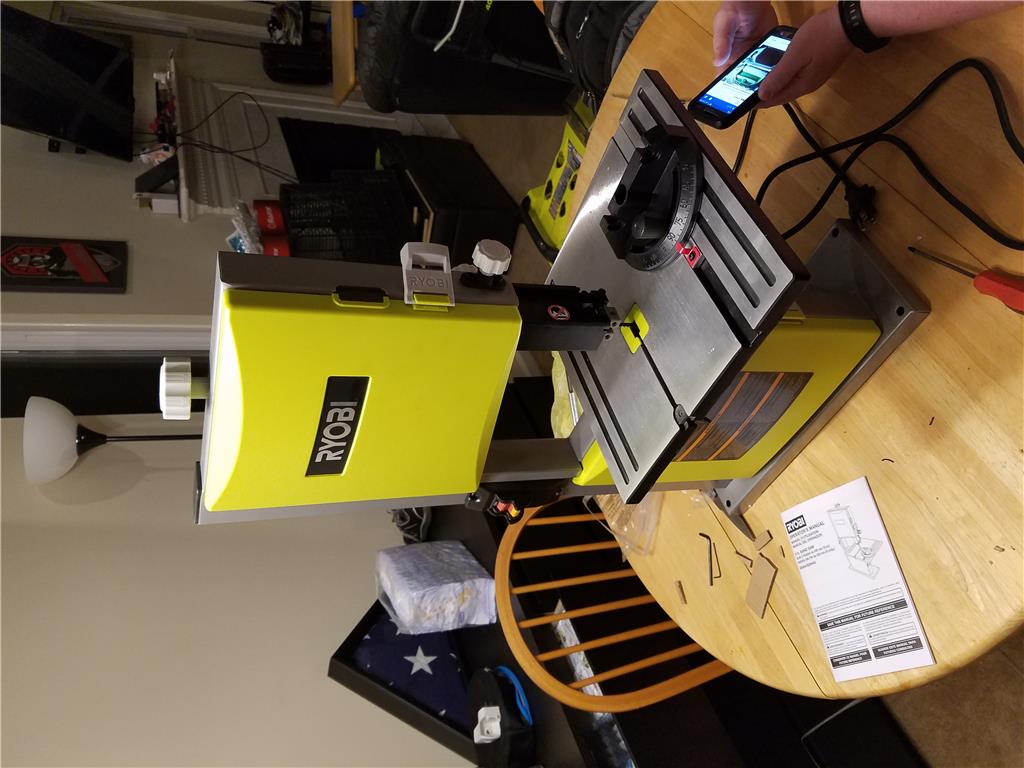

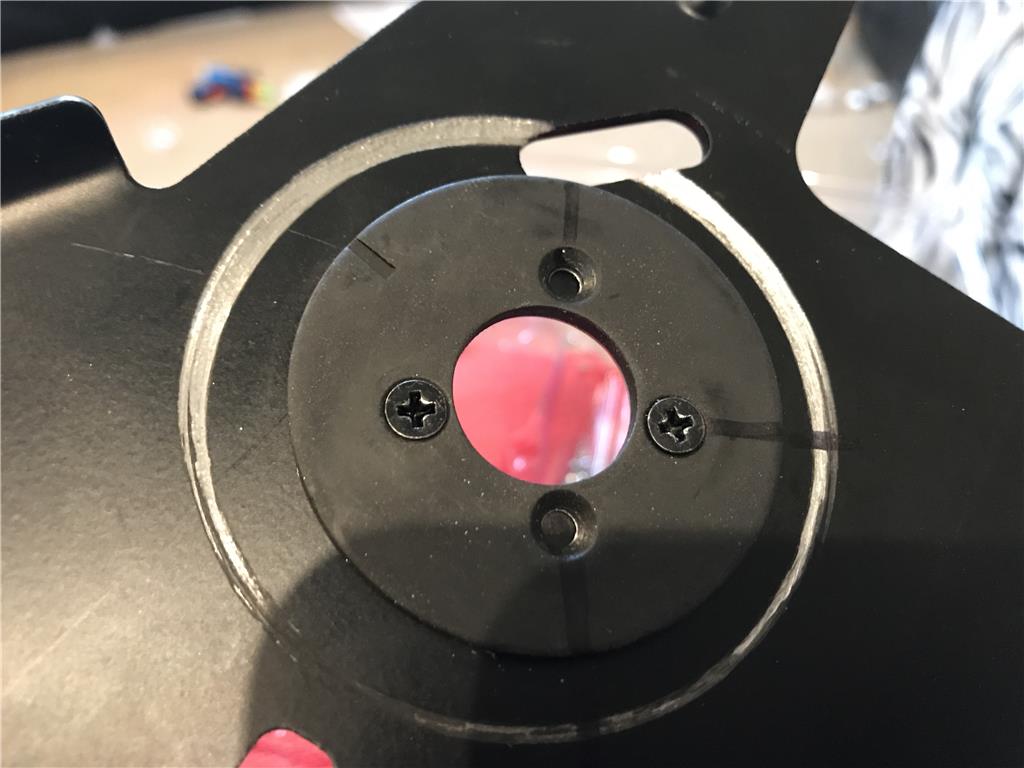

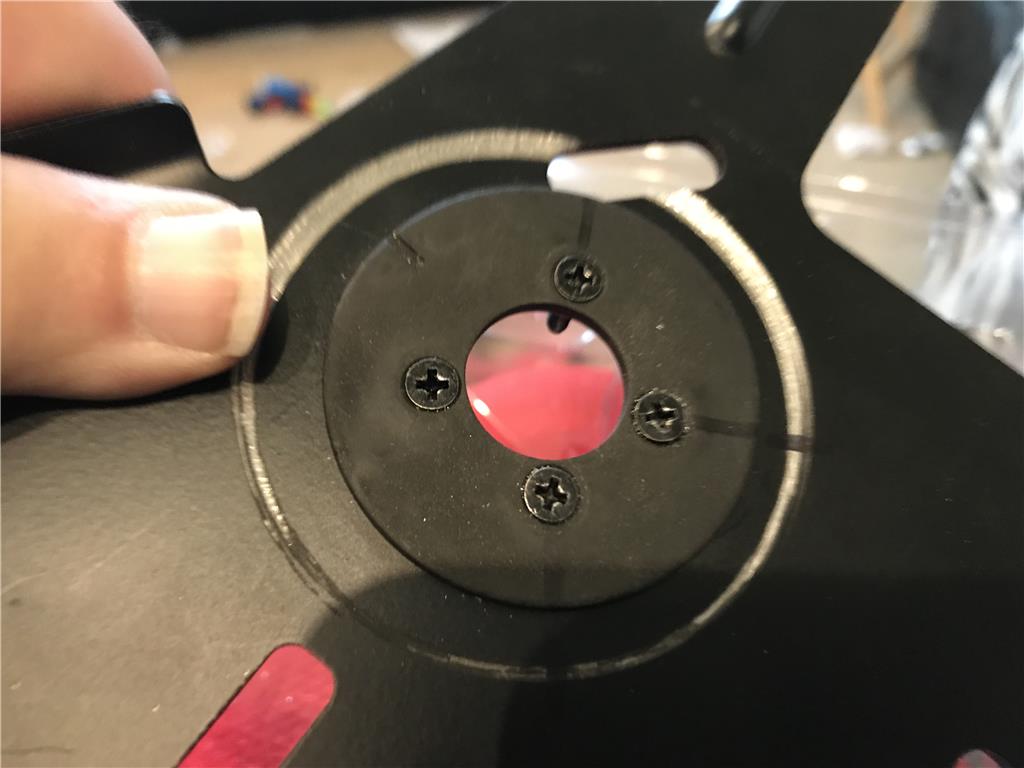

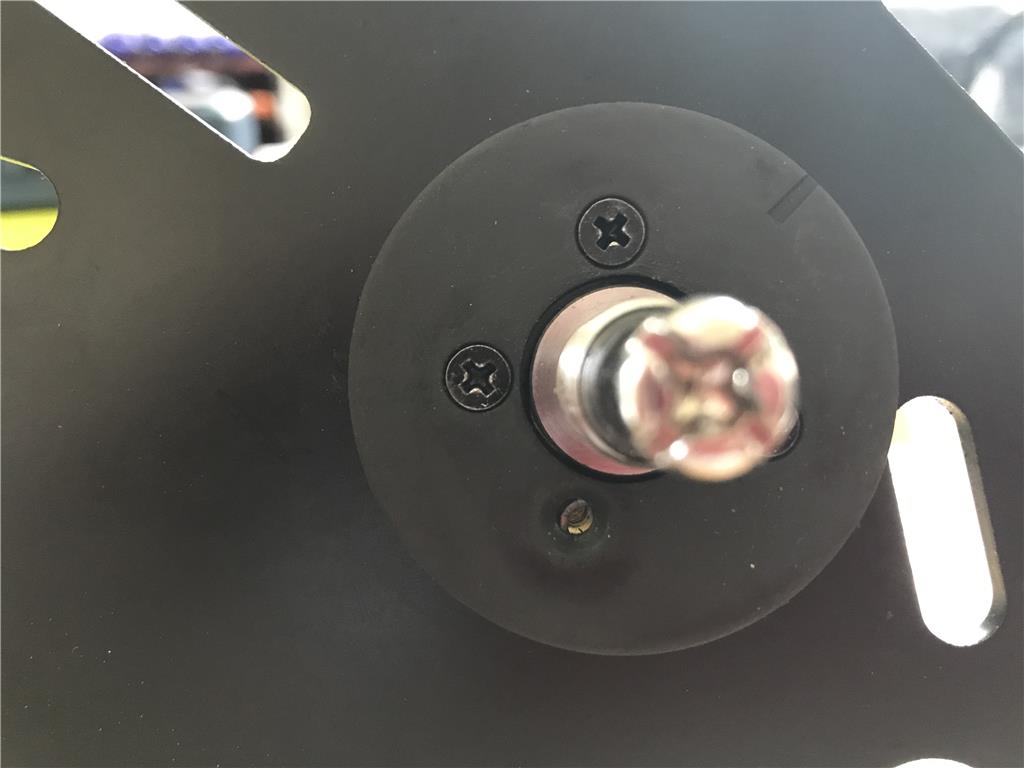

Ryobi 40v brushless lipo 2016 model mower $279.99 , batteries not included

Ryobi 40v lipo batteries x 2 $99.99 retail but both came with the trimmers at no additional cost

Ryobi 40v lipo string trimmer x 2 $149.99 retail amazon.com had it for $129.99 with a battery

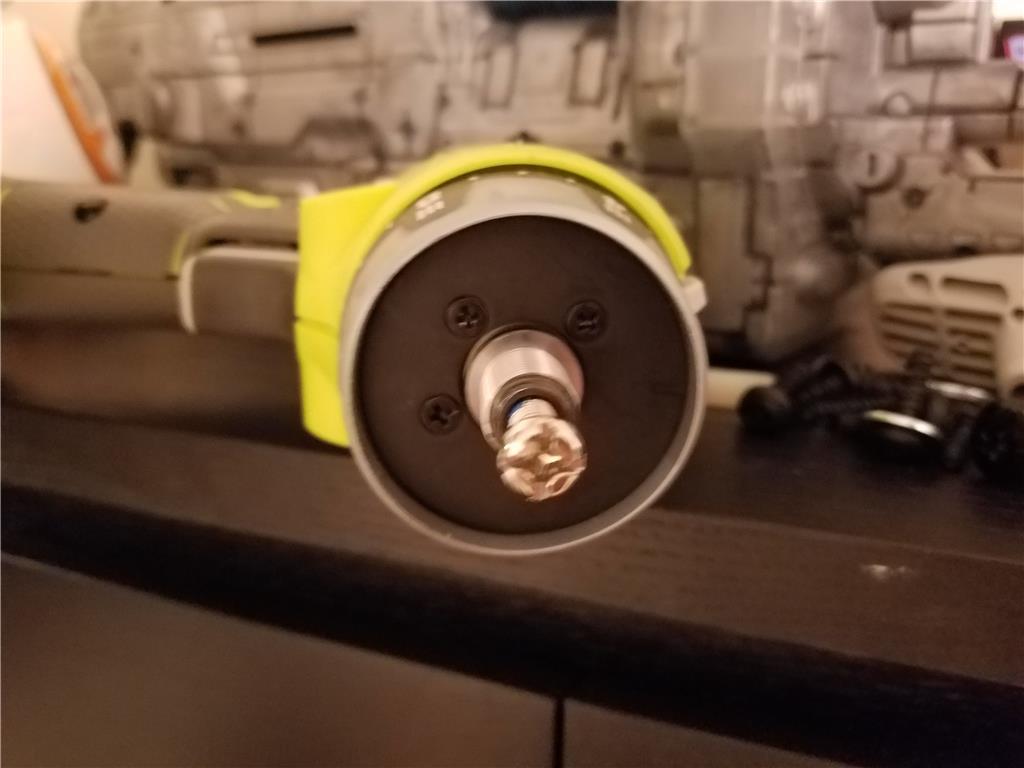

Ryobi 18v One + lipo electric drill x 2 99.99 retail, amazon.com $48 each

Zotac Pico mini PC usb powered 179.99

These are all on the way. I will list my other items as I either rob them from another project or order them.