Hello all, I am getting back in the saddle making robots now that I am moved into my new home and settled into my new job as a technician maintaining the Fiber Optics network in Chattanooga TN.

IM BACK !

By jstarne1

— Last update

Other robots from Synthiam community

Ezang's Mymodifiedadventurebot

Modified Adventure Bot with ultrasonic radar, camera, RGB animator and custom back wheels

Confoundedhound's Modified Omnibot 2000

Refurbishing an Omnibot 2000 with new paint, +8" height, Asus t91mt netbook, and planned EZ-B controller - open to...

Jeffmorris's Homemade Biped Robot

Upgrade EZ-Robot hip servos that can't lift biped legs with higher-torque servo recommendations for reliable leg...

-635971125254815084.png)

-635971009768280111.jpg)

-636393423097260688.jpg)

-636337988865509663.jpg)

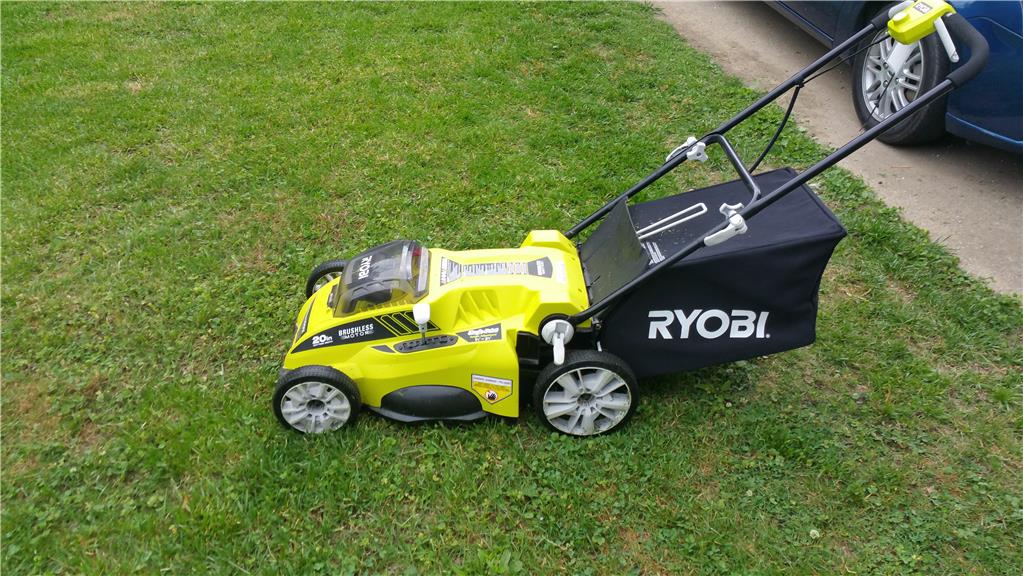

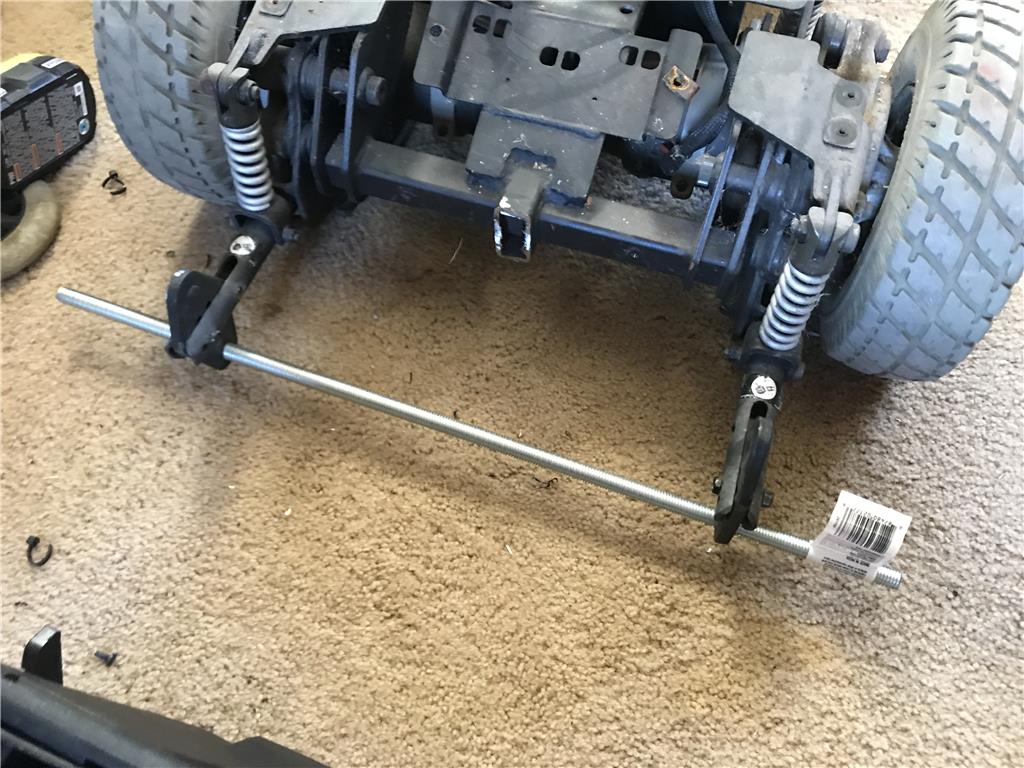

A NINJA MOWER ..... Killer of Dandy Lions. Silent but Deadly !

Just think if it had 4WD it would make a killer monster truck.

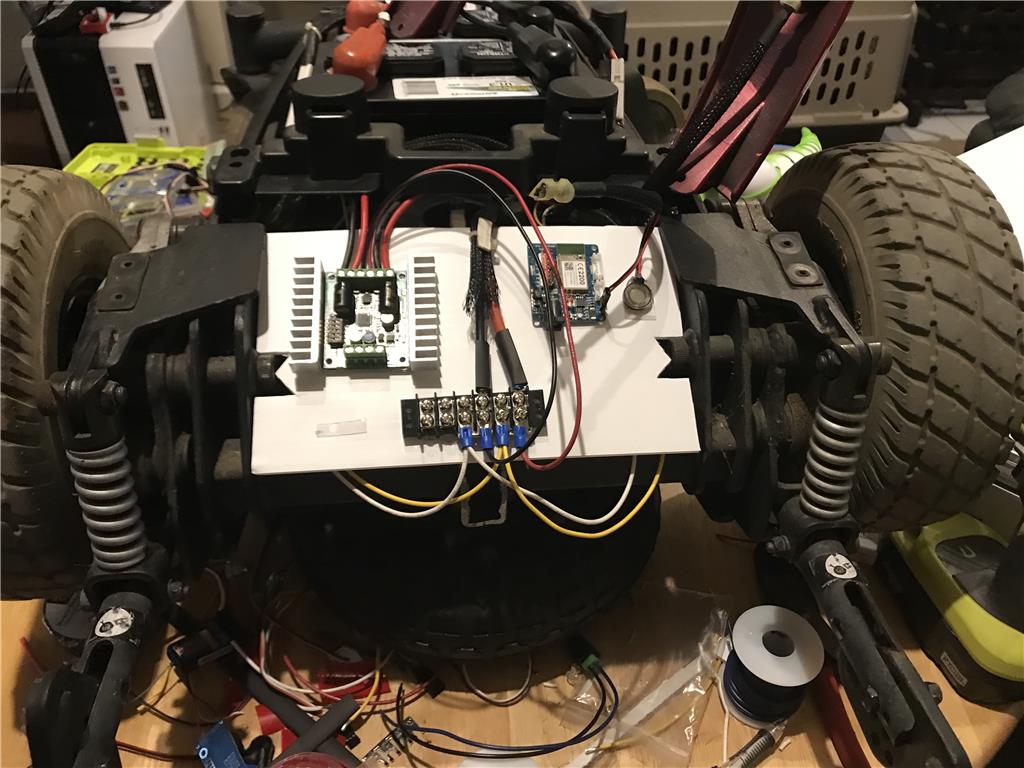

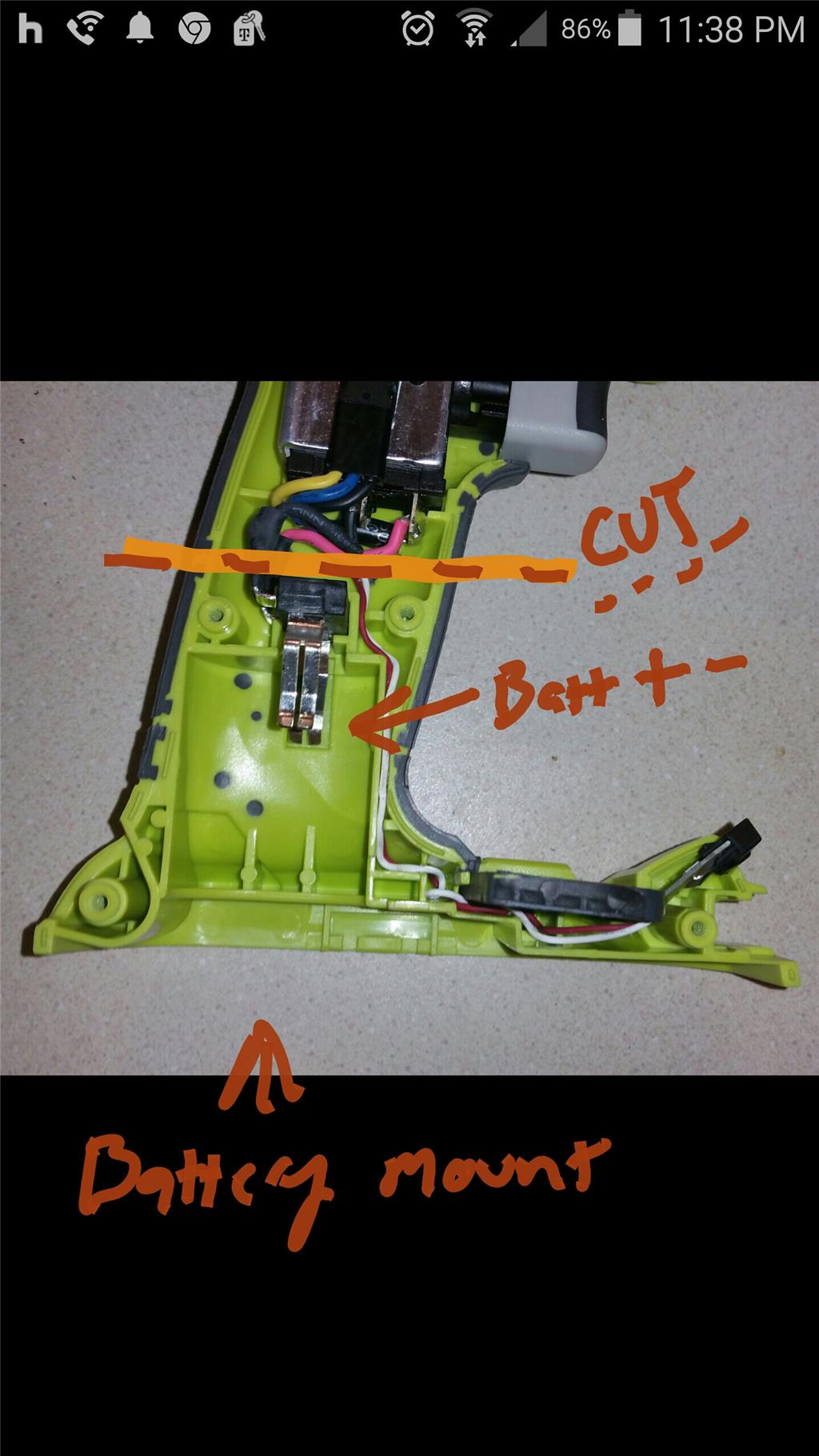

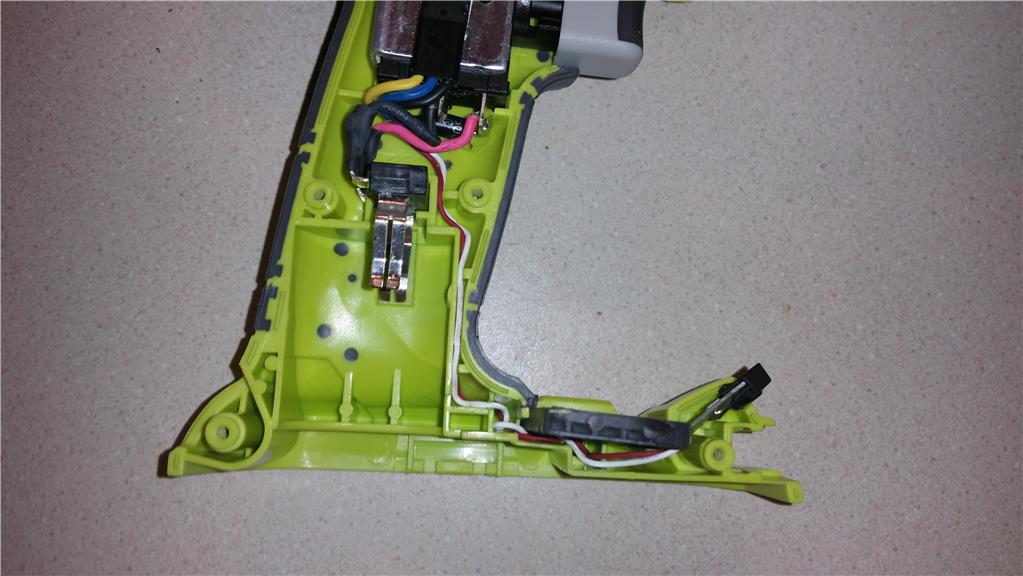

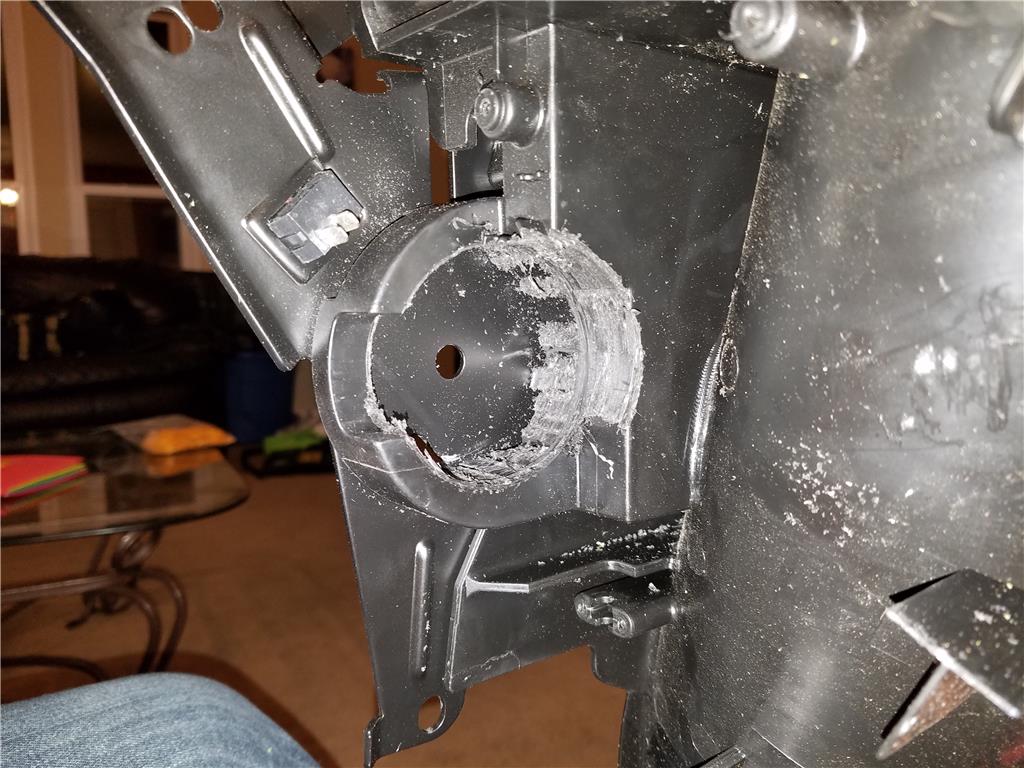

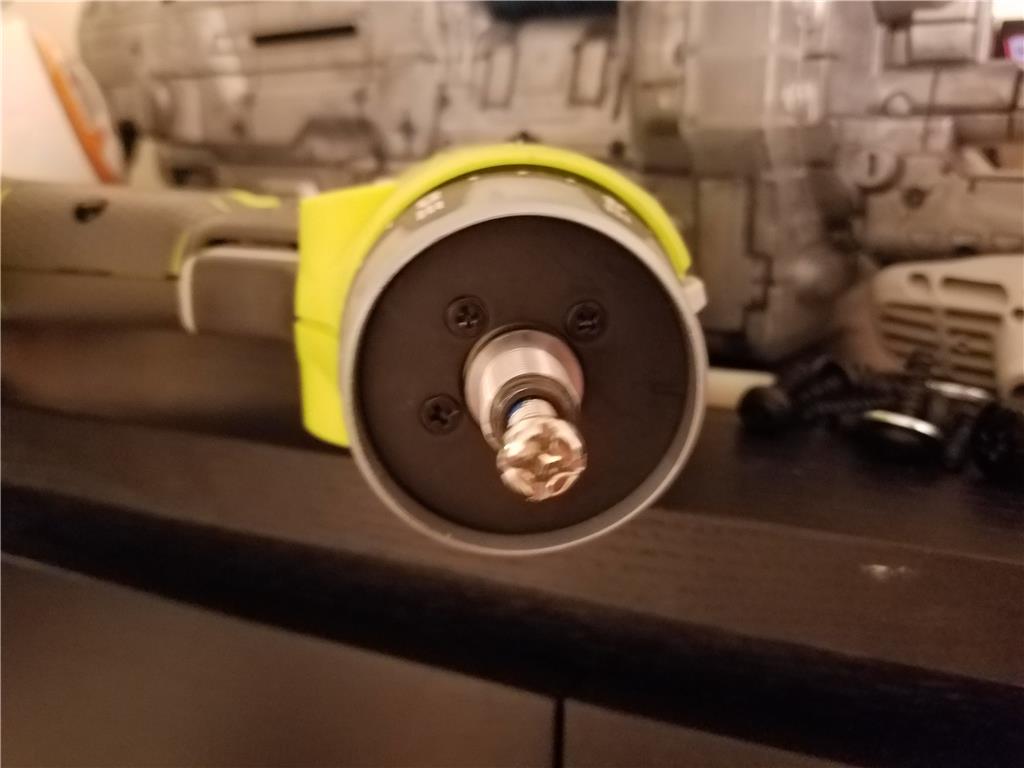

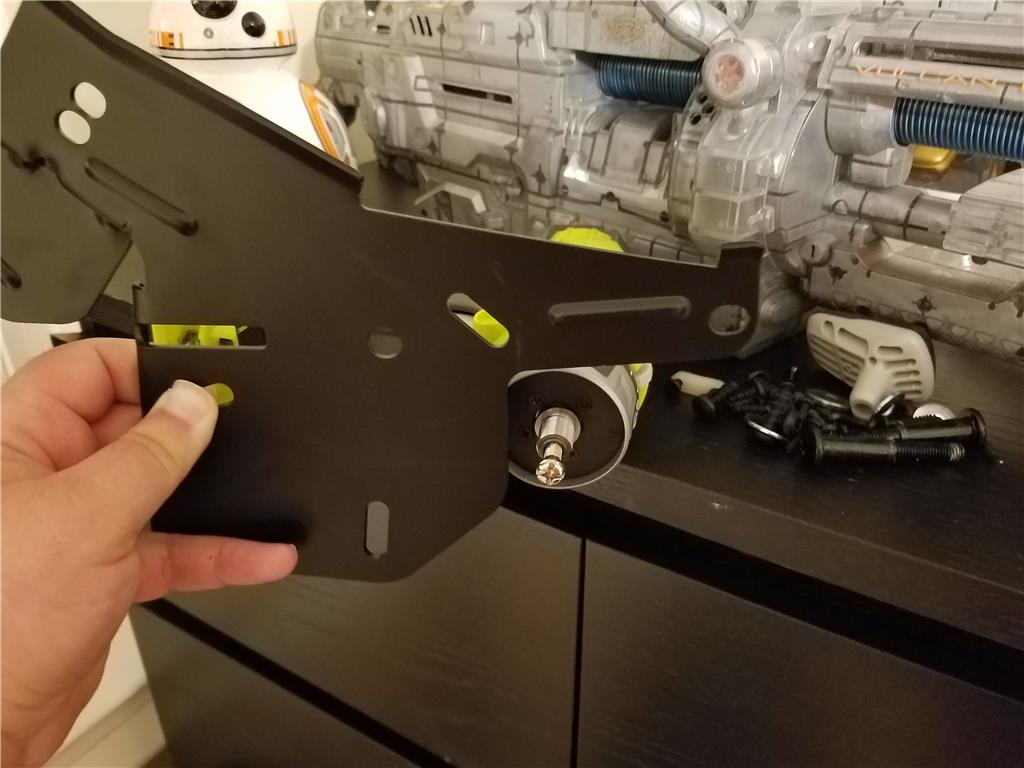

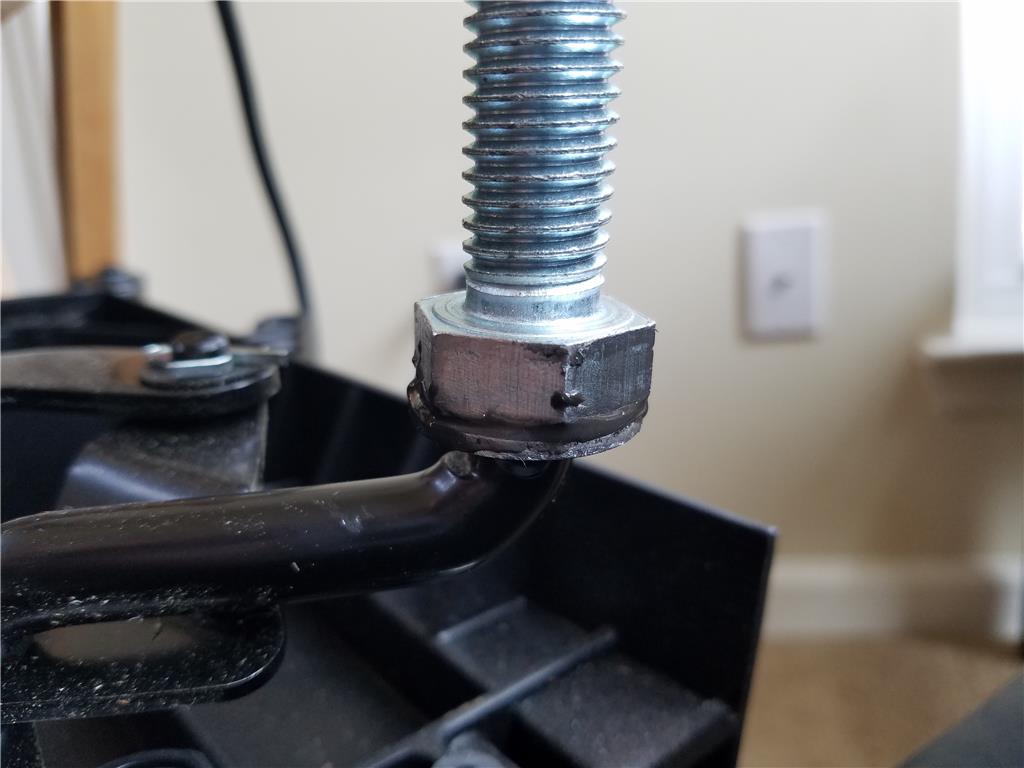

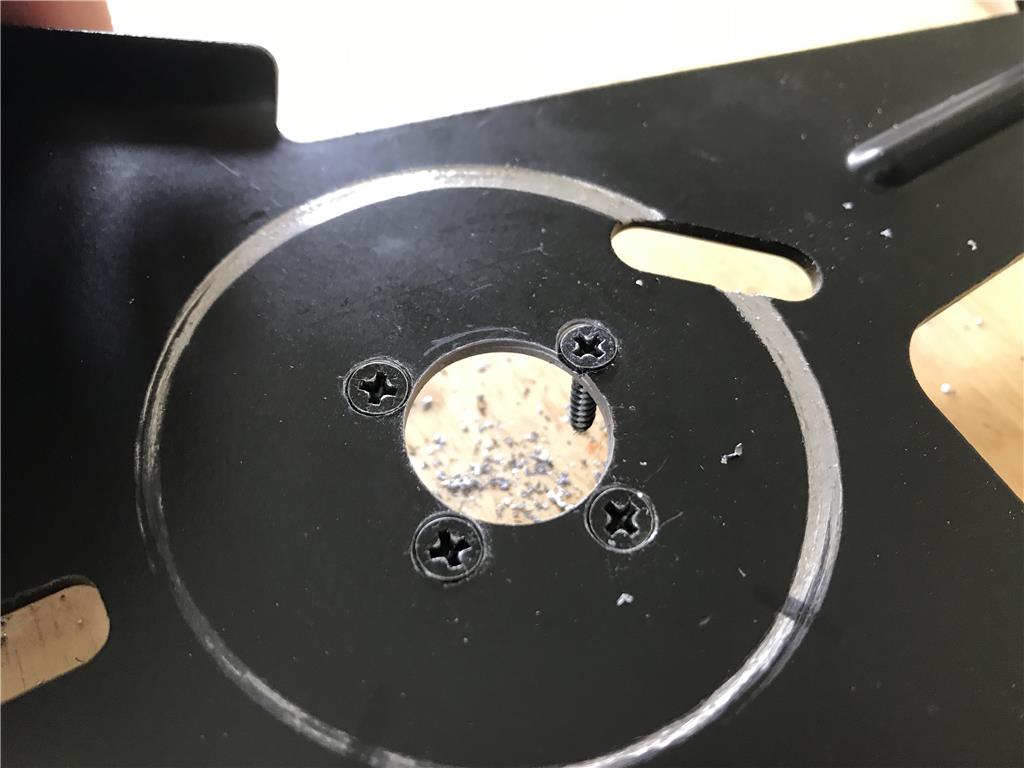

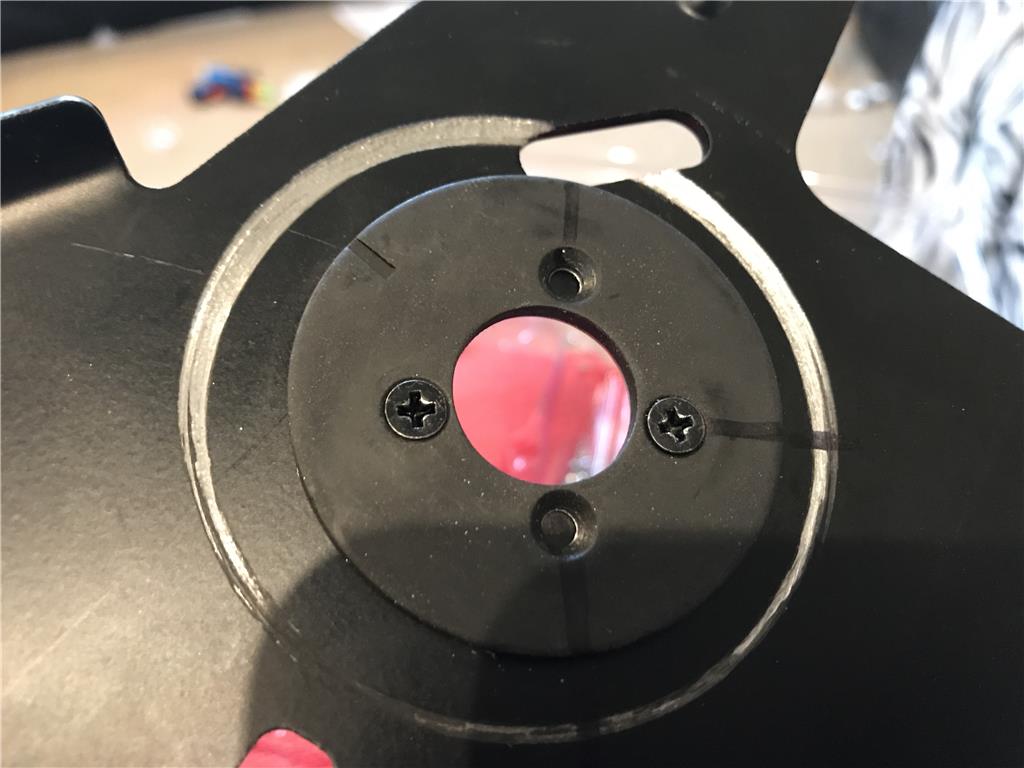

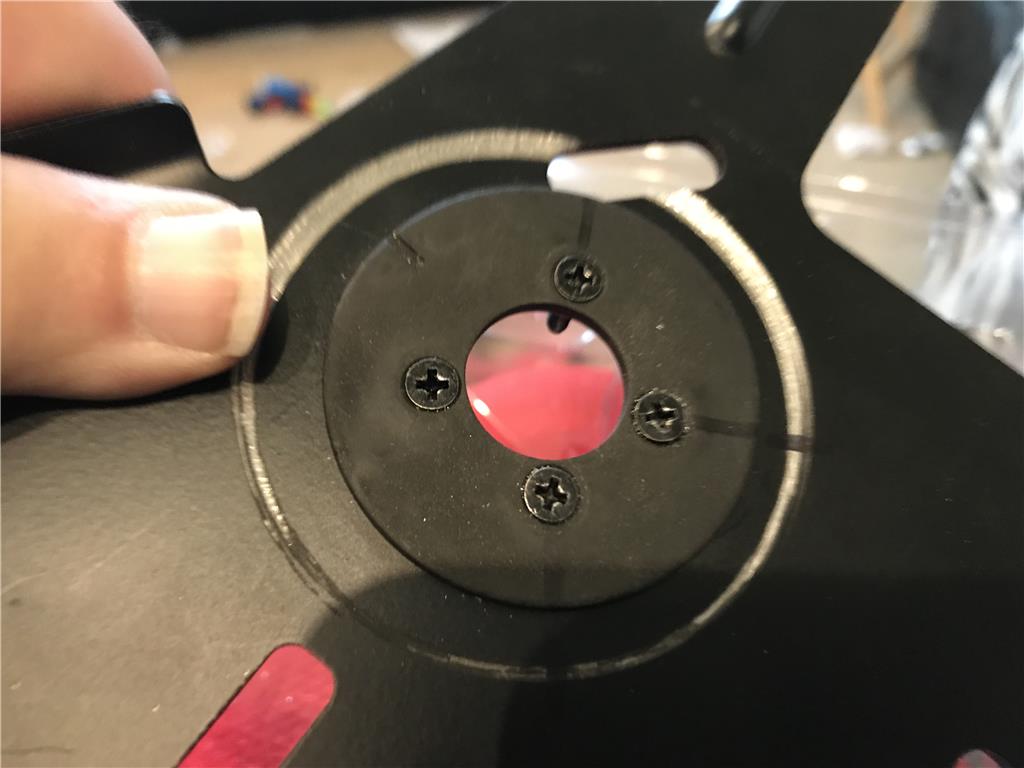

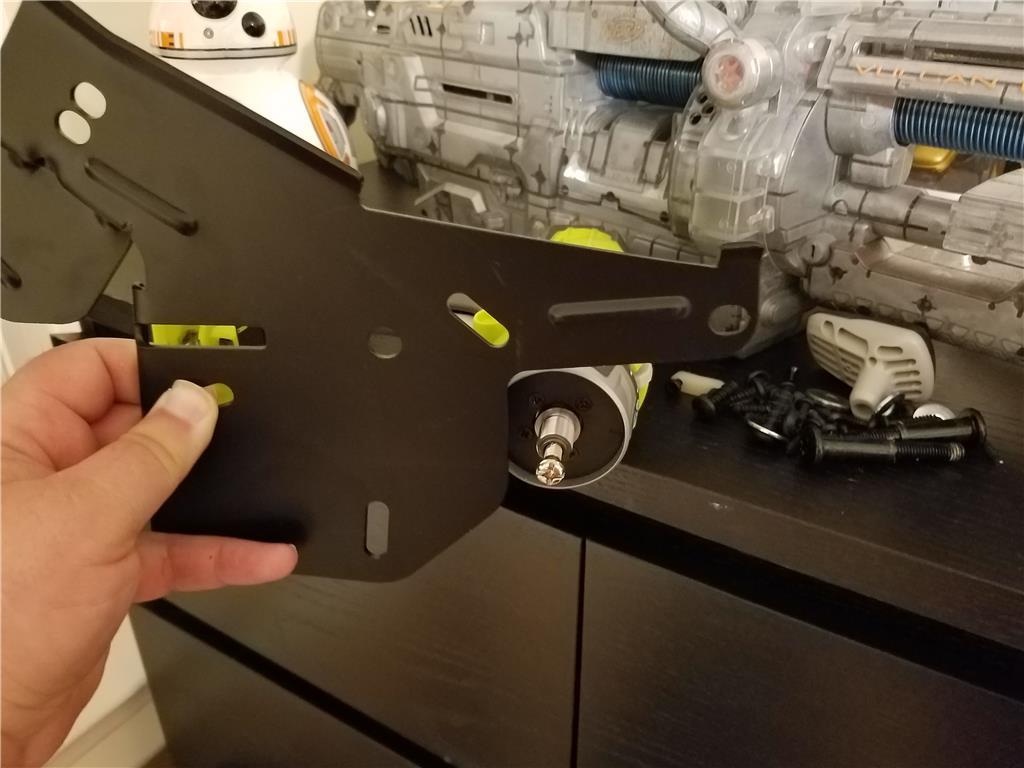

Ok so I'm fitting the mower with 5/8" wide by 3 inches long zinc coated bolts as rear wheel axles. I used a saw to cut the original 1/2 " axle down to the flat spot that the original bearing was pressed against.

Here is the first zinc steel bolt being fitted onto the bung where the original 1/2" axle was tack welded on. It has a 3 inch shafts. I used JB weld Knicks for the flat surface to flat surface weld and next I will sand the edges that squished out and apply another 1/8" layer all the way around of high strength jb weld. Once it sets I will sand that and apply a third and final layer. The goal is to basically use a whole tube on each axle to handle about 30 pounds of weight on each wheel.

To prep both the bolt head and the axle face I sanded off all powder coat with 60 grit sand paper. I will update on the next layers and test fit tonight.

The next prepped face

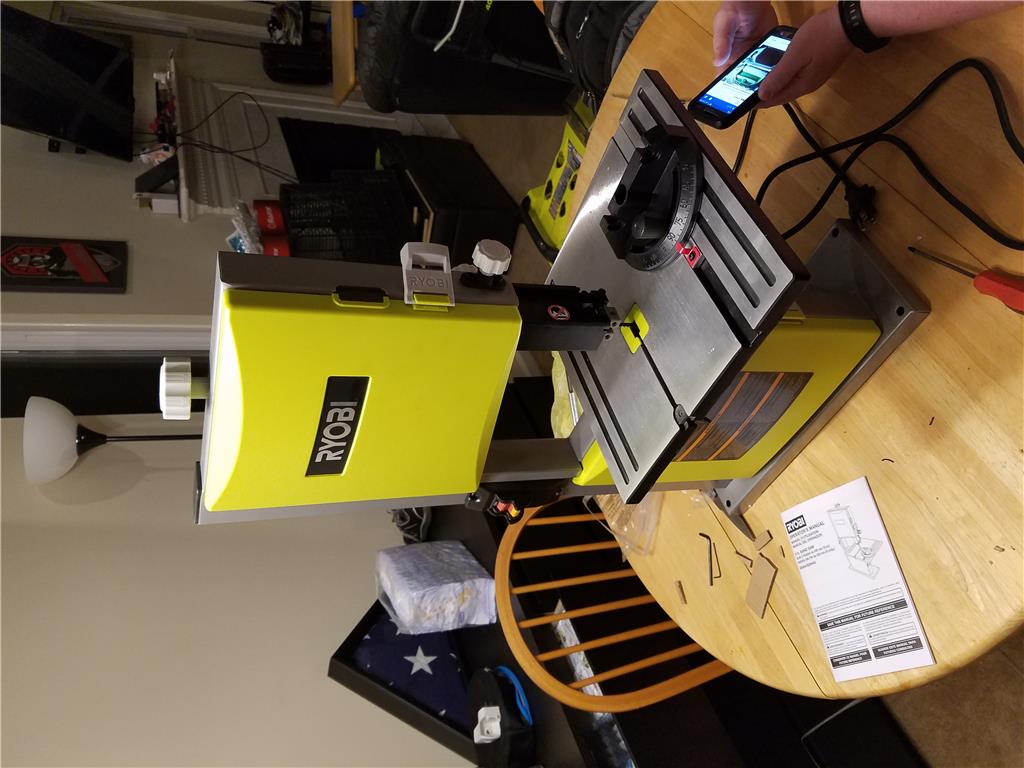

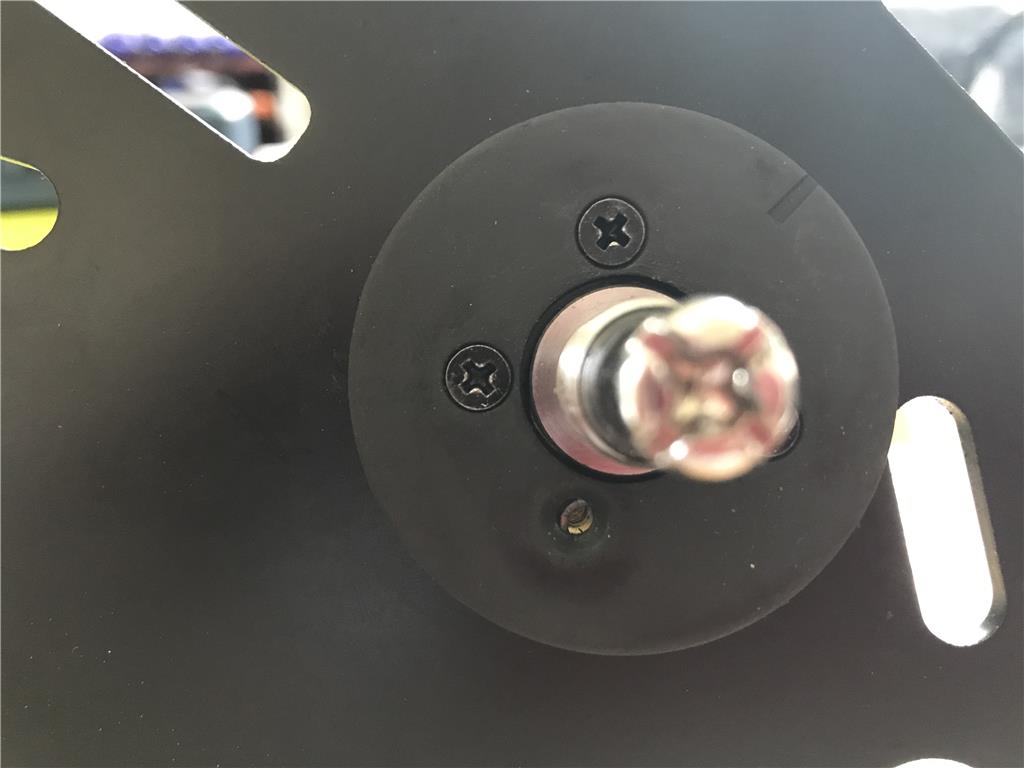

Ok so I discovered that the JB epoxy weld cannot live up to this job , so I will move on to welding tommorow. I think the axle and the bung are both some kind of steel so I should be able to use my 90 amp might Welder on them. Sadly it's been many years since I have welded anything so I will practice of a scrap piece so I do not totally bugger it up.

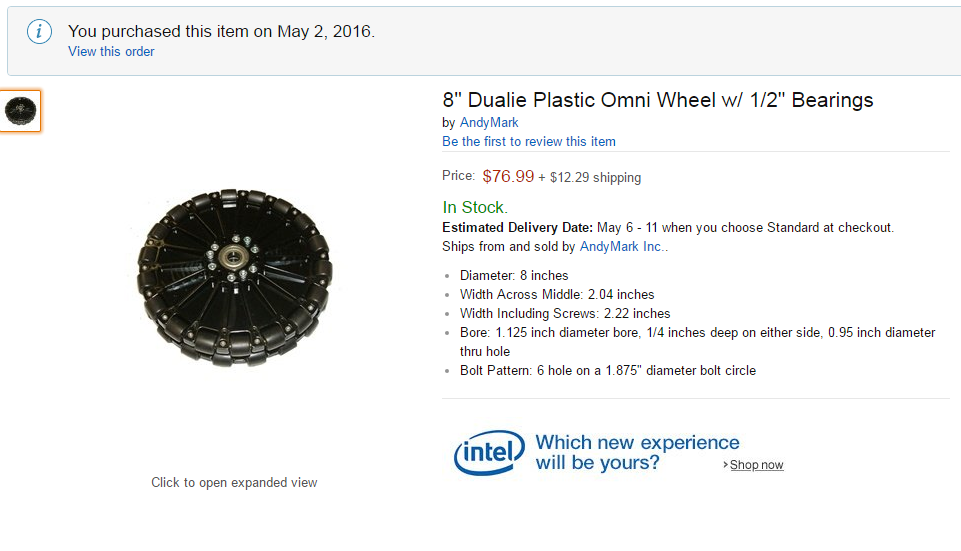

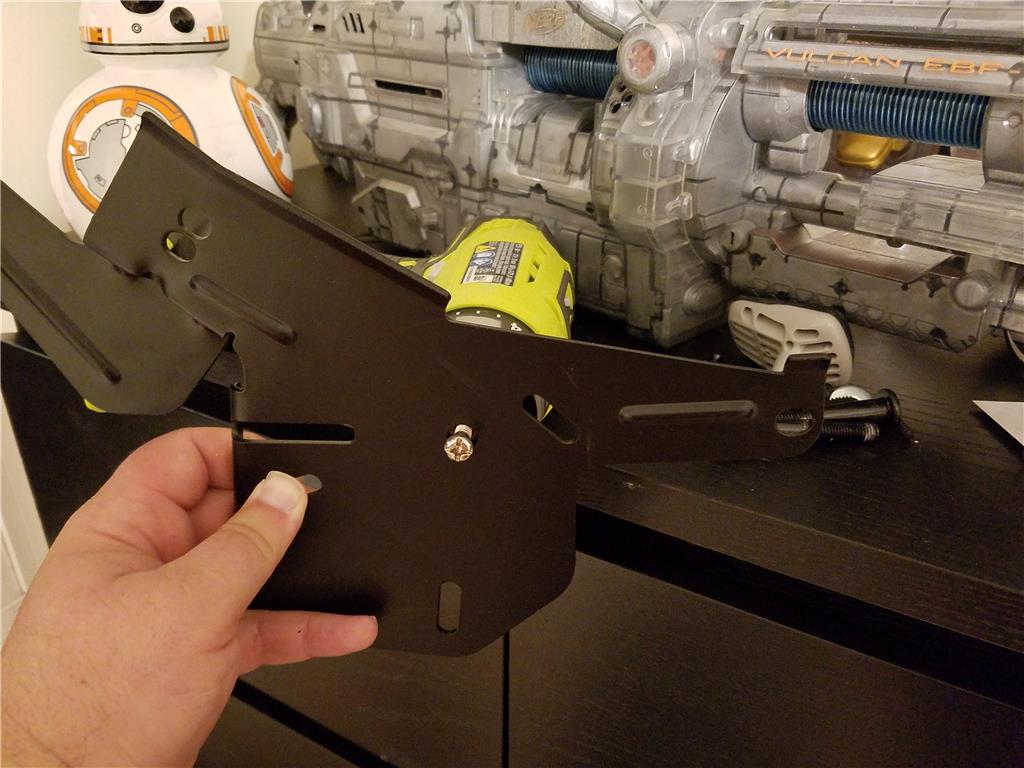

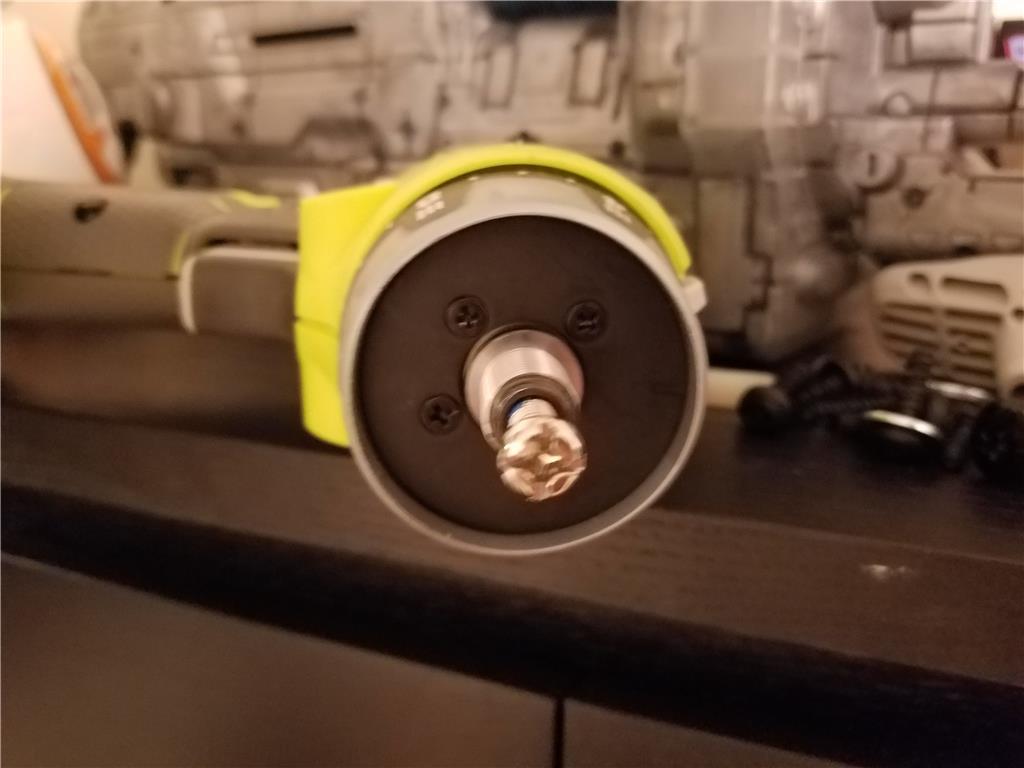

First axle tacked on in 2 or 3 places. It feels solid enough. I will wait till later once the motor is mounted to make a bead. I need to make sure everything lines up well.

Ok second axle tacked on. Here are pics with wheels on and different height settings.