Hello all, I am getting back in the saddle making robots now that I am moved into my new home and settled into my new job as a technician maintaining the Fiber Optics network in Chattanooga TN.

IM BACK !

By jstarne1

— Last update

Other robots from Synthiam community

Mikej's First Look At The Upgraded Model

UBM1 robot remake with bigger motors, stronger chassis and improved design for better performance-progress updates and...

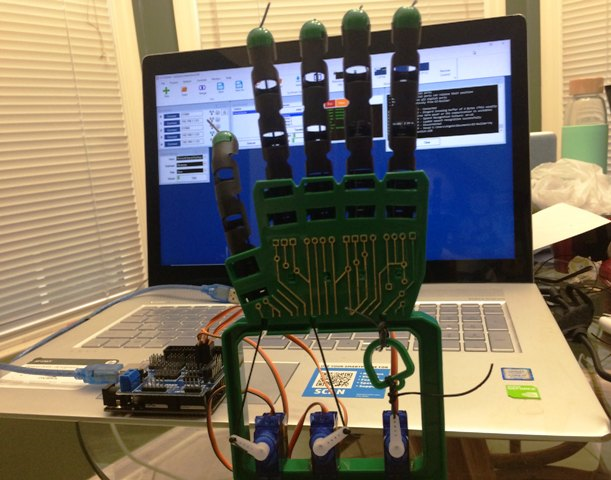

Ezang's Here Is A Picture Of The Hand I Am Practicing With

Photo of the hand I am practicing with

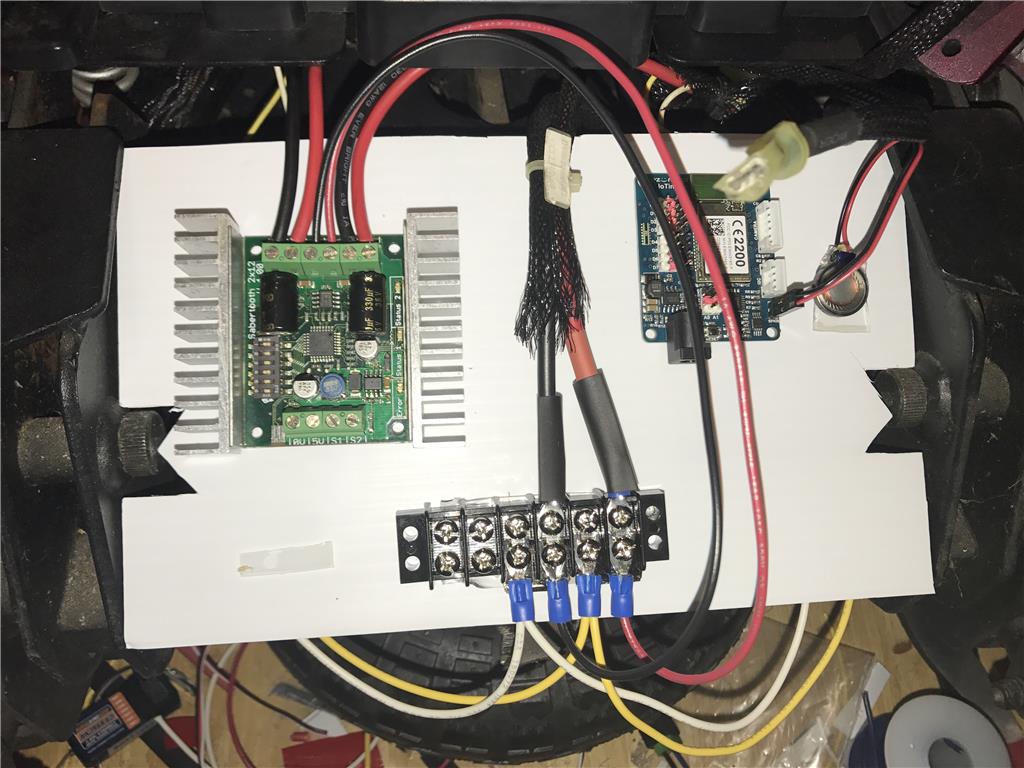

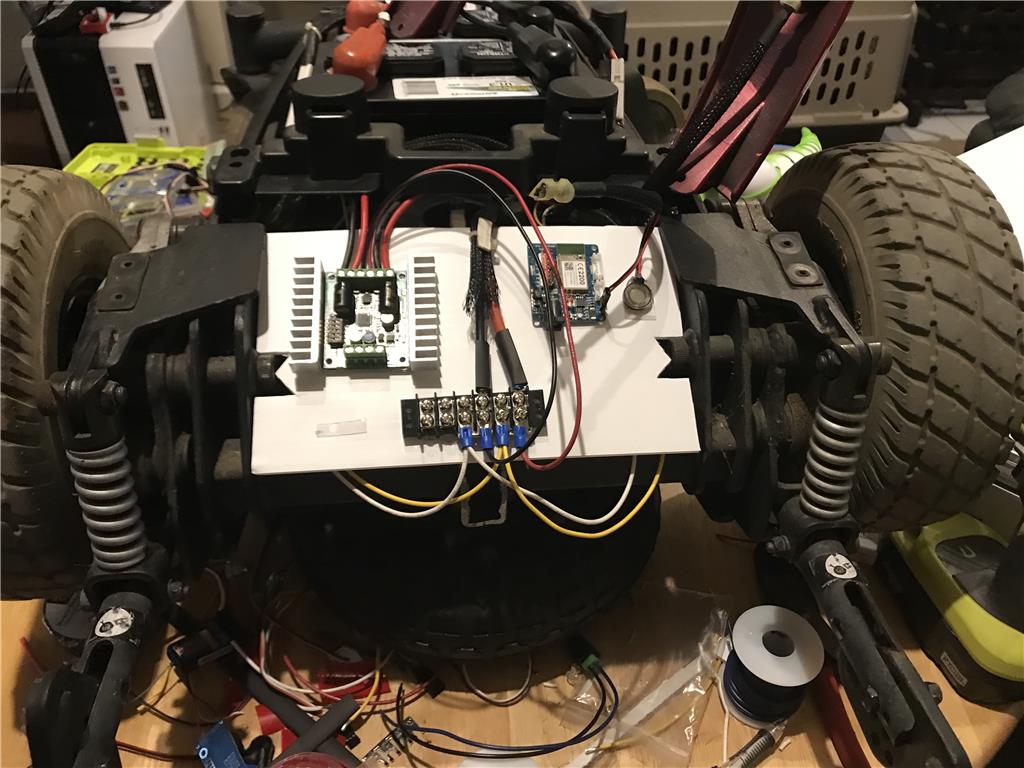

Rb550f's Ez Robot Rover V2

EZ-Robot rover CP uses Sharper Image EVAC drivetrain with EZB V3, Chumby touchscreen, fan-cooled electronics, micro and...

-635971125254815084.png)

-635971009768280111.jpg)

-636393423097260688.jpg)

-636337988865509663.jpg)

Just to throw this out there , this is the dragon con costume. I am thinking I will control all the lighting and vapor effects with a Web and phone on the chest.

LOL! "Luke, I am your father"!

Looks cool but..... Your a more dedicated fan then I would be. I couldn't keep that rig on my face while I'm walking around a convention.

That gun is sick! (sick in a good way).

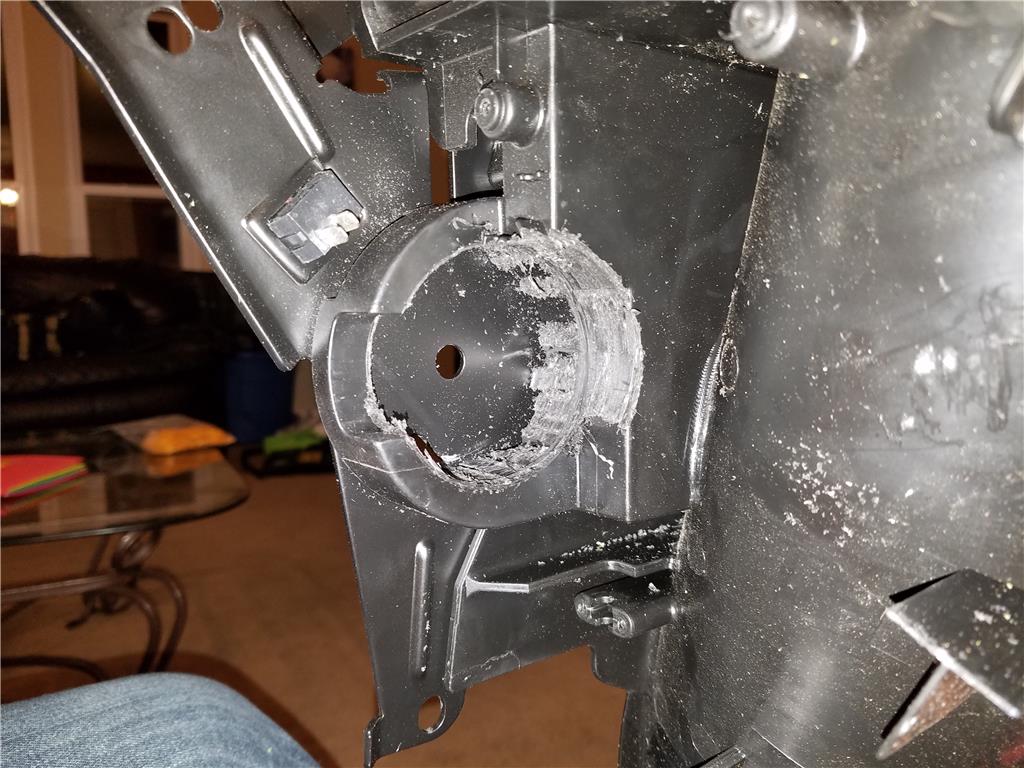

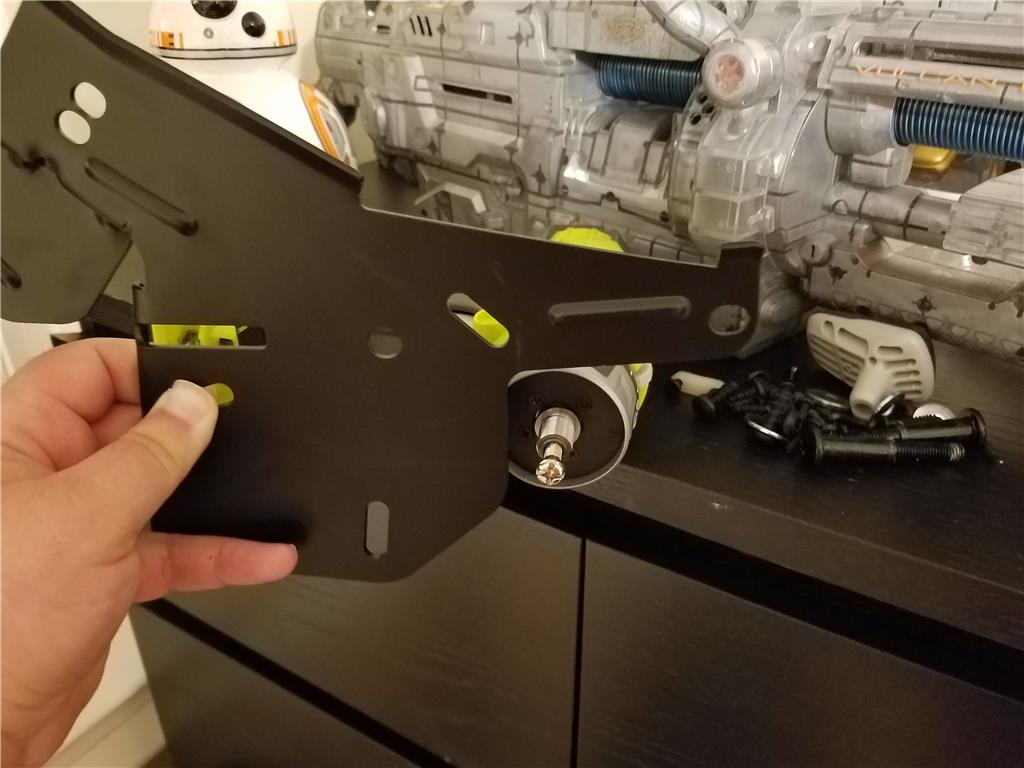

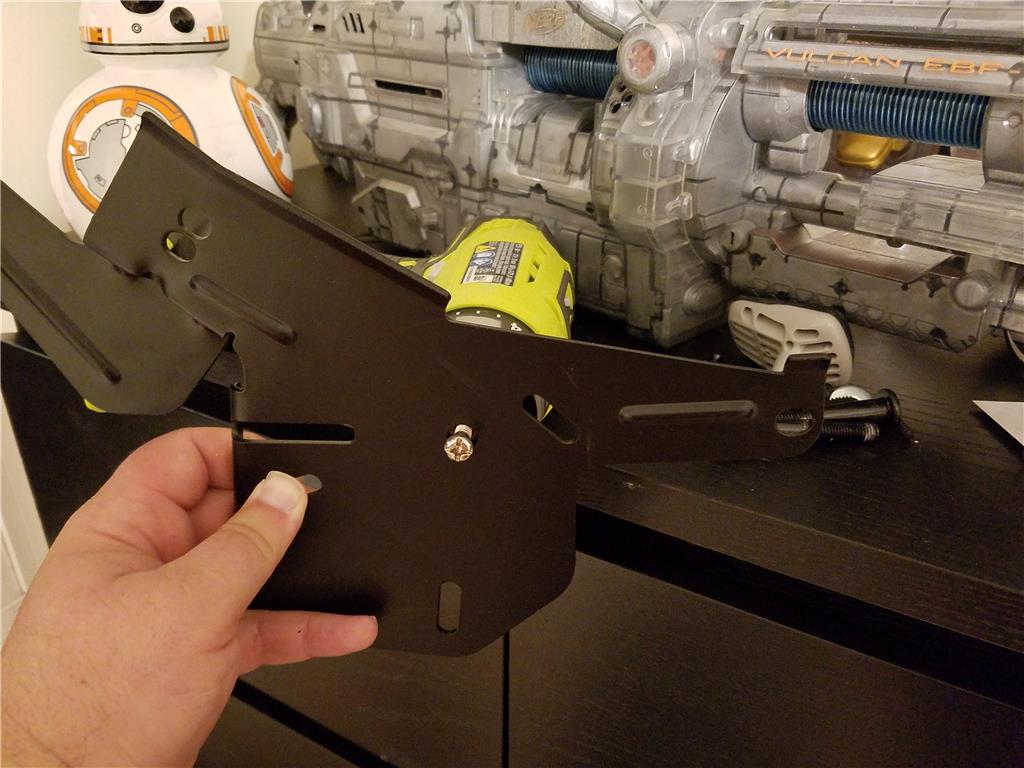

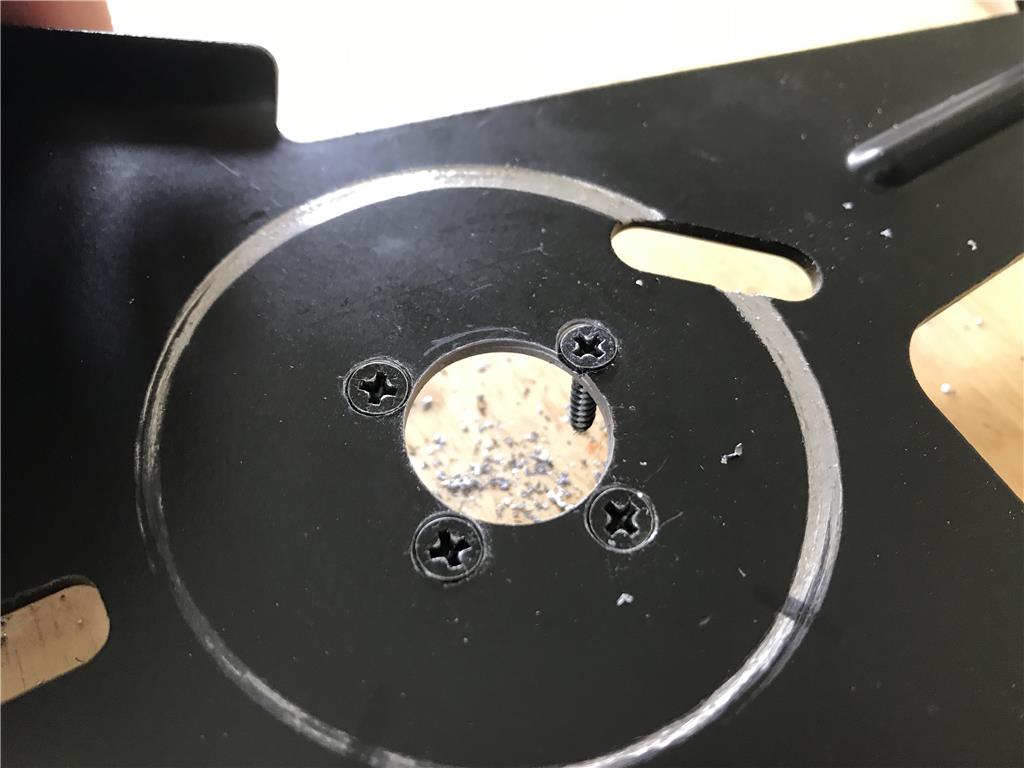

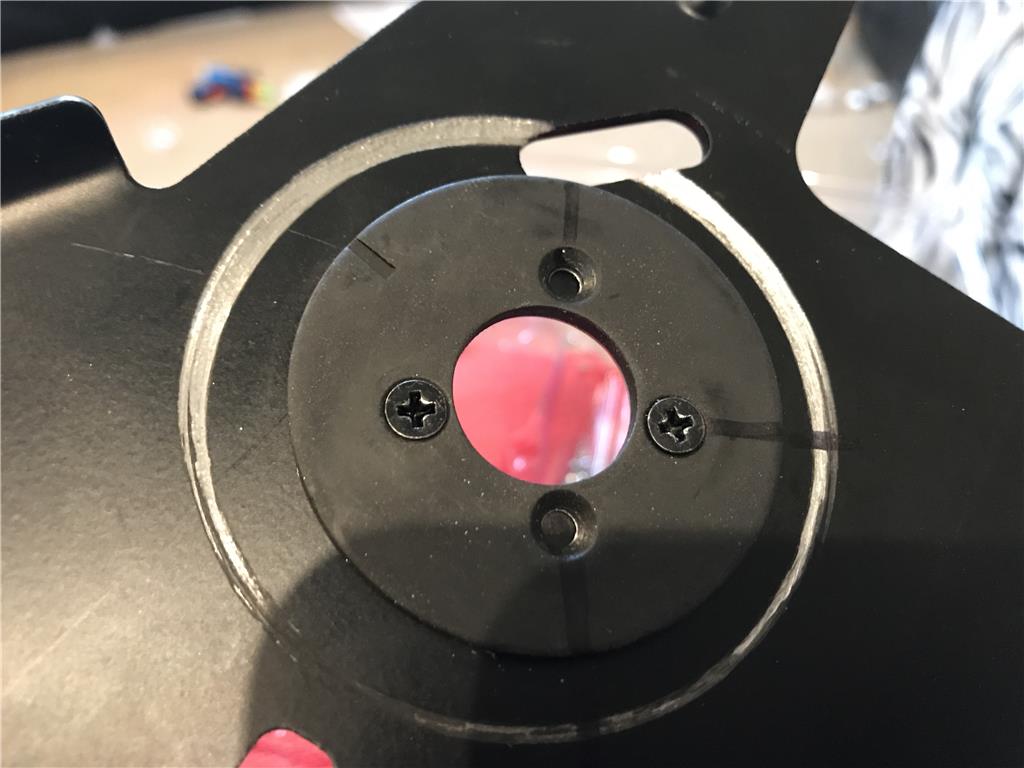

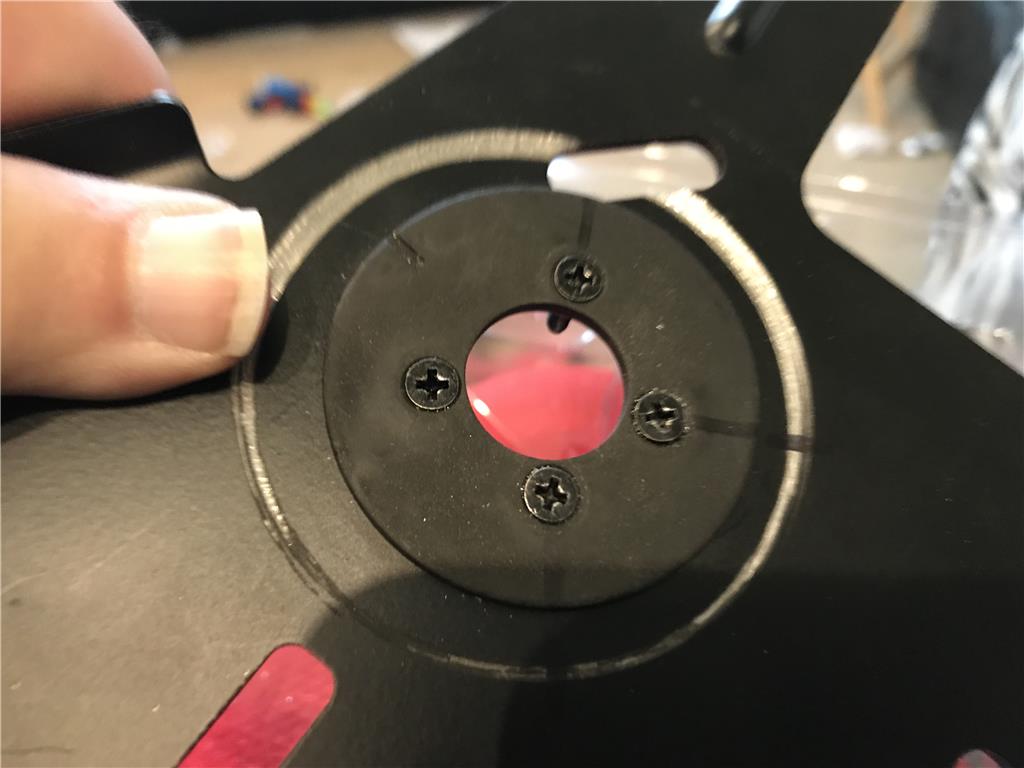

Ok so I am trying to get clever with mounting the aluminum sprockets to the wheels. I need a surface wide enough to accommodate the pre drilled mounting holes. I need at least 4 but I will probably use all eight to relieve general stress.

I purchased 2.5 inch pvc couplers and hit glued them into place with a foam board backer to hold the liquid plastic in while it cures.

Liquid in place...

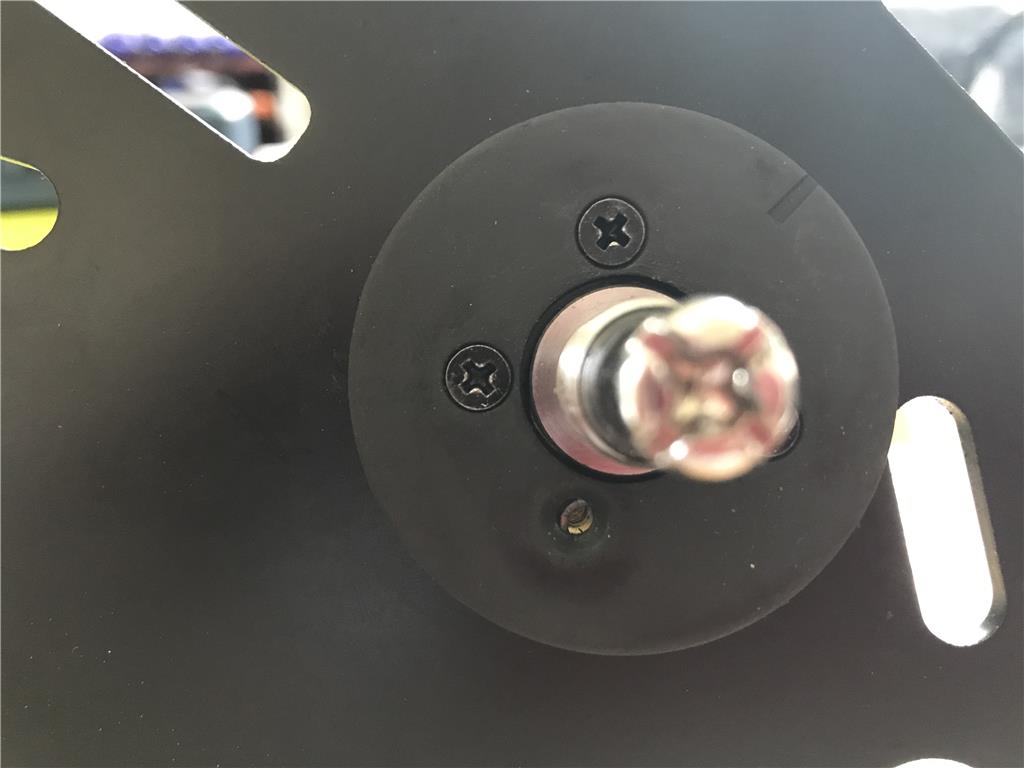

Polyurethane resin cured , 80 shore

Both are curing overnight and then I can cut the pvc couplers down to the level of the plastic surface I just made.

Looking good Josh! I wish I had time to work on bots. Can't wait to see this in action.

Where do you get your liquid plastic?

This plastic I picked up from hobby lobby. It was alumilite plastic resin. It's tough stuff not not brittle. Reminds me of abs. Also no funny smell when it cures! They have a fast cure version , 5 min but It gets very hot when curing.

Hello all, this thread was on life support , but I am bringing it back.... CLEAR! Booosh zzzt!

So I have been distracted with home improvements and car projects. I just finished the custom wheels for the Rav4 I bought a month ago.... I am a big fan of red.

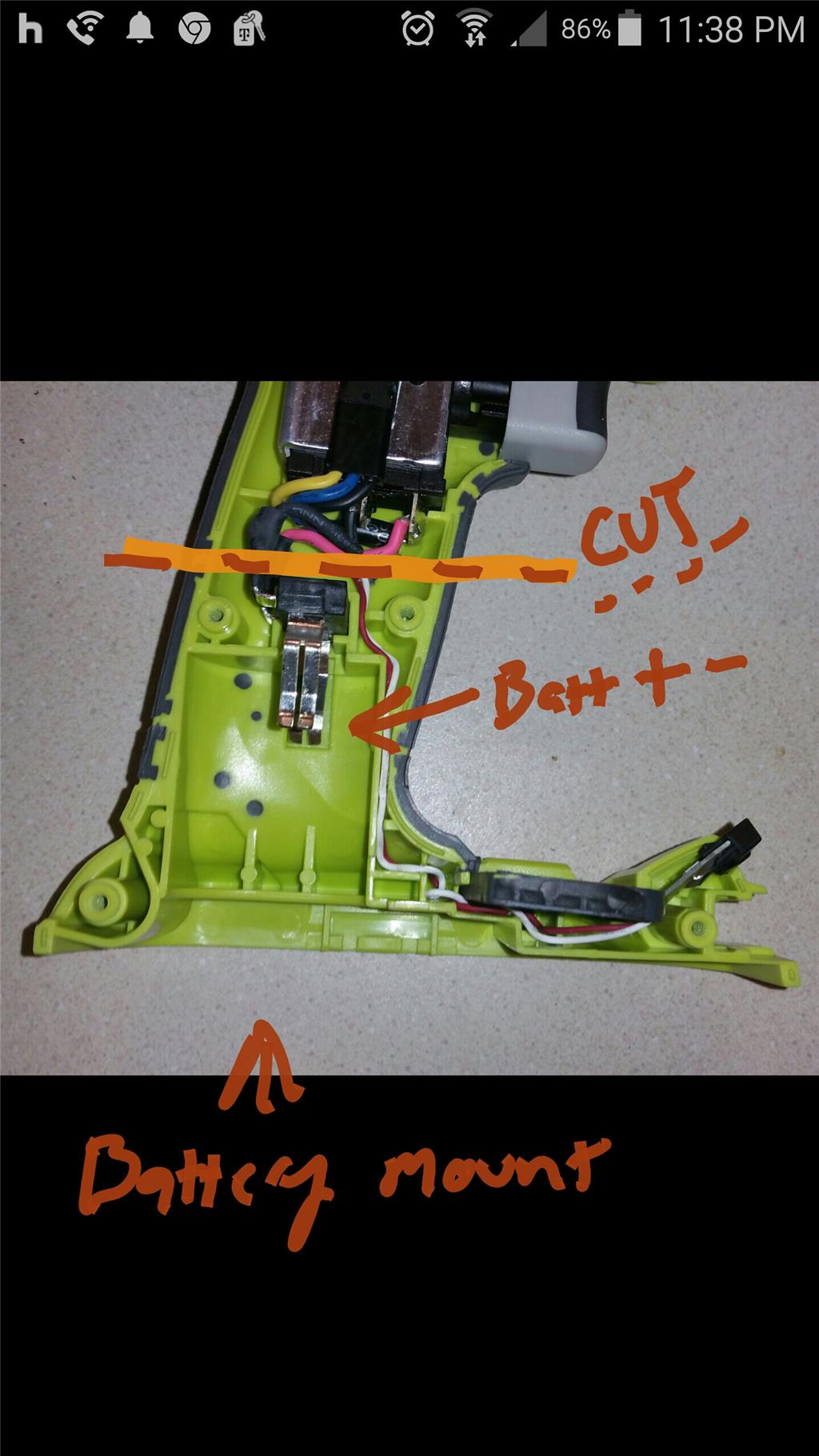

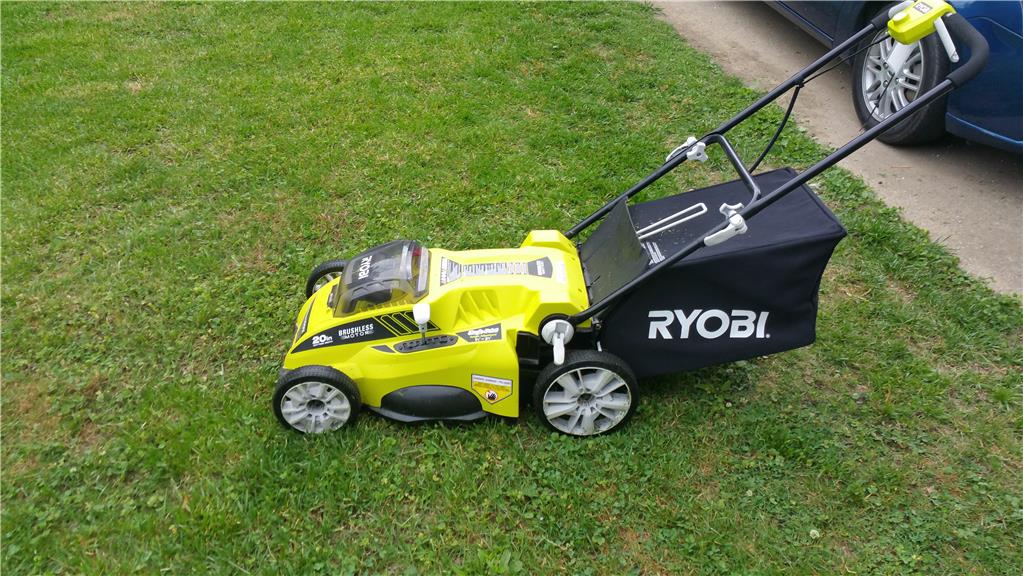

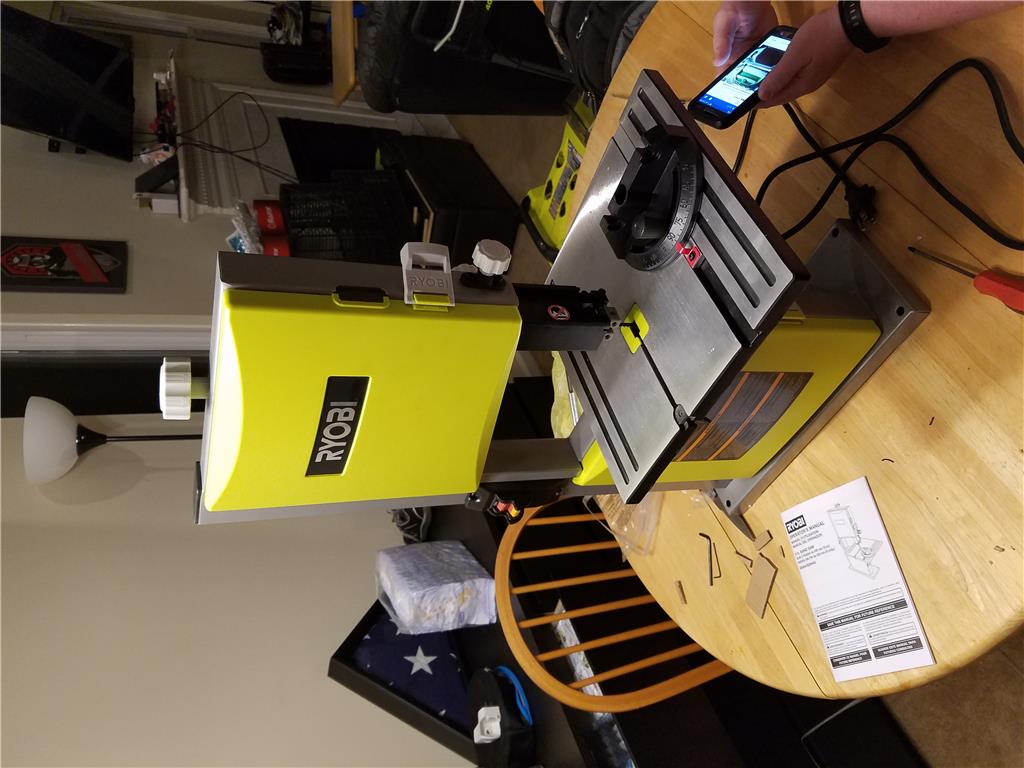

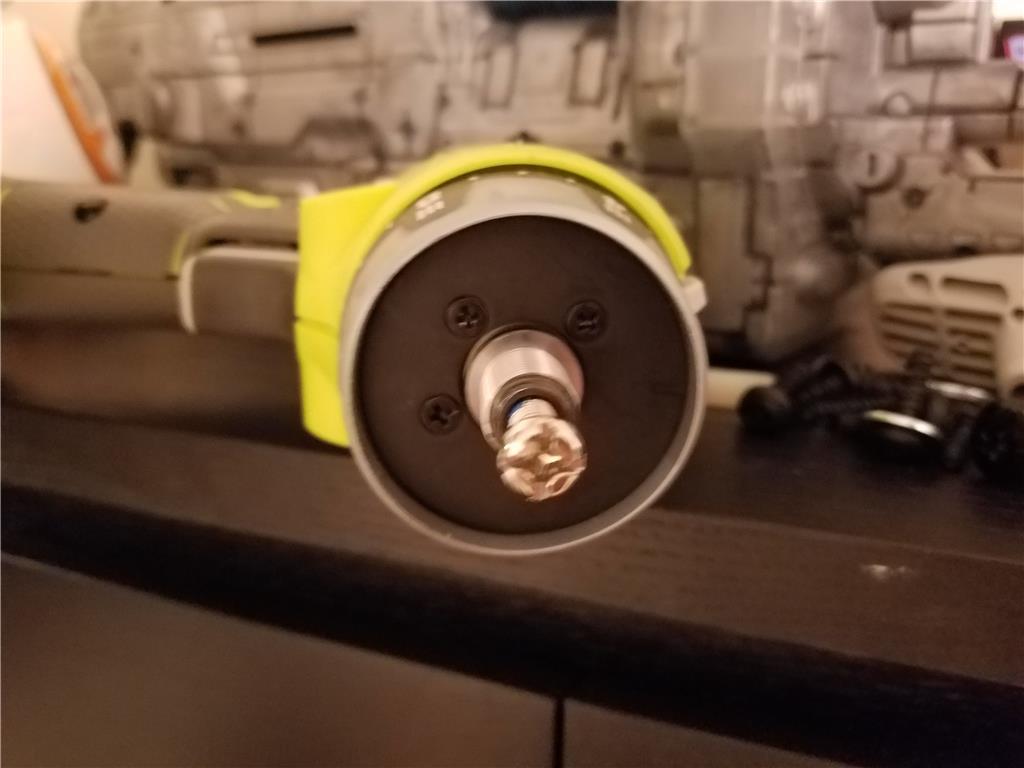

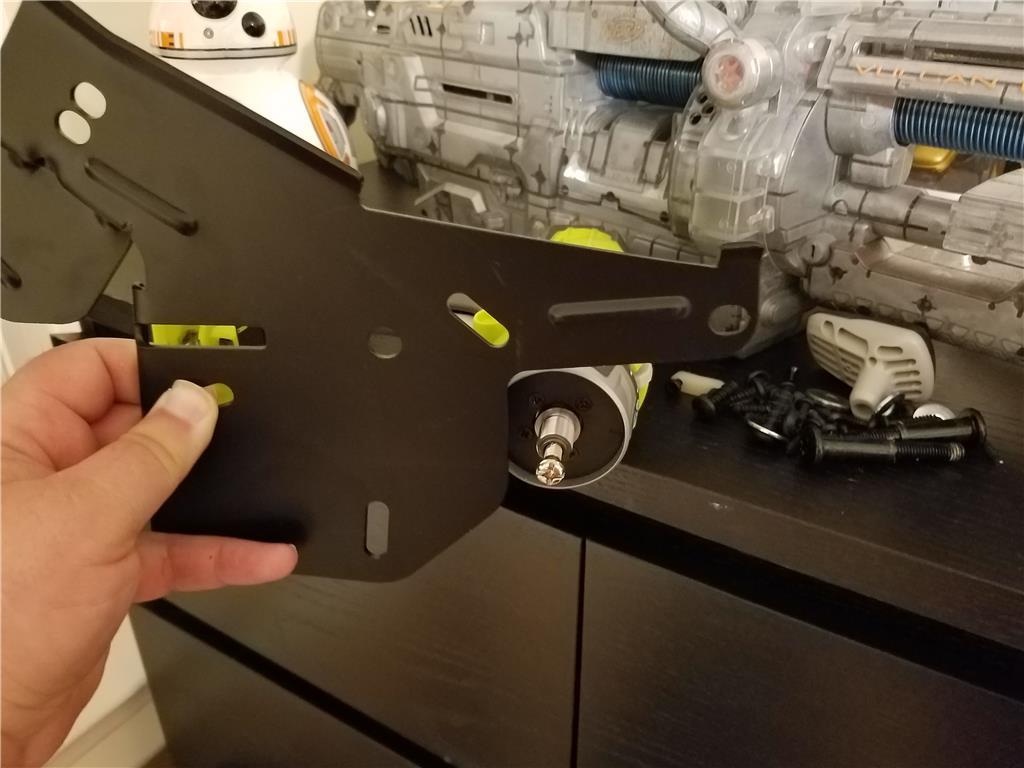

So a big incentive is the 2017 Ryobi nation contests, they have monthly and yearly as well. Up to 2500 for first place, so why not submit a robot that is 95 percent Ryobi products ! Muahaha

Think I could win?

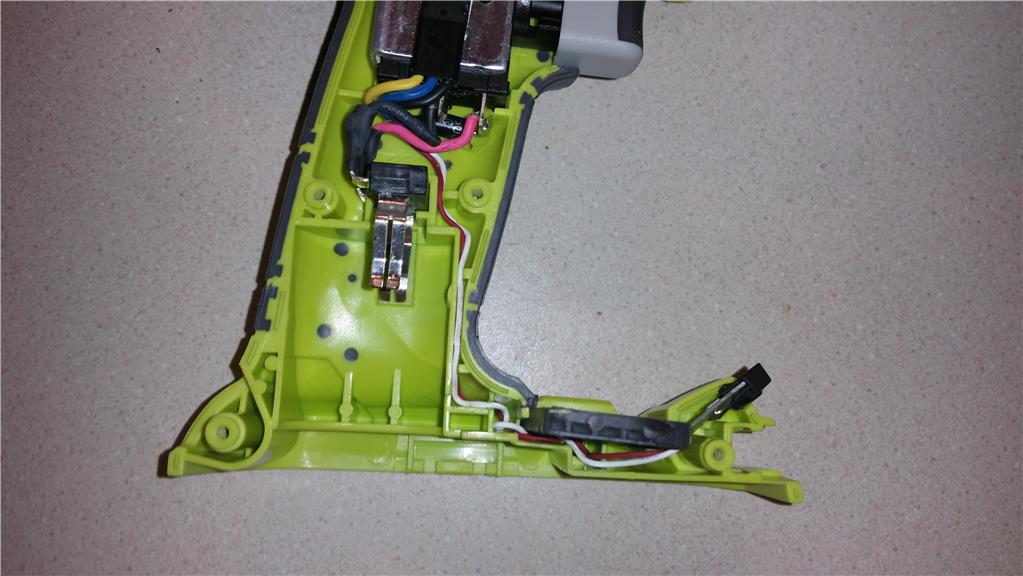

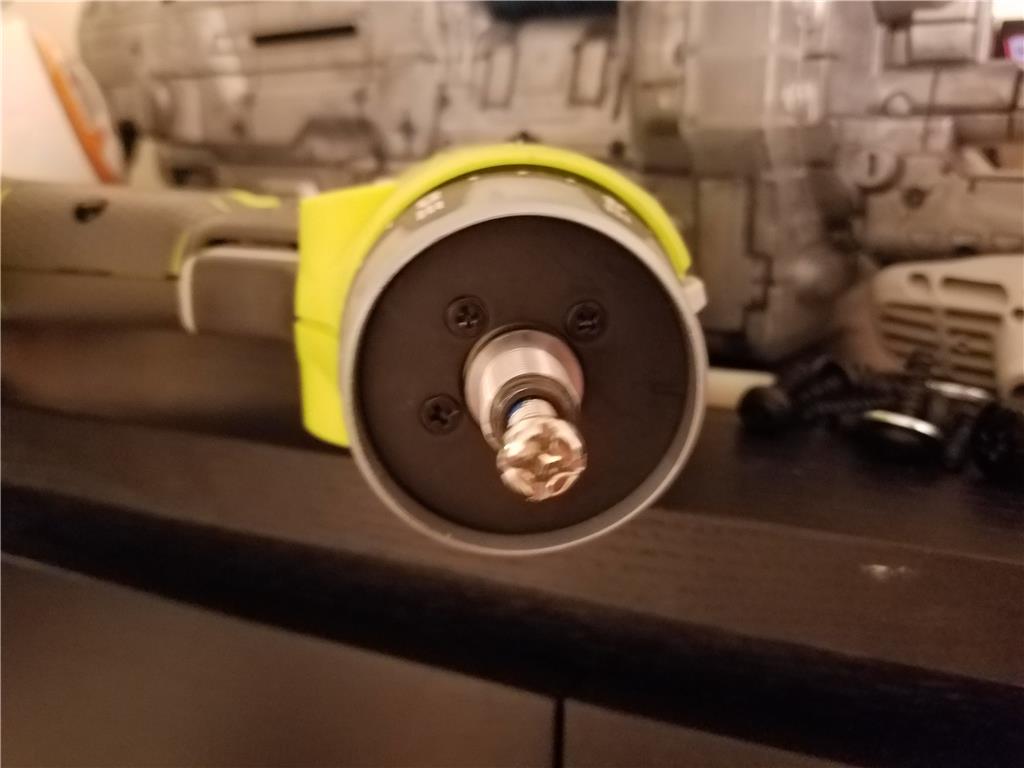

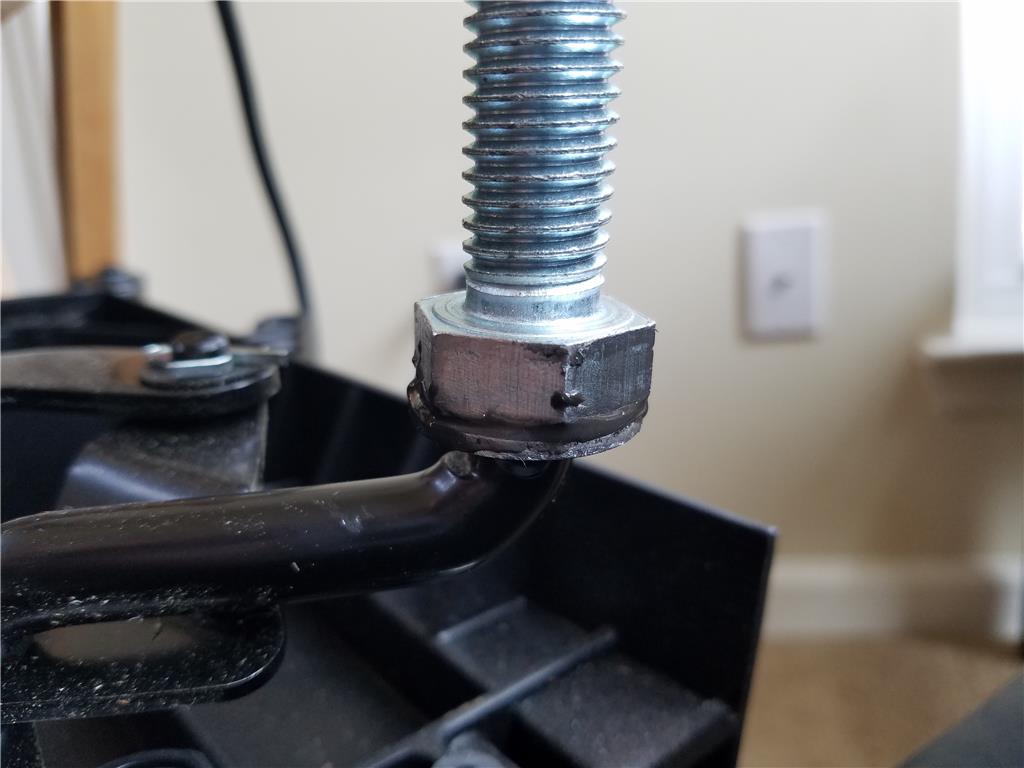

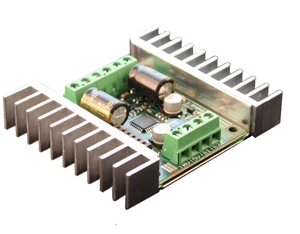

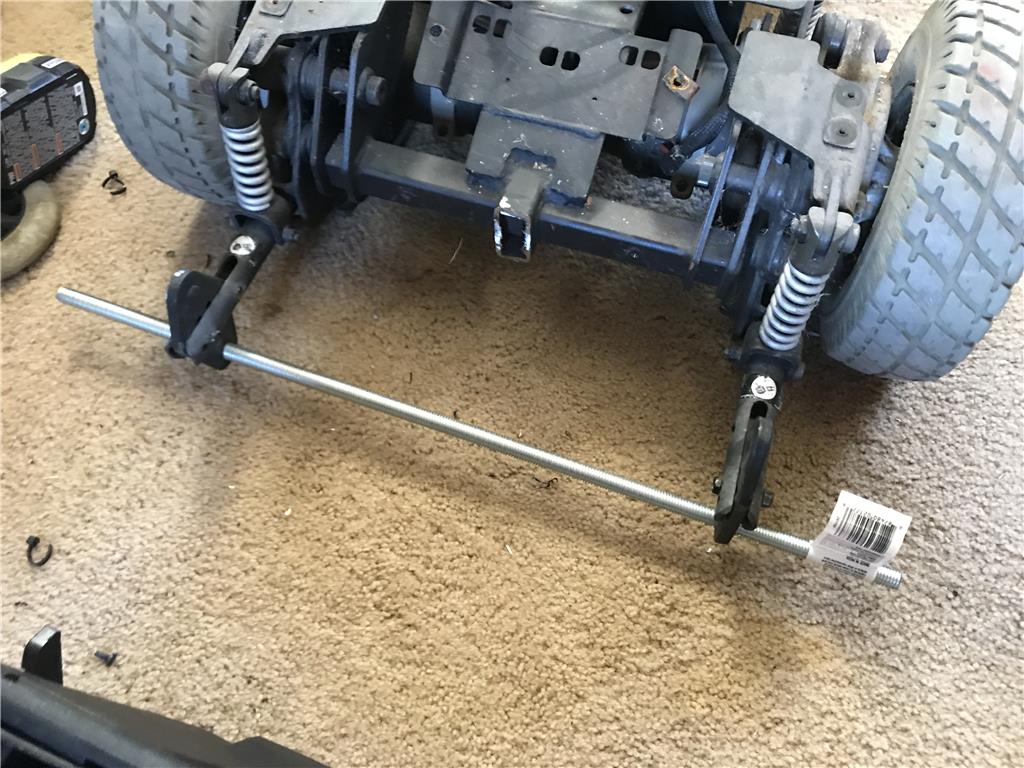

OK so back where we left off I was battling with how to handle the drill motors being mounted and the sprockets. The motor is not affixed to the gearbox so somthing has to hold them together. I was thinking of using the original casing of the drill ( and that is still possible) however I really need these things to breath so they do not get too hot. I am after all going to run them on constantly and probably half or more of their rated load. I imagine they would get toasty without air.