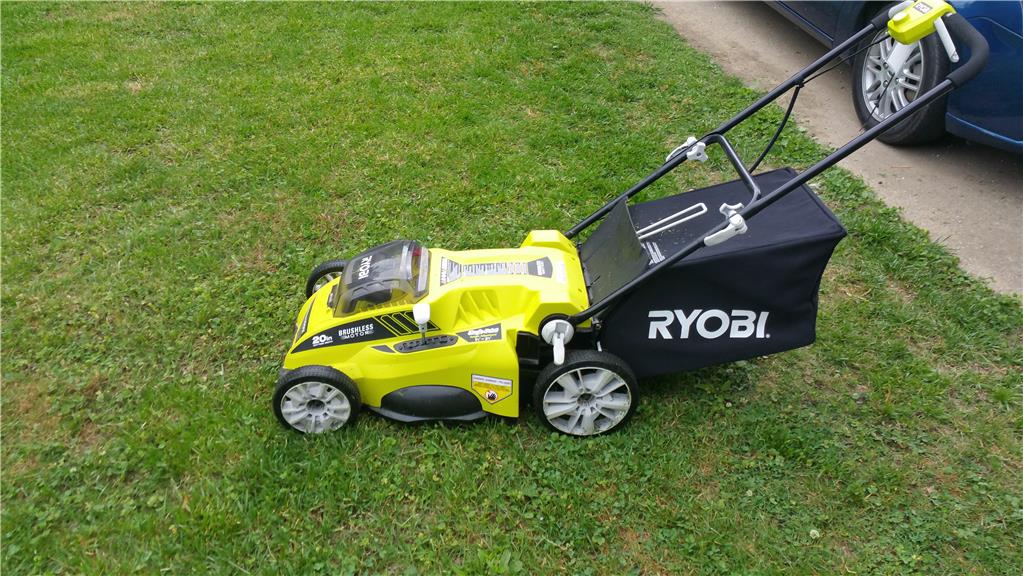

Hello all, I am getting back in the saddle making robots now that I am moved into my new home and settled into my new job as a technician maintaining the Fiber Optics network in Chattanooga TN.

IM BACK !

By jstarne1

— Last update

Other robots from Synthiam community

A's Teddy Robot

Humanoid teddy robot upper-body project inspired by the movie A.I.; Bluetooth restored via new laptop, photo build...

Luis's Using The Sure Dc Ss503v100 With Ezb4 From Ez-Robots

Connect Sure DC SS503V100 compass to EZ-Robots EZB4 via UART: RX/TX wiring, set OPT high to 3.3V, 4ft wire tested,...

DJ's Imperial AT-AT Walker Robot - The Force Is With Me!

Build an Imperial AT-AT walker robot; adding knee servos tomorrow to teach it to walk as a return to robotics.

-635971125254815084.png)

-635971009768280111.jpg)

-636393423097260688.jpg)

-636337988865509663.jpg)

Thanks Rgordon!

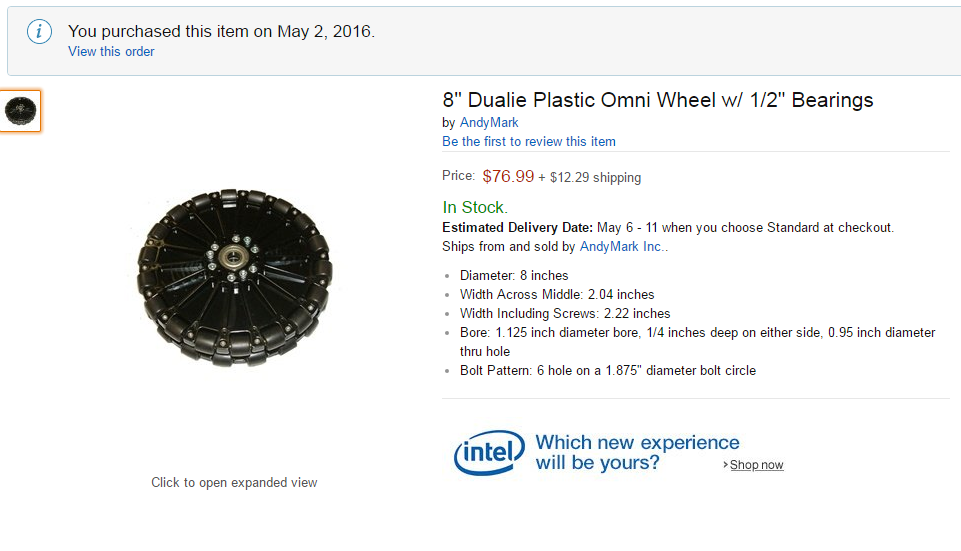

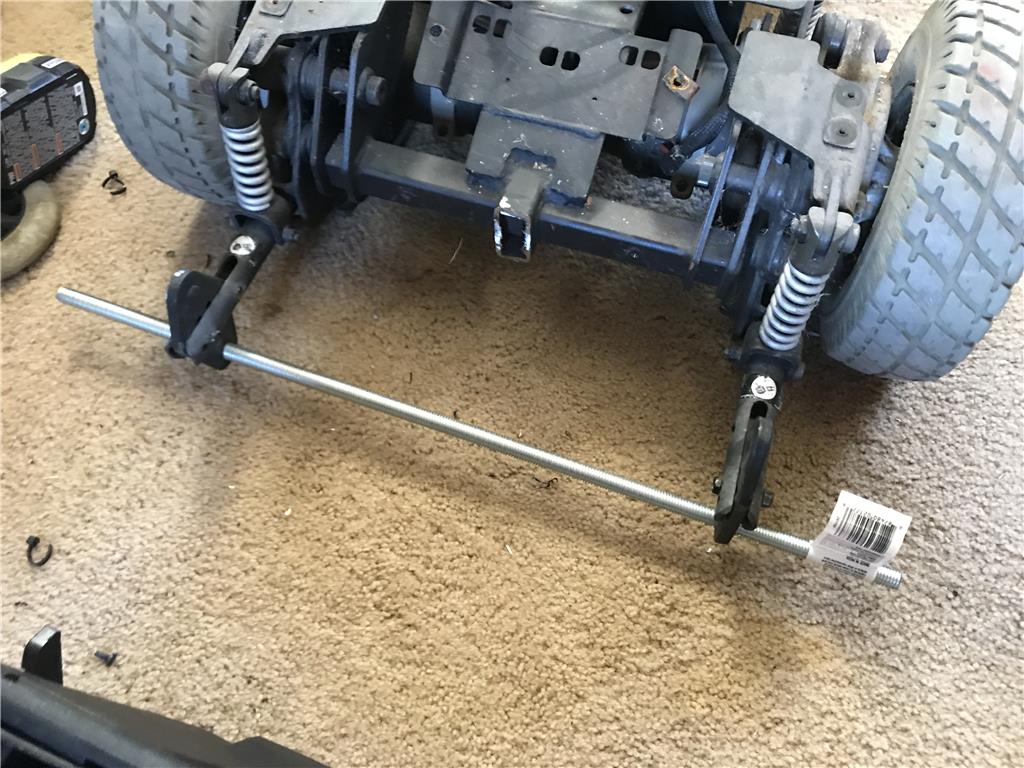

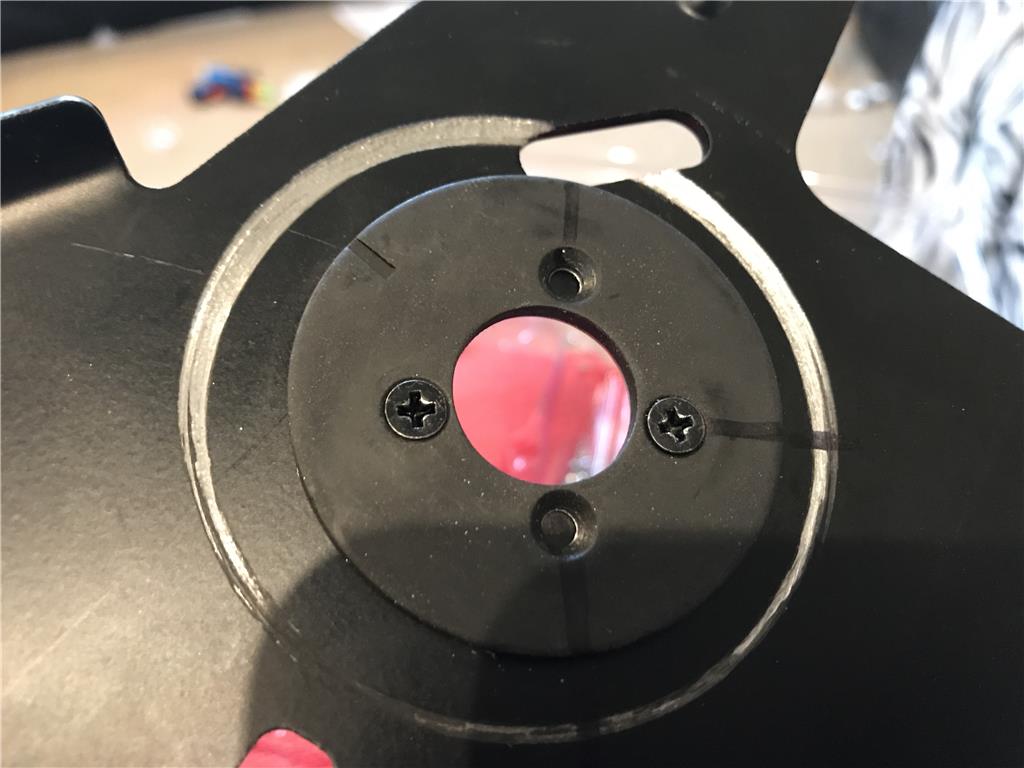

Ok as promised Andymark wheels arrived very quick. I was eager to unpack them and compare the to the wheels they intend on replacing on the robot mower. Spot on !

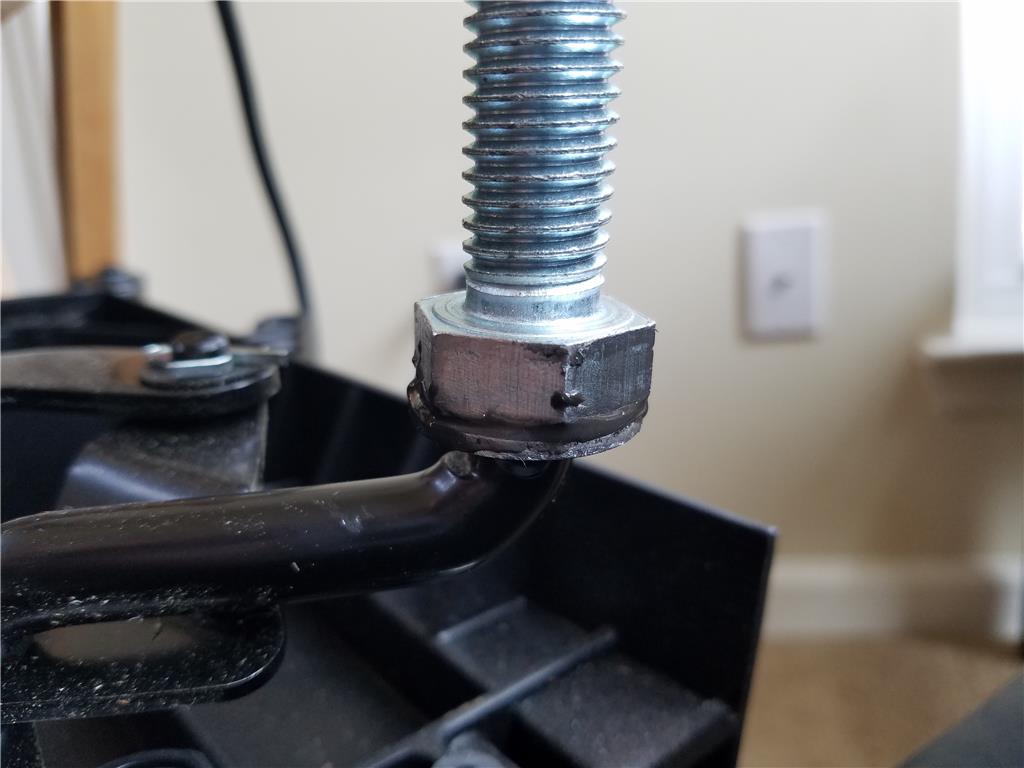

My only concern is the thickness of the bearing. We will see if I need to modify anything to get it to fit snug without wobble as this has ball bearings.

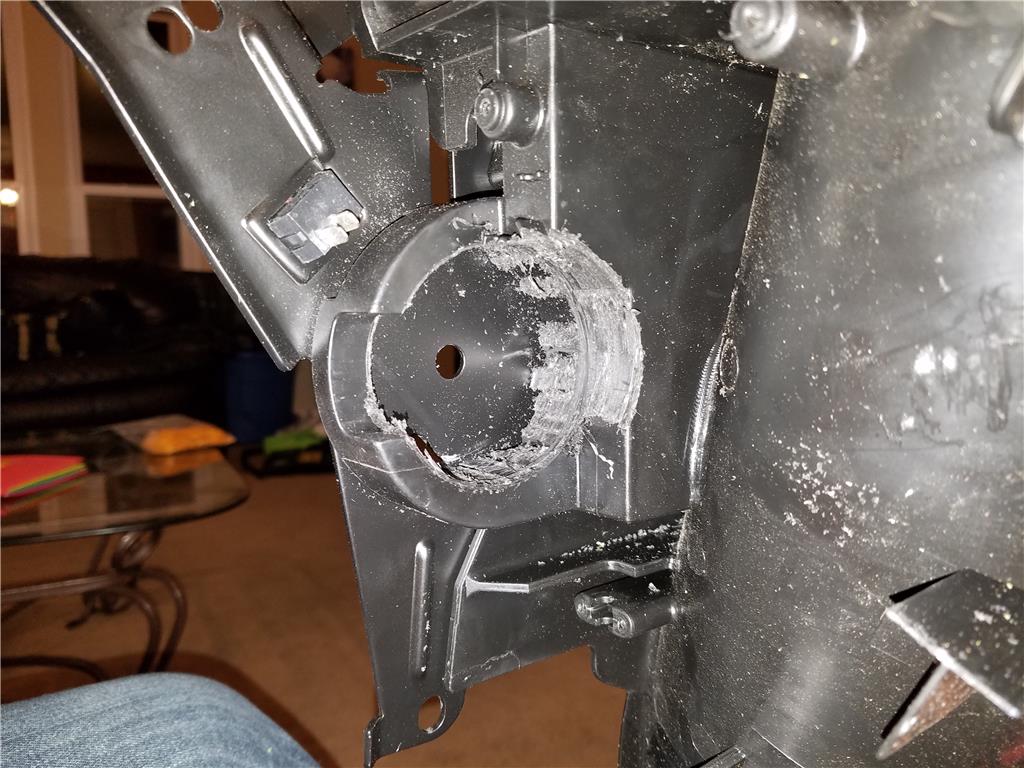

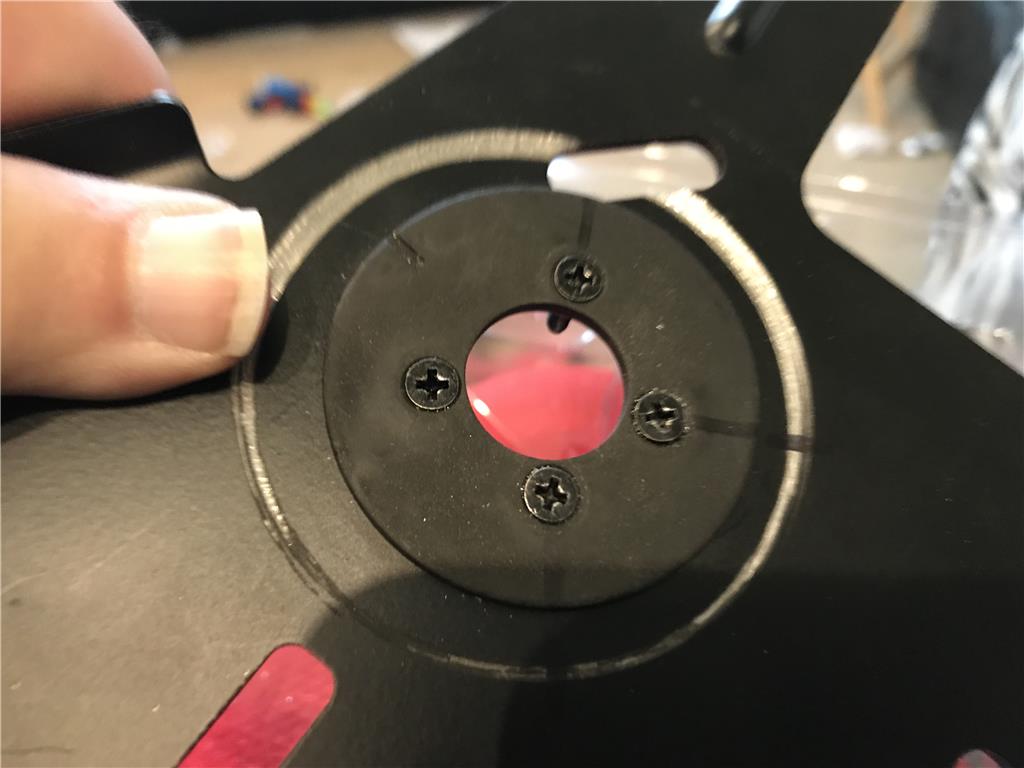

Ok I've been working on making a really big back deck , so now that rain is moving in I will move back to robots. I tried slipping the bearings onto the axle shafts and they do not fit I believe that the powder coating of the axle has made the thickness a little more that 1/2" thick. I will probably pull out a sander and remove the coating so I can get these wheels on tonight.

I am curious about how the Omni wheels will work on the lawn. Even though I have some concerns, it is a great idea. It is great to follow your projects again. Your neat ideas have been missed.

Thanks for sharing,

Ron

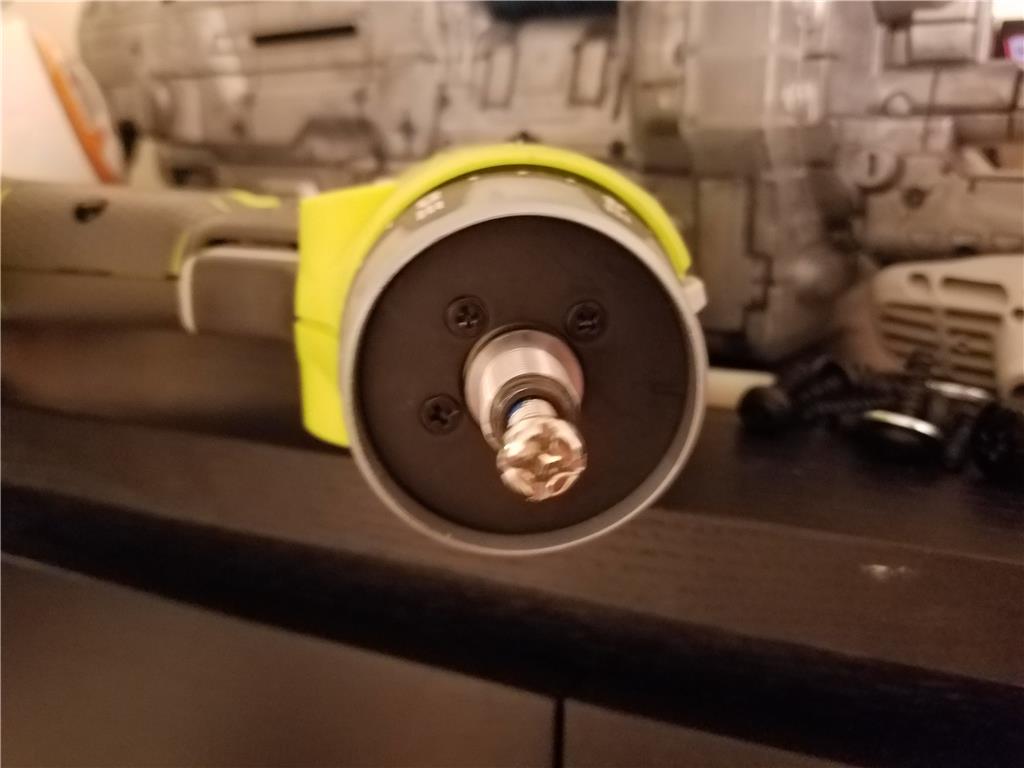

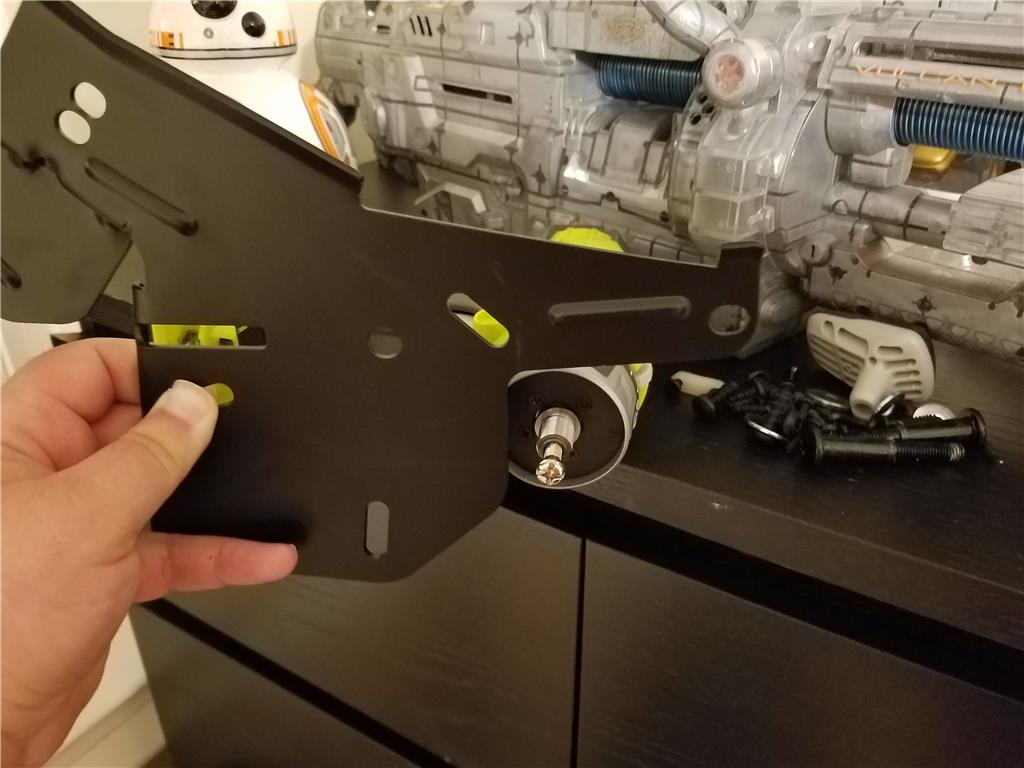

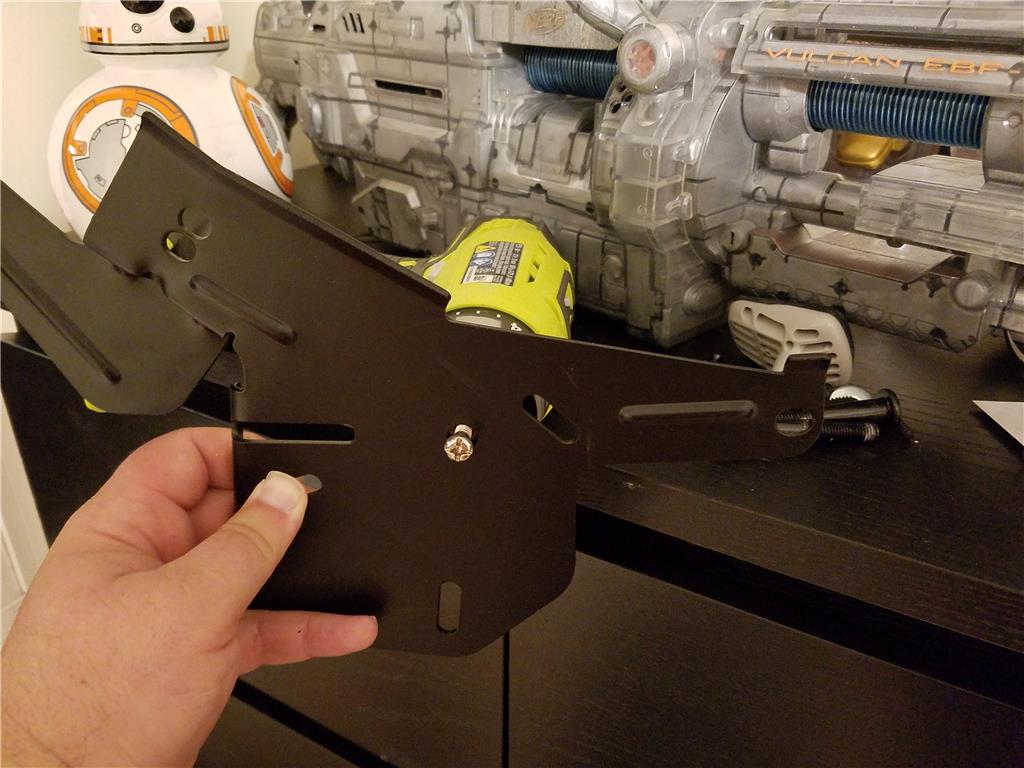

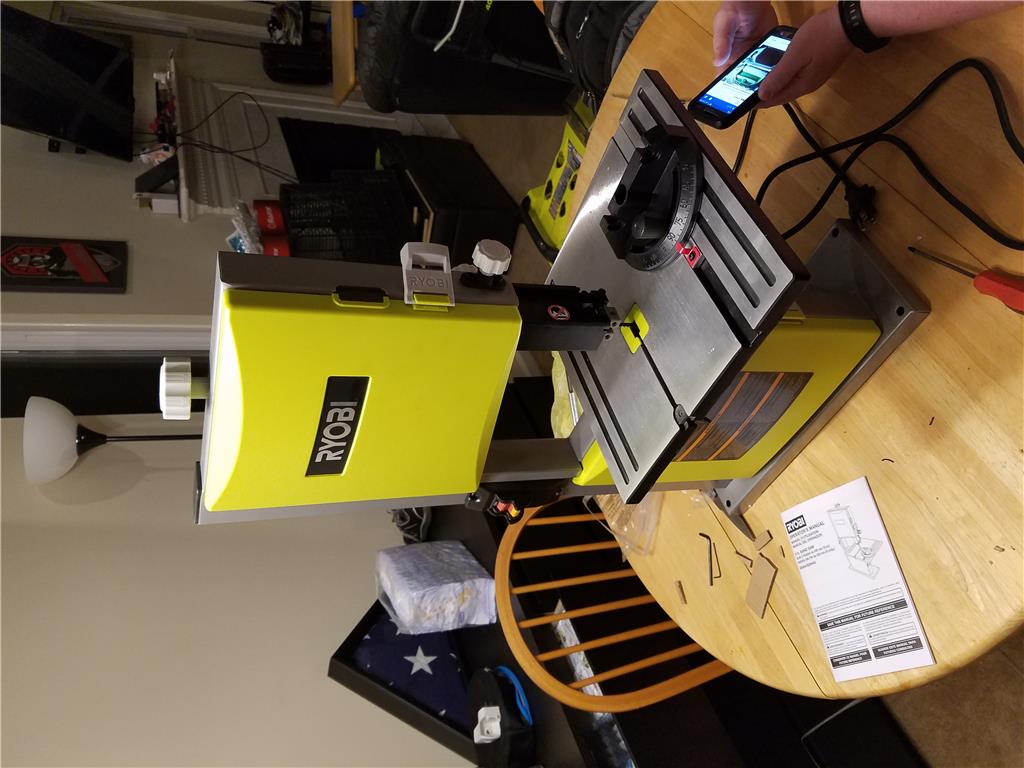

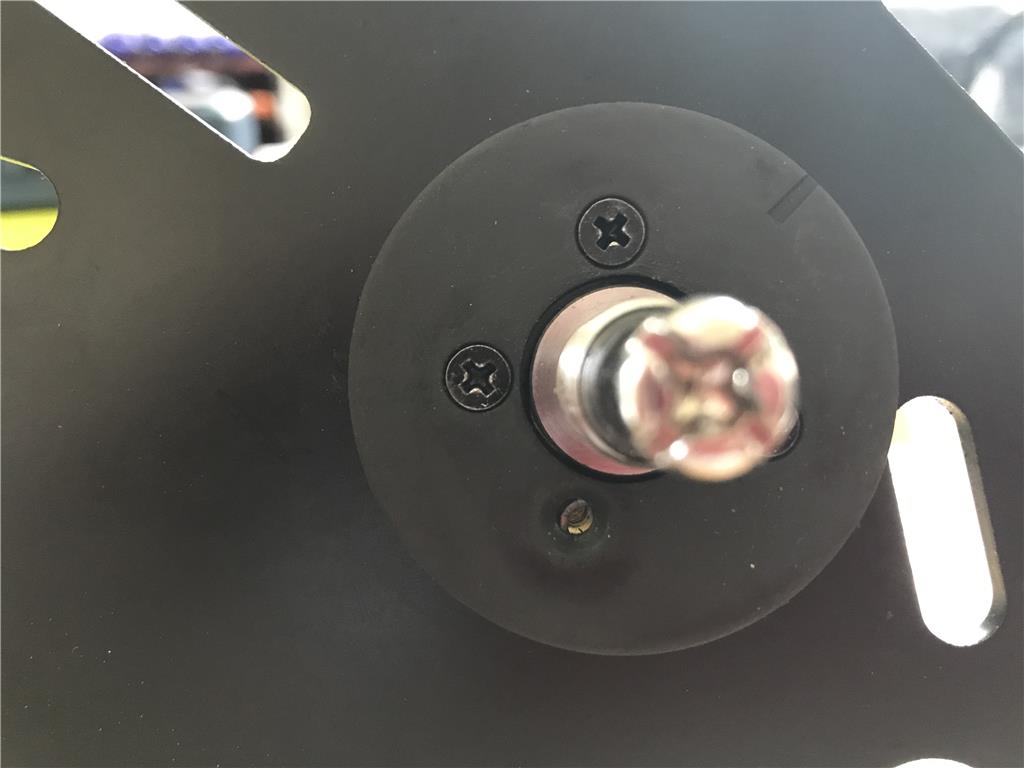

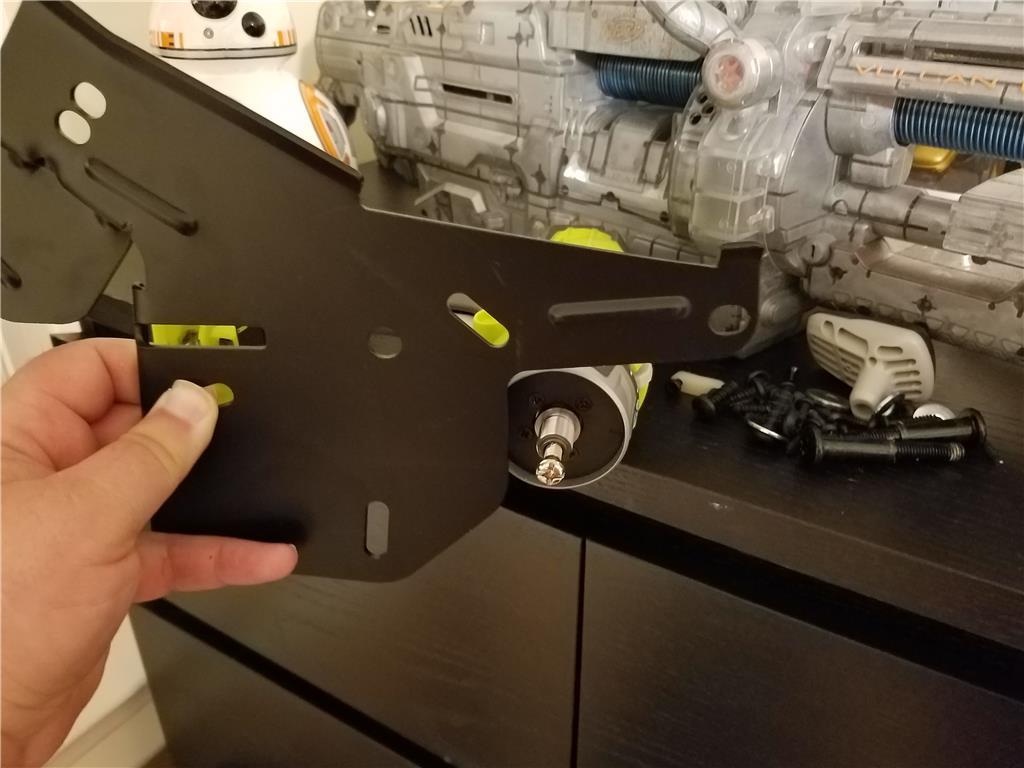

Thanks Andy! I see many other robot mowers not even bother with changing the front wheels. They just let them drag like a skid steer system. Though mine isn't much different I would feel it is a sin to drag things around lol. Anyways after minimal modification of the powder coating on the axles , the ball bearing sets I ordered now fit. I sanded the shaft down with a electric palm sander (ryobi ofcourse) with a 60 grit pad. I may try a retrofit onto the back wheels as well since these are so nice. I only had room for 3 of the 4 sets of bearings. I had to pop the outer bearing out. They are on snug ,but spin freely without any side to side wobble on the shaft.

Just in case anyone is just now tuning in , I used the original axles because they have a mechanism I can utilize to adjust the height and keep the mower level at the same time. It could all be done with one servo or linear actuator.

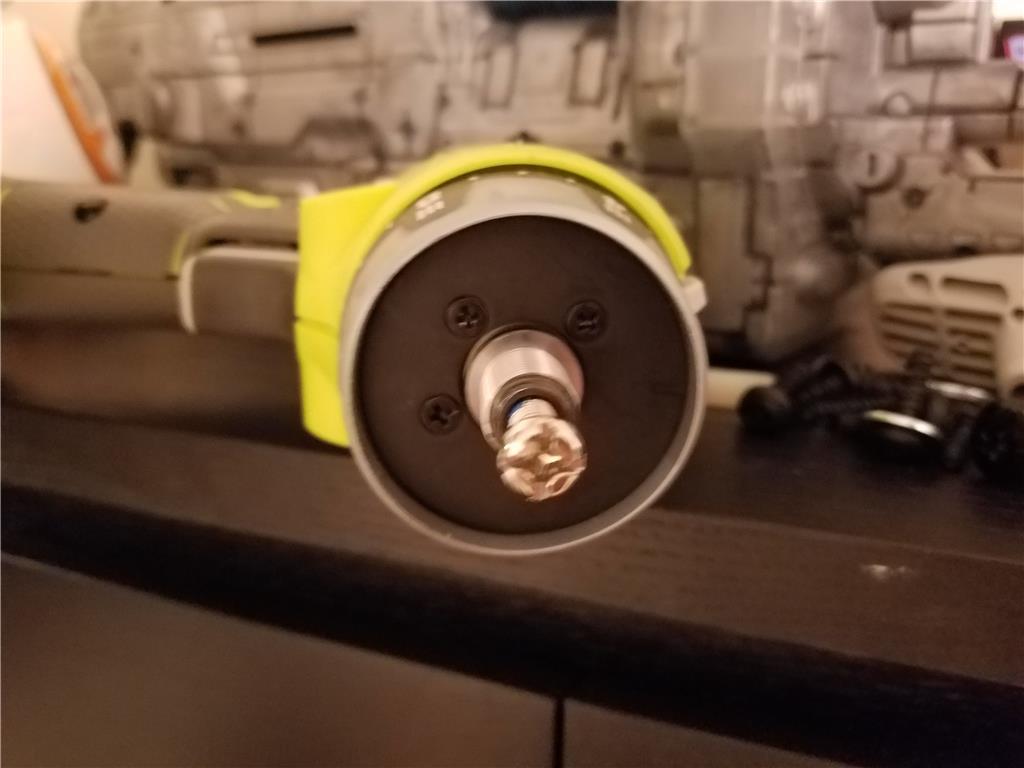

Ok tiny update , the new set of 600 Oz in Hammer drills arrived. I think I bought this set through Amazon for 42 dollars each. Great price for a brand new motor and gearbox. If you keep the clutch you can prevent stalling if you exceed the torque rating too.

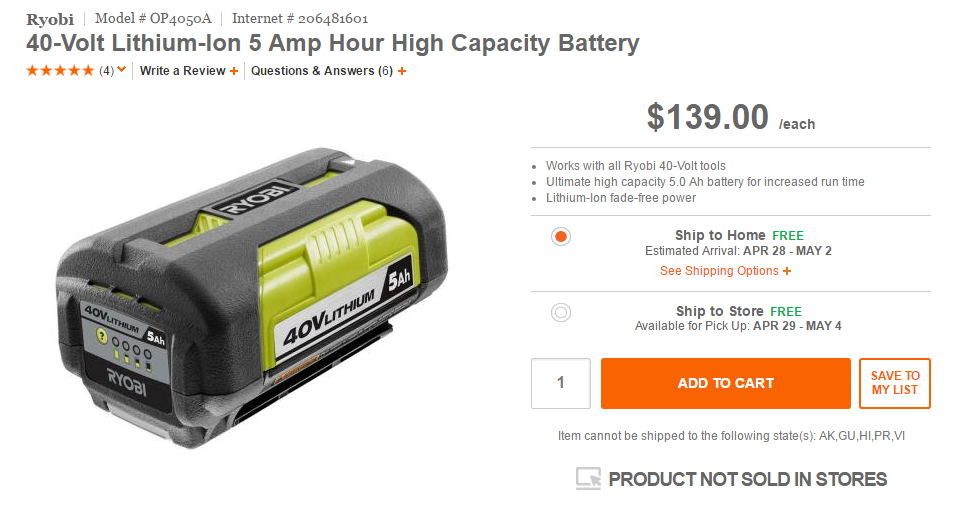

Ok so I was thinking about batteries and such. If I have drill batteries to power most the robot except the main drive motor then I will need a way to disconnect and swap them easily. The batteries come with a 5 year warranty if you register them so that's a thing. I did find out for other robots in the future that Rigid has a lifetime warrange on batteries. So if you ever need a battery for a project you can replace forever.... that's an option.

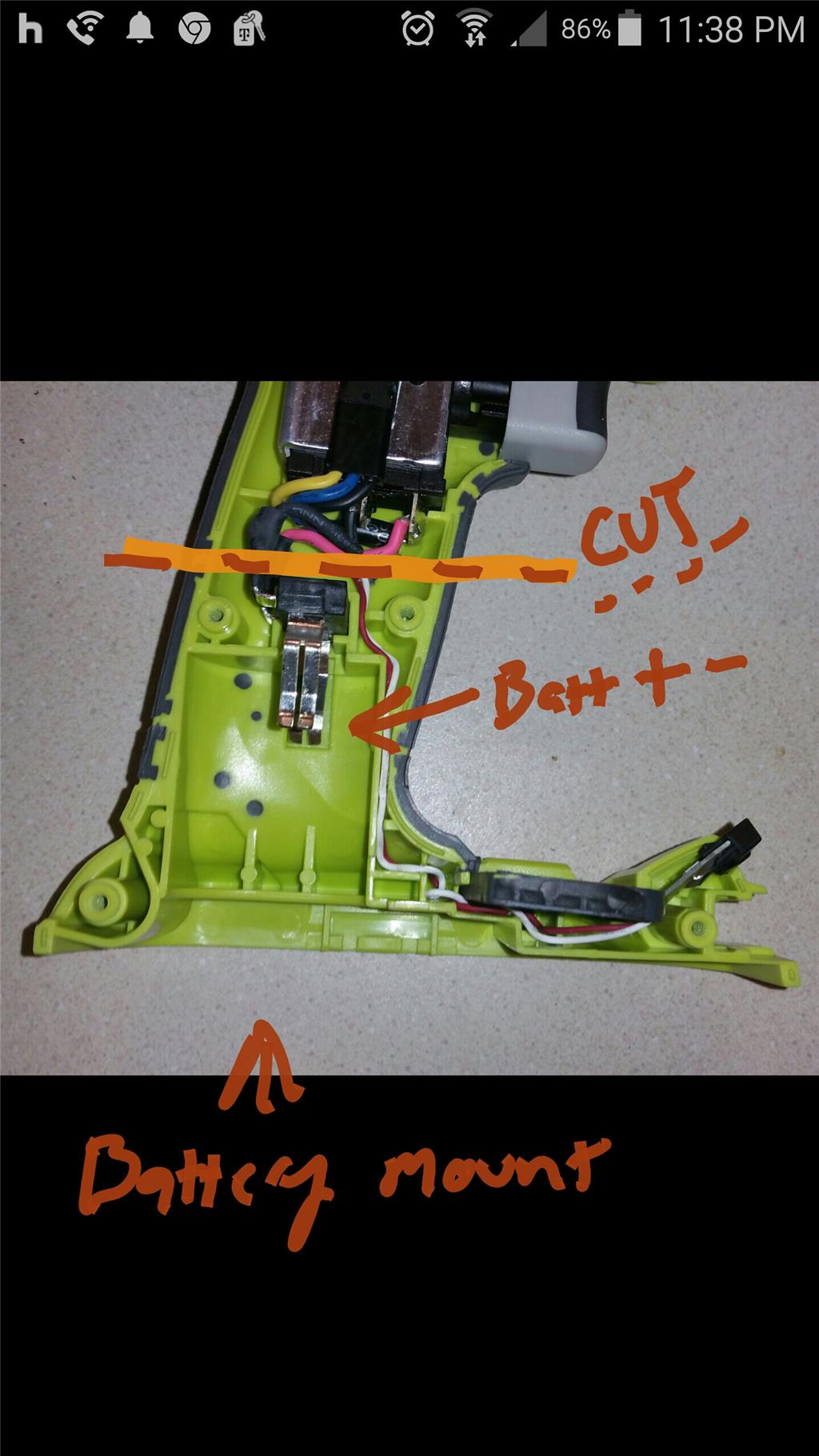

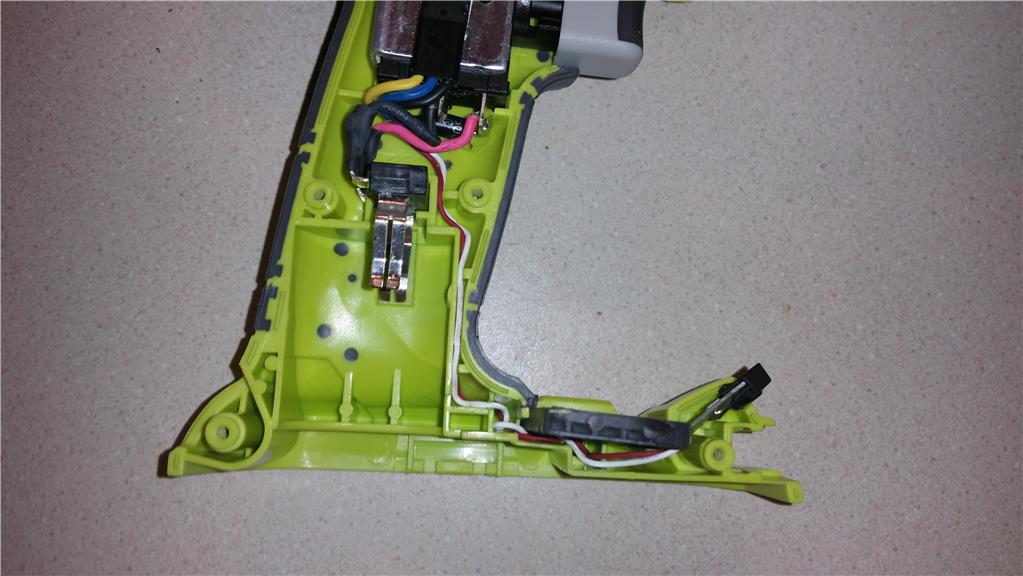

The case for this drill will not be wasted. The top half I can utilize as a sort of mount and the bottom half of the handle I will cut off just above the screws so that I can make battery mounts for them on the robot. I'm still contemplating where they will go. First place that comes to mind is the top of the robot facing down the next is to try and hide them under the shell somehow with a pigtail for charging until I get this thing a dock.

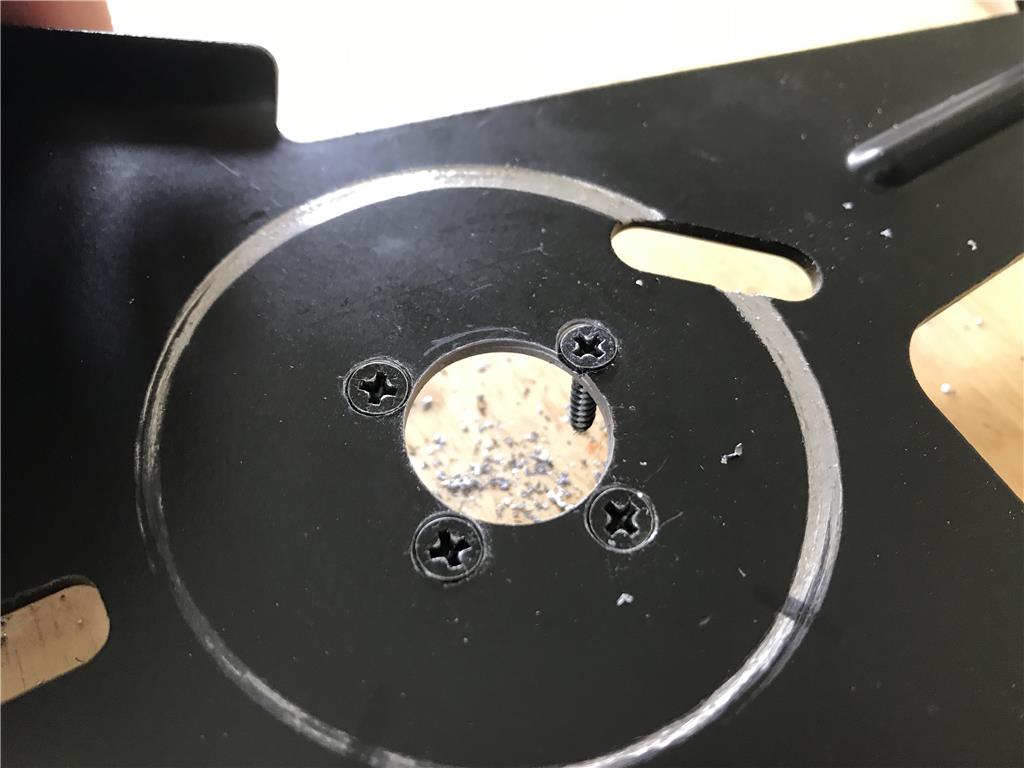

Here is the plastic chain cable with the plastic sprocket. I may upgrade to aluminum sprocket and and metal chain if this is not strong enough. Breaking strength of the plastic is 50 pounds. Looks like all I need is a couple washers , lock nut and regular nut to lock the pocket onto the motor shaft of the drill.