Hello all, I am getting back in the saddle making robots now that I am moved into my new home and settled into my new job as a technician maintaining the Fiber Optics network in Chattanooga TN.

IM BACK !

By jstarne1

— Last update

Other robots from Synthiam community

DJ's So, I Taught Jd How To Play The Piano

Robot band concept: first-version idea to assemble a robot band after the holidays.

Perry's Inmoov Conversion

InMoov converted to EZ-Robot - custom GUI for servos, face tracking, speech, Pandorabot AI, MS Cognitive, neopixel rings...

Dave's Resurrection - Another Full Sized Lost In Space B9...

Rebuild vintage B9 Robot with Synthiam ARC and EZB controls, restoring lights, sounds and motion.

-635971125254815084.png)

-635971009768280111.jpg)

-636393423097260688.jpg)

-636337988865509663.jpg)

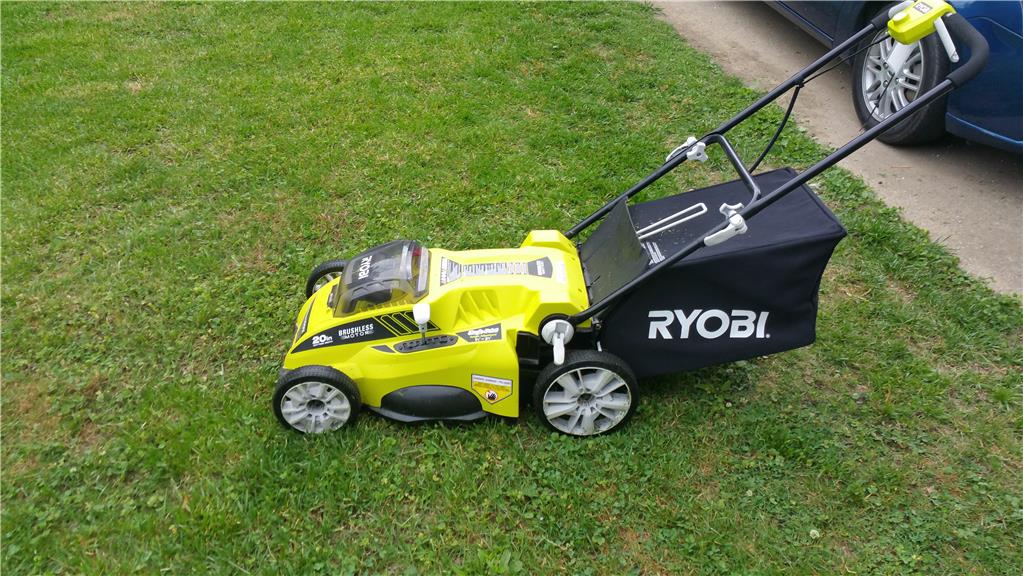

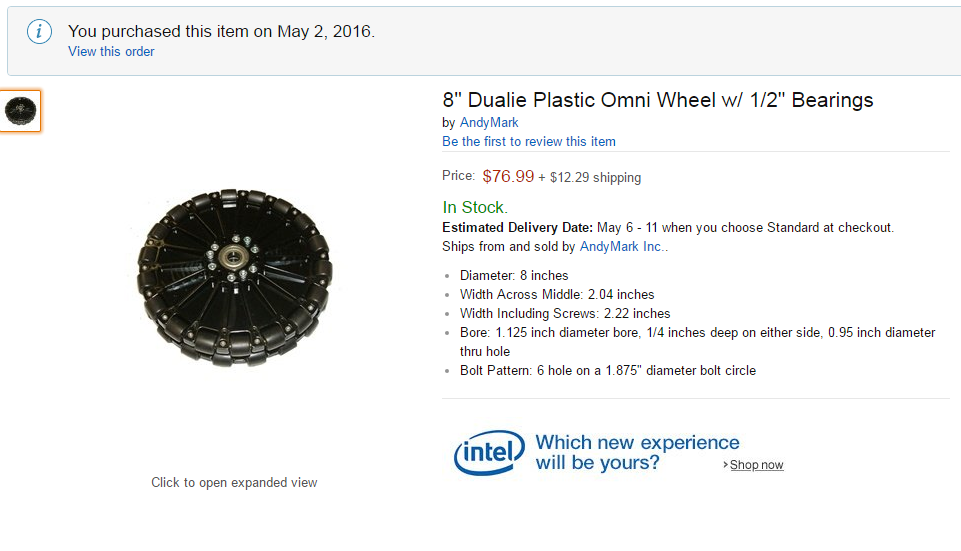

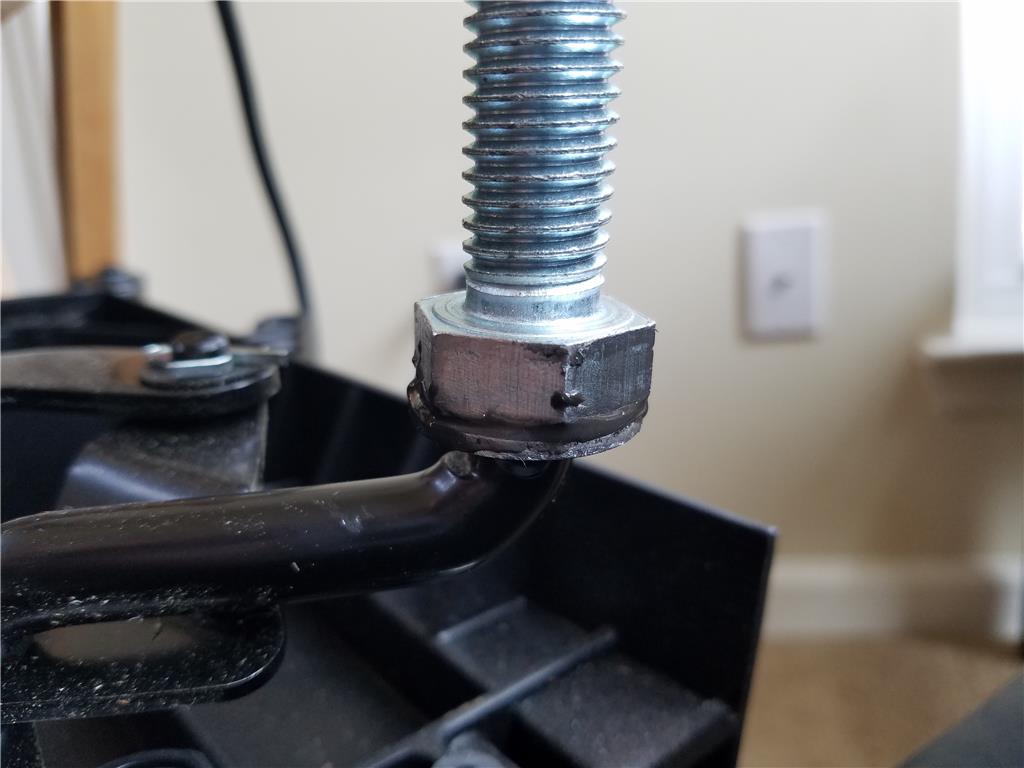

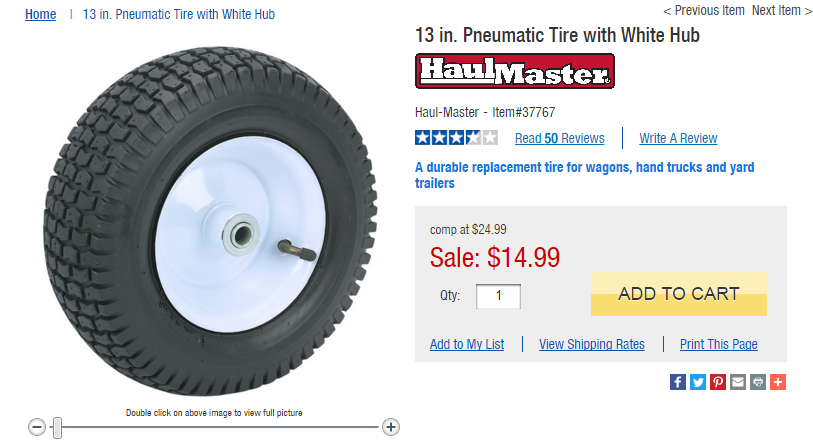

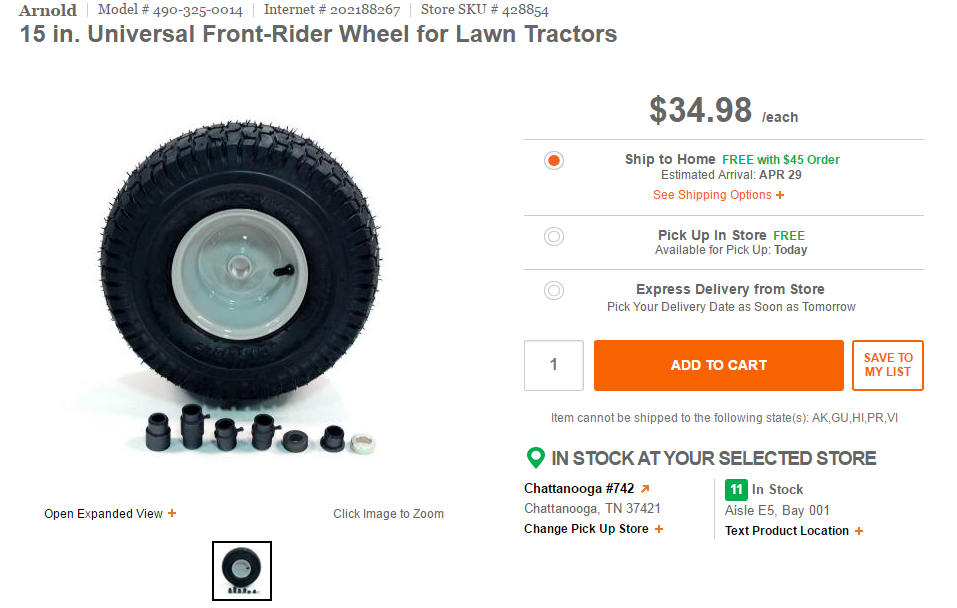

Today I had the chance to try out the mower on grass with the omniwheels on the front. I had some level of concerns that the wheels may somehow snag on uneven ground. They performed far beyond my expectation to the point I feel all lawn mowers should have omniwheels on the front ! I need to market these things! lol. Anyways the next step is to swap the read wheels out and set bearings. The hurdle here is that the shaft is only 1/2 inch but I an supposed to use 5/8 " bearings in diameter with the tires I bought.

I'm enjoying your project. Coming along nicely. I was also wondering how the Omniwheel would work on grass. Glad it worked.

Do you think you'll have it ready before the end of the grass growing session?

I also don't have anything to add other than - way to go! This is fun to watch

Hello all , yes I believe I can have something rolling around soon. It was mostly a matter of buying all the parts and now I can disassemble the mower and see what position I want to mount the motors in so the chain can wrap around a sprocket to turn the wheel.

Hello @jstarne1,

Excitement is growing. I am looking forward to see how the drive system ends up. I am sure the motor mounting and sprockets is a challenge. It will be doing a lot of work and needs to be strong. Looking forward to seeing your next post.

Ron

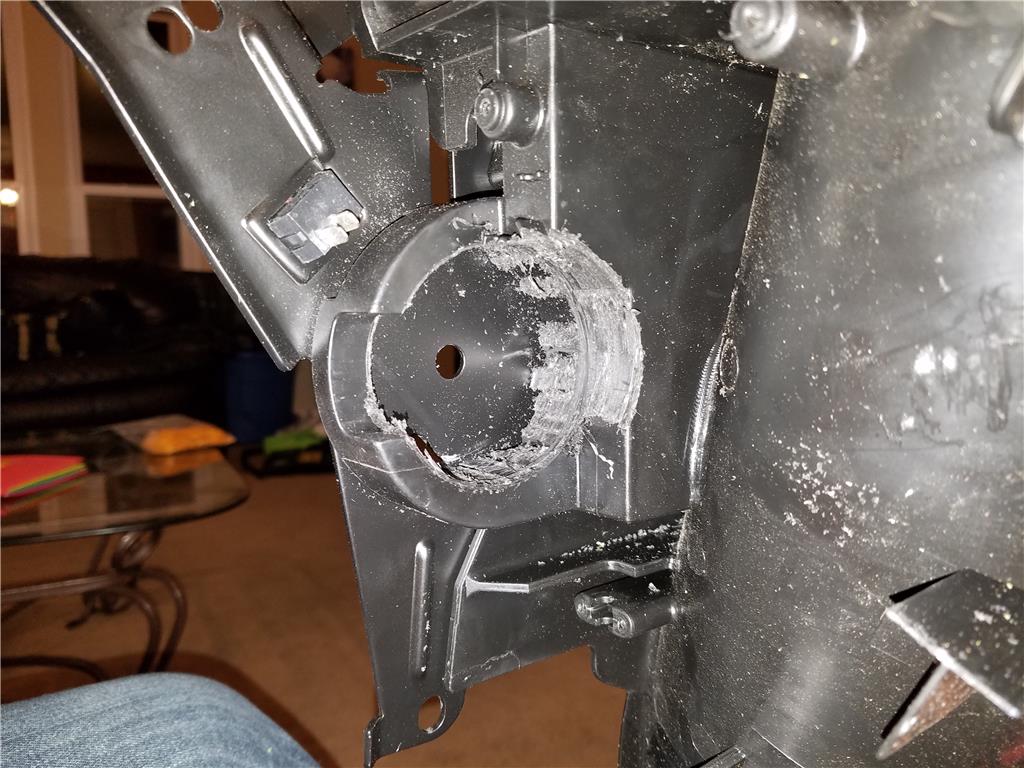

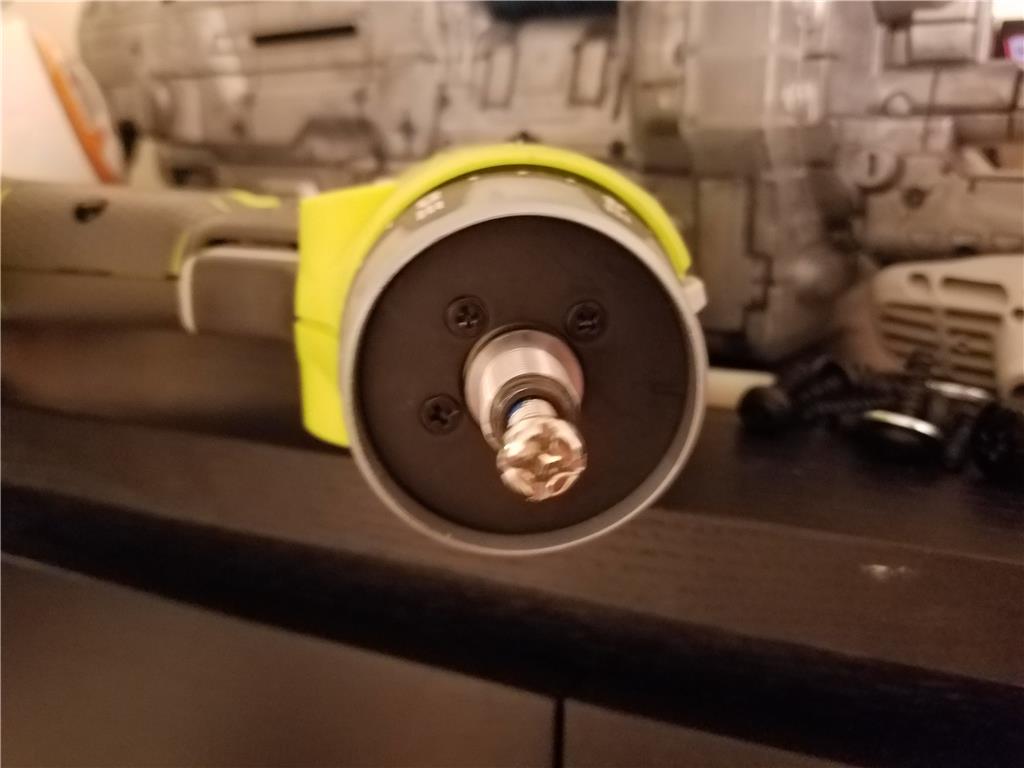

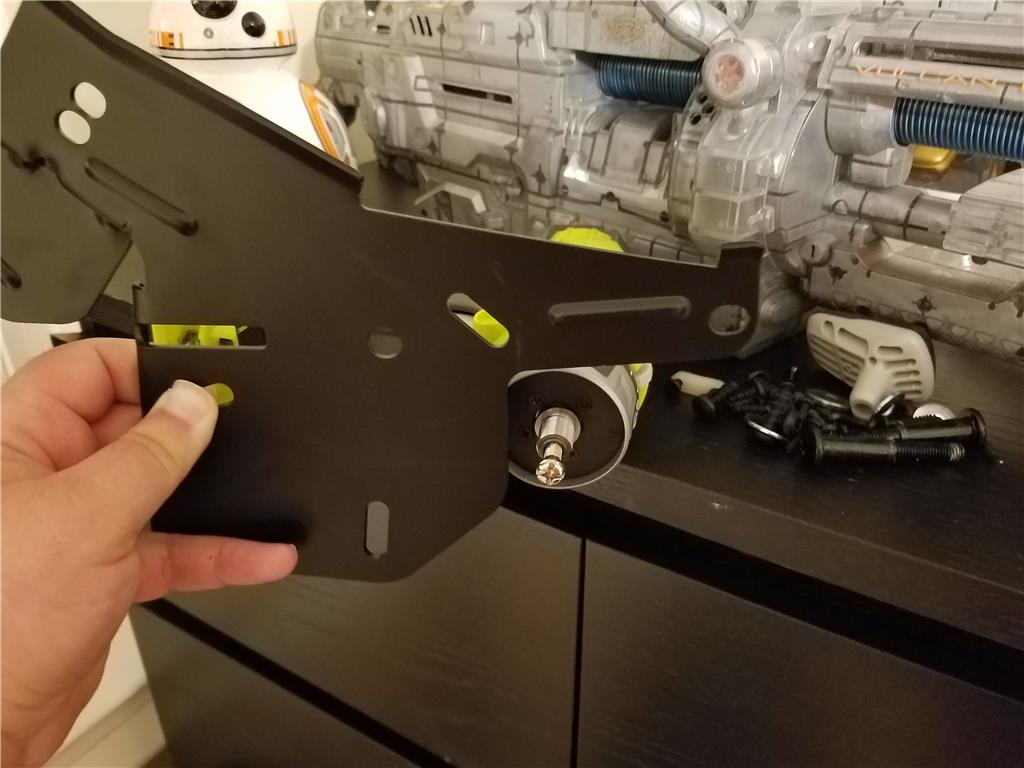

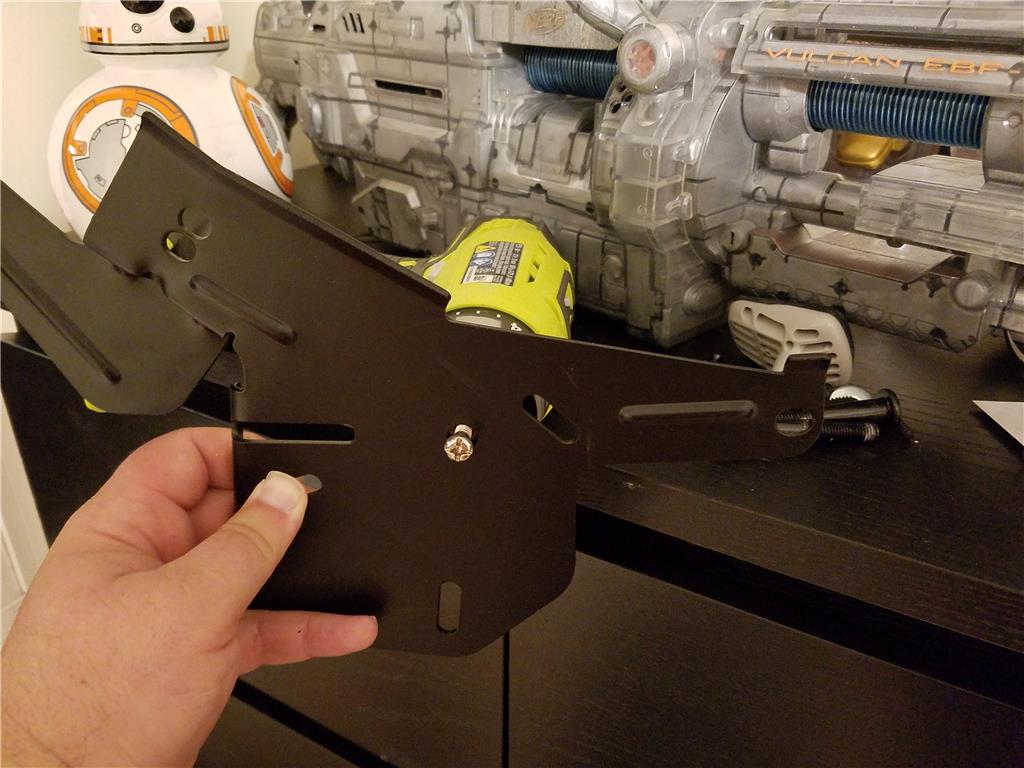

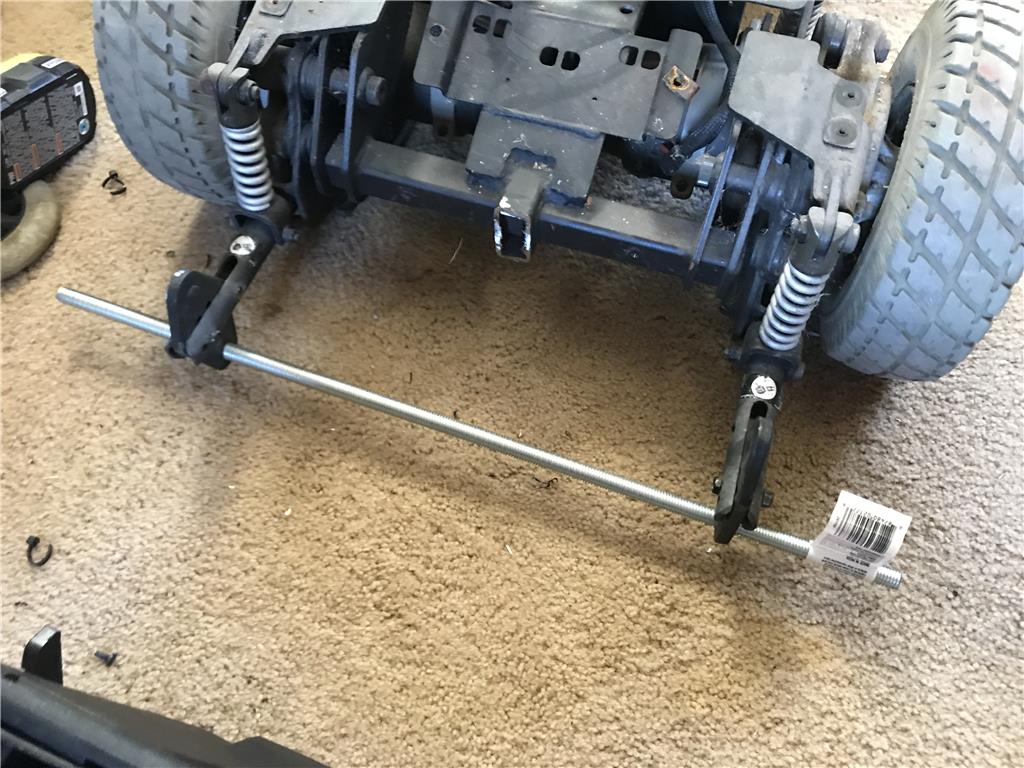

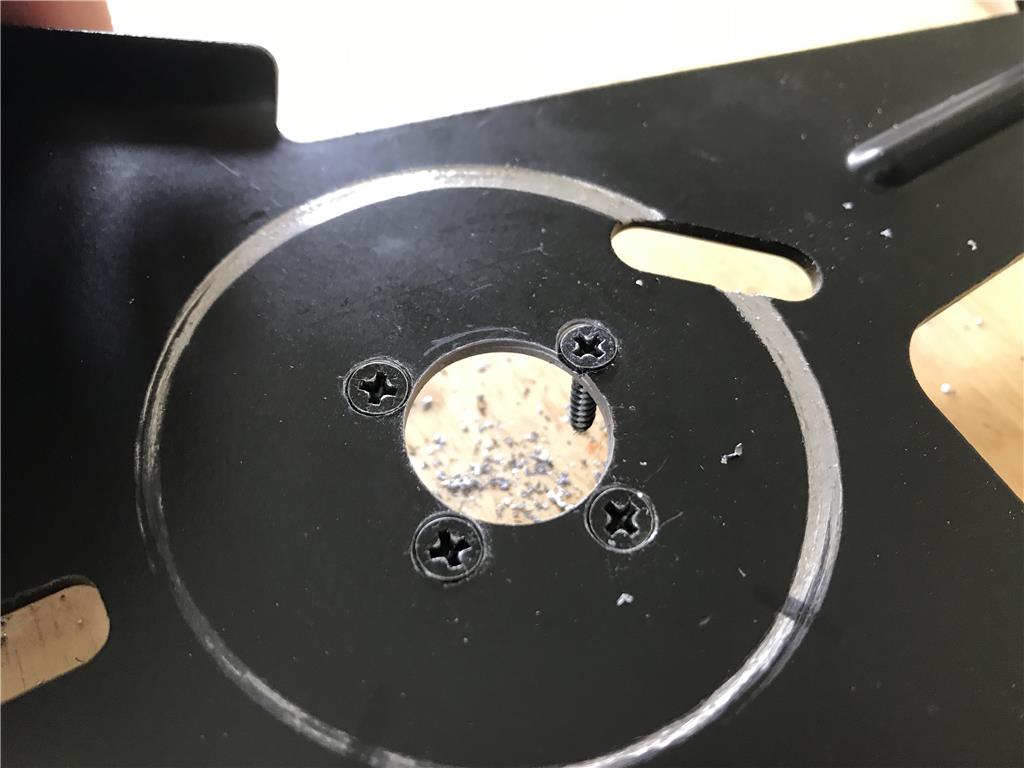

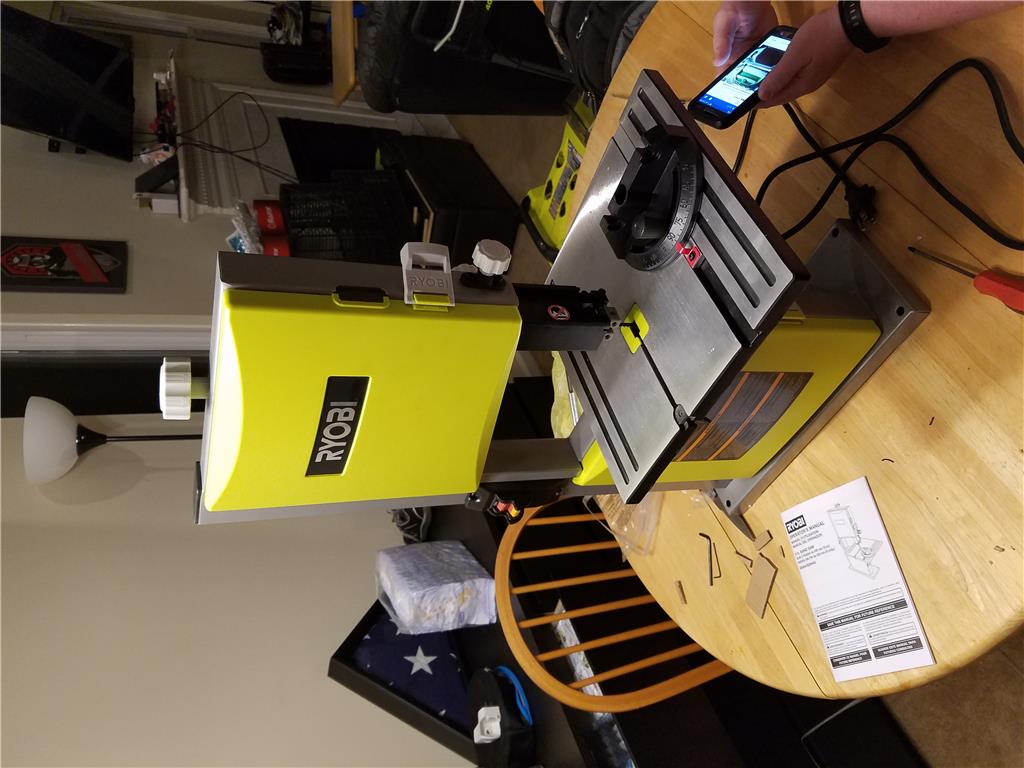

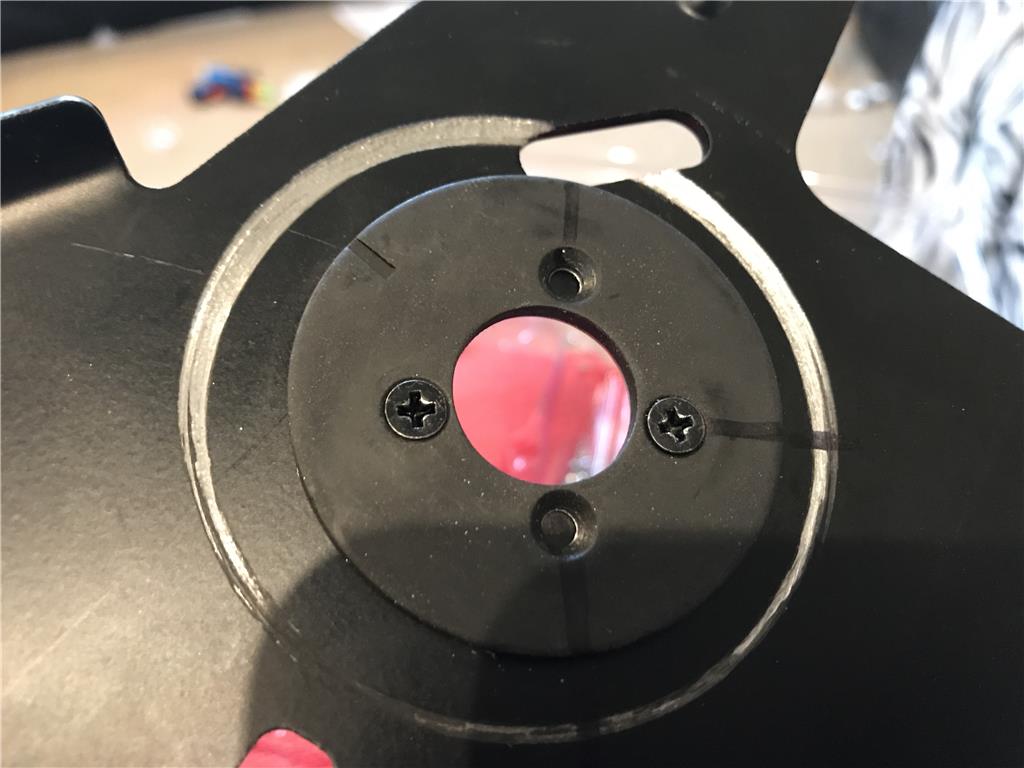

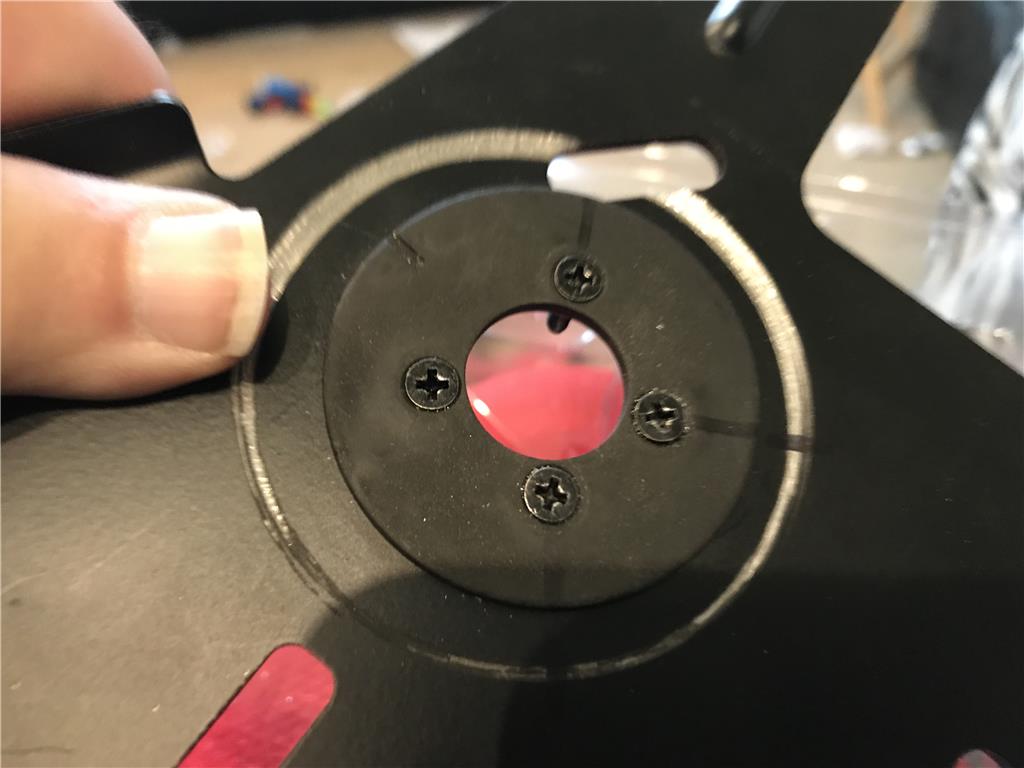

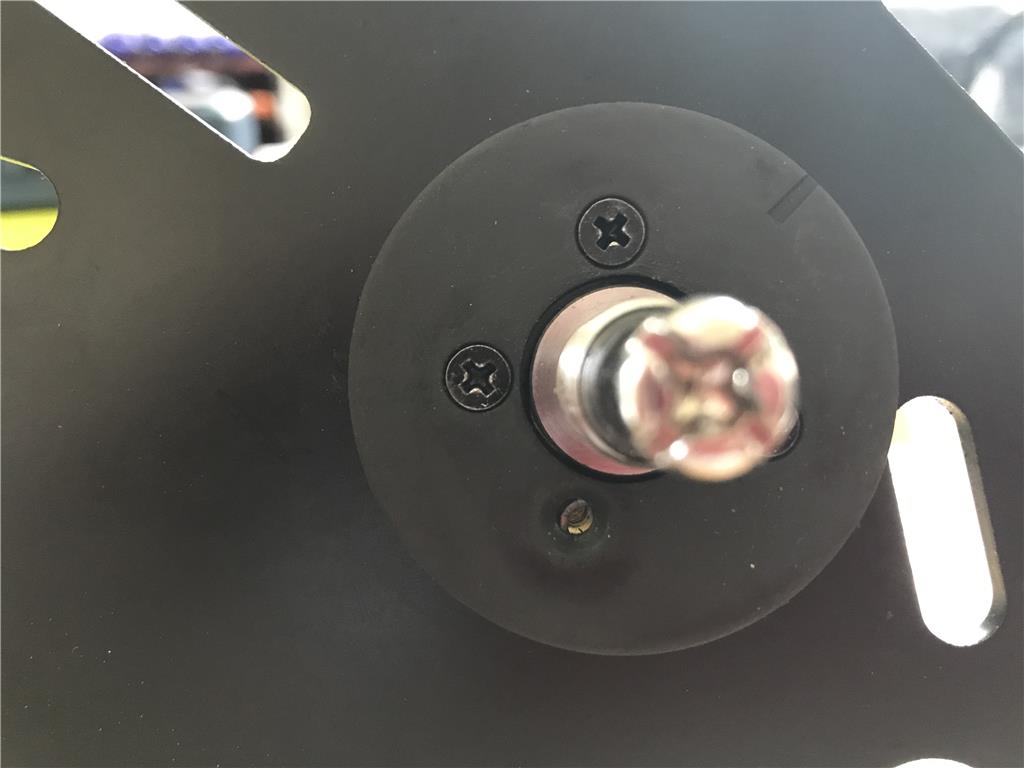

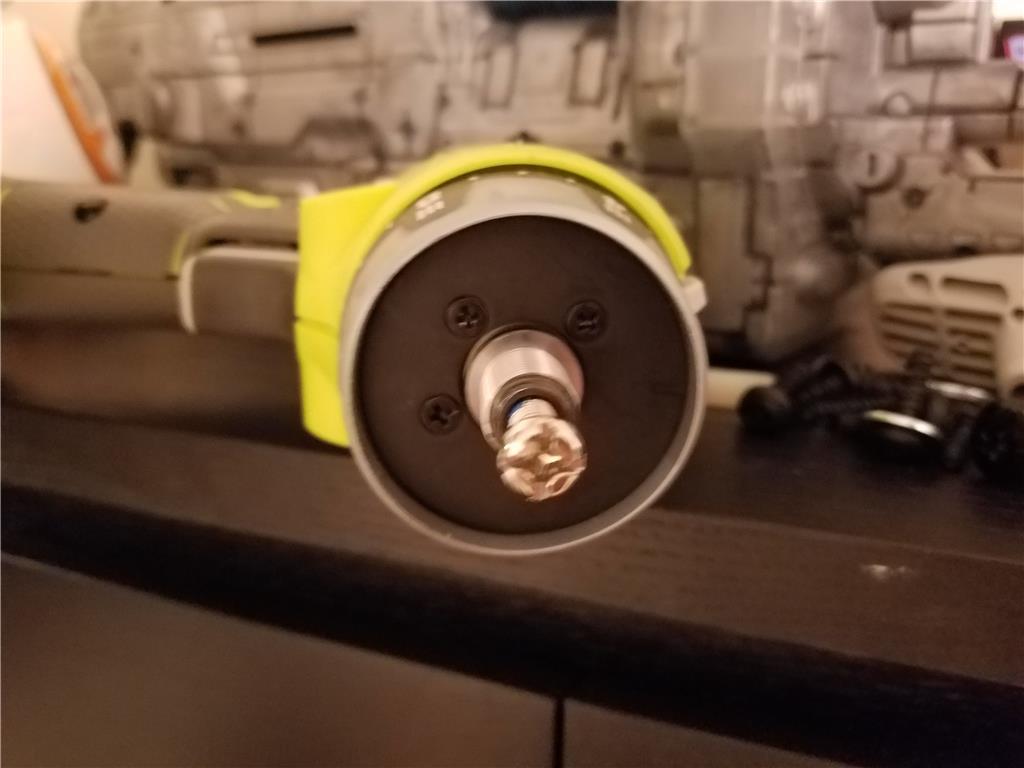

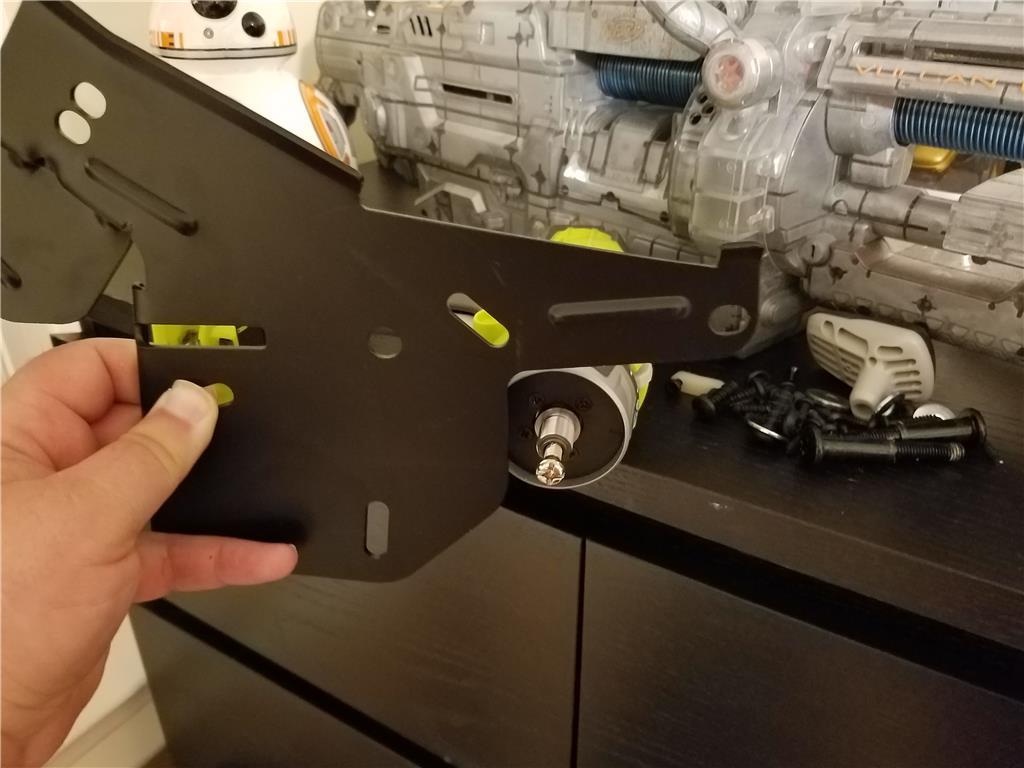

Ok I managed to get an off day tomorrow so I am not concerned about waking up too early. I started taking the mower apart. Considering it is 80 percent plastic there are many metal brackets and large solid bolts holding this together. The good news however is that these large metal brackets give me the opportunity to mount the drive motors to a particularly sturdy part of the frame. Here is a pic for reference. I may just lock the clutch with set screws and use the 4 screws in the end as a mounting point.

Hope you get some sleep in the morning.

Dude, is that a modified nerf rifle in the background? Bad to the bone. cool

Haha , yes a heavily modified nerf vulcan cannon. I'll take a pic of it tommorow. Anyways I tore down the mower to inspect the frame , wiring and general room for equipment. I mocked up the 10 inch harbor freight wheels and tires on the mower. If this thing was blacked out it would look like the batmobile! Not even kidding.