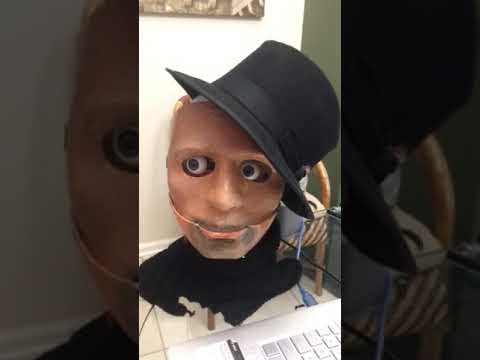

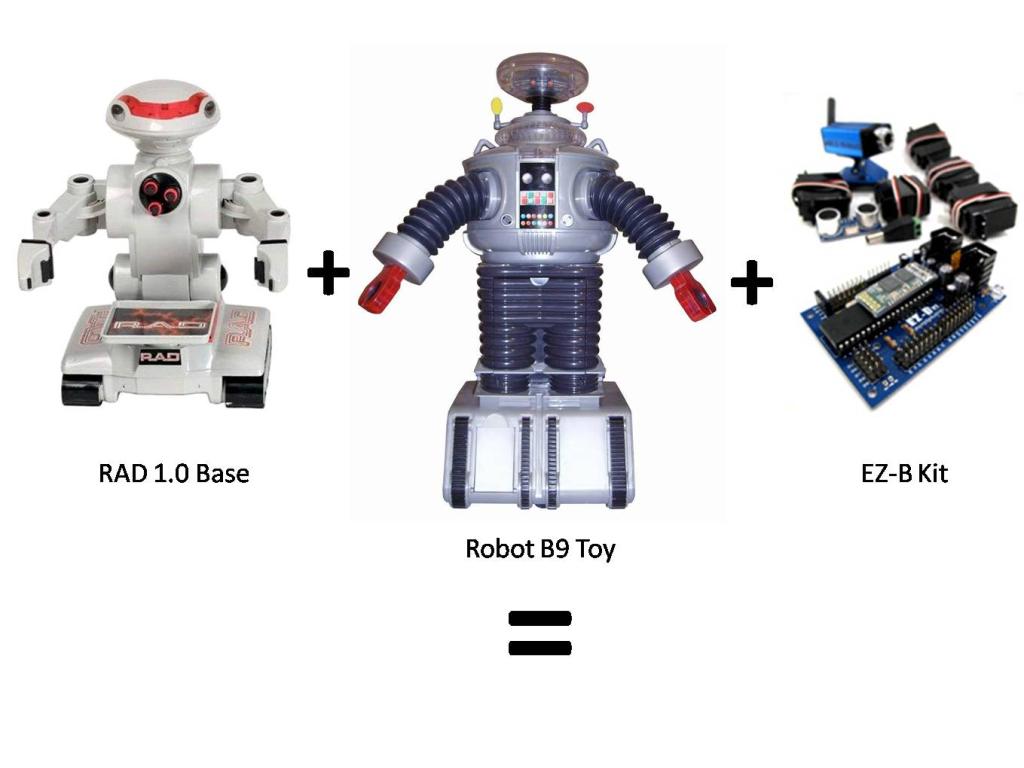

Now that I have finished B.O.B., my get your feet wet bot, I have begun my next hack. This next robot will bridge the gap between Bob and my ultimate big robot. I am starting with a remote controlled B9 toy from Trendmasters. It was very limited in what it did, and the drive section was pathetic, but it was B9!

Before Pics:

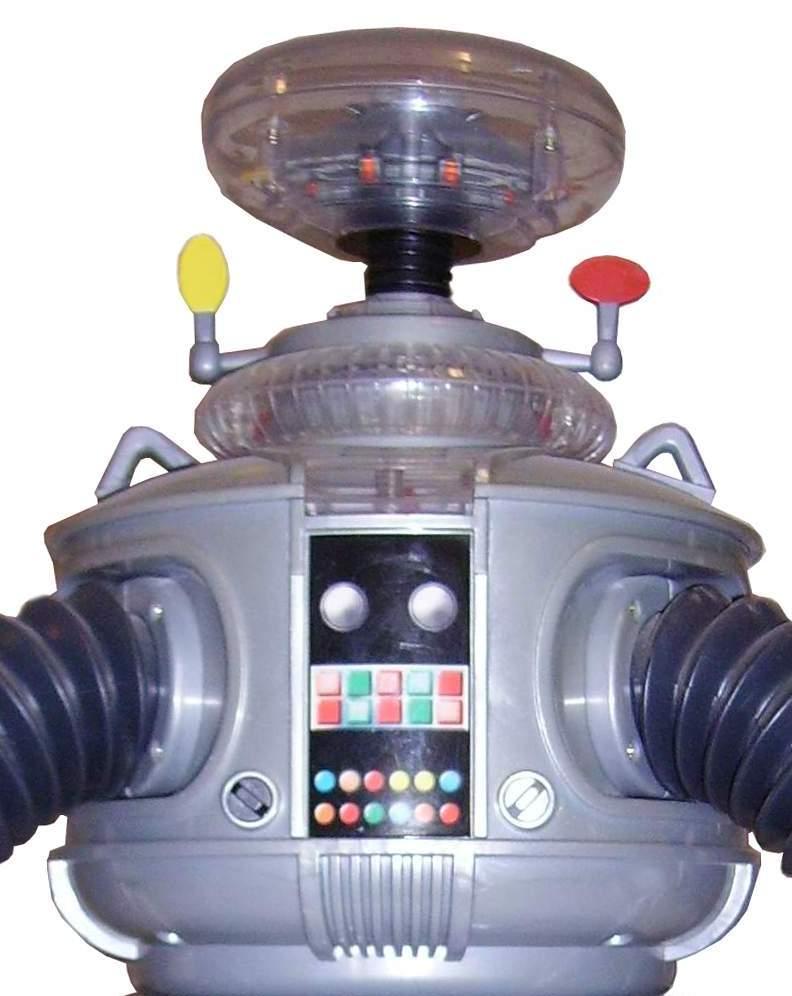

Note: the front "lights" in the chest plate is actually just a decal.Here is what B9 looks like now:

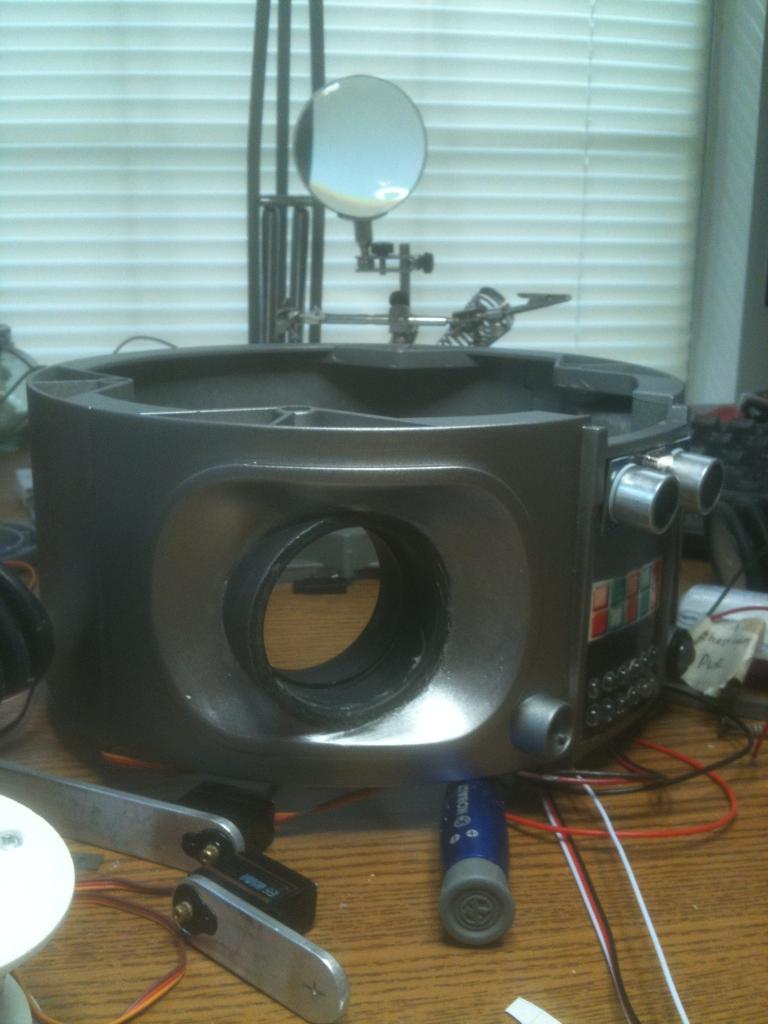

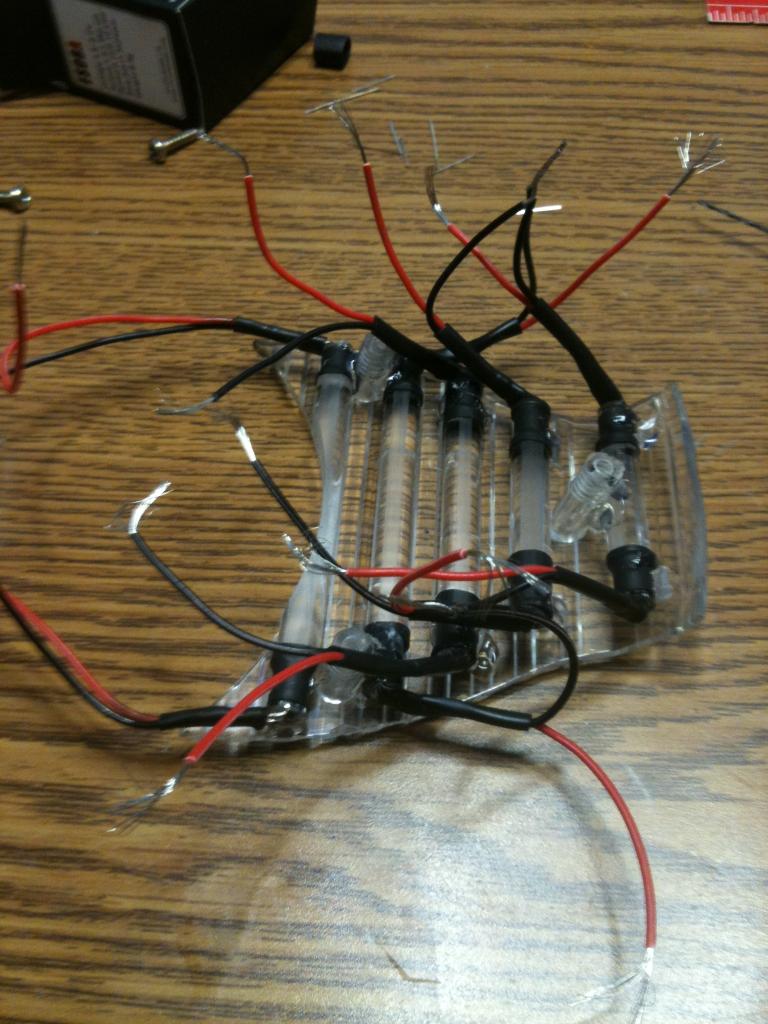

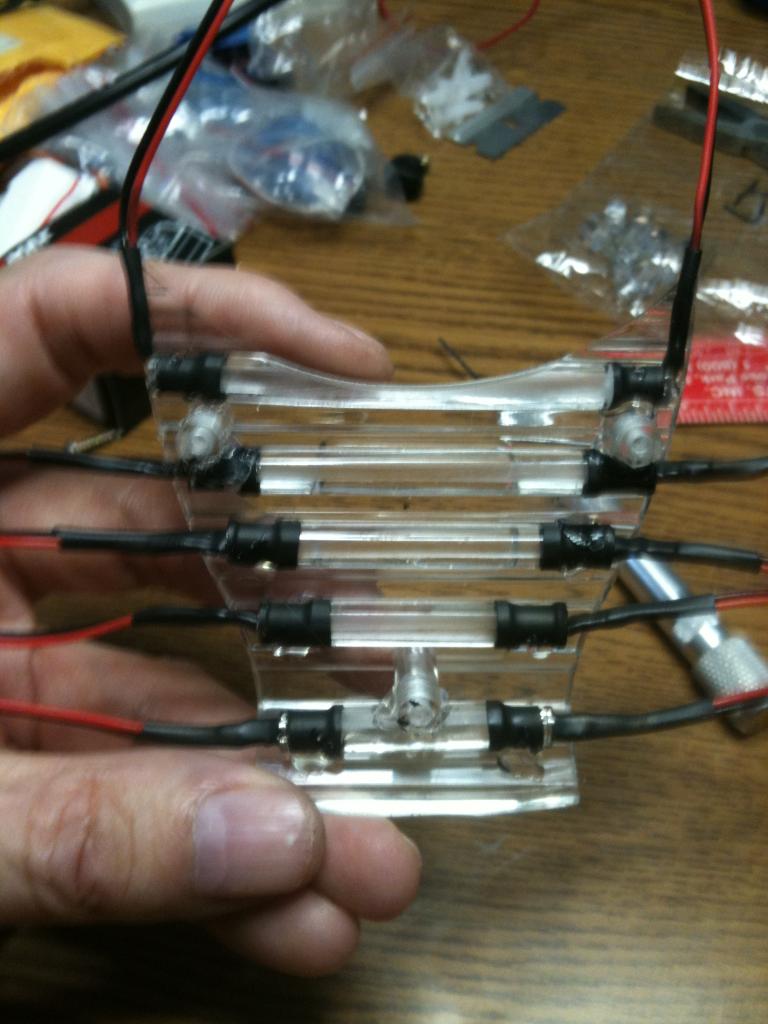

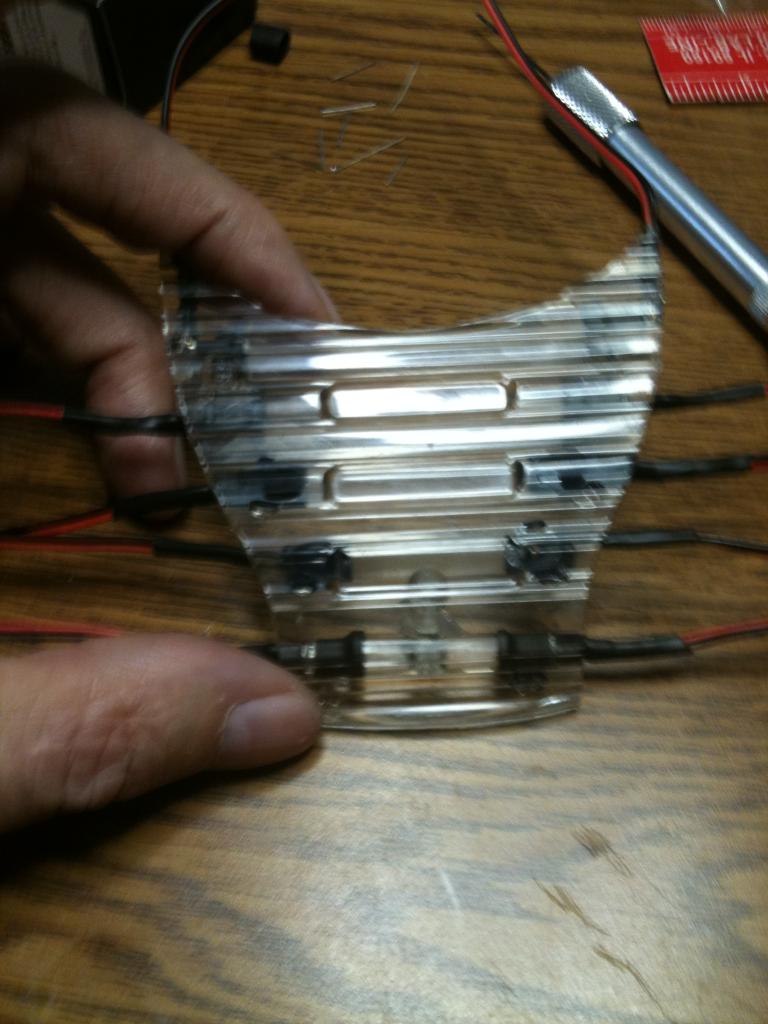

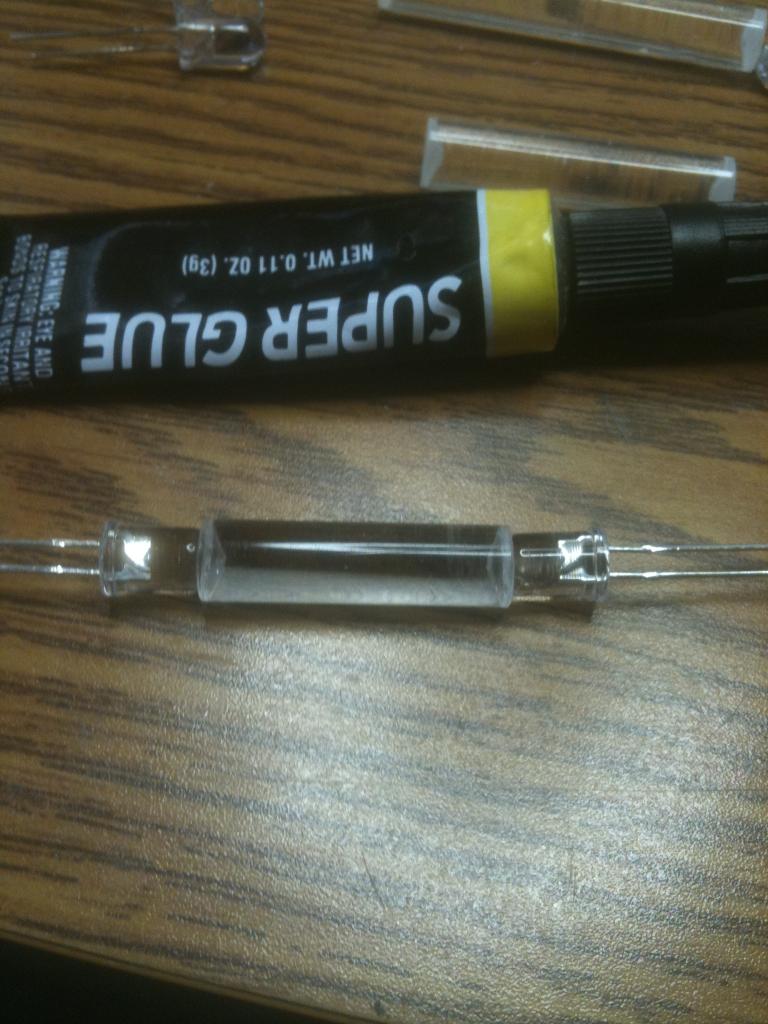

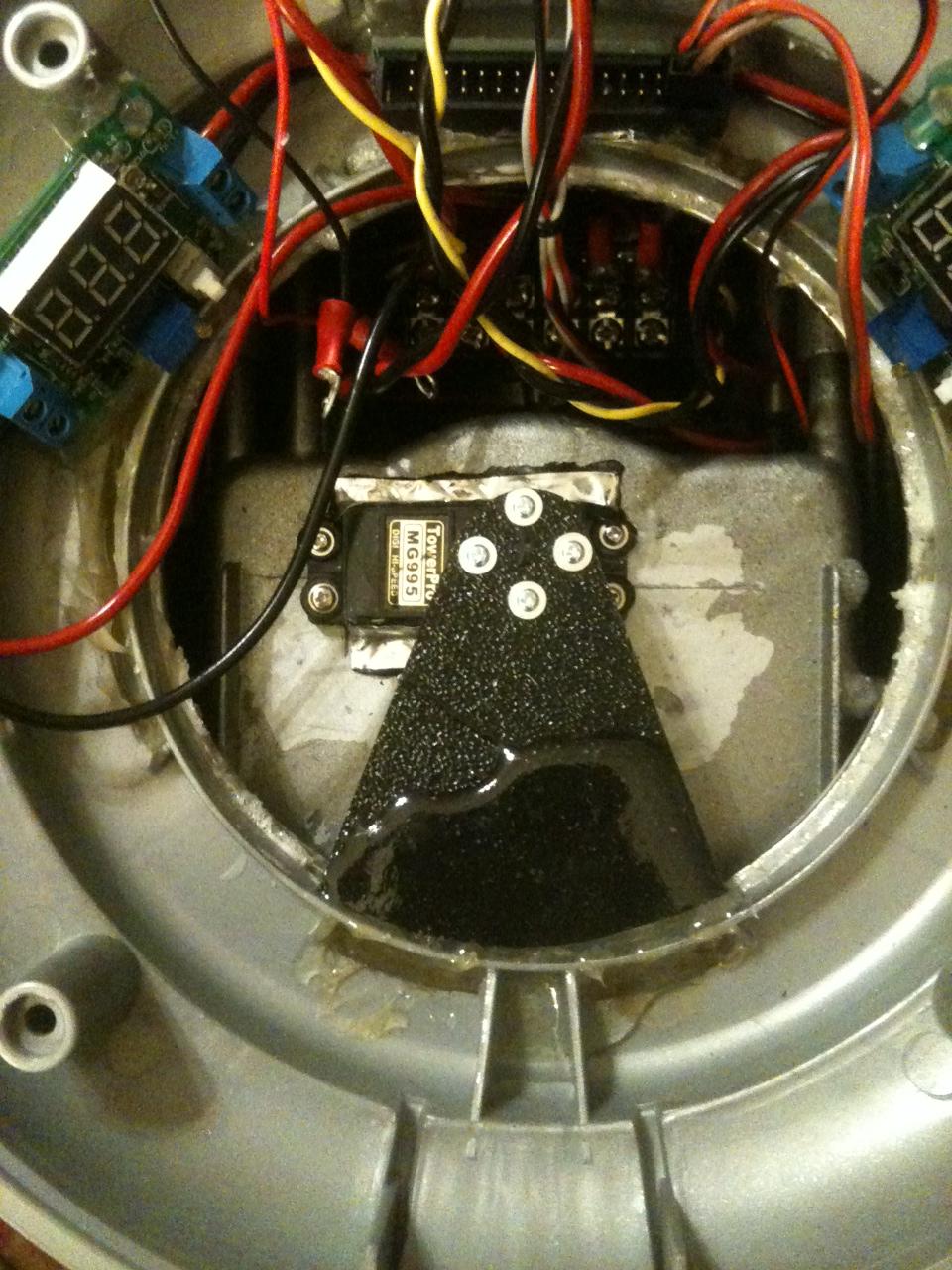

I have mounted clear LEDs in the appropriate colors in the chest at the bottom of the decal and have a flashing circuit that will blink them in the combination as seen on the series. Where the two large round circles are (white domes on the big guy) I will have my ping sensor. I have mounted pager motors in the antenna housings to turn the "sensors" as seen in the TV version. I have mounted red El Wire to his voice plate to emulate the original as well. I have also mounted a series of blinking LEDs to the "brain" section in the bubble.

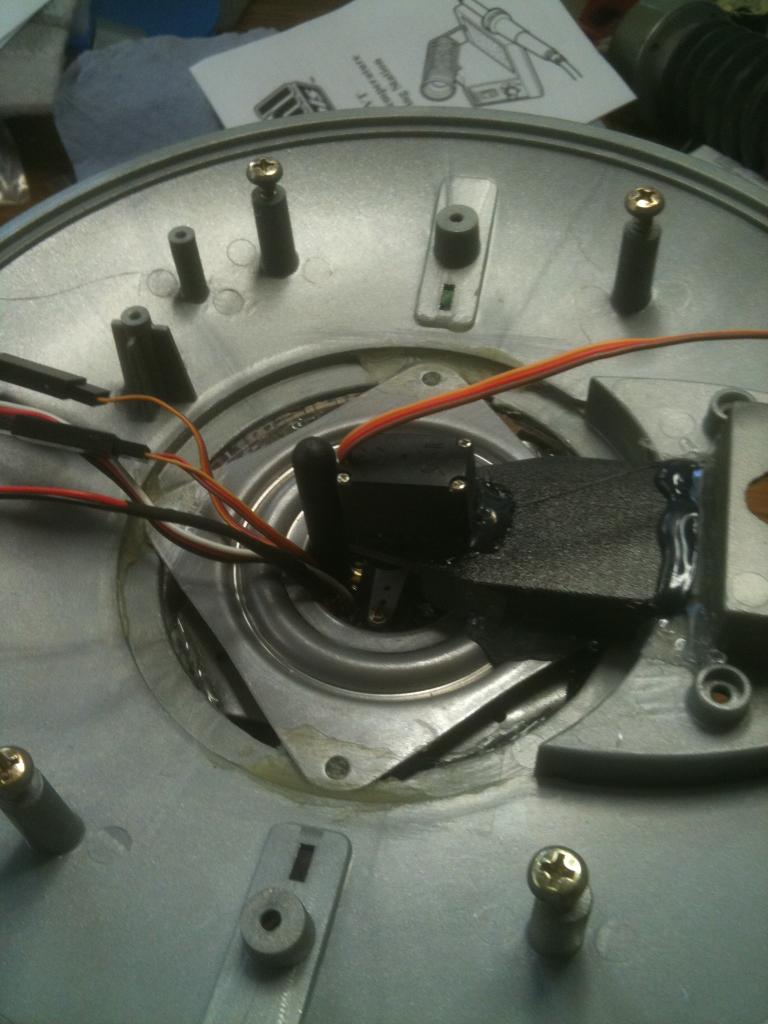

Next is to work on the rotation of the bubble and torso, articulate the arms and claws, and make a real functioning tread section. For the tread section I am adapting the base from my RAD robot. I will keep you posted with pics as I proceed.

Thanks,

Bret

Other robots from Synthiam community

Mattbrailsford's Omnimc

Khanflicks's Super Mario Humanoid Project

-634700966886250000.jpg)

-634700967015000000.jpg)

-634700967157968750.jpg)

-634702814800312500.jpg)

-634702600865468750.jpg)

-634702601116718750.jpg)

-634702602252031250.jpg)

-634702602665625000.jpg)

-634702602851875000.jpg)

-634694134410000000.jpg)

-634693960892812500.jpg)

-634693961752343750.jpg)

-634693953179375000.jpg)

-634693953336093750.jpg)

-634693164809062500.jpg)

-634693165327500000.jpg)

-634693165925625000.jpg)

-634693166147343750.jpg)

-634786542943876953.jpg)

-634796120303593750.jpg)

-634796120470312500.jpg)

-634812479455986328.jpg)

-634812479726035156.jpg)

-634812480620283203.jpg)

-634812481334052734.jpg)

-634812482341699218.jpg)

-634822681001005859.jpg)

-634822681580644531.jpg)

-634822681777470703.jpg)

-634821106166250000.jpg)

-634821106572812500.jpg)

-634821106815625000.jpg)

-634814909605058593.jpg)

-634814909850224609.jpg)

-634814910193212890.jpg)

-634814910596445312.jpg)

-634820188048437500.jpg)

-634820188647187500.jpg)

-634820189032656250.jpg)

-634718079154687500.jpg)

-634718080622031250.jpg)

-634714909191250000.jpg)

-634714909644843750.jpg)

-634713078392031250.jpg)

-634713078781250000.jpg)

-634720009877968750.jpg)

-634749341545937500.jpg)

-634749341951406250.jpg)

-634732946203437500.jpg)

-634708797562402343.jpg)

-634706000248750000.jpg)

-634705927185312500.jpg)

-634705927626406250.jpg)

-634705928146250000.jpg)

-634705929045781250.jpg)

-634705929717812500.jpg)

-634705930336093750.jpg)

-634705930540468750.jpg)

-634705931037812500.jpg)

-634709695807265625.jpg)

-634709696076181640.jpg)

-634711364771718750.jpg)

-634711364485781250.jpg)

-634712172318906250.jpg)

-634771897291406250.jpg)

-634771897466093750.jpg)

-634771897849687500.jpg)

-634771898236093750.jpg)

-634771898712187500.jpg)

-634771899102656250.jpg)

-634771899822656250.jpg)

-634771900771562500.jpg)

-634771901301875000.jpg)

-634768466924746093.jpg)

-634768467383681640.jpg)

-634772580489218750.jpg)

-634772581075781250.jpg)

-634772581532343750.jpg)

-634772581721718750.jpg)

-634773400815625000.jpg)

-634773401032187500.jpg)

-634781365777988281.jpg)

-634781366040302734.jpg)

-634781366299042968.jpg)

-634766553798554687.jpg)

-634766556025839843.jpg)

-634759732245312500.jpg)

-634765021896093750.jpg)

-634765022115000000.jpg)

-634765022326562500.jpg)

-634765023386093750.jpg)

-634765855550937500.jpg)

-634765856533437500.jpg)

-634765856756250000.jpg)

-634845177217089843.jpg)

-634845177425585937.jpg)

-634857207521406250.jpg)

-634857208212500000.jpg)

-634857208786718750.jpg)

-634826982093593750.jpg)

-634838602835000000.jpg)

-634838603089687500.jpg)

-634838603585312500.jpg)

-634871181815468750.jpg)

-634871183099531250.jpg)

-634871128238750000.jpg)

-634870976497031250.jpg)

-634870976894687500.jpg)

-634880528374375000.jpg)

-634880528707656250.jpg)

-634880529073593750.jpg)

-634892824736386719.jpg)

-634892824903066406.jpg)

-634892825090117187.jpg)

-634892825255283203.jpg)

-634880812756406250.jpg)

-634870194470625000.jpg)

-634870194829687500.jpg)

-634865232676250000.jpg)

-634863402043750000.jpg)

-634863402351562500.jpg)

-634863402584218750.jpg)

-634863404238125000.jpg)

-634869405242656250.jpg)

-634869405424687500.jpg)

-634869405586562500.jpg)

-634869405943906250.jpg)

-634869406072656250.jpg)

-634869404353281250.jpg)

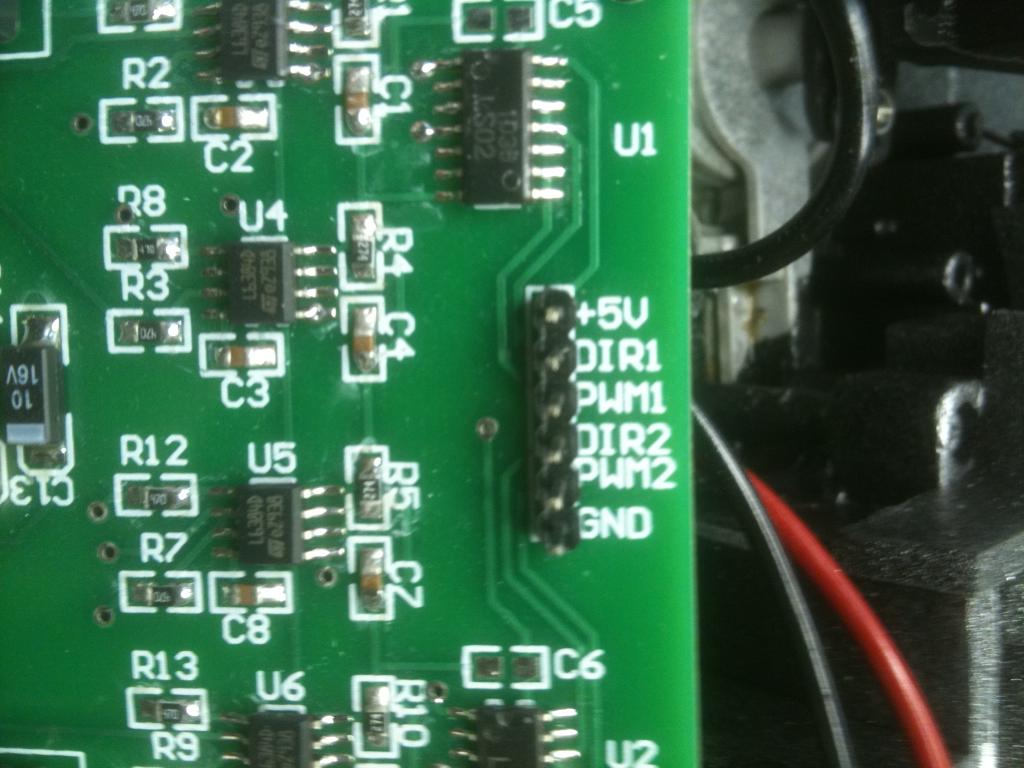

I don't know. I am not a programmer AT ALL. In the drop down lists there is a generic motor controller panel that works with the l298 where you assign your ports. But it uses one port for fwd Left, one for rev Left, one for fwd Right, and one for rev Right.

So my other robot Bob sacrificed his mobility for this motor controller to see if we can get B9 mobile.

-634759732245312500.jpg)

After fiddling for a bit I did get B9 to mover better than with the first controller, but not as good as I think he should.Here is a clip of B9 moving. This is in low gear - from the sound there is a lot of strain on those motors. Then I used the servo mod to change him into high gear and he moves forward and backward fine, but won't turn. Hmmmmmmm Is it the controller, or the motors on this RAD base?

My vote is not enough juice to the motors Brett , remember the test we did before direct to battery take in mind those motors were made to take min 7.4 volts , but that's minimum , rc battery packs usually are a couple volts over fully charged and drop under heavy load. My best recommendation is to use a 12v battery , I have a new one I can send you brett 12v 7.5ah that will fit right in where your existing battery is. , the l298 I sent you can handle 12v+ volts no problem. I and others have tested rad base at 12v , your own controller can be dialed back as you wish , dj will back me up on this , its better to overvolt then dail it back from the ezb controller to what you feel is perfect , if I send the battery I could send a couple cooling fans to keep those motors cool , and grab you some yellow or clear lubtricating grease and grease those gears up really good in the transmission box area , you can't overdue it I promise!

take in mind those motors were made to take min 7.4 volts , but that's minimum , rc battery packs usually are a couple volts over fully charged and drop under heavy load. My best recommendation is to use a 12v battery , I have a new one I can send you brett 12v 7.5ah that will fit right in where your existing battery is. , the l298 I sent you can handle 12v+ volts no problem. I and others have tested rad base at 12v , your own controller can be dialed back as you wish , dj will back me up on this , its better to overvolt then dail it back from the ezb controller to what you feel is perfect , if I send the battery I could send a couple cooling fans to keep those motors cool , and grab you some yellow or clear lubtricating grease and grease those gears up really good in the transmission box area , you can't overdue it I promise!

Dude that's awesome! How much $$?

Lol cost of shipping? I can make sure it has a charge and ship tommorow. I could trade you for your 6 volt lol.

Yeah, I'll throw that in with the roomba board for sure. I went ahead and purchased a step down regulator like the ones you have so I can drop the voltage of the battery down to 6 volts for my servos. I'll have that some time in July (China....) but I can get the drive train moving around and continue my work on his arms.

Thanks Josh, you are are truly a good guy.

Bret

Definitely run a juicy 12V SLA battery into that motor controller. I power my RAD tracks off a 9ah 12v SLA & dial the speed back with PWM.