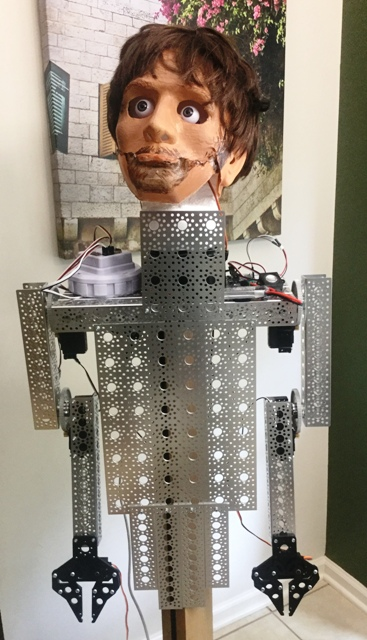

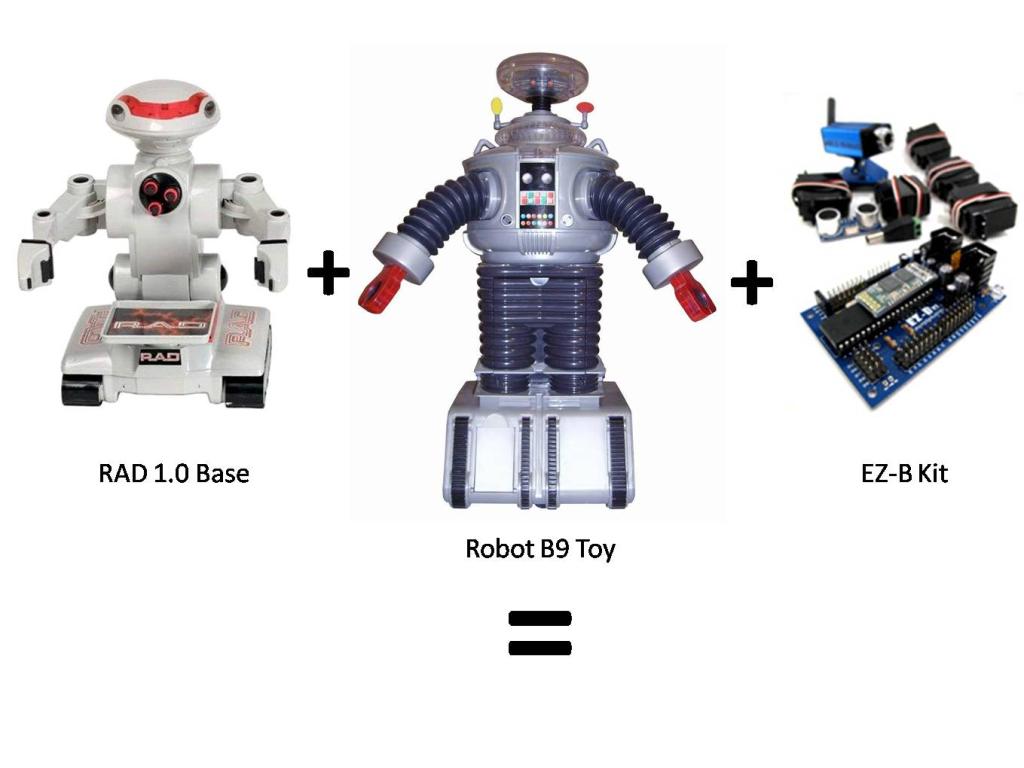

Now that I have finished B.O.B., my get your feet wet bot, I have begun my next hack. This next robot will bridge the gap between Bob and my ultimate big robot. I am starting with a remote controlled B9 toy from Trendmasters. It was very limited in what it did, and the drive section was pathetic, but it was B9!

Before Pics:

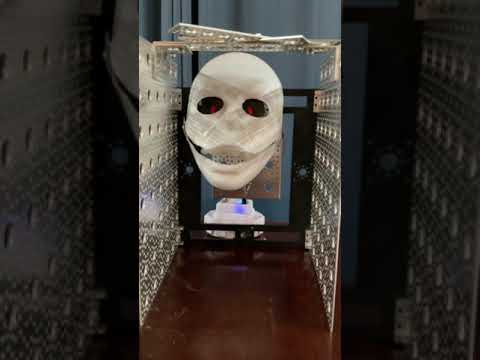

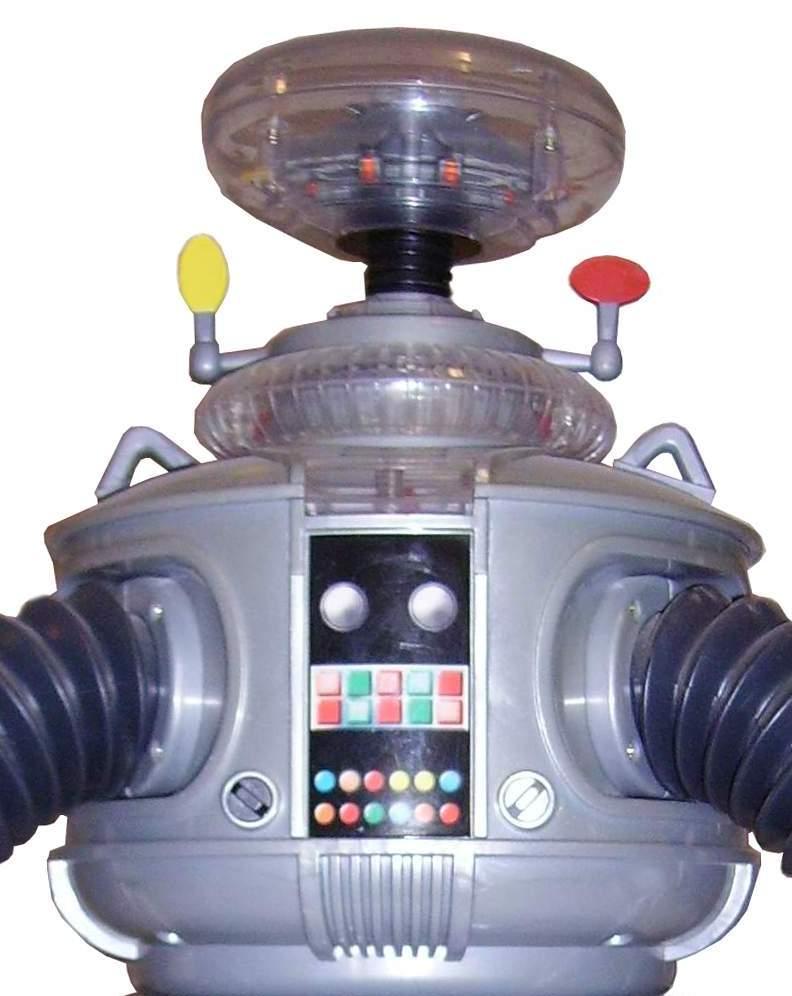

Note: the front "lights" in the chest plate is actually just a decal.Here is what B9 looks like now:

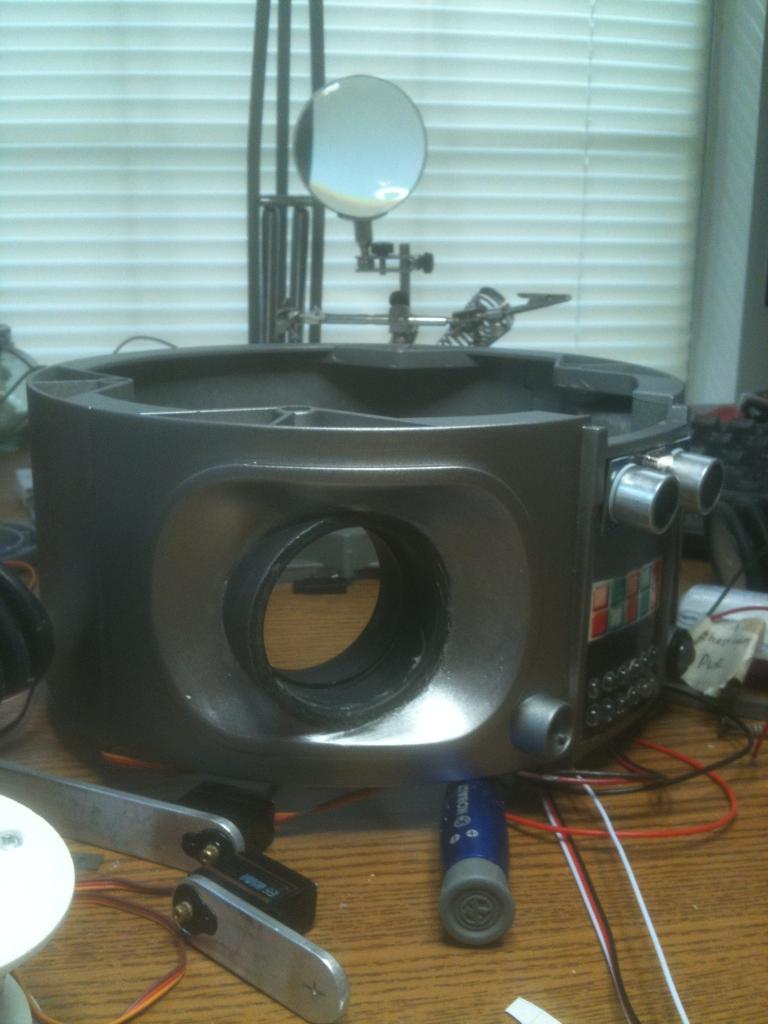

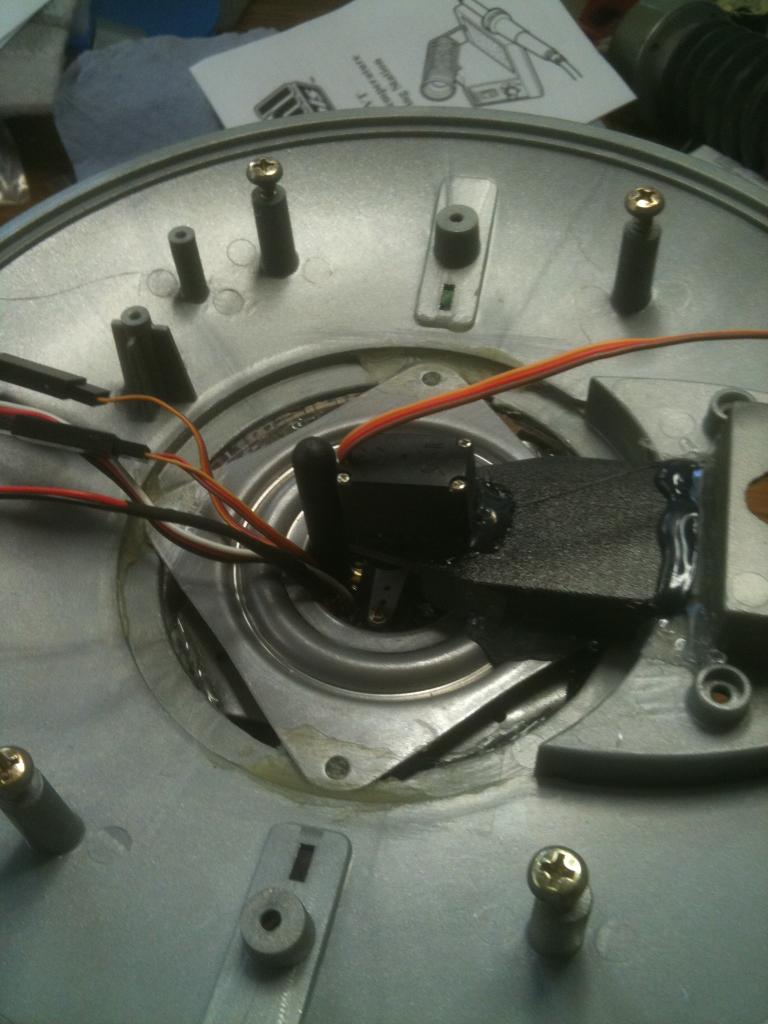

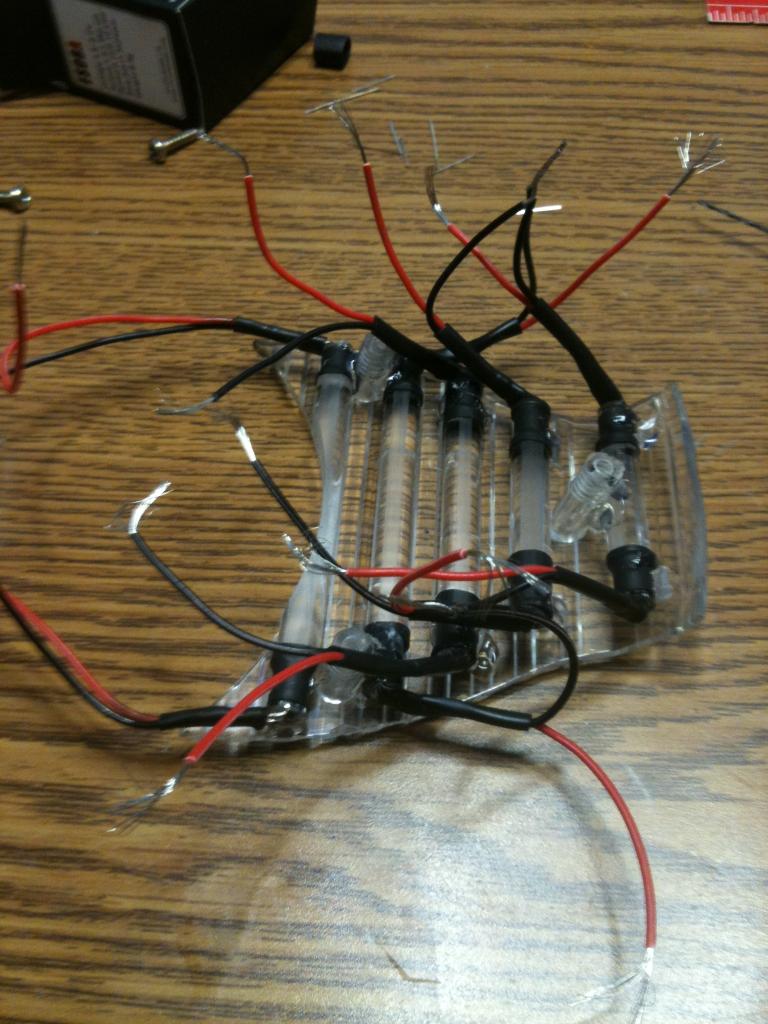

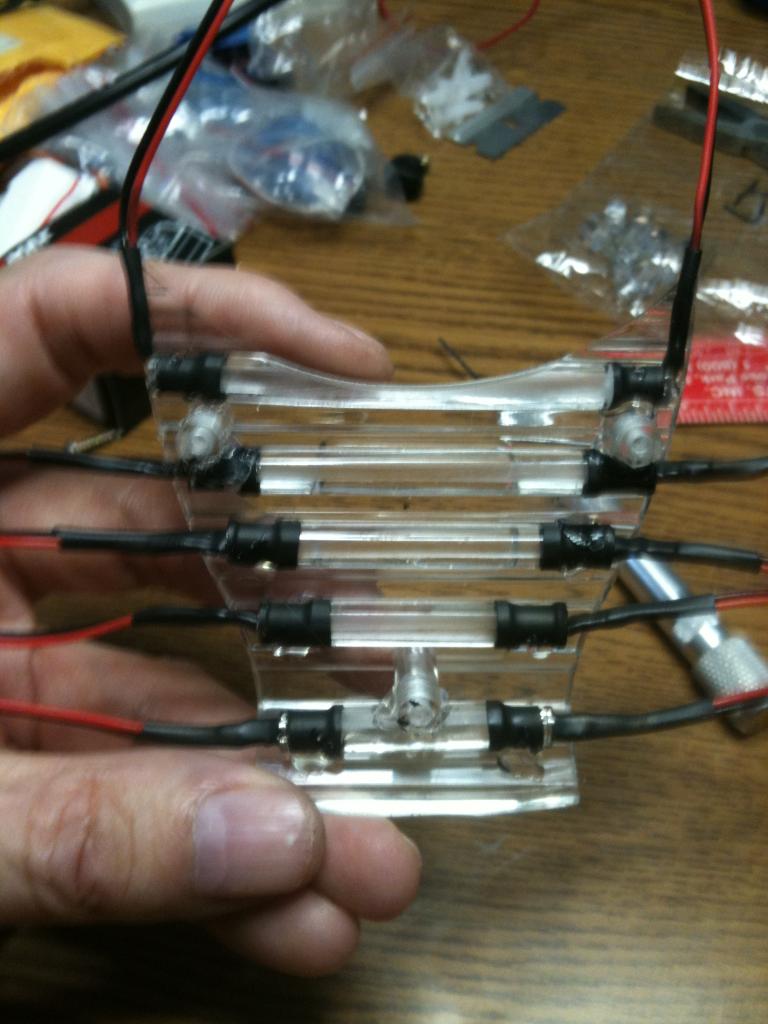

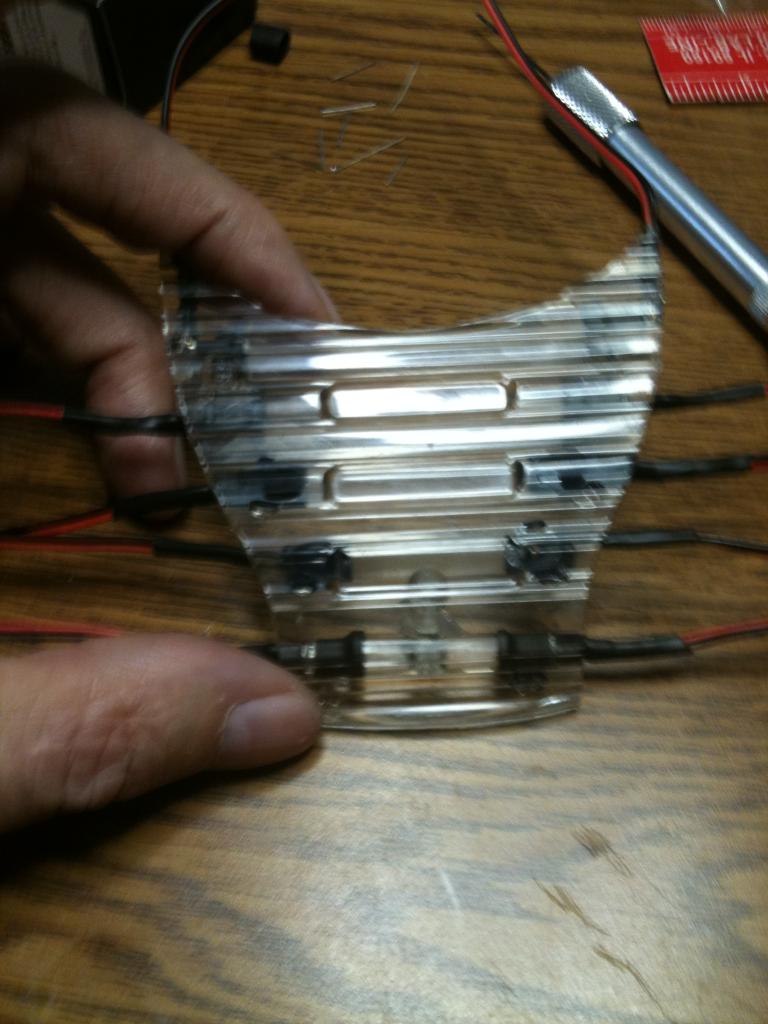

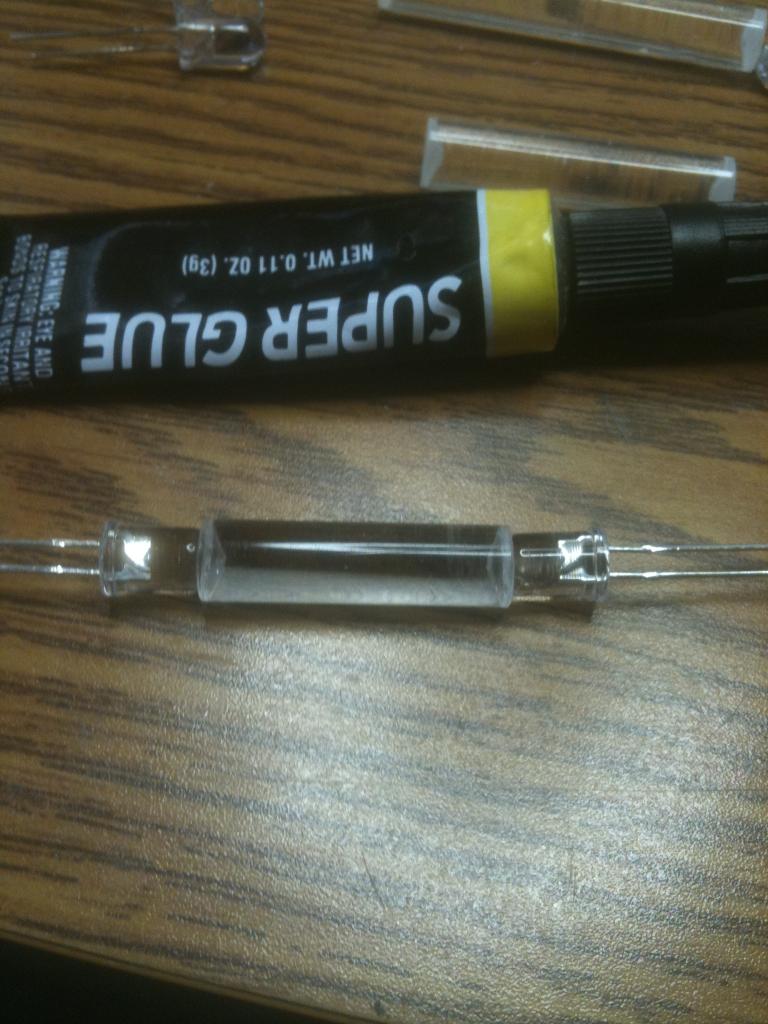

I have mounted clear LEDs in the appropriate colors in the chest at the bottom of the decal and have a flashing circuit that will blink them in the combination as seen on the series. Where the two large round circles are (white domes on the big guy) I will have my ping sensor. I have mounted pager motors in the antenna housings to turn the "sensors" as seen in the TV version. I have mounted red El Wire to his voice plate to emulate the original as well. I have also mounted a series of blinking LEDs to the "brain" section in the bubble.

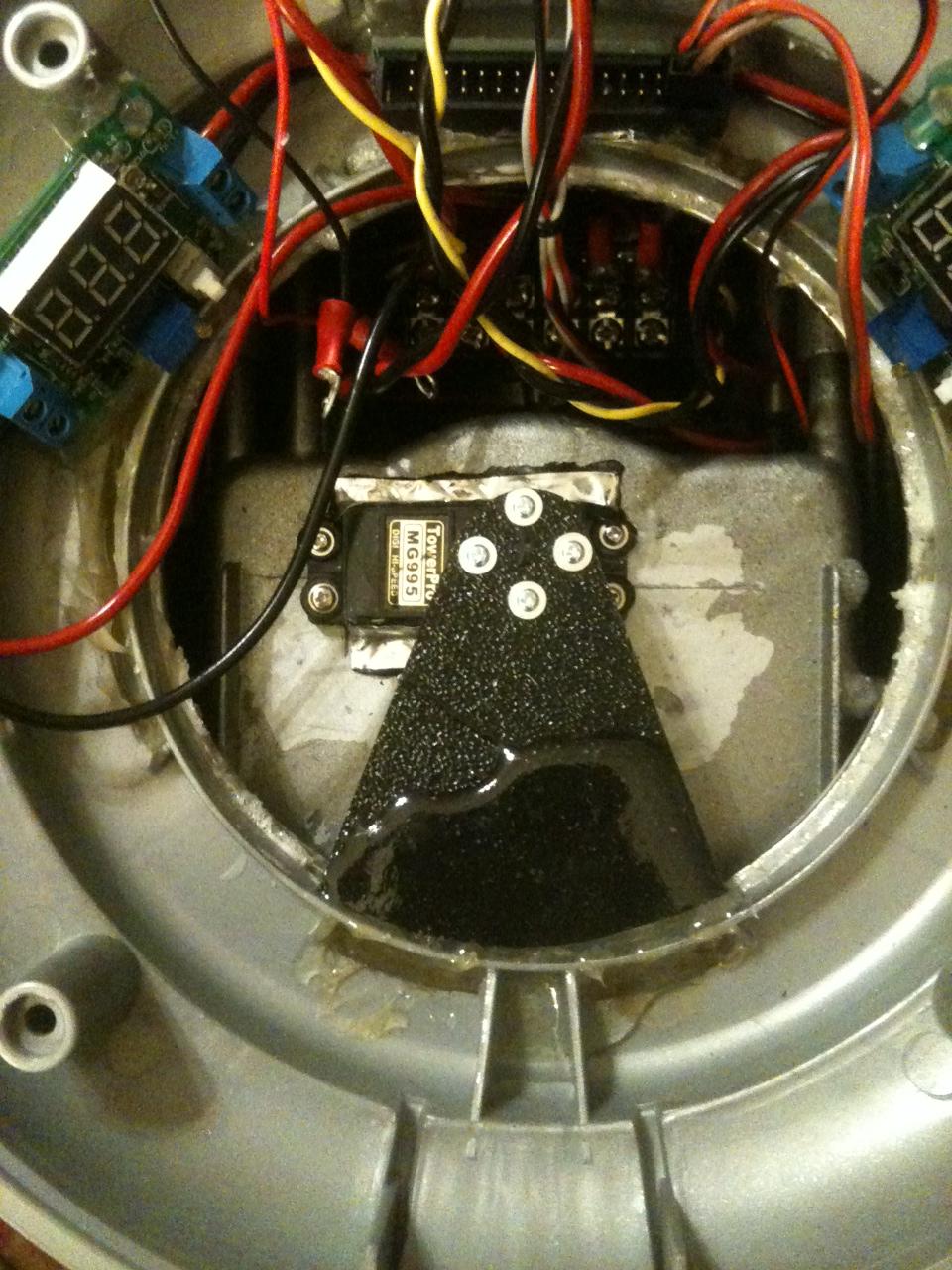

Next is to work on the rotation of the bubble and torso, articulate the arms and claws, and make a real functioning tread section. For the tread section I am adapting the base from my RAD robot. I will keep you posted with pics as I proceed.

Thanks,

Bret

Other robots from Synthiam community

Steve's R2-D2 Hasbro Toy Hack

Ezang's New Robot Head Video Project 6/15/2021

-634700966886250000.jpg)

-634700967015000000.jpg)

-634700967157968750.jpg)

-634702814800312500.jpg)

-634702600865468750.jpg)

-634702601116718750.jpg)

-634702602252031250.jpg)

-634702602665625000.jpg)

-634702602851875000.jpg)

-634694134410000000.jpg)

-634693960892812500.jpg)

-634693961752343750.jpg)

-634693953179375000.jpg)

-634693953336093750.jpg)

-634693164809062500.jpg)

-634693165327500000.jpg)

-634693165925625000.jpg)

-634693166147343750.jpg)

-634786542943876953.jpg)

-634796120303593750.jpg)

-634796120470312500.jpg)

-634812479455986328.jpg)

-634812479726035156.jpg)

-634812480620283203.jpg)

-634812481334052734.jpg)

-634812482341699218.jpg)

-634822681001005859.jpg)

-634822681580644531.jpg)

-634822681777470703.jpg)

-634821106166250000.jpg)

-634821106572812500.jpg)

-634821106815625000.jpg)

-634814909605058593.jpg)

-634814909850224609.jpg)

-634814910193212890.jpg)

-634814910596445312.jpg)

-634820188048437500.jpg)

-634820188647187500.jpg)

-634820189032656250.jpg)

-634718079154687500.jpg)

-634718080622031250.jpg)

-634714909191250000.jpg)

-634714909644843750.jpg)

-634713078392031250.jpg)

-634713078781250000.jpg)

-634720009877968750.jpg)

-634749341545937500.jpg)

-634749341951406250.jpg)

-634732946203437500.jpg)

-634708797562402343.jpg)

-634706000248750000.jpg)

-634705927185312500.jpg)

-634705927626406250.jpg)

-634705928146250000.jpg)

-634705929045781250.jpg)

-634705929717812500.jpg)

-634705930336093750.jpg)

-634705930540468750.jpg)

-634705931037812500.jpg)

-634709695807265625.jpg)

-634709696076181640.jpg)

-634711364771718750.jpg)

-634711364485781250.jpg)

-634712172318906250.jpg)

-634771897291406250.jpg)

-634771897466093750.jpg)

-634771897849687500.jpg)

-634771898236093750.jpg)

-634771898712187500.jpg)

-634771899102656250.jpg)

-634771899822656250.jpg)

-634771900771562500.jpg)

-634771901301875000.jpg)

-634768466924746093.jpg)

-634768467383681640.jpg)

-634772580489218750.jpg)

-634772581075781250.jpg)

-634772581532343750.jpg)

-634772581721718750.jpg)

-634773400815625000.jpg)

-634773401032187500.jpg)

-634781365777988281.jpg)

-634781366040302734.jpg)

-634781366299042968.jpg)

-634766553798554687.jpg)

-634766556025839843.jpg)

-634759732245312500.jpg)

-634765021896093750.jpg)

-634765022115000000.jpg)

-634765022326562500.jpg)

-634765023386093750.jpg)

-634765855550937500.jpg)

-634765856533437500.jpg)

-634765856756250000.jpg)

-634845177217089843.jpg)

-634845177425585937.jpg)

-634857207521406250.jpg)

-634857208212500000.jpg)

-634857208786718750.jpg)

-634826982093593750.jpg)

-634838602835000000.jpg)

-634838603089687500.jpg)

-634838603585312500.jpg)

-634871181815468750.jpg)

-634871183099531250.jpg)

-634871128238750000.jpg)

-634870976497031250.jpg)

-634870976894687500.jpg)

-634880528374375000.jpg)

-634880528707656250.jpg)

-634880529073593750.jpg)

-634892824736386719.jpg)

-634892824903066406.jpg)

-634892825090117187.jpg)

-634892825255283203.jpg)

-634880812756406250.jpg)

-634870194470625000.jpg)

-634870194829687500.jpg)

-634865232676250000.jpg)

-634863402043750000.jpg)

-634863402351562500.jpg)

-634863402584218750.jpg)

-634863404238125000.jpg)

-634869405242656250.jpg)

-634869405424687500.jpg)

-634869405586562500.jpg)

-634869405943906250.jpg)

-634869406072656250.jpg)

-634869404353281250.jpg)

Ndavid what controller are you using?

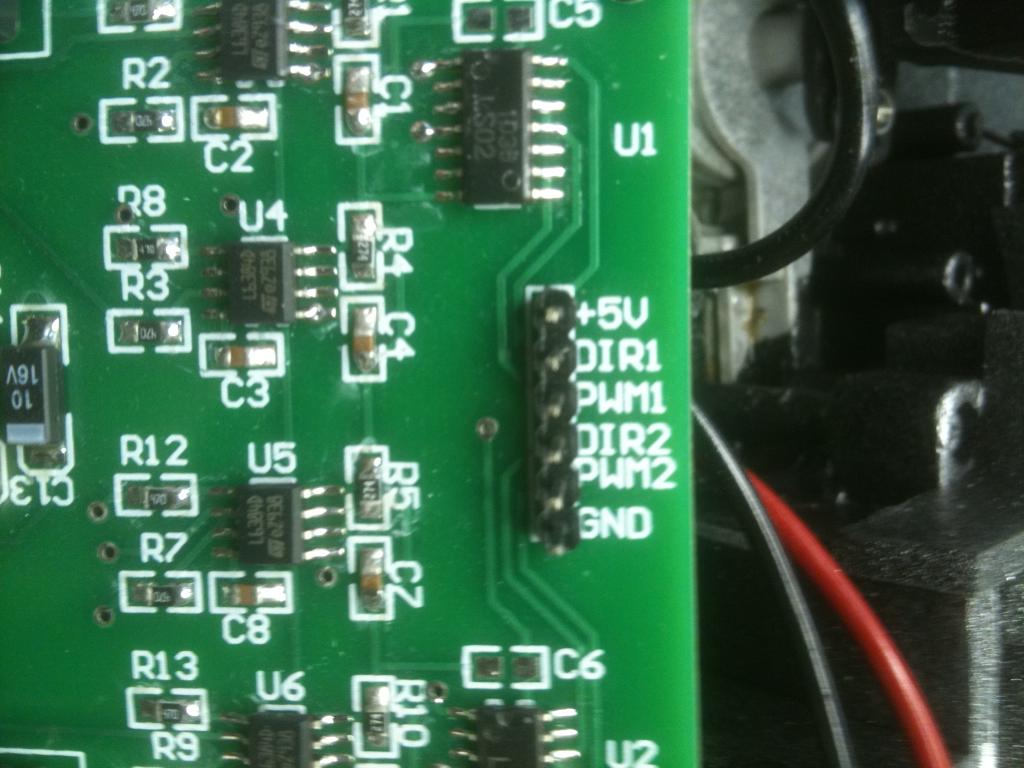

L298N dual H-bridge Specifically: cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=160755601853

Ok that's what I sent Brett.

That's fantastic! Glad to know that 12v is the way to go. I think I will use a couple of those step down regulators so I don't overload them. Maybe one for left side and one for right side. I had just upgraded my wiring to 18ga, do you think that is good enough for the 12v?

@ndavid79 - that is the same motor controller I used in Bob. So that works well with your RAD tracks and 12v?

Don't worry about the step down/voltage regs on the track motors, just dial the PWM back, to the motors its the same difference, but should give better torque. I only ran mine for like 10min so far, as I just temp wired it to test before starting in on building it a body. IIRC, I had set the PWM at somewhere around 70-75% to get a decent indoor speed (meaning not to fast) with just the 6.2lb battery on it, unfortunately I don't know what gear it was in. Turning on these rubber tracks will always be much harder on the motors then going straight, mine (my RAD tracks & my complete unmodded RAD 2.0) makes a more struggling when turning as well. Can't promise anything, but I'll try to get it wired up again & take a video this week.

18ga should be good, it's what I'm using.

Brett I'm sending upgraded wire to go from batt to motor controller , and 12 ga pure copper multistrand from controller to motors , remember to twist the wires , it reduces electrical rd interference with WiFi and Bluetooth

You should have a goody box tommorow! Ha ha , lets see b9 on 12v