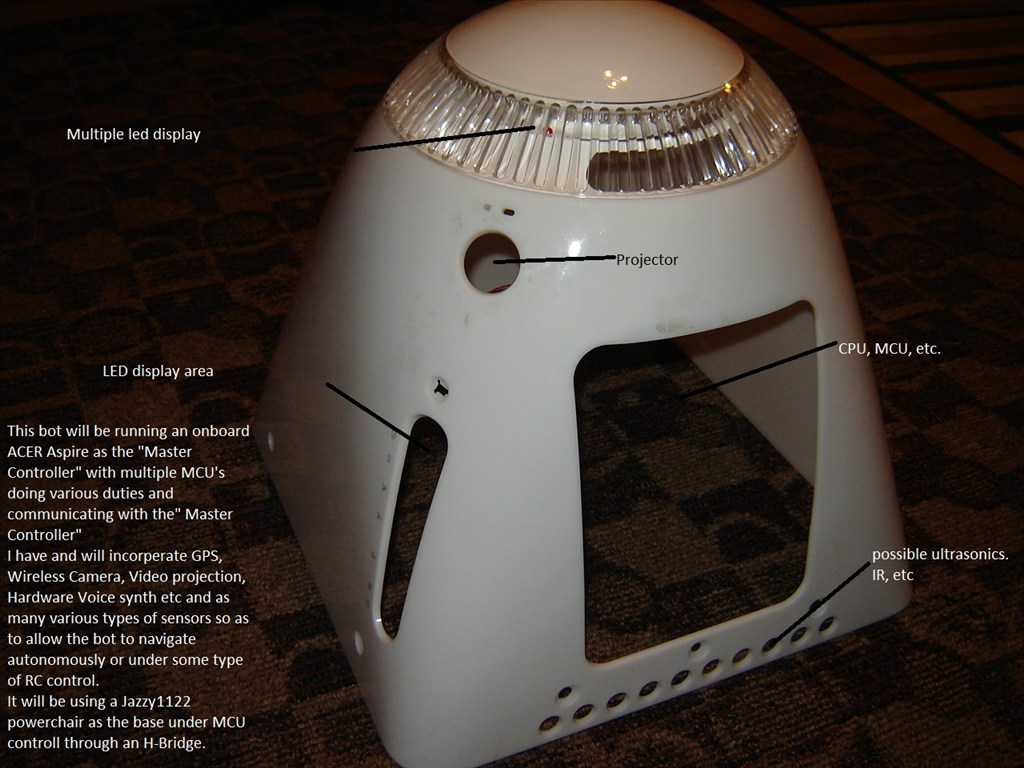

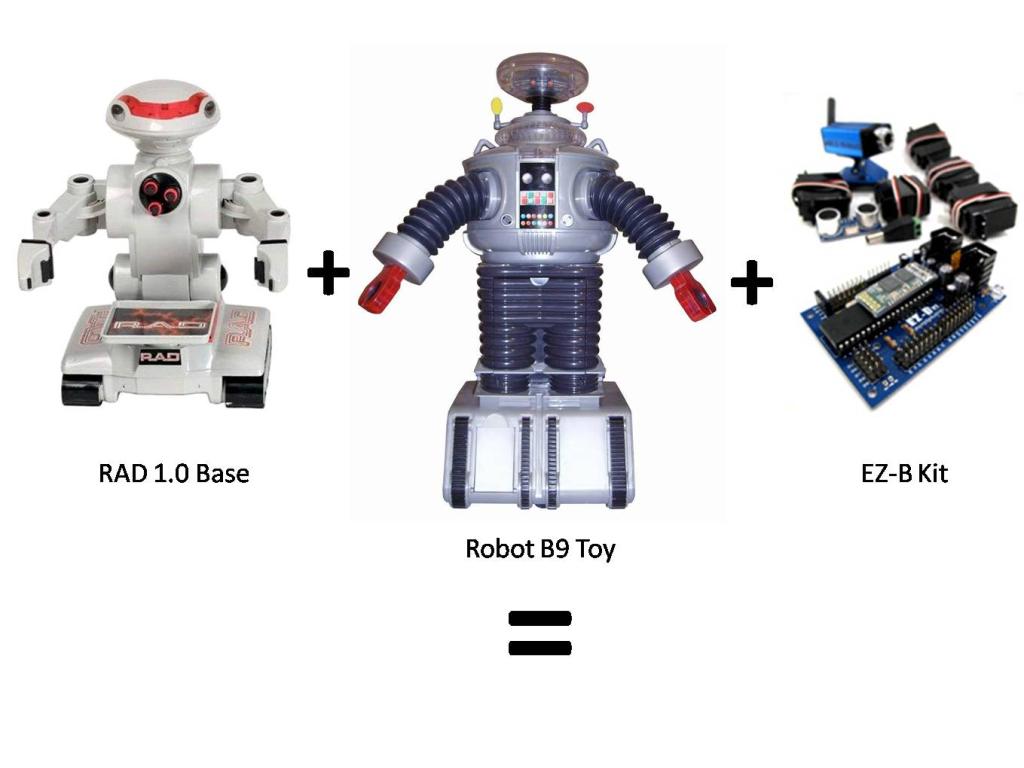

Now that I have finished B.O.B., my get your feet wet bot, I have begun my next hack. This next robot will bridge the gap between Bob and my ultimate big robot. I am starting with a remote controlled B9 toy from Trendmasters. It was very limited in what it did, and the drive section was pathetic, but it was B9!

Before Pics:

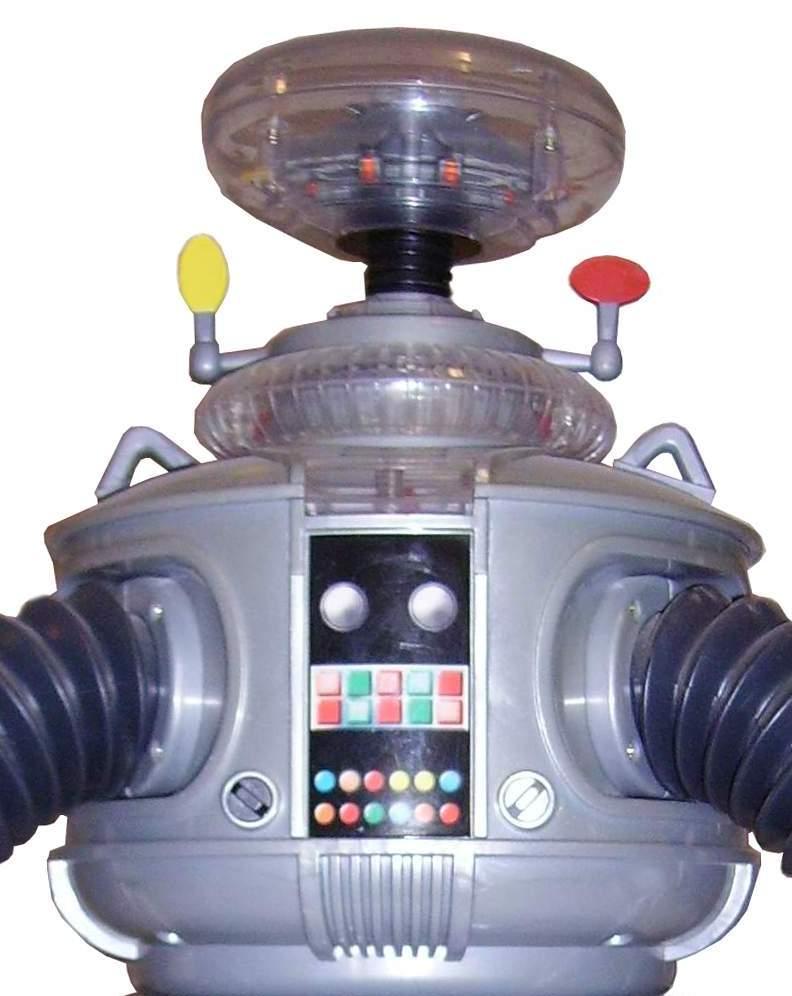

Note: the front "lights" in the chest plate is actually just a decal.Here is what B9 looks like now:

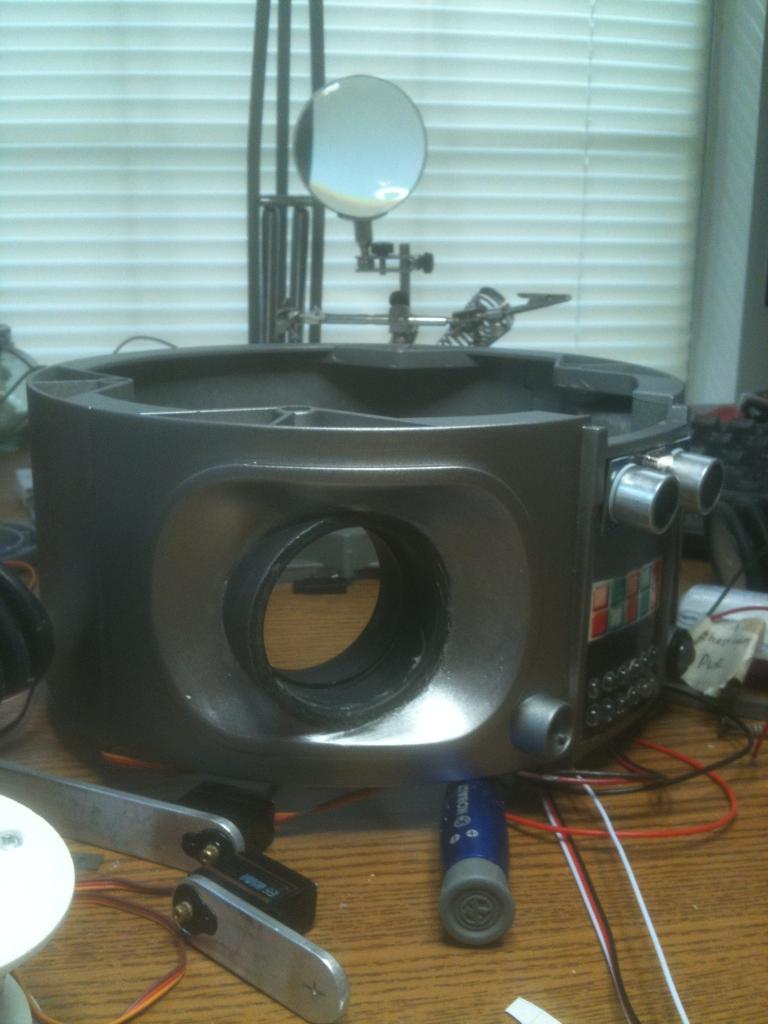

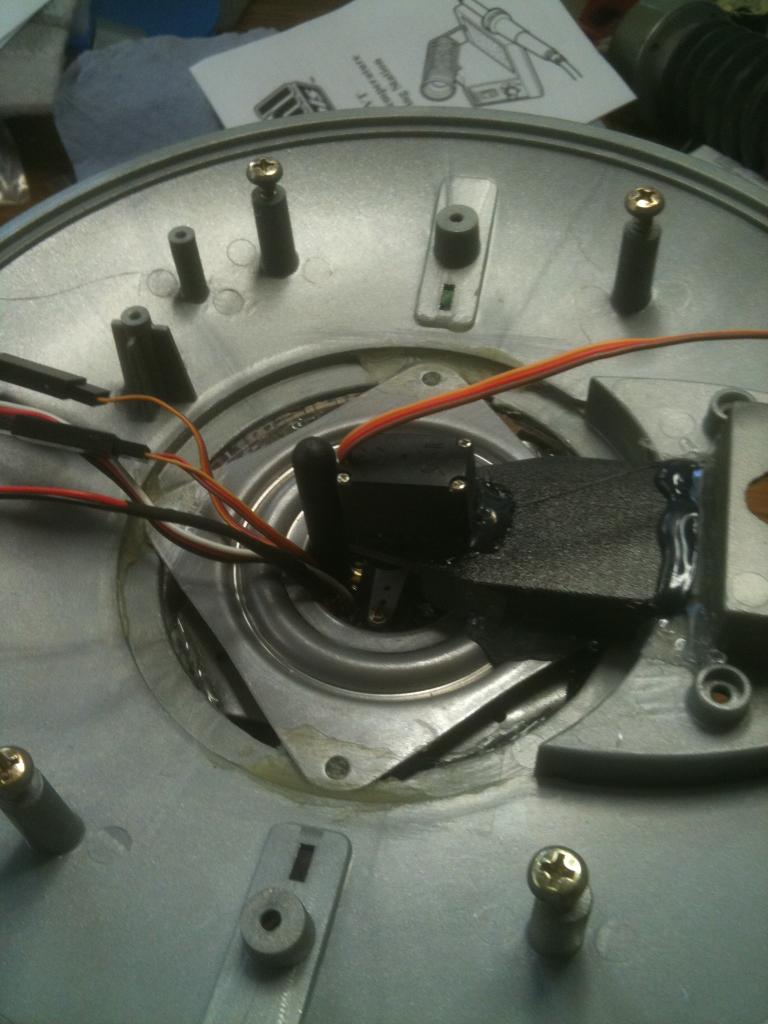

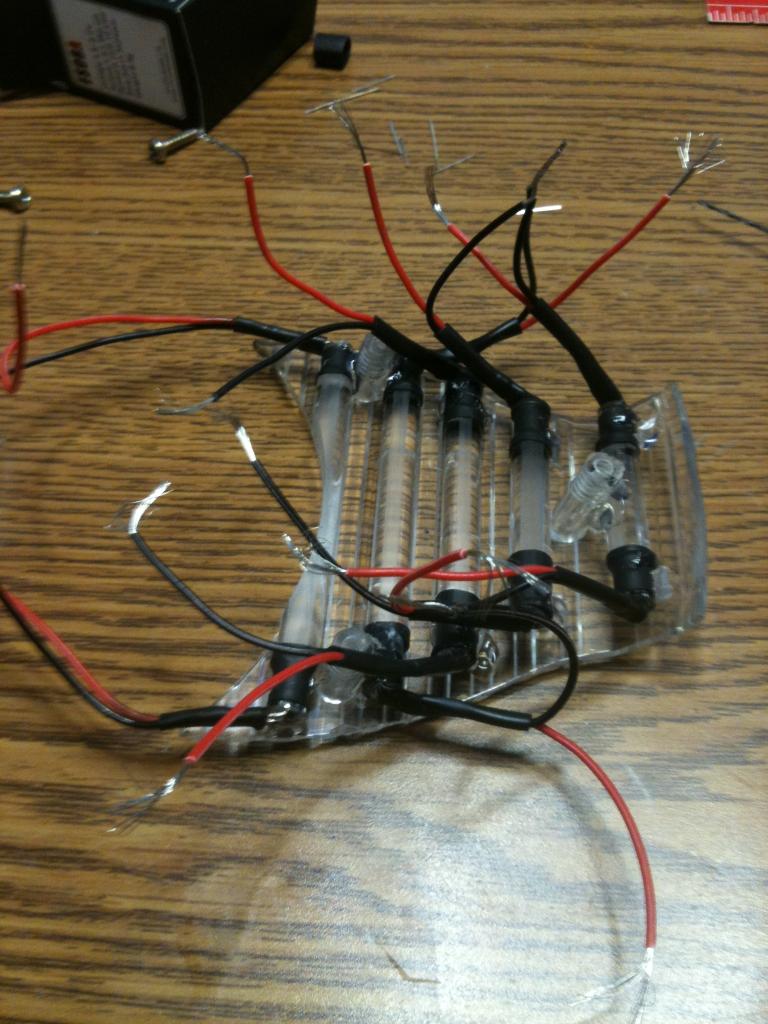

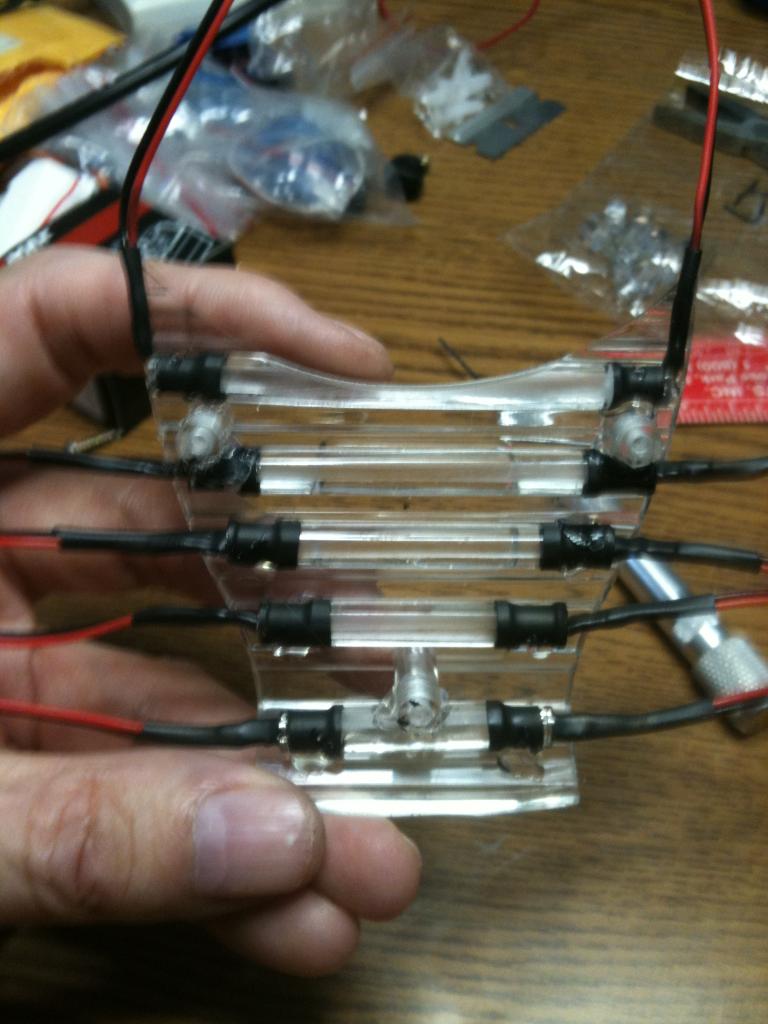

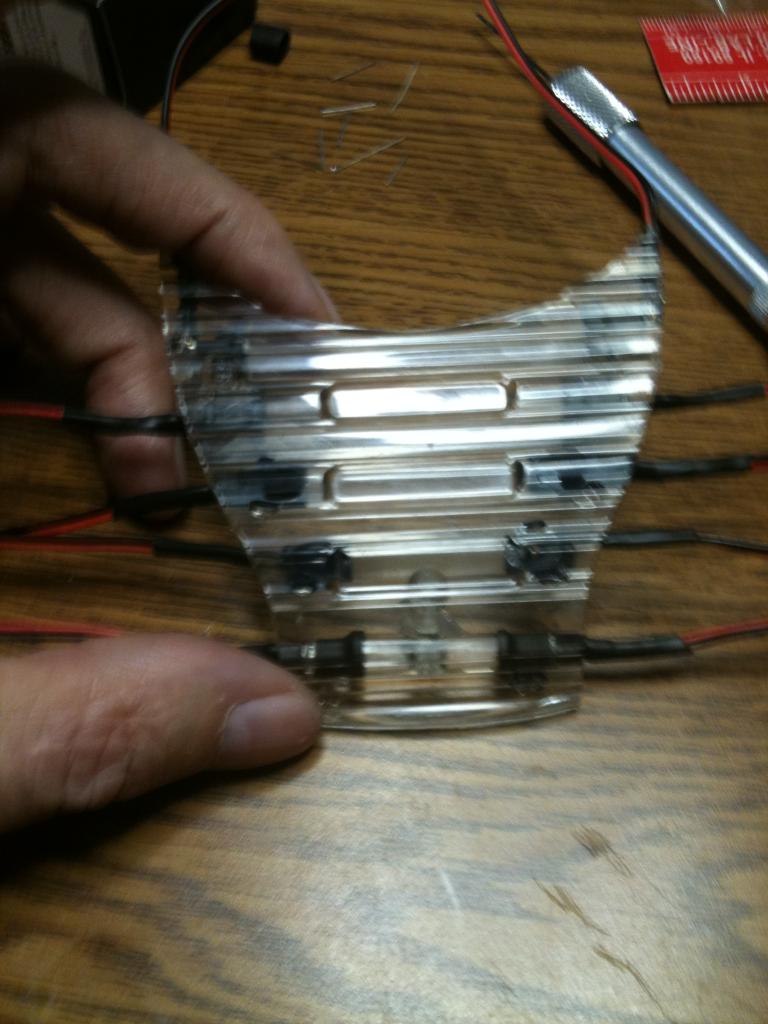

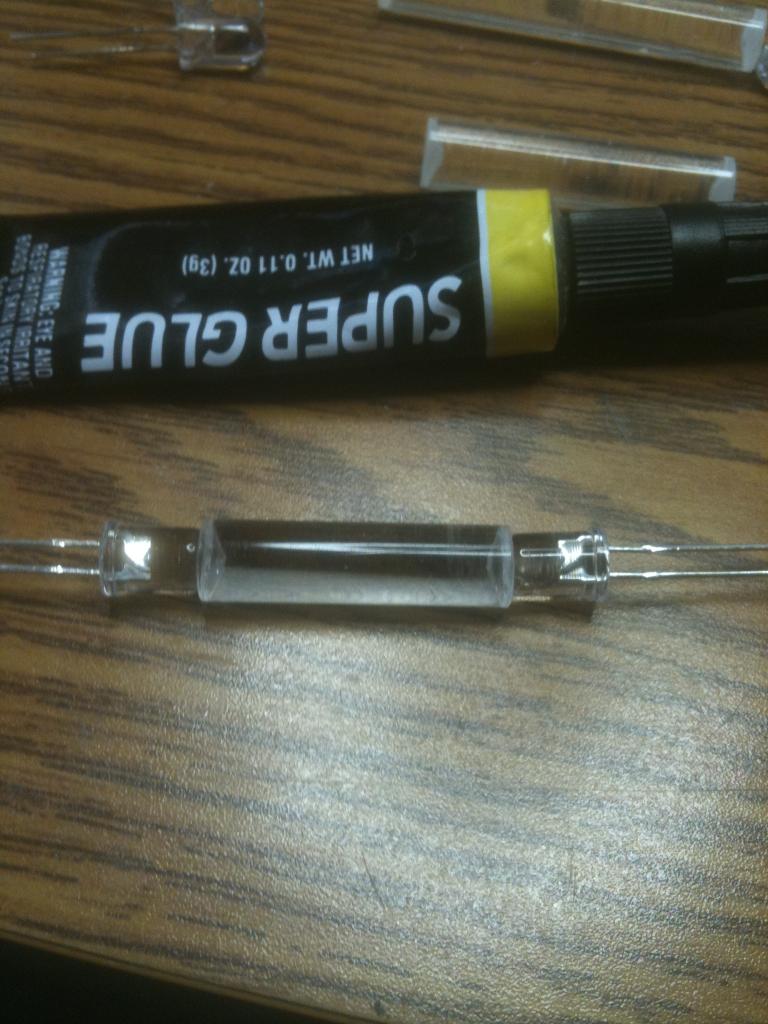

I have mounted clear LEDs in the appropriate colors in the chest at the bottom of the decal and have a flashing circuit that will blink them in the combination as seen on the series. Where the two large round circles are (white domes on the big guy) I will have my ping sensor. I have mounted pager motors in the antenna housings to turn the "sensors" as seen in the TV version. I have mounted red El Wire to his voice plate to emulate the original as well. I have also mounted a series of blinking LEDs to the "brain" section in the bubble.

Next is to work on the rotation of the bubble and torso, articulate the arms and claws, and make a real functioning tread section. For the tread section I am adapting the base from my RAD robot. I will keep you posted with pics as I proceed.

Thanks,

Bret

Other robots from Synthiam community

Steve's Resistance Is Futile 7 Of 9 Borg From Star Trek, My...

Putt's Bigmack

-634700966886250000.jpg)

-634700967015000000.jpg)

-634700967157968750.jpg)

-634702814800312500.jpg)

-634702600865468750.jpg)

-634702601116718750.jpg)

-634702602252031250.jpg)

-634702602665625000.jpg)

-634702602851875000.jpg)

-634694134410000000.jpg)

-634693960892812500.jpg)

-634693961752343750.jpg)

-634693953179375000.jpg)

-634693953336093750.jpg)

-634693164809062500.jpg)

-634693165327500000.jpg)

-634693165925625000.jpg)

-634693166147343750.jpg)

-634786542943876953.jpg)

-634796120303593750.jpg)

-634796120470312500.jpg)

-634812479455986328.jpg)

-634812479726035156.jpg)

-634812480620283203.jpg)

-634812481334052734.jpg)

-634812482341699218.jpg)

-634822681001005859.jpg)

-634822681580644531.jpg)

-634822681777470703.jpg)

-634821106166250000.jpg)

-634821106572812500.jpg)

-634821106815625000.jpg)

-634814909605058593.jpg)

-634814909850224609.jpg)

-634814910193212890.jpg)

-634814910596445312.jpg)

-634820188048437500.jpg)

-634820188647187500.jpg)

-634820189032656250.jpg)

-634718079154687500.jpg)

-634718080622031250.jpg)

-634714909191250000.jpg)

-634714909644843750.jpg)

-634713078392031250.jpg)

-634713078781250000.jpg)

-634720009877968750.jpg)

-634749341545937500.jpg)

-634749341951406250.jpg)

-634732946203437500.jpg)

-634708797562402343.jpg)

-634706000248750000.jpg)

-634705927185312500.jpg)

-634705927626406250.jpg)

-634705928146250000.jpg)

-634705929045781250.jpg)

-634705929717812500.jpg)

-634705930336093750.jpg)

-634705930540468750.jpg)

-634705931037812500.jpg)

-634709695807265625.jpg)

-634709696076181640.jpg)

-634711364771718750.jpg)

-634711364485781250.jpg)

-634712172318906250.jpg)

-634771897291406250.jpg)

-634771897466093750.jpg)

-634771897849687500.jpg)

-634771898236093750.jpg)

-634771898712187500.jpg)

-634771899102656250.jpg)

-634771899822656250.jpg)

-634771900771562500.jpg)

-634771901301875000.jpg)

-634768466924746093.jpg)

-634768467383681640.jpg)

-634772580489218750.jpg)

-634772581075781250.jpg)

-634772581532343750.jpg)

-634772581721718750.jpg)

-634773400815625000.jpg)

-634773401032187500.jpg)

-634781365777988281.jpg)

-634781366040302734.jpg)

-634781366299042968.jpg)

-634766553798554687.jpg)

-634766556025839843.jpg)

-634759732245312500.jpg)

-634765021896093750.jpg)

-634765022115000000.jpg)

-634765022326562500.jpg)

-634765023386093750.jpg)

-634765855550937500.jpg)

-634765856533437500.jpg)

-634765856756250000.jpg)

-634845177217089843.jpg)

-634845177425585937.jpg)

-634857207521406250.jpg)

-634857208212500000.jpg)

-634857208786718750.jpg)

-634826982093593750.jpg)

-634838602835000000.jpg)

-634838603089687500.jpg)

-634838603585312500.jpg)

-634871181815468750.jpg)

-634871183099531250.jpg)

-634871128238750000.jpg)

-634870976497031250.jpg)

-634870976894687500.jpg)

-634880528374375000.jpg)

-634880528707656250.jpg)

-634880529073593750.jpg)

-634892824736386719.jpg)

-634892824903066406.jpg)

-634892825090117187.jpg)

-634892825255283203.jpg)

-634880812756406250.jpg)

-634870194470625000.jpg)

-634870194829687500.jpg)

-634865232676250000.jpg)

-634863402043750000.jpg)

-634863402351562500.jpg)

-634863402584218750.jpg)

-634863404238125000.jpg)

-634869405242656250.jpg)

-634869405424687500.jpg)

-634869405586562500.jpg)

-634869405943906250.jpg)

-634869406072656250.jpg)

-634869404353281250.jpg)

Nice, can't wait to see your future progress!

how much was the shell....or toy or whatever it was.(lamp?)

@hoolagen1 - this was a remote control toy from Trendmasters in 1997/98. I paid $79.00 for it back then. Don't know what they go for now but imagine you can get them on ebay likt the omnibots and stuff.

That's going to be a lot of fun. Looking forward to seeing your progress.

Thanks!

Your picture reminds me of this episode when the robot got taken apart.

They got him back together though. I am sure that you will too. I look forward to seeing him moving around on his own.

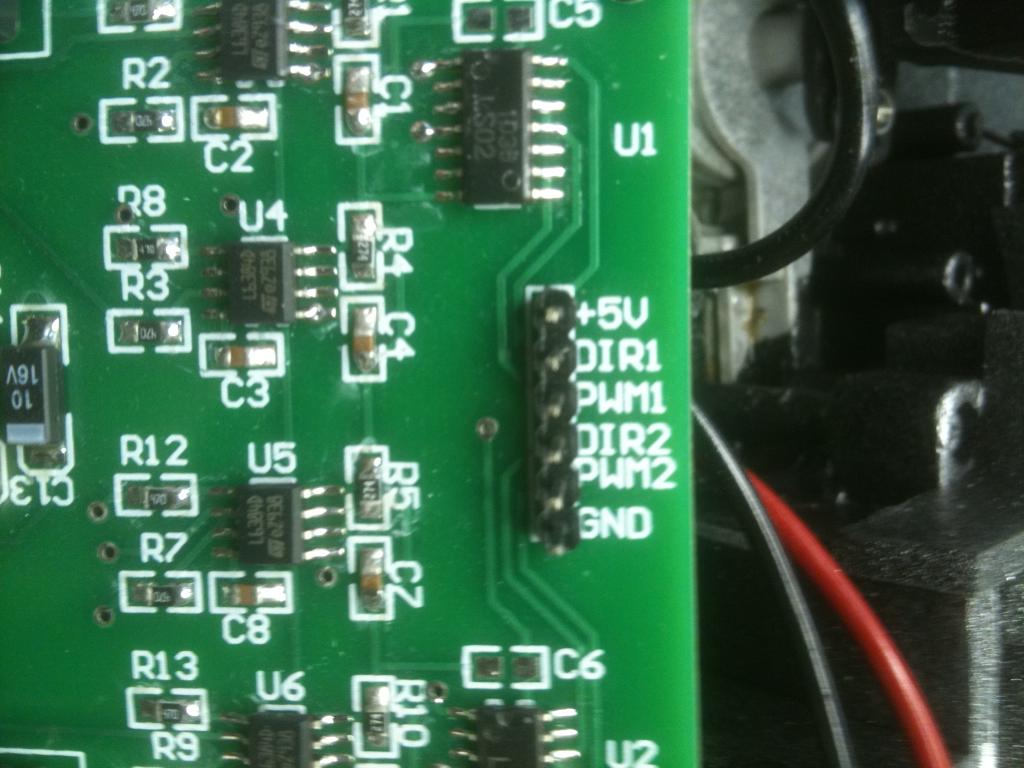

Thanks! - So I have the lights in the bubble and lower chest finished. I also have motors mounted in the radar pieces (eventually these will be controlled via the EZ-B and an H-bridge) but for now I just want to show them working. I am moving my power supply between features just to show you how they work, as I have not ordered my next EZ-B yet (gotta save my pennies). But you sorta get the idea.

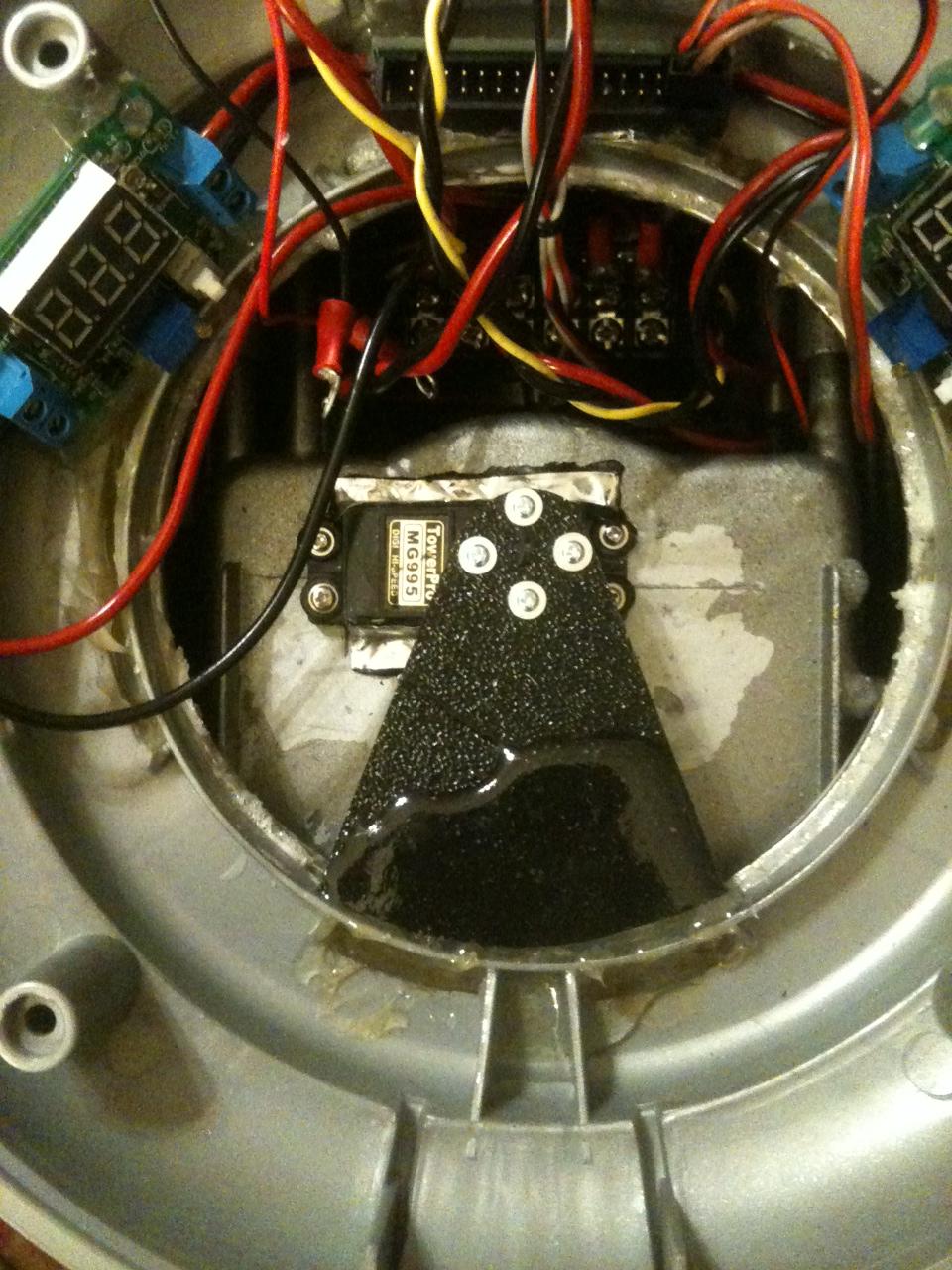

I have a 5 and 1/2" acrylic lazy susan bearing coming in so I can rotate the waste, and a servo attached to the bubble's neck will rotate that. But I will have to do some cutting to the bot to get the collar section to rotate, but that is where I want to mount the camera. I'll have to see what I can do there. I also have a plan to get a fairly full range of movement out of the arms that will mimic the original robot from the series.Looking good so far! Can't wait to see it all back together. Any plans yet for the arms?