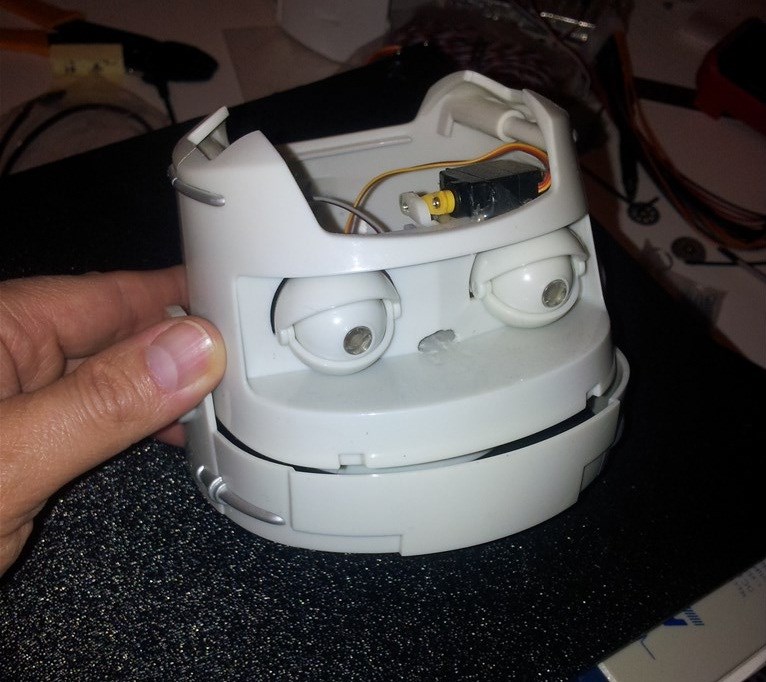

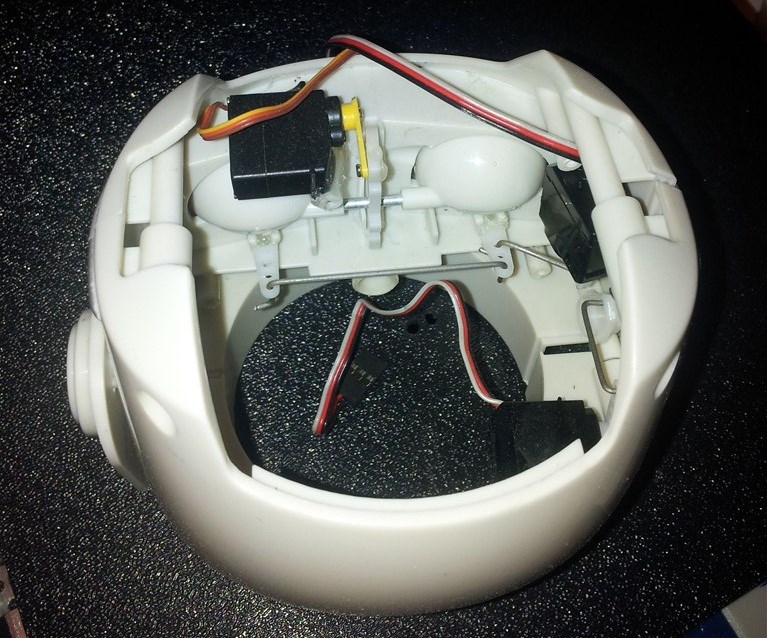

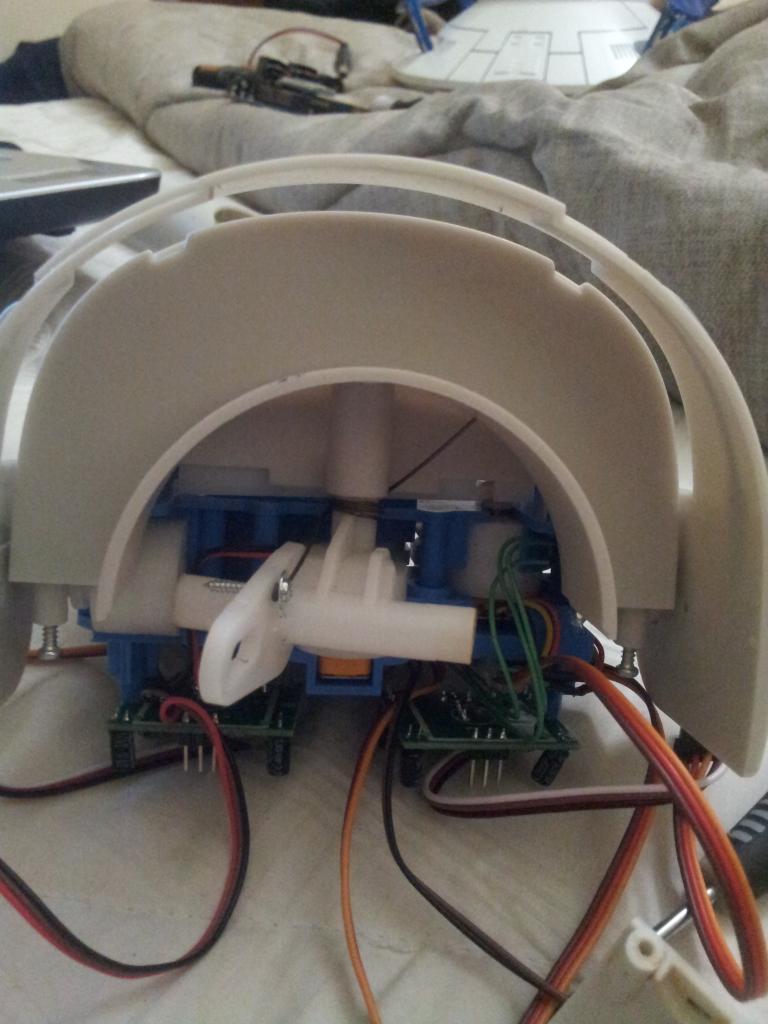

It's just a concept right now but I wanted others to see that the scale doesnt quite match. Right now its just stacked on there and neck is a little too long.

By Troy

— Last update

Other robots from Synthiam community

DJ's Apple Watch Robot Control

Synthiam ARC adds Apple Watch support to the ARC iOS app, making the watch more useful and fun for ARC users.

DJ's Ez-Robot Takes The Secret Challenge Competition

EZ-Robot sponsors kids building an Off-Roadbot for Western Canadian Robot Games-assembling platform, motors, controller,...

Bhouston's My New Robot

Introducing a new robot with a short demo video showcasing progress and community support.

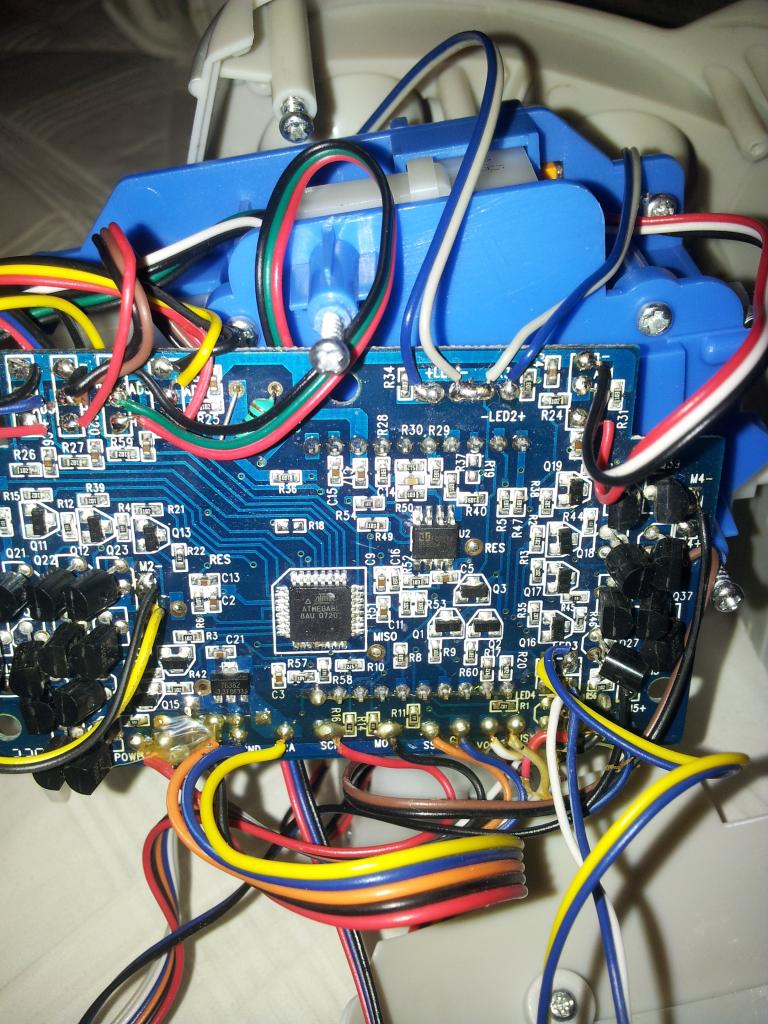

I will have to check when I get home.

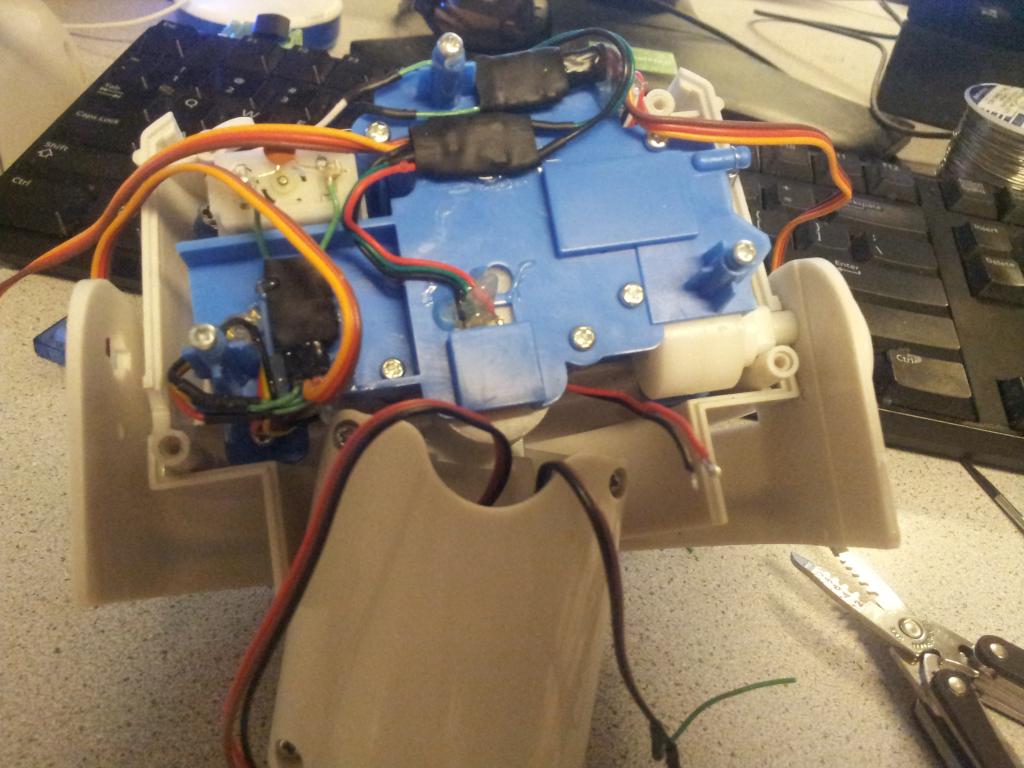

I can say current is a bigger issue that voltage , because when you push more voltage or current through a chip it gets hot. I see your trying to basically make the motors work like a servo I wouldnt use more than 7.4 in that case , but if you used a h bridge to power them and only the pot and board for feedback 12 is doable. Try 12 direct bypassing your servo board and see if it opens and closes much quicker. If you like the ad speed you know which route to take.

its like any chip if its made for a certain voltage and you go higher in voltage it wiil get ruin most h-bridge chips in servos have 2 seperarate voltage ,one for logic other for motors ,most tied the pins together,but if using a higher rated motor can drive the correct pin with a higher voltage also current is another problem that ruins a chip

look at the micro that DJ is using in EZB its rated for about 54. max if you drive it with 12 volts it will smoke

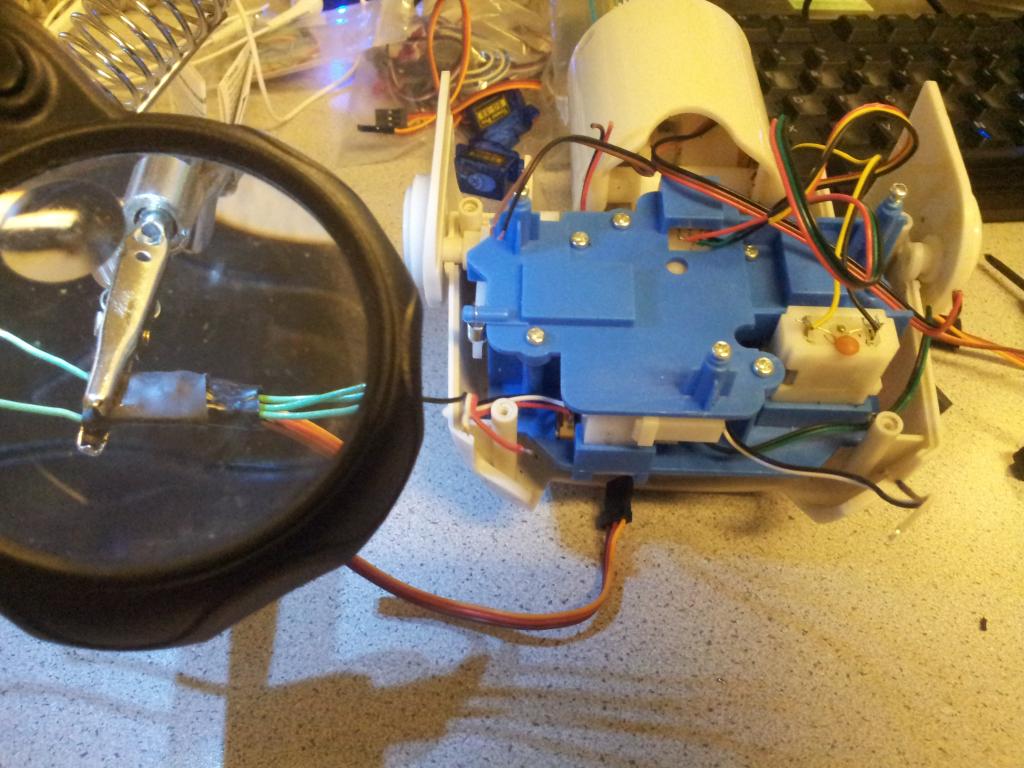

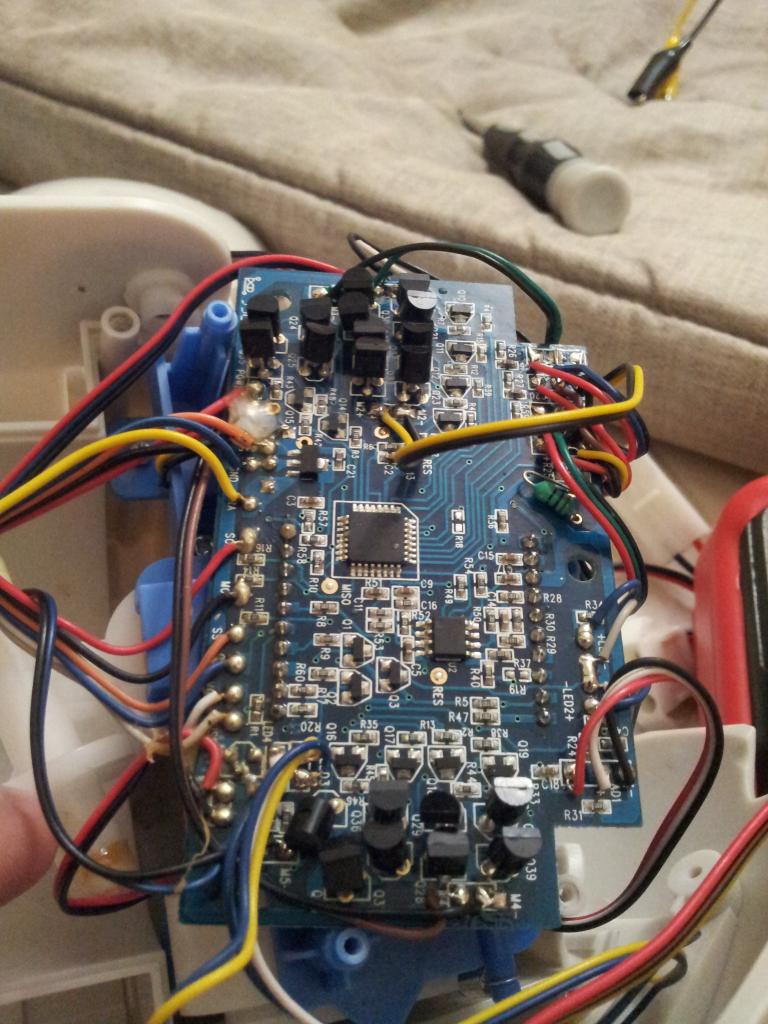

I want these claws to open and close quickly like castanets.

that also depends on the gear ratio,besides the voltage lower the gear ratio faster the speed and less torque if go higher on the gear ratio less speed more torque

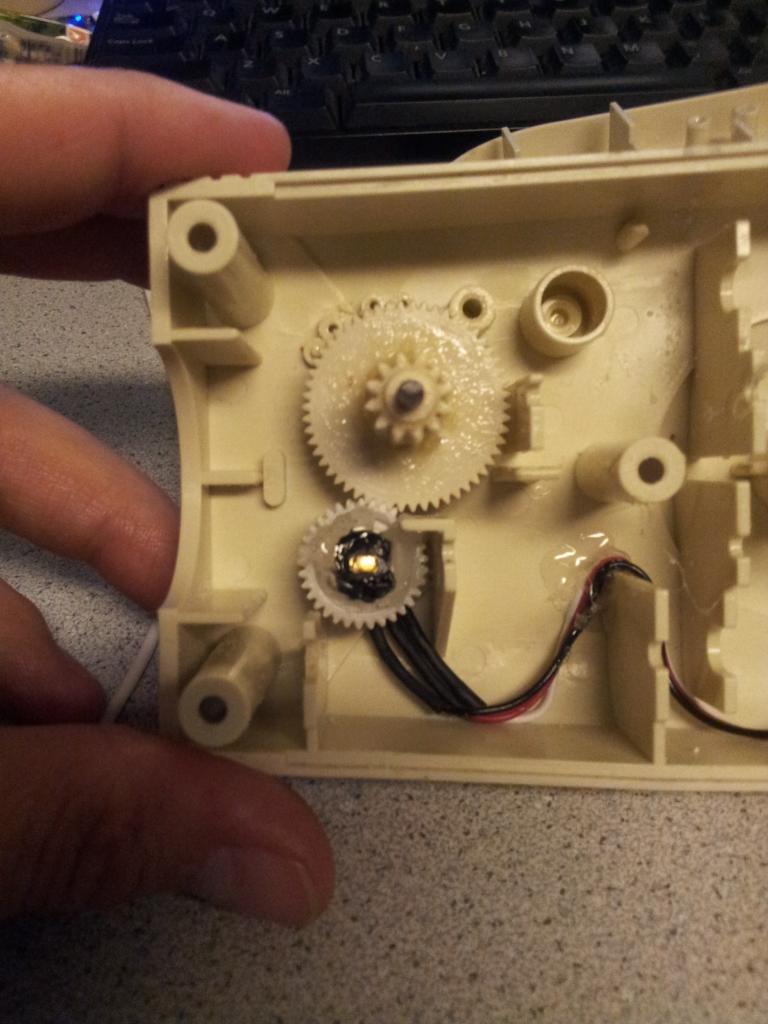

so what you need to do is remove some gears if you want to open and close faster

umm...I was really joking.

here is a good chart and info on motors,it has also a simulator for each motor now i dont know what motor you are using ,but as you can see in the chart some rated for 3 to 12 volts or 6-12 volts and normal voltage they run at,if you run higher or lower voltage the efficiency wont be good,and you can move the sliders in the simulator mabuchi motors

in the link i only selected only a few by a certain size of motors you can change it for the motor you are using the simulator chart is my favorate i can see what voltage and current and torque changes with the sliders adjusted

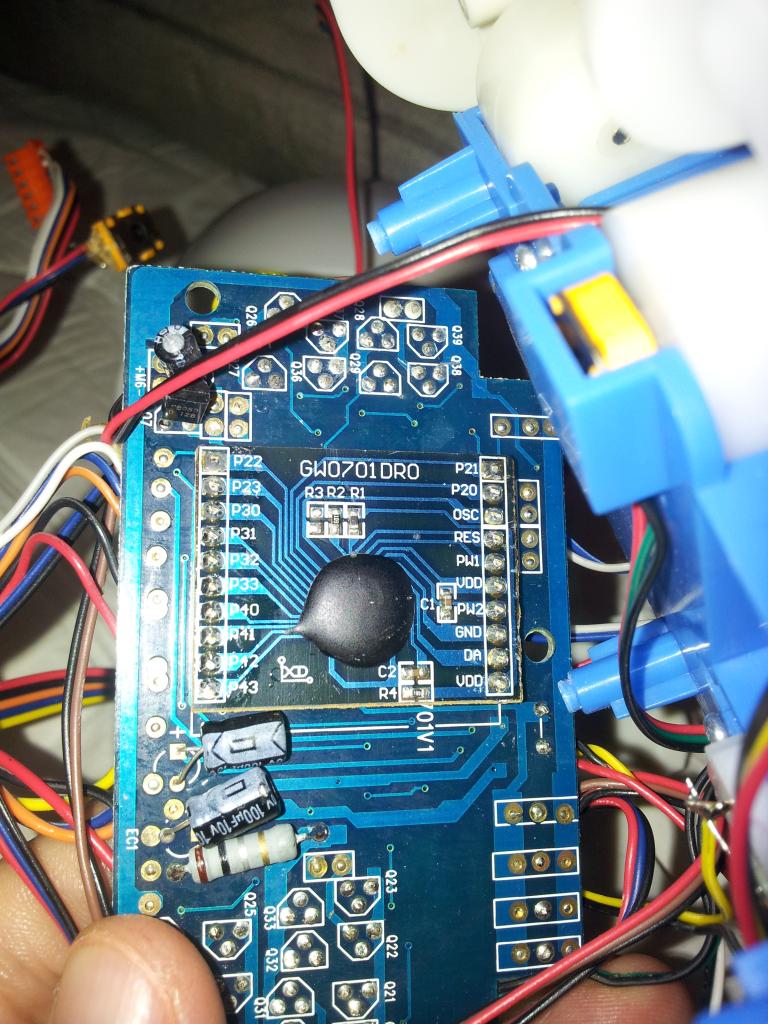

@glickclick !vdude stop the presses! O don't know why I didn't tell you earlier. Aftermarket doorlock actuators and electronic push/pull 5 wire solenoids can do that! Both run 12v , very strong and have auto start stop points.

Here's an example , half the case length is not even needed to work! https://www.ebay.com/itm/2-HEAVY-DUTY-POWER-DOOR-LOCK-ACTUATORS-POWERFUL-MOTORS-/320349936822?pt=Motors_Car_Truck_Parts_Accessories&hash=item4a96581cb6&vxp=mtr

They use mabuchi 280 motors , all you need to do is mod it to where your potentiometer is connected to the output shaft for greater control! Omg I can't believe I didn't think of.it!