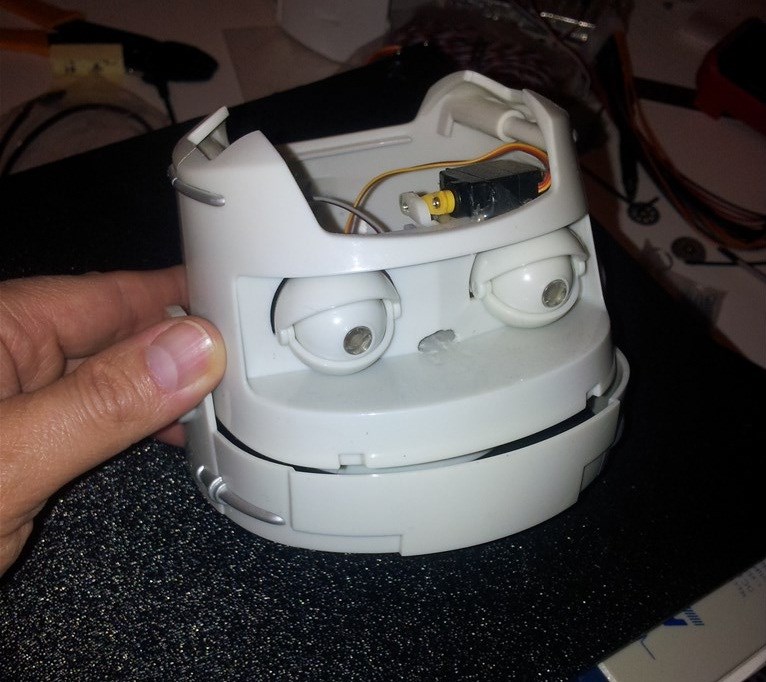

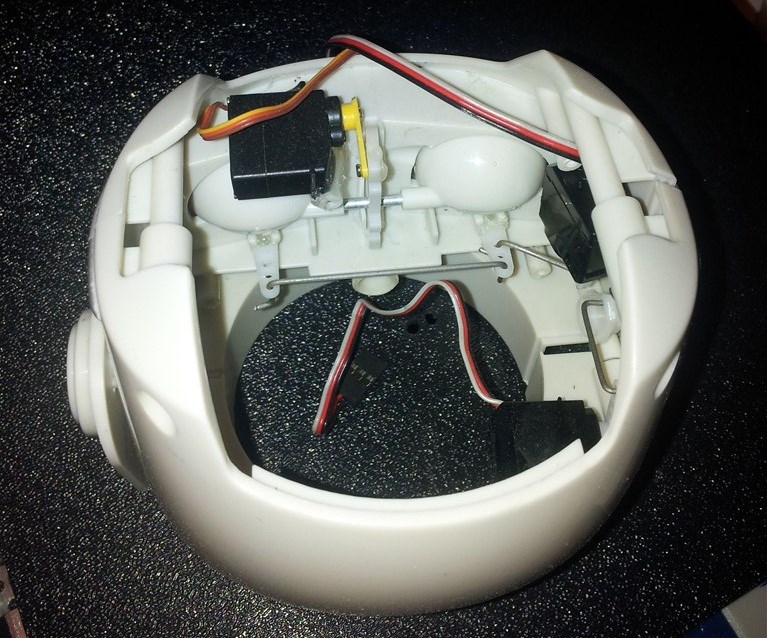

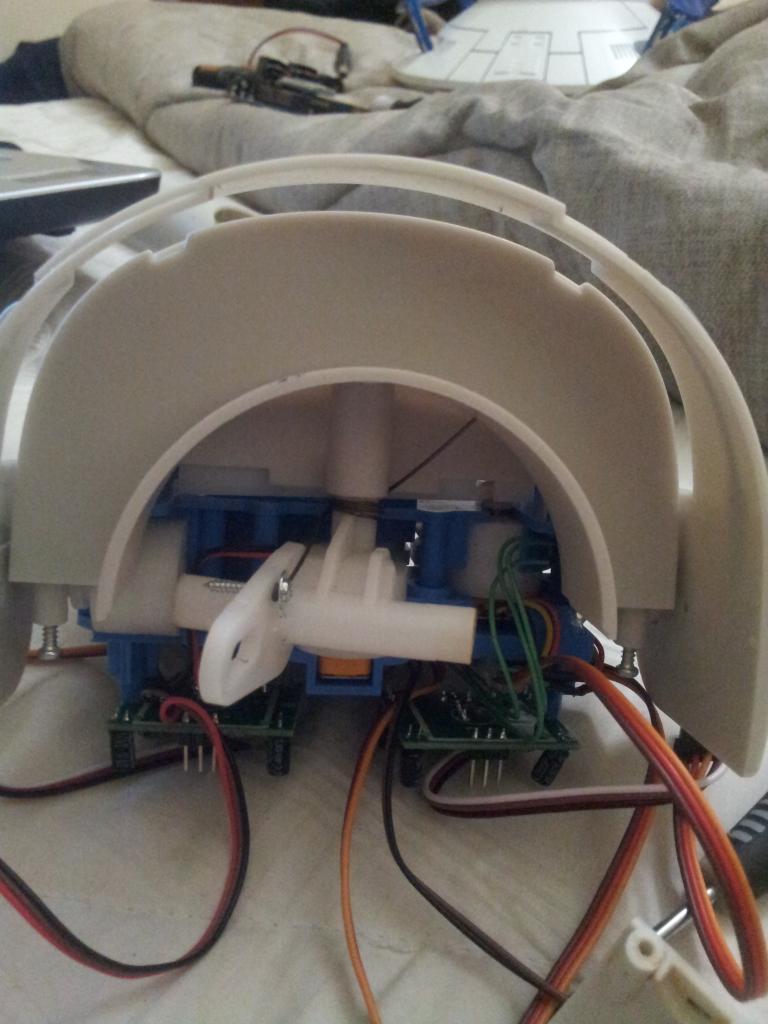

It's just a concept right now but I wanted others to see that the scale doesnt quite match. Right now its just stacked on there and neck is a little too long.

By Troy

— Last update

Other robots from Synthiam community

Lsradets's EZ-Inmoov Robot Head

EZ-InMoov robot head with Synthiam 3D-printed parts and EZ-Robot electronics, programmable via Synthiam ARC for...

Rb550f's Okio J5 Style Robot Project

OKIO J5-style 44" robot built from an upright vacuum: Dremel head, LED eyes, HD USB camera, Windows 10 tablet,...

Ezang's Robot Arm PCA 9685 Arduino On ARC

Control PCA9685/Arduino-driven MG996R servos and gripper on DF Robot Hexa Base Rotate Kit; Synthiam ARC auto-positioning...

Oh so they arent solenoids and can vary the throw? I wonder how much current thats gonna draw. The speed of castanets was a joke.

Well I know it was an exaggeration. I just remembered that they are cheap , quick and strong.

Josh, you know what, after testing the speed without the board on 7.5 and 12v it seems a bit slow. So Im thinking of using your idea if it fits. Maybe one with 7.2 and the other with the actuated for gesturing. I was never really intending to do more than gesture anyways. Good find Josh!

I'm 1000 percent sure it can fit in the upper arm which is hollow and run a flex cable to the claw since its a simple push pull , fitting in.the forearm could work with cutting the actuators down some.

mostly very high current,like all door locks i replace a few on cars and forgot about them.not same one but others boy did i hate working on cars,not as enjoying at working on electronics,plus added work work travel

They use mabuchi 280 motor , it varies from one actuator to another.

thats about a 3 amp motor

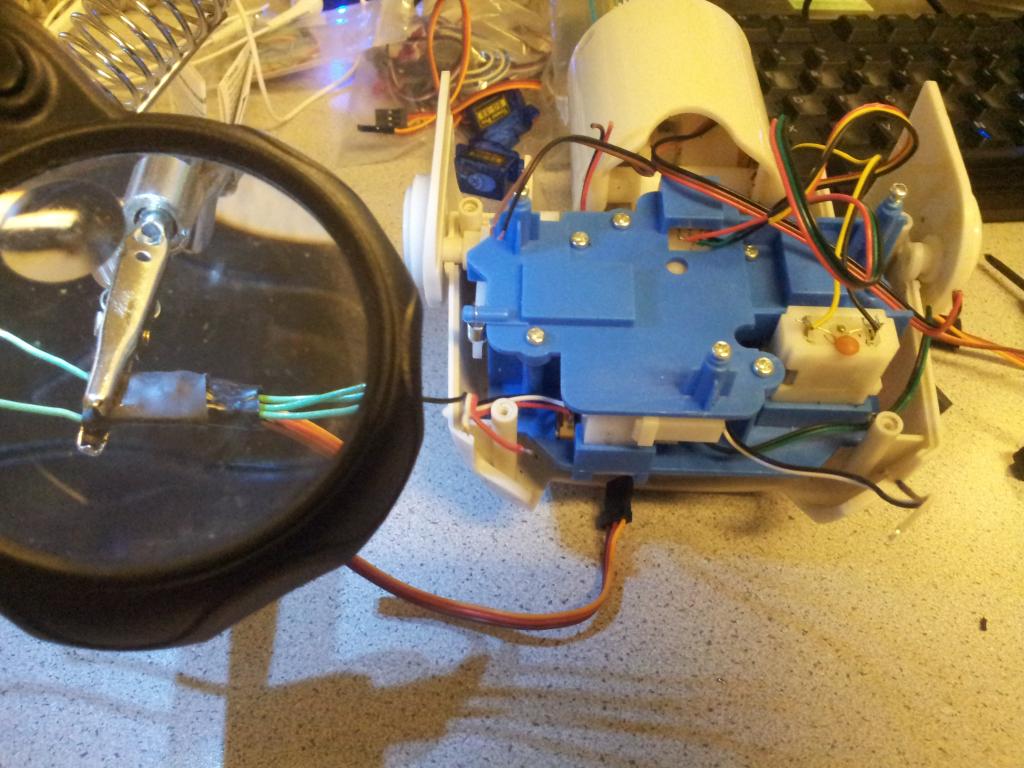

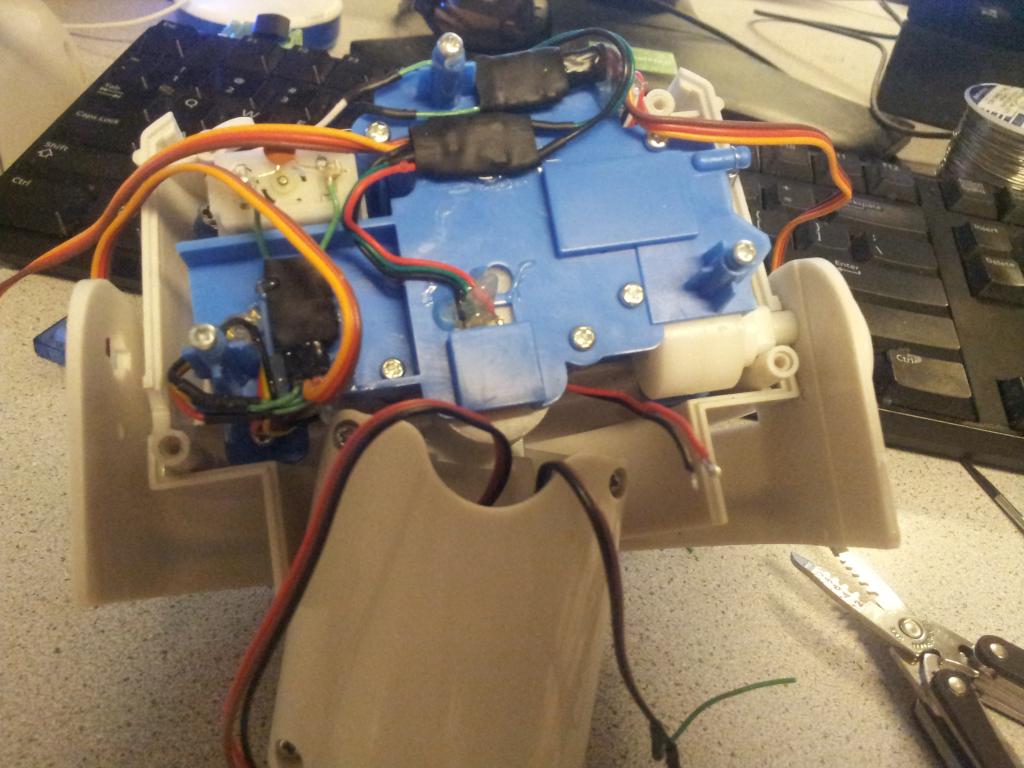

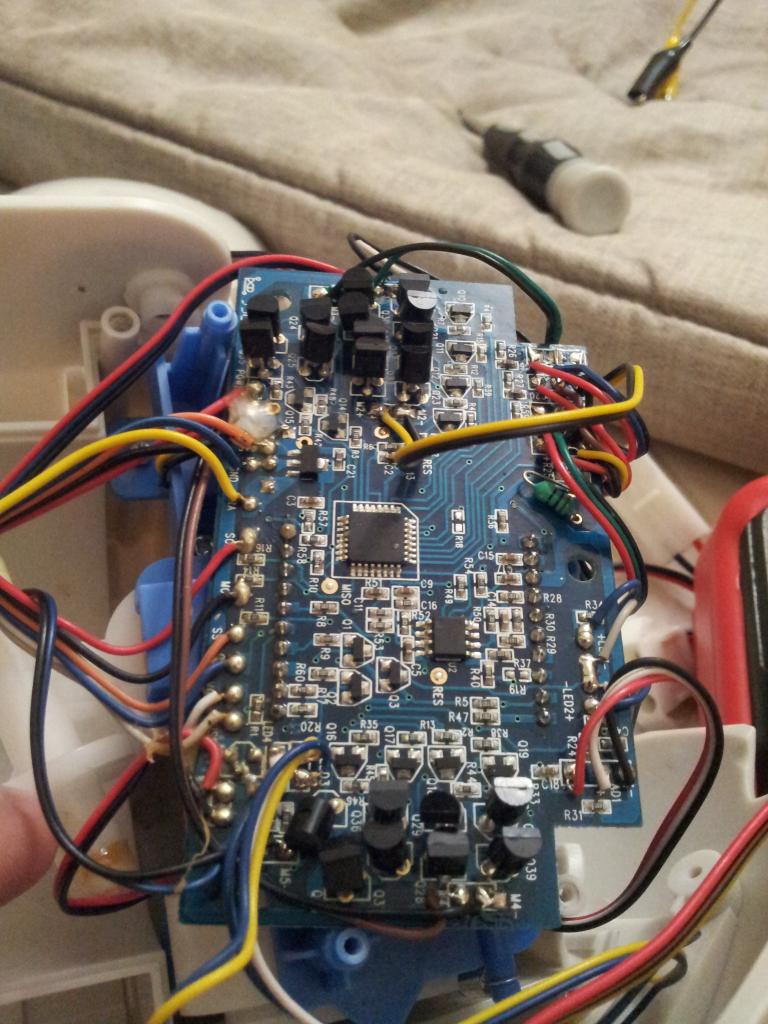

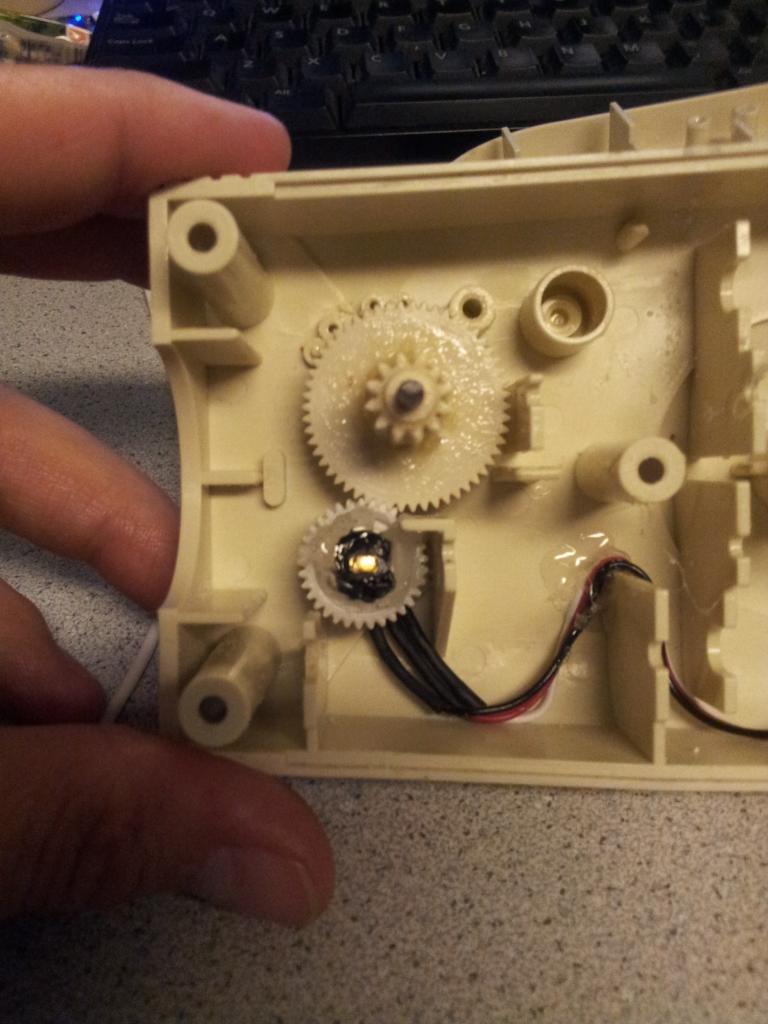

I found a solution for my bot's head wobble without using new servos and pushrods. After I got the parts in to try the pushrods it quickly because apparent that I would have to modify quite a bit and the neck would be much thicker with servos inside. I re-examined the problem and thought of putting tension on the neck to reduce the slop or slack that caused the servos to overcorrect when trying to go from one position to another. I looked at what I had on hand and saw that the springs that hold the tray door closed would work great. They even fit around the axle too. I tested it and it worked. Take a look.

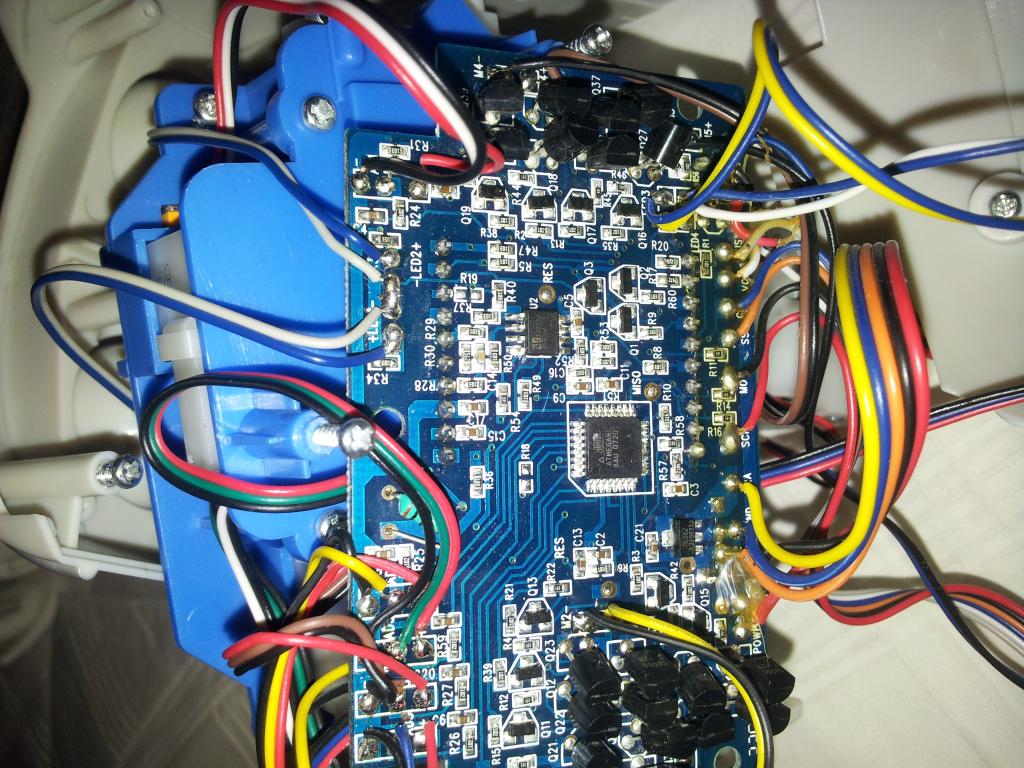

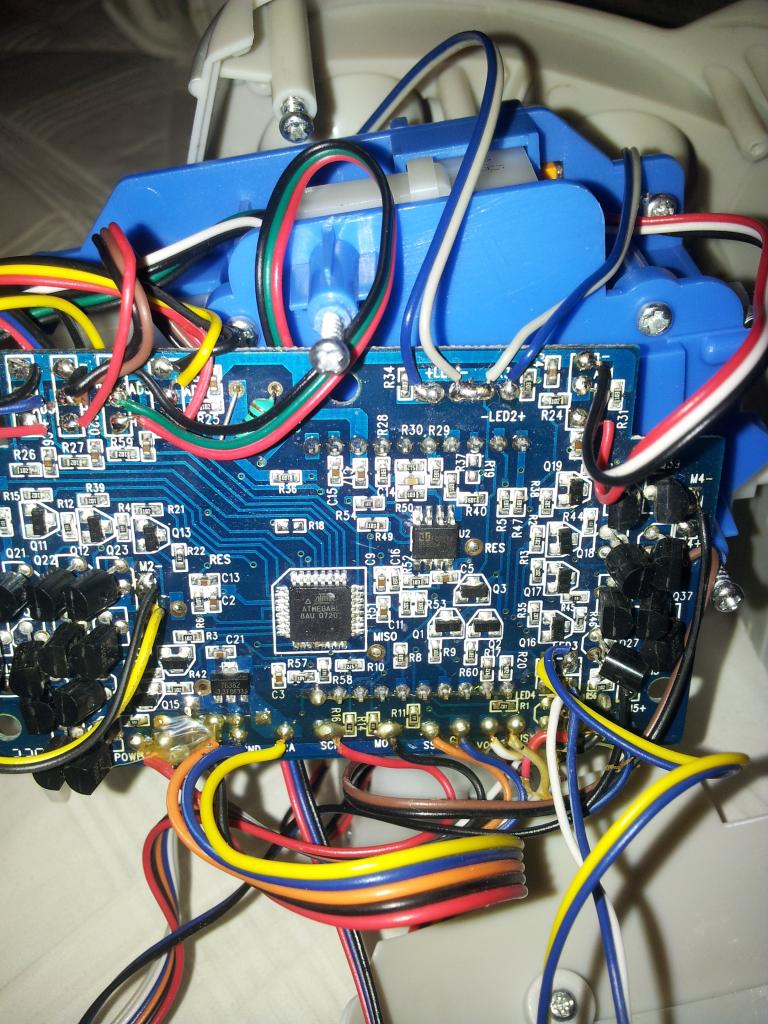

Oh yeah the two little boards are from the motion sensors. I desoldered the sensor from the board and put them on his ears and the boards fit within the head. I haven't tested them yet.

I'm now working on putting my claw mod together with my modded elbow. The other video was on the other arm's claw.