This is my InMoov Project which is a downloadable open source 3d printing project that I am working on. Robot is life sized. I am using EZ- Robot and EZ Face.

I will possibly be using a Kinect for advanced recognition and hopefully EZ will support this or some one else will come up with a plug in also. If not I will probably use VB.net and attach.

By jphillipsnj

— Last update

Other robots from Synthiam community

Randez's Randez's Omnibot2000 Thread...

Refurbishing a 25-26" tall build with greasy elbow leak and melting 3" wheels; planning urethane tire molds or...

Imrisaac's Ez-B Project V3.0

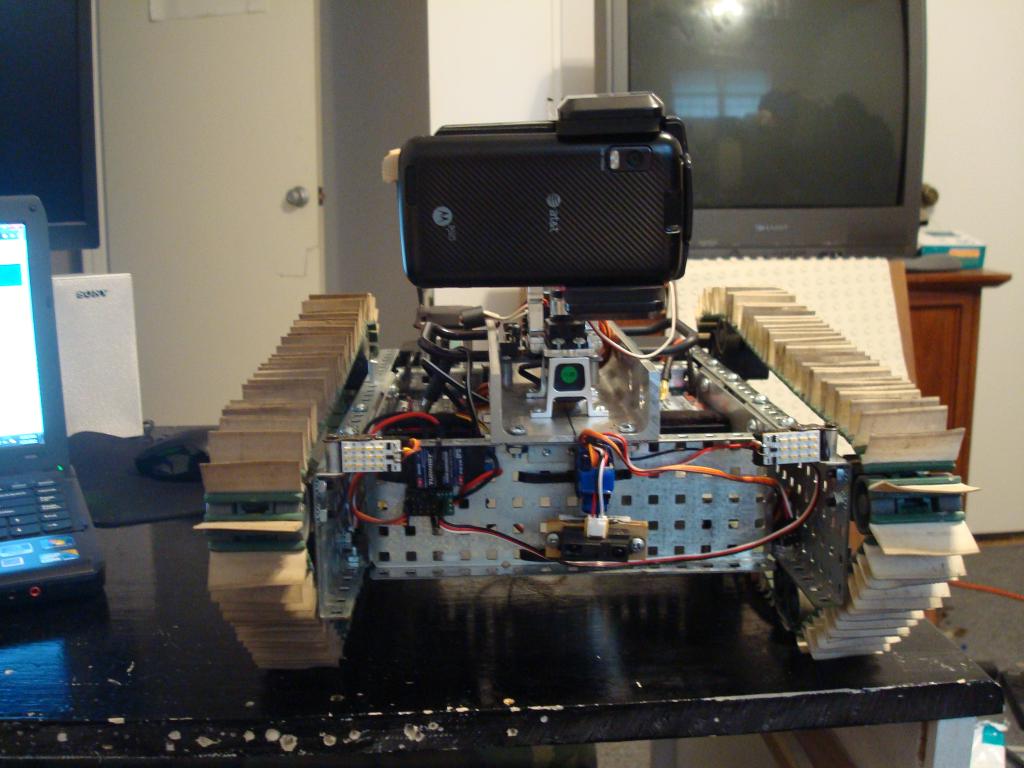

Surveillance tank with EZ-B and XBee XSC900 for long-range control, Android IP camera streaming video, Vex treads,...

Rgordon's Project Questor

Questor: compact autonomous test robot with EZ-B control, camera 'nose', IR LEDs, remote-control option and...

The InMoov will be my next robot project hands down! Great job Jack!

how much time needs the Makerbot Replicator 2 for the parts ? how much material costs do you have?

I hope, one day he can walk and go out with my dog thanks for the video

thanks for the video

Great job Jack ! I'm impressed ! Pls hurry with the Kinect. I'm interested.

Smarty,

I think it take about 400 hours to print entire. 10% of all parts are either warp or get messed up.

PhG,

I probably will get to until summer. The arms and hands are a lot of work.

Both,

Be careful of parts you download and stick with same version on parts. Some different versions the parts are not interchangeable. The head, torso, neck, shoulders, and bicep are pretty good. Forearm I am having a lot of issues with.

Left Arm Complete. Working on Right shoulder now. Right forearm complete. Should have most of project done soon.

Hi Jack, I got my EZBv4 controllers a couple of weeks ago and I've been playing with them. I have been trying to get a Sound servo to moving the mouth of my InMoov correctly. Have you got this feature to work for you? Where are you at with your InMoov?

I had a lot of problems getting things to fit together as well. One thing I found, was to decrease the number of shells and increase the fill. I printed most everything at 3 shells and had troubles but at 2 shells things fit together better.I think it's the way makerbot adds shells that make the difference.

most exciting robot.awesome.

bhouston,

I finished all the parts and rebuilt left arm. I have all servos but have been busy over the summer so not much else done. The site now has a way7 to do stomach which I intend to do also. When fall comes and I am stuck indoors I will finish hopefully by years end. I am using PLA and 2 shells for project. Some pieces that take a lot of strain I am using 50+ % fill.. I have broken a couple of worm gears in the bicep.

Not sure about upgrading to new version. I am using 3 V3 controllers now... one in each arm one in torso. Mouth moving but very slow. Never could get eyes to move because of camera size. Only have one camera working... I cannot get EZ to use both cameras. Facial recognition working with EZ-face ok as well as tracking colors.

I am using 23 servos so far but looks like at least 4 more for stomach.

I will probably use a wheeled base.. not sure yet. I do not think the plastic would be very durable in the legs, but I will see what Gael comes up with.

I am in NJ where are you located?