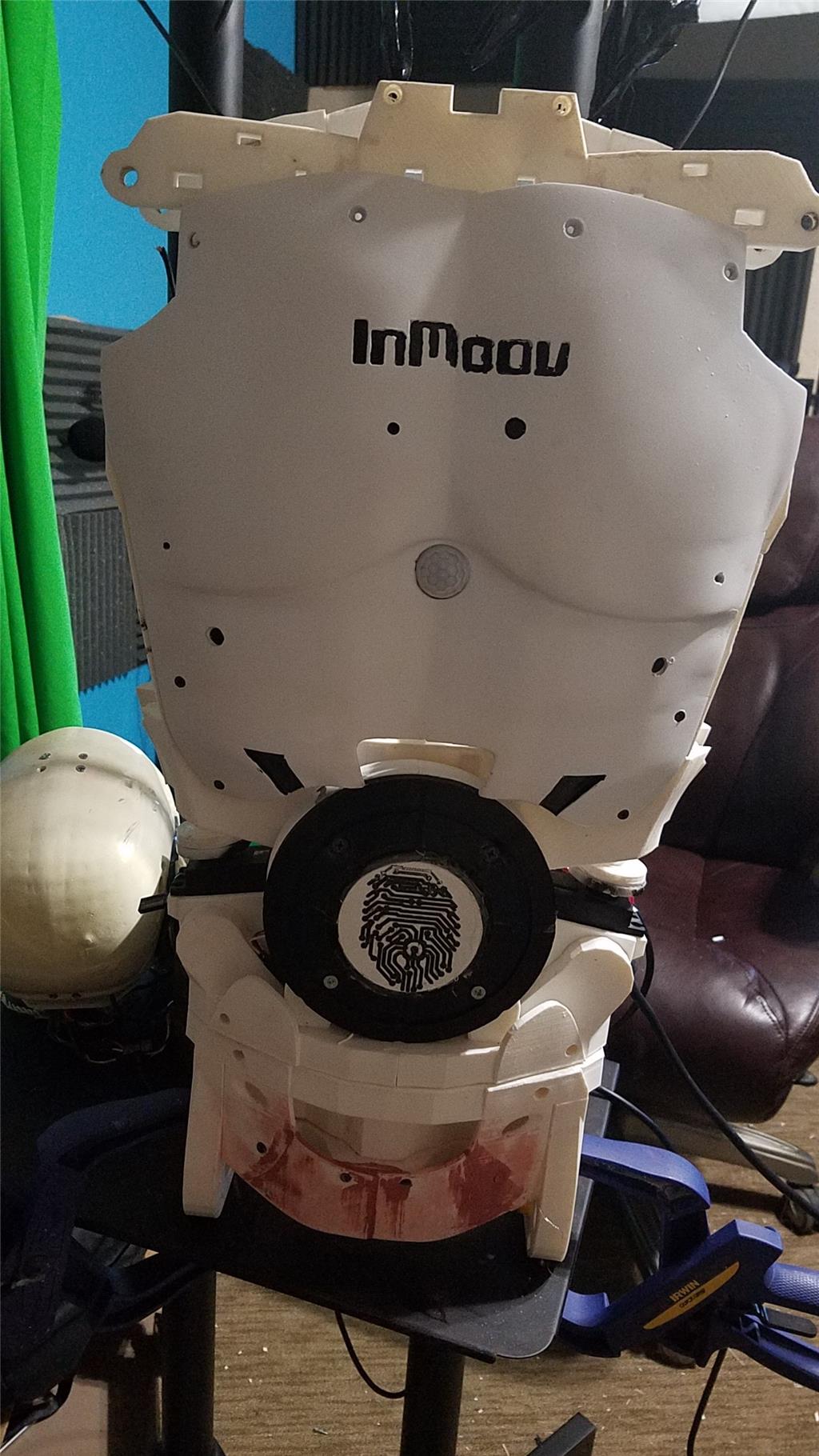

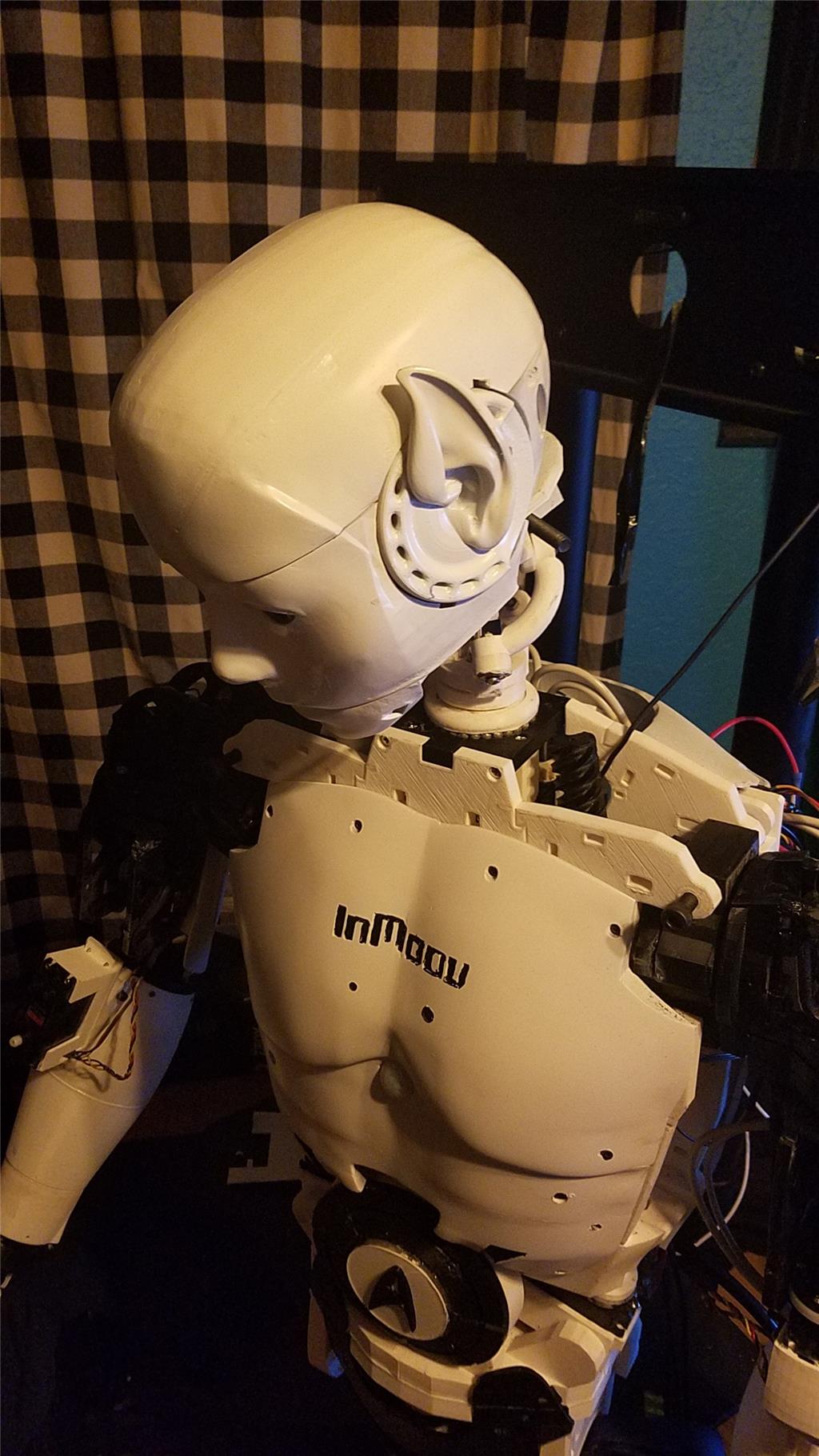

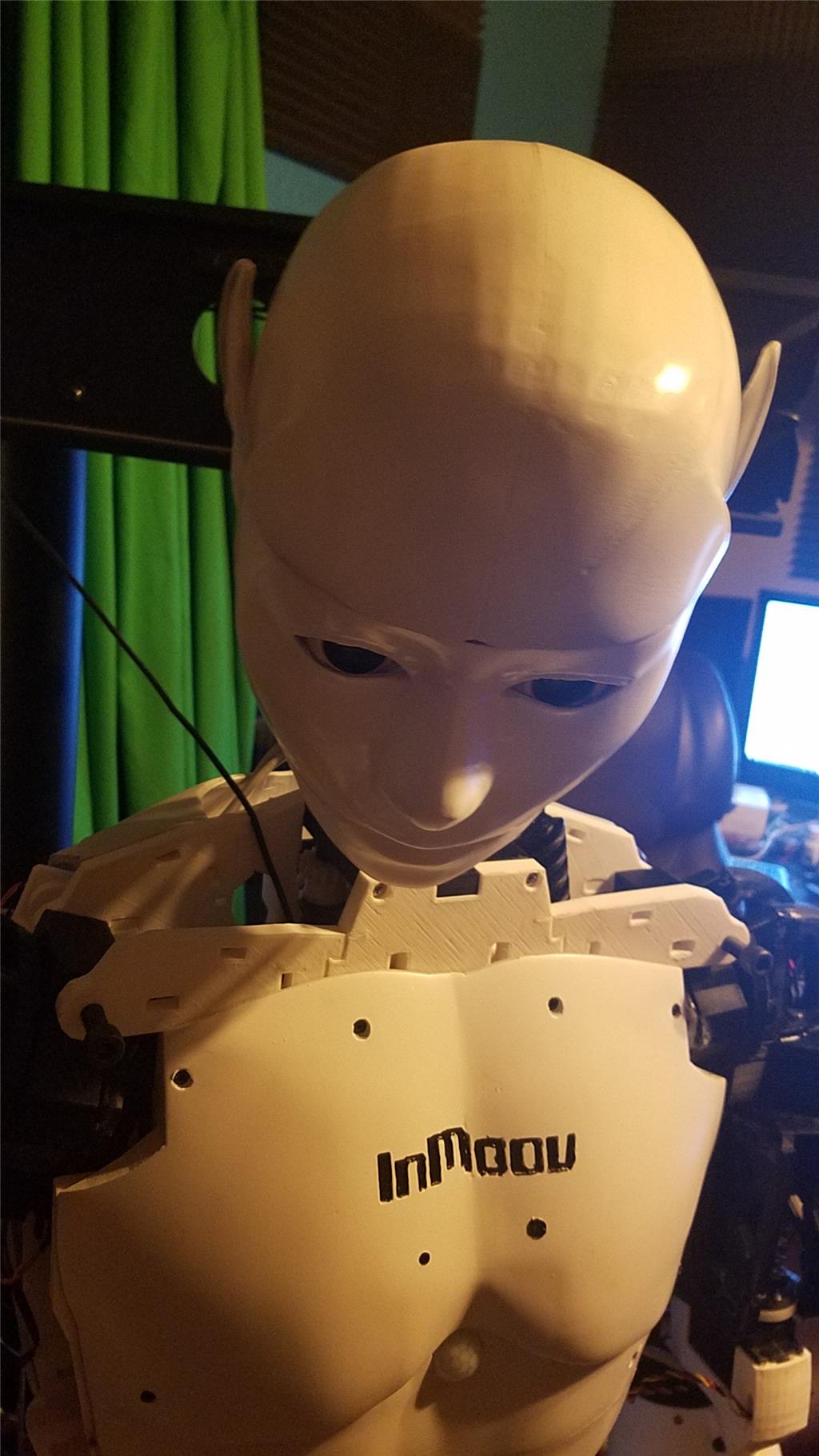

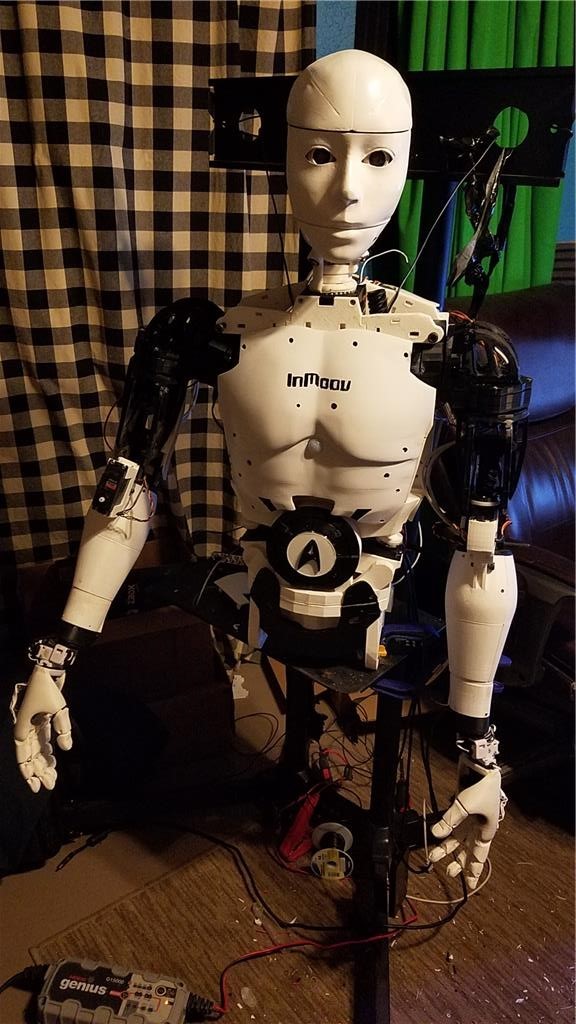

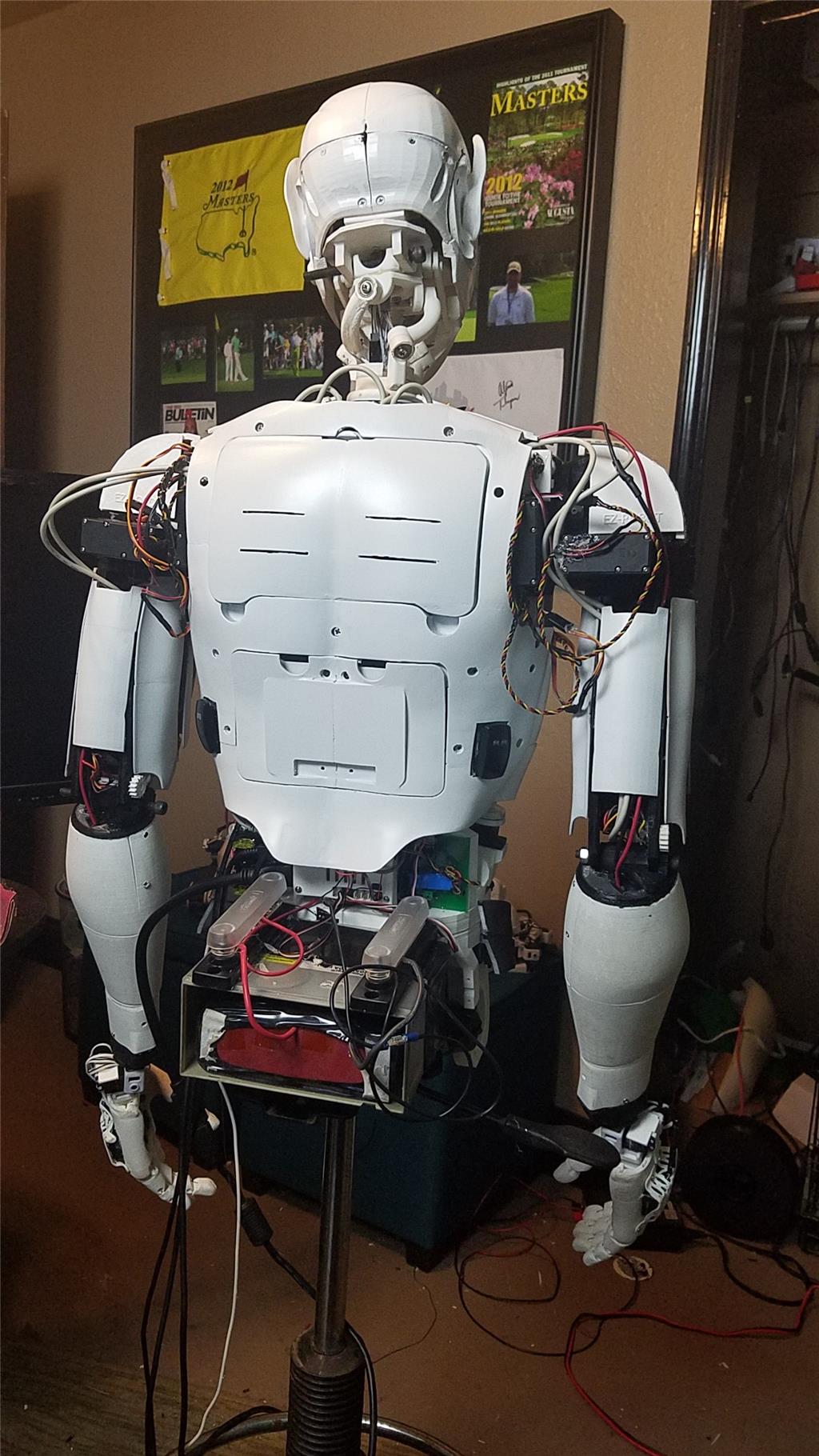

I have decided to start my InMoov project. I think I will call him Spock out of respect to Leonard Nimoy who passed away on the day that I started this project.

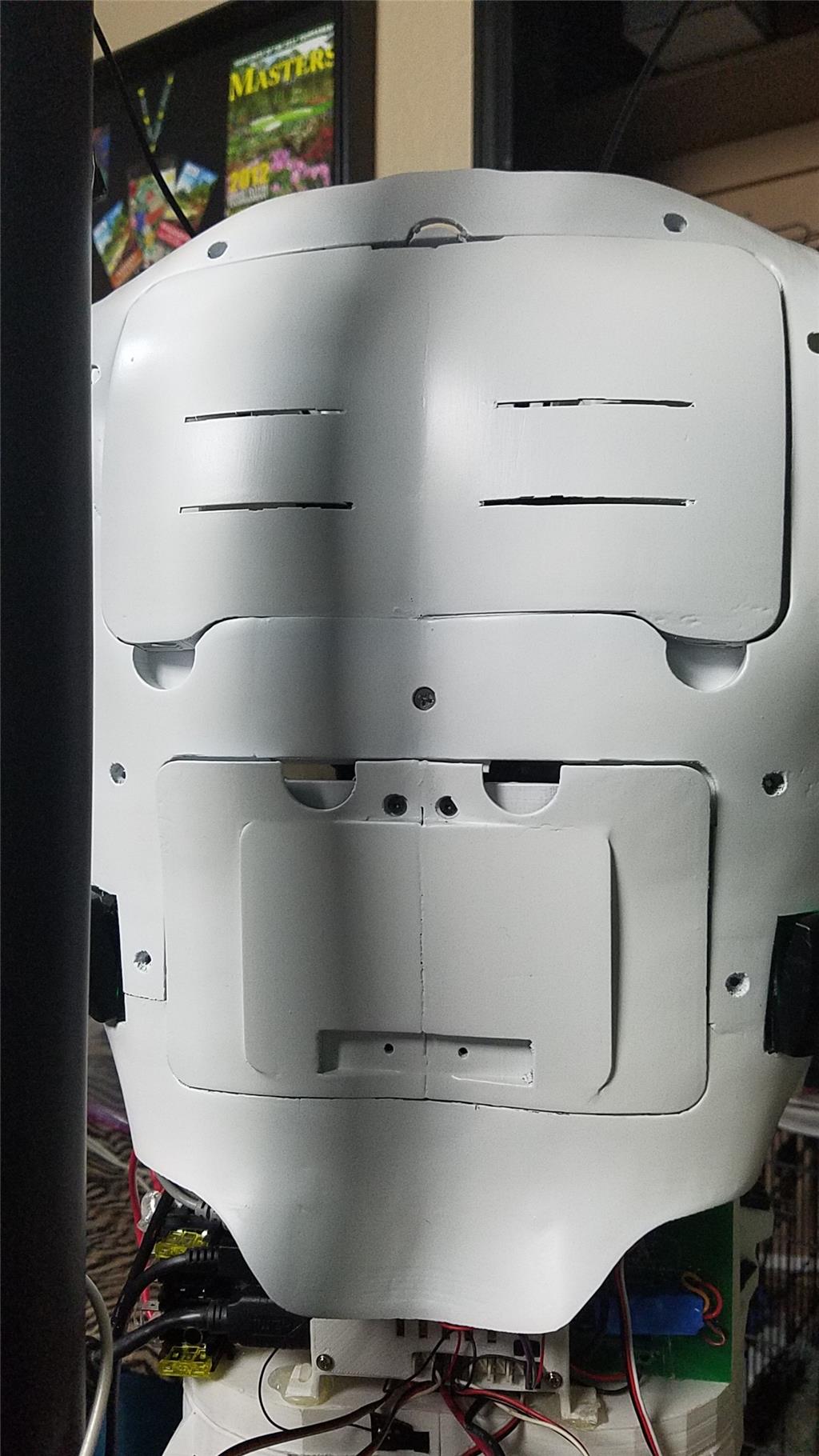

I am editing this post so as not to confuse people with the current configuration. I continue to update this post with the latest photos. If you are reading this for the first time, don't be confused. There have been a lot of changes to the InMoov over the past couple of years including starting over.

https://synthiam.com/Community/Questions/7398&page=21 Post 203 starts the rebuild of the InMoov.

I have decided to use an onboard computer. I chose the Latte Panda due to it having an onboard arduino Leonardo and also because it uses little power.

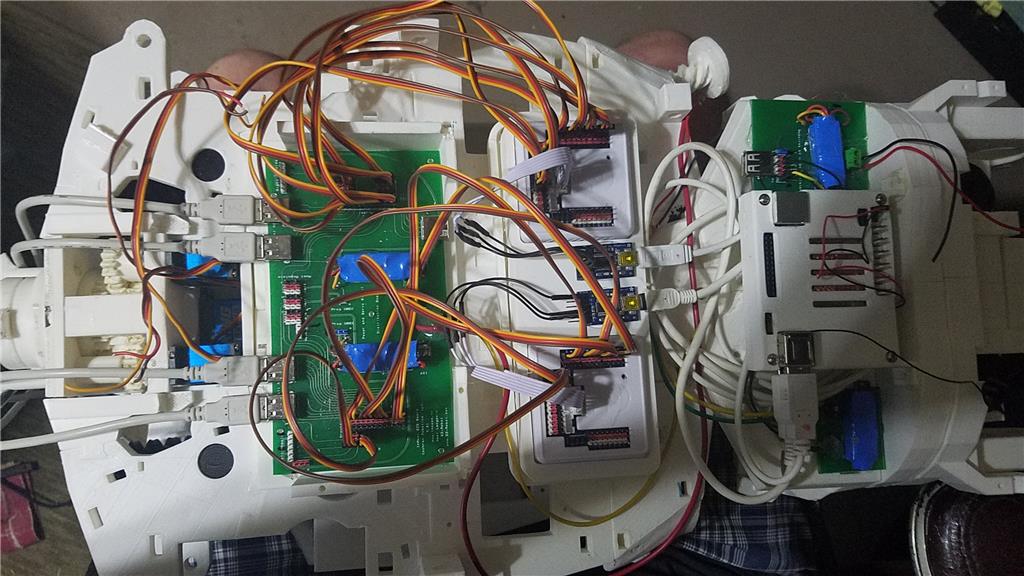

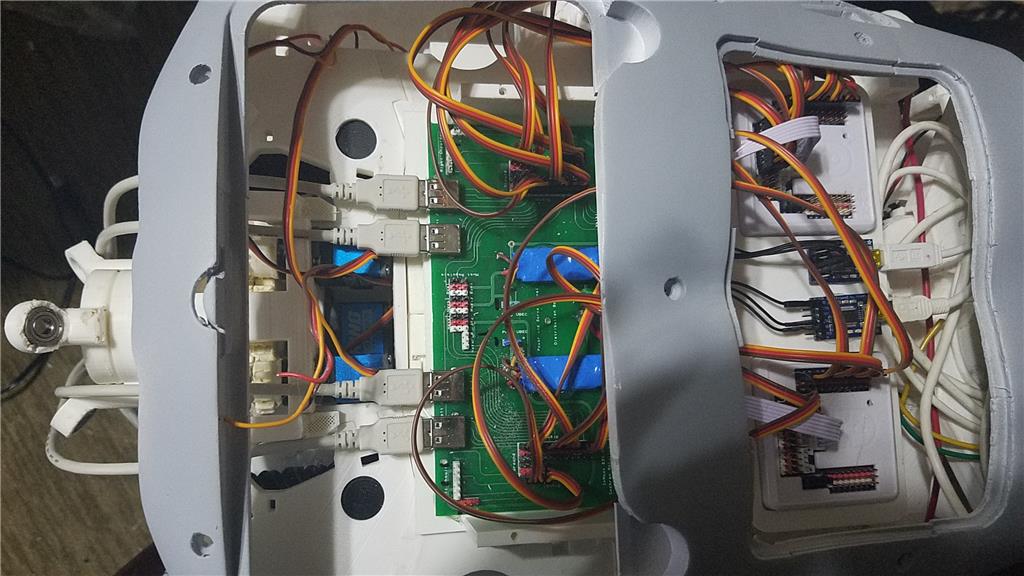

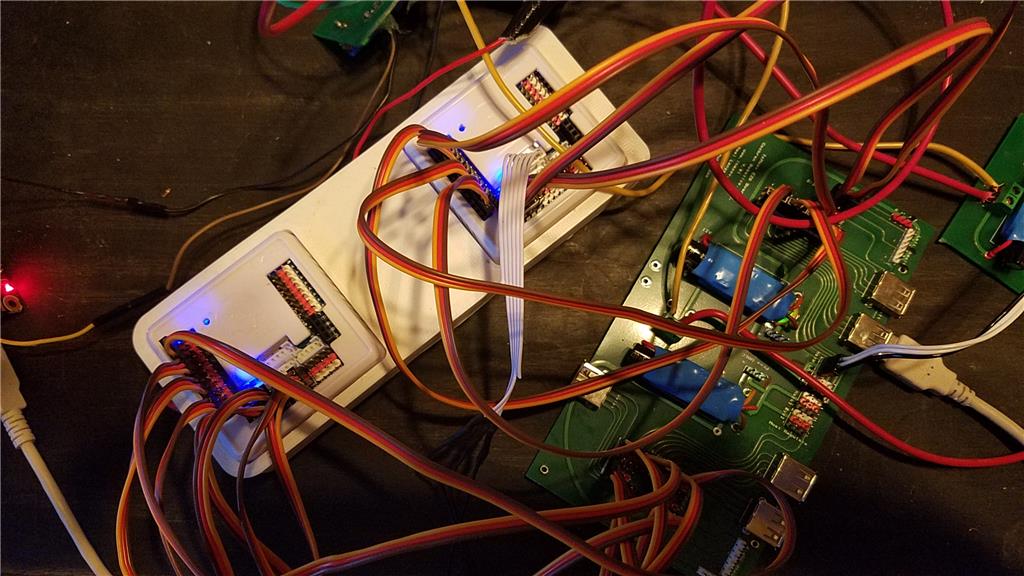

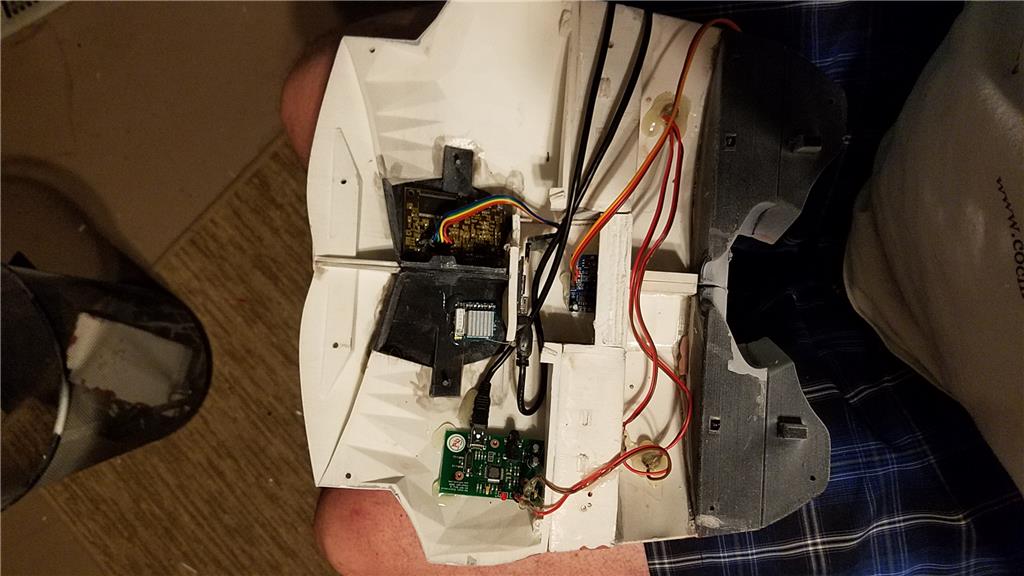

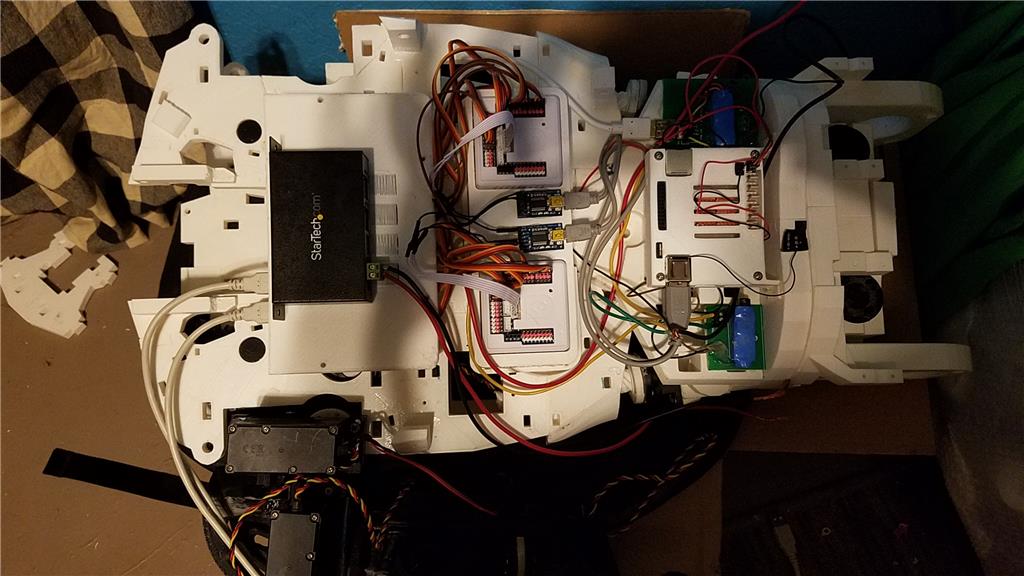

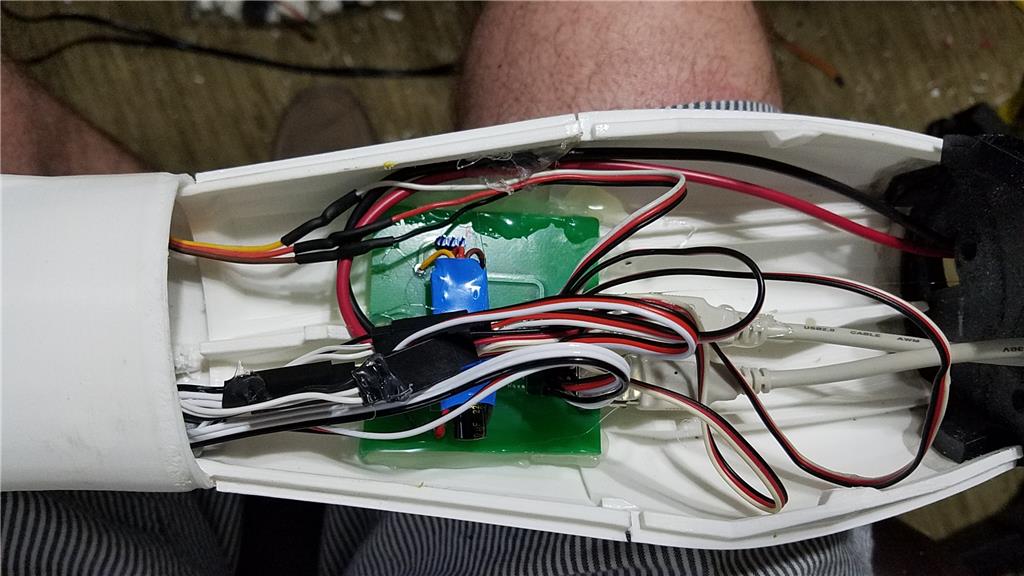

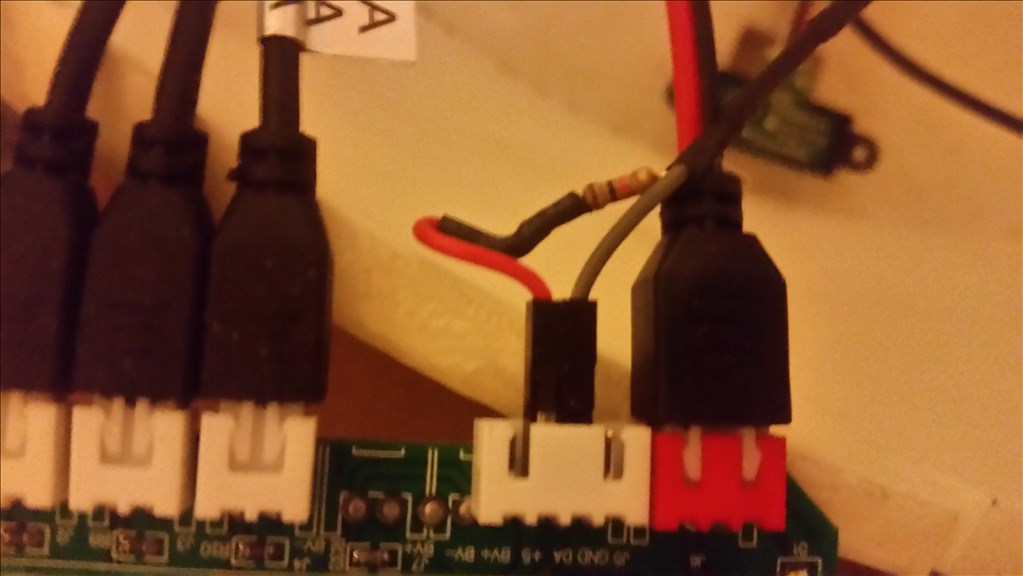

I used 2 EZ-B controllers connected via the camera port to Adafruit FTDI friend boards. This allows the Latte Panda to have a non-wifi dependent connection to the EZ-B's. I use a powered USB hub connected to the USB3 port on the Latte Panda to attach other items.

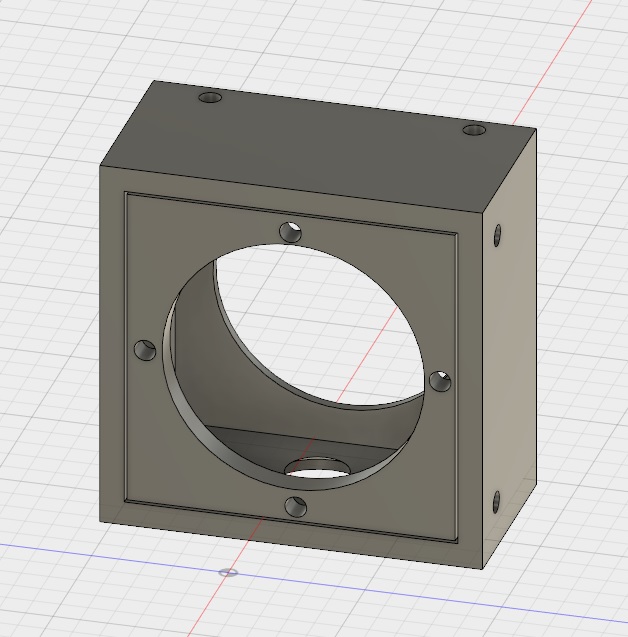

The Omron HVC-P is used to identify people, emotions, human bodies, hands, age and gender. It is attached to the Latte Panda via an FTDI friend which is then connected to the powered USB hub. It is mounted in the chest of the InMoov. I also use a 3 element microphone which is a MXL AC-404 microphone. It is disassembled and the board and microphone elements are mounted in the chest of the InMoov. This mic board is connected to the Latte Panda via a usb cable which is attached to the powered USB hub. There is a USB camera in the eye of the InMoov which is connected to the Latte Panda via the powered USB hub.

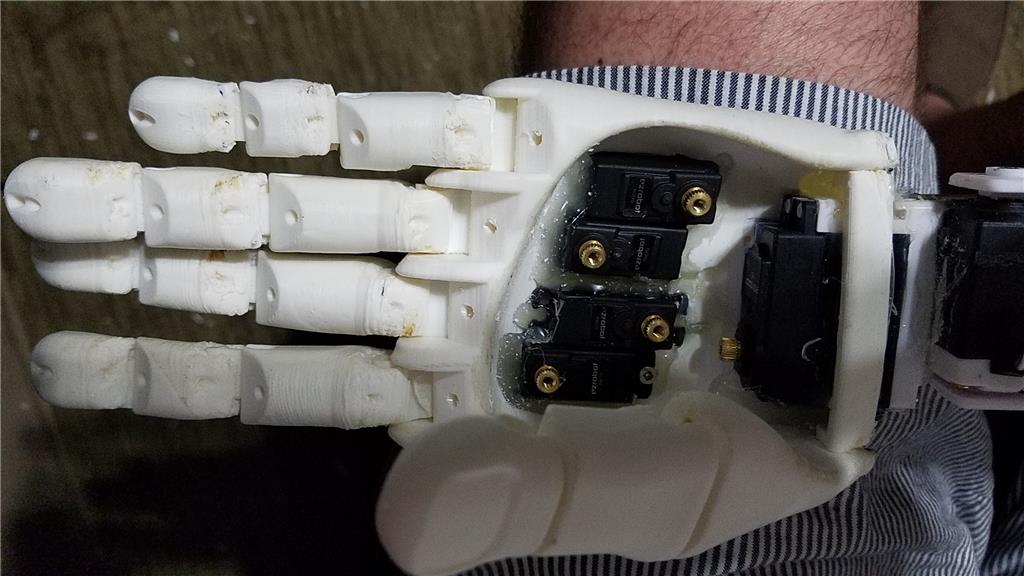

I chose to use the Flexy hand with the InMoov. The design is far more rugged than the original hand and works very well. There are 4 EZ-Robot Micro Servos in the palm of each hand which controls the main fingers. The thumb is controlled by an EZ-Robot HD servo. The wrist waves and uses an EZ-Robot HD servo to do this motion. I use the standard Rotational wrist.

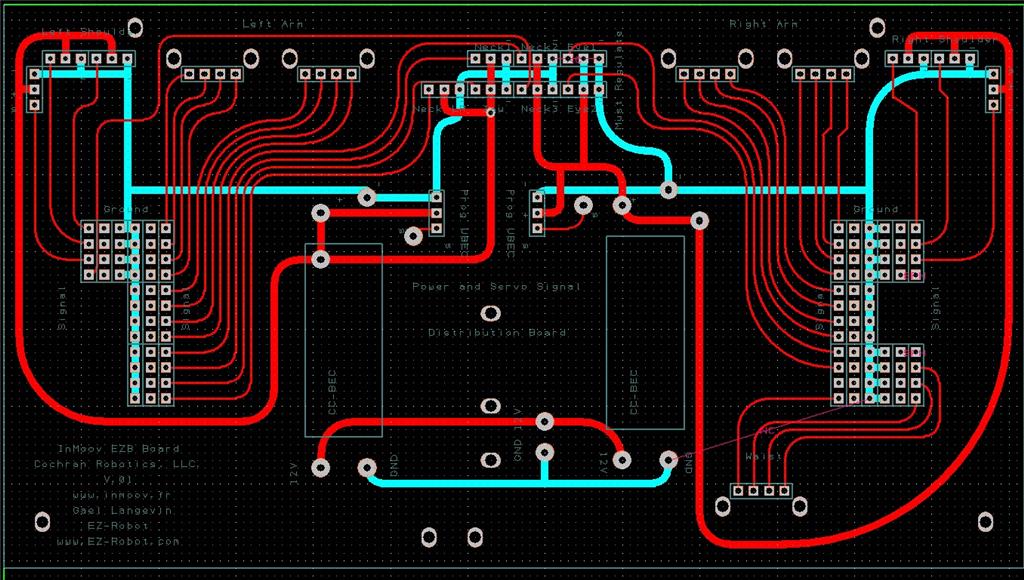

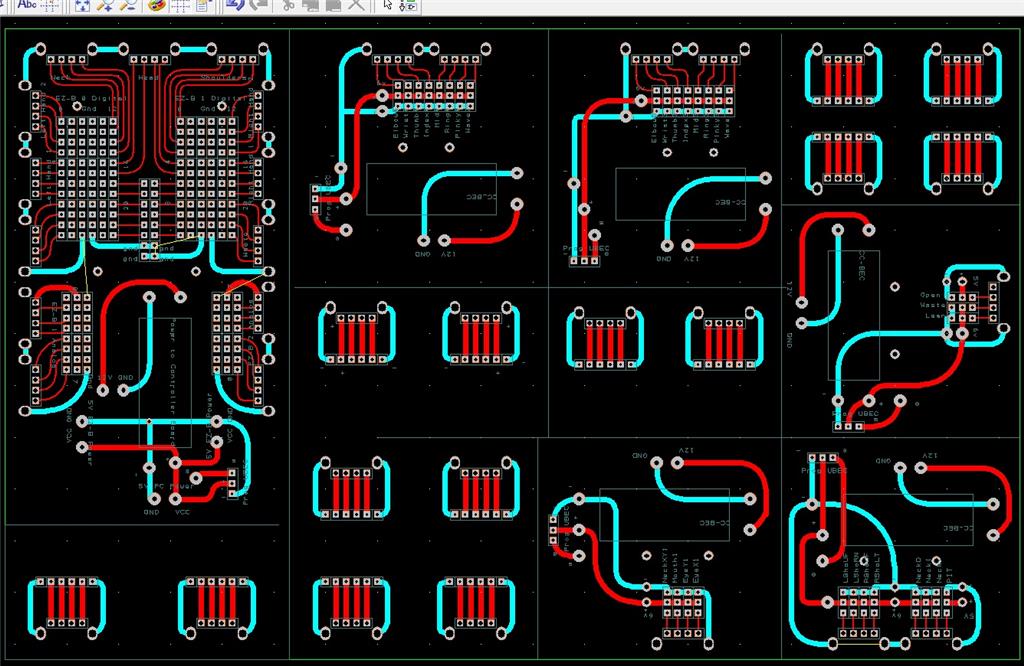

I have castle BEC's for power in the following locations set to the following voltages. Forearm's - 6.2 V - Controls fingers, wrist and elbows Custom power distribution board (2) set to 6.2 V controlling head, neck and Shoulder servos. EZ-B's - set to 6.1 V - it is mounted in the controller mounting plate and connects to the EZ-B fused power boards from a power base. Latte Panda - Set to 5.1 V and is mounted to the EZ-B controller mounting plate. Waist - set to 6.2 V and is mounted in the lower right side of the back. This provides power to the lean and pivot waist motors..

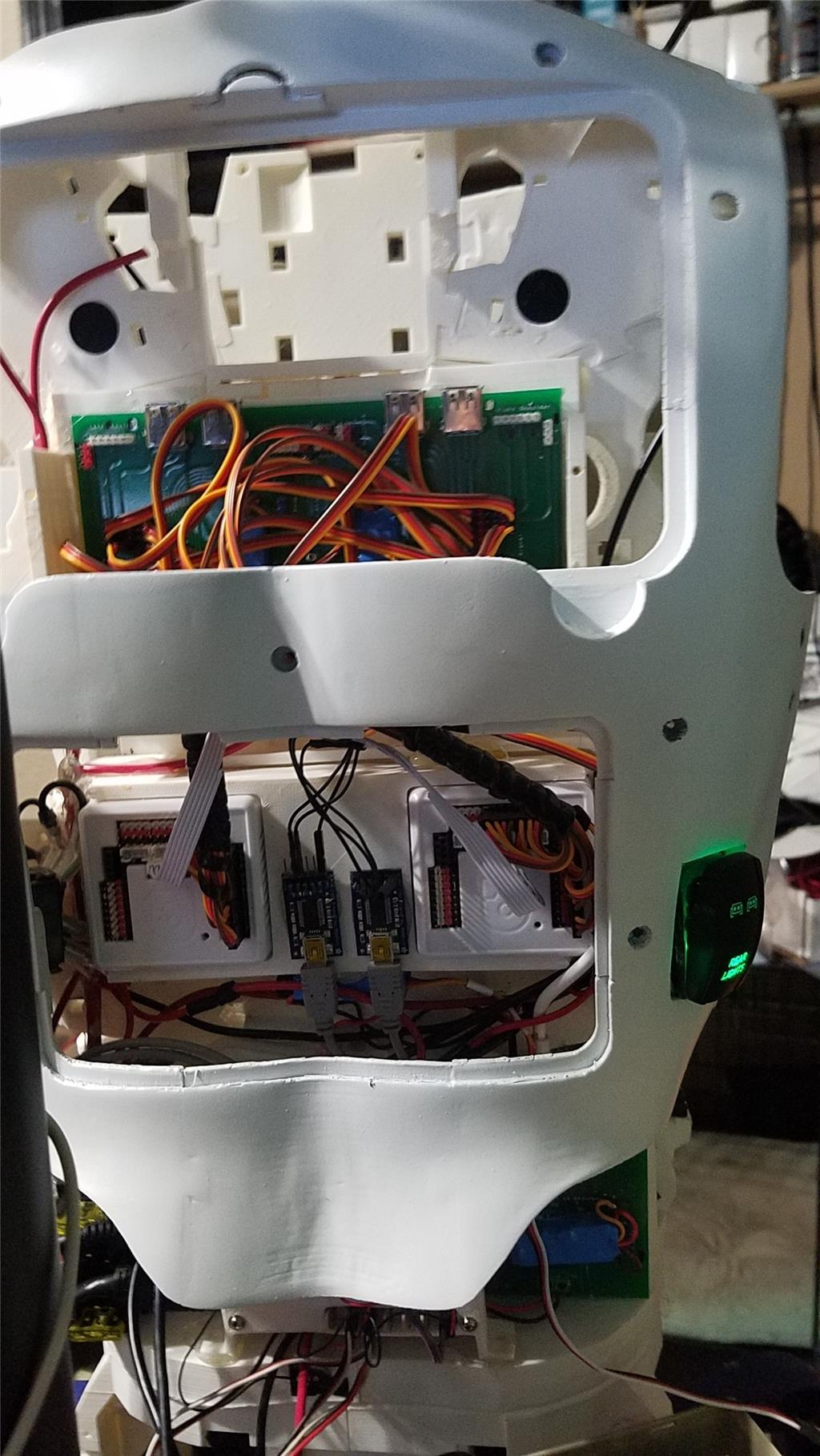

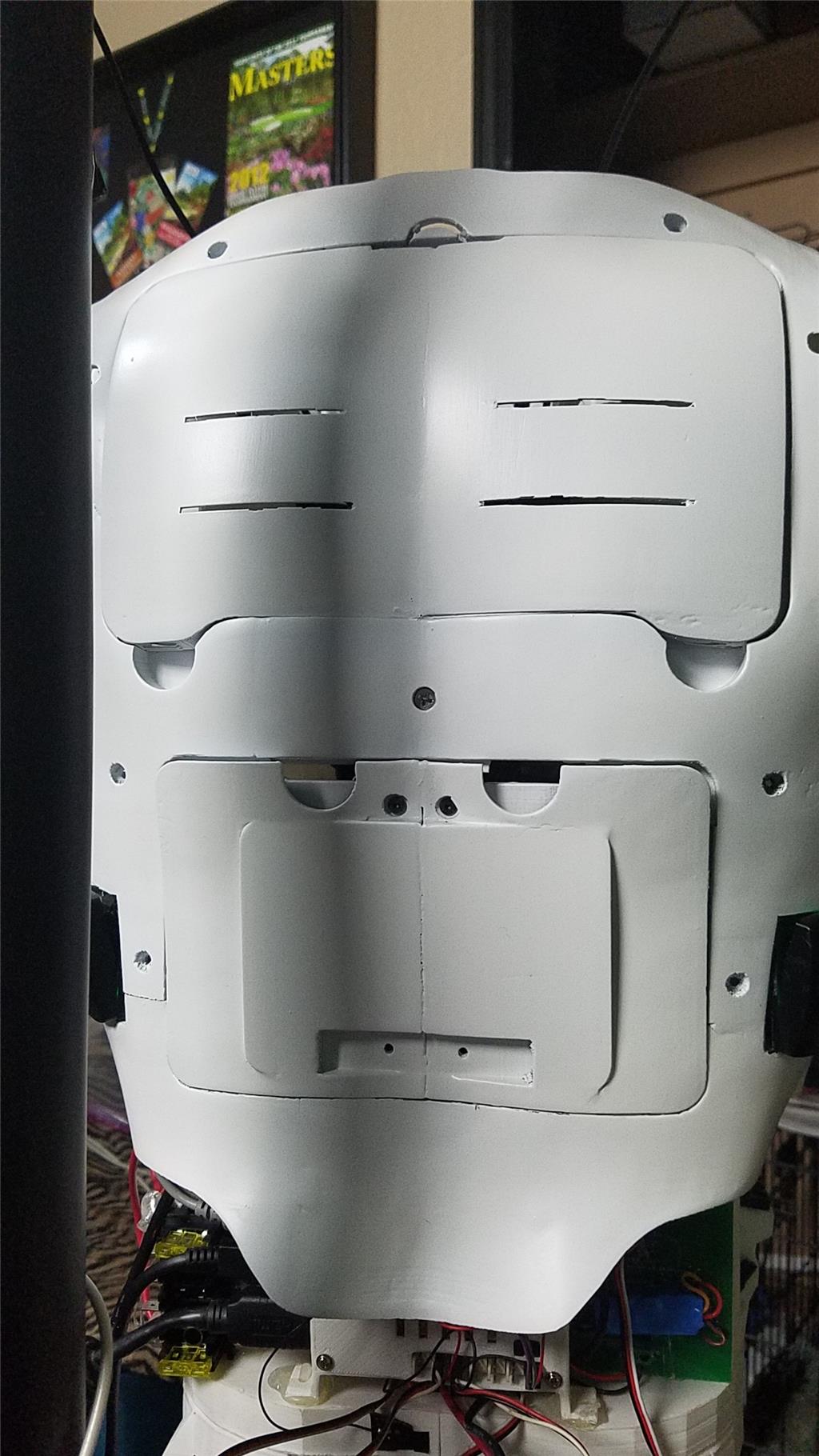

There are some custom power and signal distribution boards. These are in the forearms, lower back and in the upper back. The upper back or main board connects to these distribution points via USB cables to provide signal to the other boards for servos. The main board also has servo connector pins that are for the neck, head and shoulders. This allows the power to be distributed between multiple BEC's and also allows the servo signal cables to be shorter and more protected via the USB cables.

For power I use a LiFePo4 battery that is rated at 30 amps. It has the balanced charging circuit built into the battery and also has a low voltage shutoff built into the battery. This protects the battery and allows the battery to be charged with standard car chargers.

I put switches on the back on the InMoov which are rated at 20 amps at 12 volts. These are rocker switches that allow the user to pretty much slap the switch to turn it off. There are two of these switches. The servos for the elbows and fingers are on one switch. The latte panda, neck, shoulders, EZ-B's, waist motors and some lighting is on the other switch.

I also added a fuse block. This allows 20 amp fuses to be put in line to help protect things. The switches above drive the fuses for each of of the motors listed in that section.

Other robots from Synthiam community

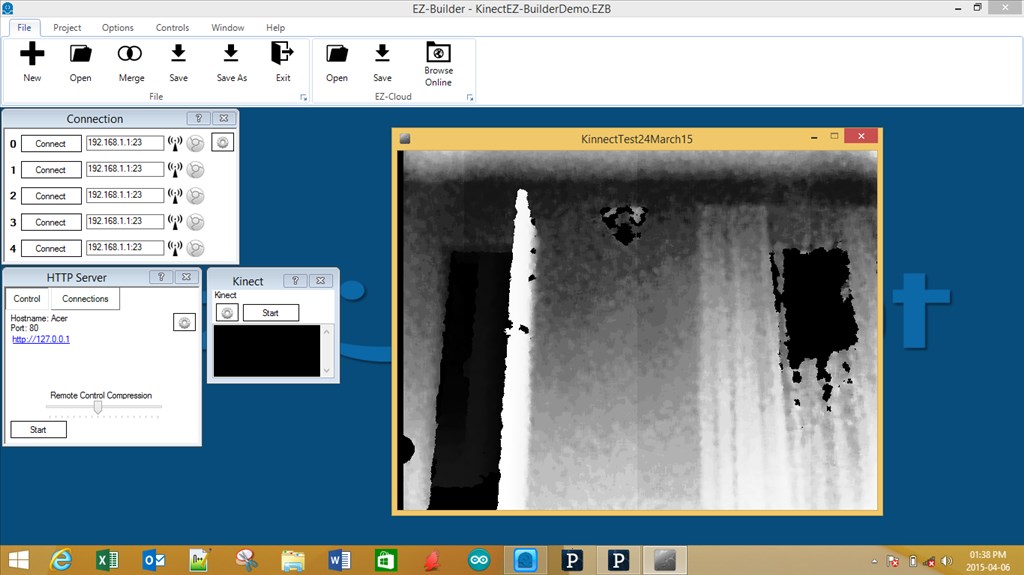

Ianmbrick's Project To Link A Microsoft Kinect Xbox 360...

-636504920452491494.jpg)

Sssuhl's Late 2017 Wall-E (Yet Another Wall-E)

-636348381130562972.jpg)

-636348716348649435.jpg)

Great

That looks like a 300 ohm resistor? I assumed pull-ups ran from 10k-100k, although I'm not even close to being up on these things.

Will give this a shot when time permits and let you know how things turn out.

Thanks for your help ...

I cant remember why I choose the resister that I did. I think that I saw it on a website when I was working on getting the bit-bang serial stream to figure out what the readings were at different distances. That was about 6 months ago so my memory is a bit foggy.

Also, the bit-bang serial being returned may be a bit different with the unit that you are using. It looks a bit different than mine but not much. It will be interesting to see if the same settings in the arduino code work or if they will have to be tweaked.

@Herr Ball, from the colour code that looks like a 10k resistor to me.

Tony

I don't know if I have ever mentioned it or not but I am colorblind. It makes matching resistor colors a bit difficult for me so I have to go off of what the little bag that it was in said. I sadly didn't document it and the bag has been trashed.

Btw, this is why I have black and white socks only...

Resistor is carbon film type Brown - black - orange = 10K Forth band is tolerance and gold = 5%

Tony

hi iam ram charan from india could you tell me something about how to connect ez-b v4 to ssc-32 because for my robot i need to use 34 servos and we can connect 23 servos to ez-b v4 but i can't buy 2 or more ez-b v4 microcontroller please help me

I don't use these but from looking at the manual, I believe this is how I would go about connecting it.

The three pins behind the FTDI chip are Tx, Rx and GND. Commands sent from the SSC32U are done using the Tx pin while commands to be received by the SSC32U are done via the Rx pin. These pins allow you to easily send commands to the servo controller from another microcontroller. To do so, connect the Tx pin on the microcontroller to the Rx pin on the SSC32U, the Rx pin on the microcontroller to the Tx pin on the SSC32 and GND to GND

The EZB has 3 or 4 UART connection possibilities. If you are not using the black pins just to the right of the I2c headers, I would use it because it sounds like all of your digital pins will be in use, which is where the other UART pins are.

The only thing that you have to be careful of is that the black header for UART is 3.3V so please read the manual so that you will know if these pins on the scc are compatible.

Hello David,

now coming up more the interessting things of my inmoov.

I make some experiments with the Object Reco and Face Reco.

And then i remember EZ-AI again.

So i understand: The Main Idea of EZ-AI is a Database, where i can save Informations for example for Objects or Variables. This Informations i can load back again to ARC.

Its like that the roboter can detect my face (object), then can say the saved object Name (Boris) and can check what infos are in the database saved for my name (for example when i have birthday)

IS this right?

For Face Detection for EZ-AI what you use?

EZ-Face or the internal Face-Detection?

I think to invest time to understand your EZ-AI, because it will be cool if a roboter can remember things and the easiest why is a database. The Next step will be if the roboter can update the database himself. But this for the future.

Boris