Hi all,

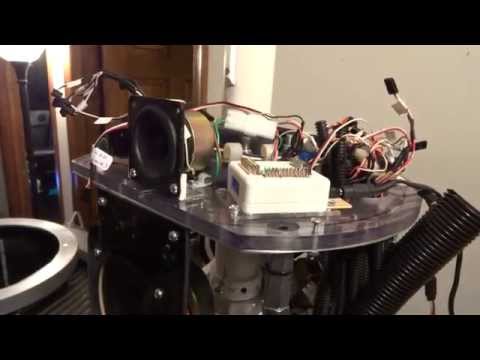

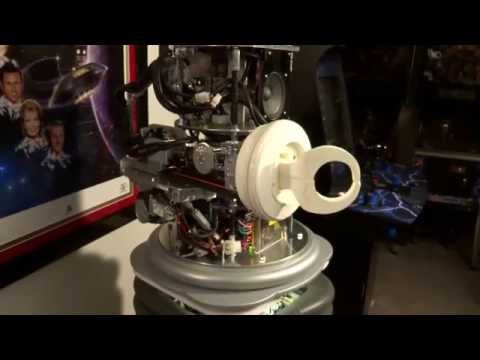

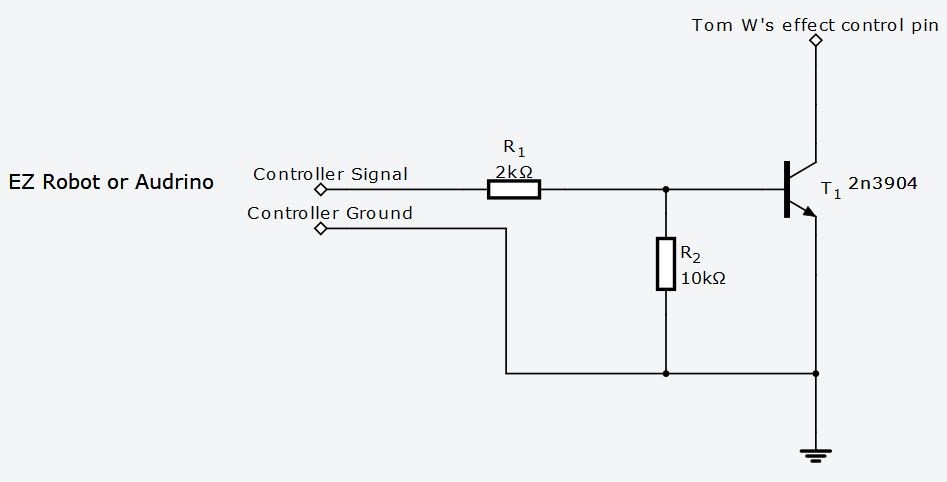

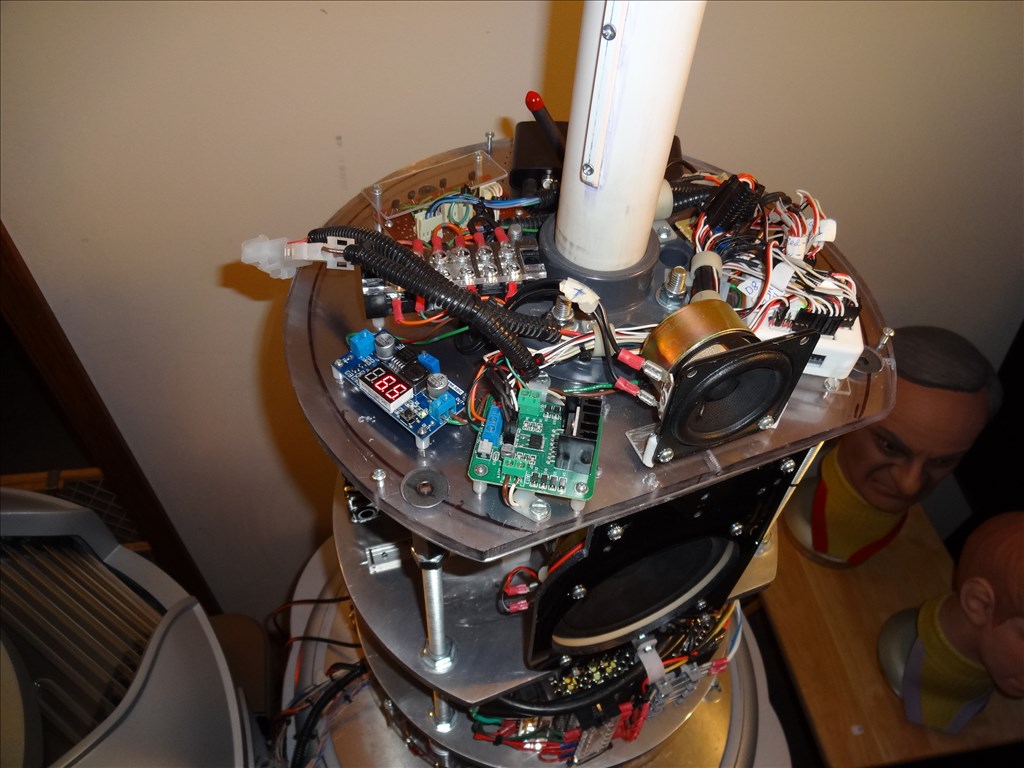

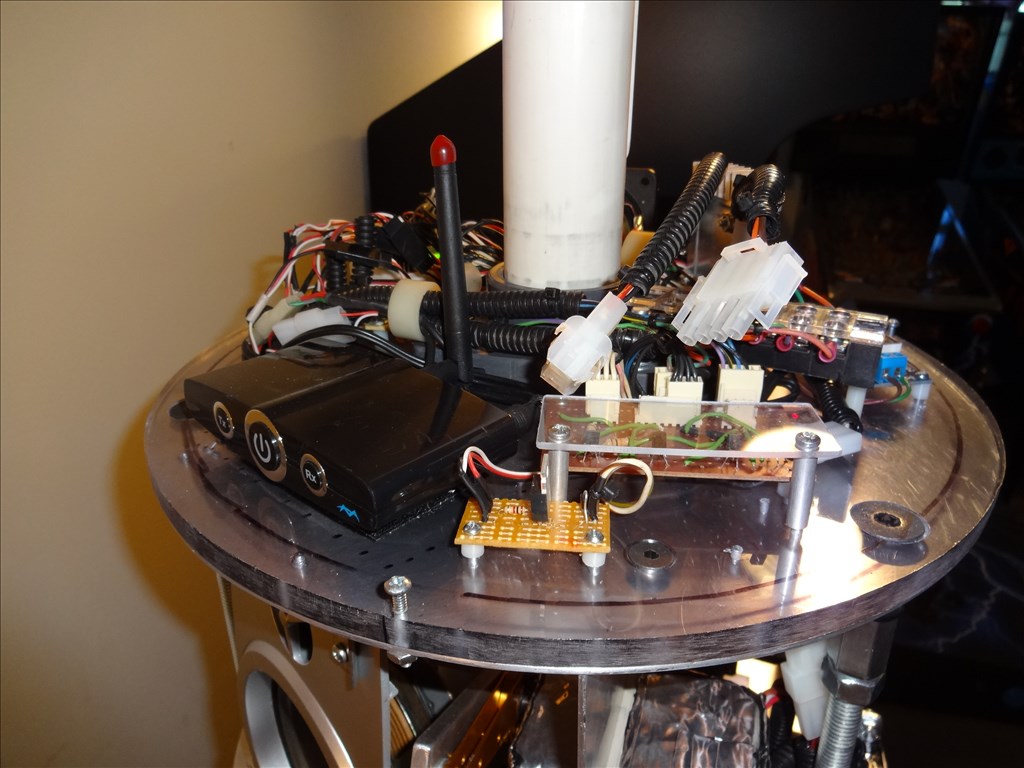

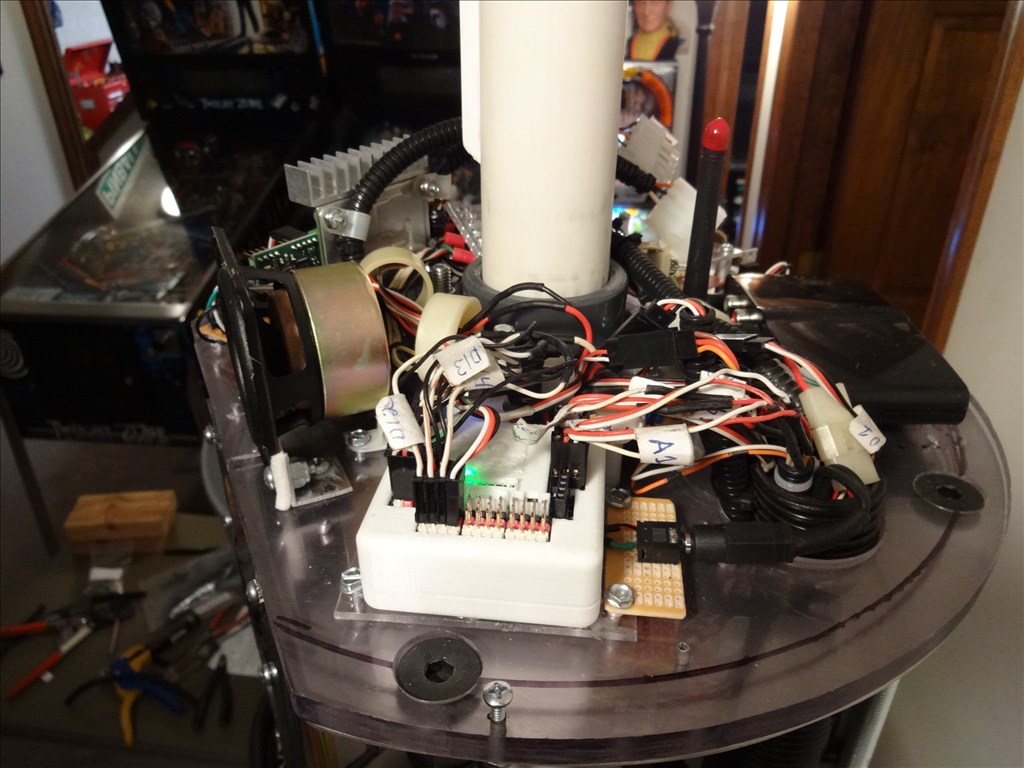

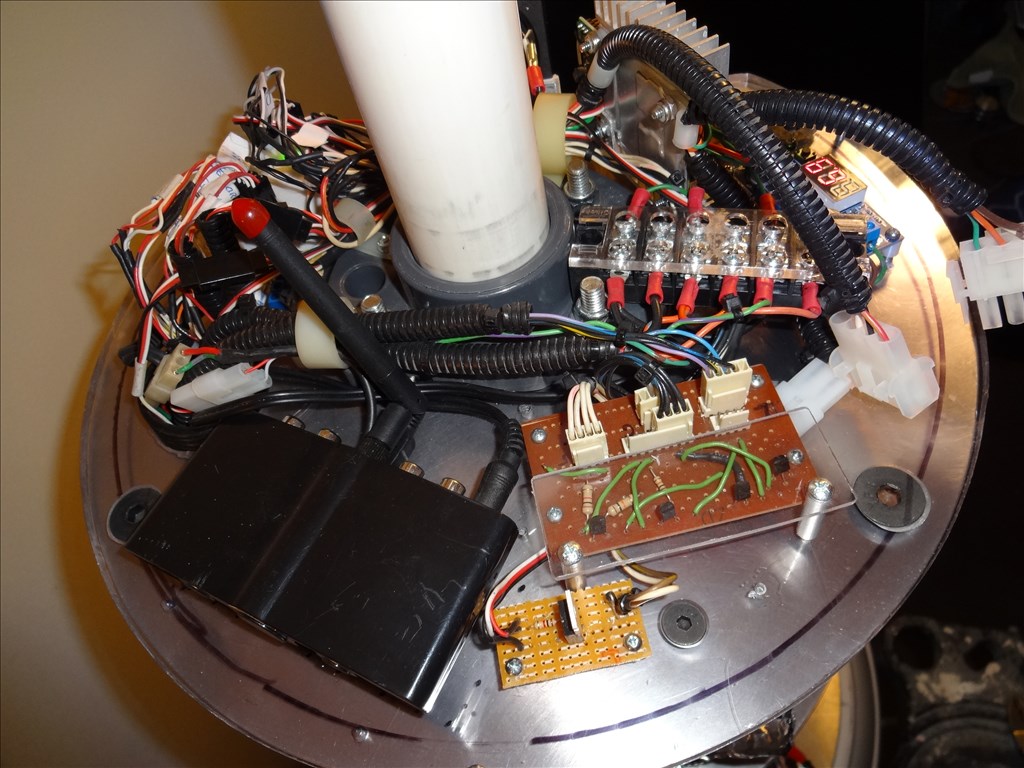

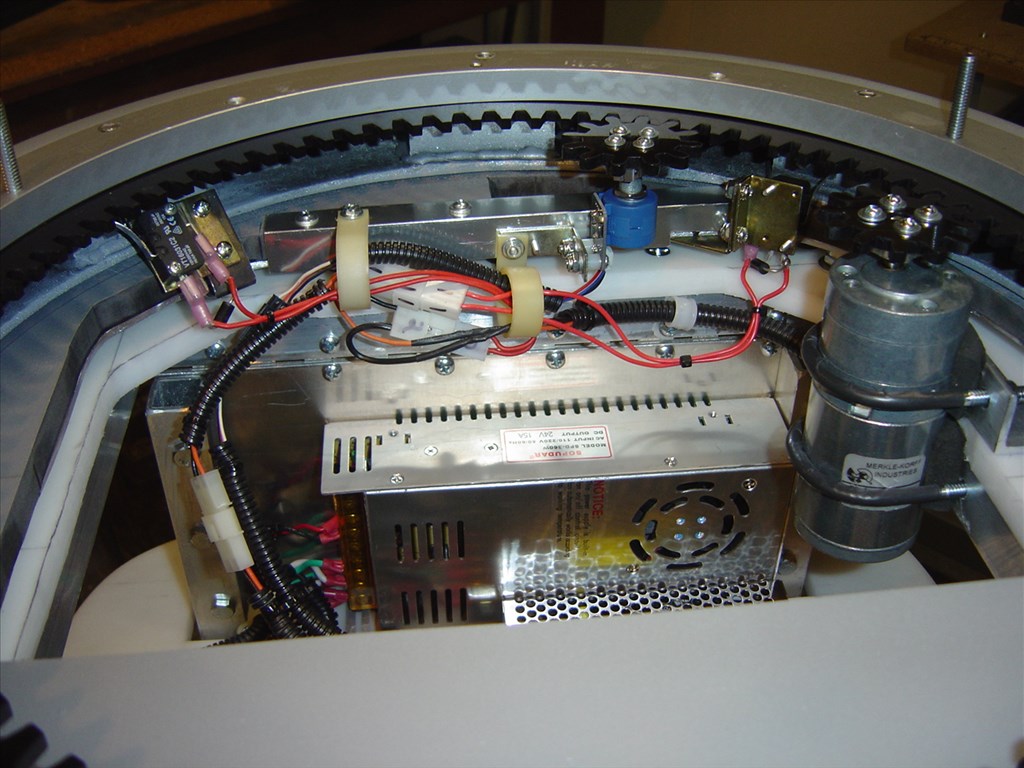

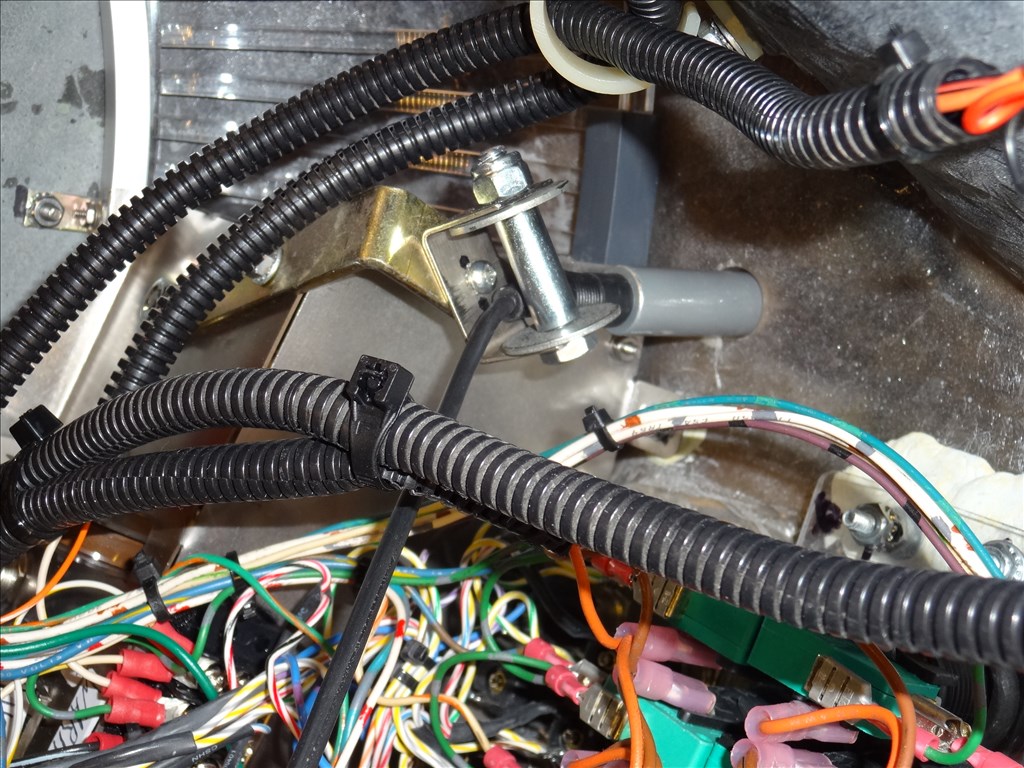

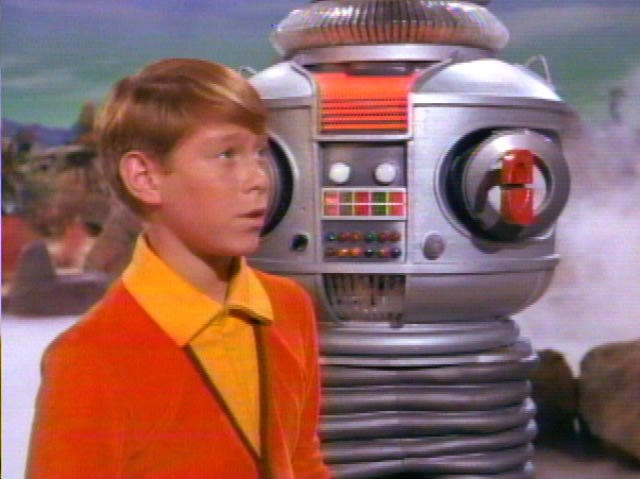

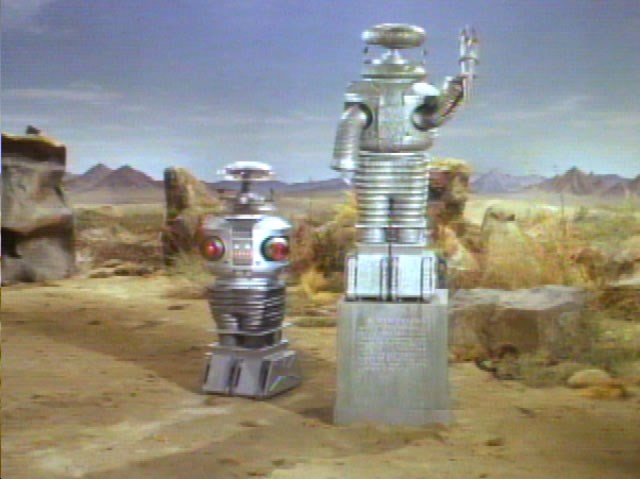

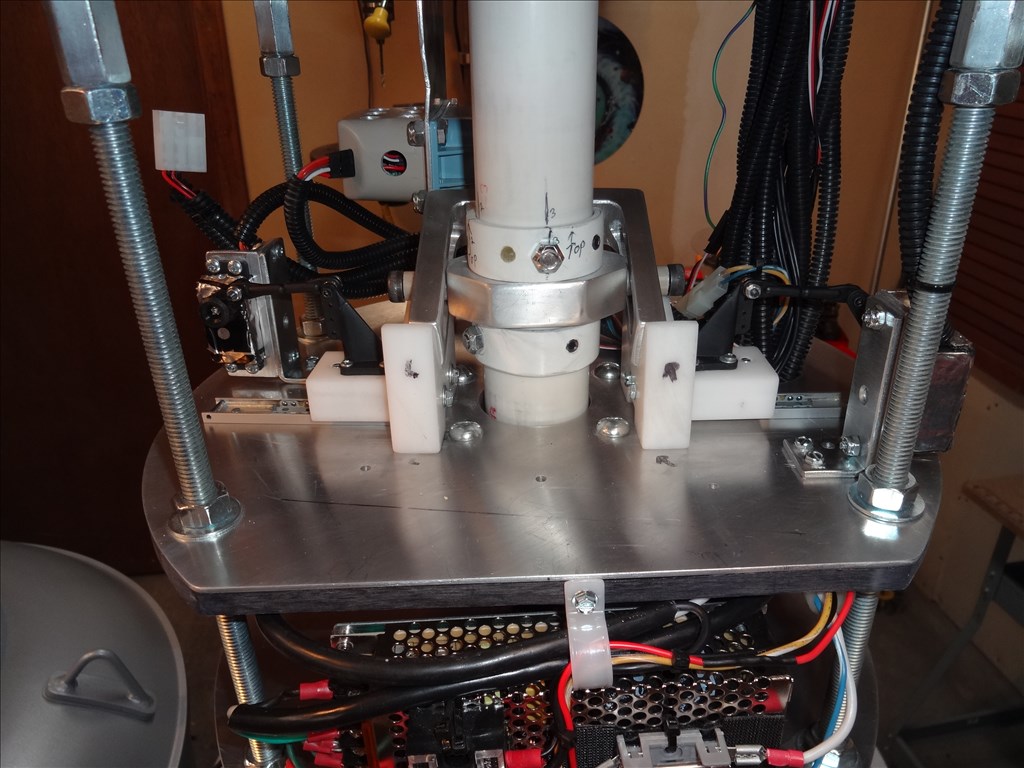

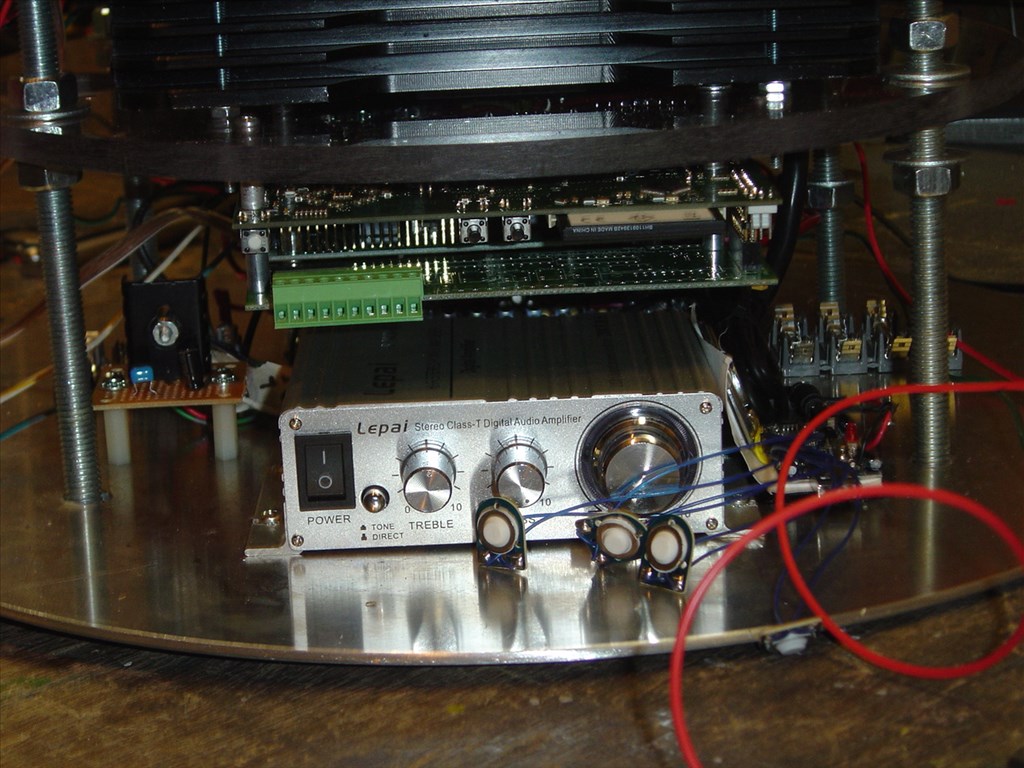

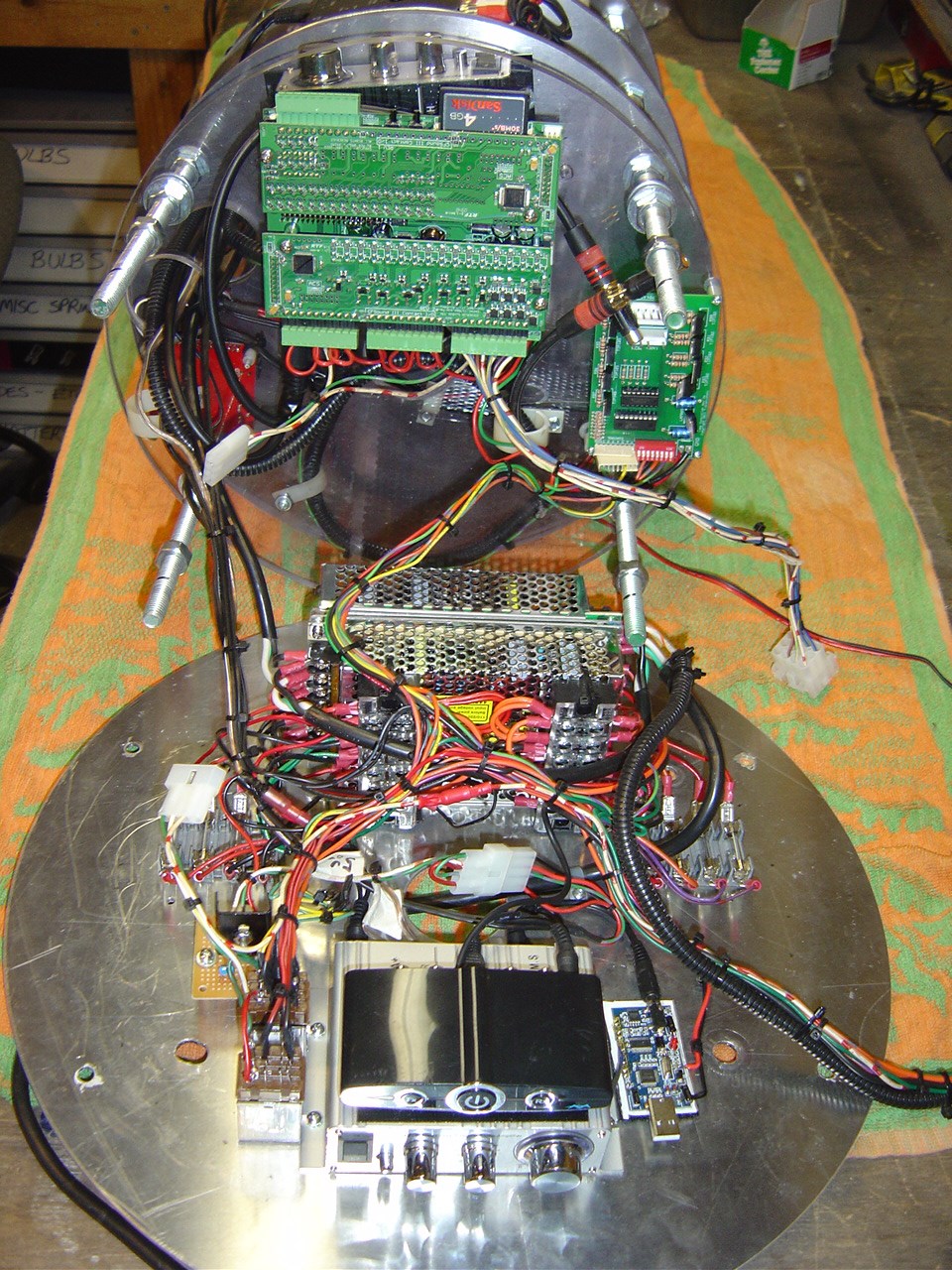

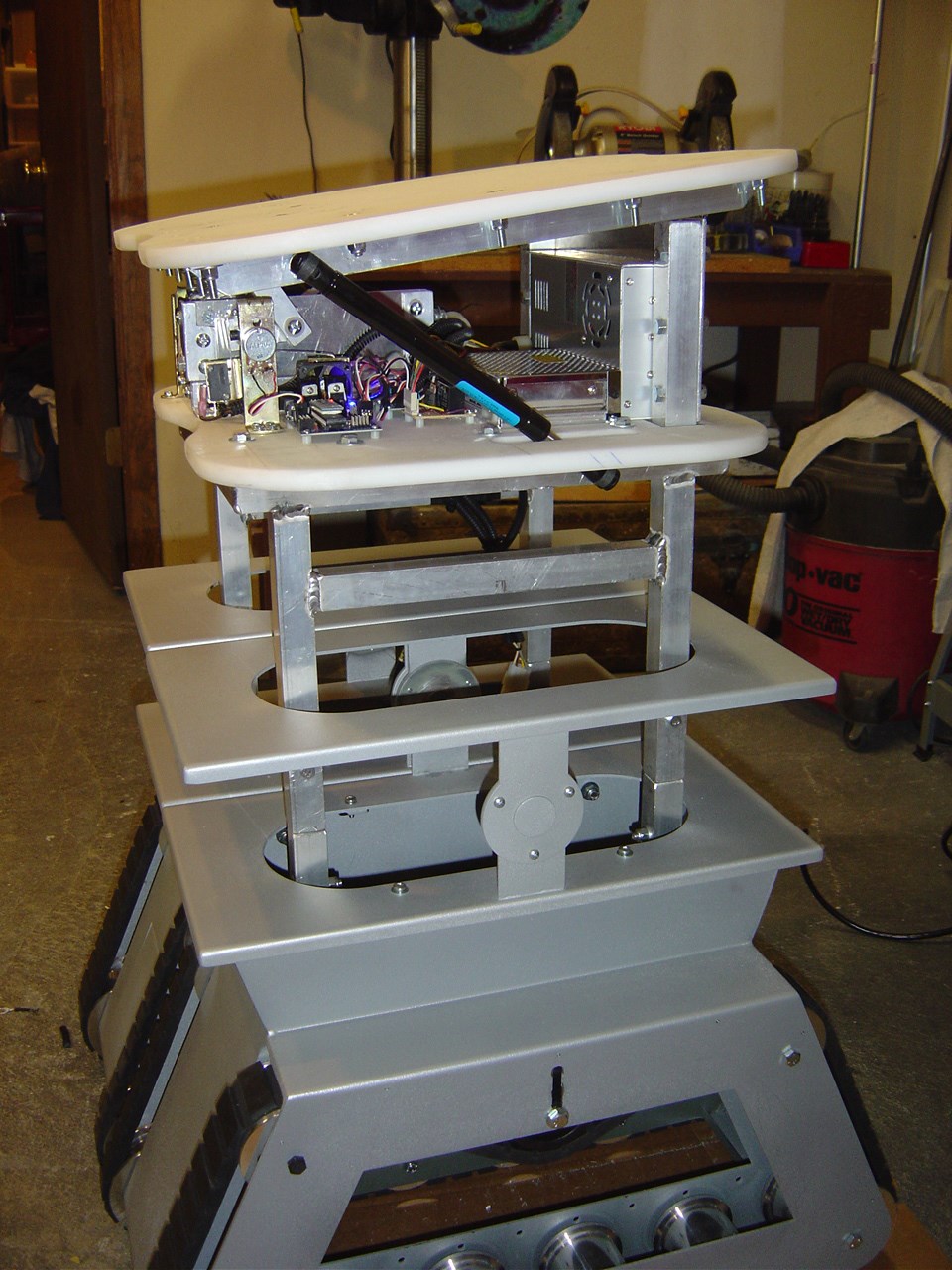

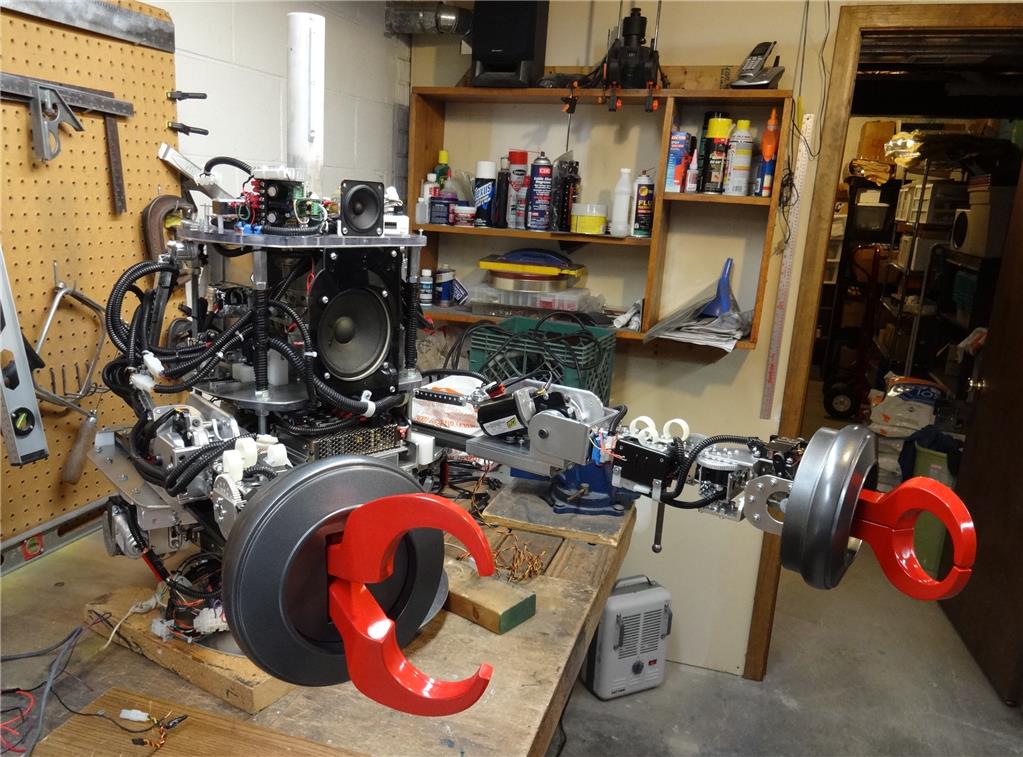

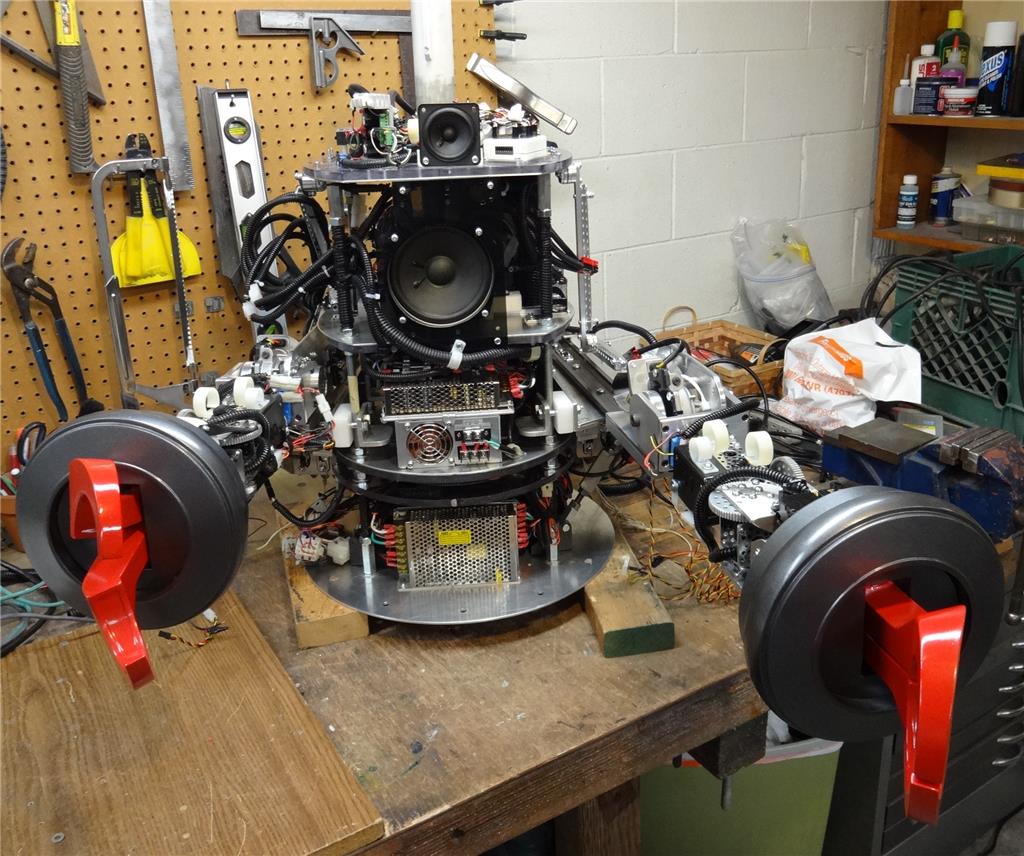

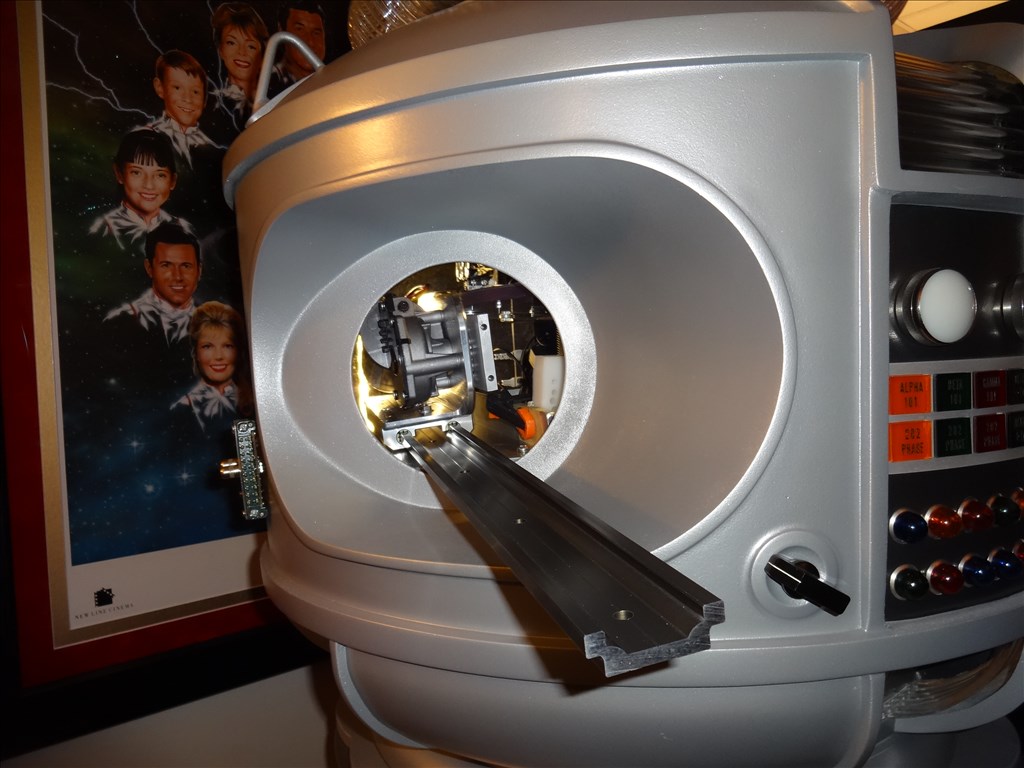

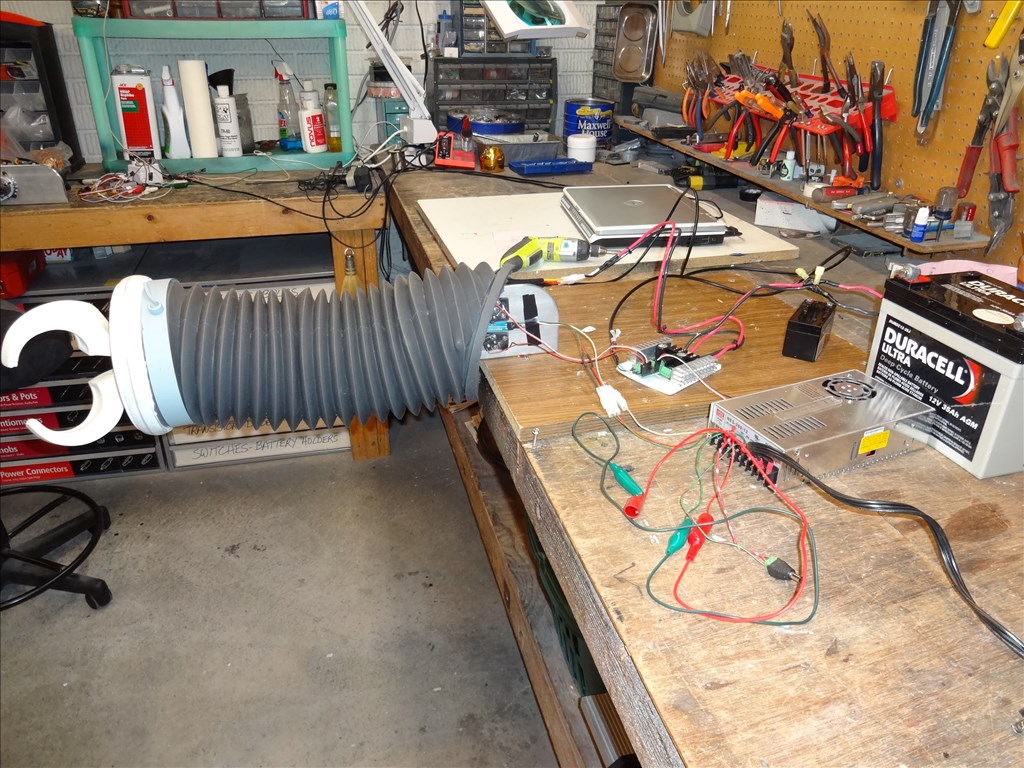

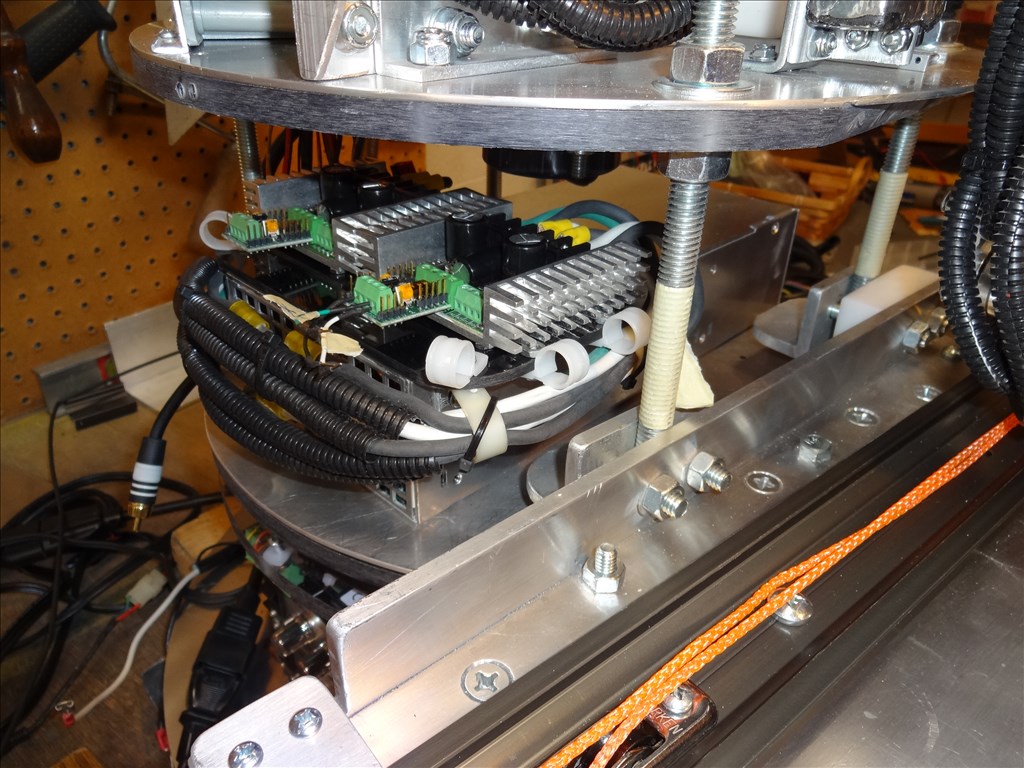

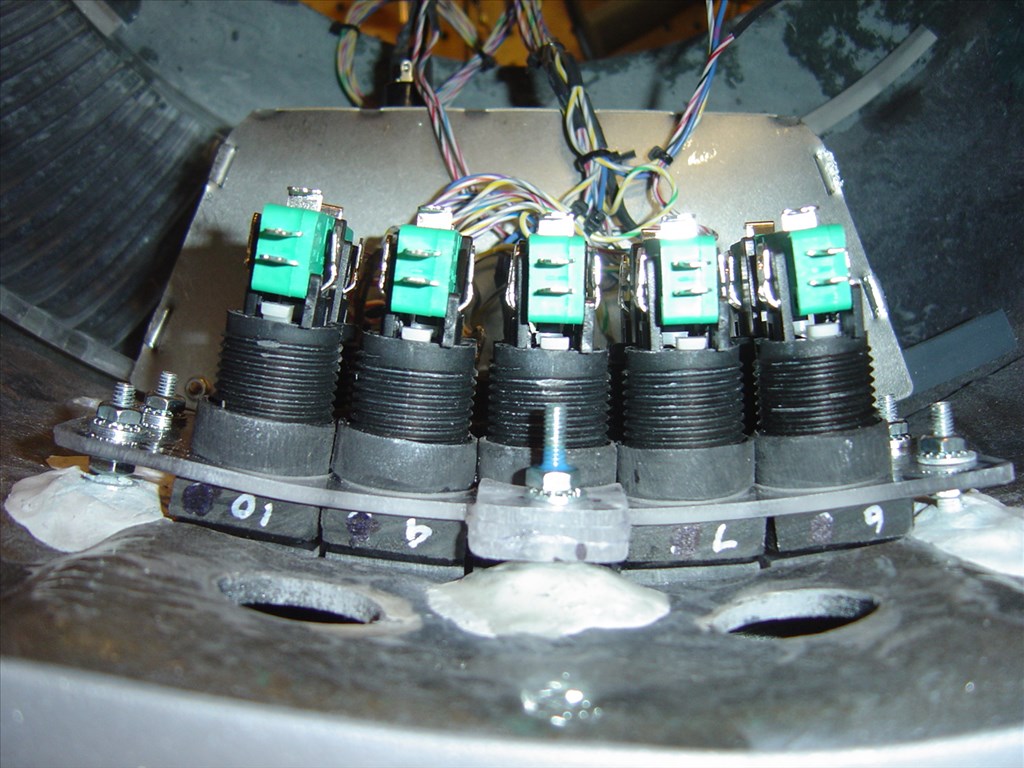

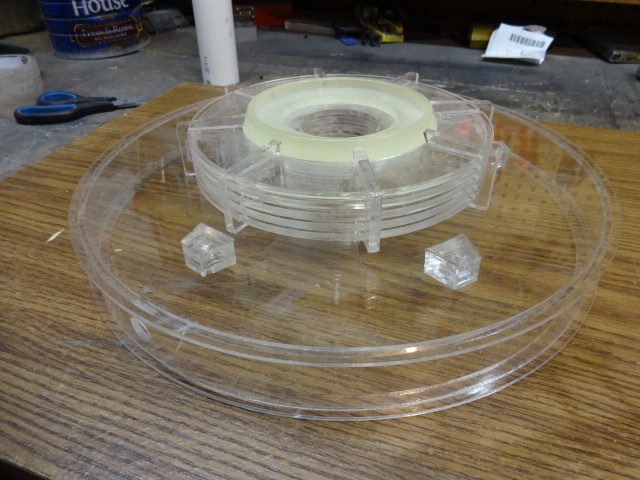

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

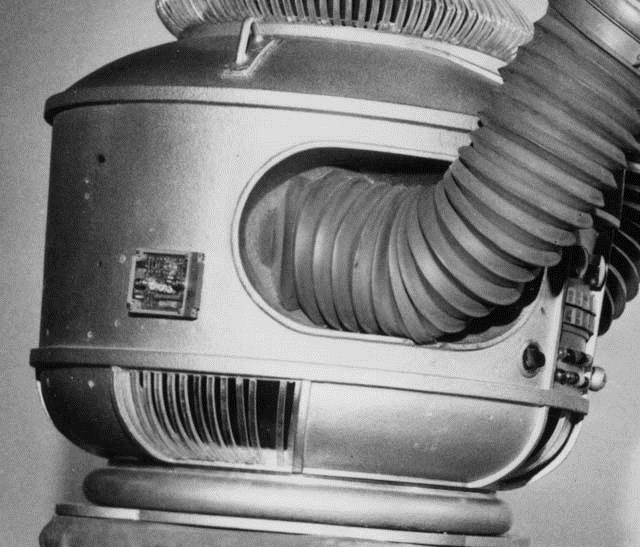

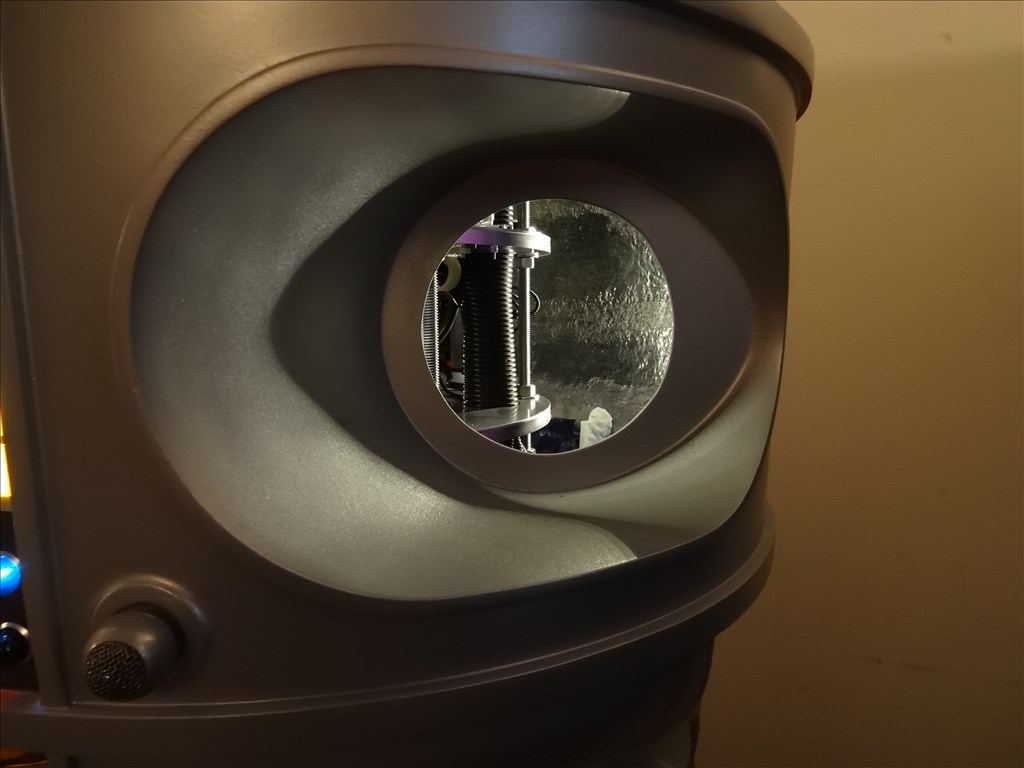

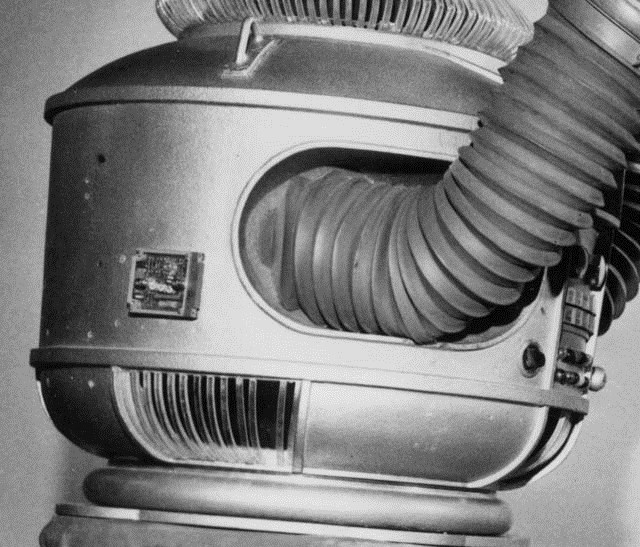

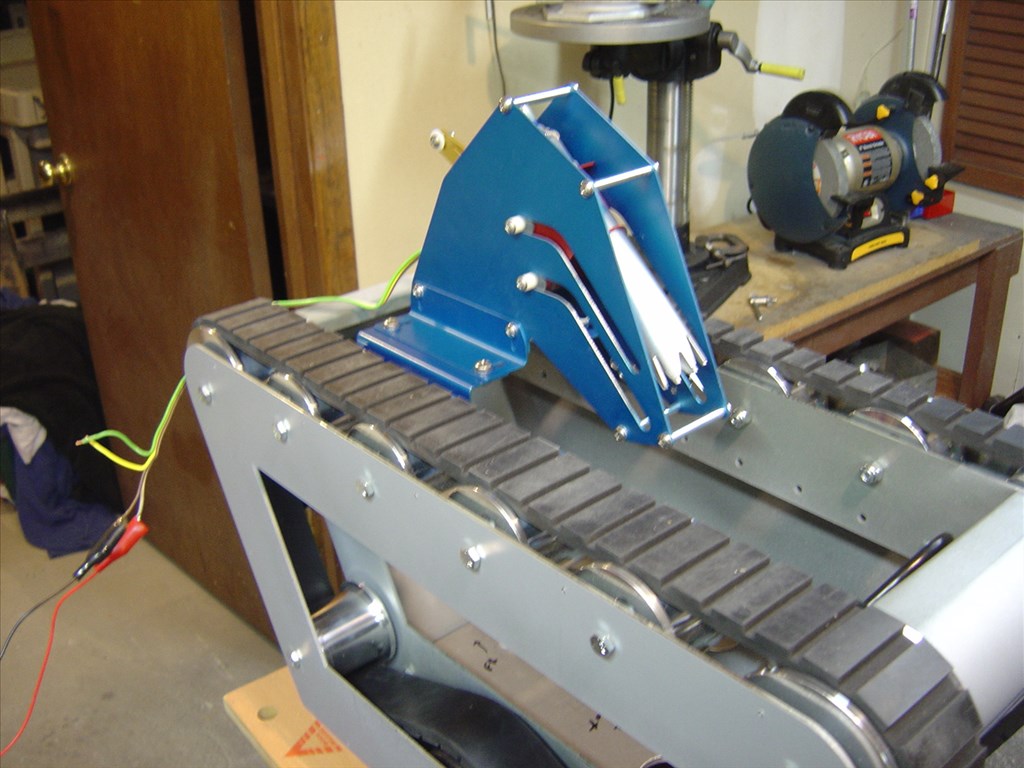

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

Lumpy's Lumpy's Roomba Rover

PJ's Ez-Truck

-635353562186322812.png)

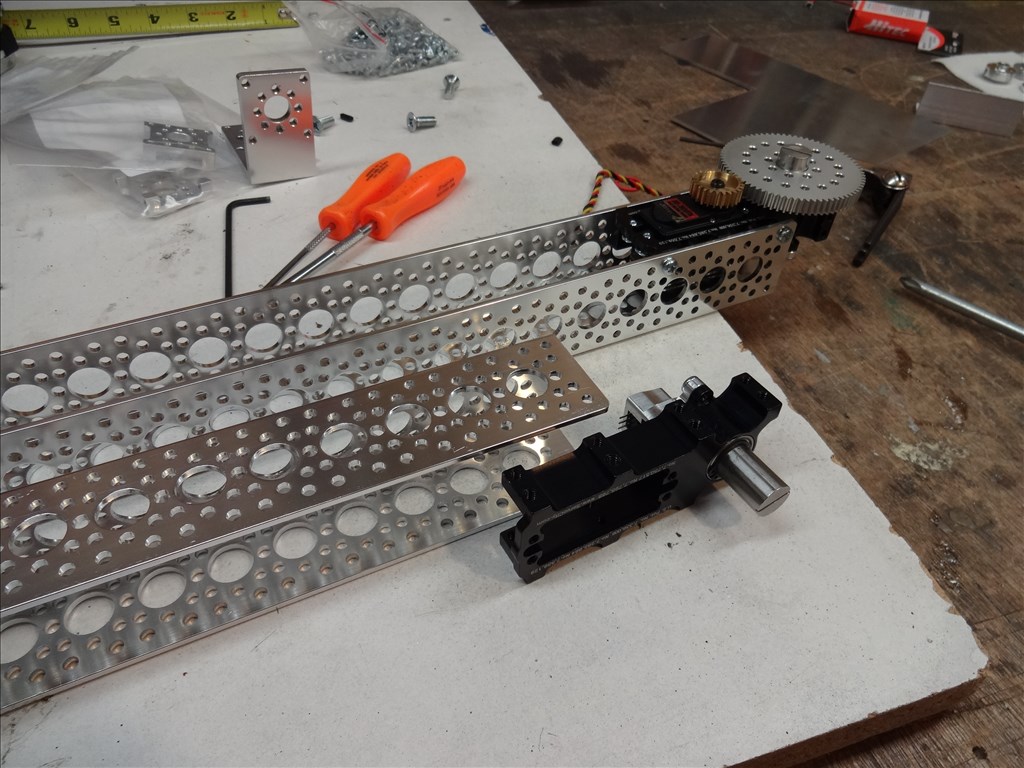

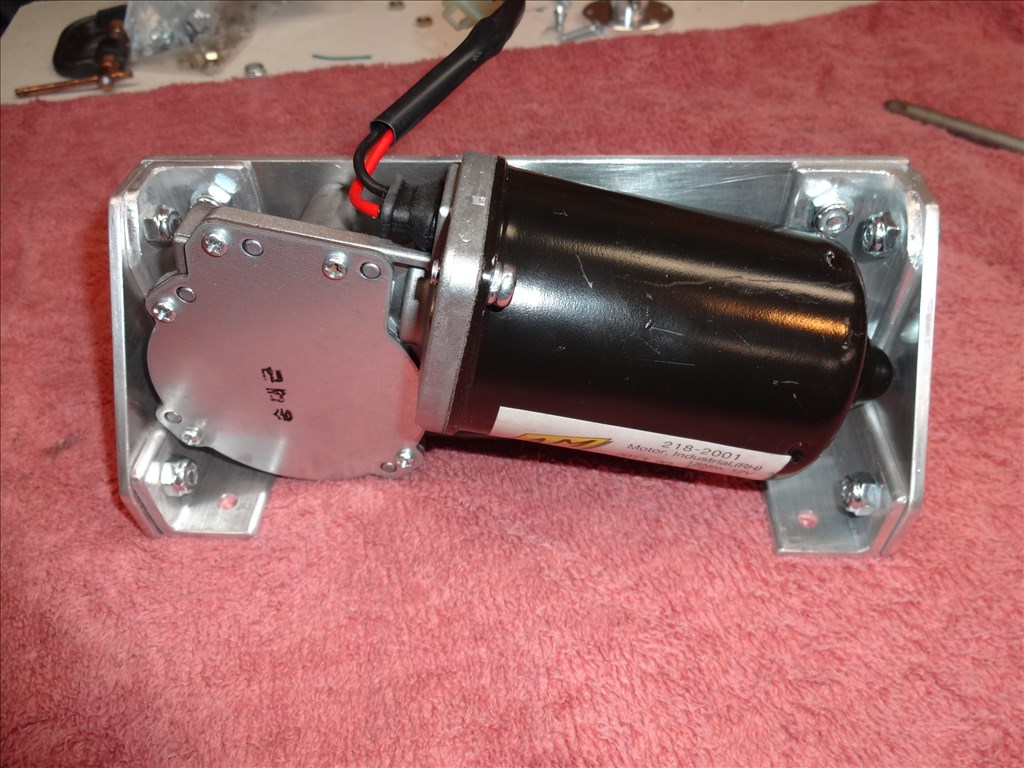

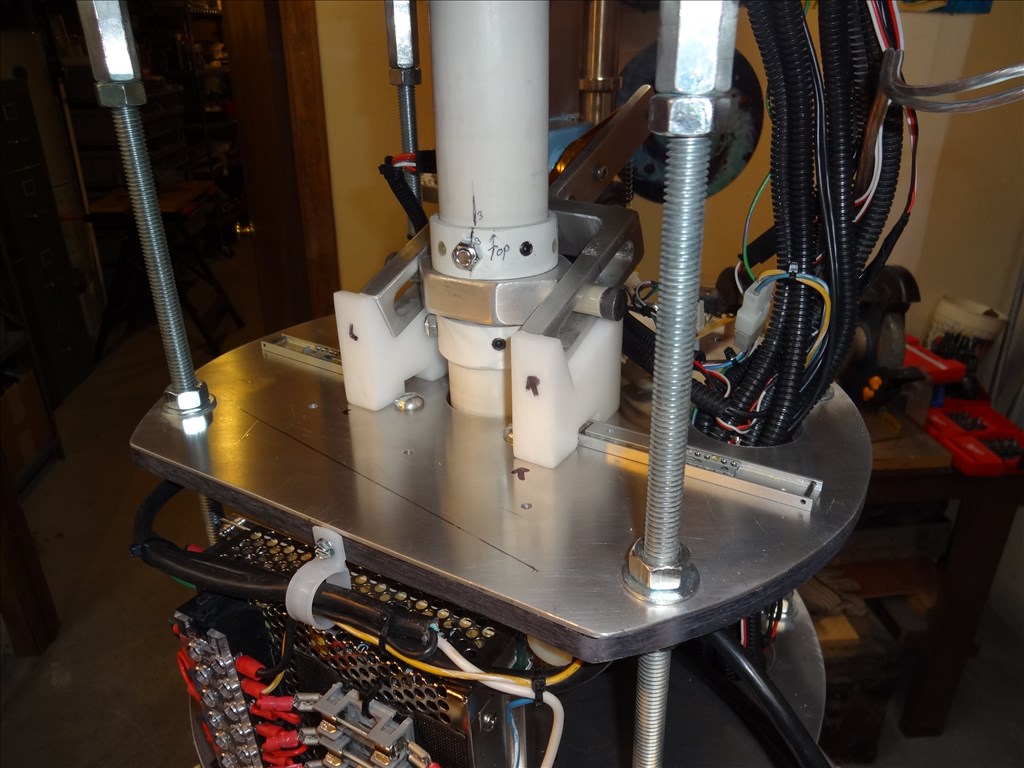

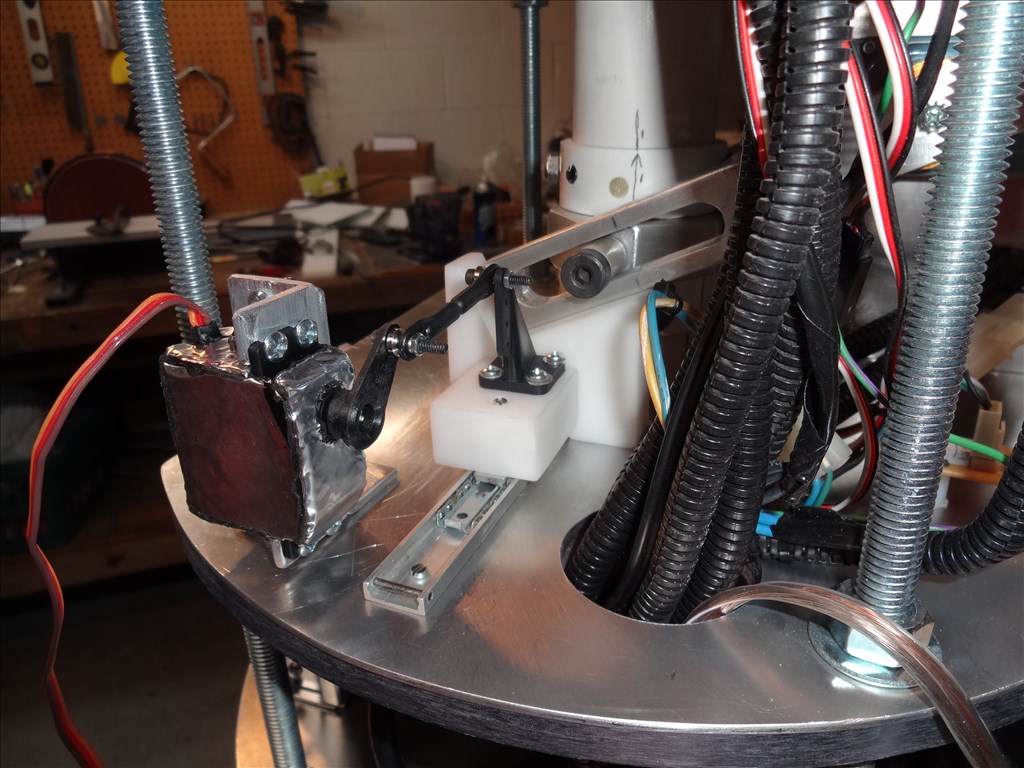

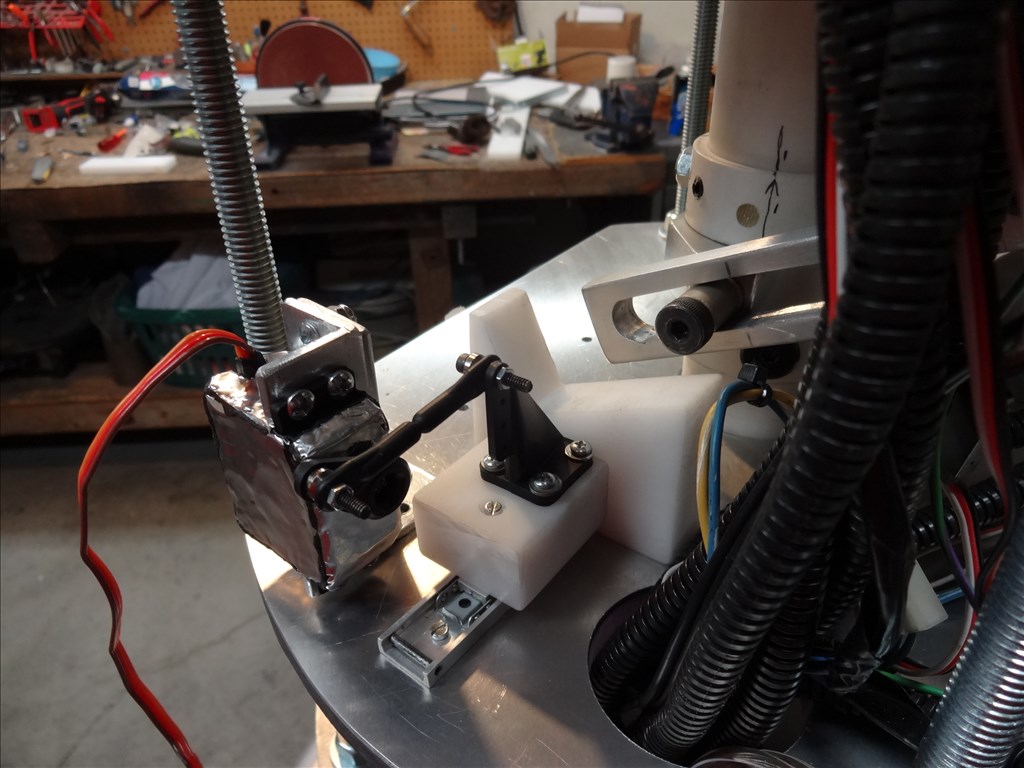

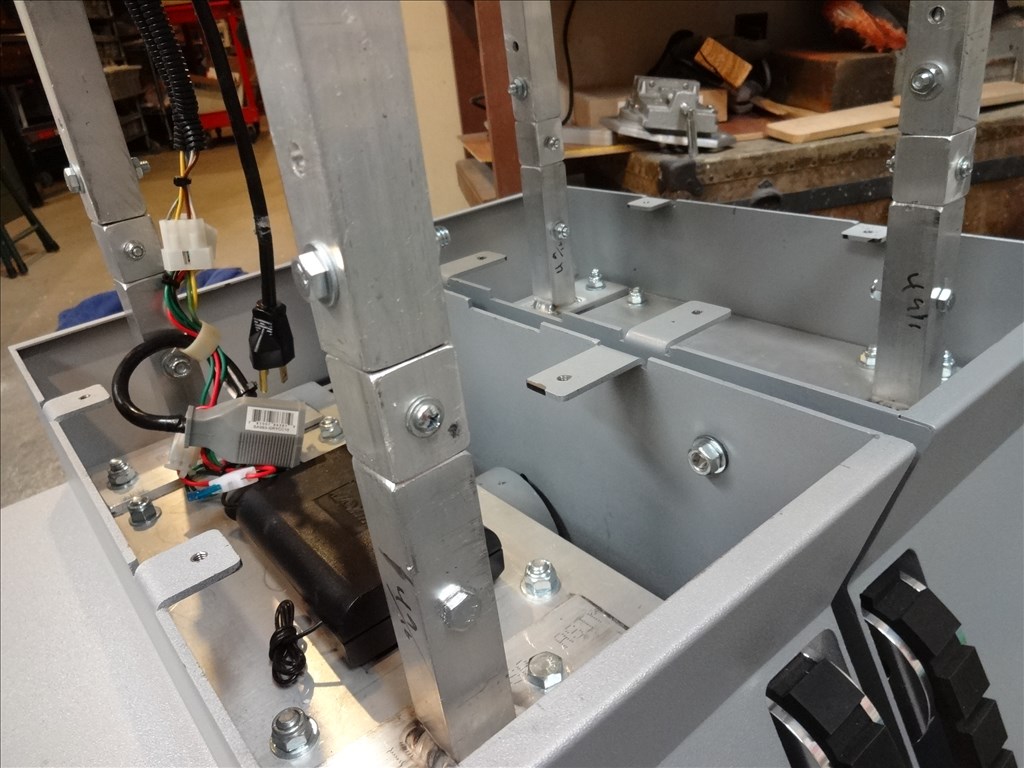

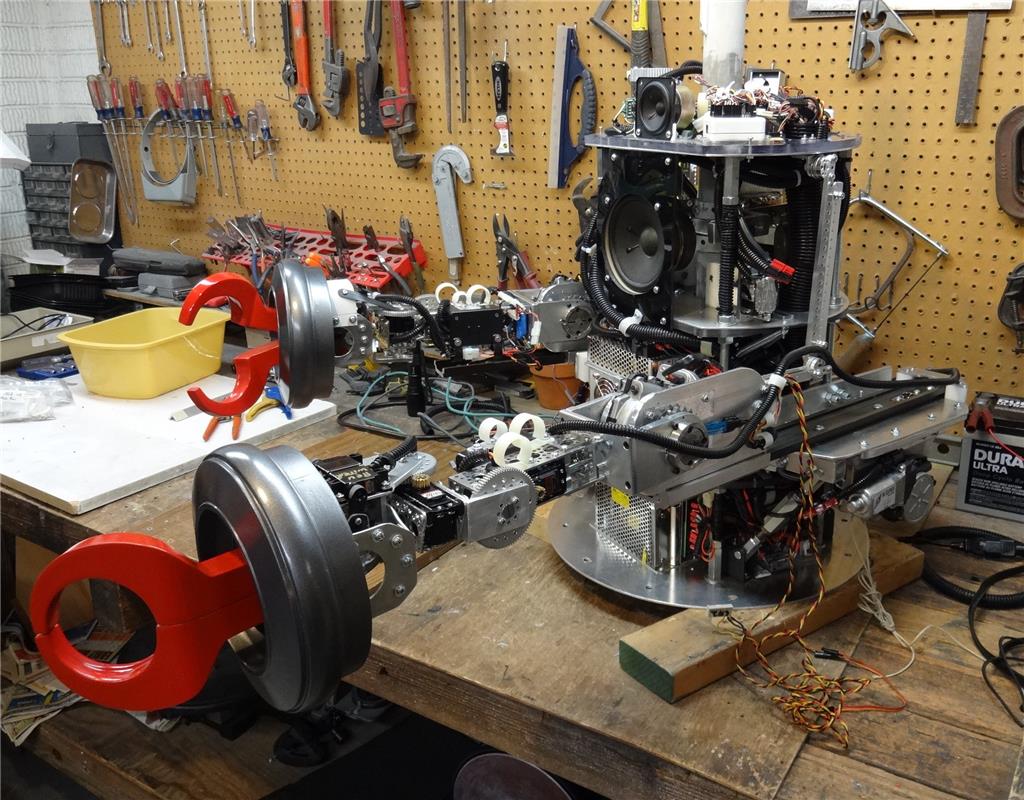

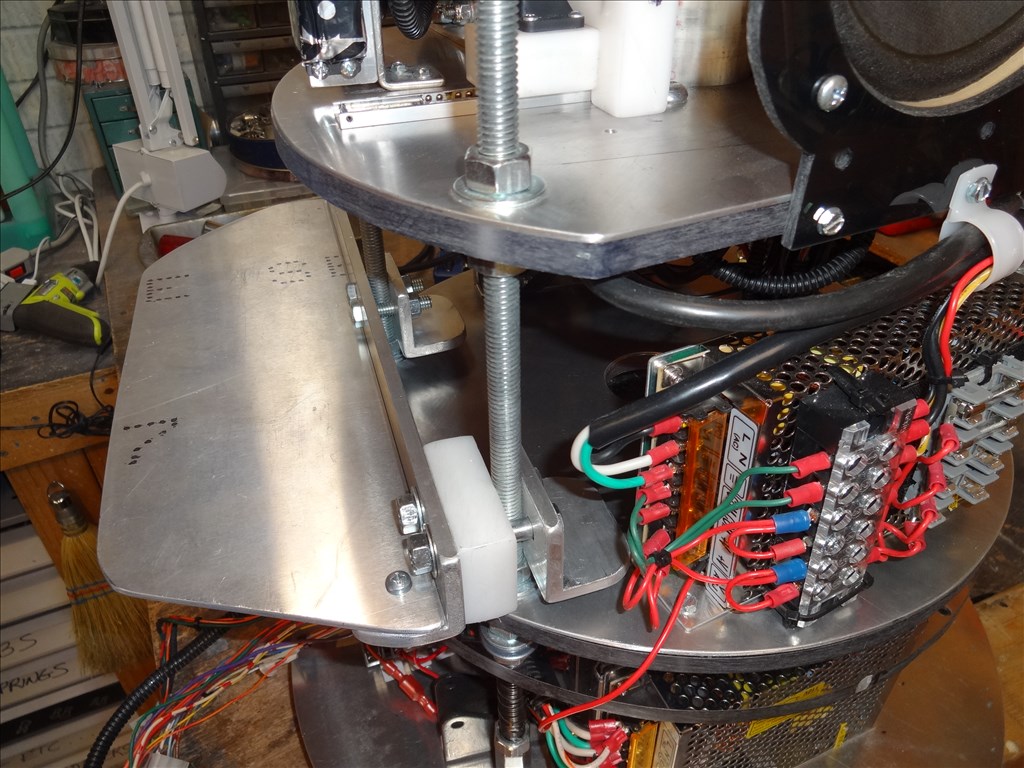

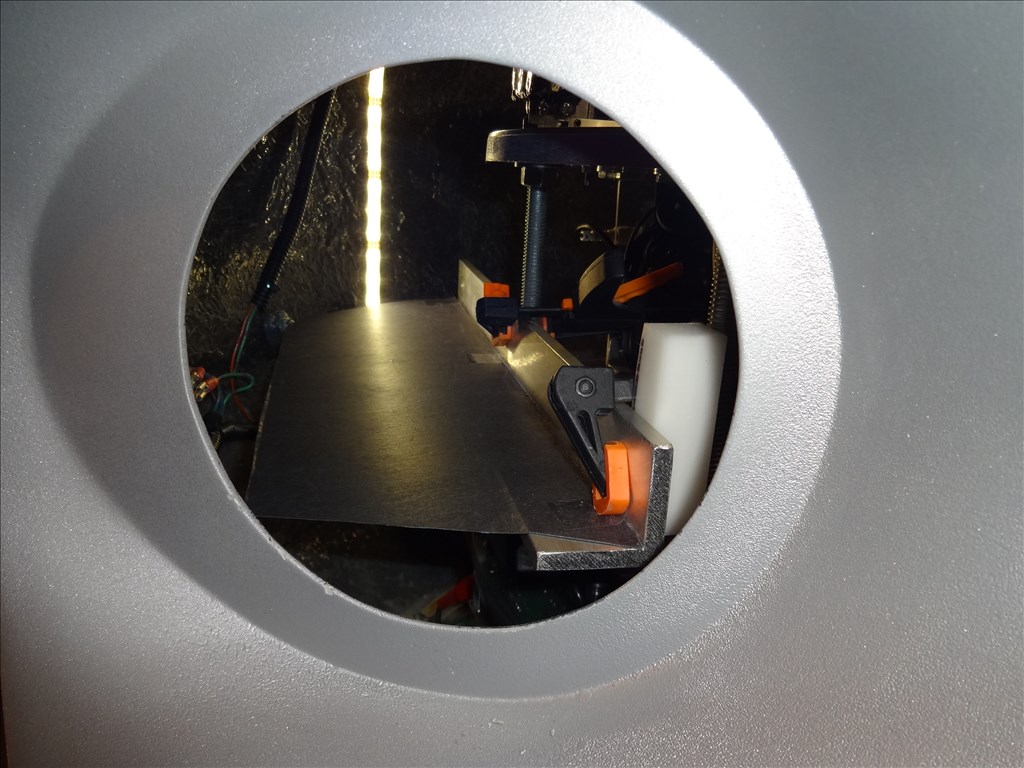

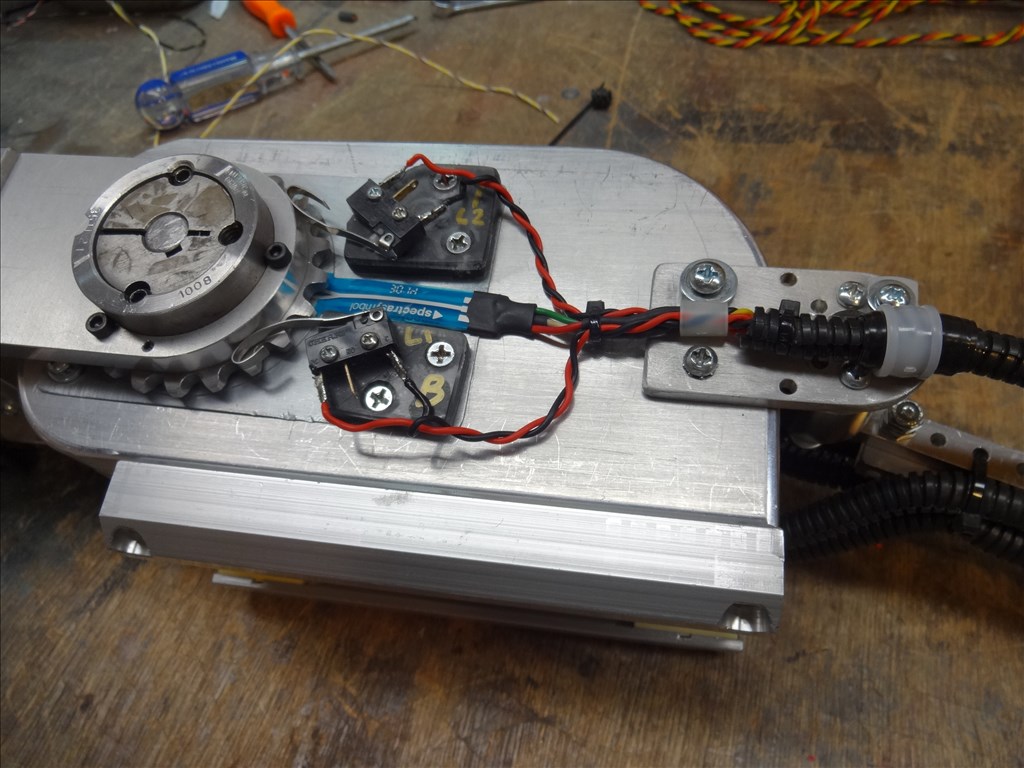

Thanks for the tip WarPig. Actually I've already bought a pair of a similar type of rails thinking this was the answer. After they arrived I found these were way too high profile and too heavy. I only have about 1 inch clearance under the motor mount to play with.

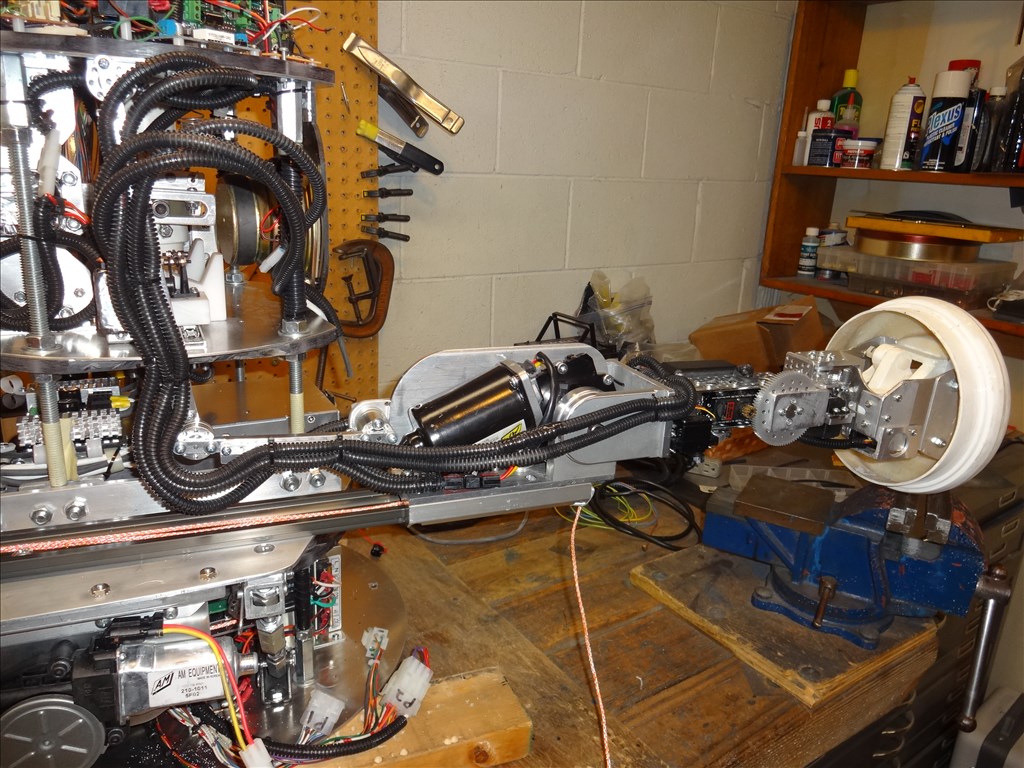

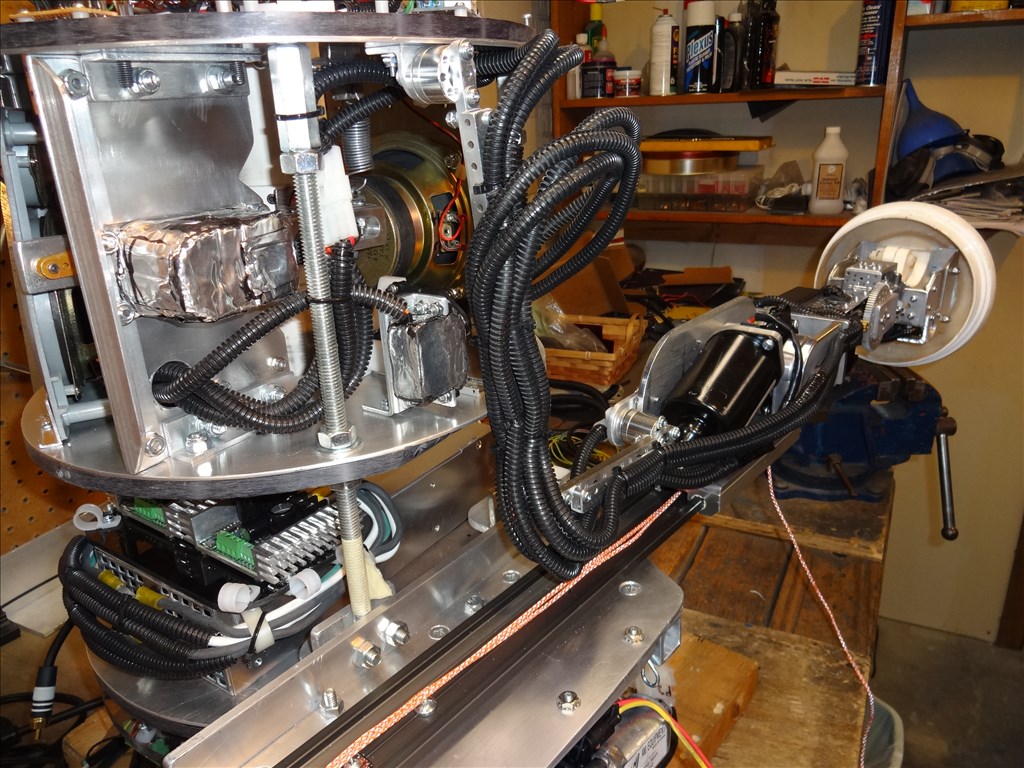

However I do think I've found the answer. Igus Plastics makes low profile and very strong linear slides and guides in their Drylin line. I'm actually using one of their plastic bearings in the rear pivot joint of my elbow motor mount. It's rated to handle the weight and stress of my elbow and run consistently for over 5400 hours before it wares out. That's like the elbow mount going up and down constantly for over 3/4 of a year. It makes the pivot point of the motor mount glide like ice on ice.

igus trademark linear guides

I have high hopes for this product! I'll be looking into finding the proper size to support my load to see if it will actually work.

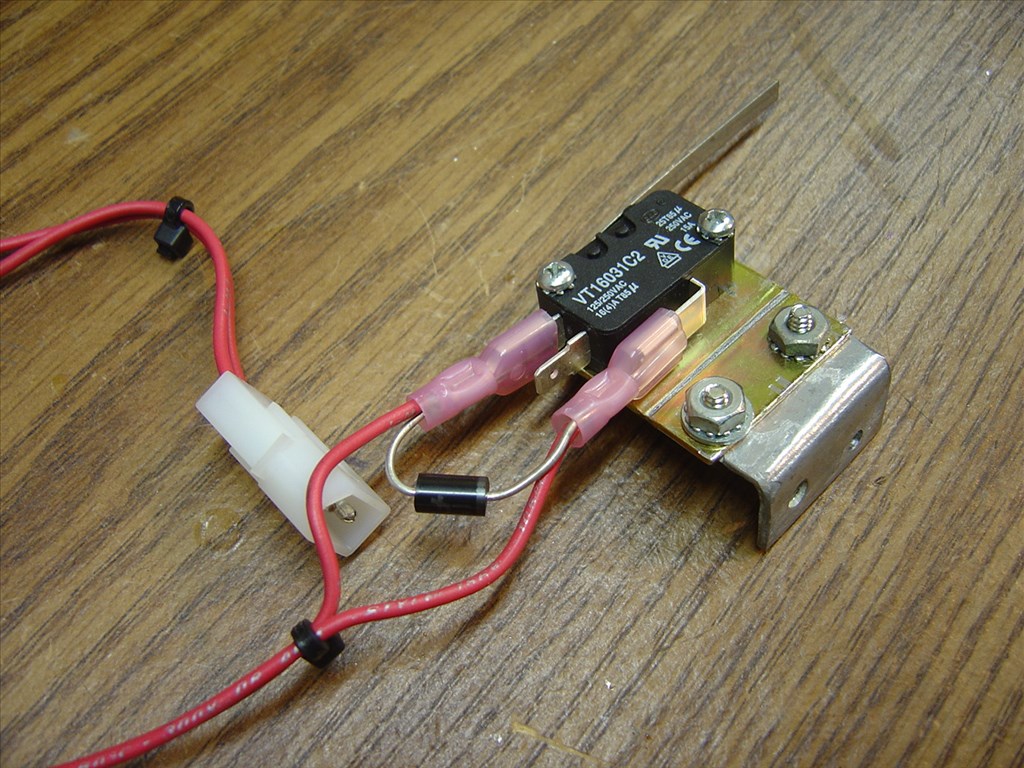

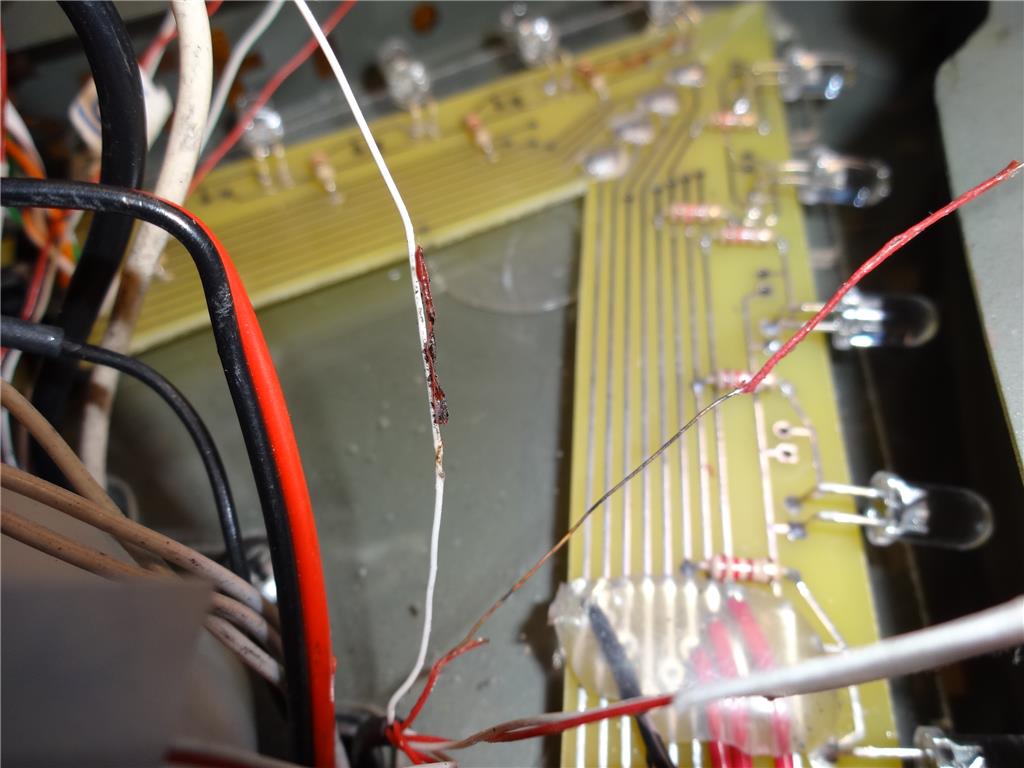

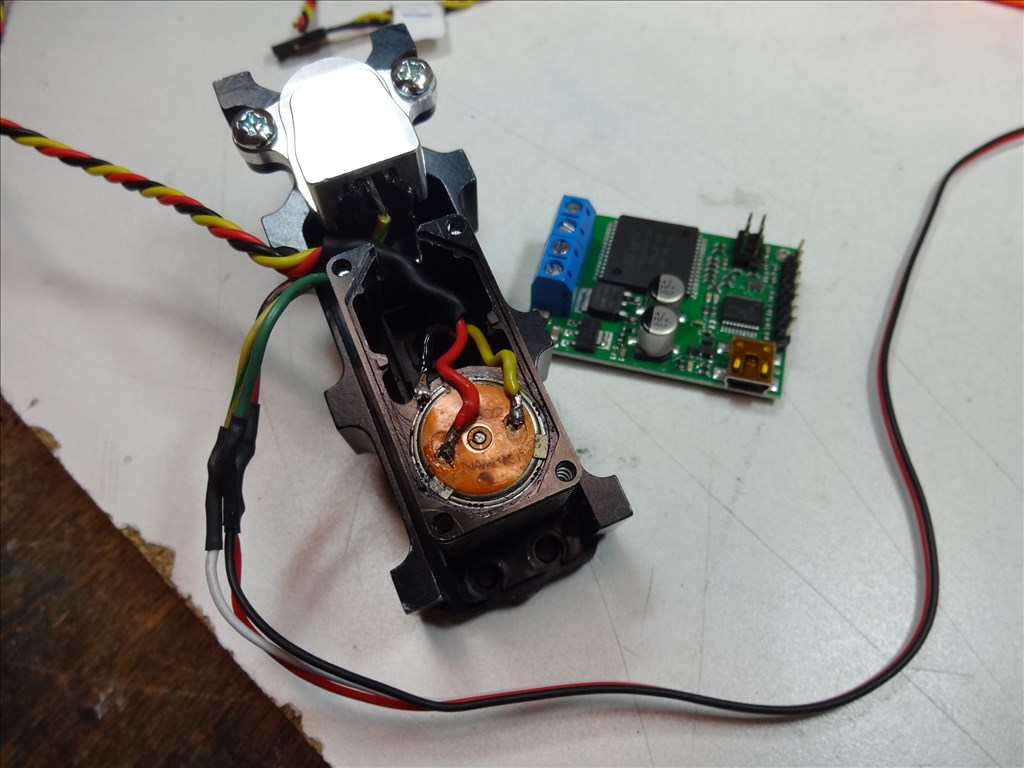

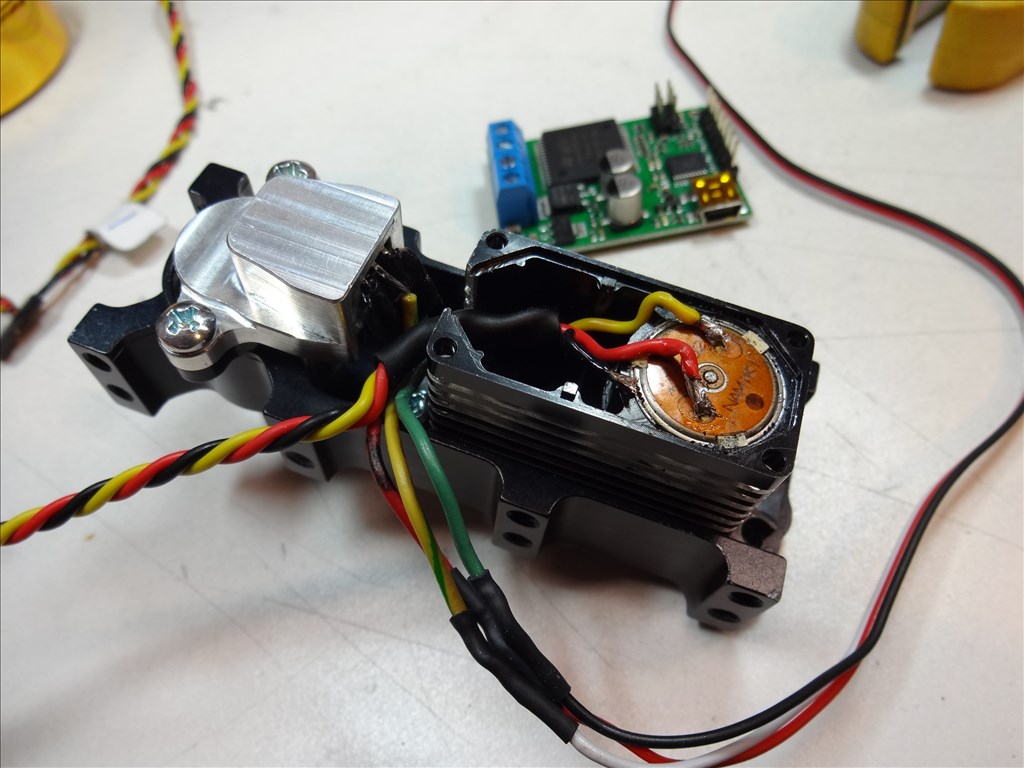

Sorry guys. I know a few of you were waiting on my second video showing what's under the skin of the arm as it moves. It's going to be a few more days until I can get that done. I was doing some final adjustments and tweek and stupidity ran a servo past it's stopping point. Woops.

After the new servo gets here this weekend (hopefully) I'll install it and shoot the video.

Thanks, Dave Schulpius

Oh my! Nice find Dave. Let me know how they work out!

Ya Will, I'm real hopeful that these will work. The specs on the one that will fit nicely under the elbow motro say it will hold up to about 1800 lbs static load. Not sure yet on a asymmetrical like mine but the sales men seems to think with the proper one this will work out great.

Hi all,

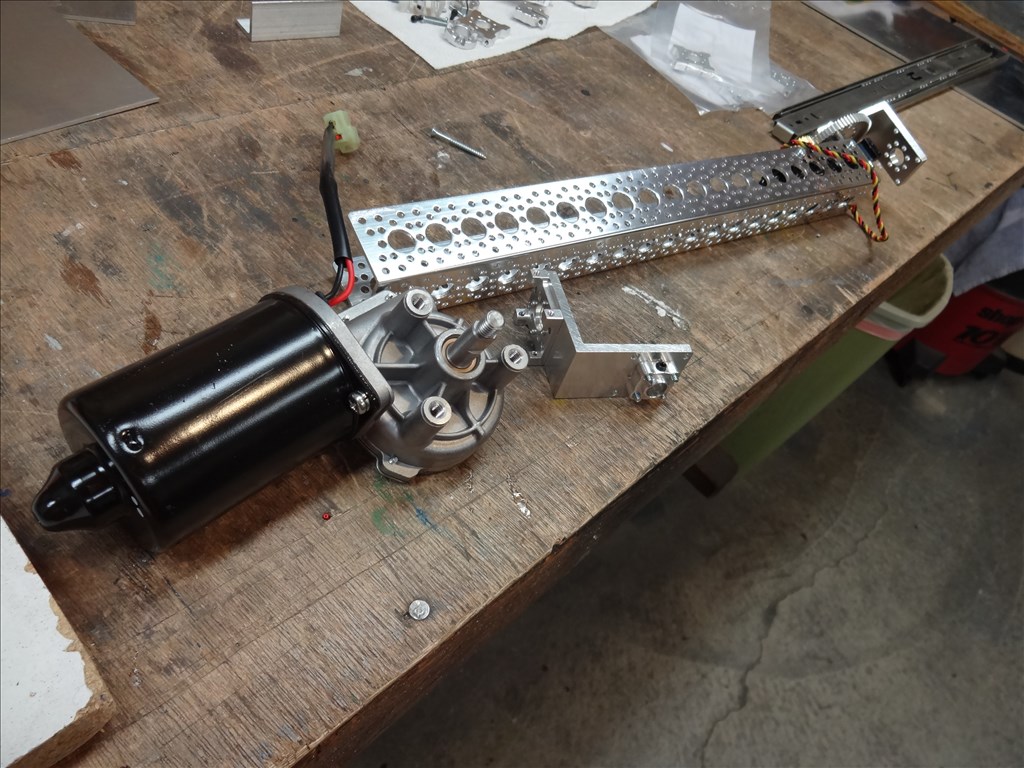

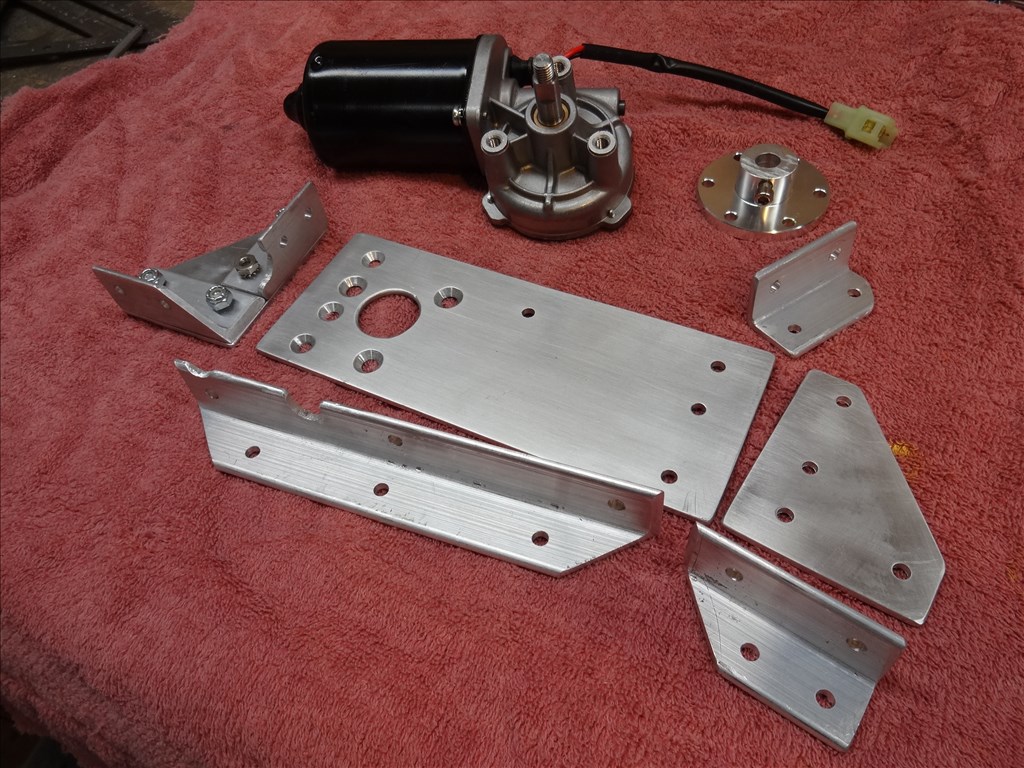

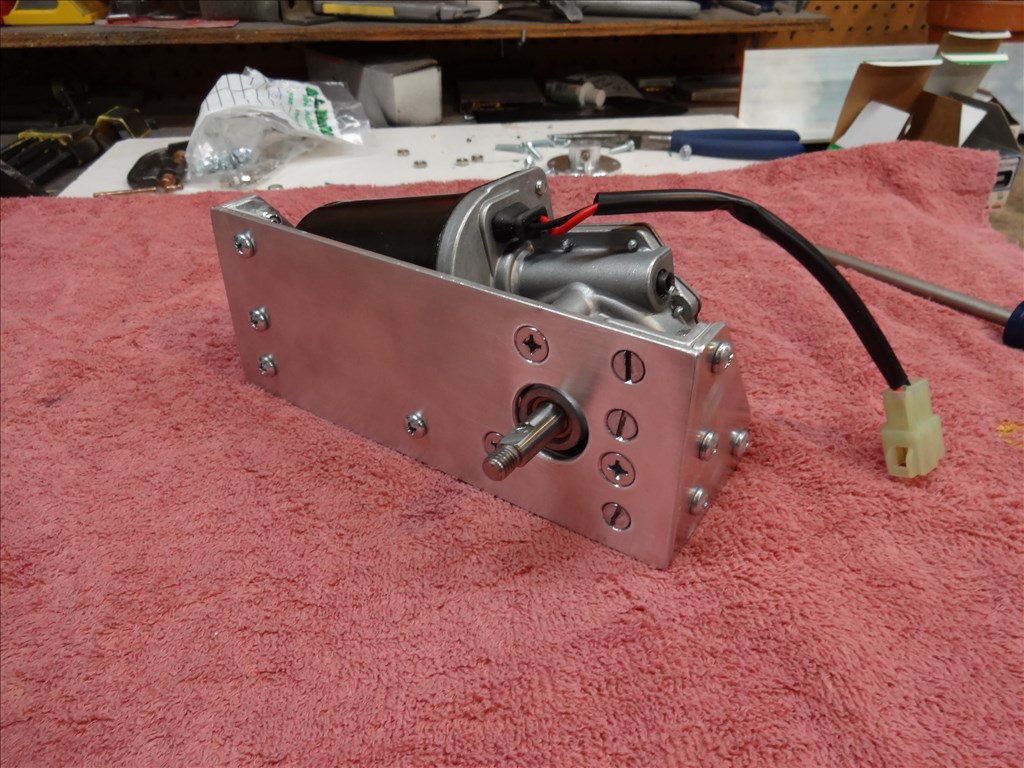

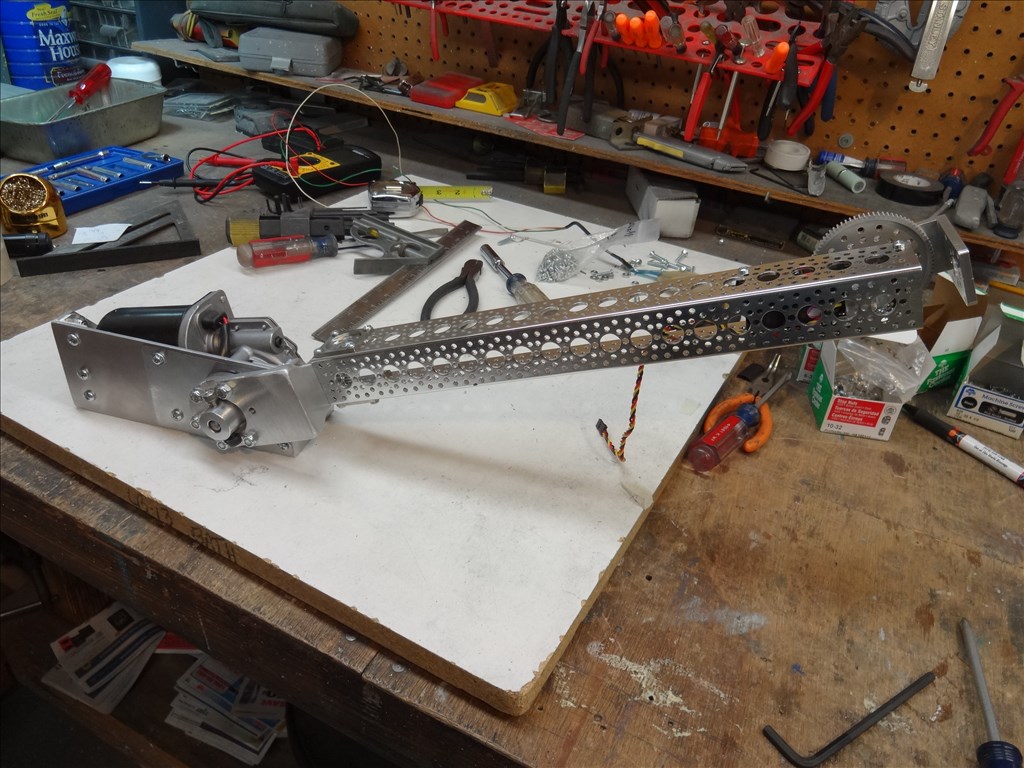

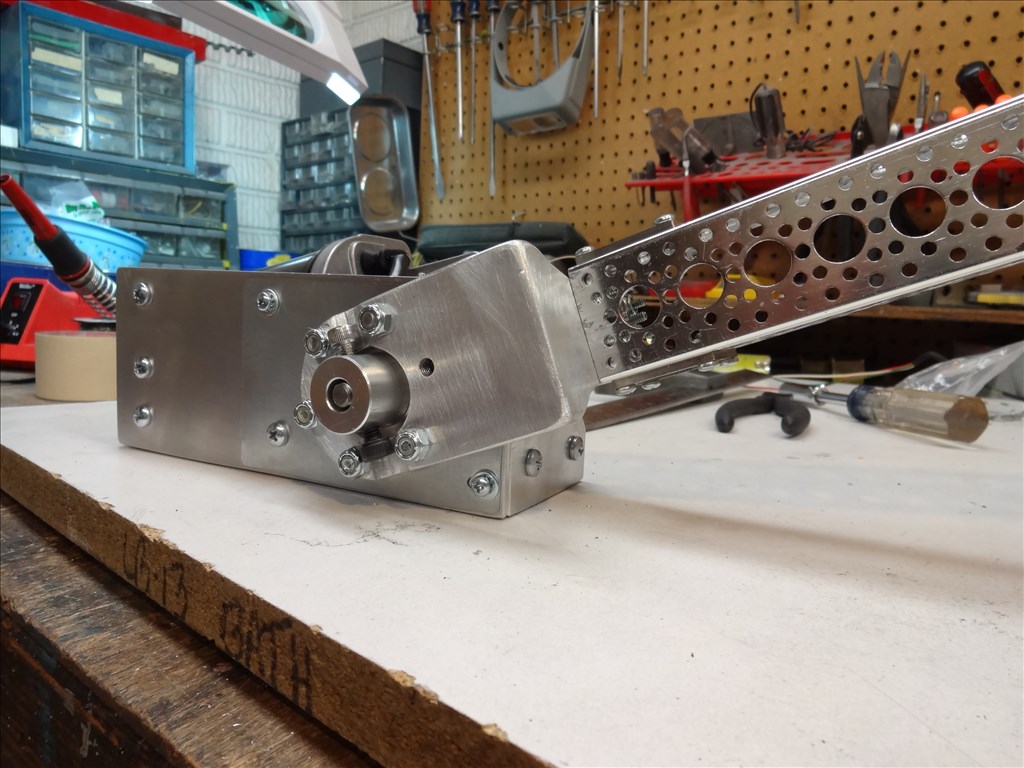

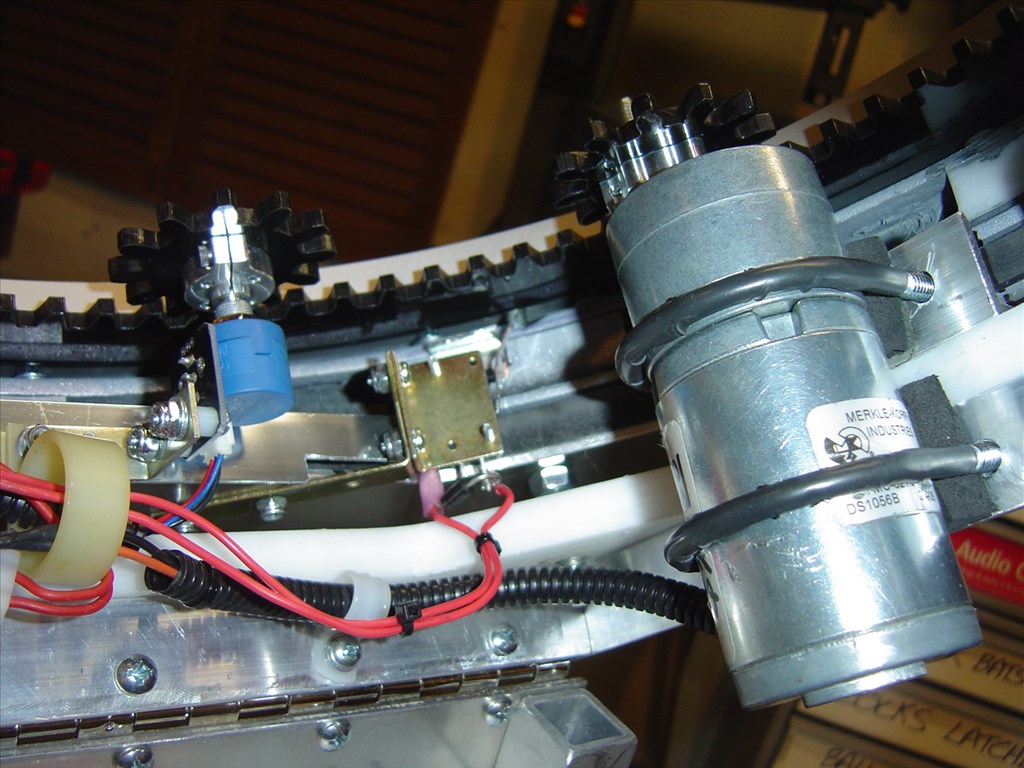

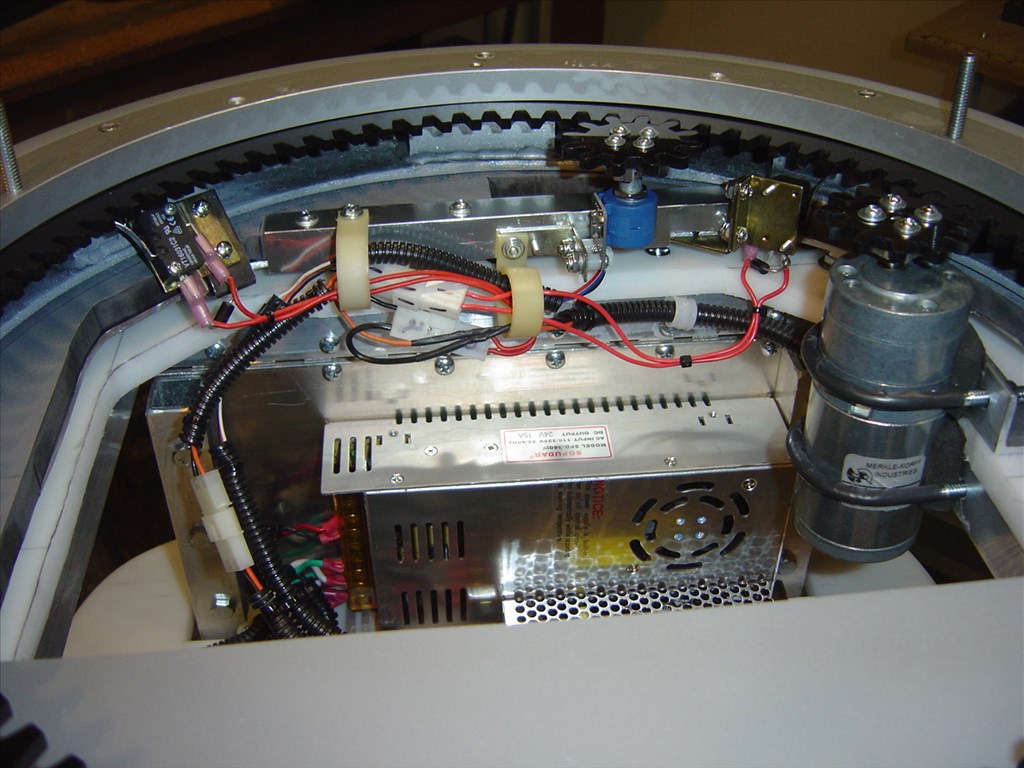

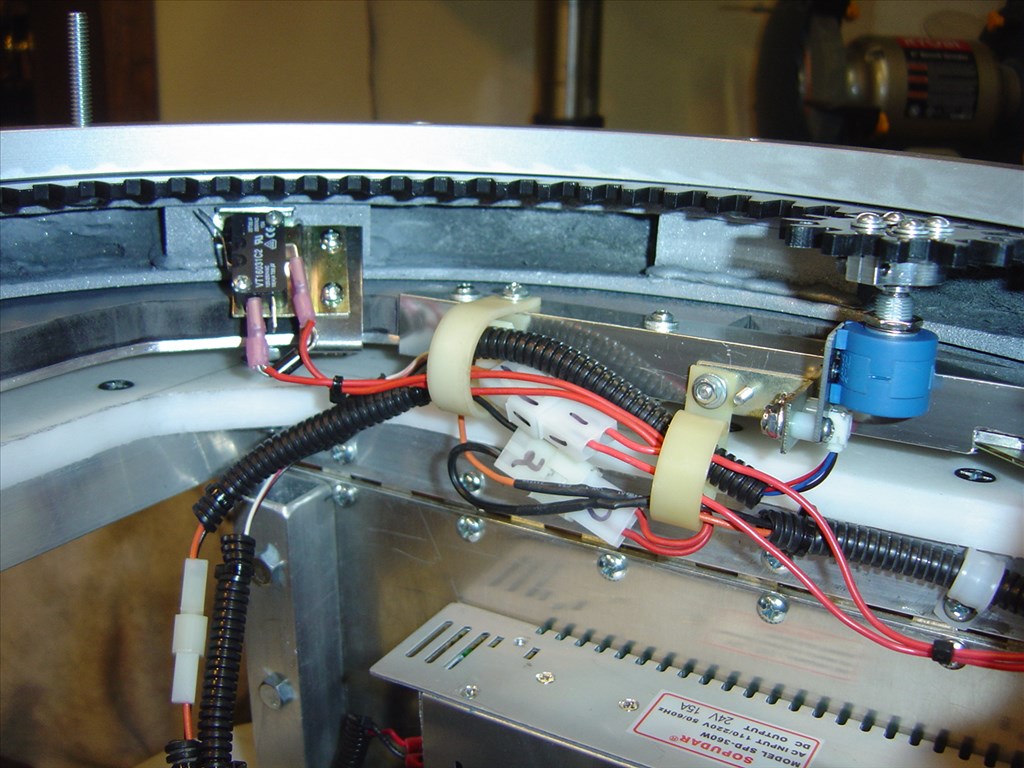

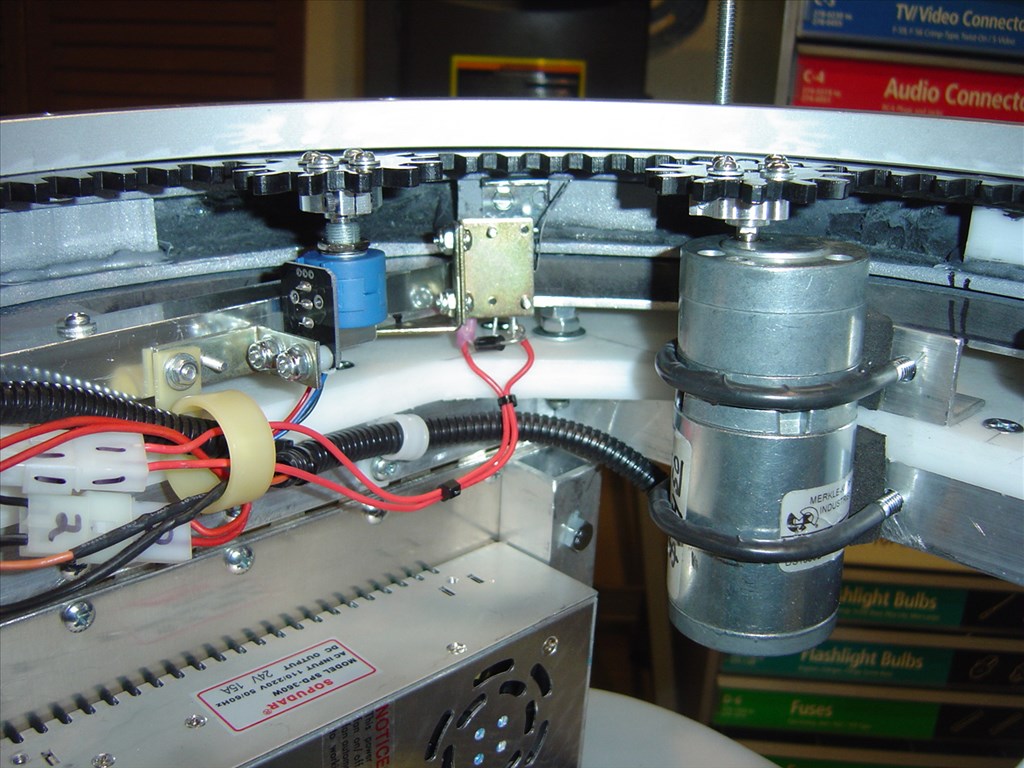

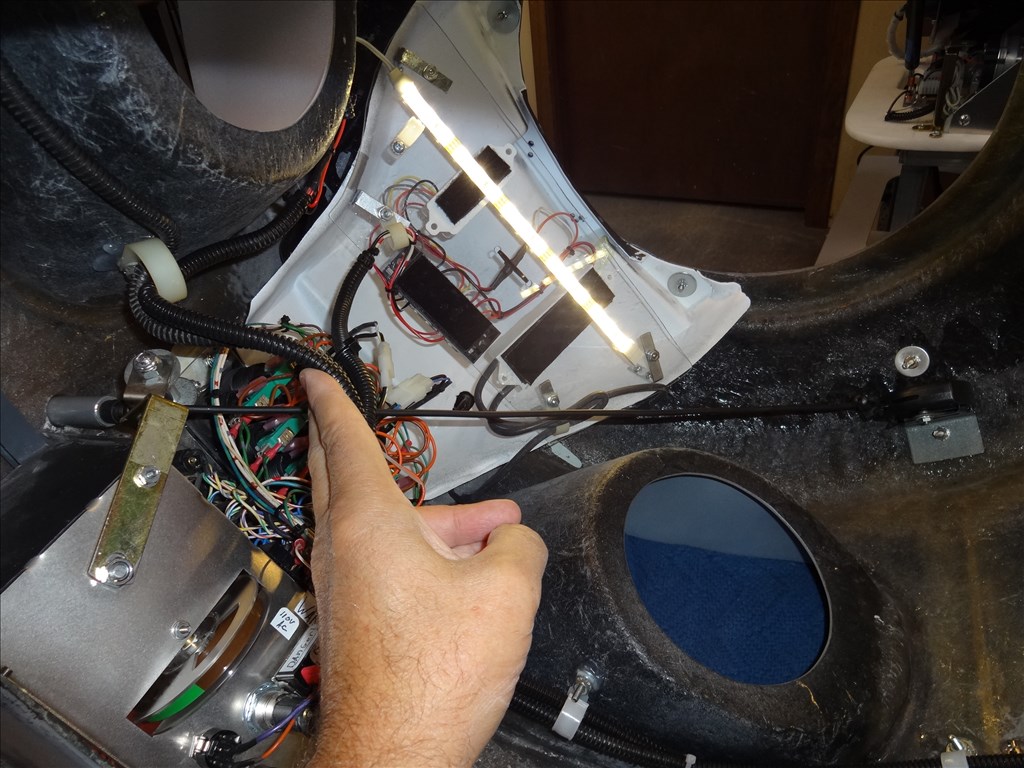

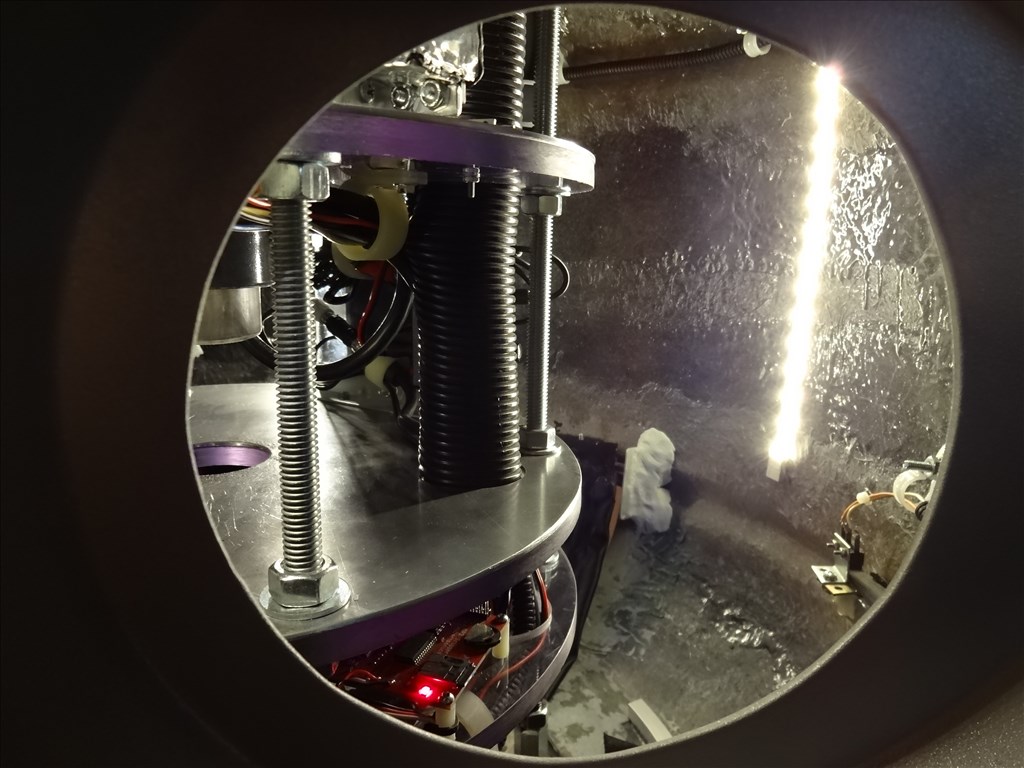

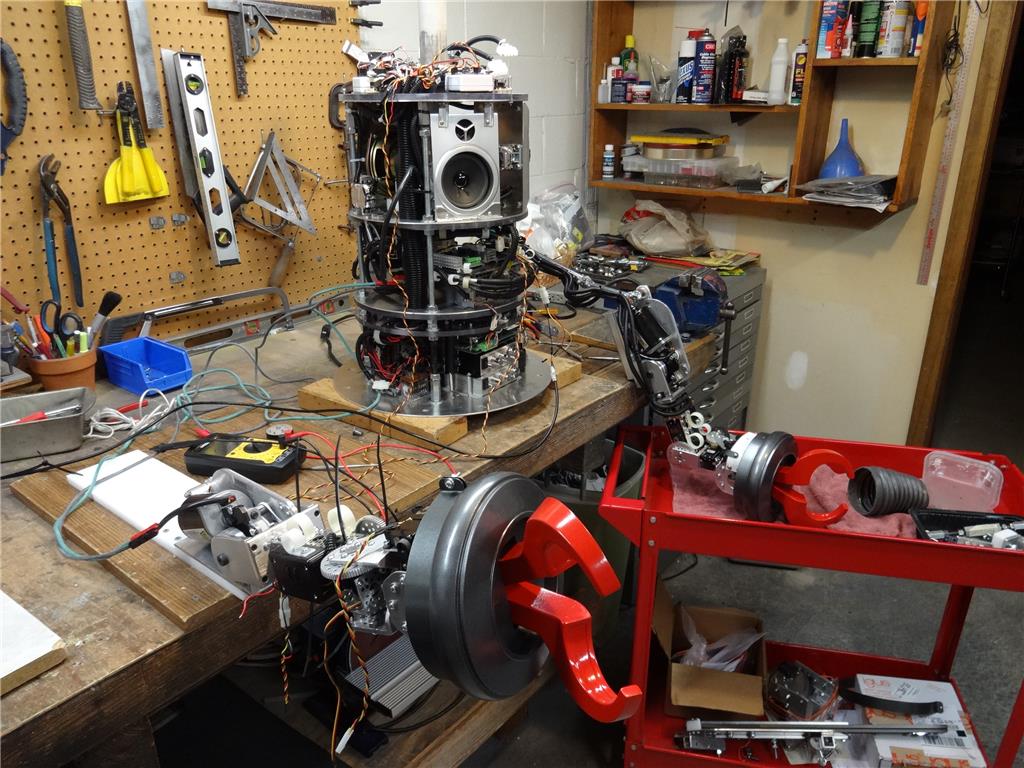

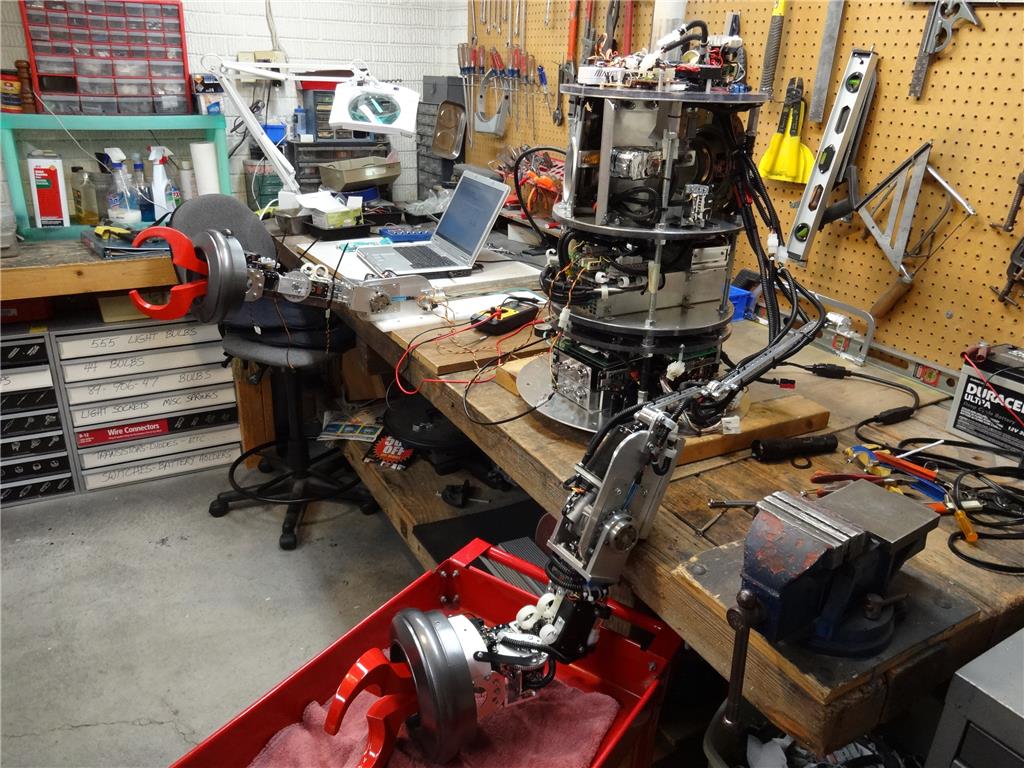

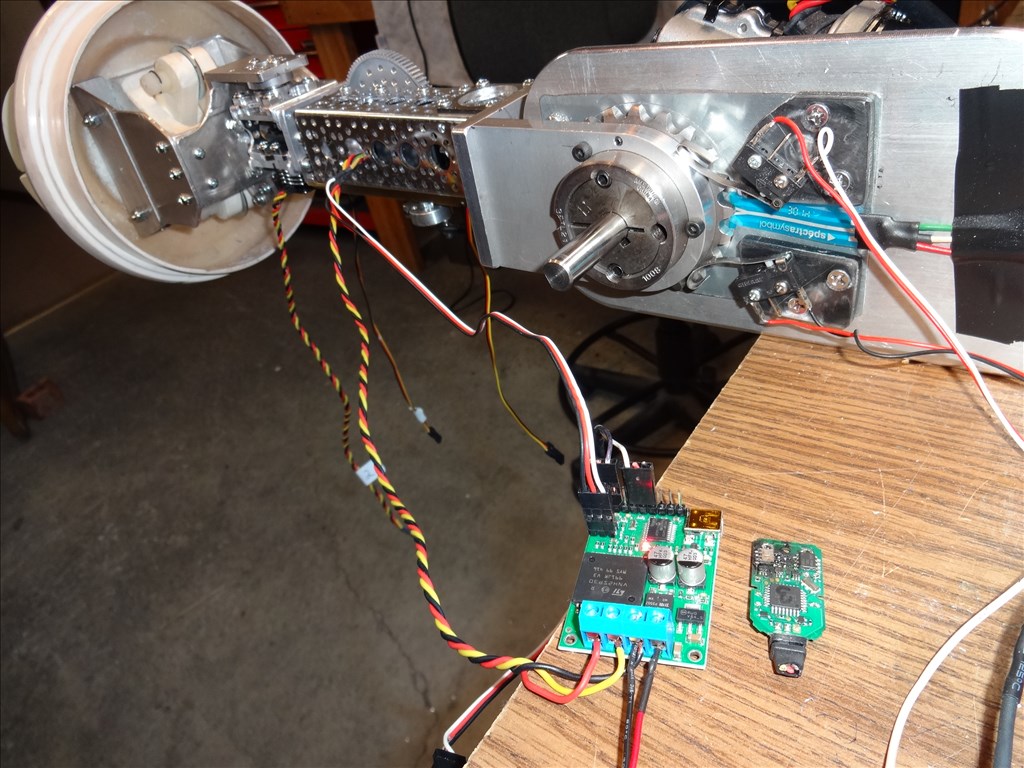

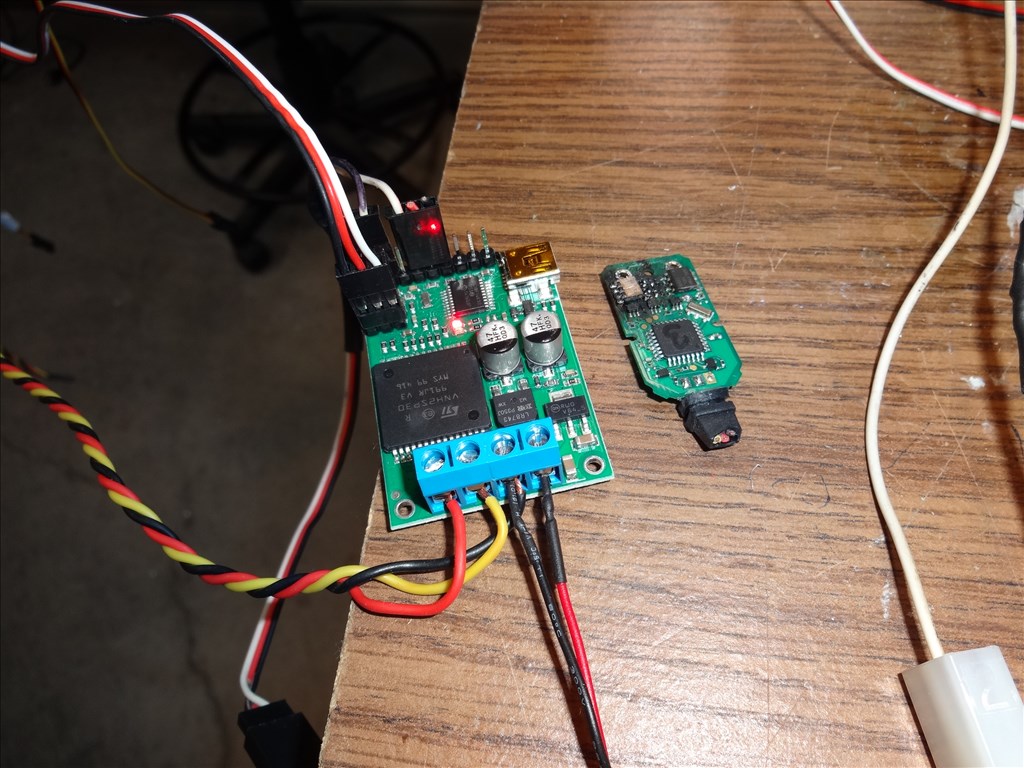

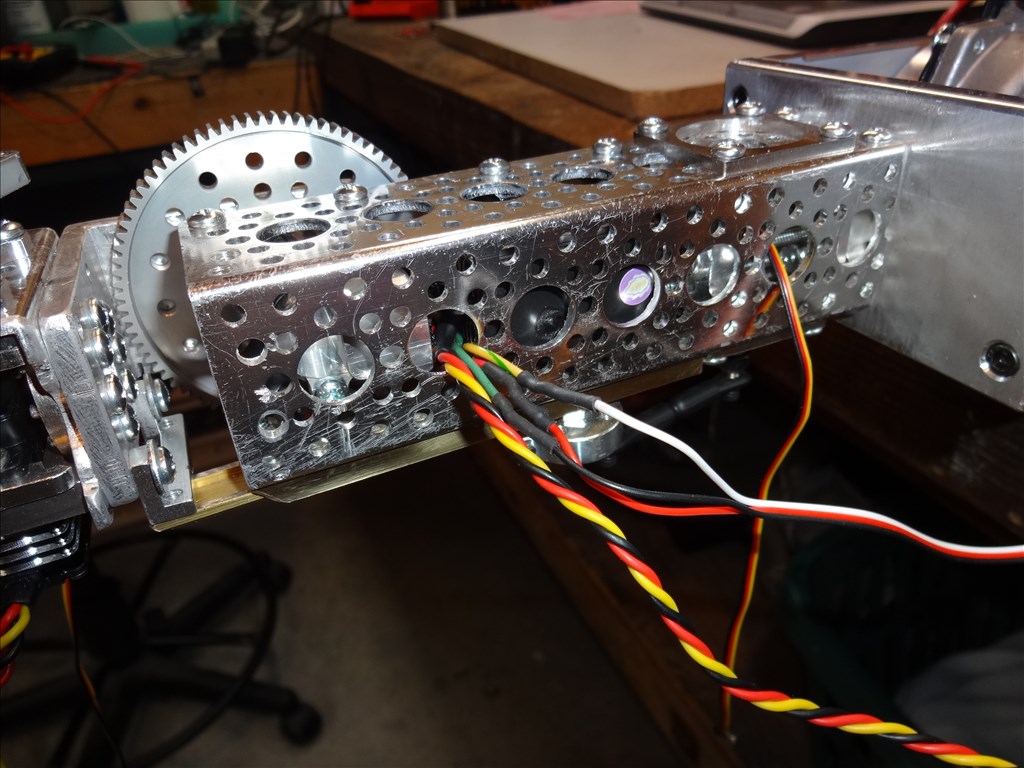

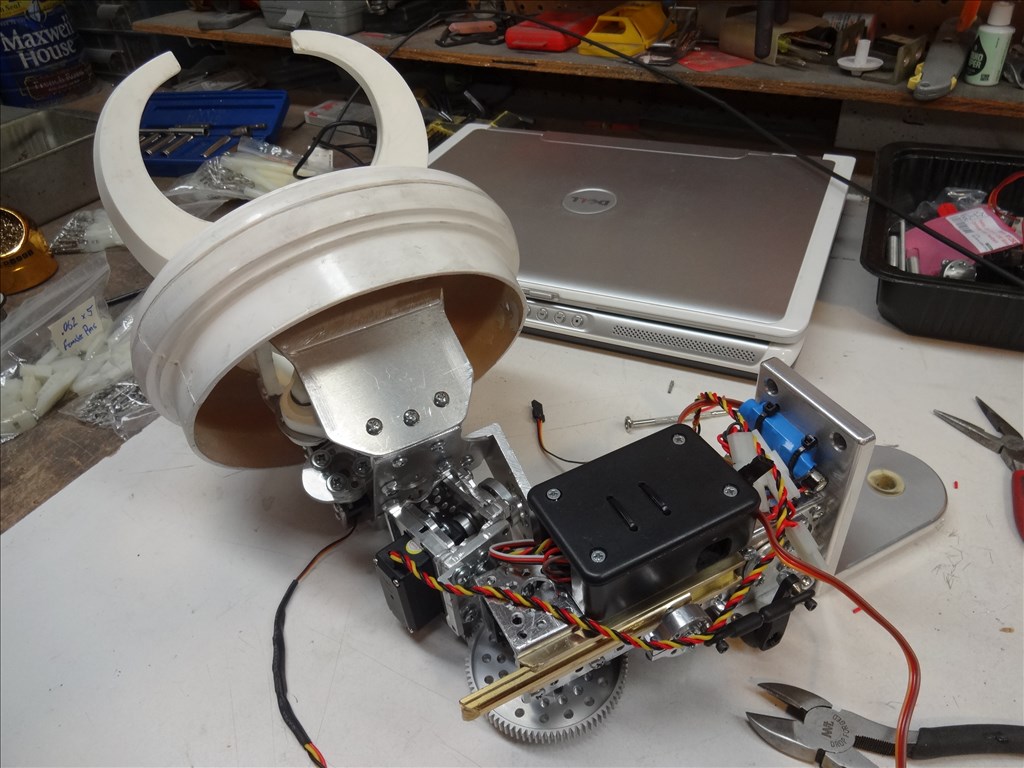

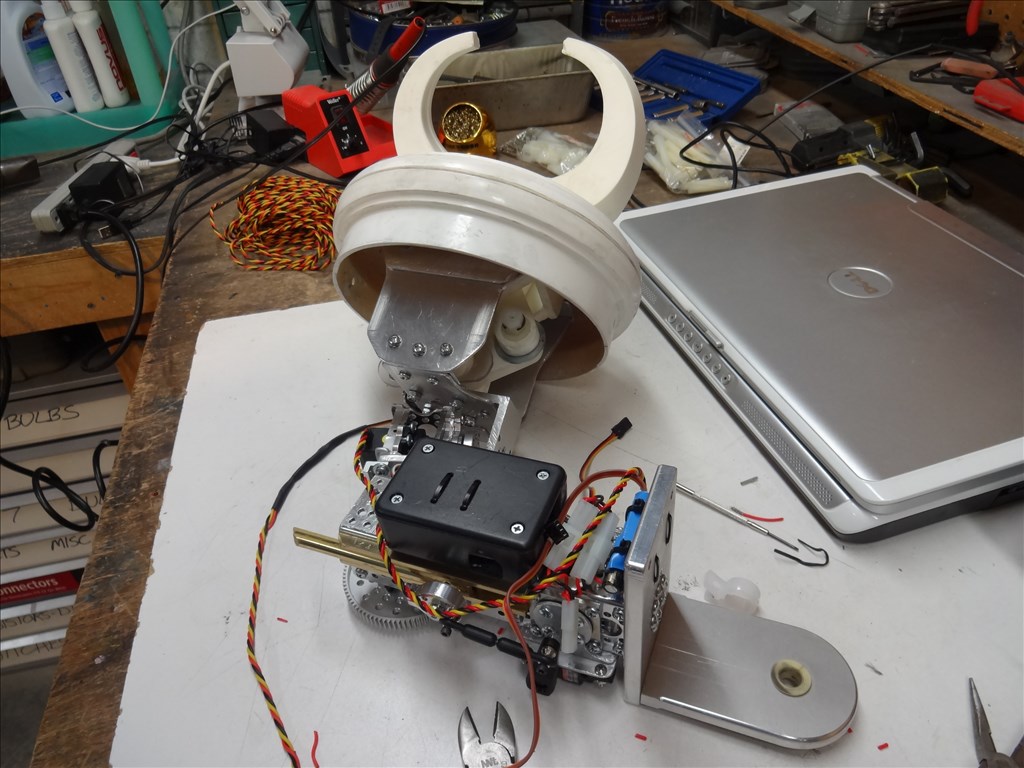

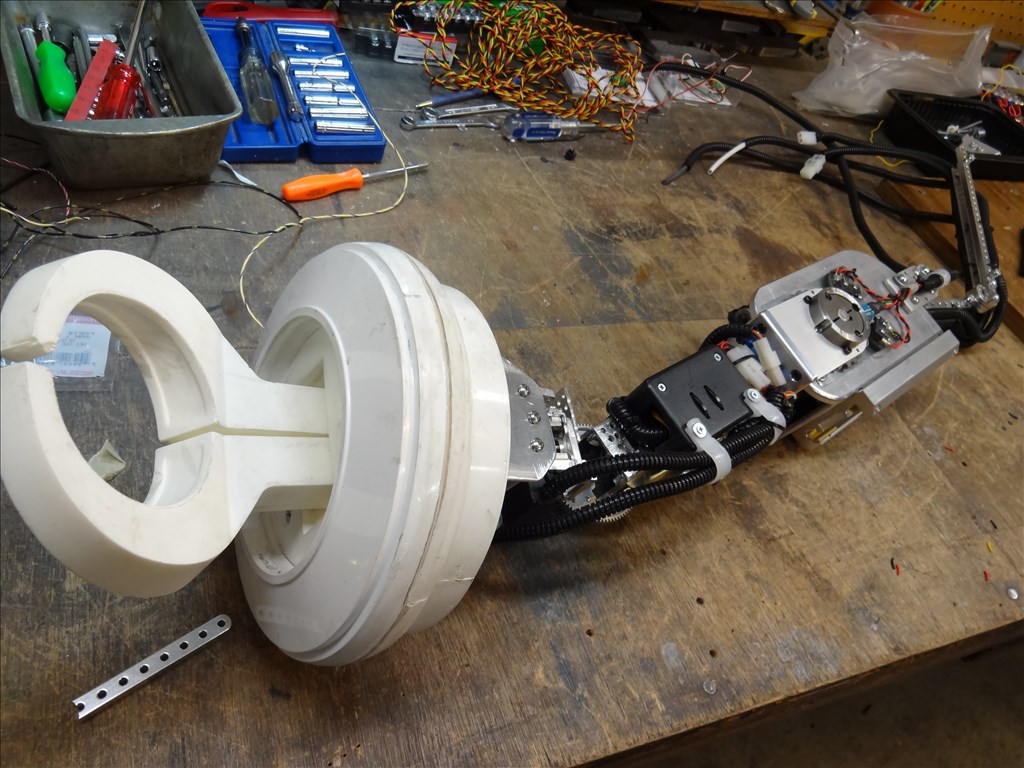

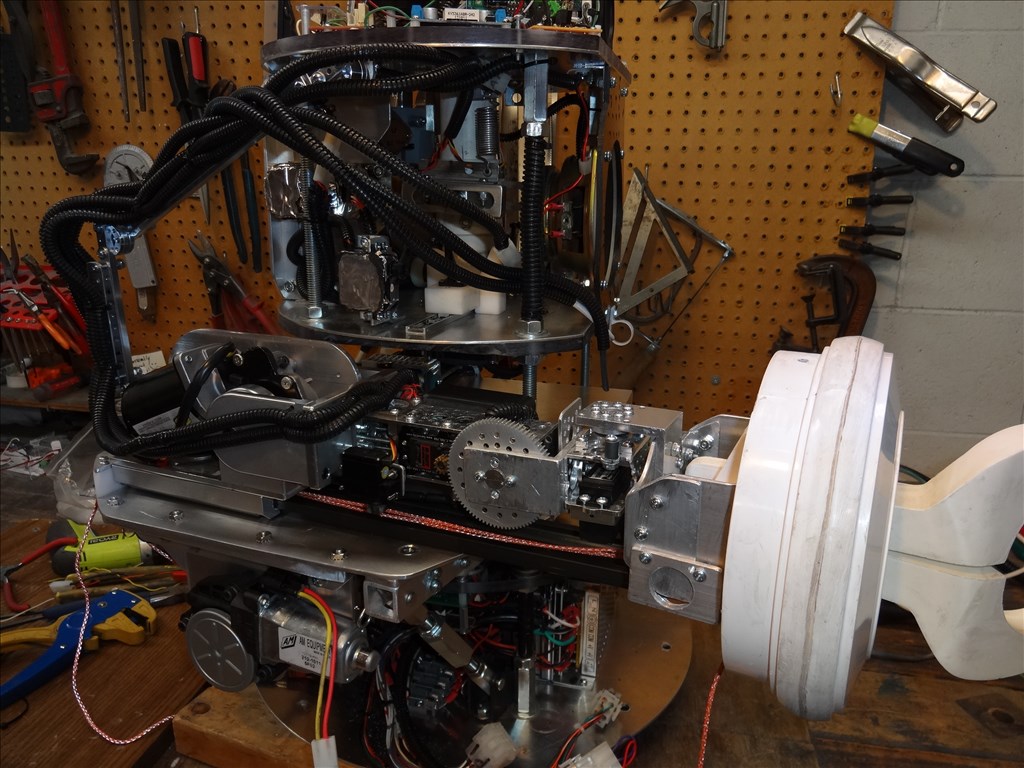

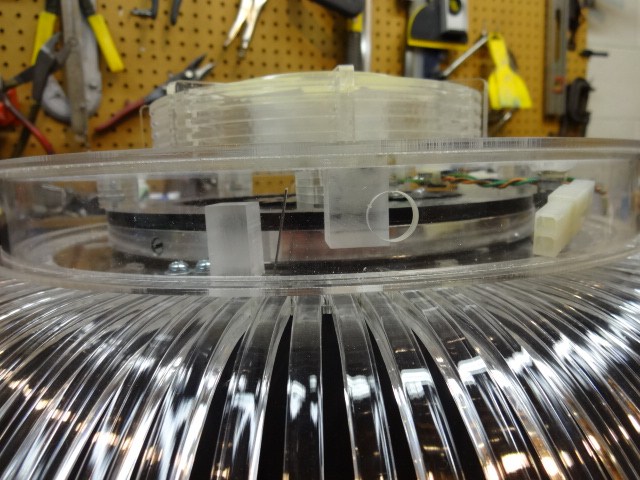

I finally got a chance to make another video of my Arm with the skin off. Now you can see just what make this monster move.

I'm afraid I kinda over did it and and took many minuets of content. In fact I ran out of memory in the camera and had to cut the session up in two parts. While the second part is uploading I'll post the first part.

Enjoy:

Hi all, here's part 2. Sorry it's so long. Enjoy!

Information can never be too long Dave. Great video and lots of information! Very nice job!

Dave - that is AWESOME!

Question: are you using resin claws and wrist cuffs, or Craig's fiberglass wrist cuffs?

Man, I'd hate to get hit by one of those suckers if he starts flailing!