Hi all,

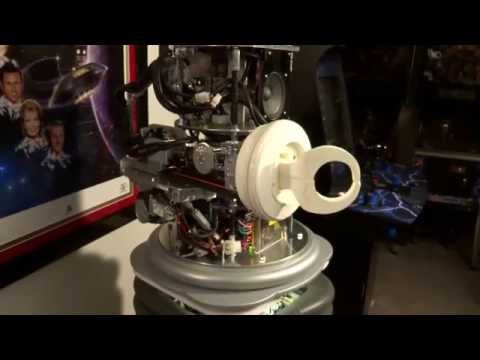

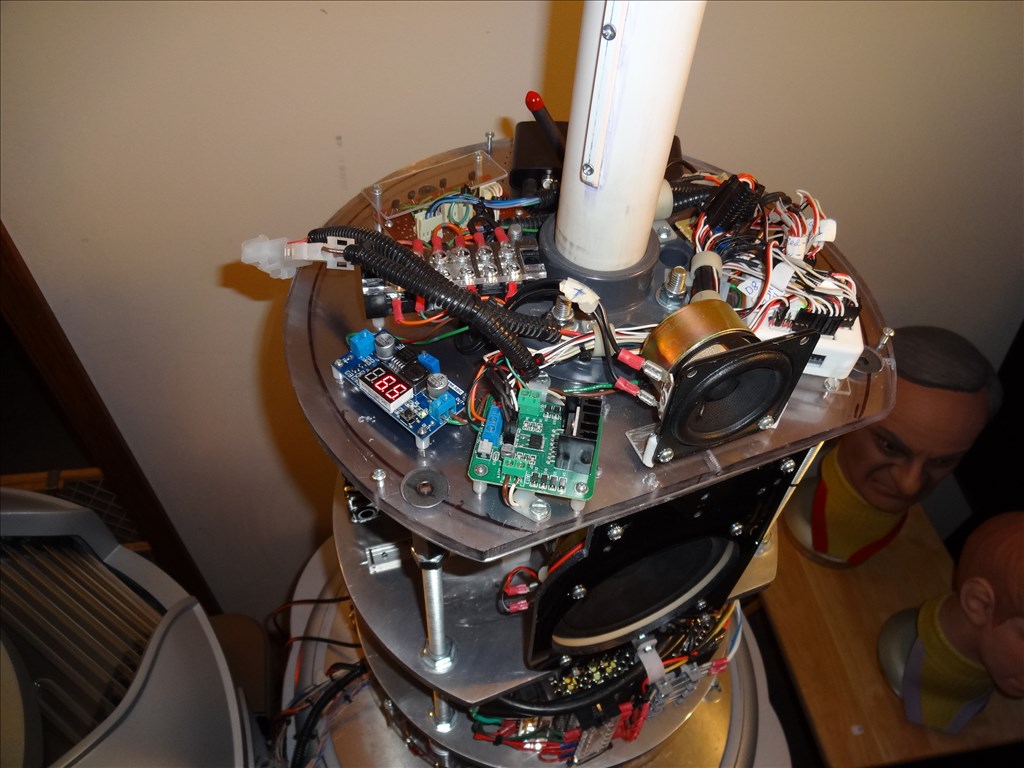

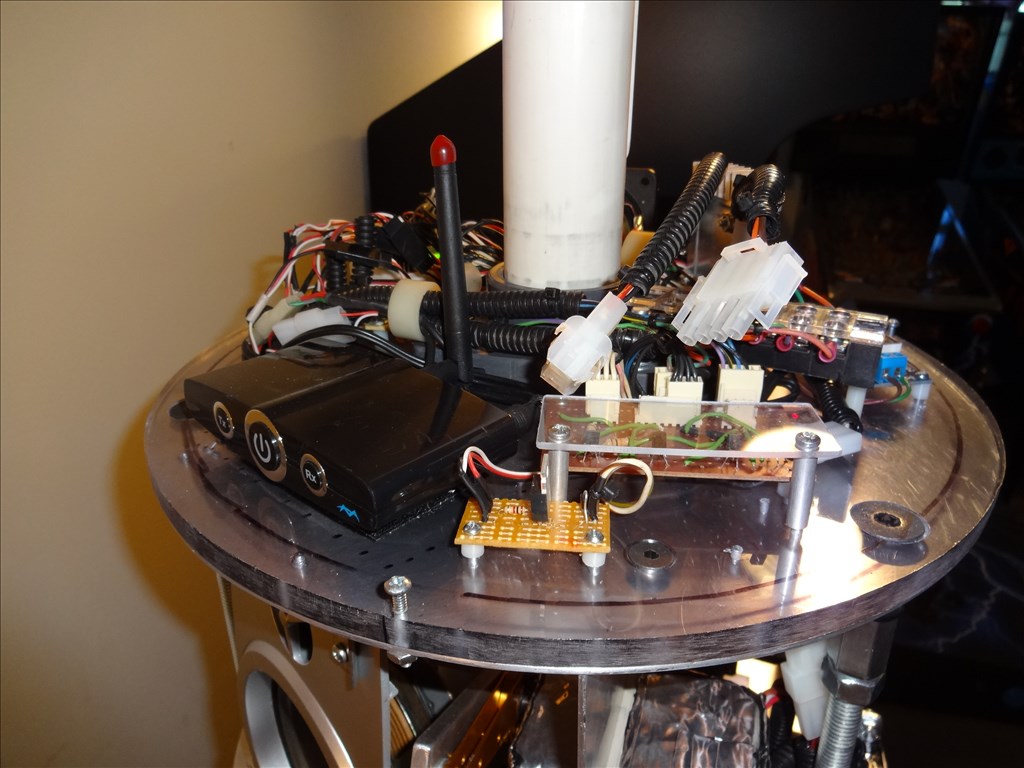

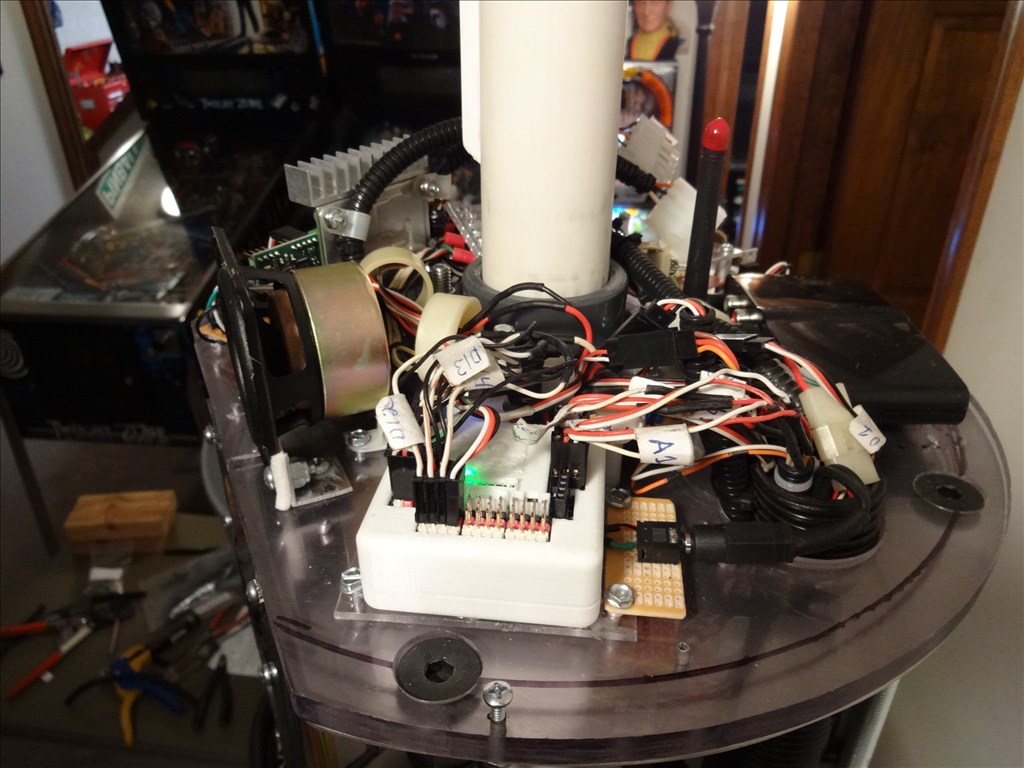

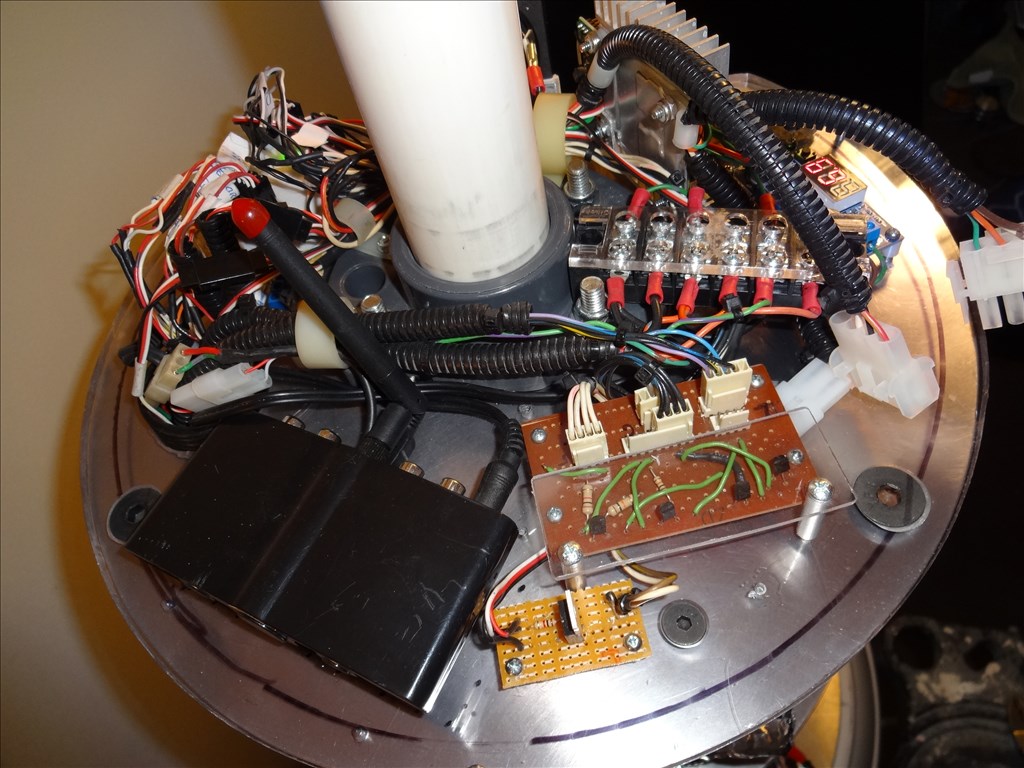

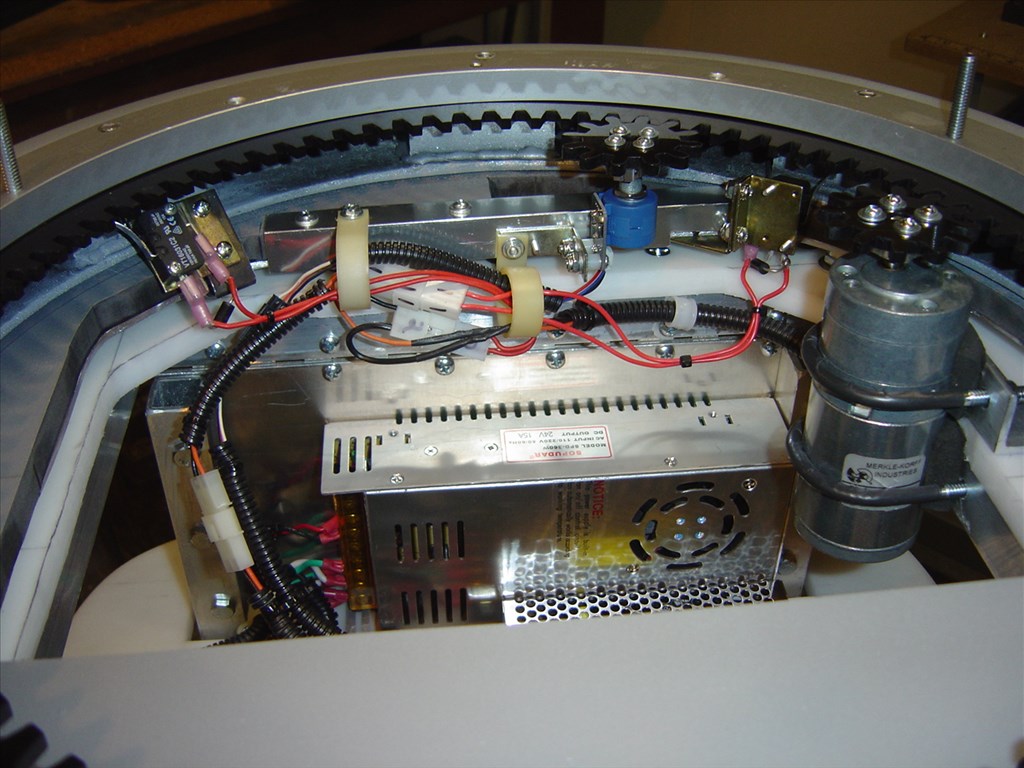

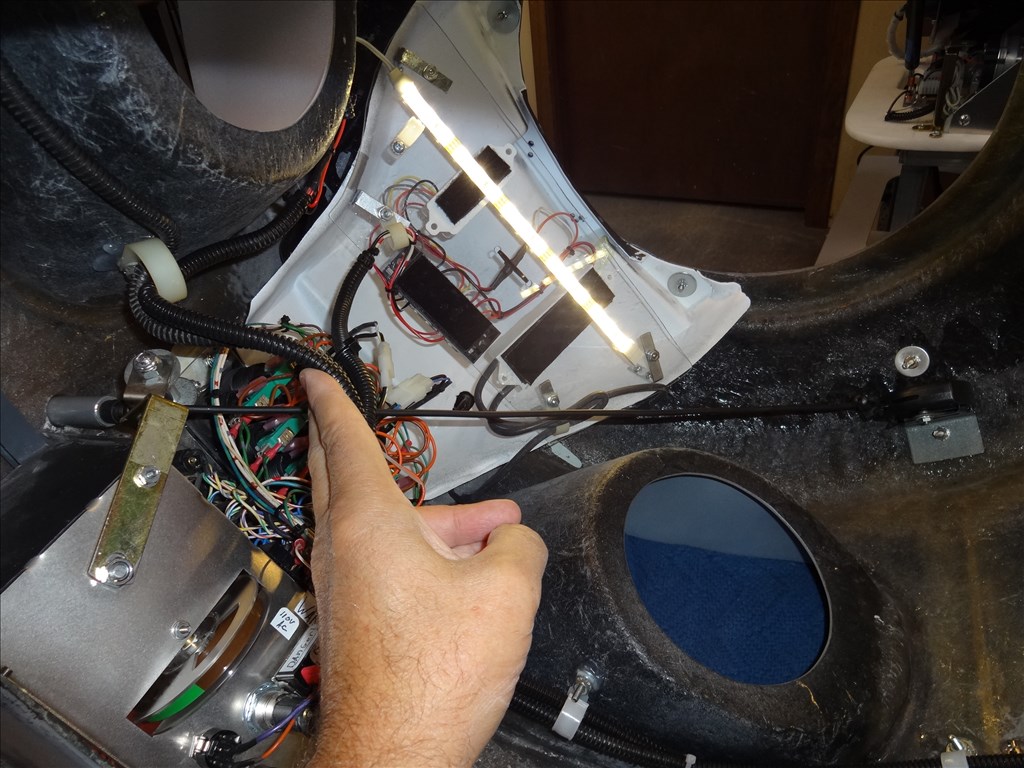

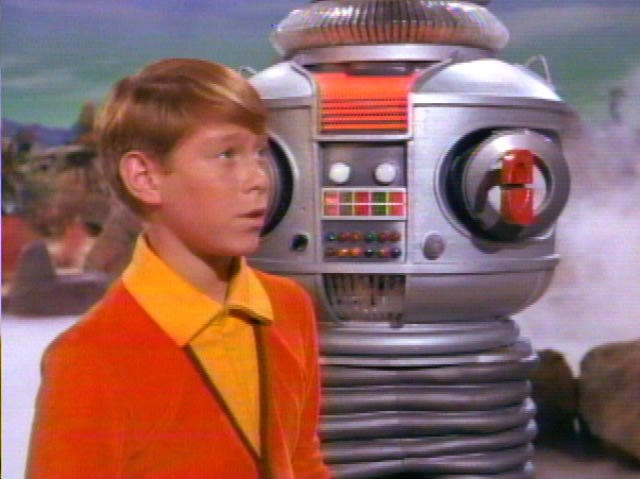

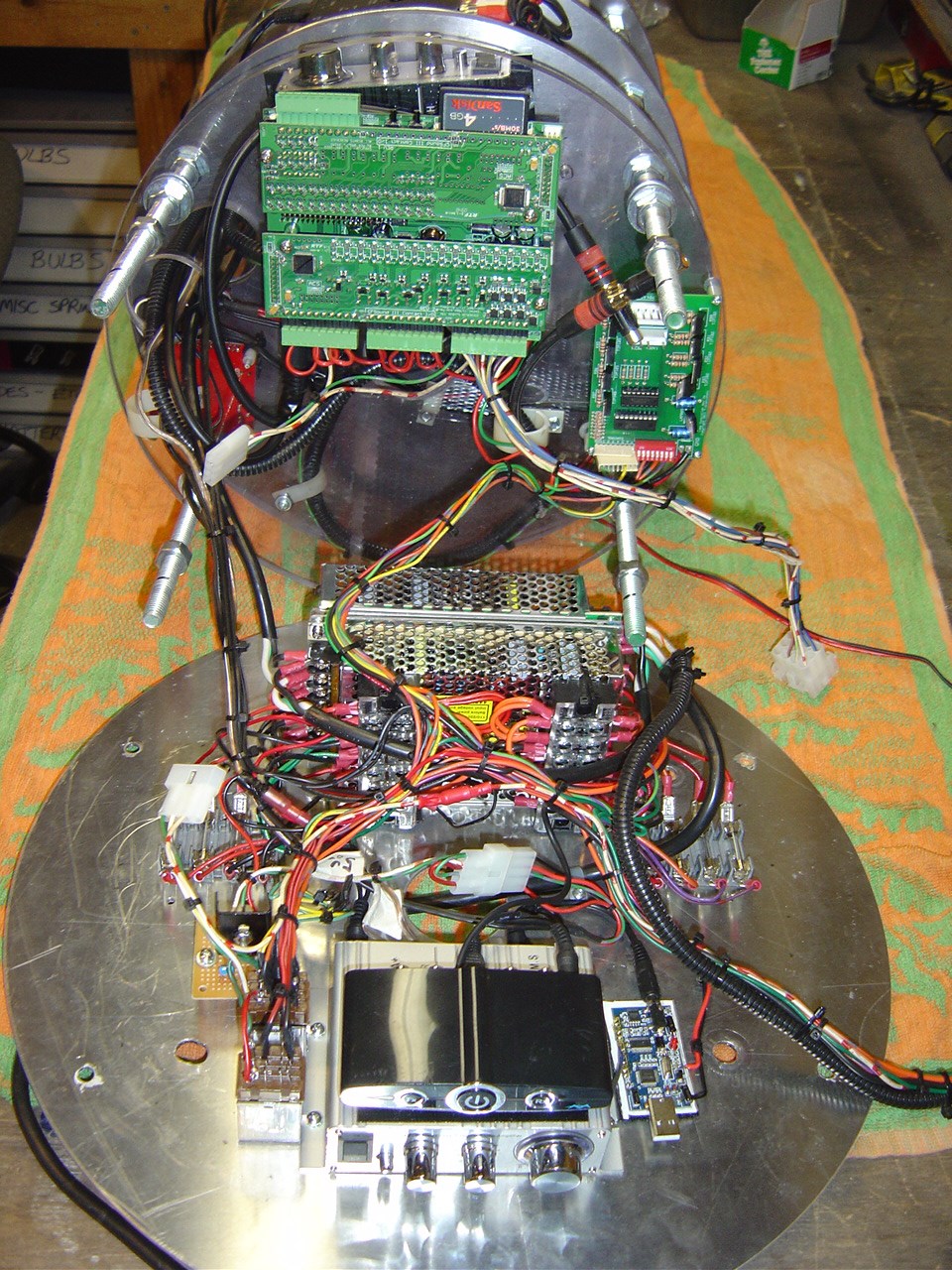

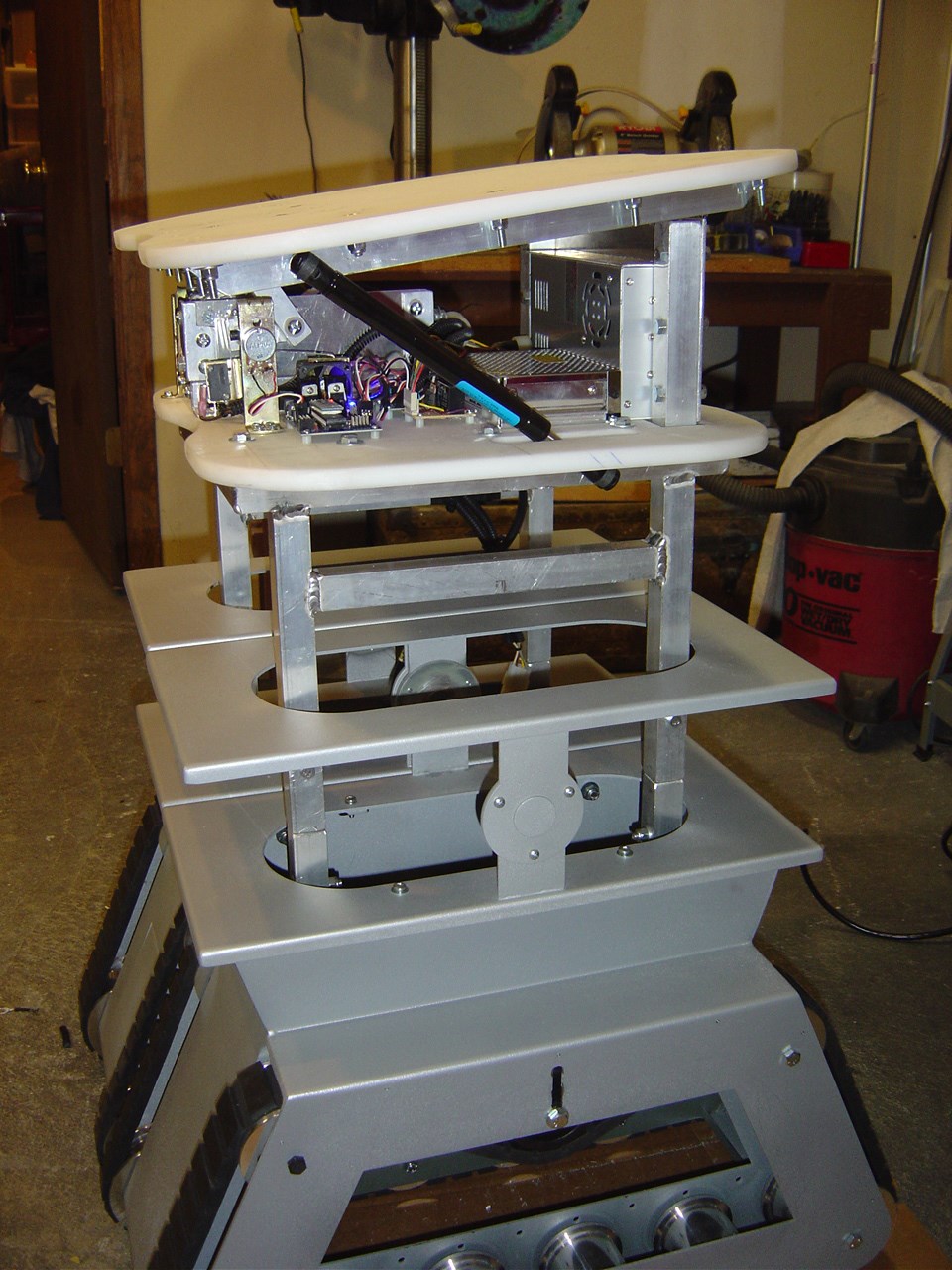

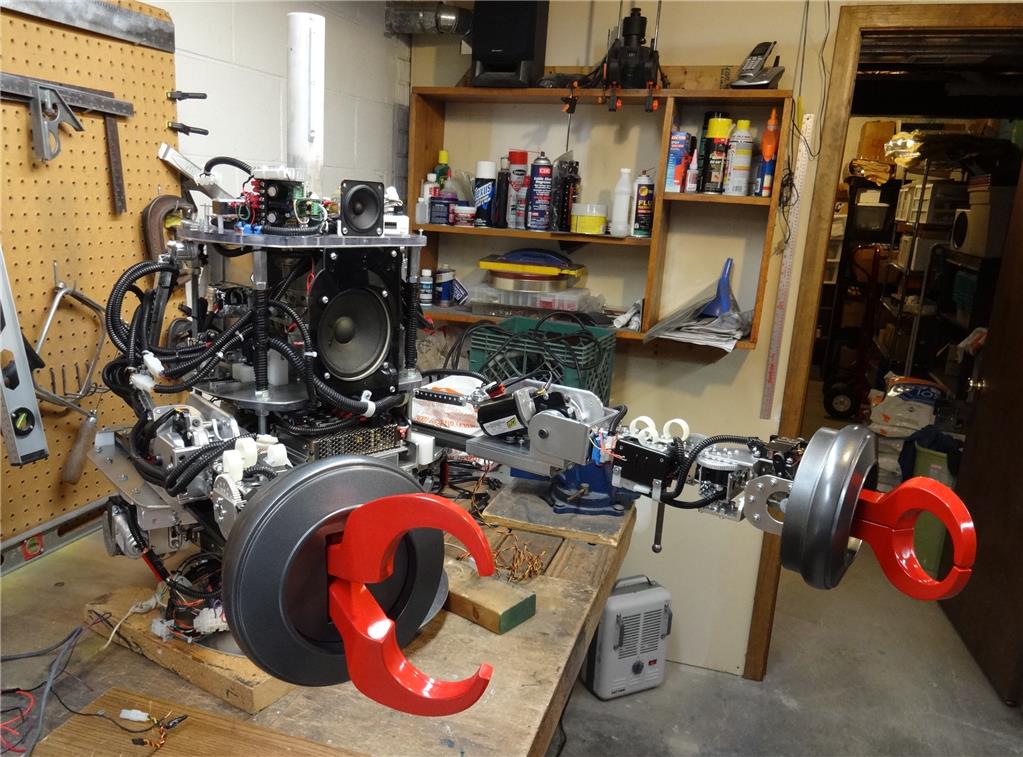

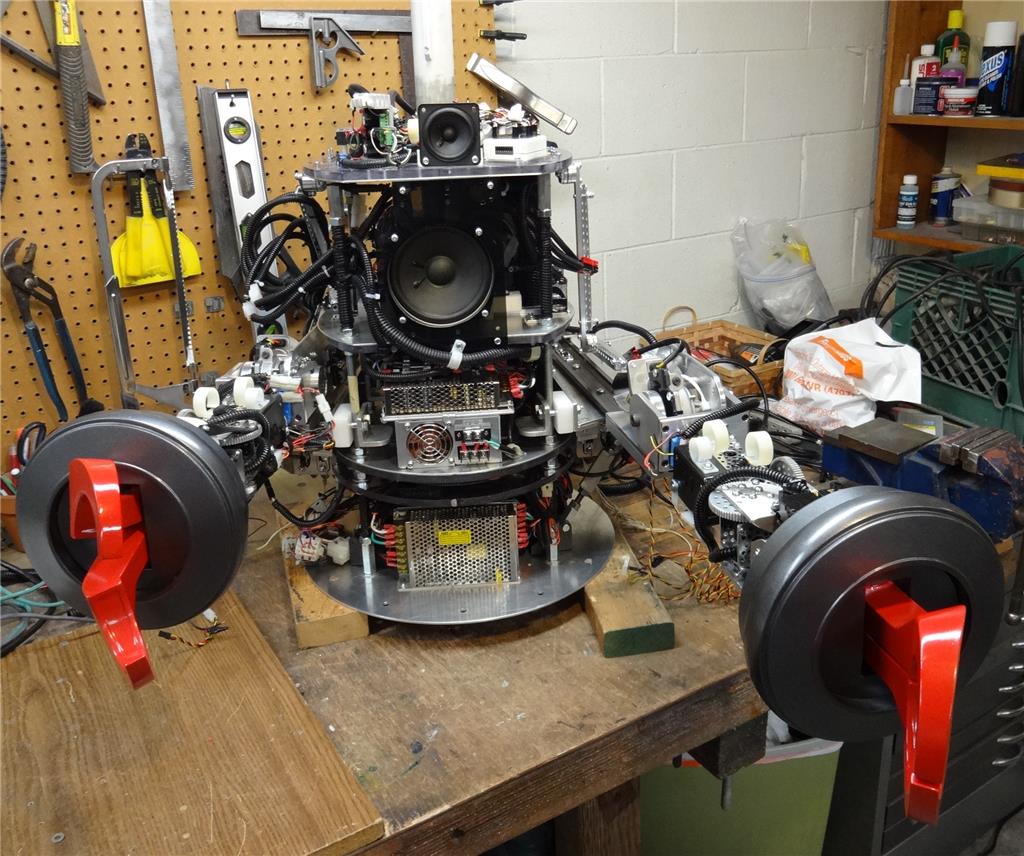

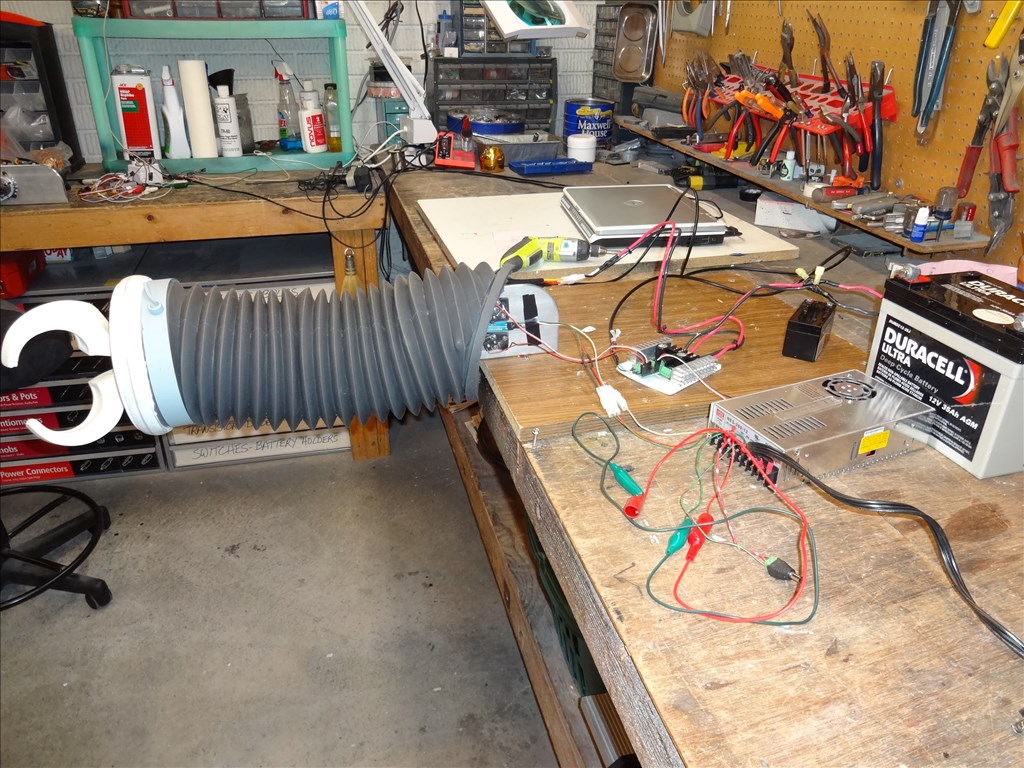

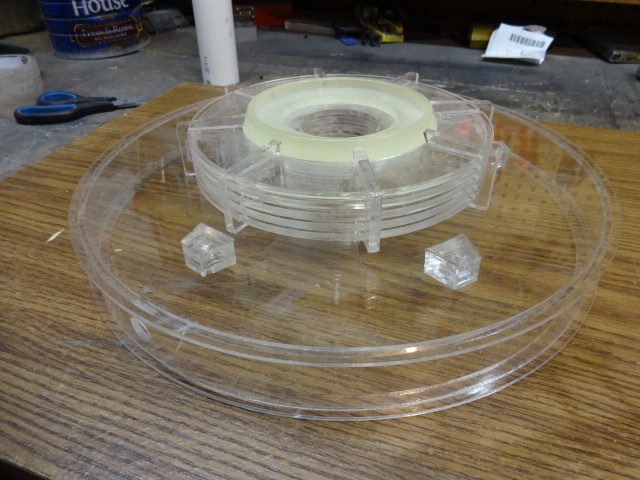

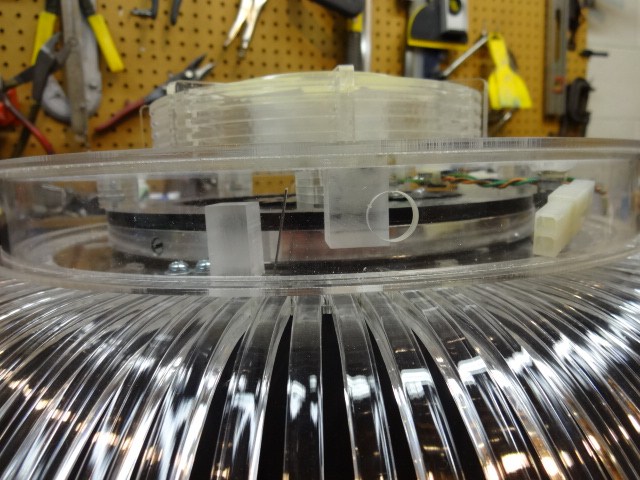

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

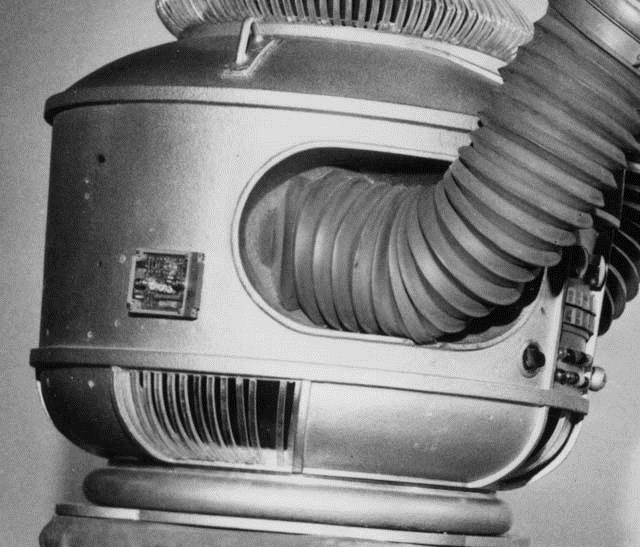

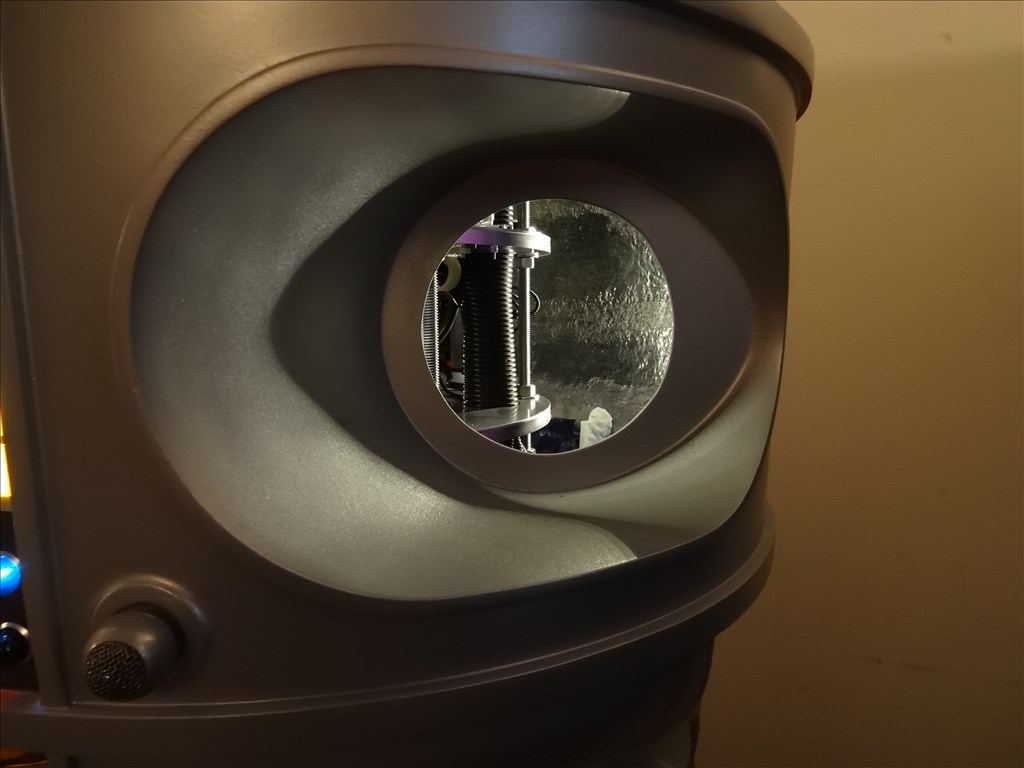

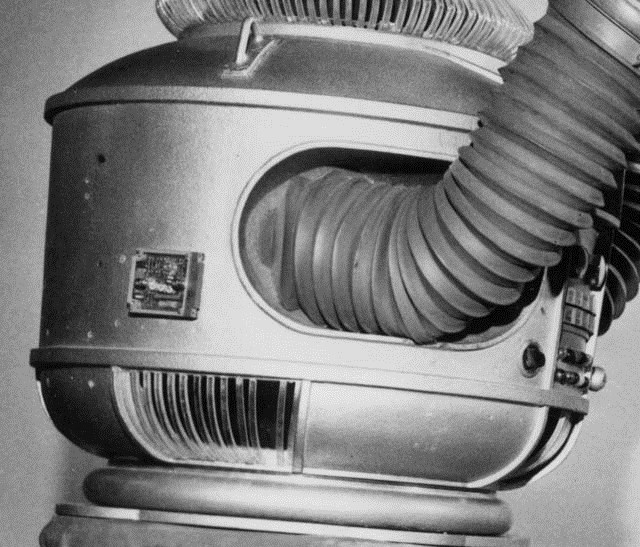

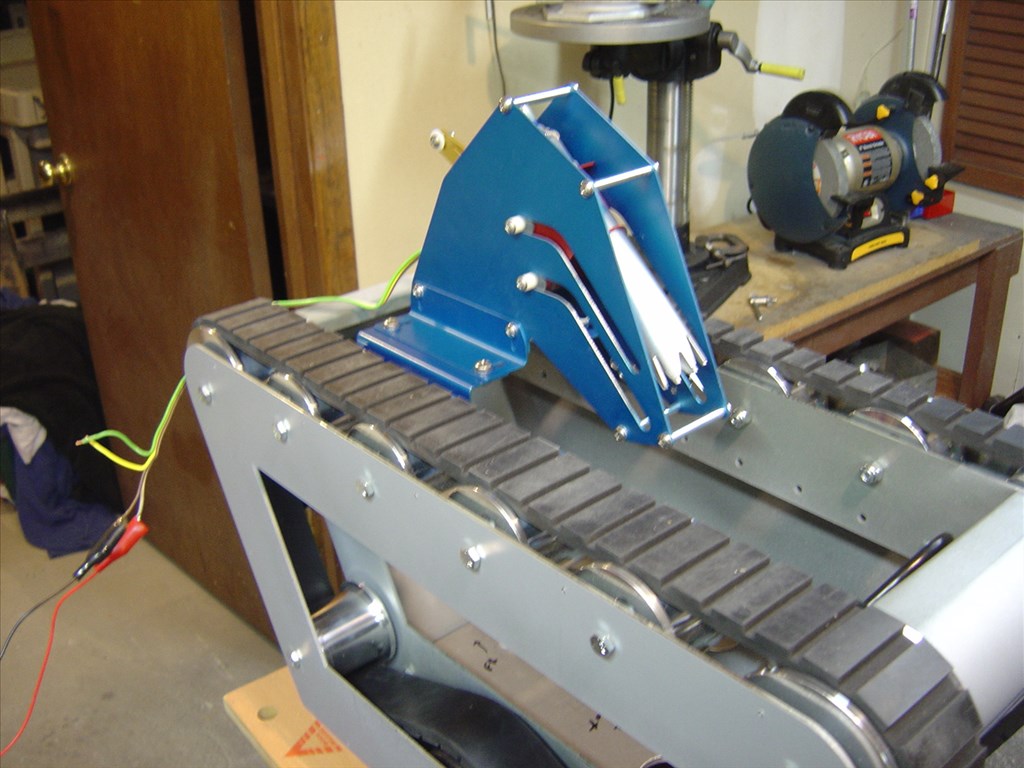

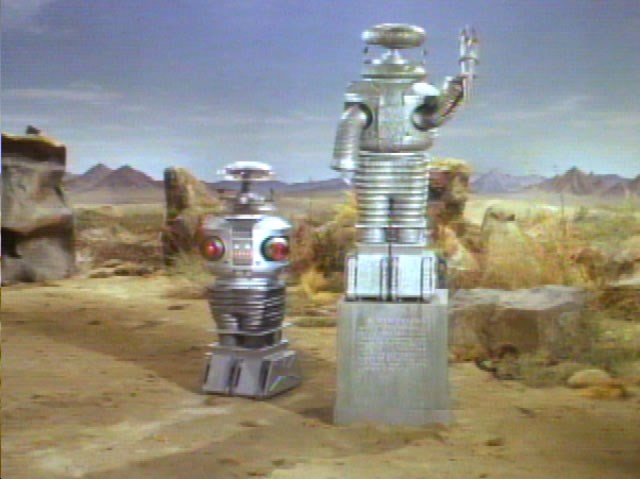

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

Ericez's Mini Chappie Project

DJ's Six Hexapod Robot Tracking Ball

-635353562186322812.png)

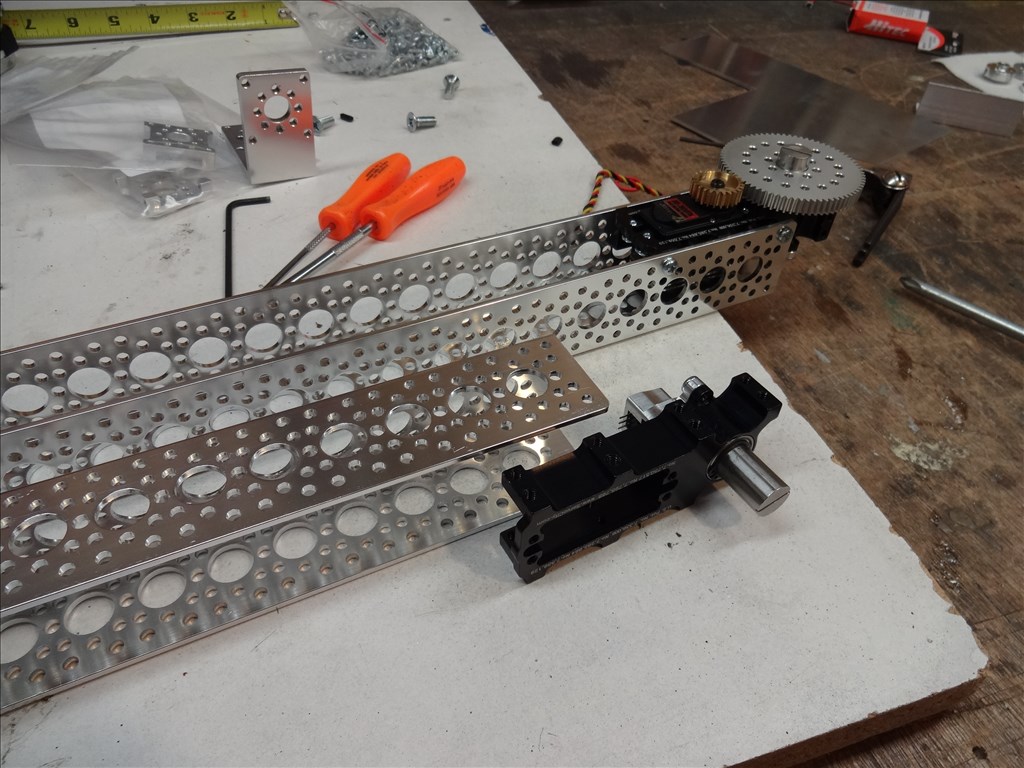

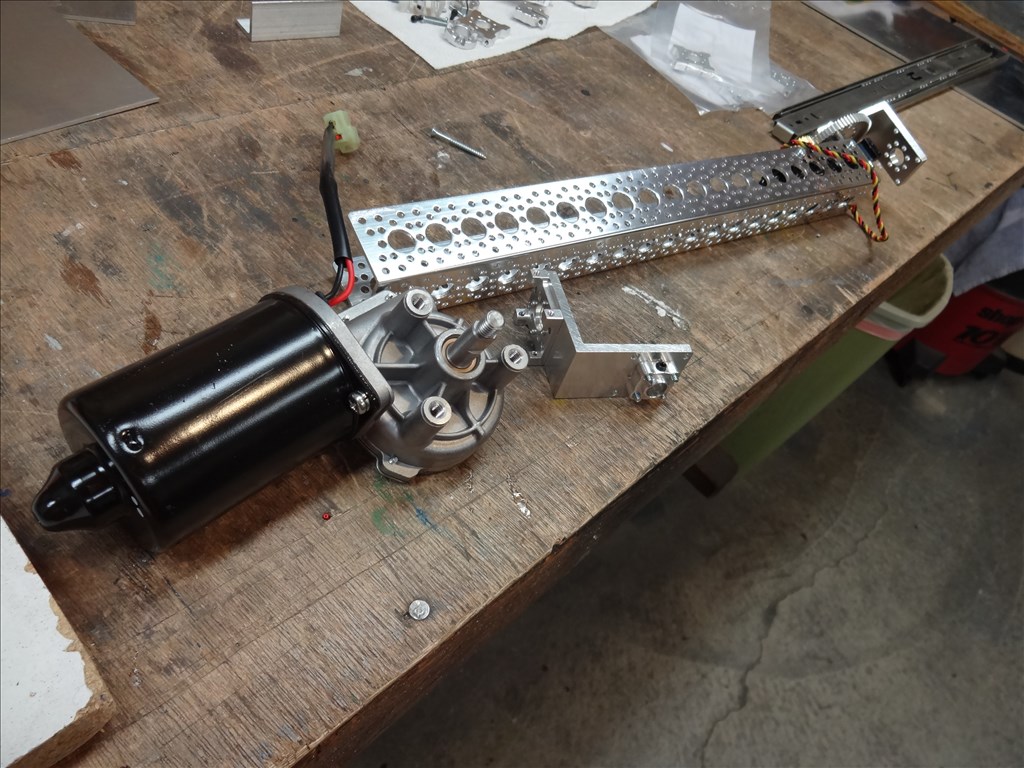

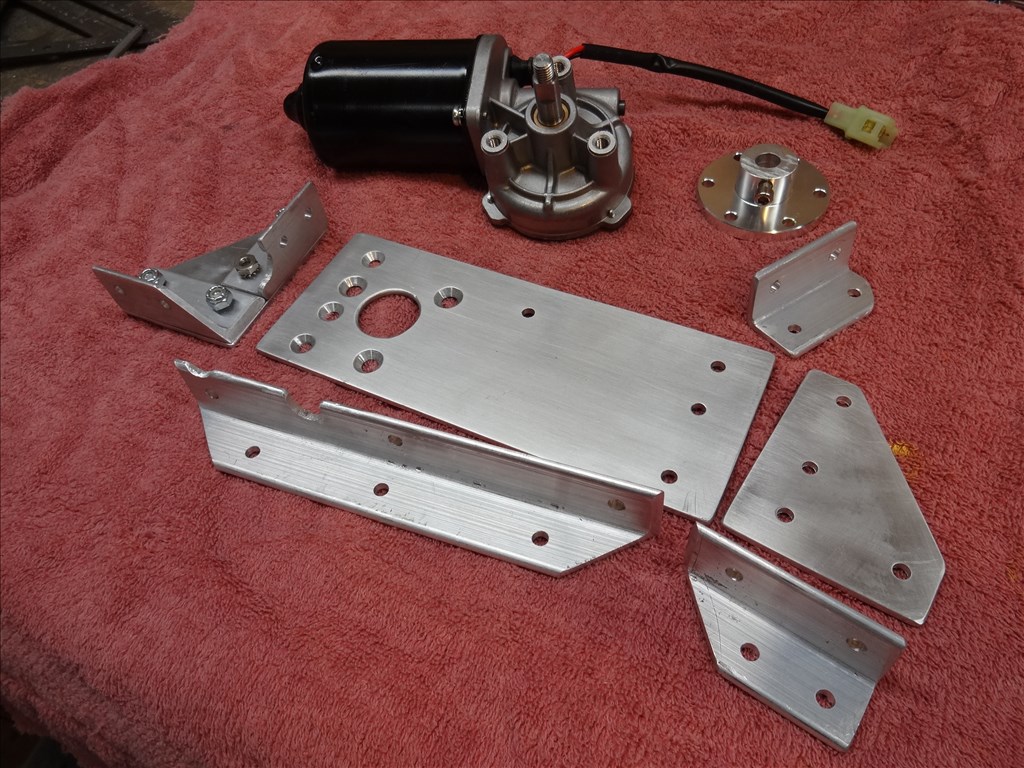

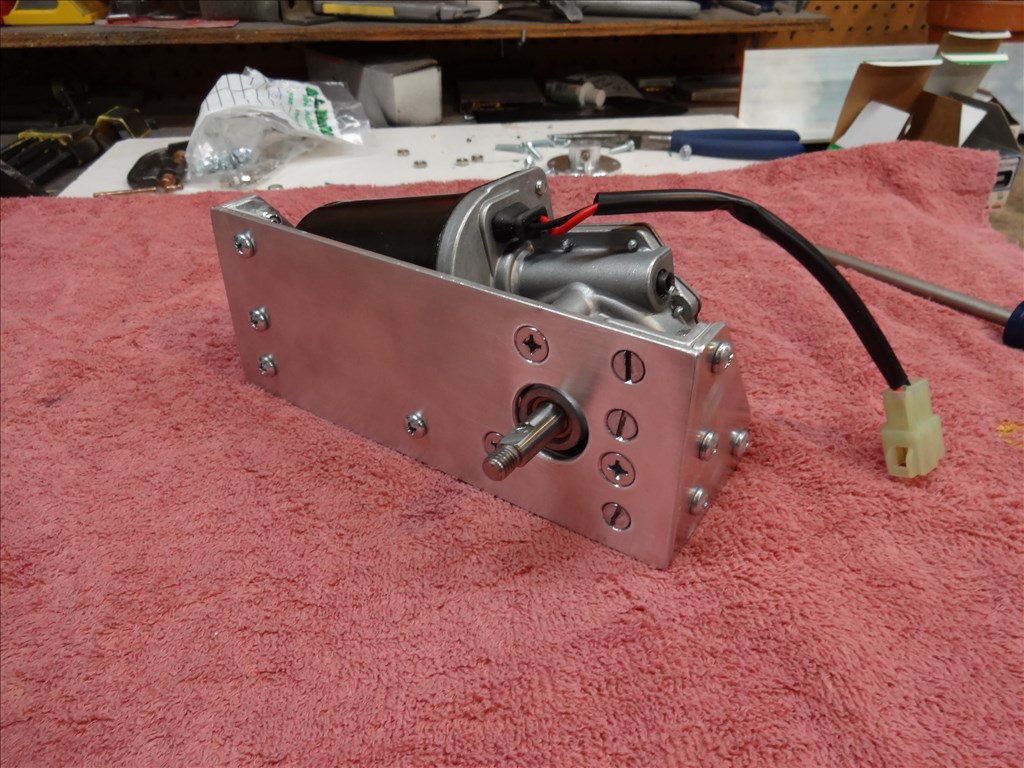

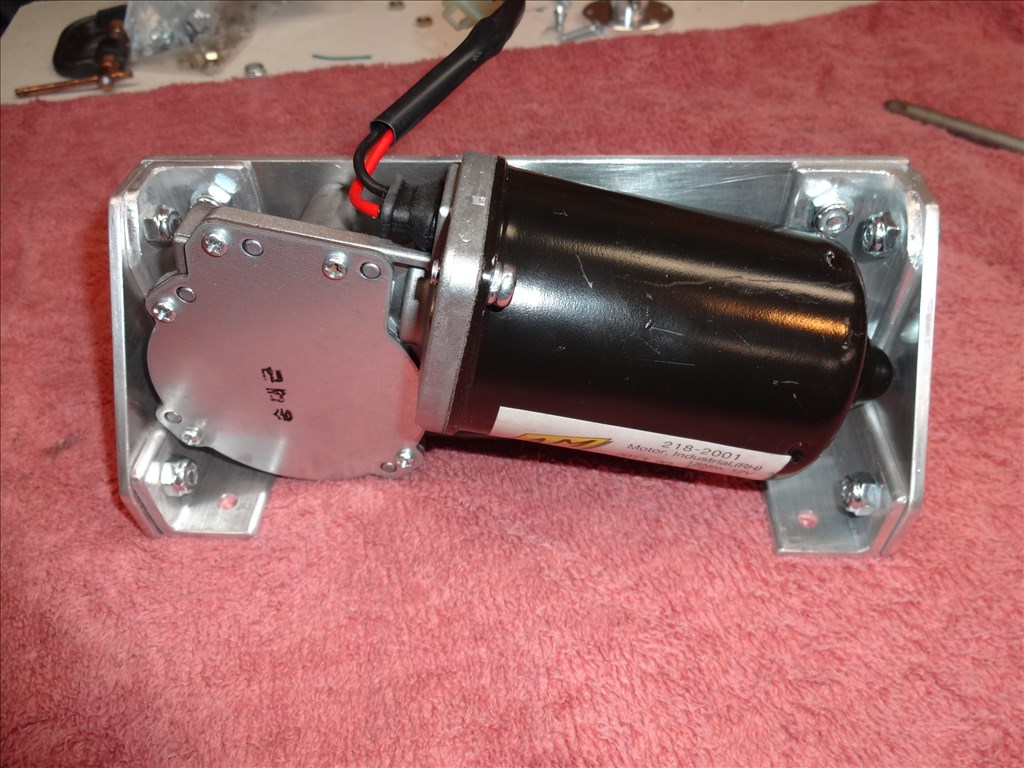

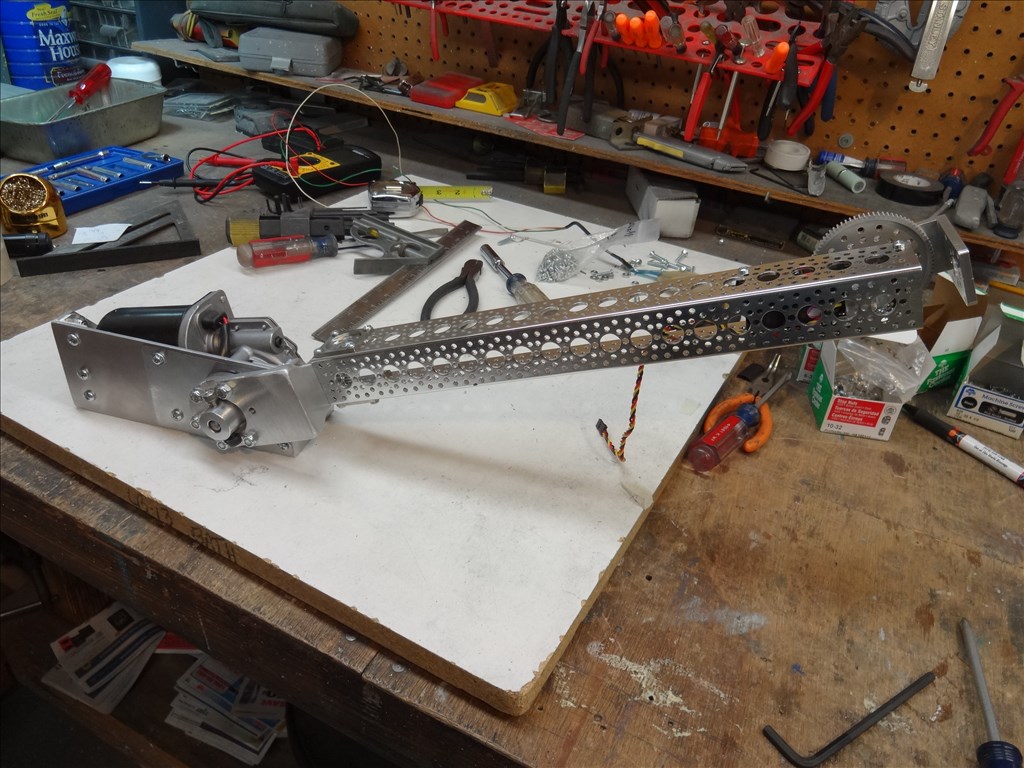

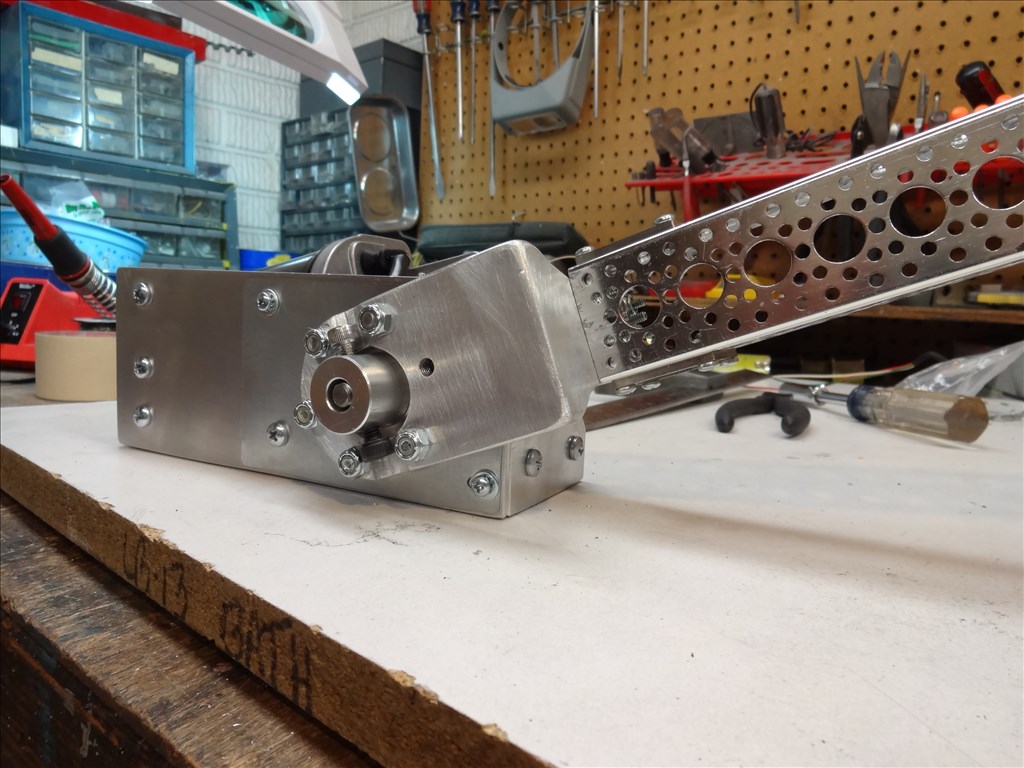

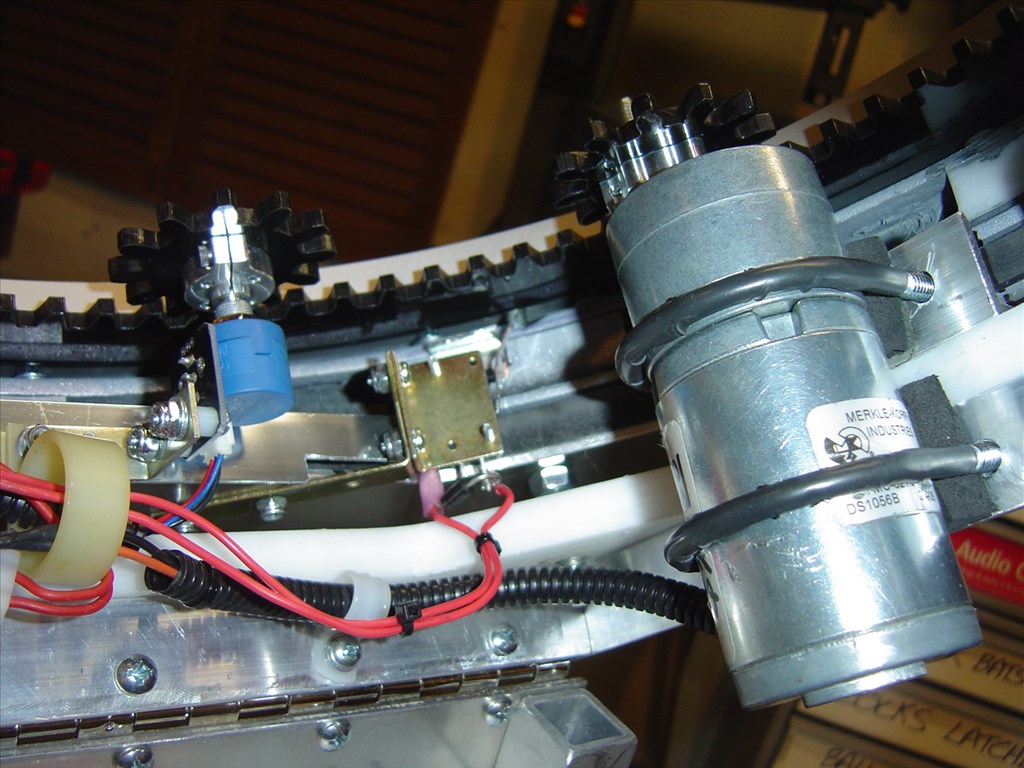

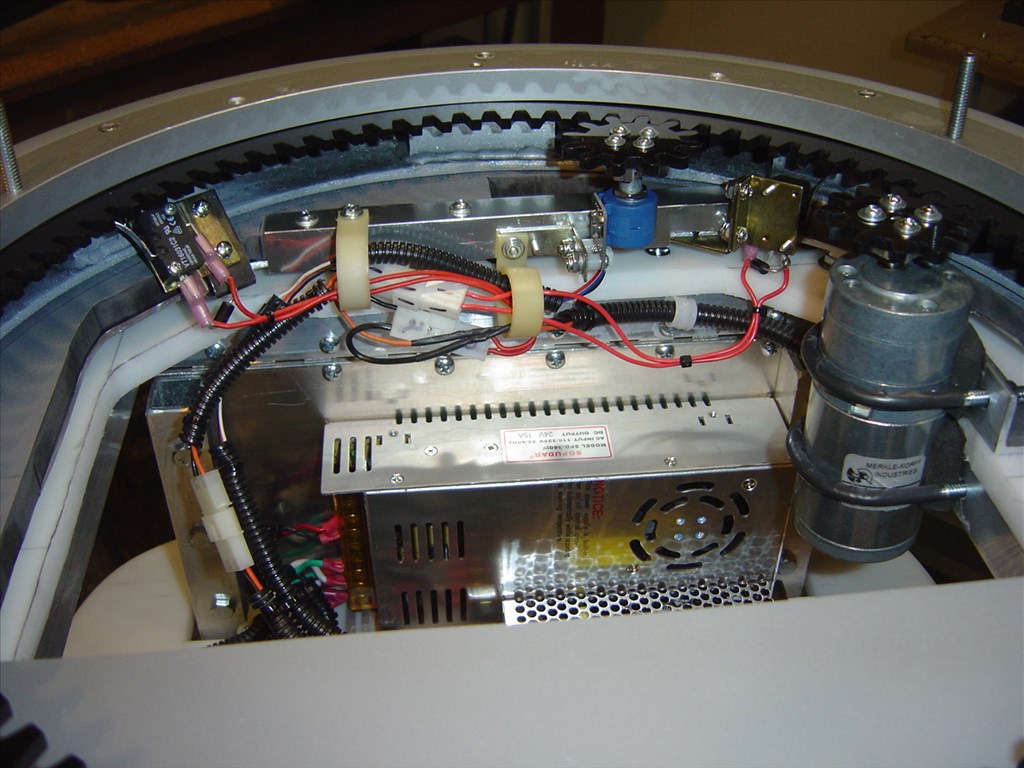

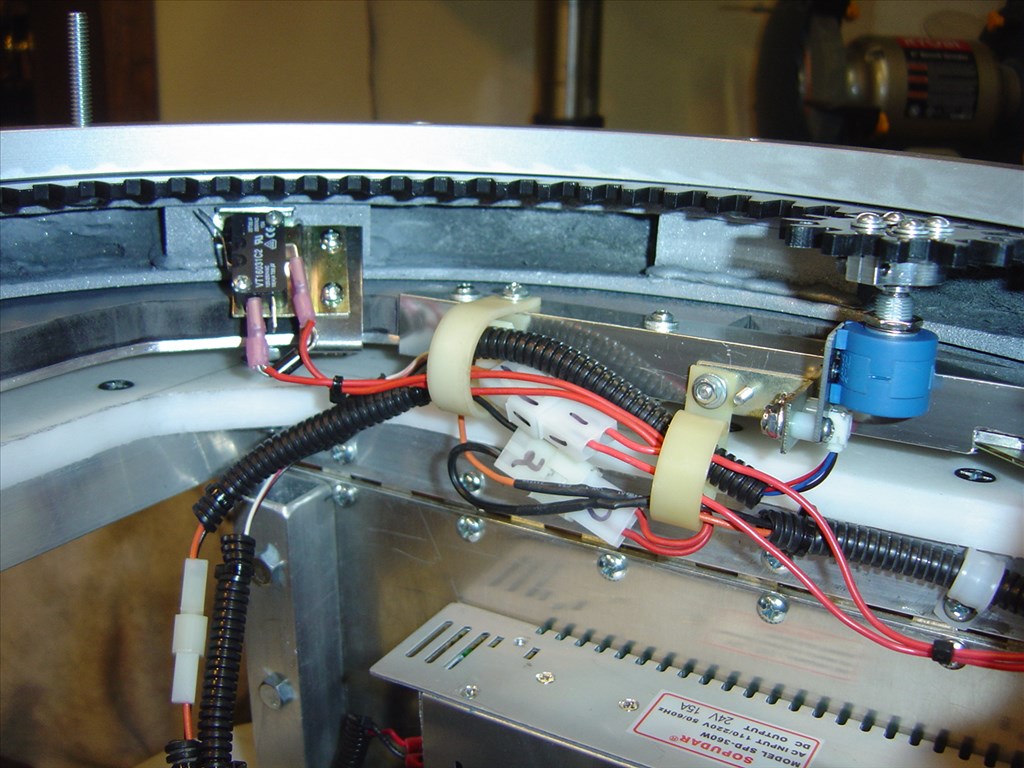

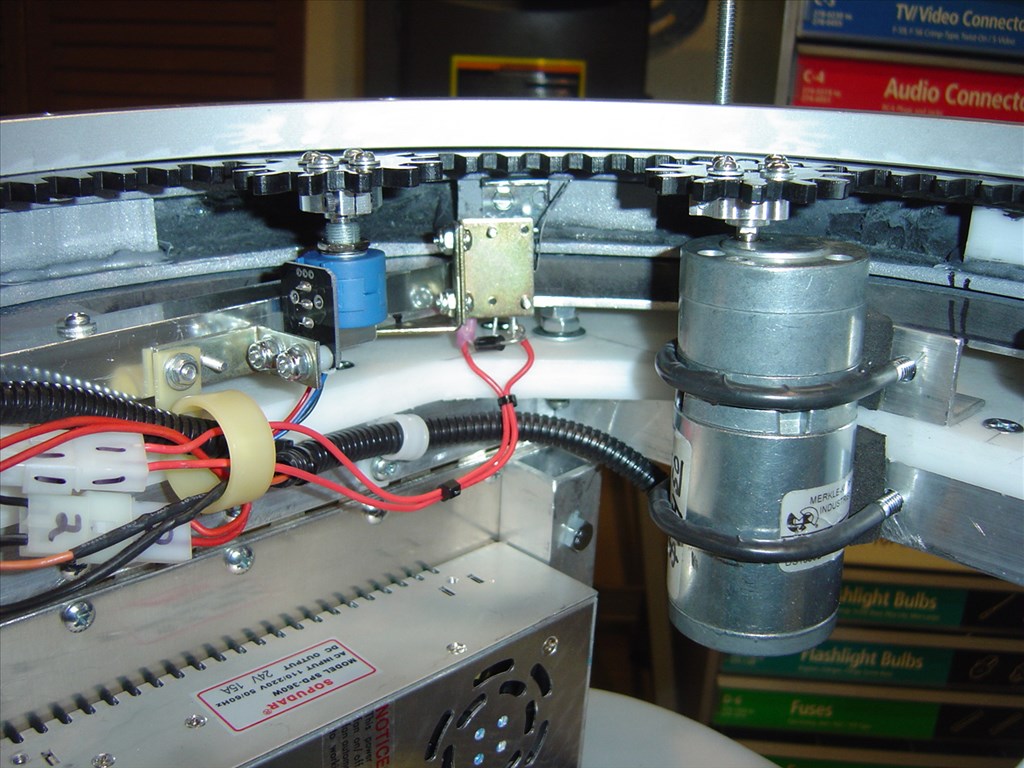

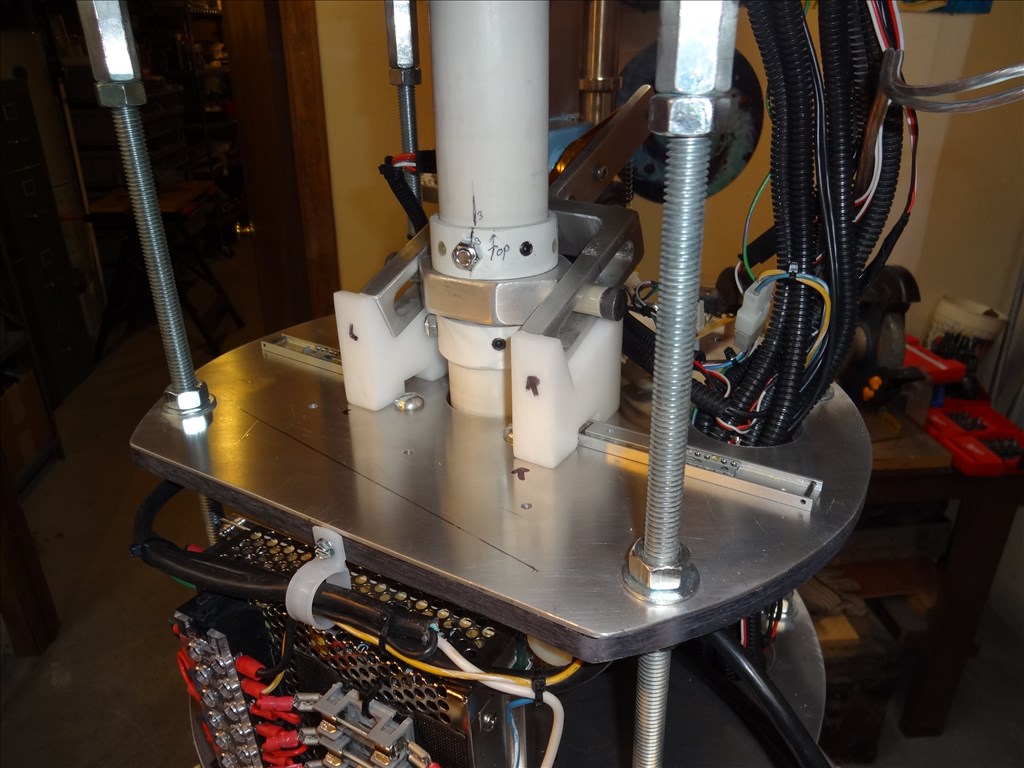

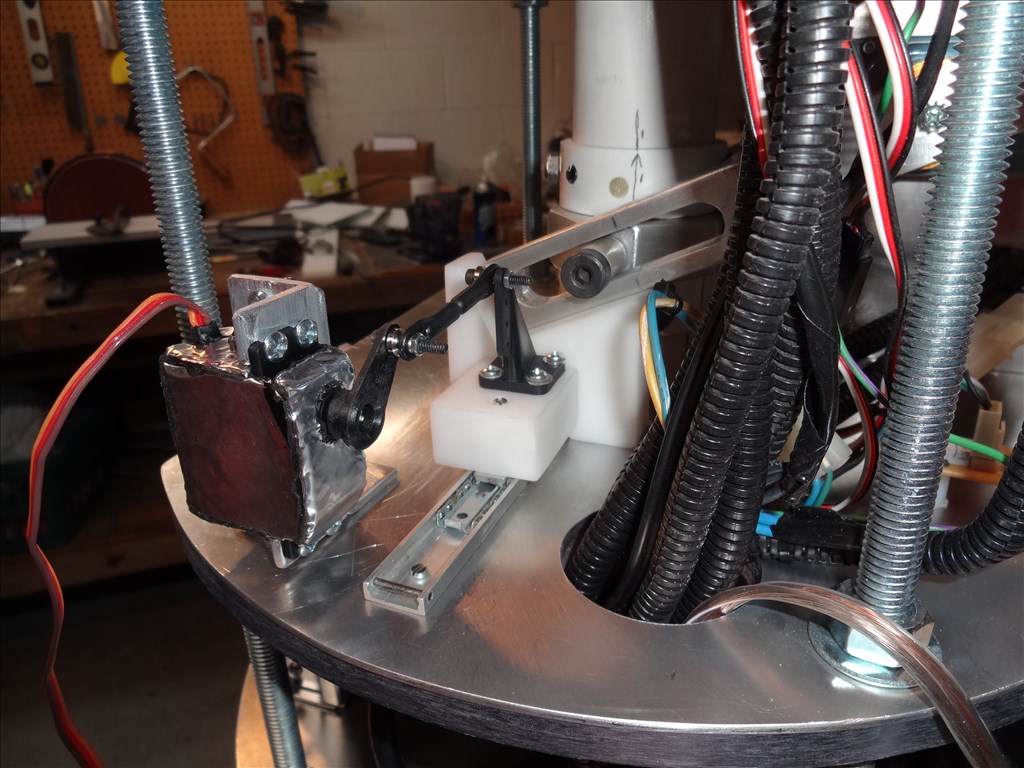

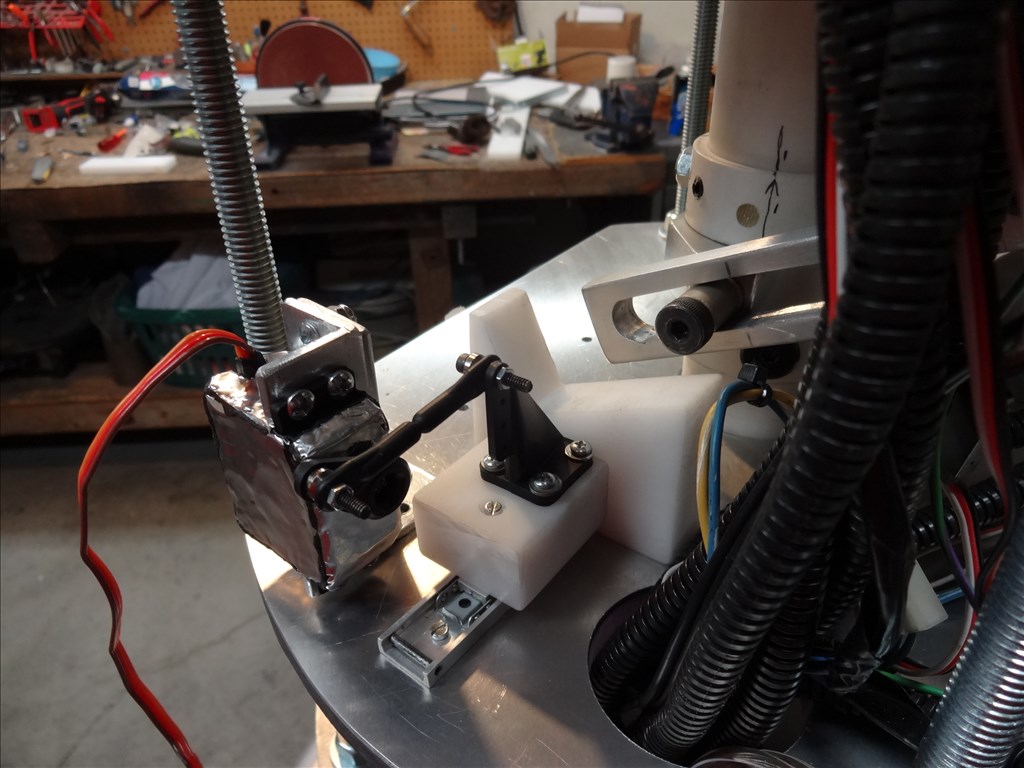

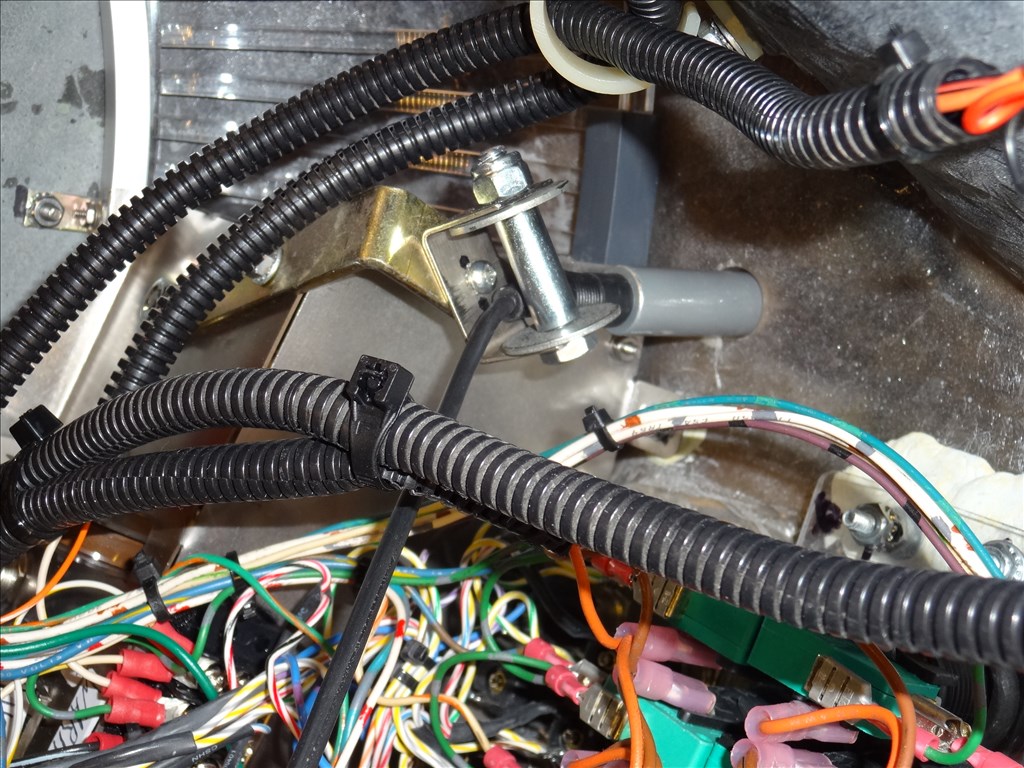

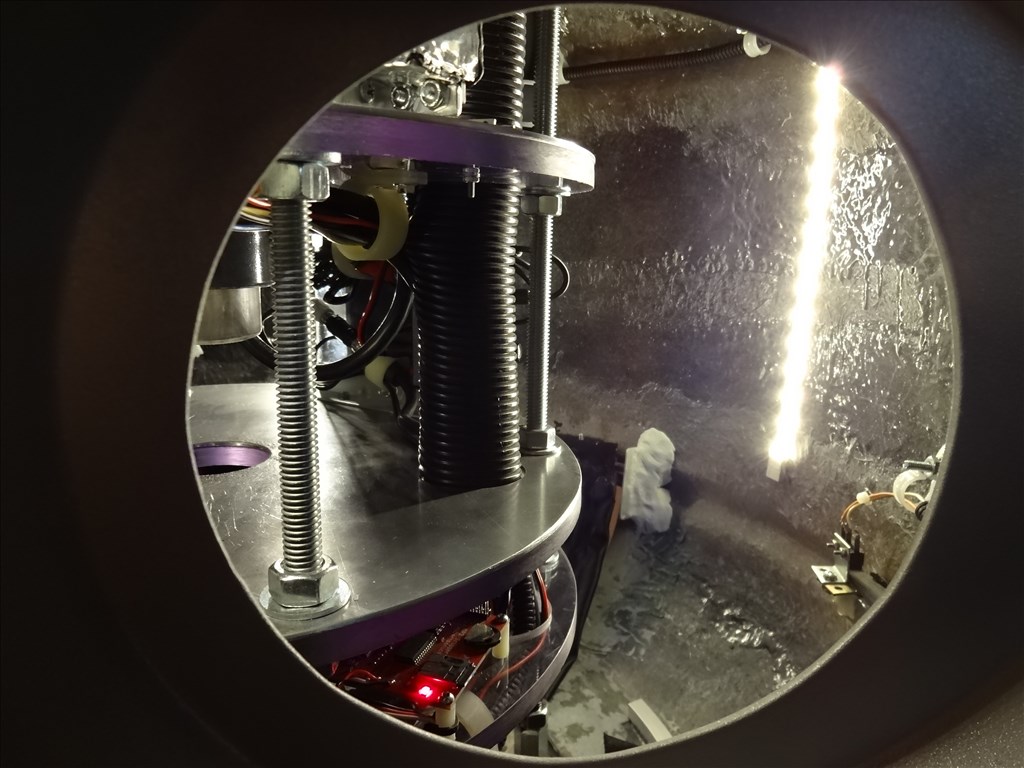

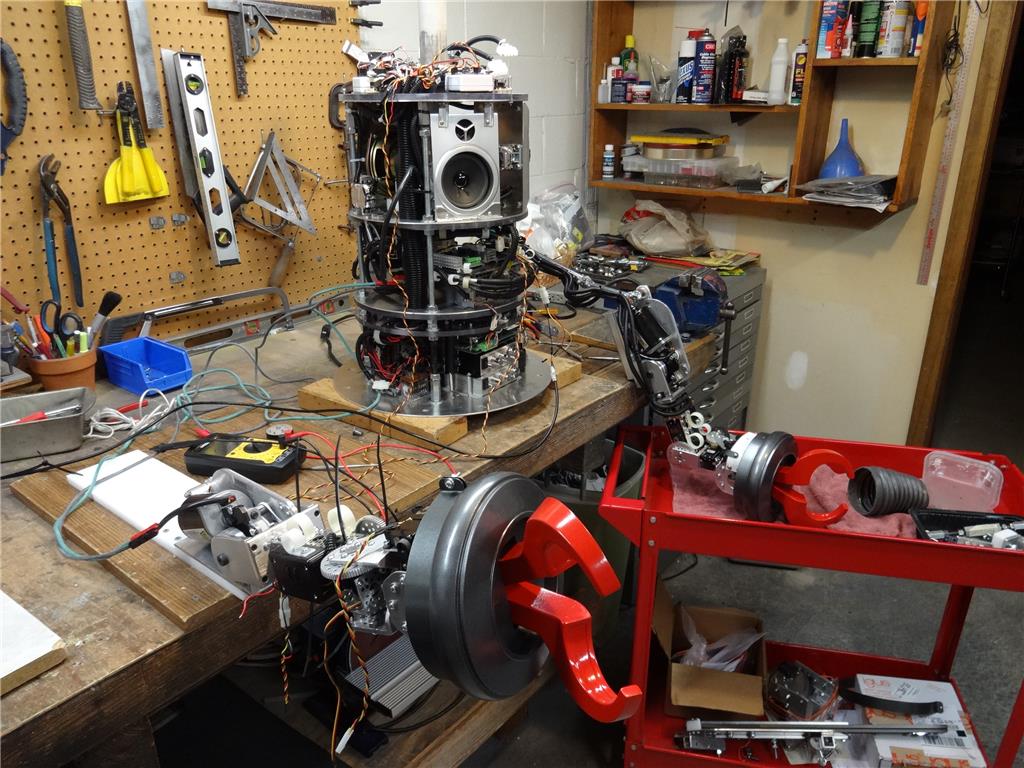

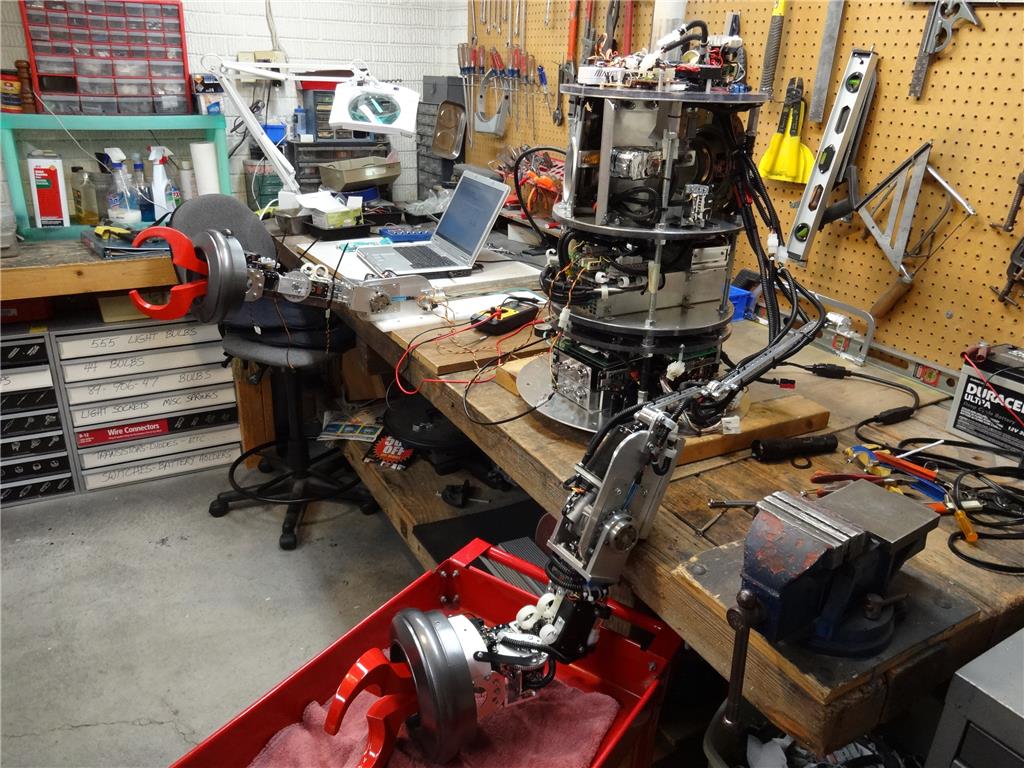

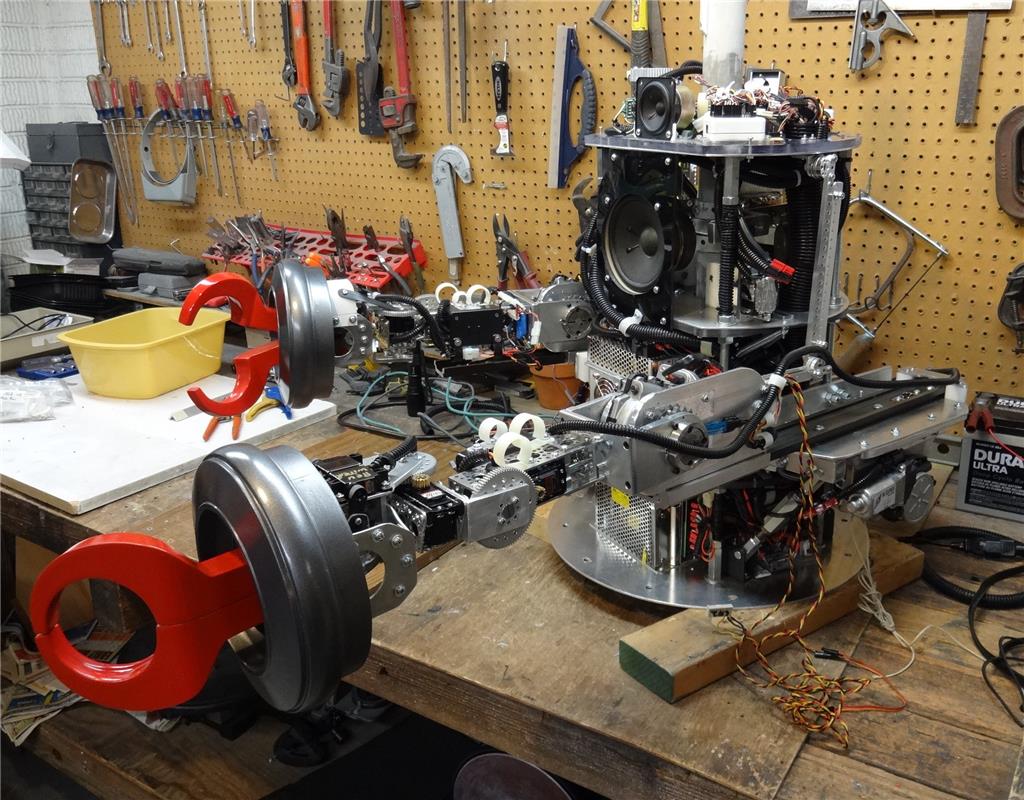

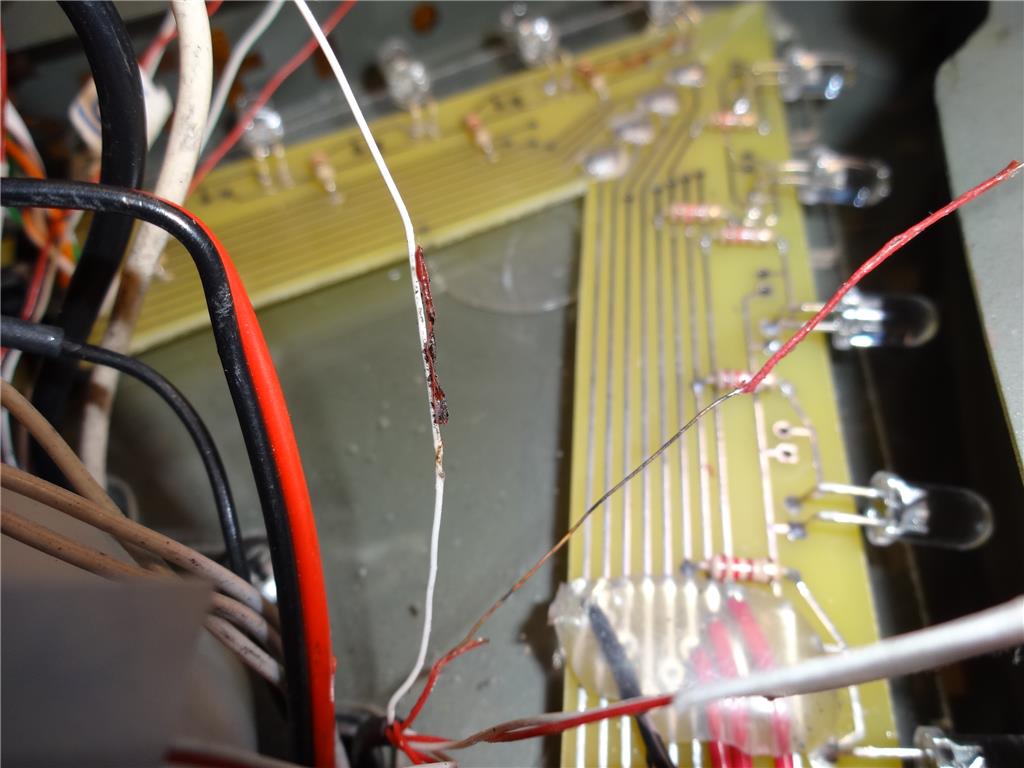

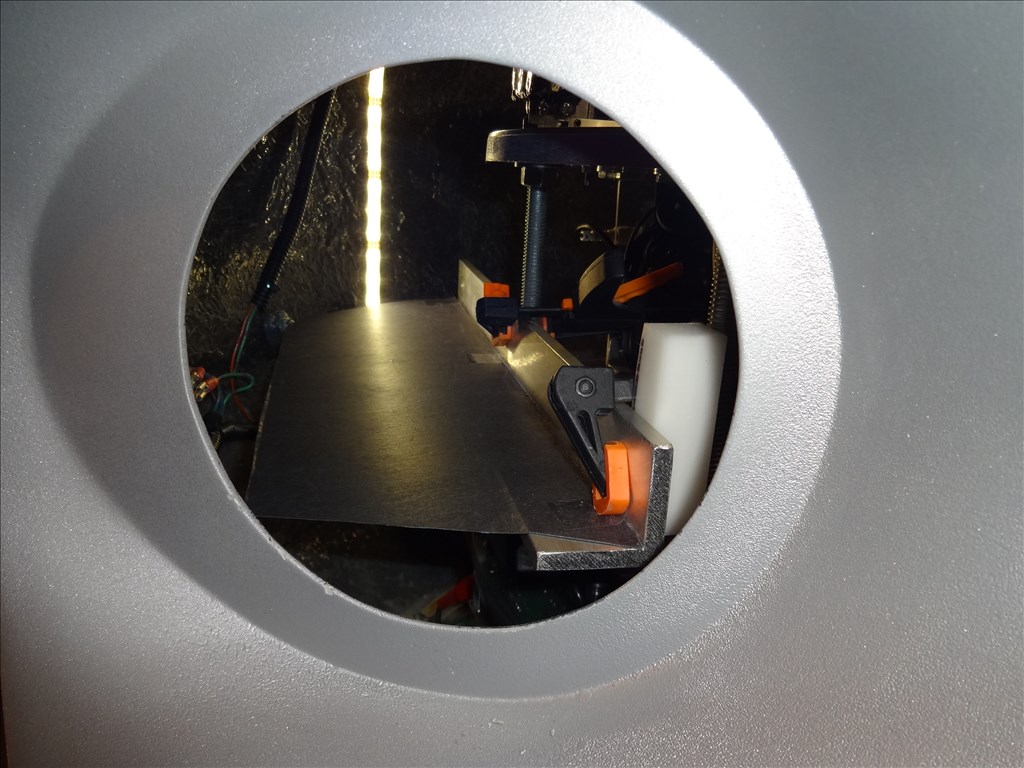

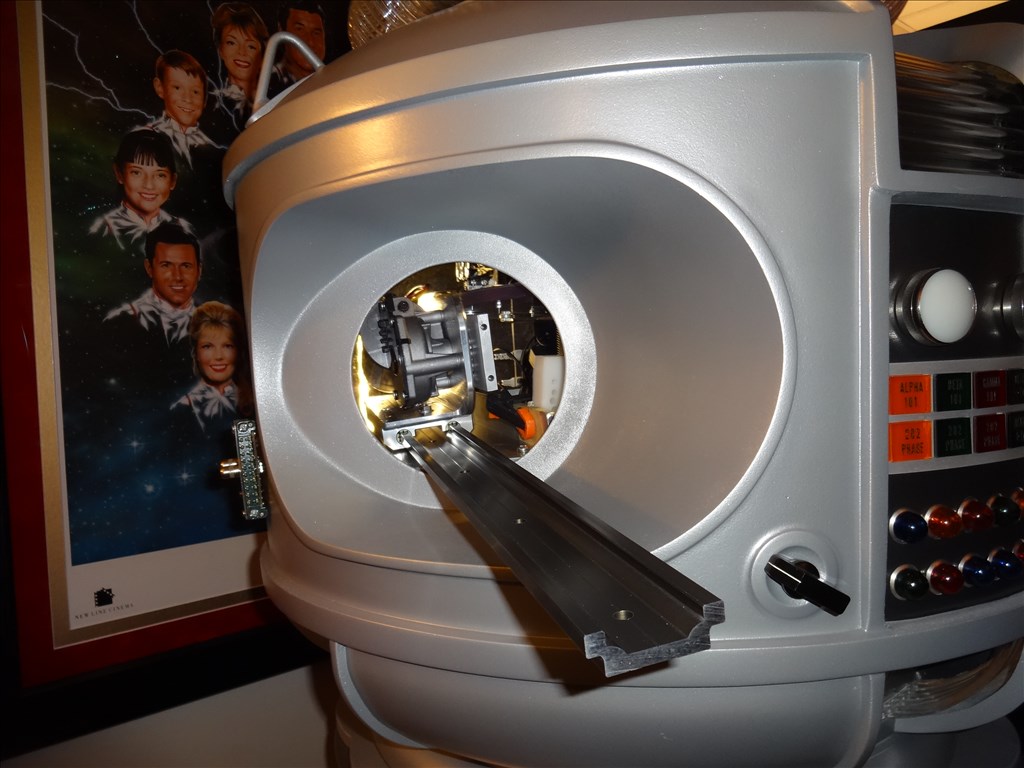

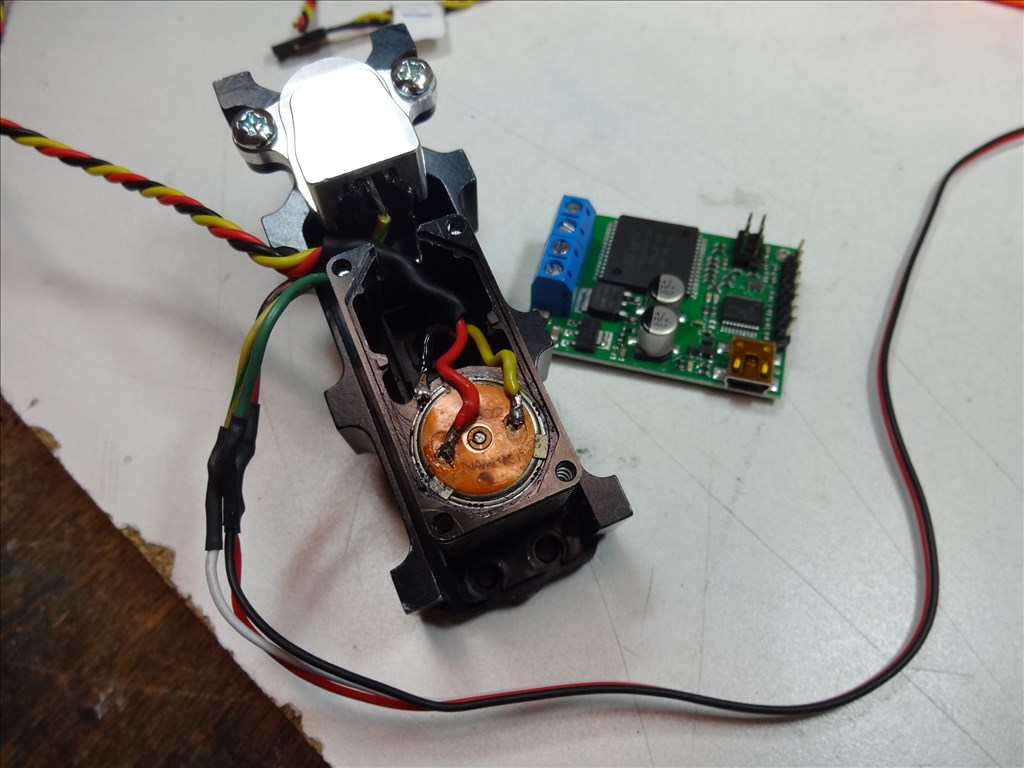

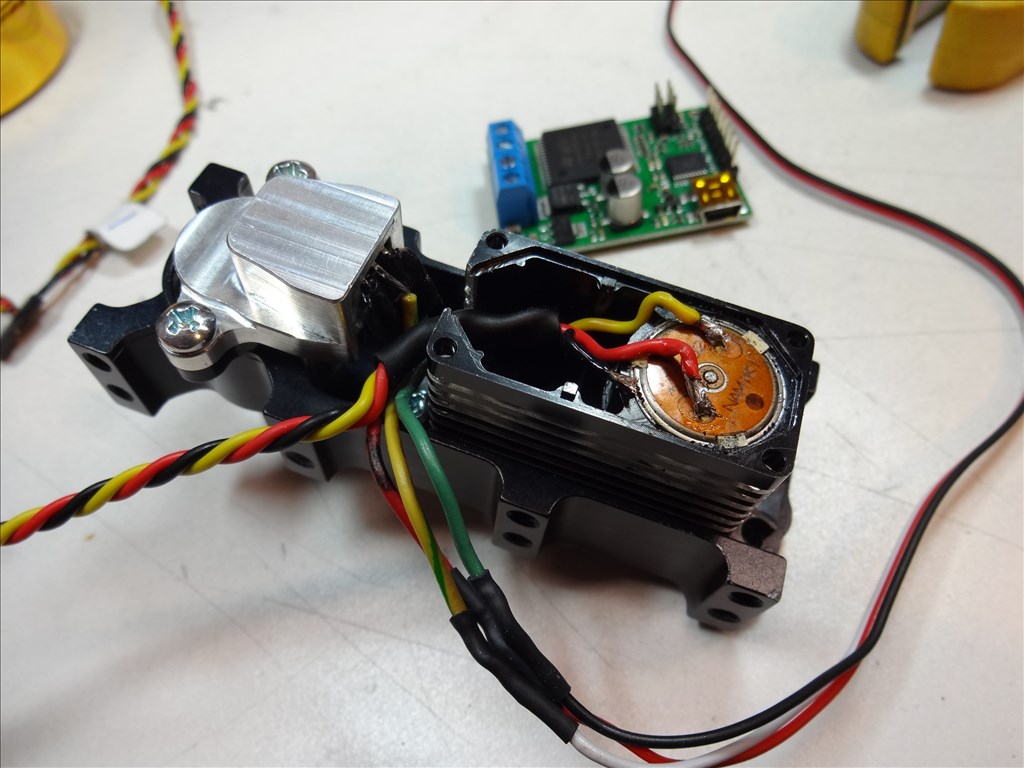

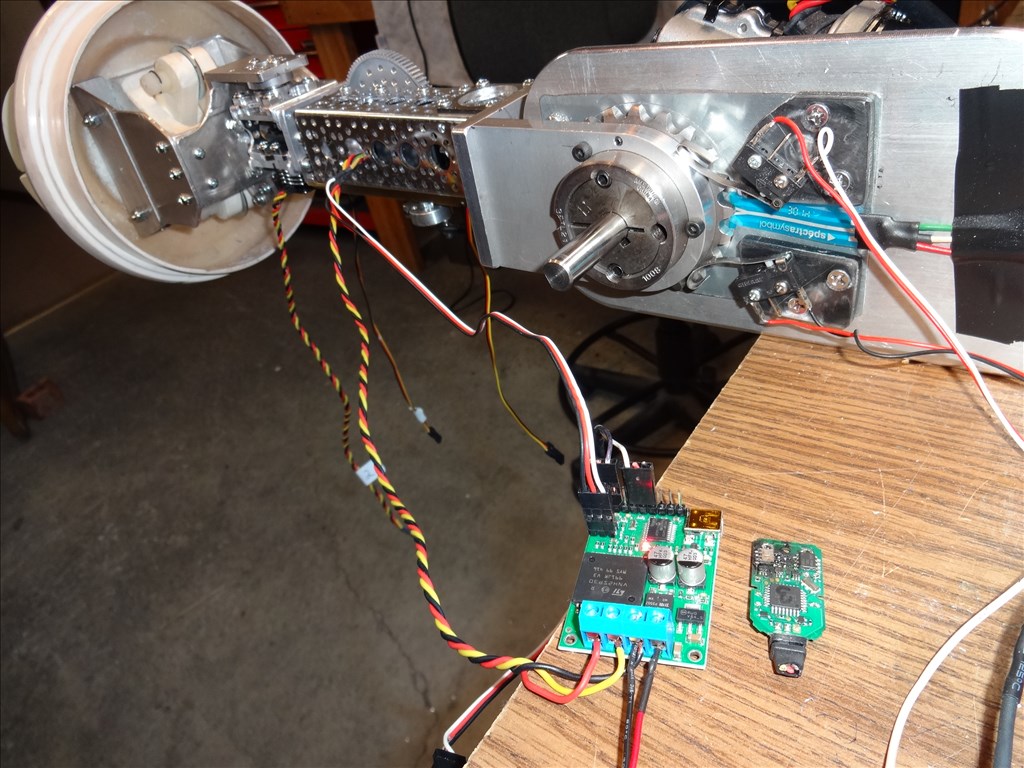

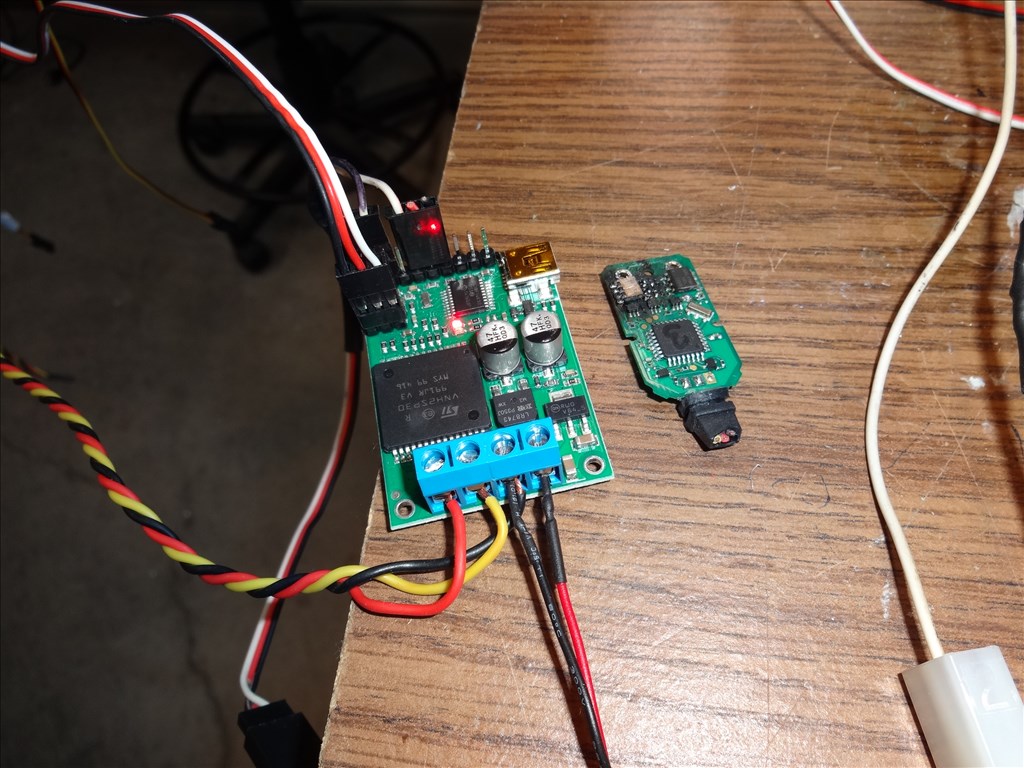

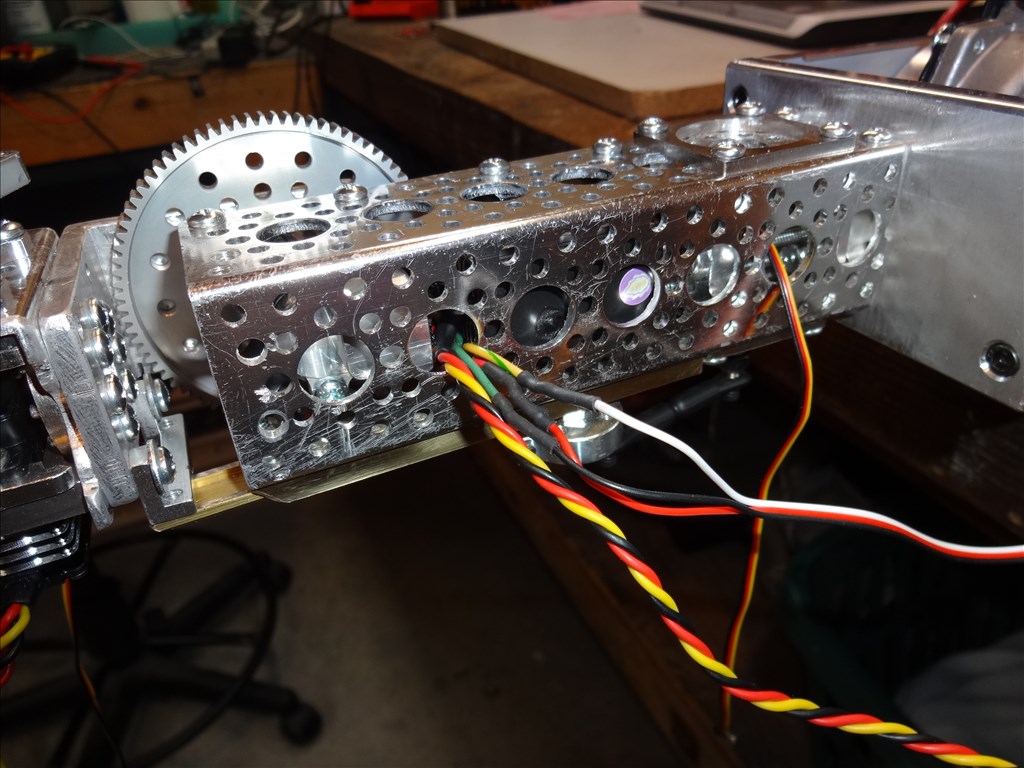

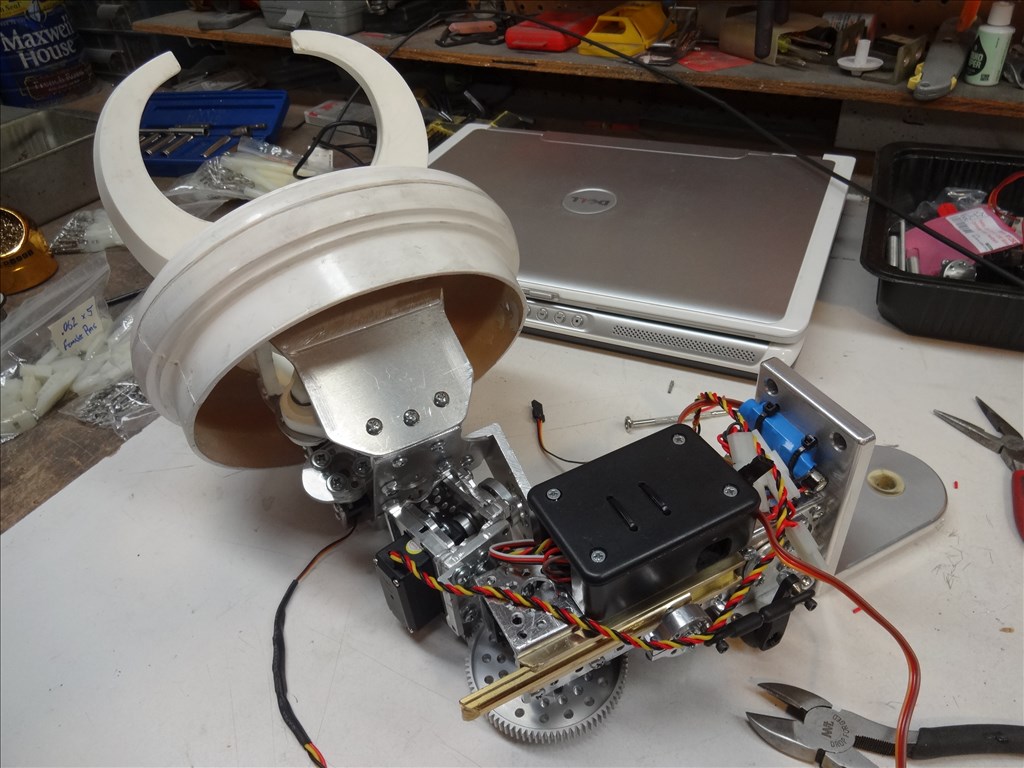

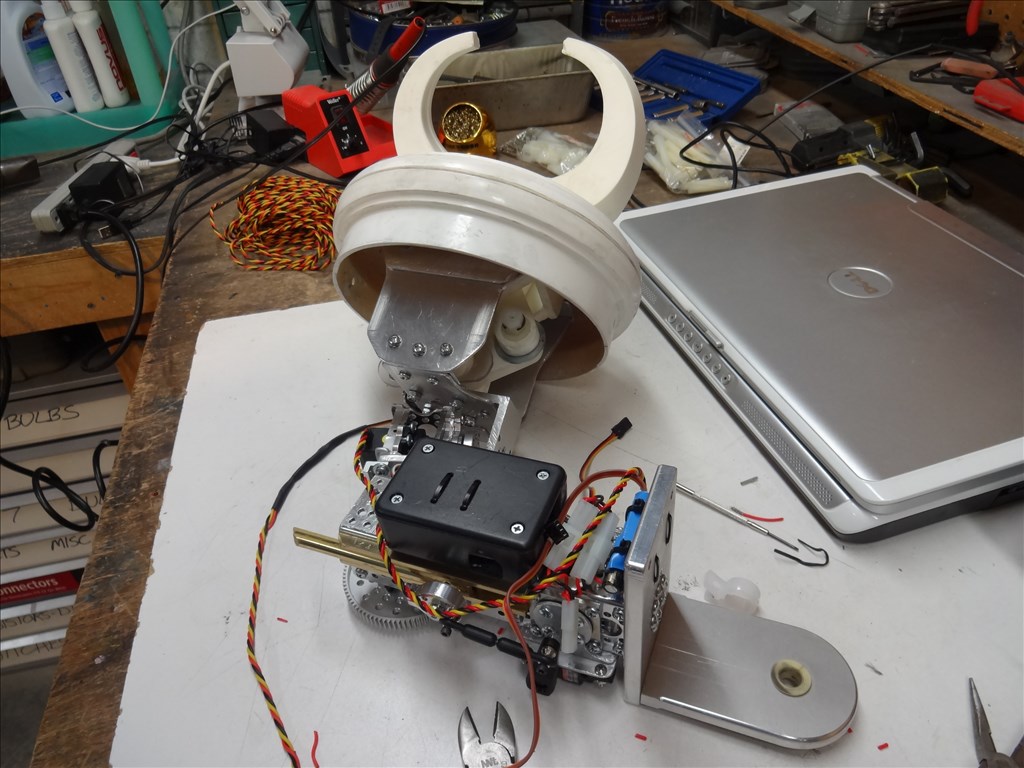

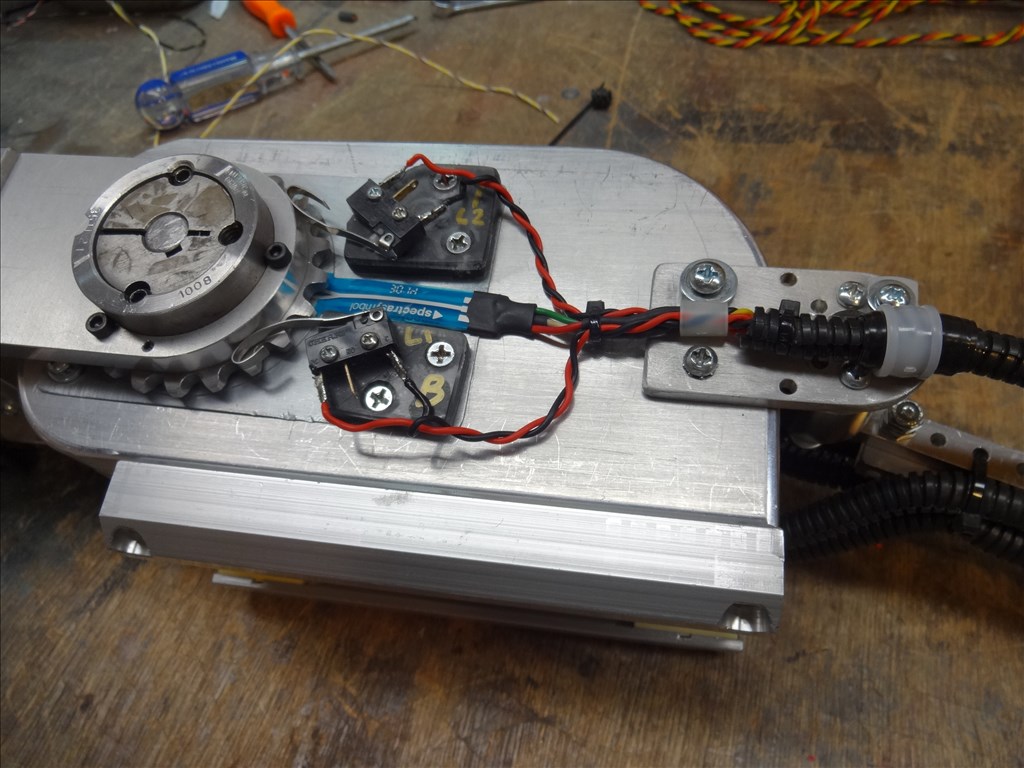

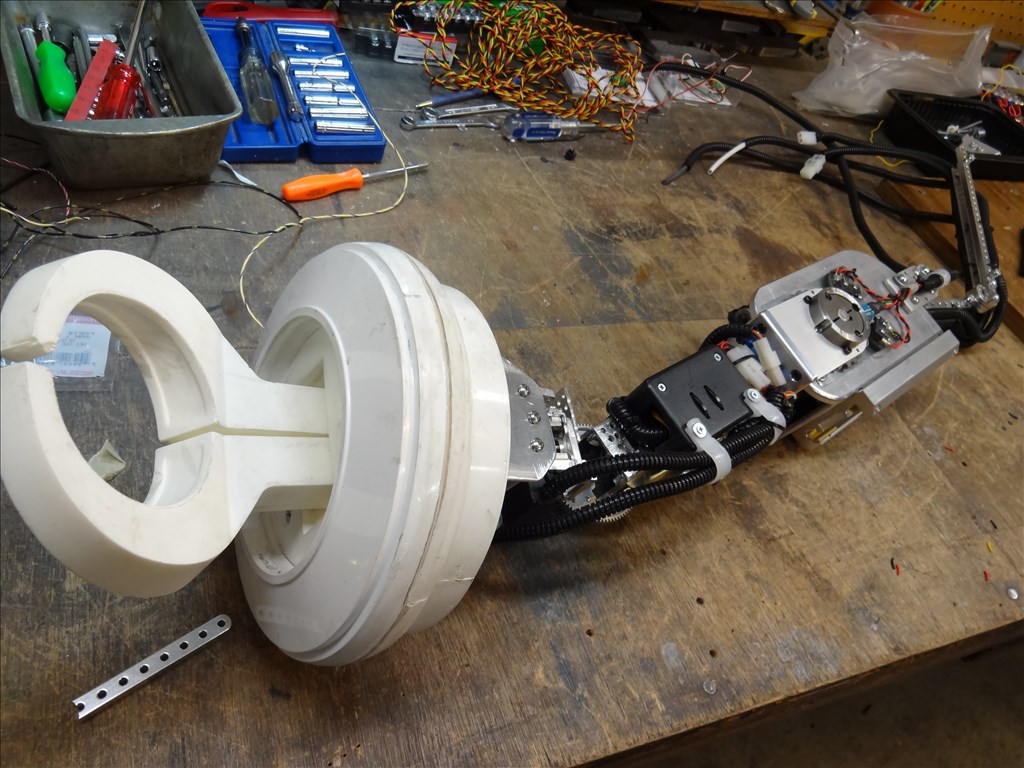

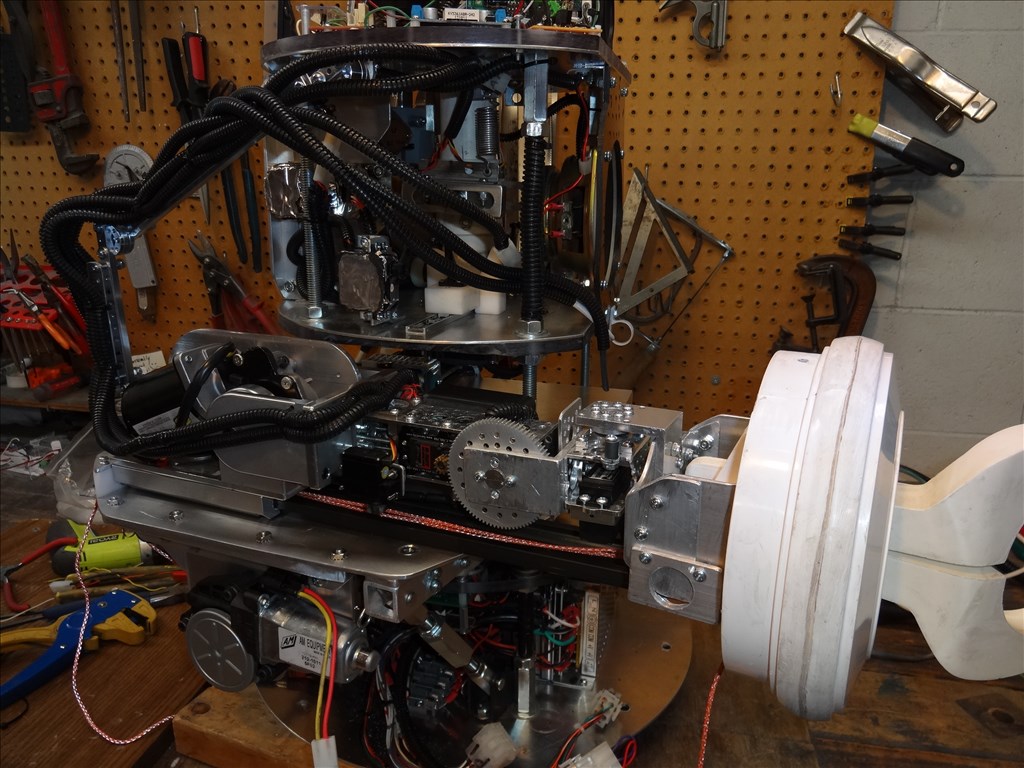

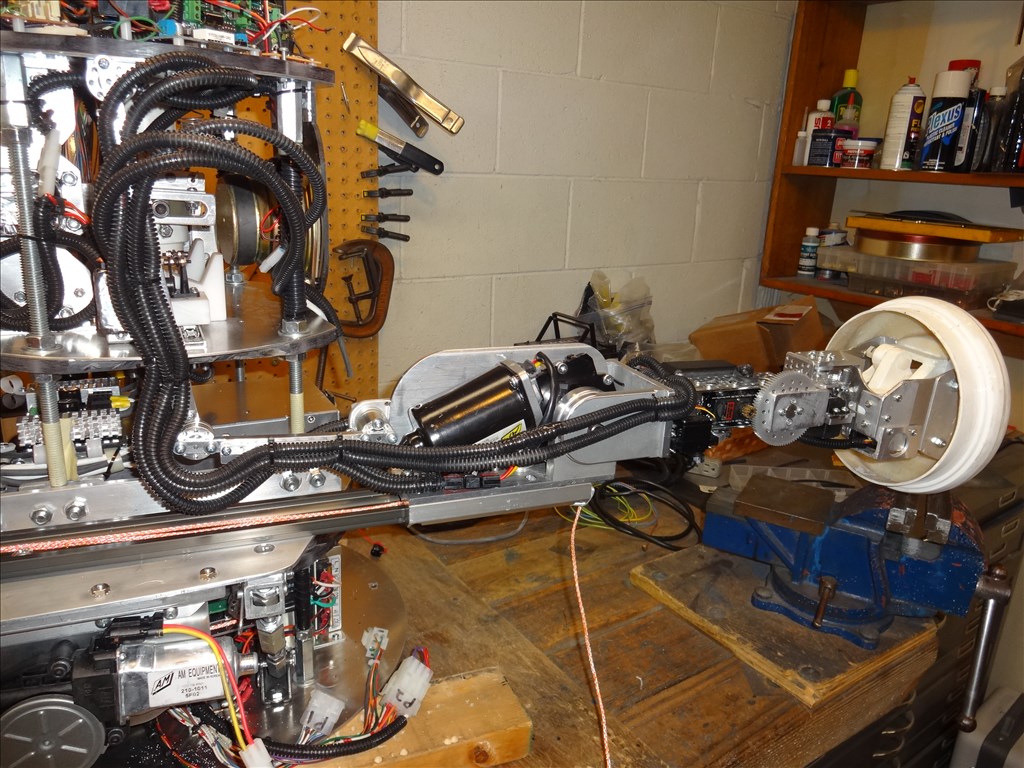

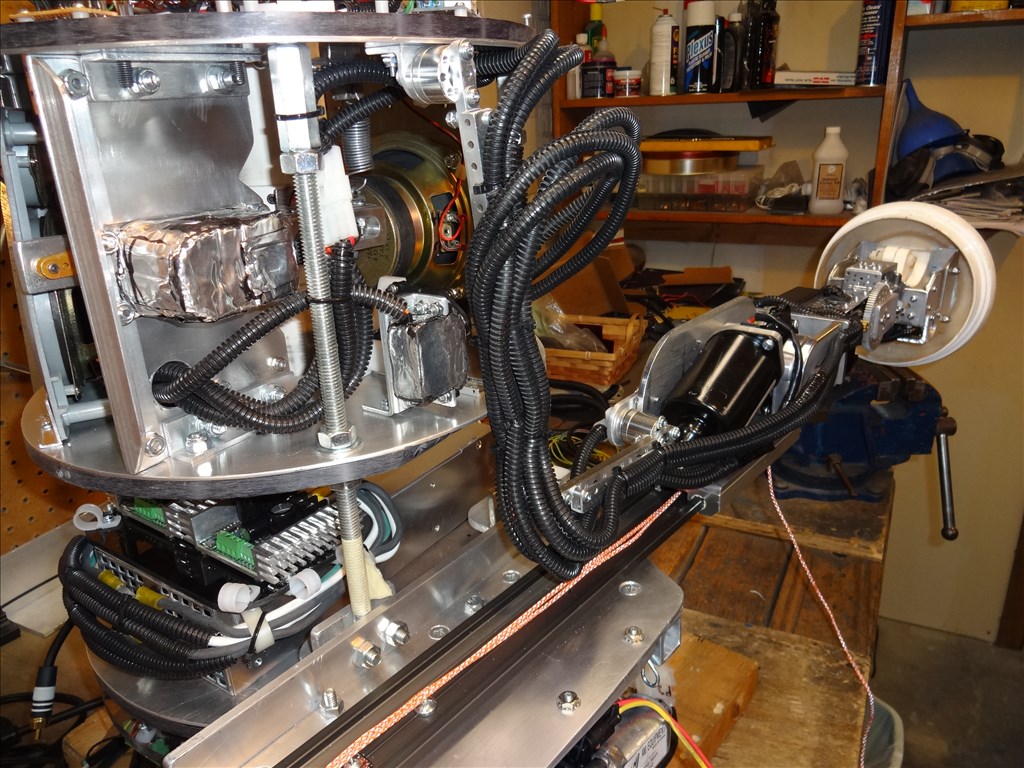

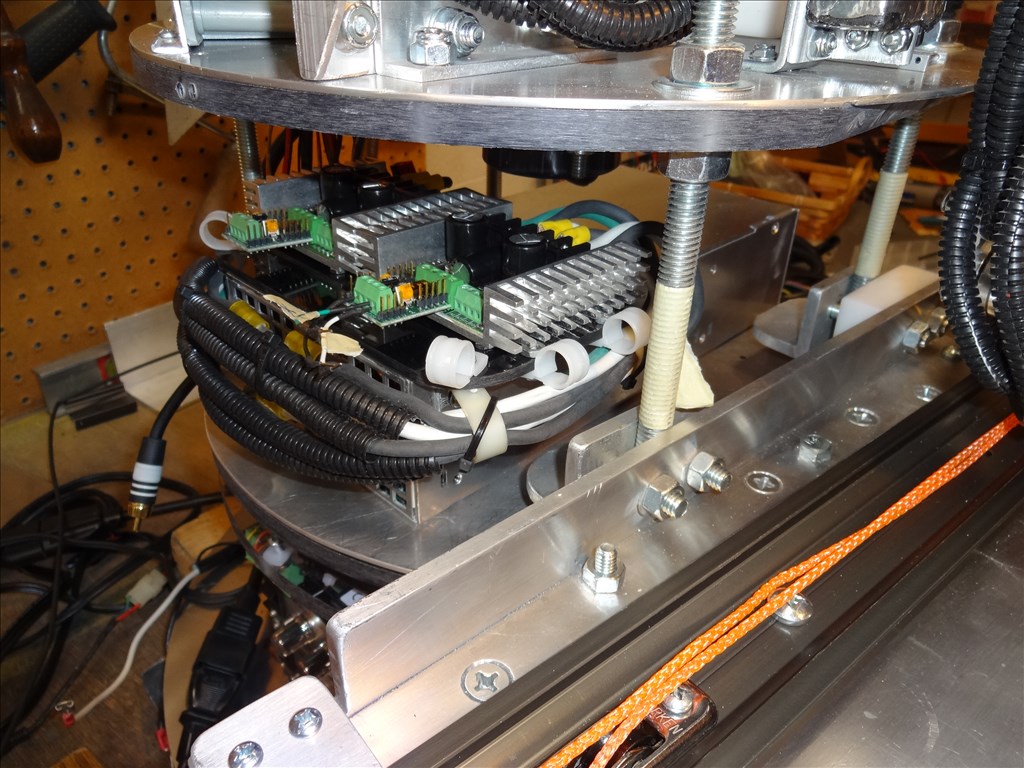

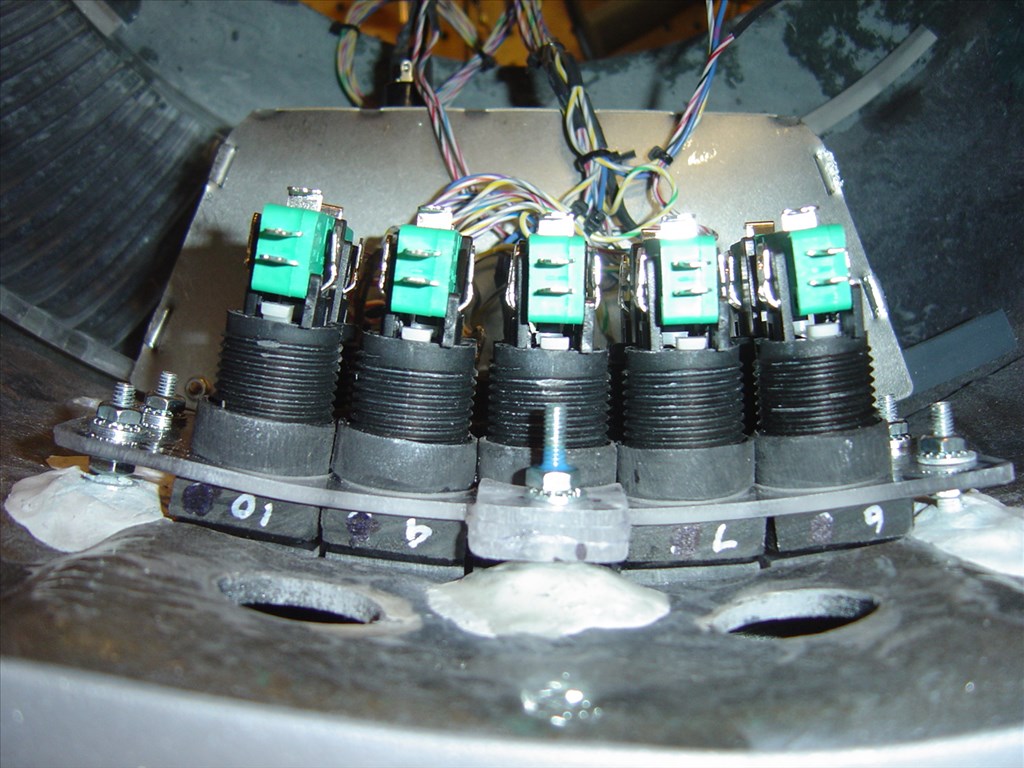

Rex, thanks for the kind words and tip. I'd love to see your big robot completed someday. A screw drive train like a power seat setup is certainly a possibility. I'm really tight on space and that's been a huge issue throughout this entire process. Heck, I spent three whole days rebuilding parts of this arm to just shave off two inches. That will put the tail of the elbow motor closer then 2 inches to the rear wall of the torso when retracted. This arm hasn't been inexpensive to build. I perhaps tripled the actual cost buying different motors, structural parts and controllers while I was designing it. The biggest expense was the cost of getting my prototype elbow motor mount turned into a work of art by having one machined by a professional. That was the key to this motor being able to smoothly lift the needed weight out in front of the motor and also return accurate feedback information from the pot to the Kangaroo. My hand built versions caused too much binding at the pivot points.

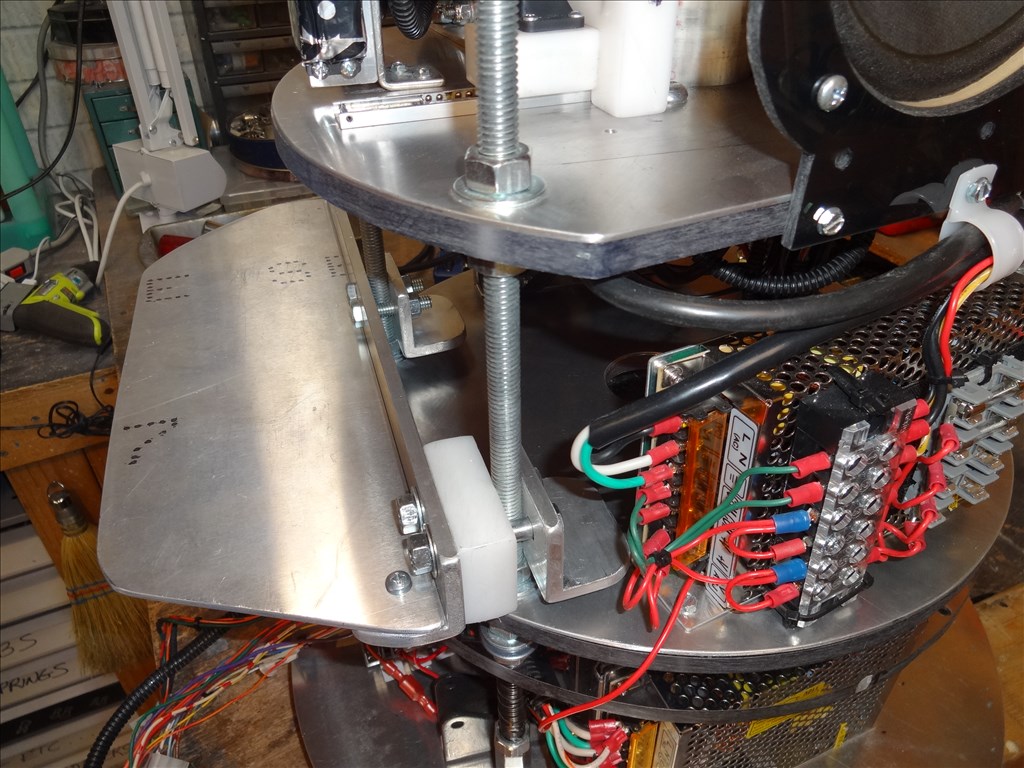

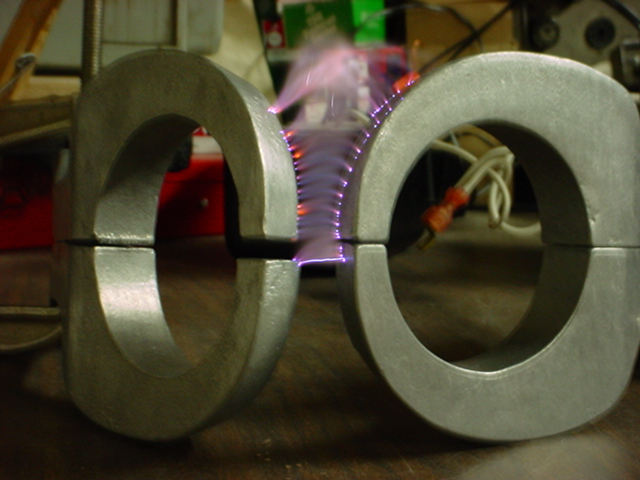

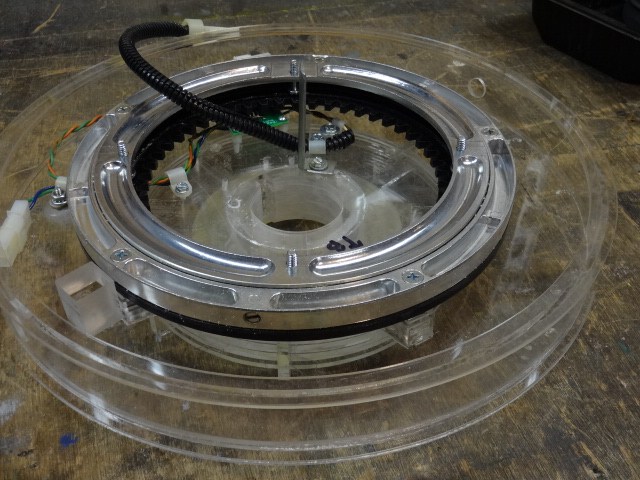

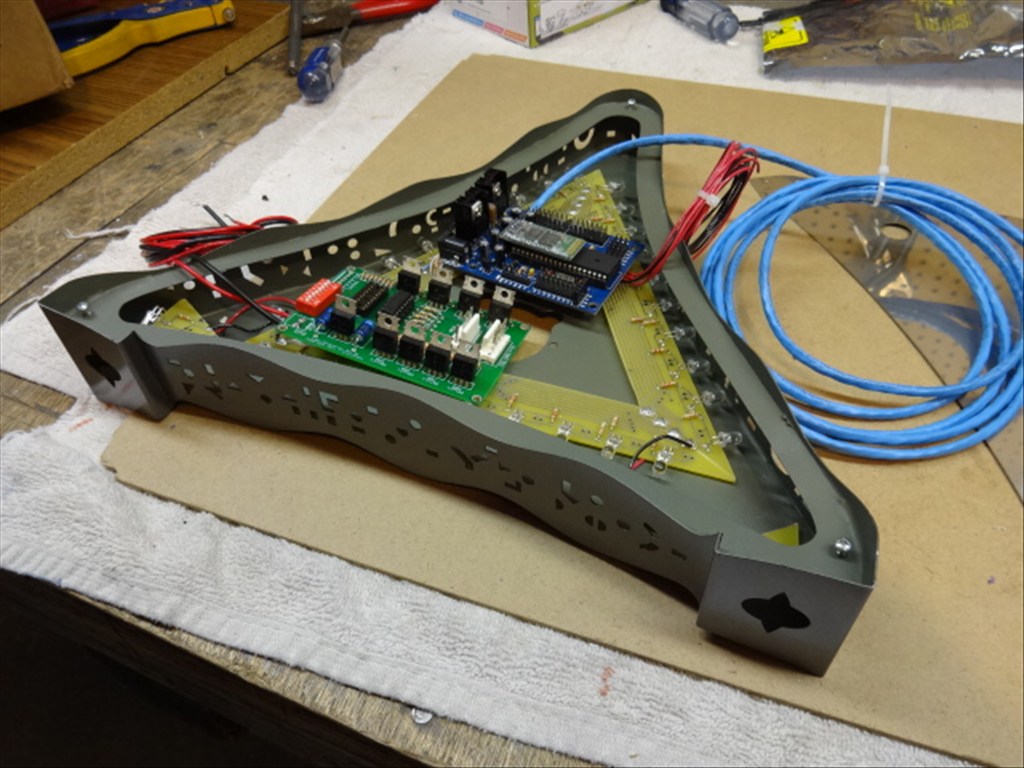

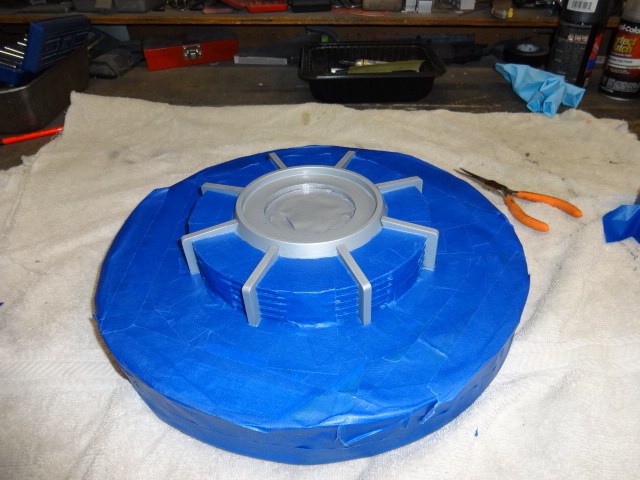

Will, yes the linear rail is currently at the top of my list right now. Just need to find a strong and low profile one that will work. For a rail system to work however I think the rails will have to run from the rear of the torso and extend out of the arm holes almost 7 inches or more. The sliding platform would have to attach to the bottom of the elbow motor mount so the fourarm and claw would extend forward over the edge. Here's the aprox weights and mesurments : Elbow motor and mount: 4 lbs Fourarm and wrist servos: 1 lb Wrist donut and claw section: 2 lbs Rubber skin: 1 lb. Overall length: 21" from tail of motor to front of wrist donut. (elbow motor mount is 7" long x 3" wide x 4" tall). That only gives me about an inch below the motor mount for a rail and platform and still fit into the rubber arm and torso arm hole.

Like I said above, tight tolerances everywhere . eyeroll

I love that vid of the arm range of motion. People might think there is someone inside of it.

Hi Dave,

May I say again, Absolutely Amazing work!

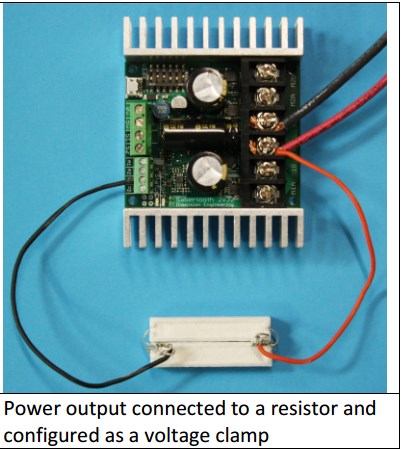

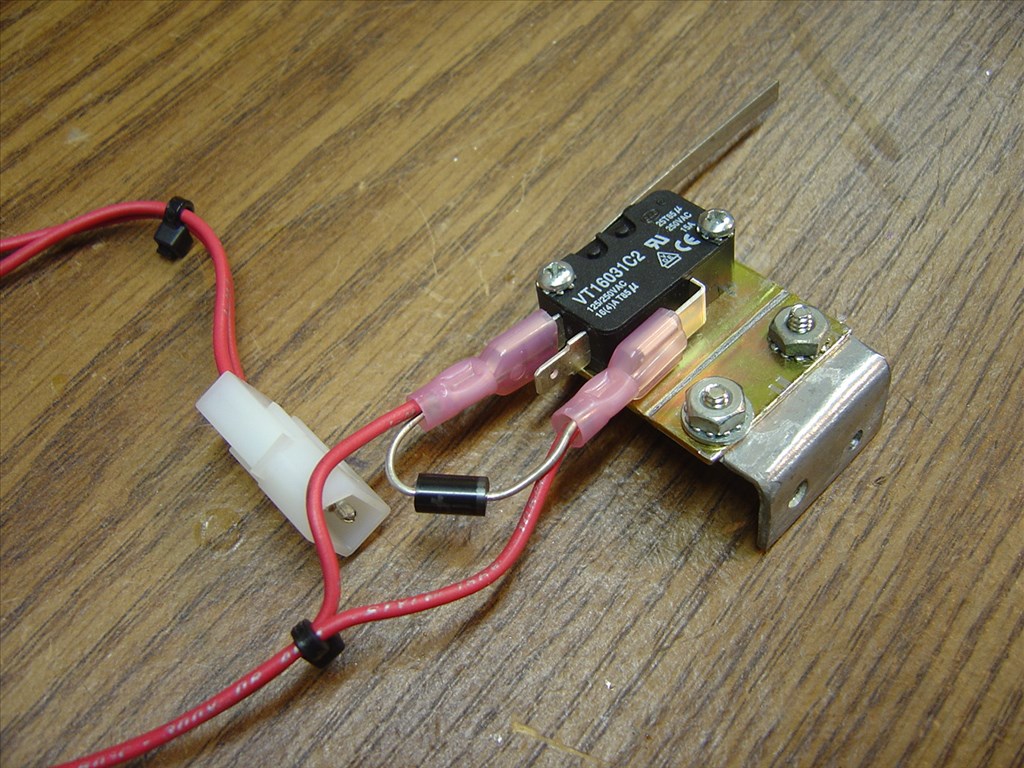

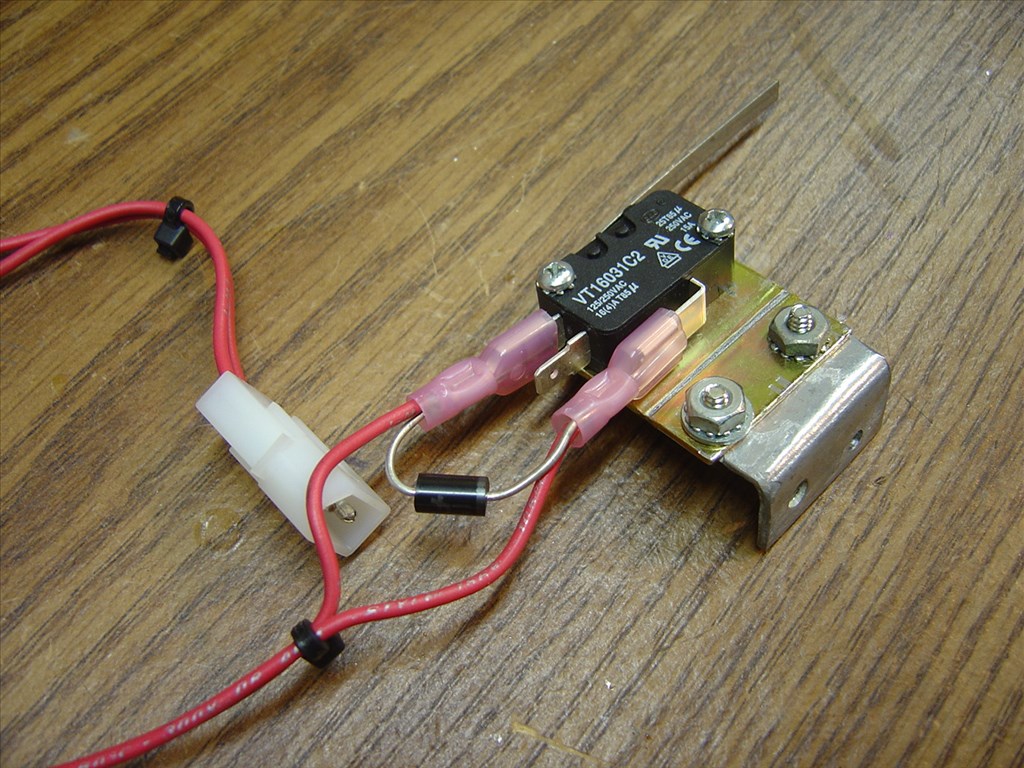

I had a thought about retracting and extending your arms, I recently ordered a high speed 4-in-stroke high speed linear actuator from the Robot Shop for my Bubble lifter mechanism, I don't have it yet though. They are available in from 4" to 18" strokes and three different speeds and lifting forces. I don't know if the actuator will fit within the limited space you have. I was thinking to mount the arm mechanisms on high quality draw slides and slide everything with the actuator. They have built in limit switches but no feed back for position which means they will be either fully retracted or fully extended, but this may be OK for the extension of the arms. With my bubble lifter 4" actuator I plan to mount external limit switches and a 4" linear slide potentiometer to the side of the actuator so I can control it with a Sabertooth and Kangaroo.

Here is the link to the actuators

https://www.robotshop.com/en/catalogsearch/result/?q=high+speed+Tubular+Actuators&order=stats_sales_order_count&dir=desc

There is also another company making high speed actuators called Progressive Automations and here is a link to a YouTube clip showing one in action

Any how, just food for thought.

Again, Simply Amazing job on your B9 arms, a work of Genius

Steve Neal

Throwing out some more links to help you brainstorm....

www.servocity.com/html/flange_nuts.html

EDIT: I see @steve.neal had posted same video about Progressive

Click To Watch Video

9 inches per second

www.progressiveautomations.com/actuator-tubular-high-speed-linear-actuator-stroke-size-2-force-11-lbs-speed-905sec-p-102.aspx

www.ebay.com/itm/Linear-Actuator-High-Speed-Stroke-10-Force-11-lbs-Progressive-Automations-/280873887546?pt=LH_DefaultDomain_0&hash=item416563673a

Thanks for the ideas guys! The high speed actuators from Progressive Automations may be the bets bet for a motor. My big challenge is the rail system that it will have to slide on and how to mount it t the CSS.

Dave- the movements in this arm are unreal! I can't wait to see the video where you show us the inside. Well done sir!

Thanks Aislinn. There's no way in h e double hockey sticks that I could have been able to do this without EZ Robot. These are just crudescribed and simple scripts I'm running. I can't wait till I can write better ones and maybe use the Auto Position control.

Dave,

How about the rails used on CNC machines as your rail?

Something like these (two per arm): https://www.ebay.com/itm/2-Set-10-inches-long-LINEAR-RAIL-SHAFT-ROD-20mm-with-4-SBR20UU-cnc-router-/400834421180