Hi all,

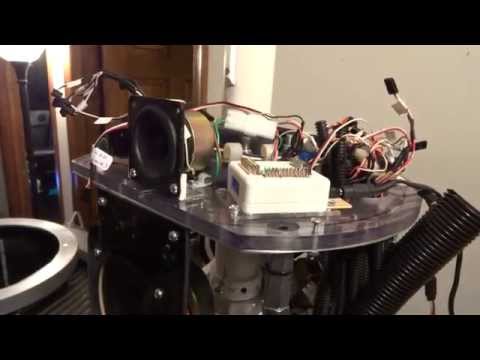

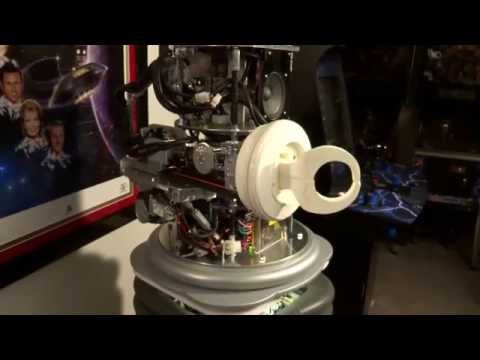

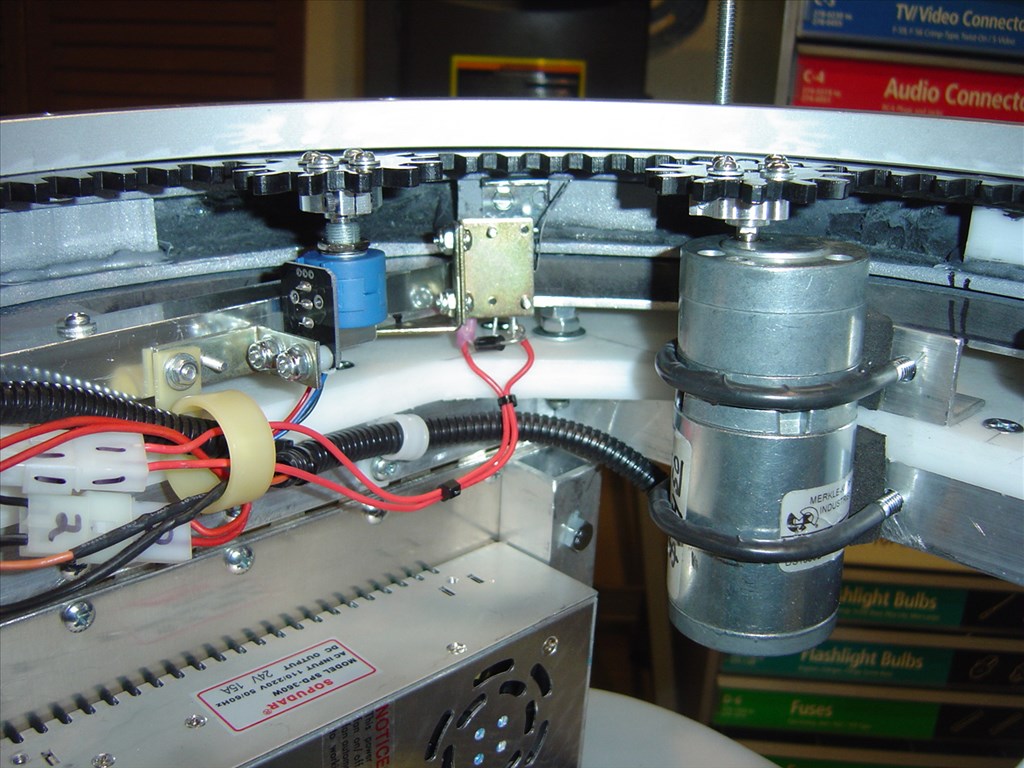

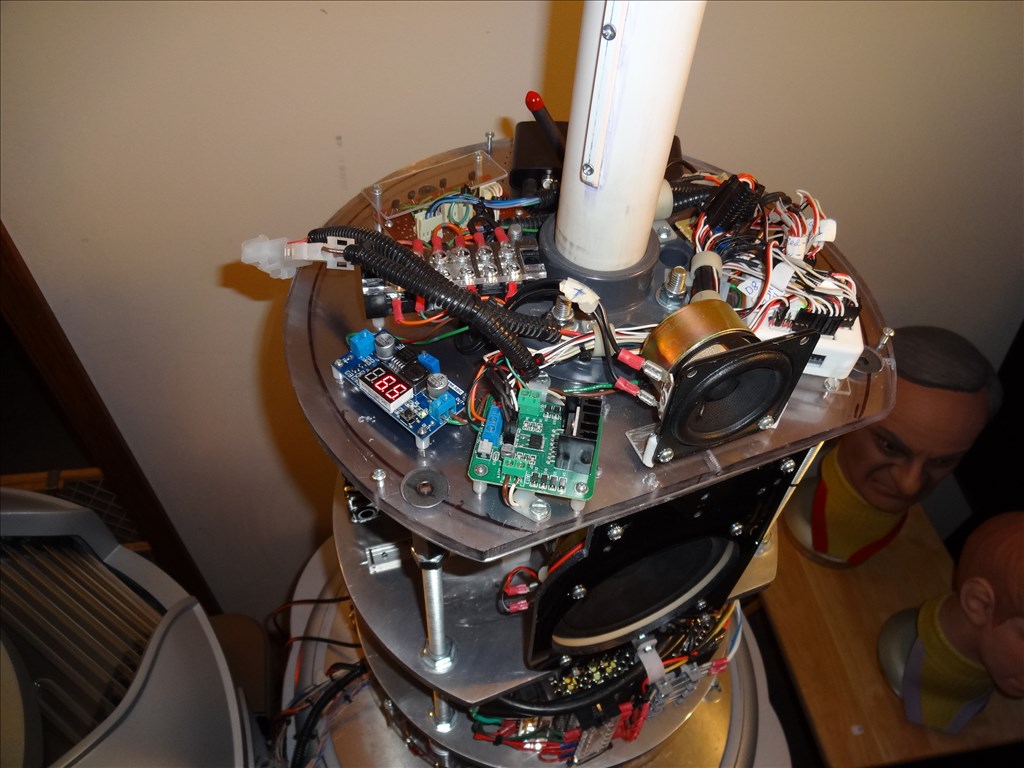

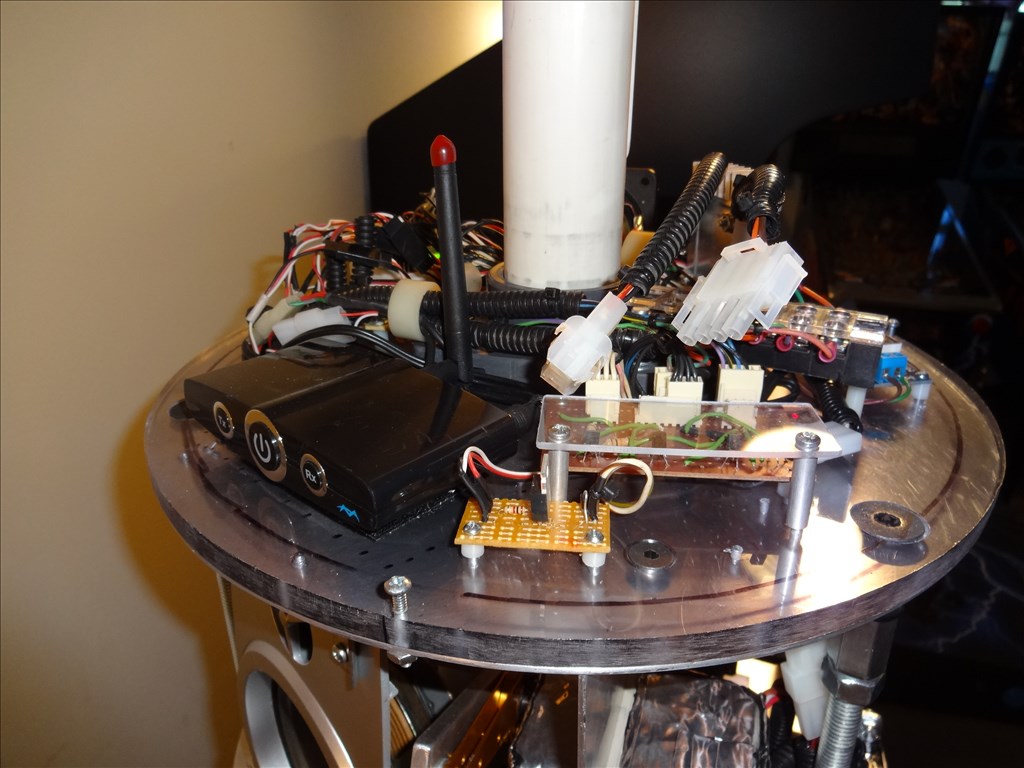

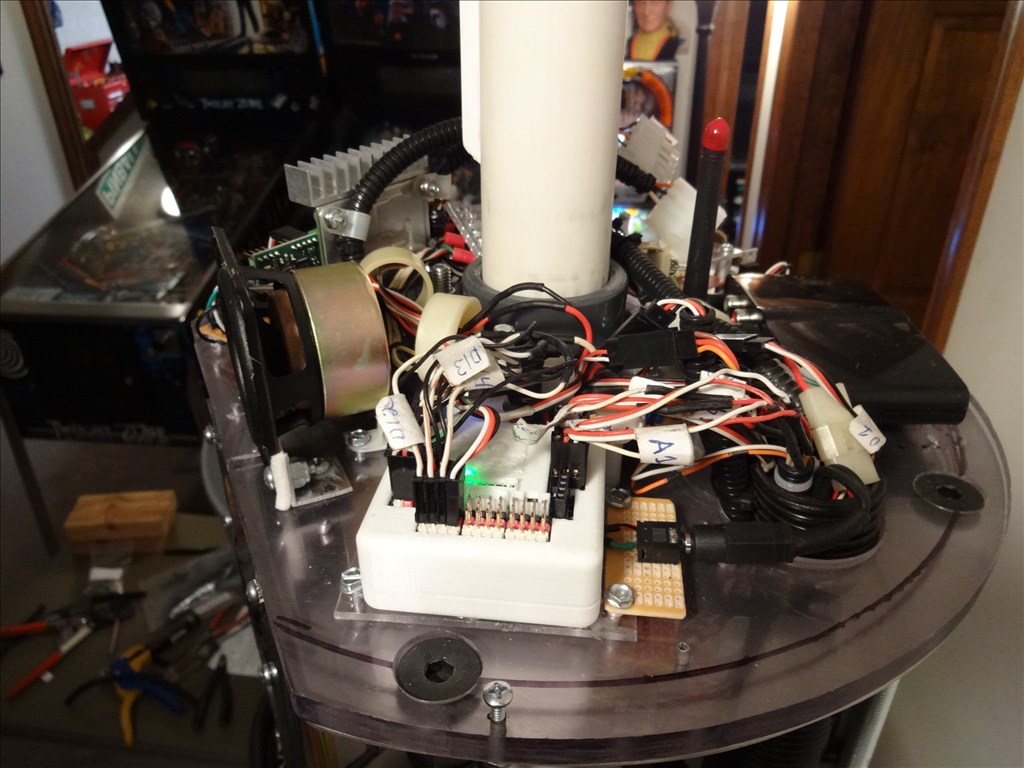

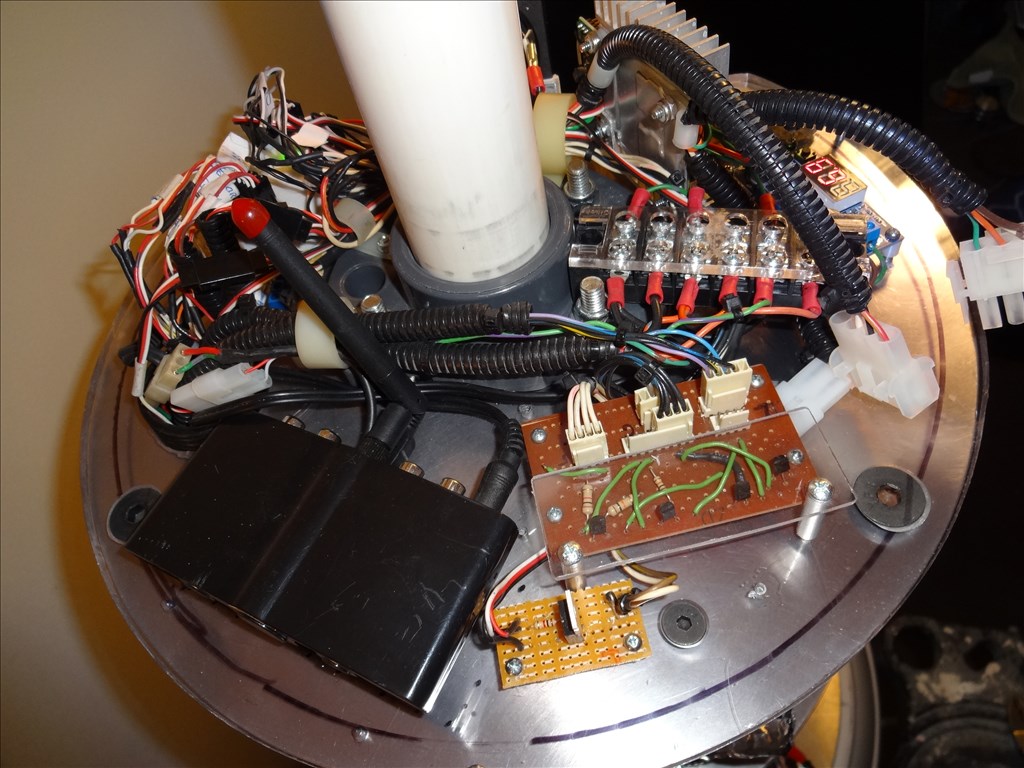

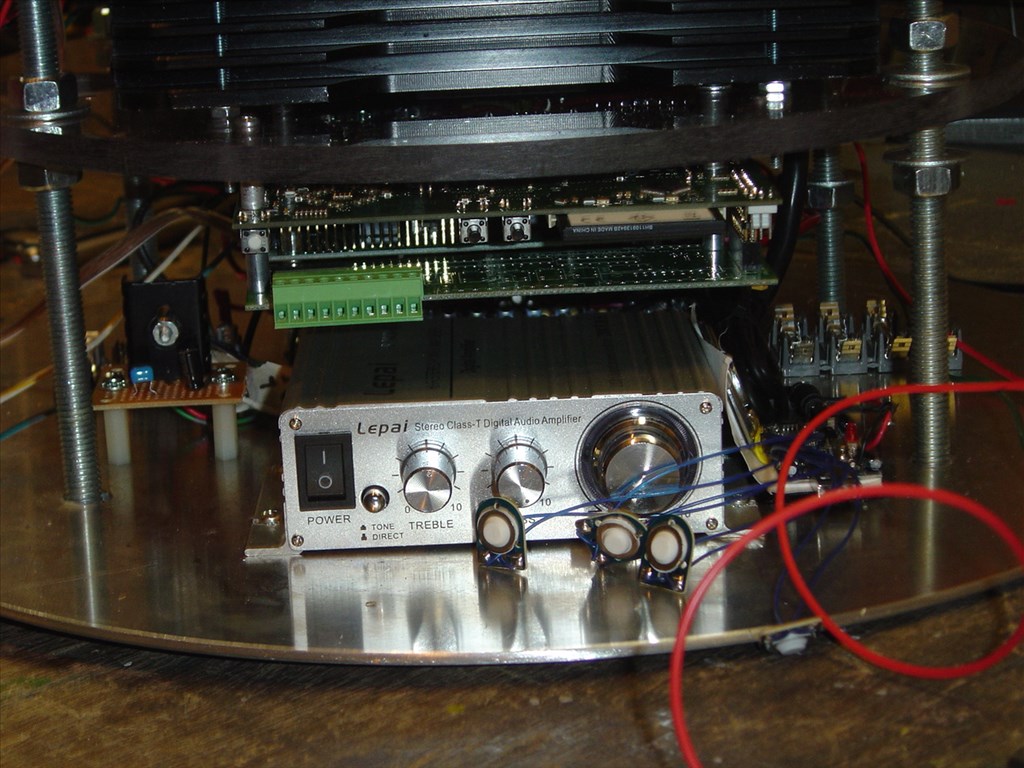

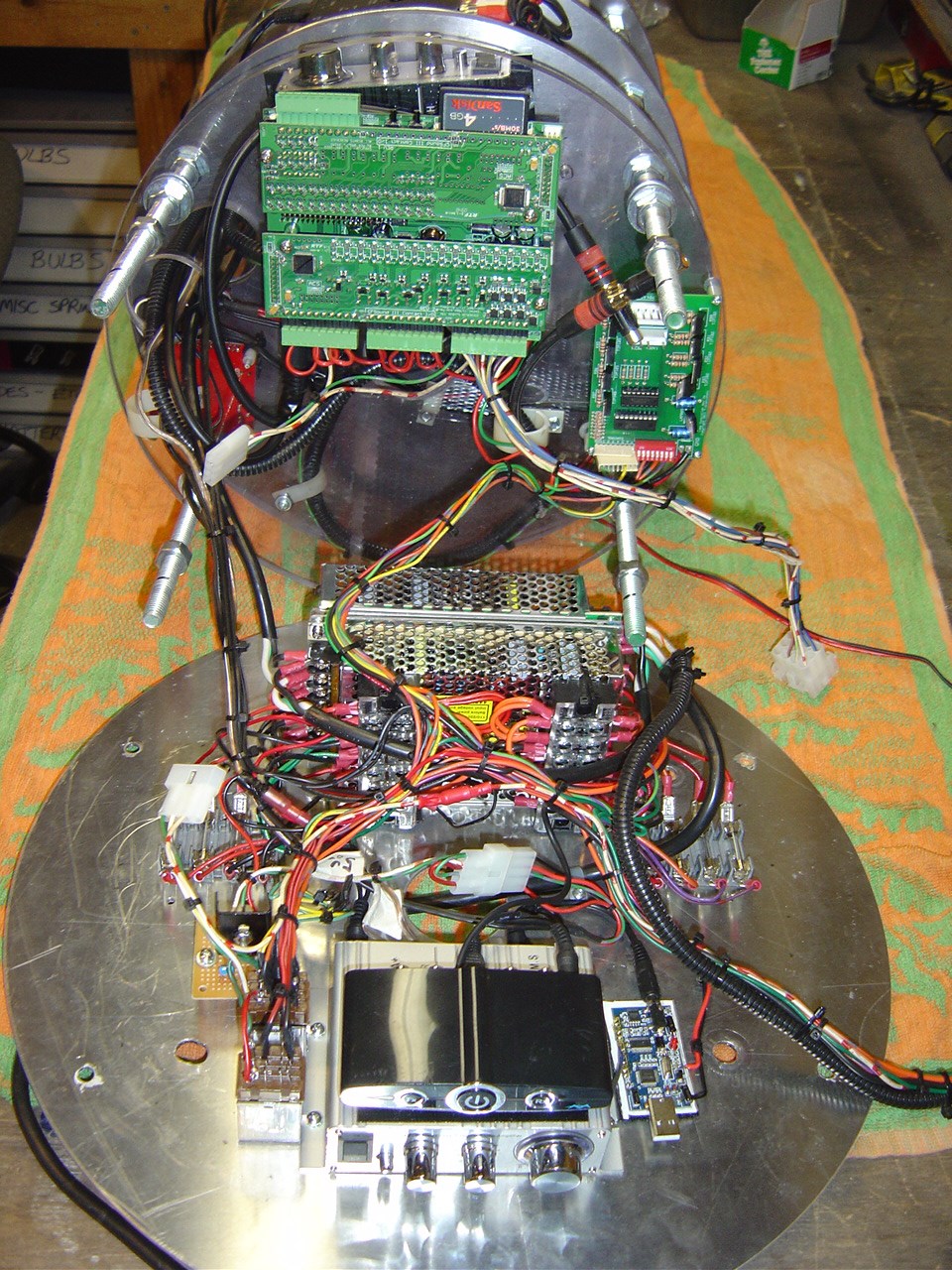

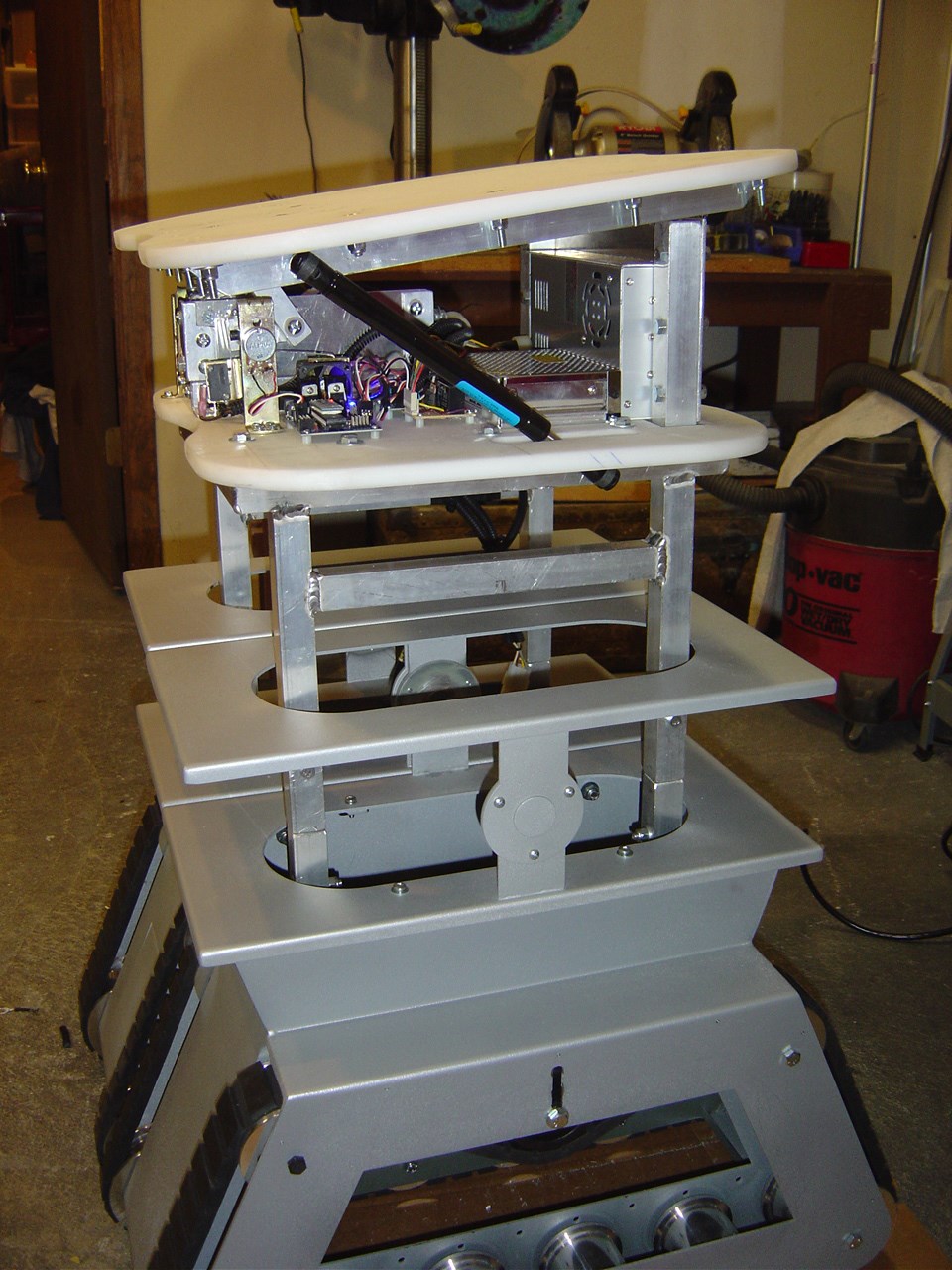

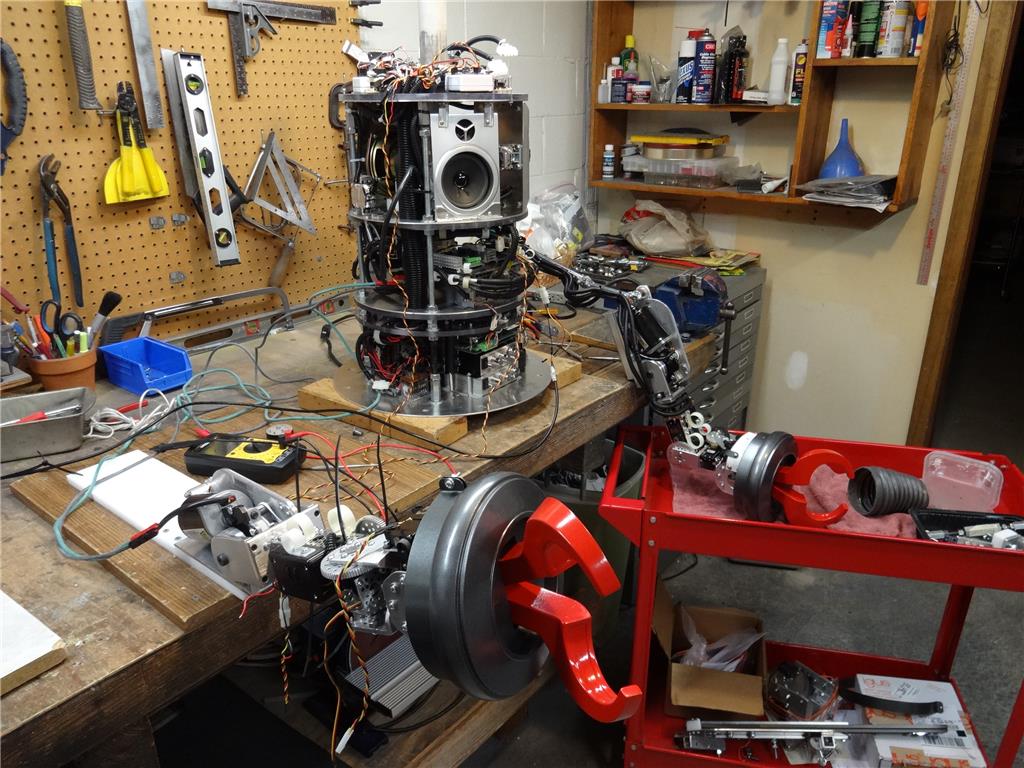

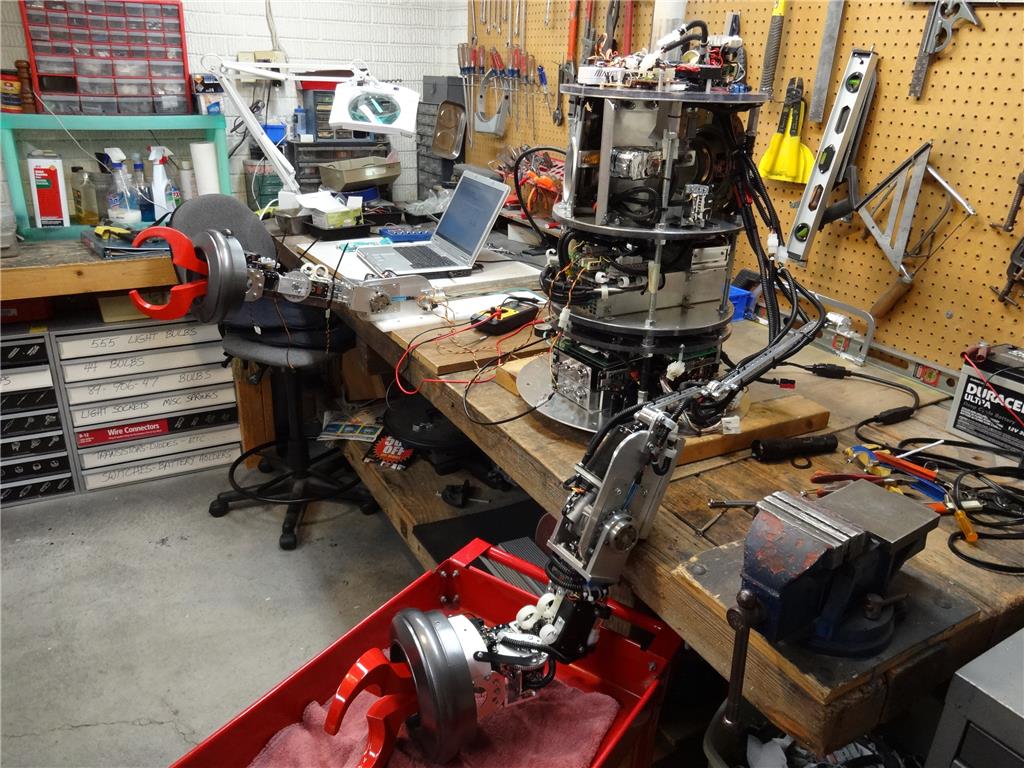

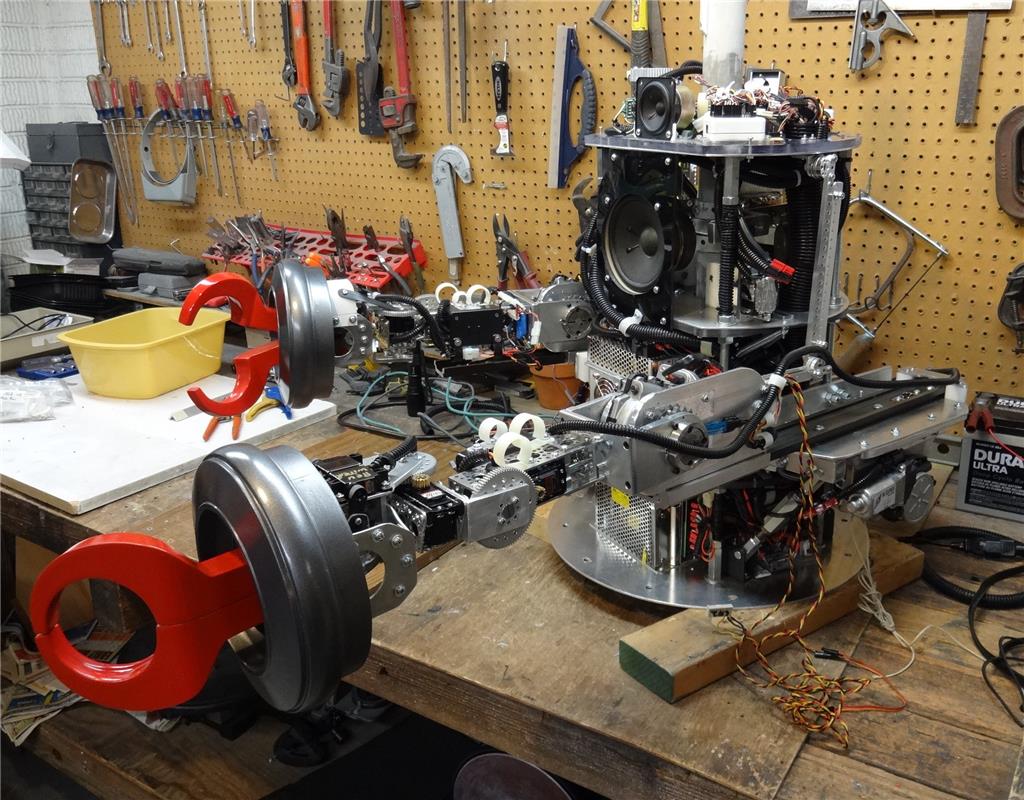

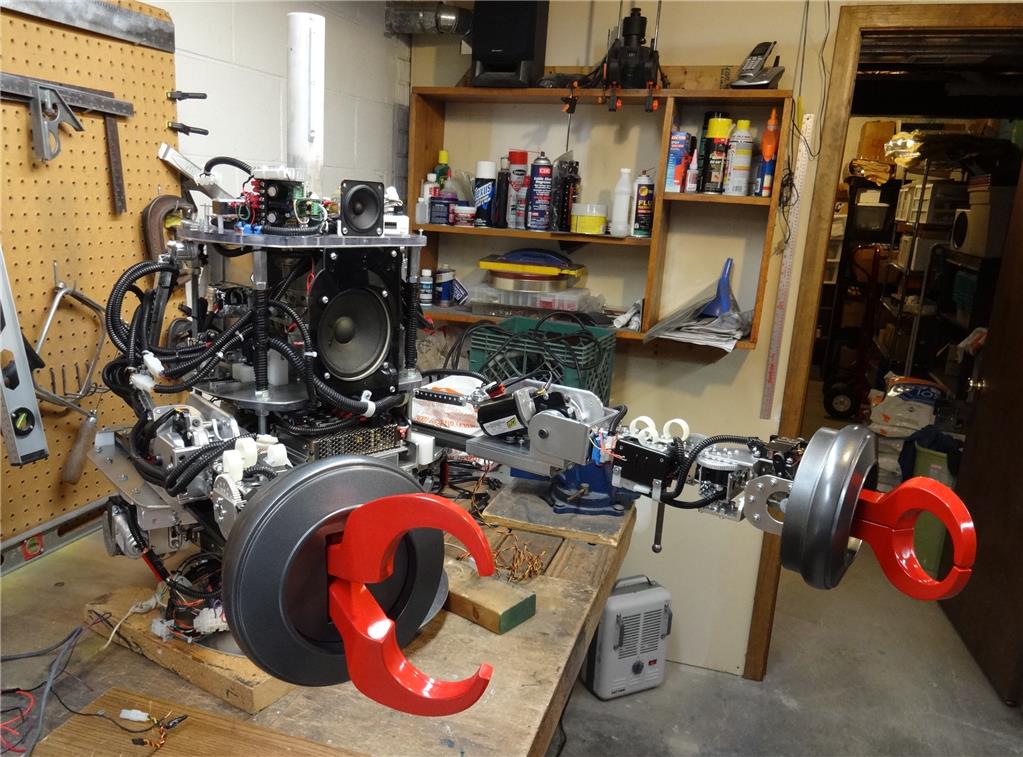

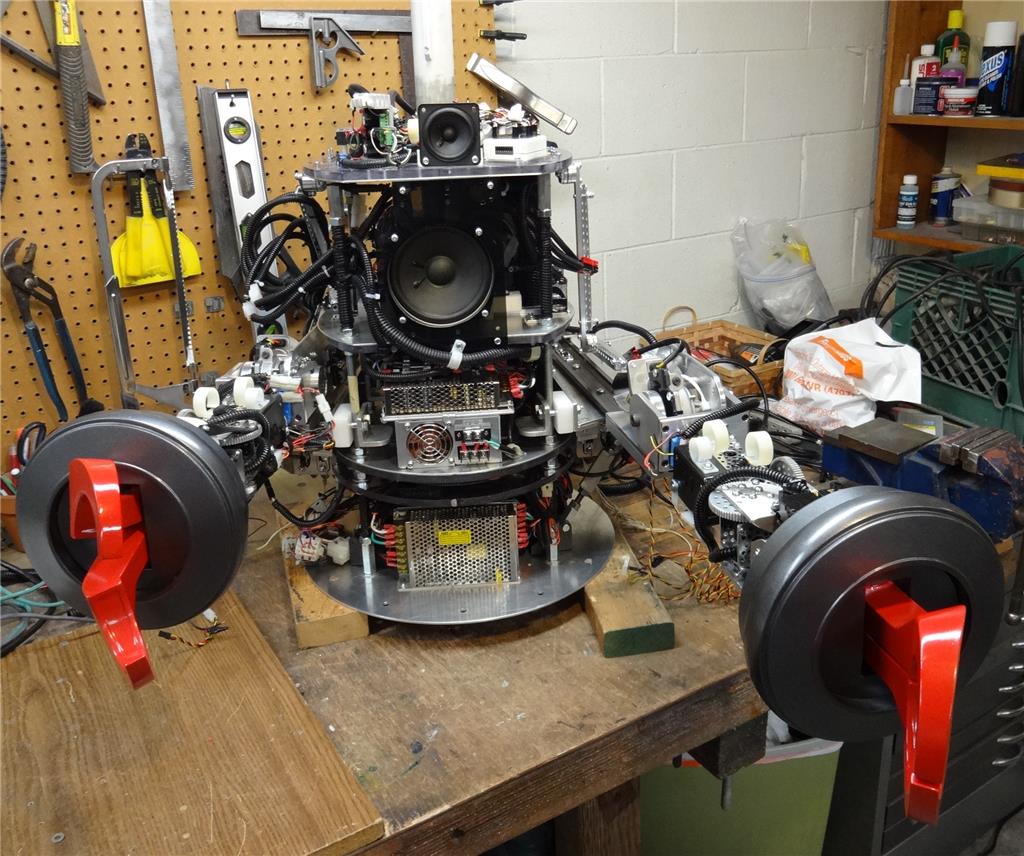

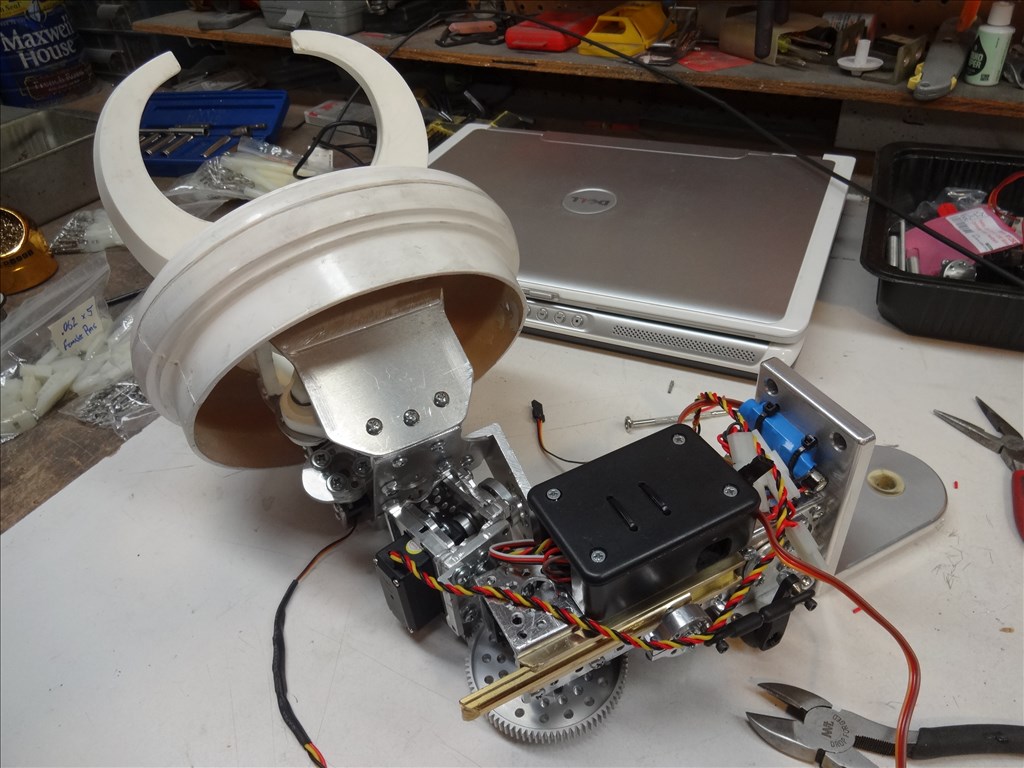

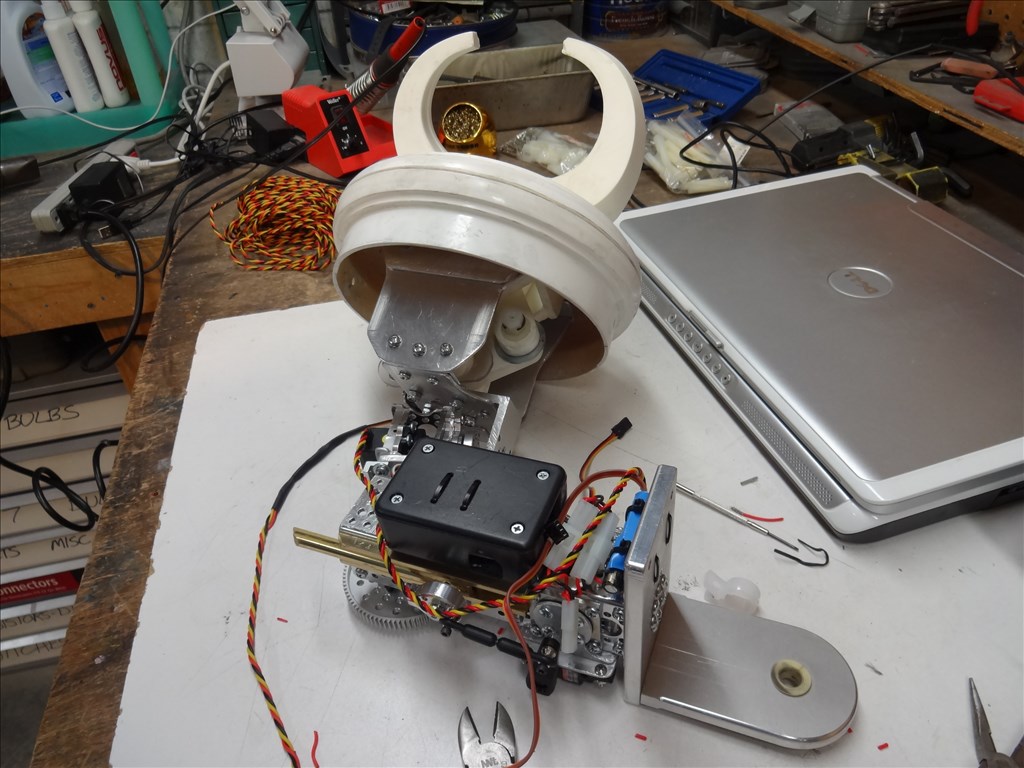

I'd like to share a video I just took of my full size Lost in Space B9 robot that's controlled by two EZ-B controller boards. Right now they are controlling limited movement and voice response of a few motors, lights and sound files played from a Sparkfun MP3 Trigger board. Although I'm just starting with the animation and have more building on the actual robot the result (mostly thanks to the EZ Robot controller board) is shocking. Please have a look at this (4 minute) You Tube vid and enjoy.

Please excuse some Technical camera lighting and sound issues. This is the first time I'd made and posted a vid online.

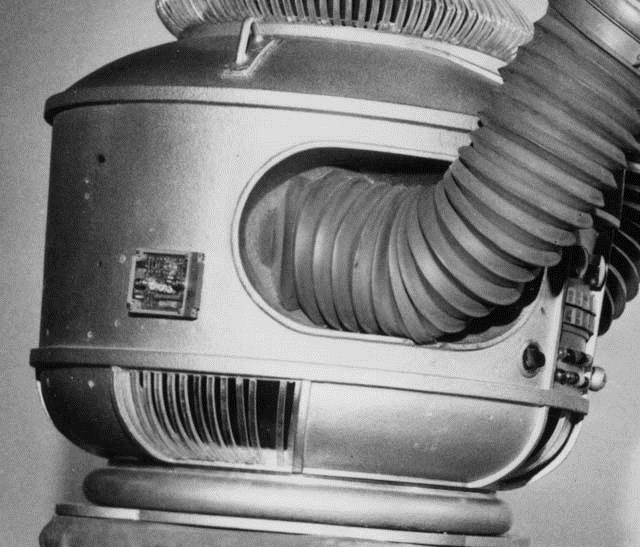

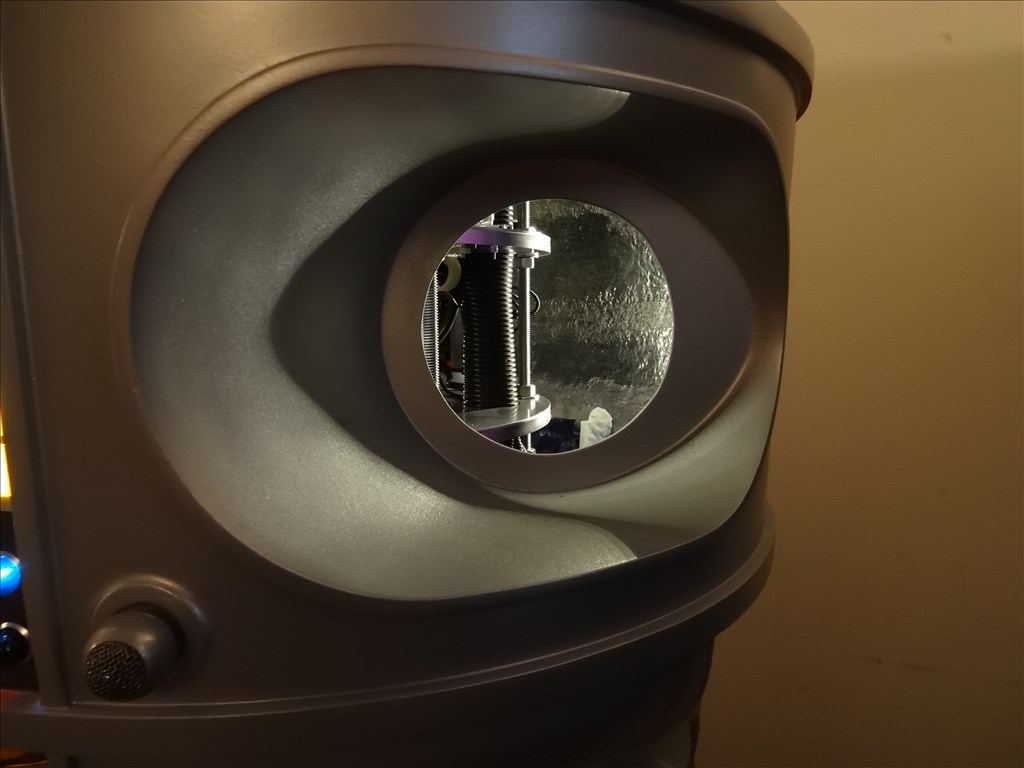

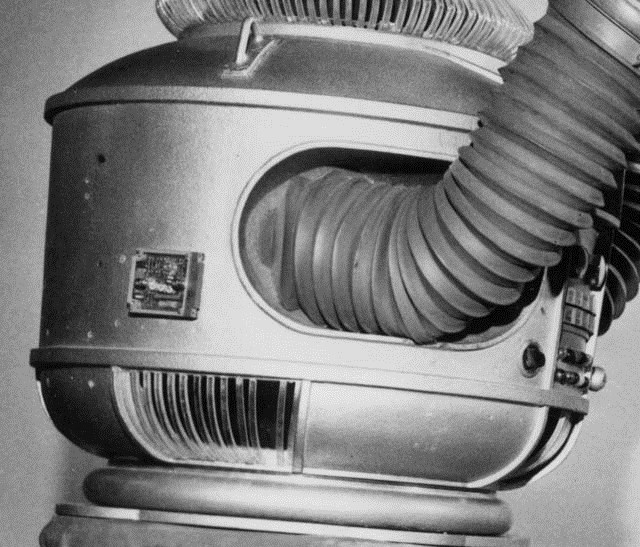

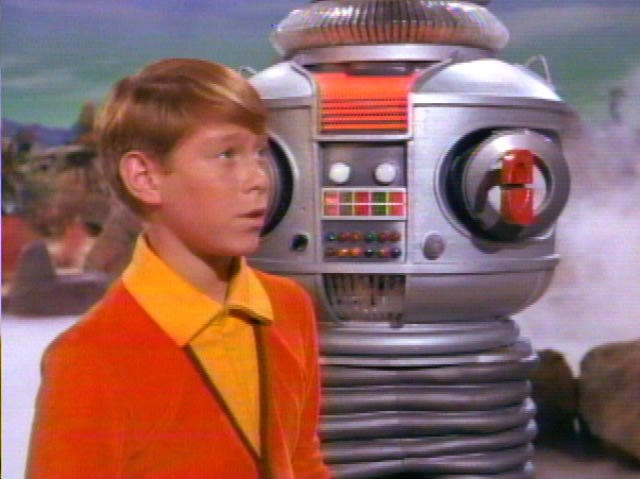

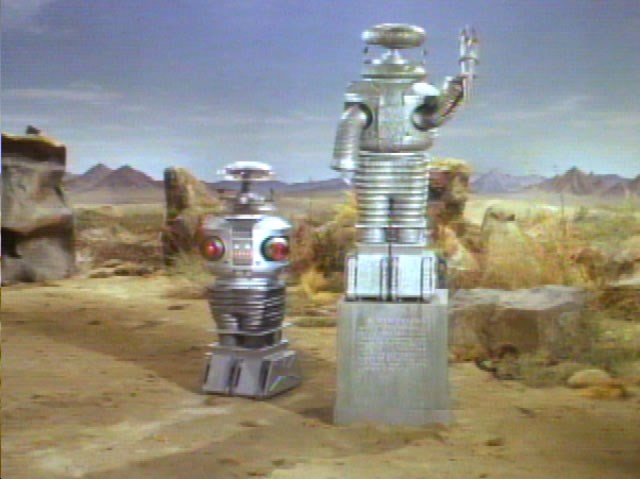

EDIT 8/2/13: Just realized I have no good pictures of how my B9 will look when complete. Here's one of the actual TV robots from the 60's TZ show Lost in Space and one recent shot of where I'm at with my build over 1 1/2 year after I started. Enjoy:

Thanks, Dave Schulpius

Other robots from Synthiam community

J's My Hexapod Project

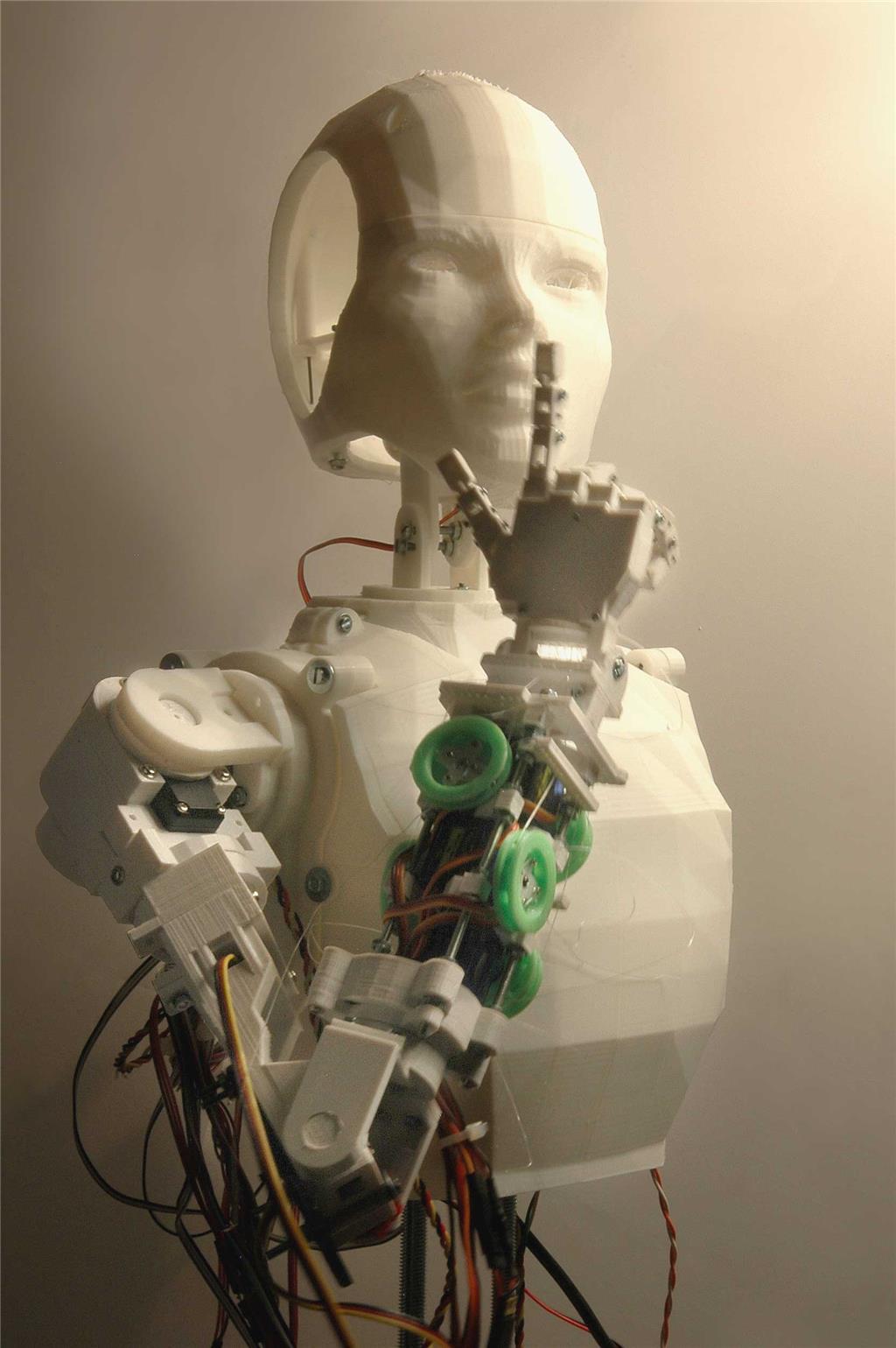

Buratino's Buratino - Humanoid Animatronic

-635353562186322812.png)

DAVE i hope you got my apology before the thread was removed on the tutorial problem.

You know you are my friend and have very good wisdom and would not say anything bad about you. only i just put 2 and 2 together and thought you was talking about me like others where doing

No worries.

just i still feel bad

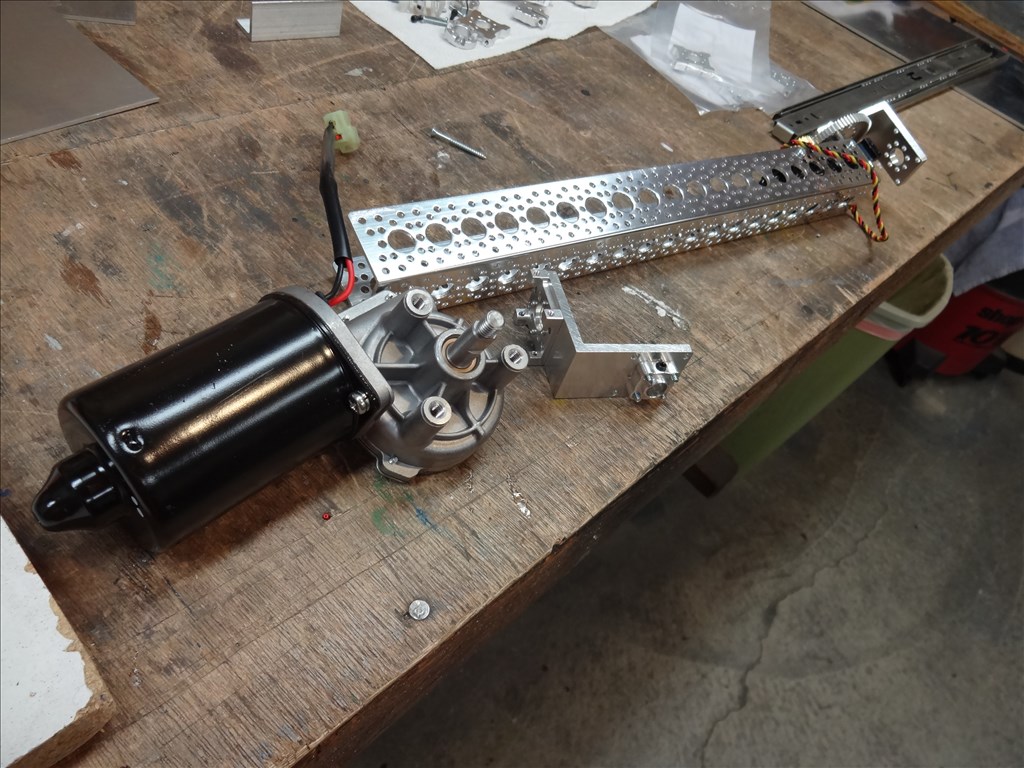

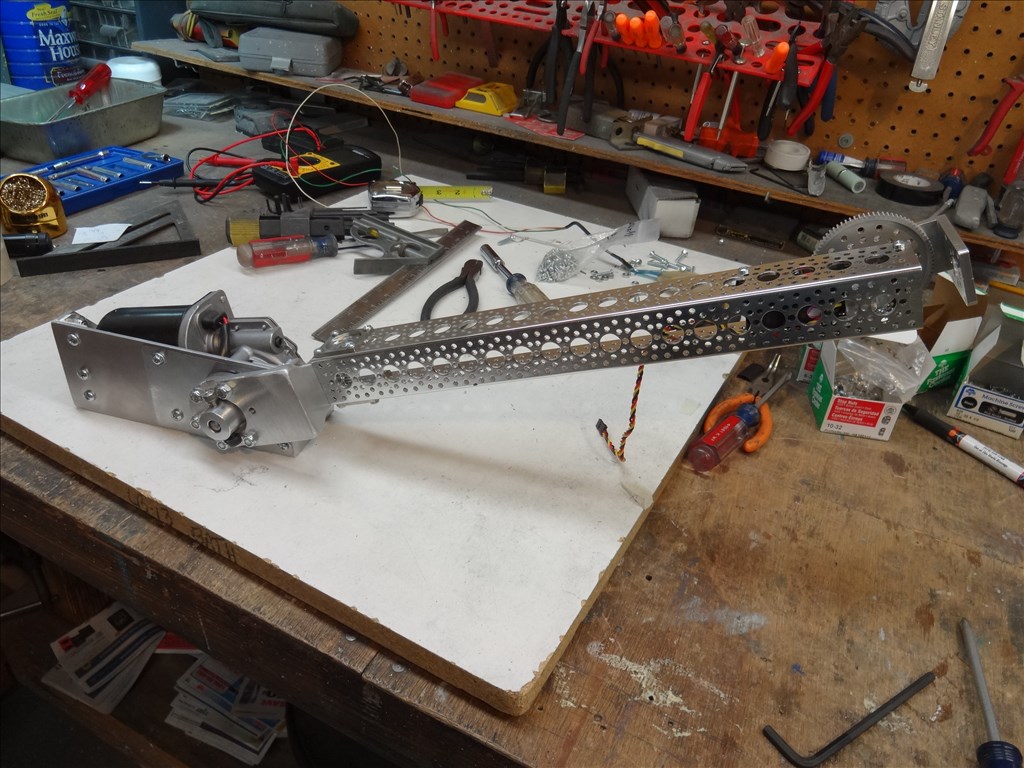

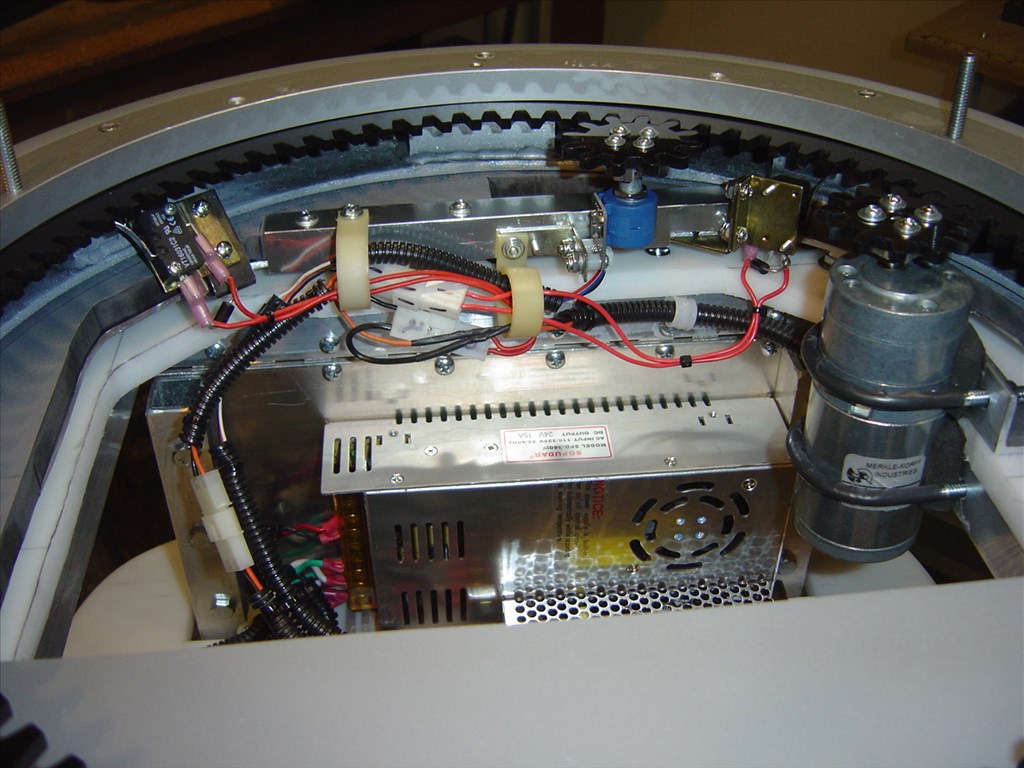

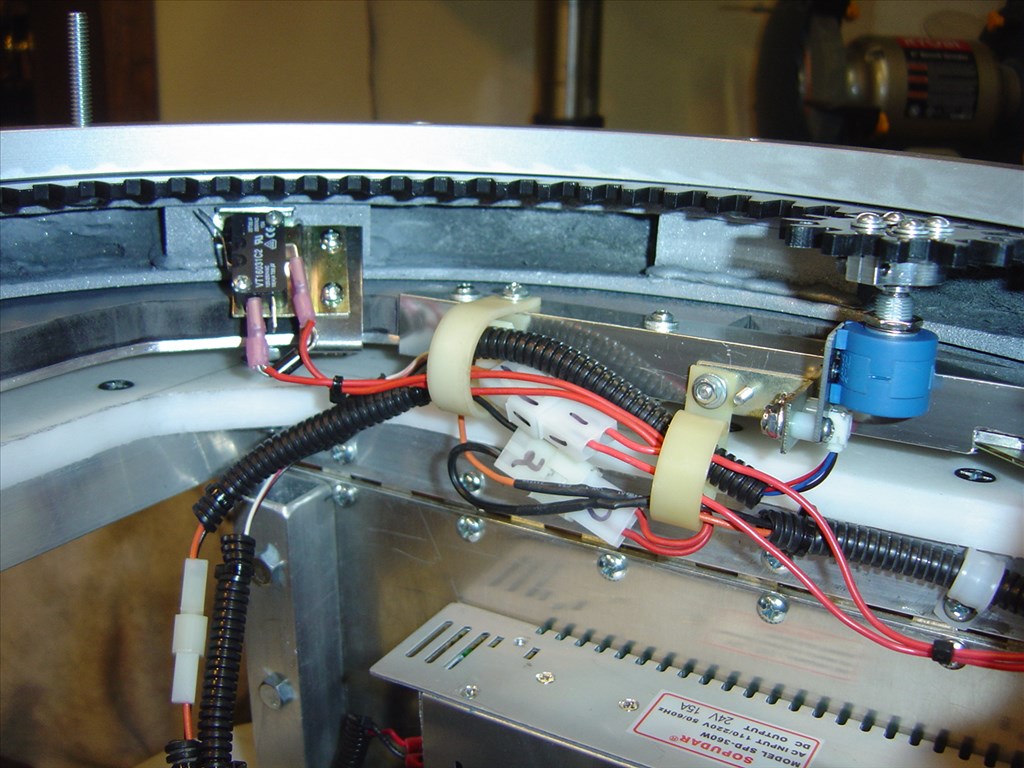

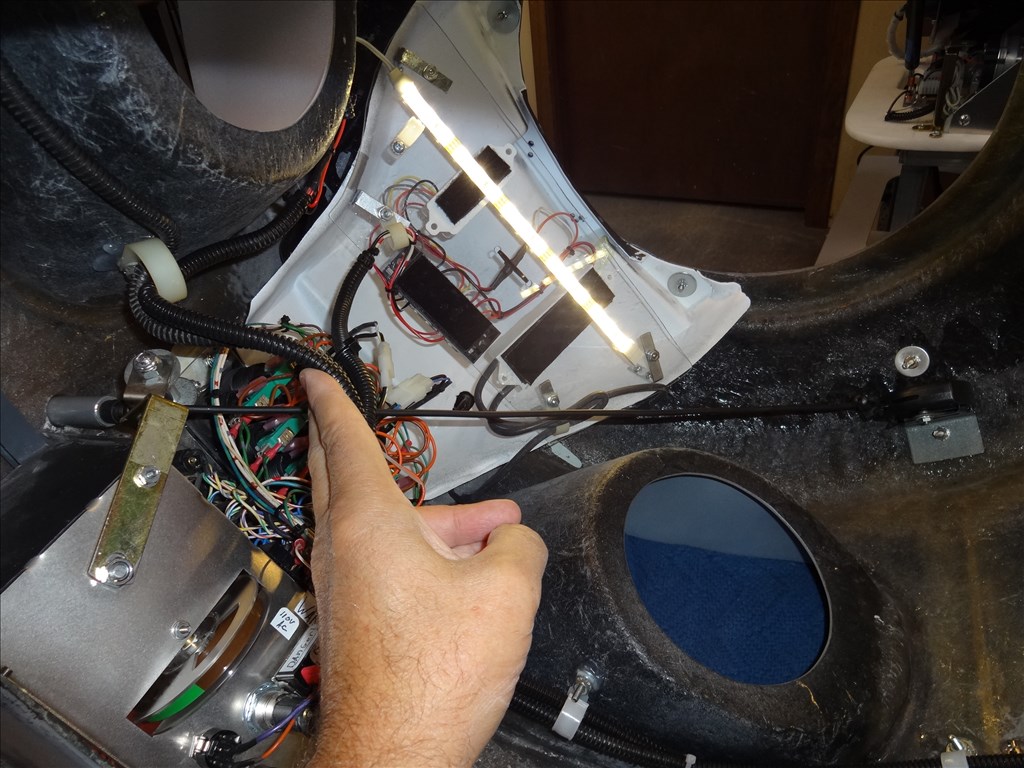

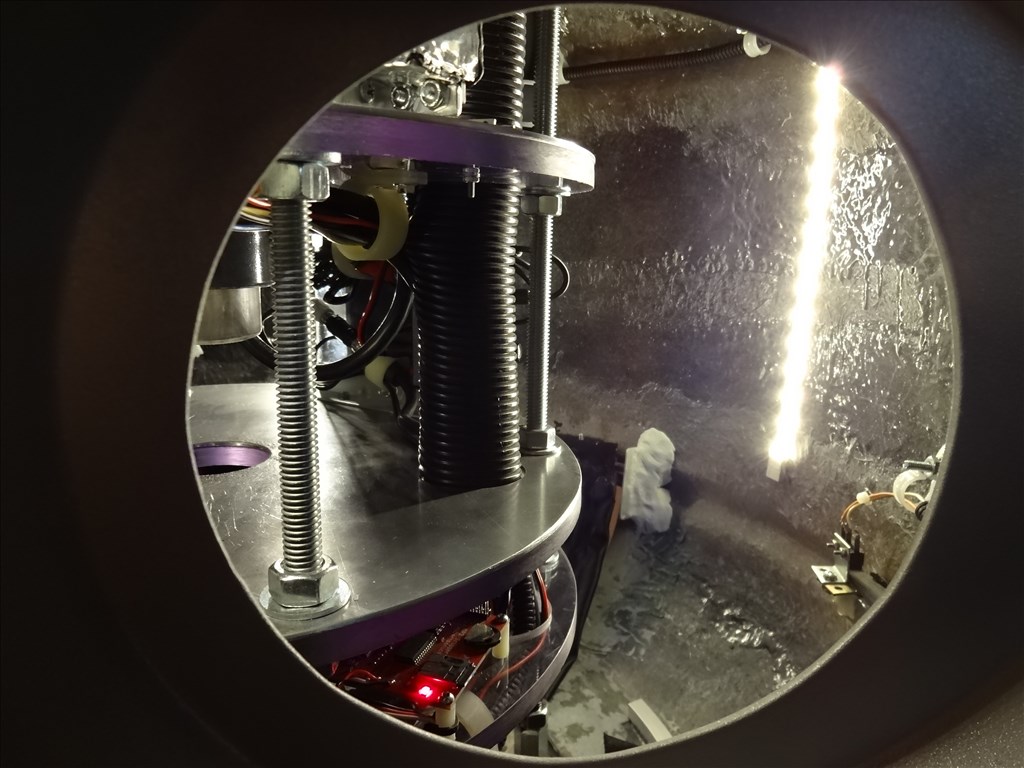

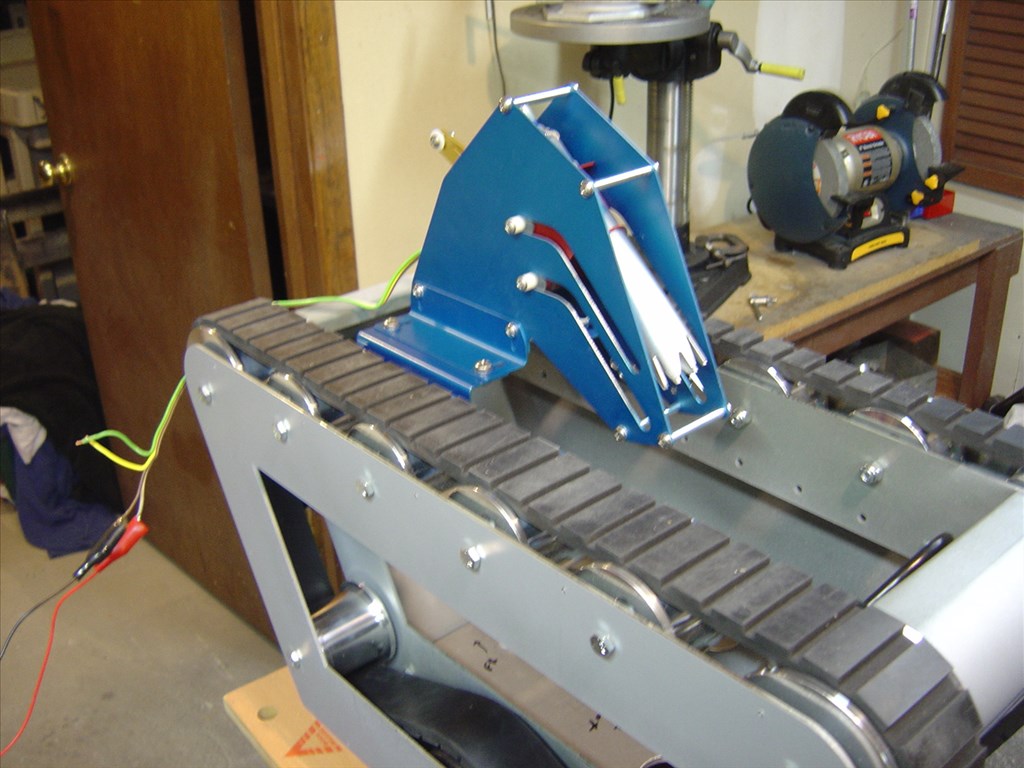

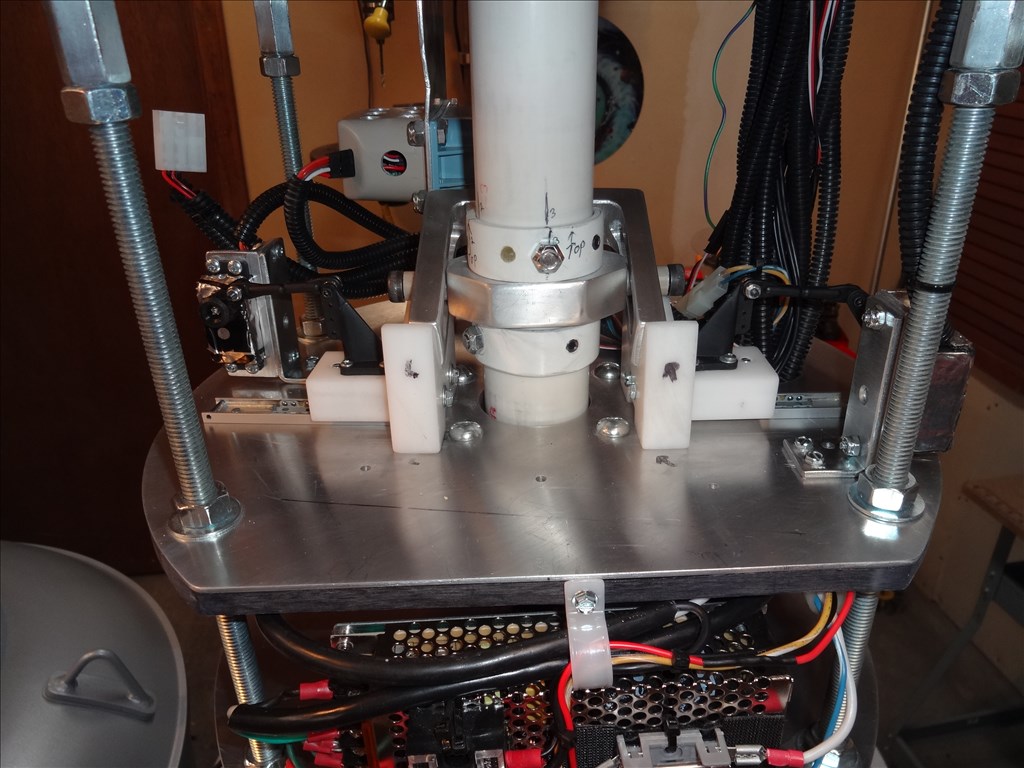

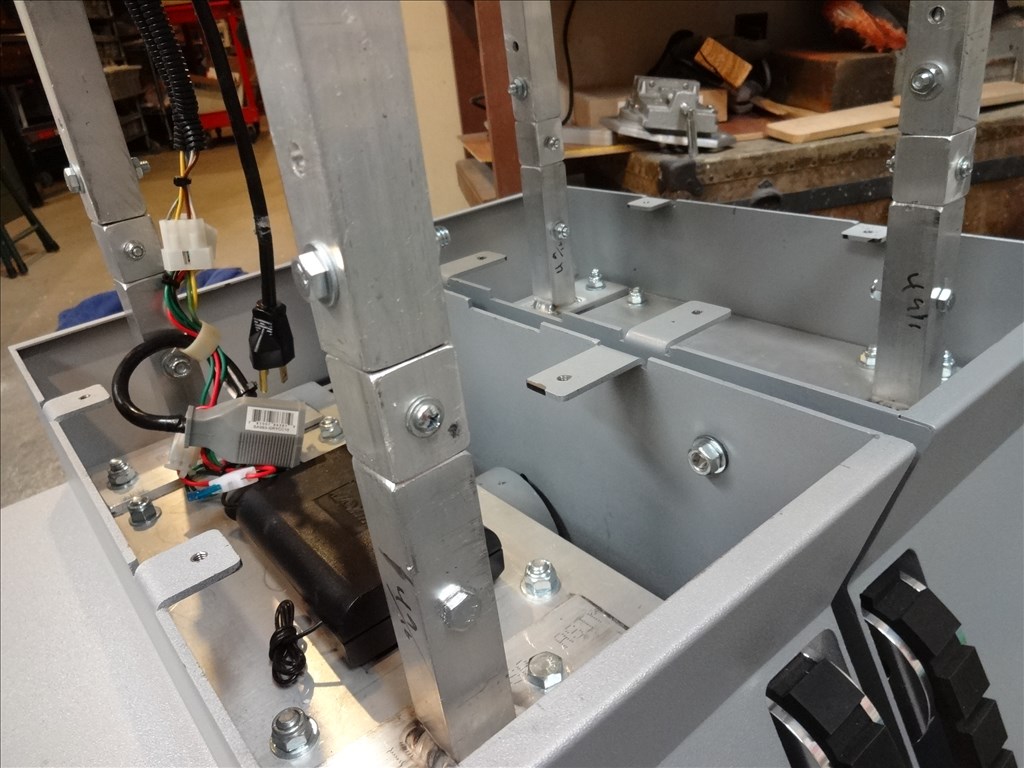

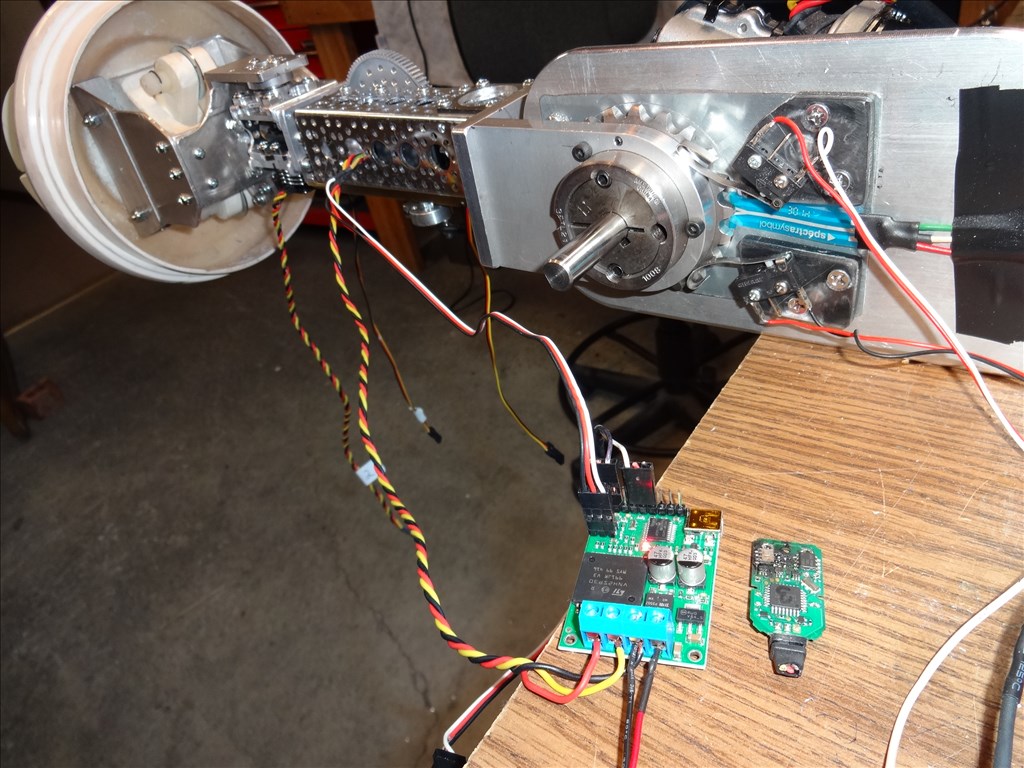

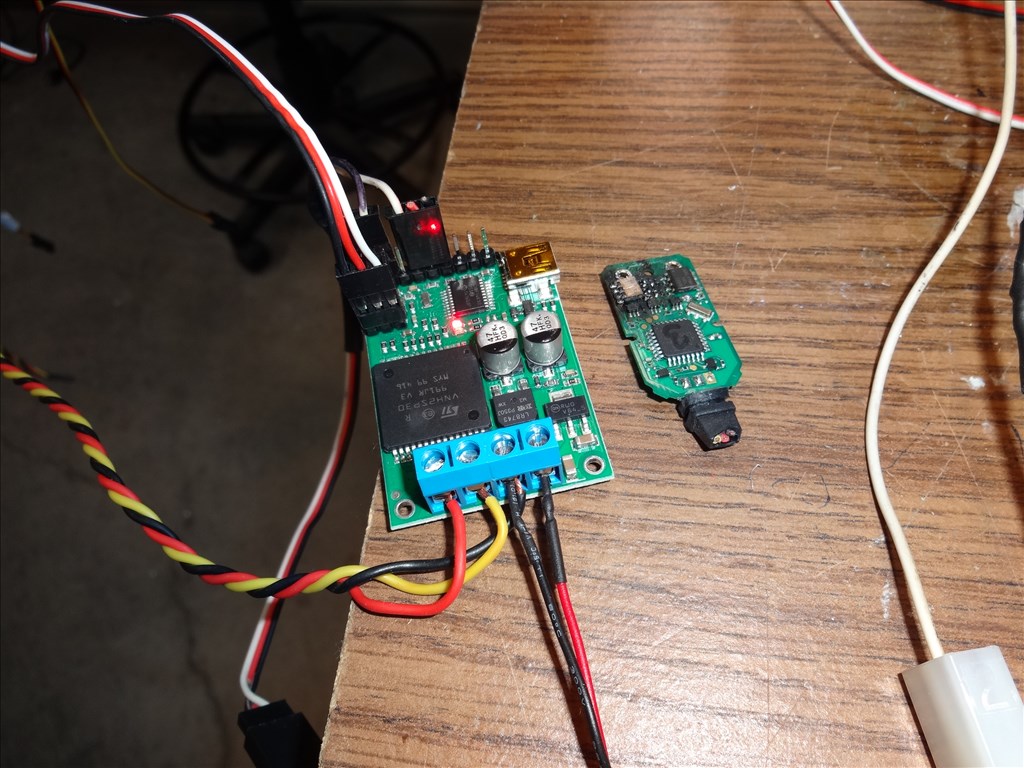

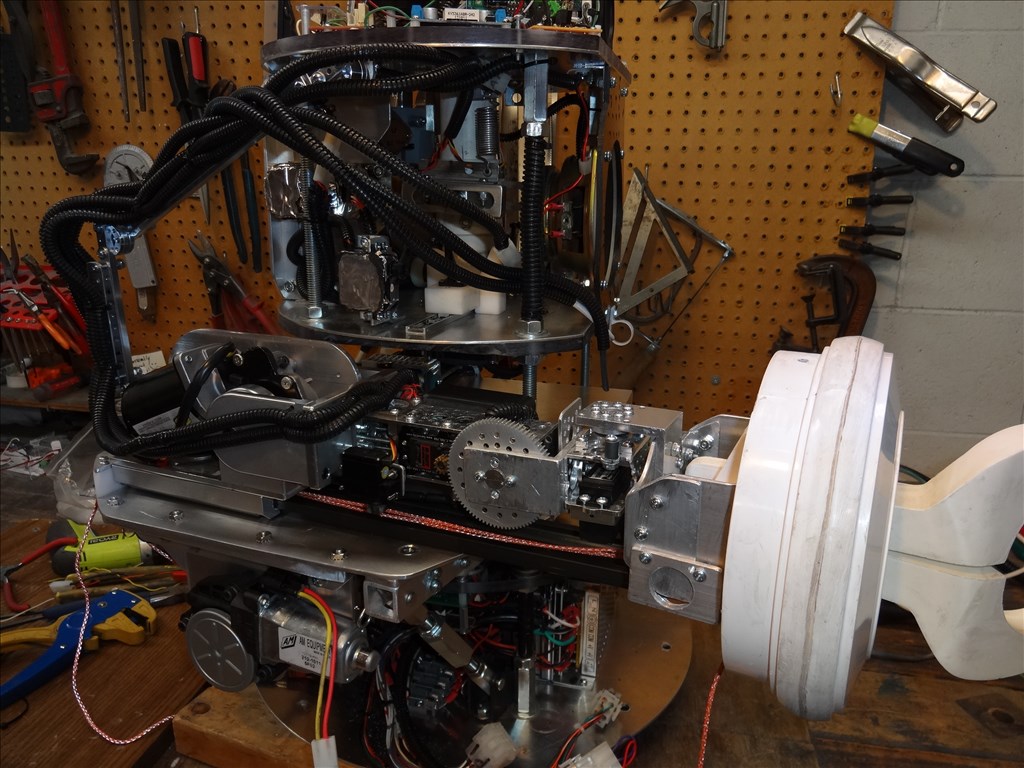

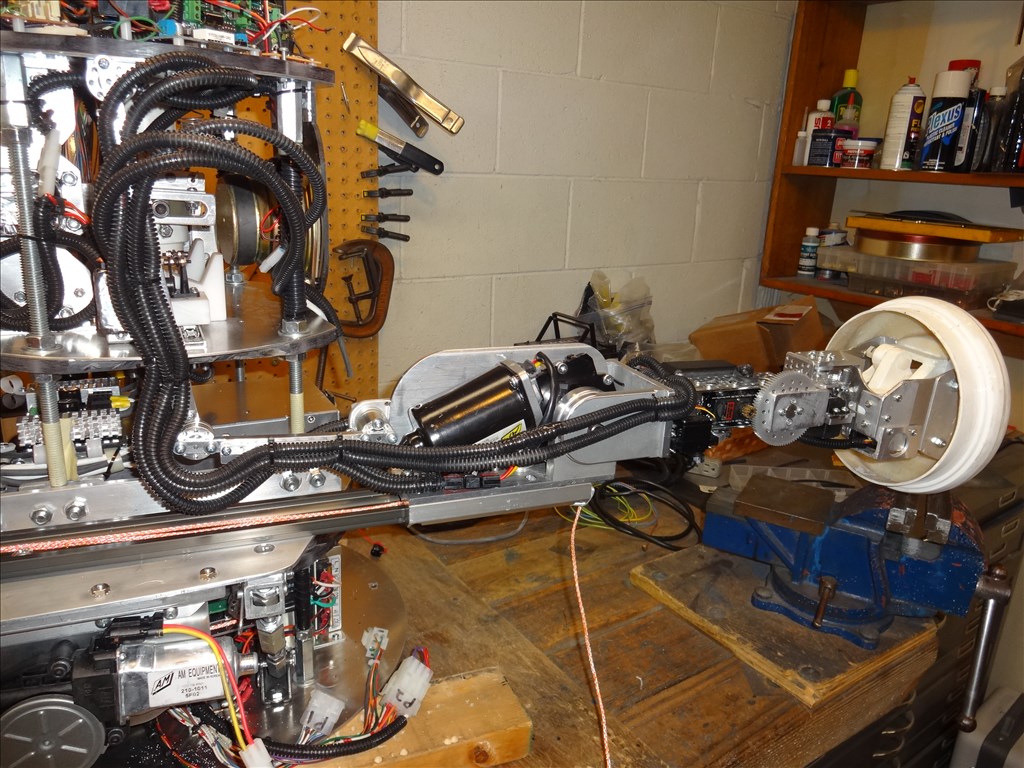

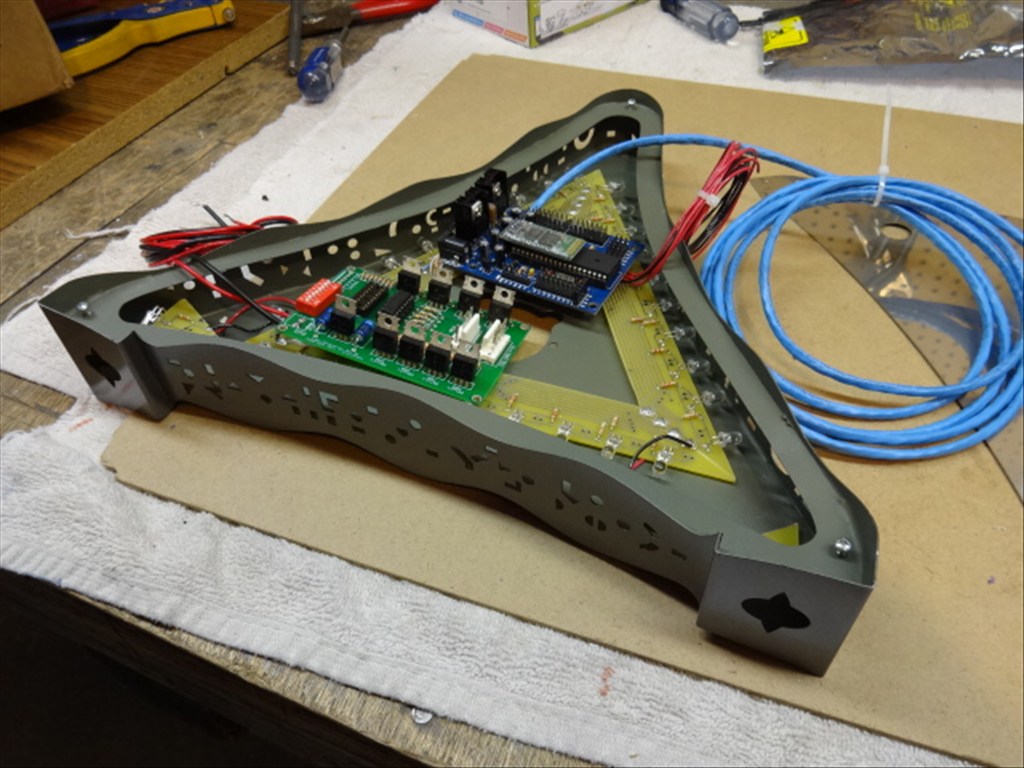

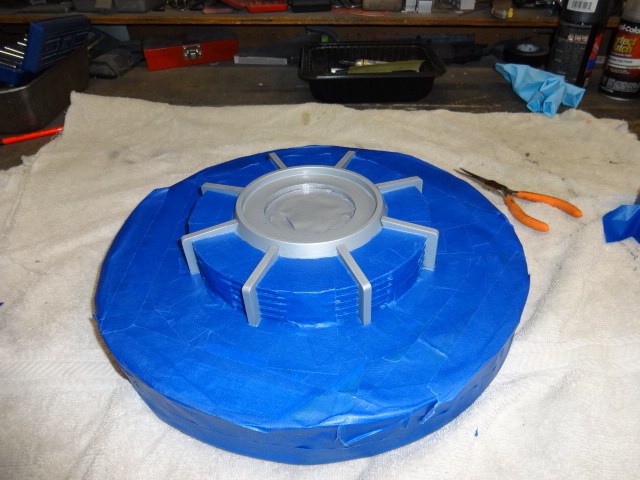

I've been working on a way to keep a servo holding a load for a long while. What I want to do is have my bubble lifter hold the bubble/brain up about 1 inch while B9 is active. Total travel distance from fully down to fully up is about 3.5 inches. Doesn't seem like much but the effect is just right compared to the TV robot. So simply put; I want to have 1" down to show anger, sad and other negative emotions along and 2.5" up to show interest, excitement and positive emotions.

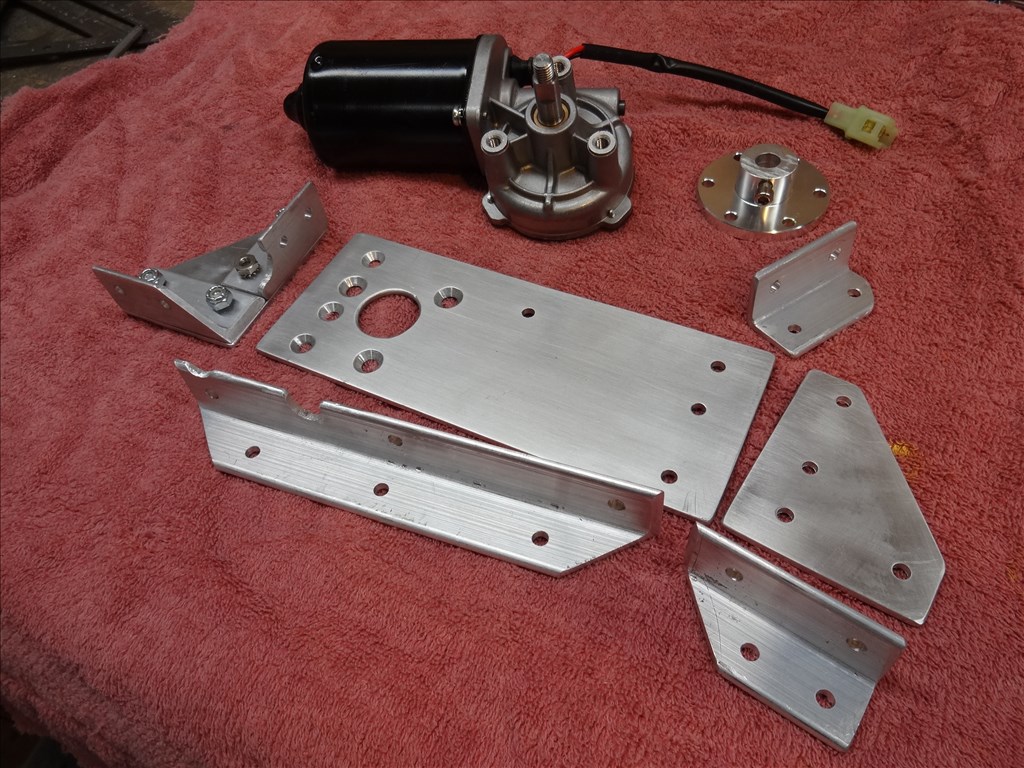

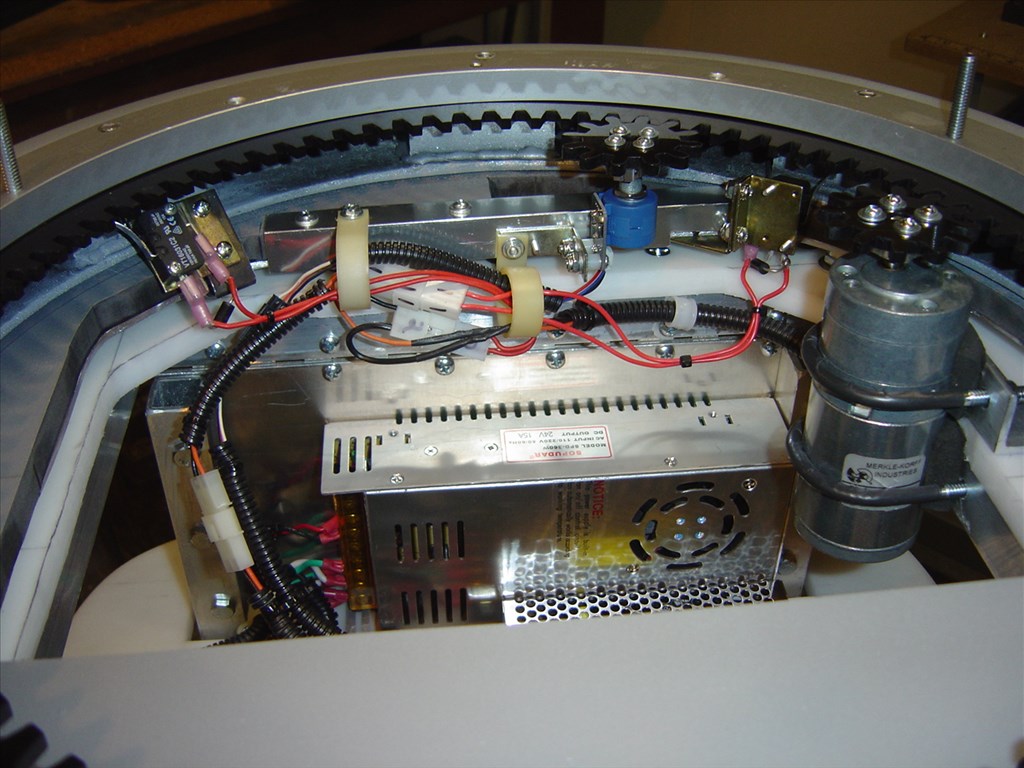

I understand this action of holding a load will eventually wear out or burn up a servo no matter how heavy duty it is. After all, my bubble section weighs over 15 lbs and the HD servo I bought cost about $250 USD. I don't want to burn this sucker out or strip it's gears. After weeks of brain storming and several different "mind designs" I decided on using supports under each side of the lifting fork to support the load. Then I'll have smaller servos controlled by ARC pull the supports out. This will allow the HD lifting servo to let the load "drop" the 1 inch I need to show the negative emotions.

I wanted to accomplish a number of things in this design. First was to keep things simple and the other was keep all the stress off all the servos and the mini drawer slide I'm using as a track to move the blocks back and forth and keep them in line. Also as in the rest of my build, I want this to last forever.

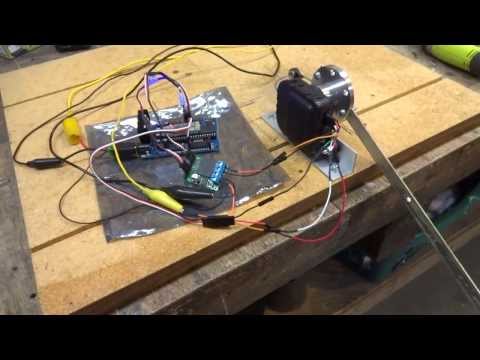

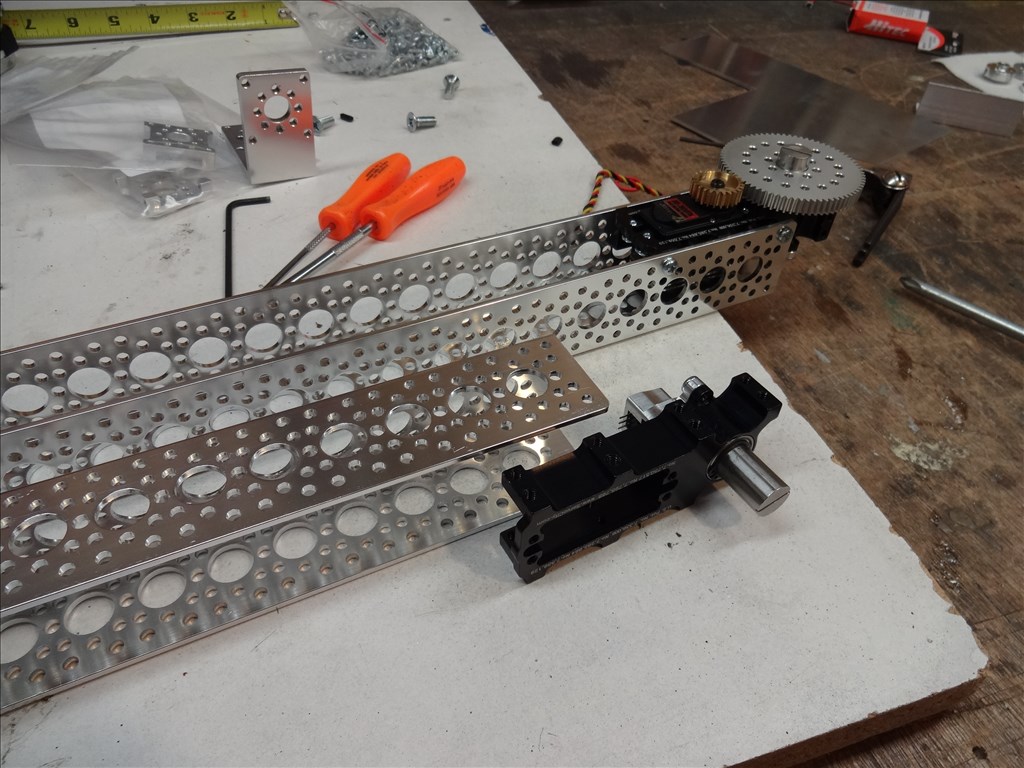

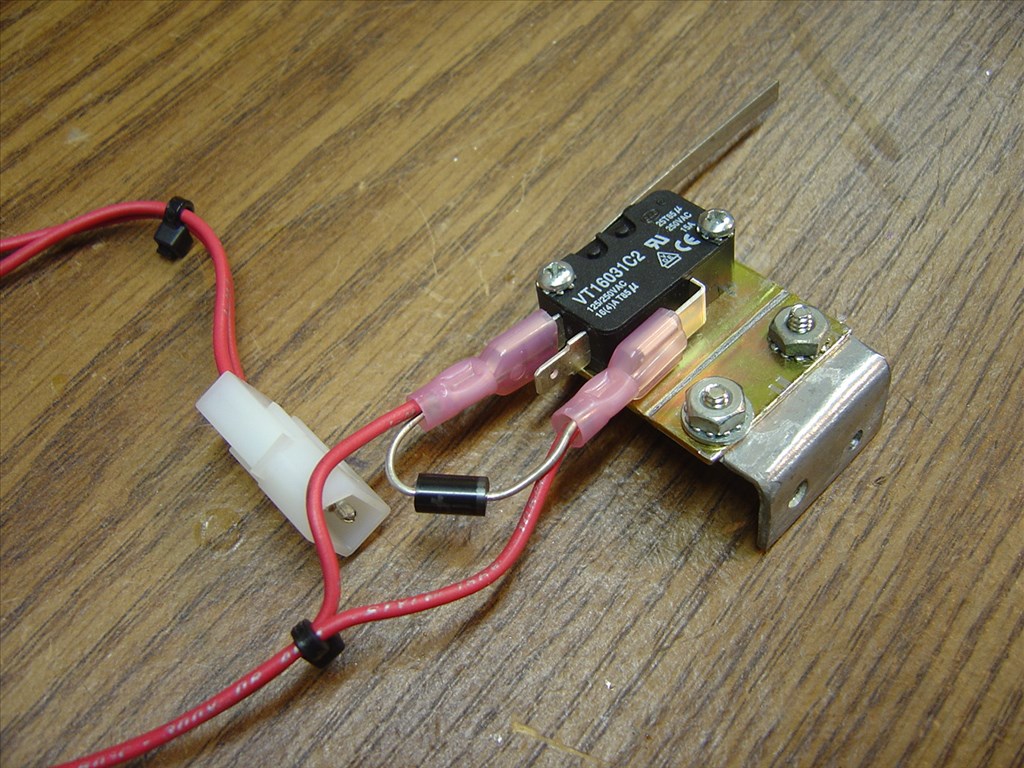

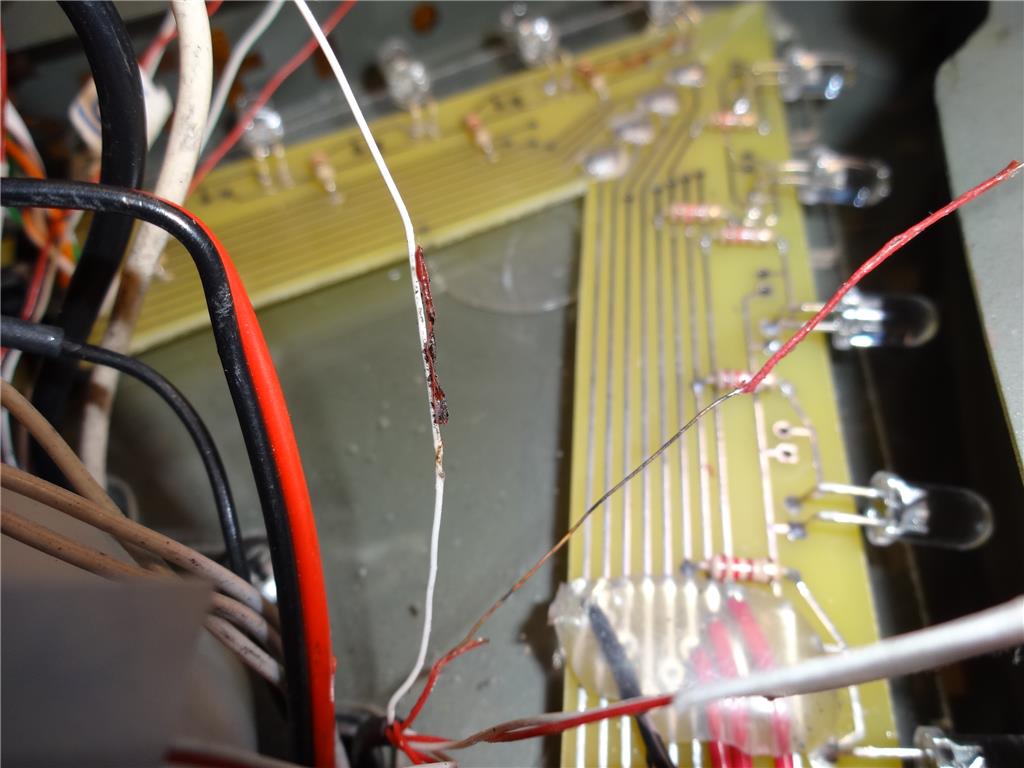

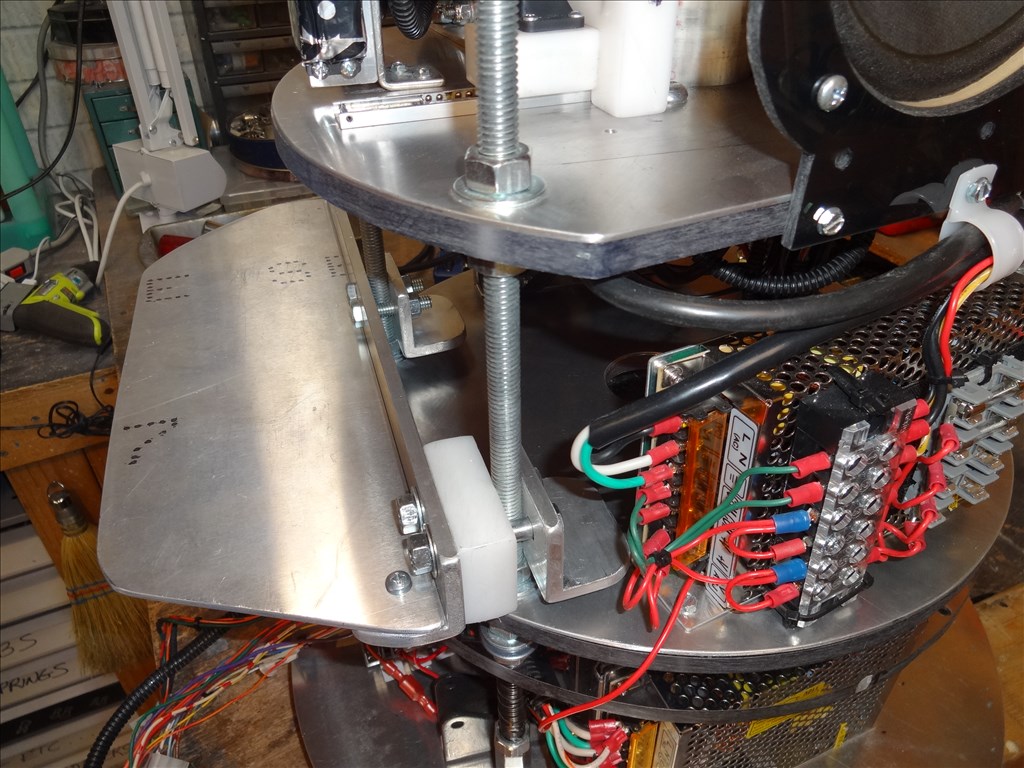

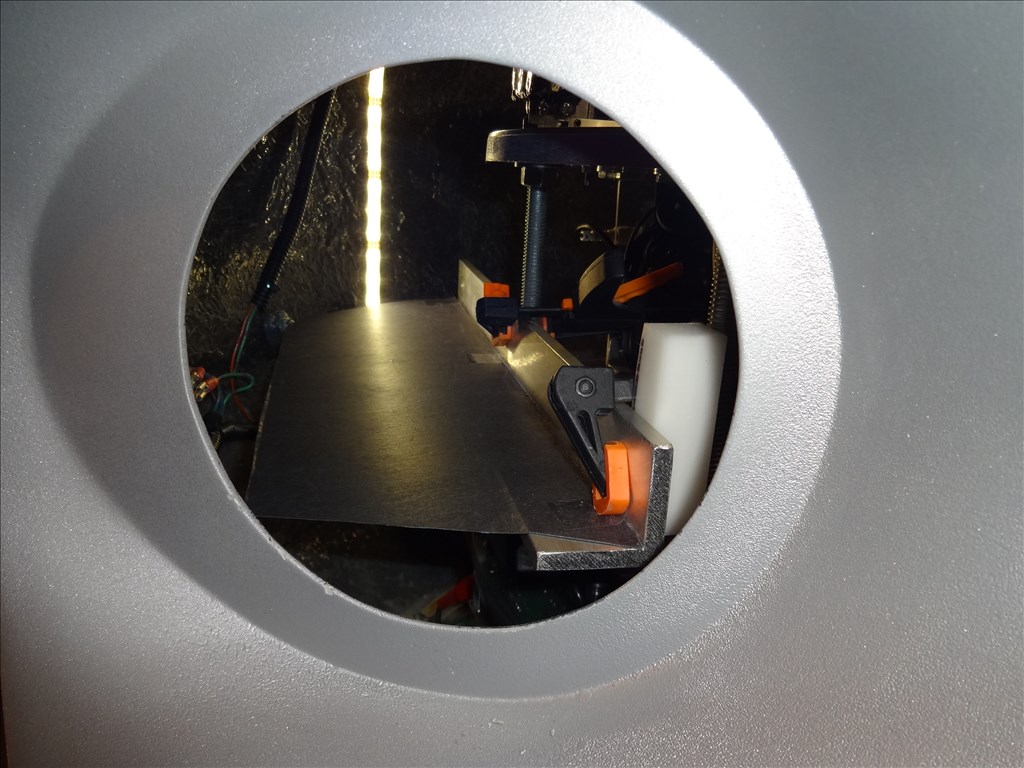

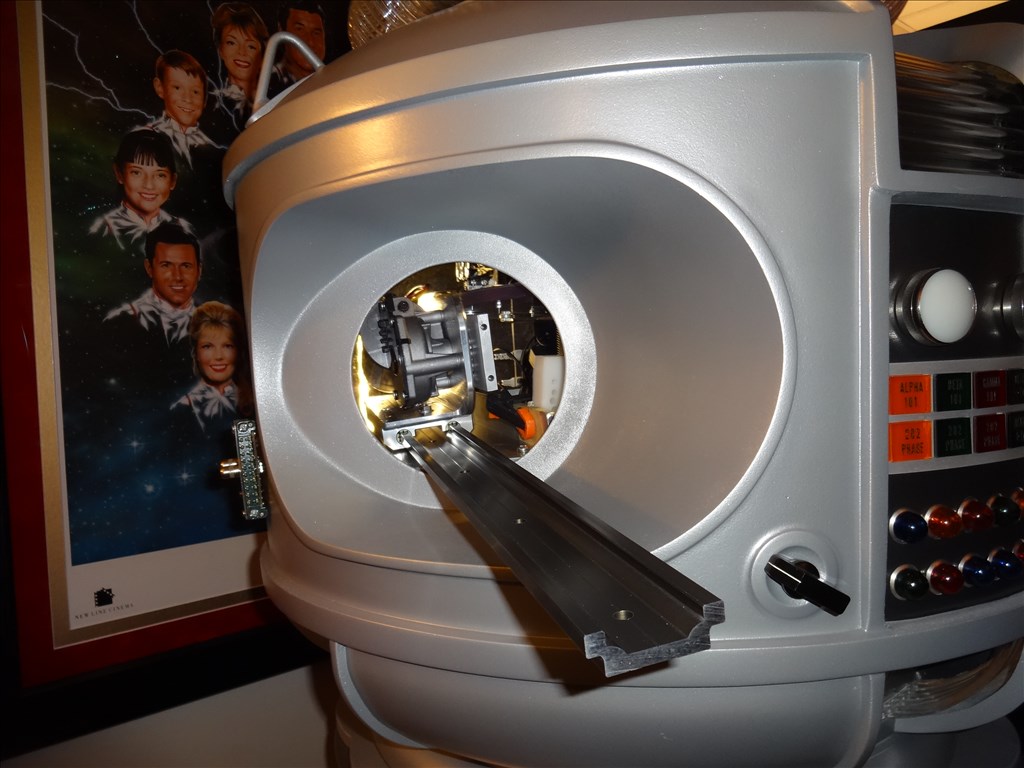

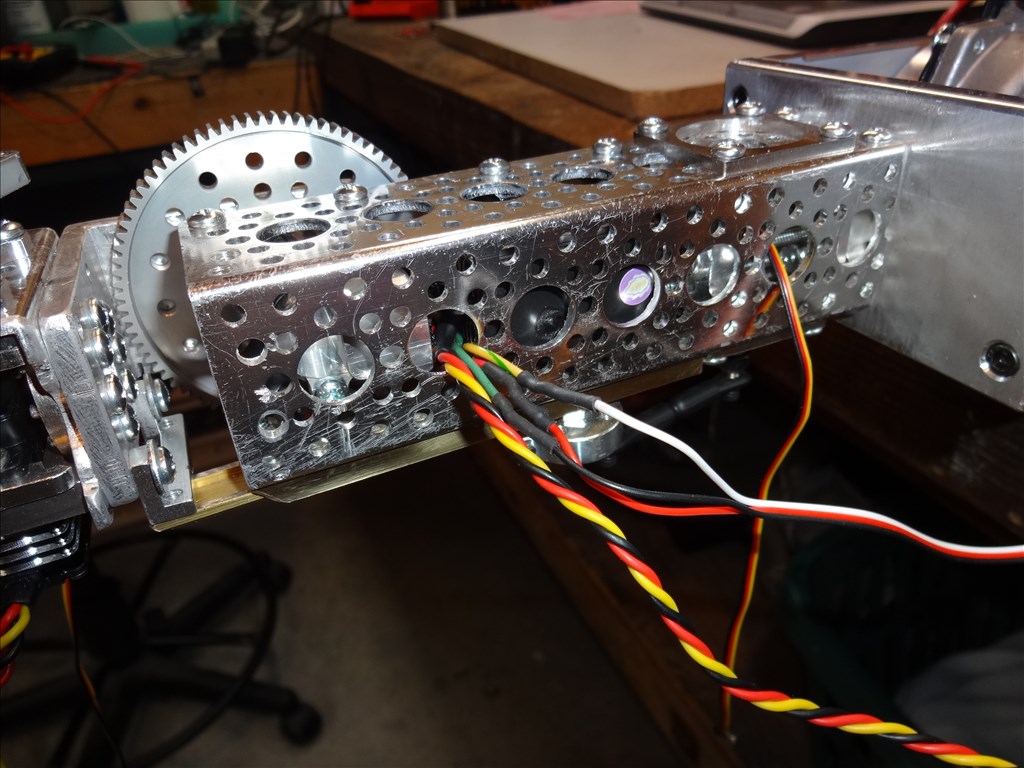

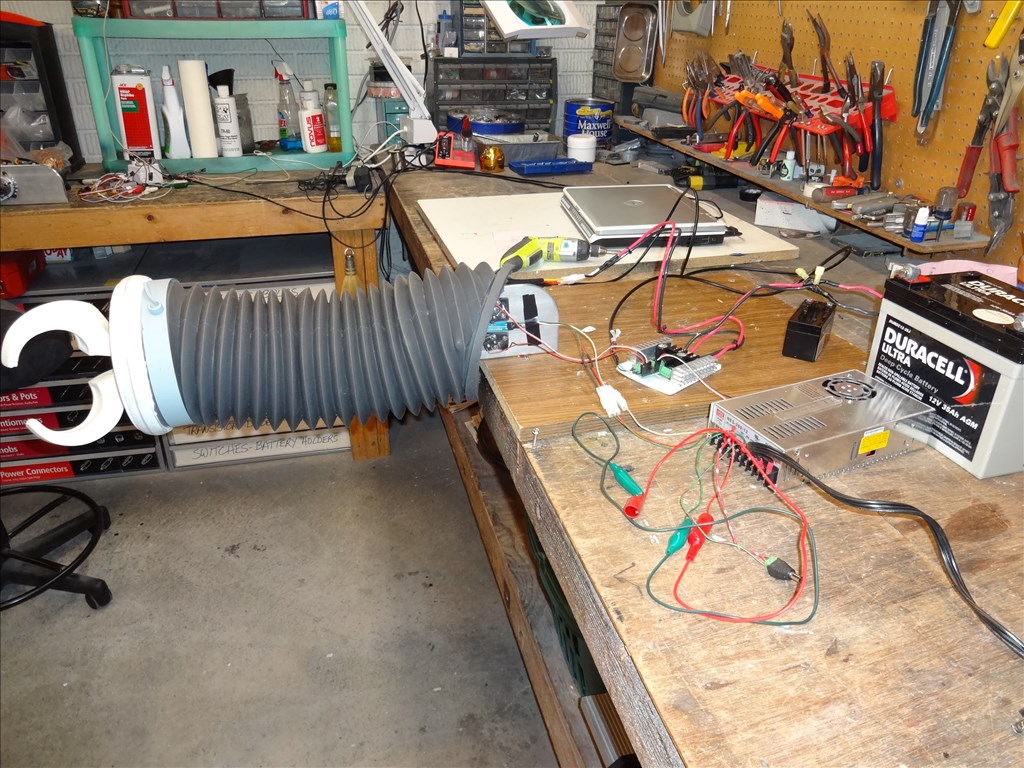

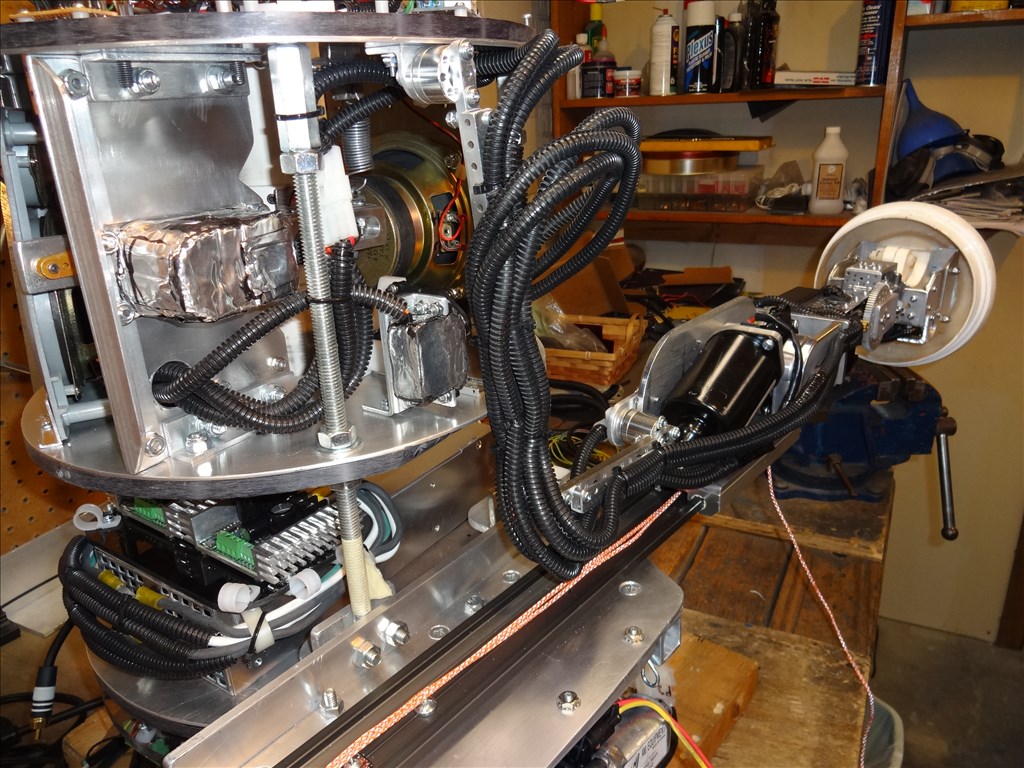

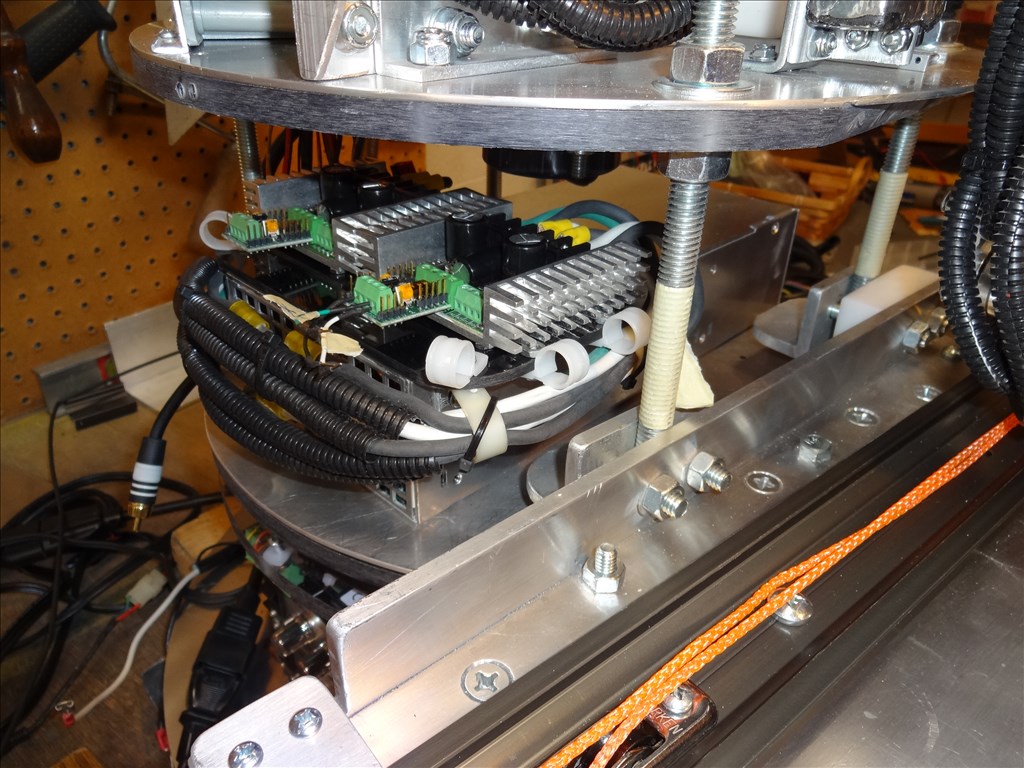

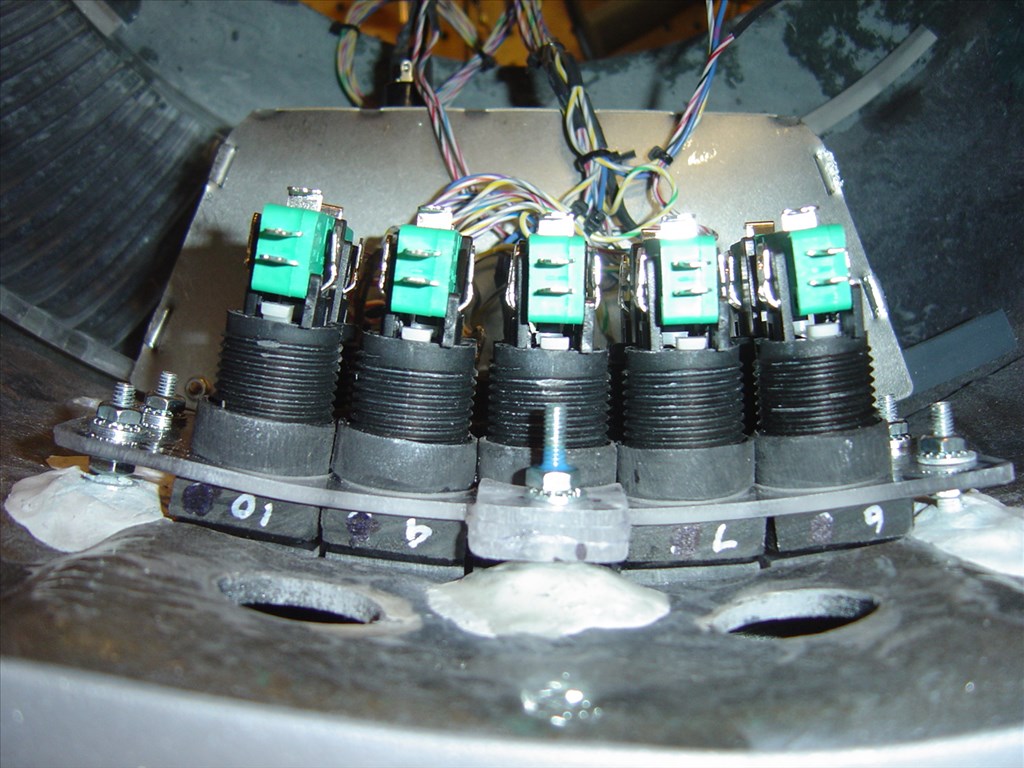

I've got it half built (one side of the lifting fork supports) and it seems to work great. Here are a few pics of my progress so far. I'll make a video of ARC controlling it after I get it all built.

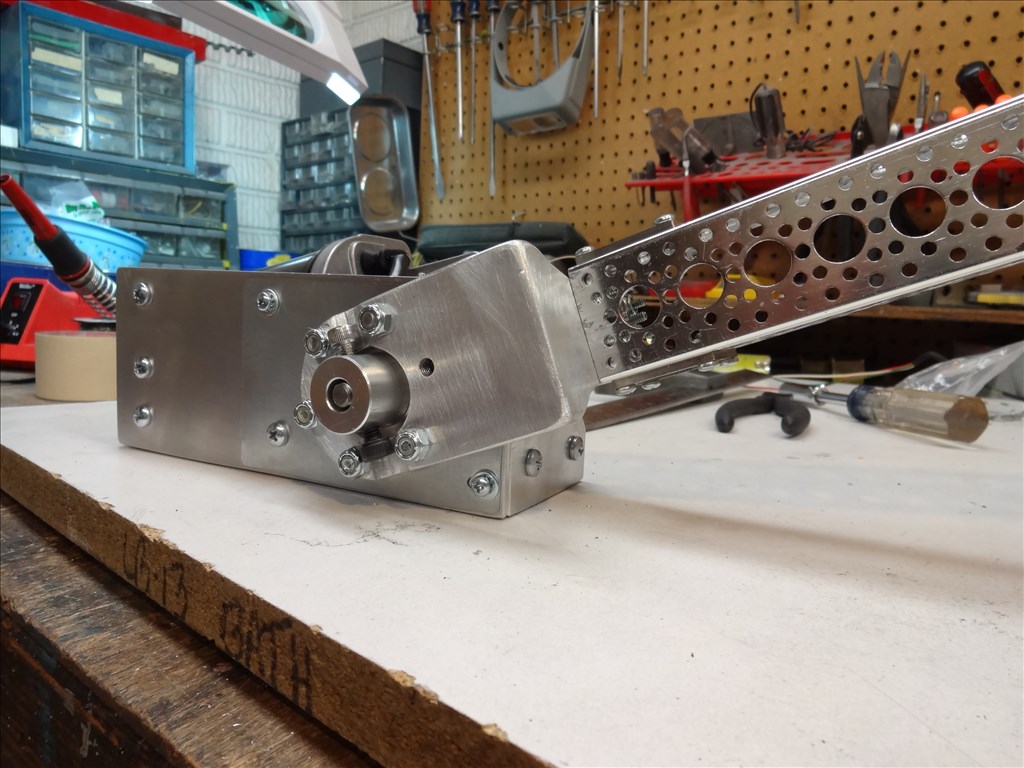

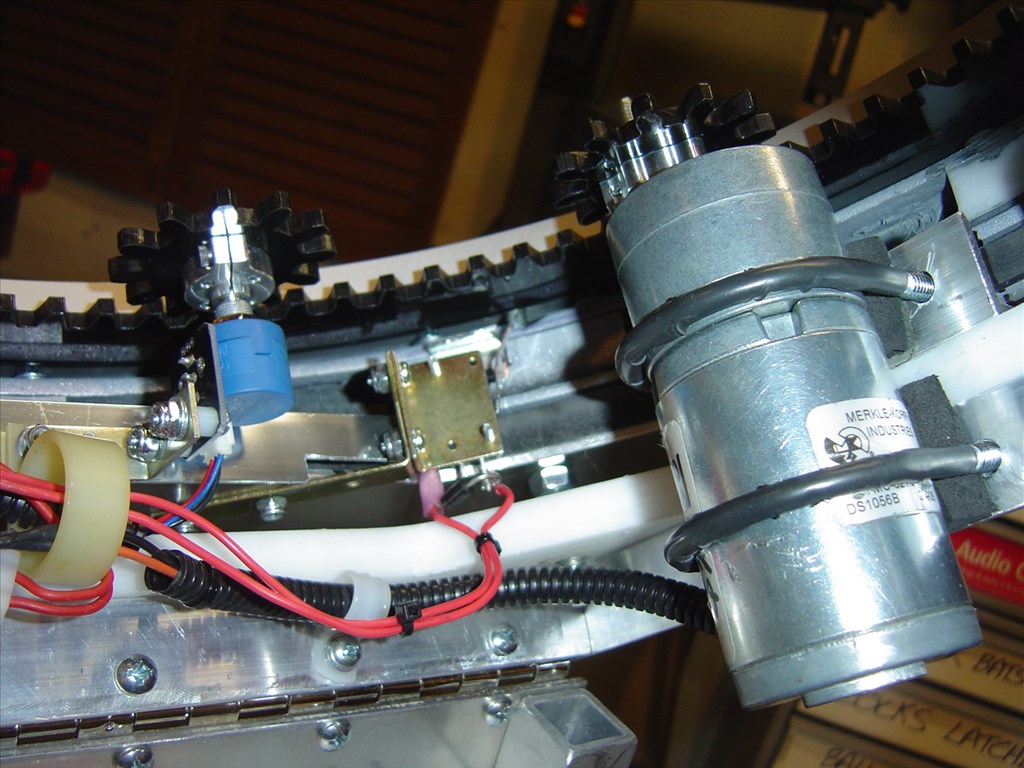

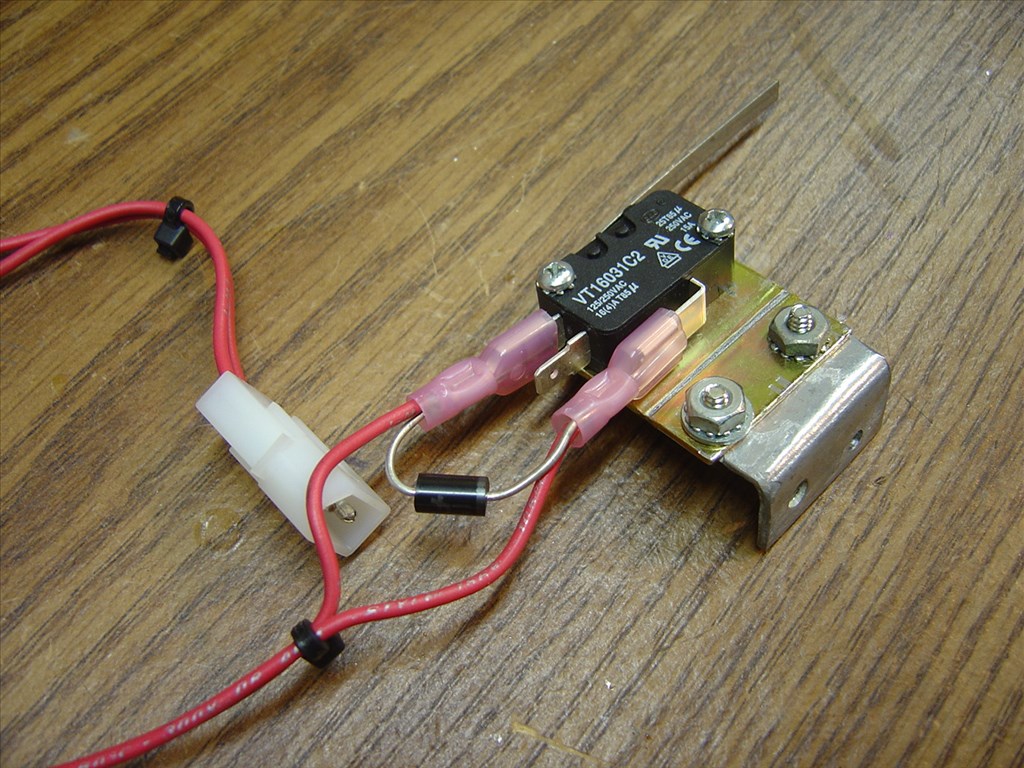

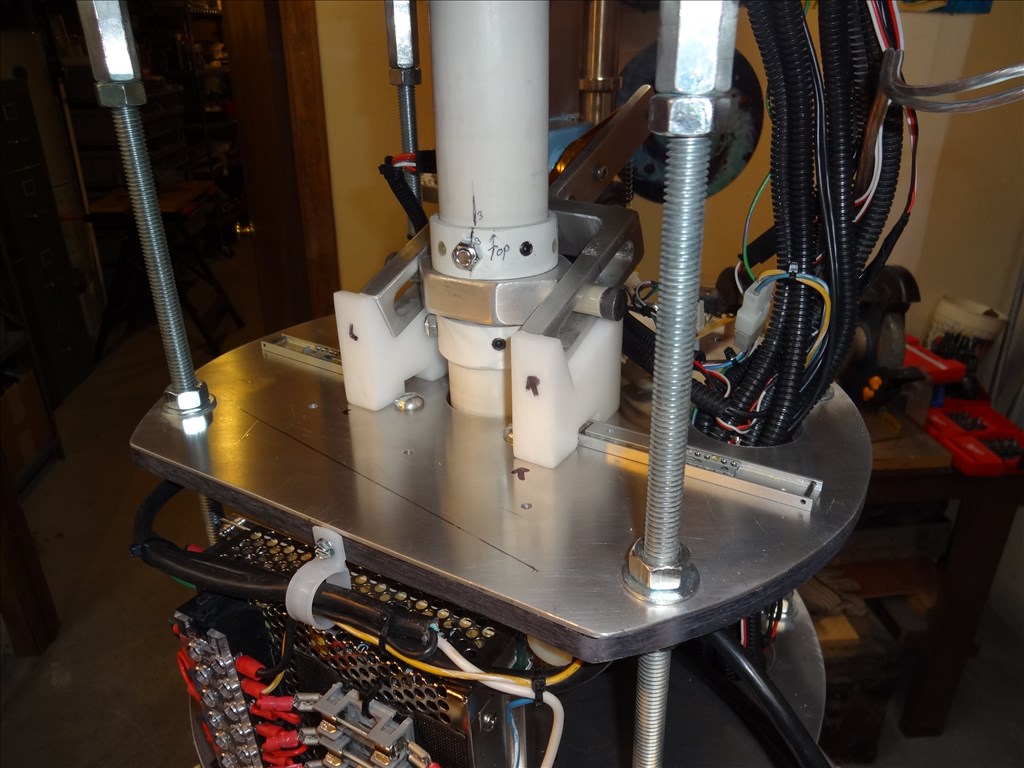

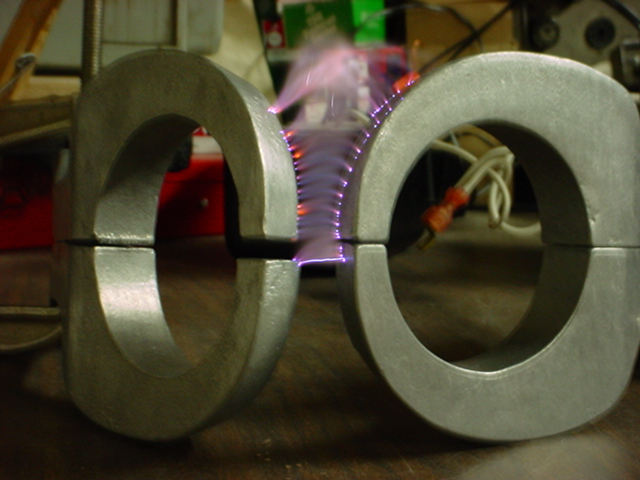

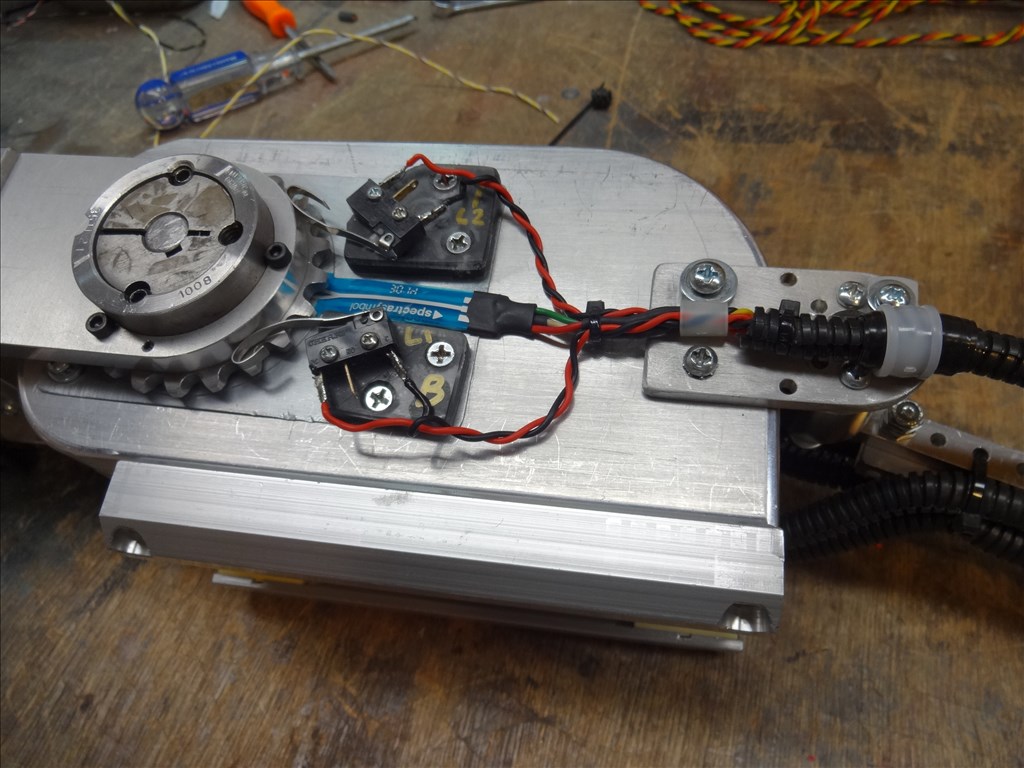

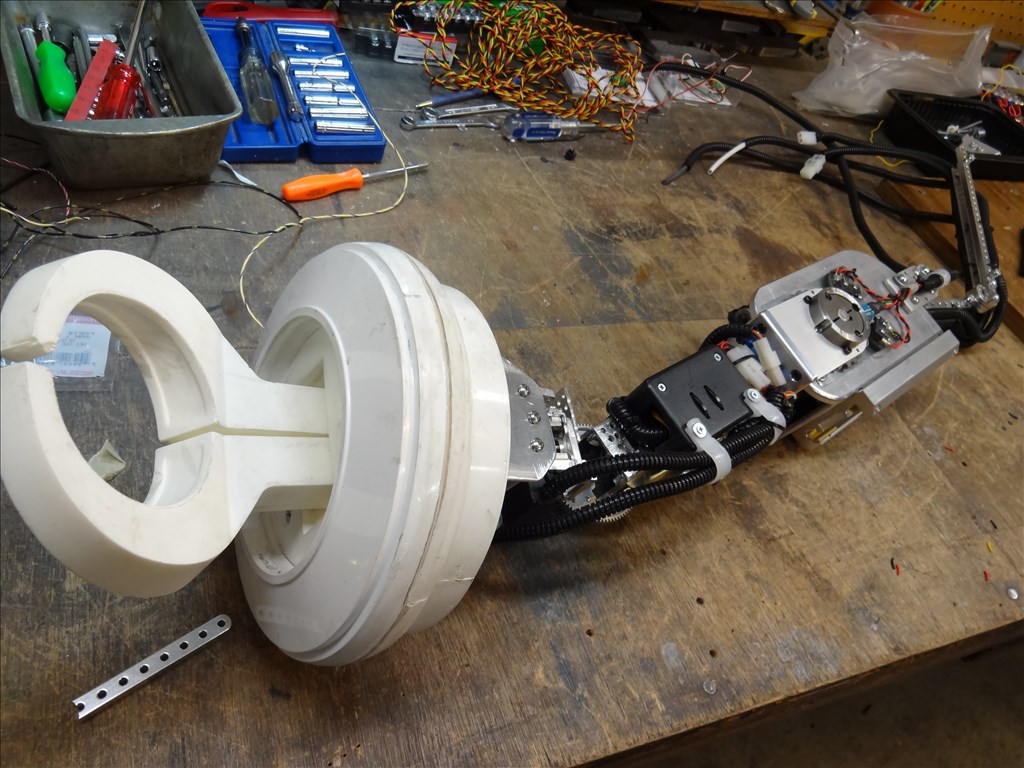

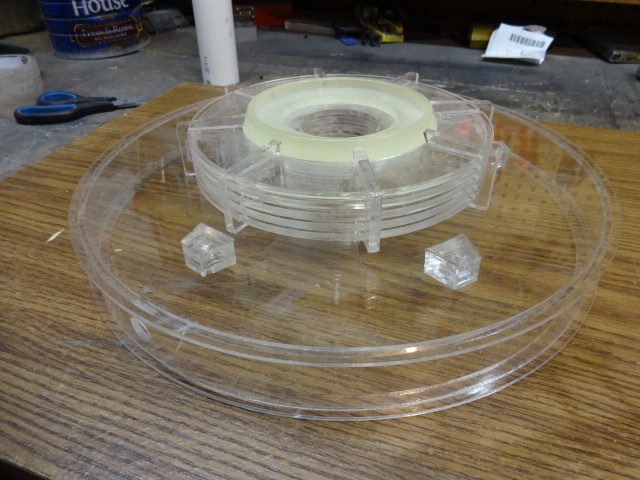

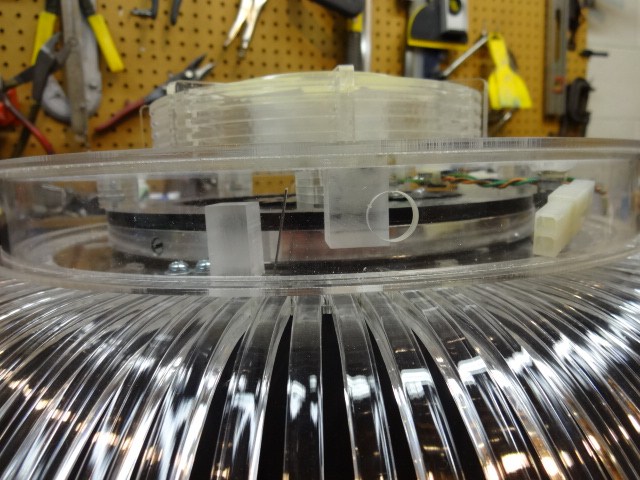

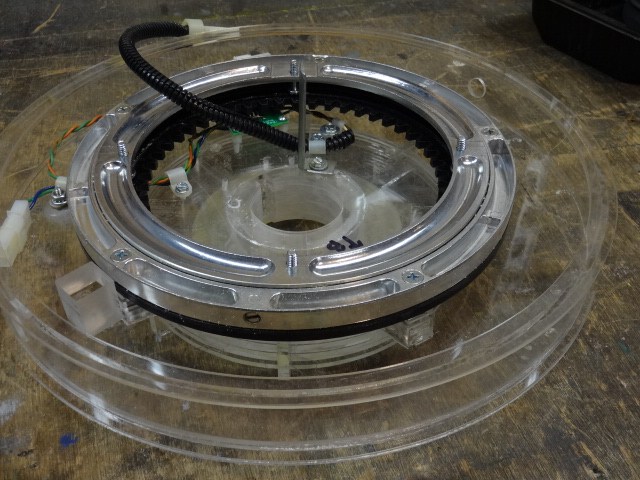

Here's a test fit of the supports I built out of Acetal. A very strong, slippery and workable plastic. It should last and not wear out.

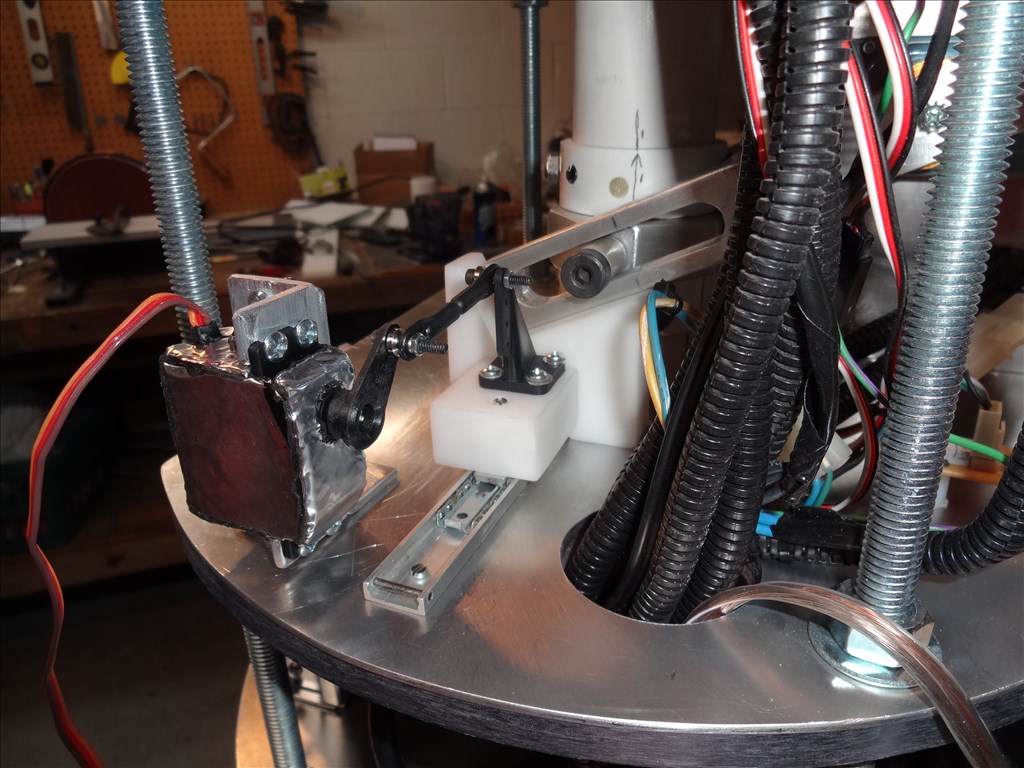

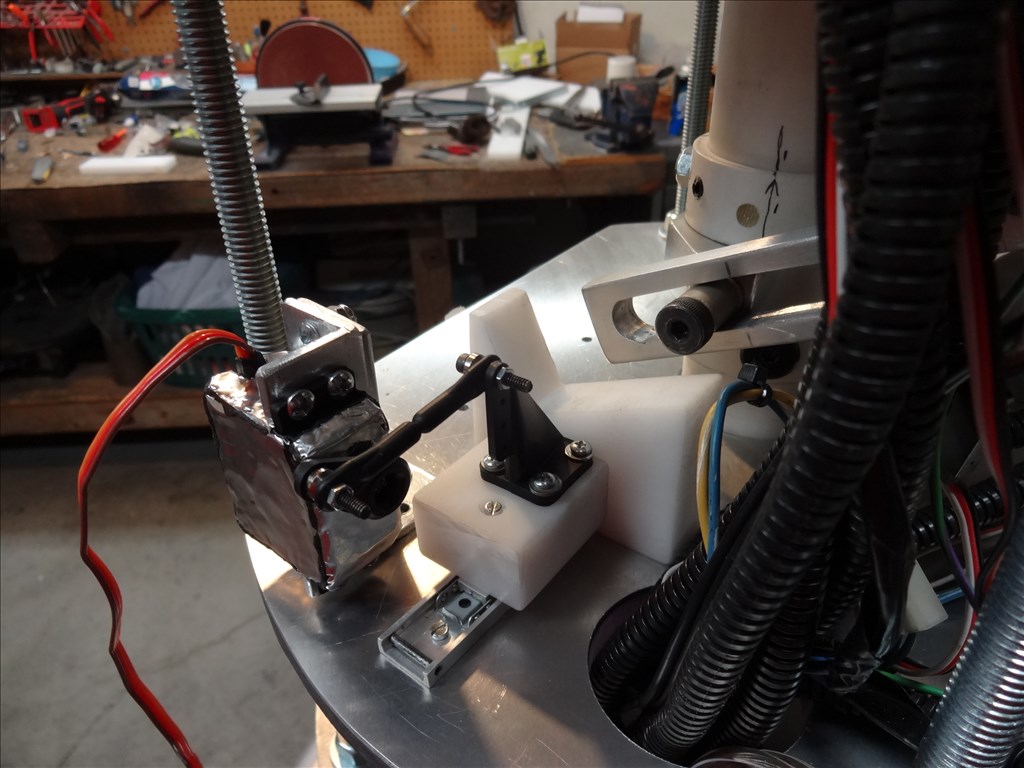

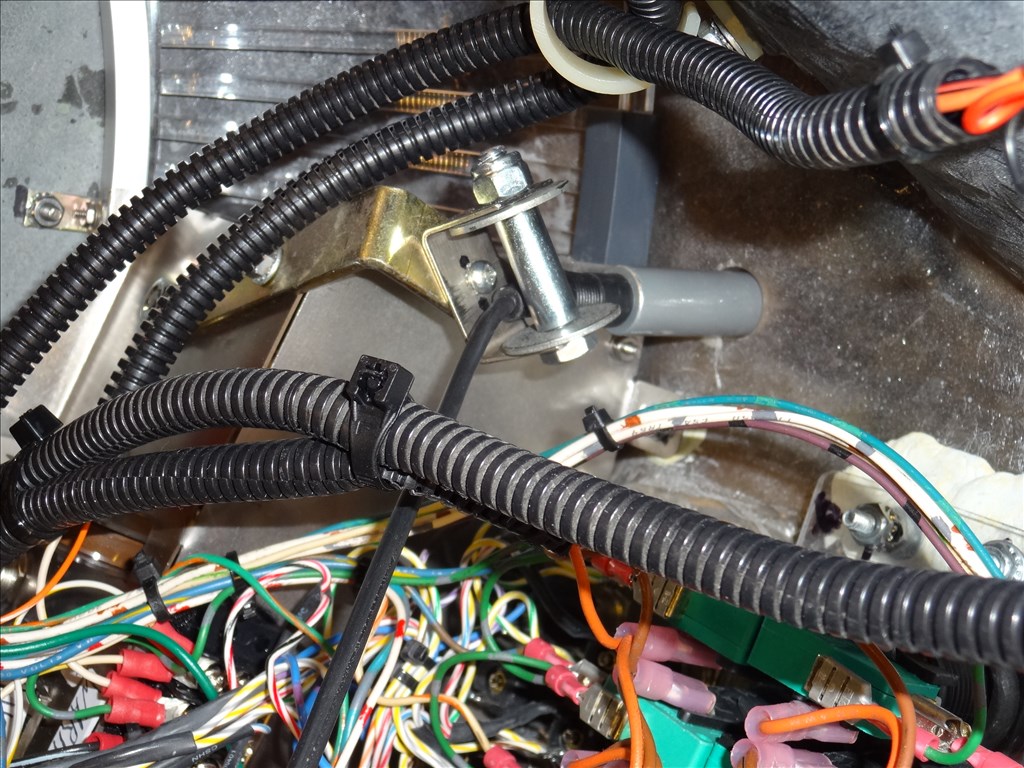

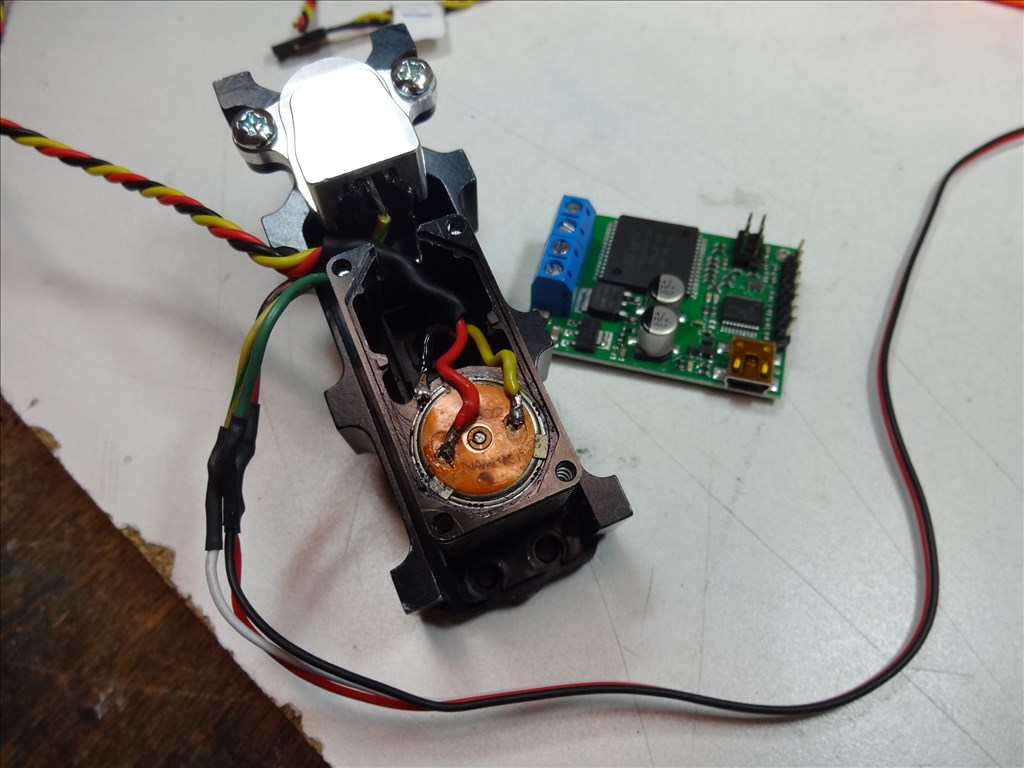

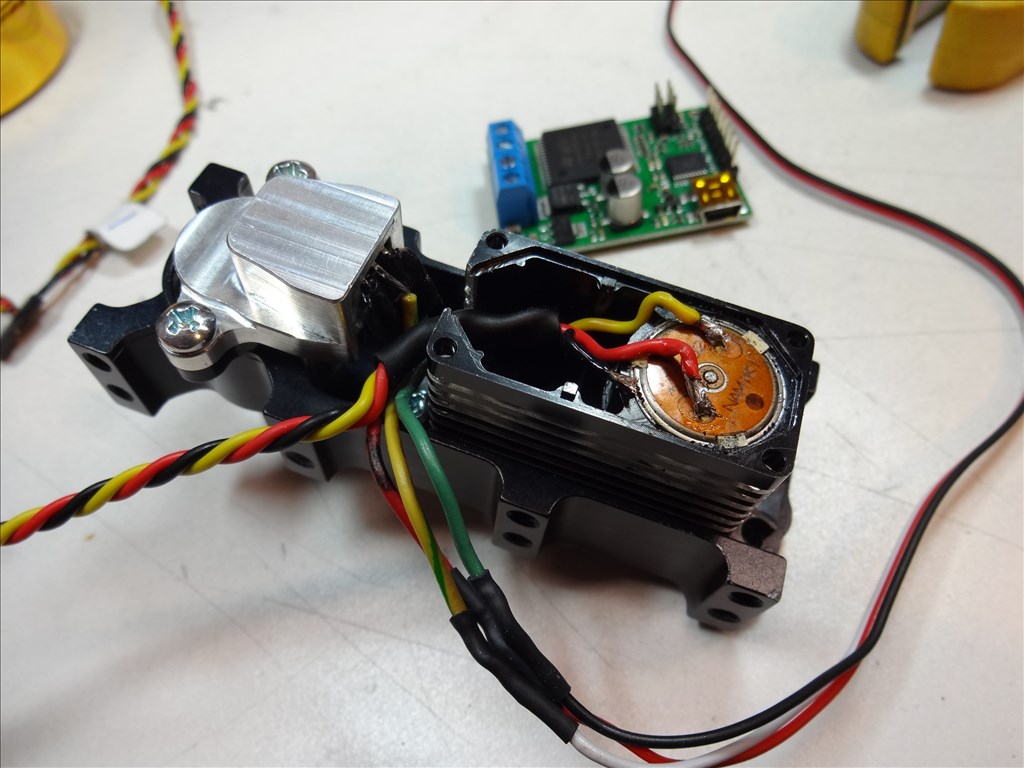

Here are a couple pics of one side of the support completed. I'm just using a standard (EZ Robots kit) servo with standard servo linkage to pull the blocks out from under the lifting fork. The block is cut so it straddles a mini drawer slide (used in doll houses) so it puts no stress or weight on the slide. A simple EZ Script lifts the main lifting servo a fraction and then pulls the blocks out. Then the main lifting servo can lower the load. The silver cover over the standard servo is Dynamat for sound proofing. It does quiet the servo down enough to keep the whine from sounding like my ex-wife but it still can be heard. It's livable now.

Quality work Dave! Thank you for posting your photos. LMAO on Ex-wife reference.

Thanks Troy. It a good thing I didn't know about Dynamat when I was married to them (yes, 4 times tired)

Super job there Dave. Top quality construction as usual. Wish I had your talent.

This is a really neat idea Dave, a simple solution for a problem many of us have. I only wish I had your manufacturing skills. So Professional.