Hi

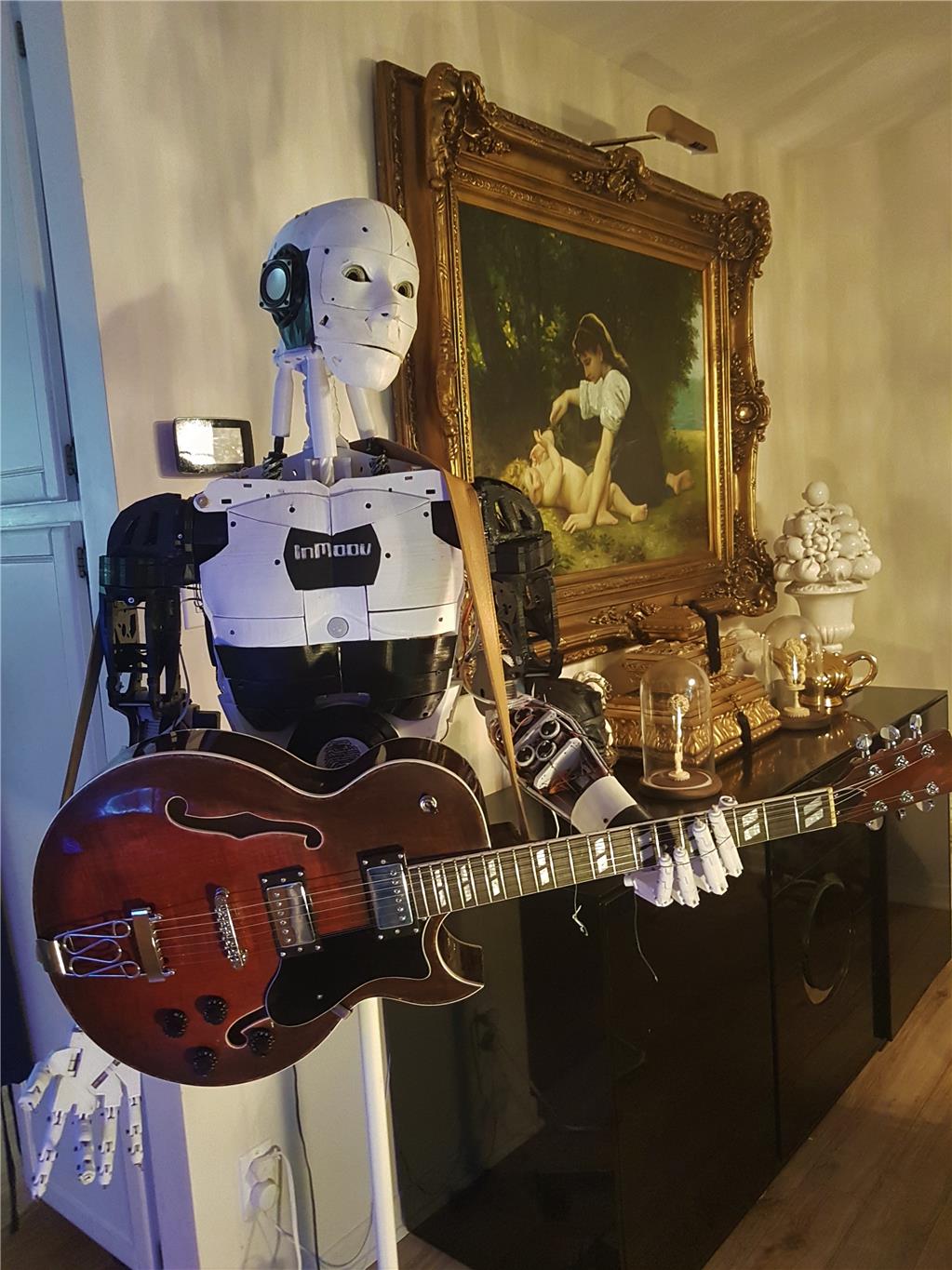

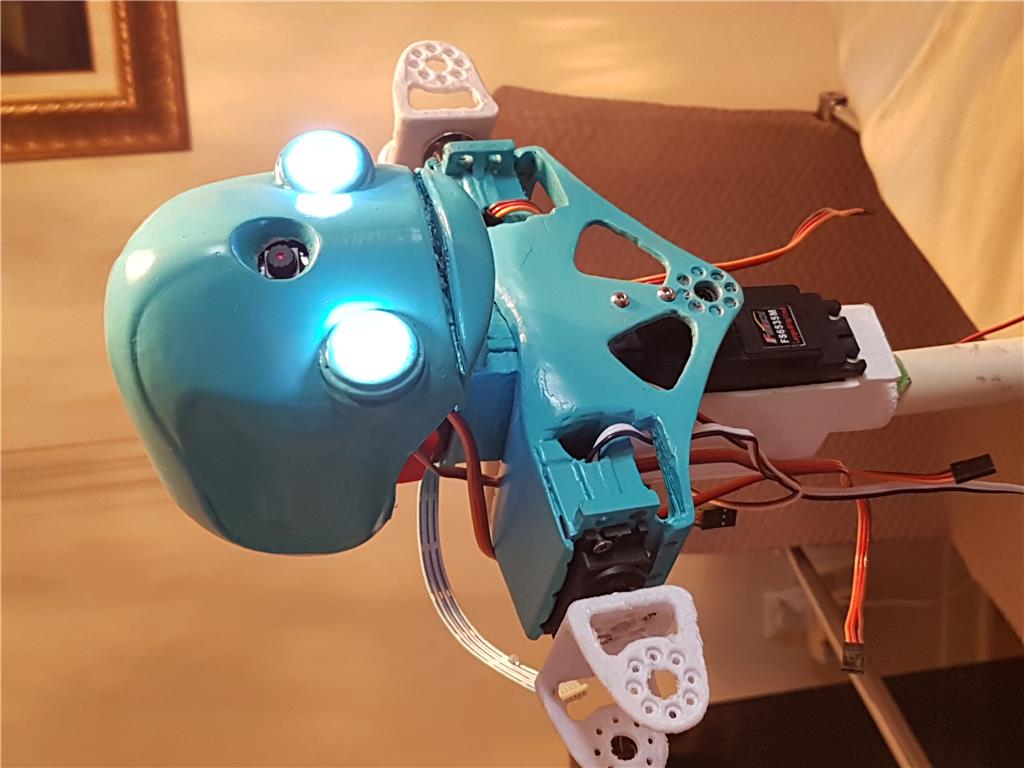

I have been printing the files that were generously supplied by Mickey666mauss for his creation of Zoe. I was interested in the original Zoe head as it just appealed to me as I wanted to have a socially interactive robot and I feel that robot would not be viewed as to human looking and get a negative reaction. like my inmoov and buddy my human looking robot head seem to get on occasion. I wanted to have my Zoe have a mouth so emotion could be verbal. so I have added a mouth on zoe which I think looks very good and also works very well. Other changes I have made to Mickey's design, I have a lot of regular servos mostly metal gear, I decided to make my version of zoe with standard servos and using a EZ-robot V4 Controller as this is what I am more comfortable with. of course I had to alter the parts of zoe to fit standard servos, which was not an easy task as I feel I am not that good with Cad design. but I managed to make due. This version of Zoe will be mobile mounted on a mobile base and I have lots of design to complete to make that happen. My version of Zoe is not complete but most of the parts have been printed. I have had a belt self destruct on my delta printer and I am waiting for a replacement and during this pandemic it will take a while. the arms are almost complete but I will add pictures of that and Zoe moving later. the pictures I have downloaded show Zoe and Zoe with eyes illuminated. the camera is also installed the lights are bright so Zoe can see better in the dark.

By nallycat

— Last update

Other robots from Synthiam community

Toymaker's My Little Dewey (Drone 1) New Home

Inventor/roboticist studio features an Alexa-controlled Dewey Drone aboard the Space Freighter Valley Forge diorama from...

DJ's Detect Multiple Colors

ez-robot camera detects faces, objects, glyphs, QR codes and colors; works with JD Humanoid and any ez-robot...

Jstarne1's Hulkbuster Ironman Suite , Lighting, Sound...

Custom Hulkbuster Iron Man suit with servo helmet lift, glowing repulsors, sound effects, 3D fit measurements and...

Please do so, I am currently working on a two stage cycloidal gearbox...and am hoping that the centered mass of the offset disks will be reducing the vibration!

A planetary gearbox is also something I am conidering...I had the feeling that it would produce too much backlash, but that should also be possible to get sorted out!!

Sorry for hijacking this thread, lets start a new one!!

OMG, I am such a noob...just blew up a power supply!!!

The magic blue smoke had not happened for a long time...these drone motors draw a crazy current!!

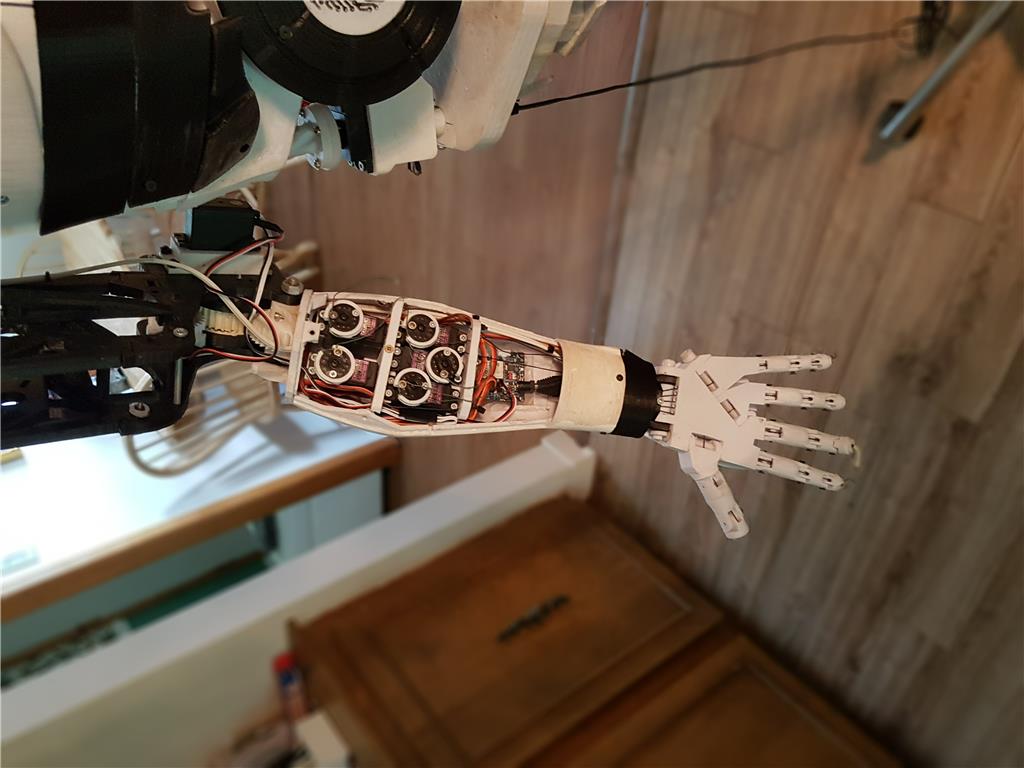

@Mickey666Maus Sorry to hear about your power Supply. Talking about gears My inmoov Brucee is using a planetory gear on his elbow joints. it is powered only by an ez-robot HD standard servo, lifting all that weight. and it is not that slow. I originally printed the gears using PETG but there was a bit of flex between the four center gears and the outer gear causing slippage because of the large amount of weight from the arm. PLA filament developed cracking. ABS to much flex. the best is carbon graphite filled nylon very tough and easier to print then standard nylon no warping or shrinking that regular nylon does, and it is self lubricating.

@mickey oh no! What happened??????

Hahahaha, I really don't know...but I guess you should not use 1.5Amp psup for a motor that can draw 14Amp easy!! :,D

Hahahaha yeah that might be your problem.

@nallycat that filament you are talking about sounds great...I would really like to check it to, I am always printing in ABS...I never noticed it had that much flex!! Good point!!

I actually always wondered, how you guys are managing to move all that weight of the Inmoovs with standard servos...would be fun to open a thread concerning all those issues! Like good printable gearboxes, different types of filament and motors!!

The Cycloid Gearbox does have issues with vibration...I will try to put a little demo together soon!!

Here is a picture of Bruce-e elbow this is showing PET-G as it is white and I it is now Black, I didn't take a new picture, you can see the EZ_Robot HD standard servo and the planetory gear is the top gear The nylon carbon fibre filament I get it from SPOOL3D but I understand nylonX is also very good, you have to use hard steel or a ruby nozzle on you printer as this stuff is very abrasive. I also use .6 instead of .4 nozzles.