jstarne1

USA

Asked

— Edited

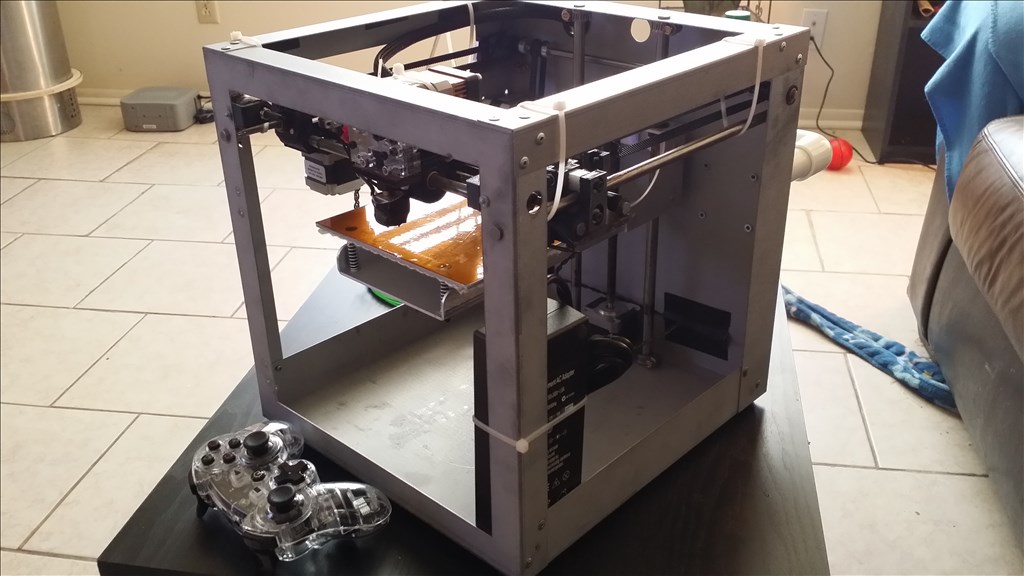

I ordered a Solidoodle 2 Pro which arrived today. I also ordered with that 2 rolls of filament. It should be 4 total pounds of material to start with.

Alright so i recieved my response back from solidoodle. They feel we need to do a live chat to get the settings tweaked to figure out the wierd patterns I had on some prints. In the meantime I have two prints , a ironman thumb and servo blank as well going on the platform and I will see if any weirdness happens with them.

Email response: Josh,

Please call me to resolve this issue. I think we might need to do a team viewer session.

We can be reached Monday - Friday

We are in the office from the hours of 9:00AM - 6:00PM EST.

Our phone number is 347-457-6608

Please note, our lunch hour is 12:30-1:30PM

Regards, Joel

, it's already past 6pm , i received the email about 15 min till 6pm so there wasn't time to troubleshoot today. I will update everyone with what they do.

I've been interested by 3D printing for a while. seeing as solid doodle is much cheaper as other printers i'm really interested. I do have some questions...

Do you recommend solid doodle for a not very well funded nearly high school student?

What common problems will I face.

how difficult is it to learn how to use the software?

does software come with the printer?

What version of printer should I use?

Thanks for any answers and I hope I don't hijack the thread. Very interested in how your iron man suit comes out.

Tech.

Hey Tech, I've been doing a lot of research on this matter lately. I'm getting a Solidoodle 2 Pro soon. at $599 assembled, It's ultimately one of the best printers in my opinion. I researched the intro levels of a bunch of printers and while there are a few that are slightly cheaper the have smaller print areas. It appears to me that others look cooler but that's about it. They all seem to do the same thing at the same speed. It's also actually available. A lot of the sub $1000 printers are pre-order or kick starters so there's no real consumer feed back. The only drawback I see to the solidoodle is that it lacks end-stops that prevent issues like what Josh had. I'm not sure if any sub $1000 printer does. If you're only printing smaller things that don't use up alot of the print area I don't think it should be a problem.

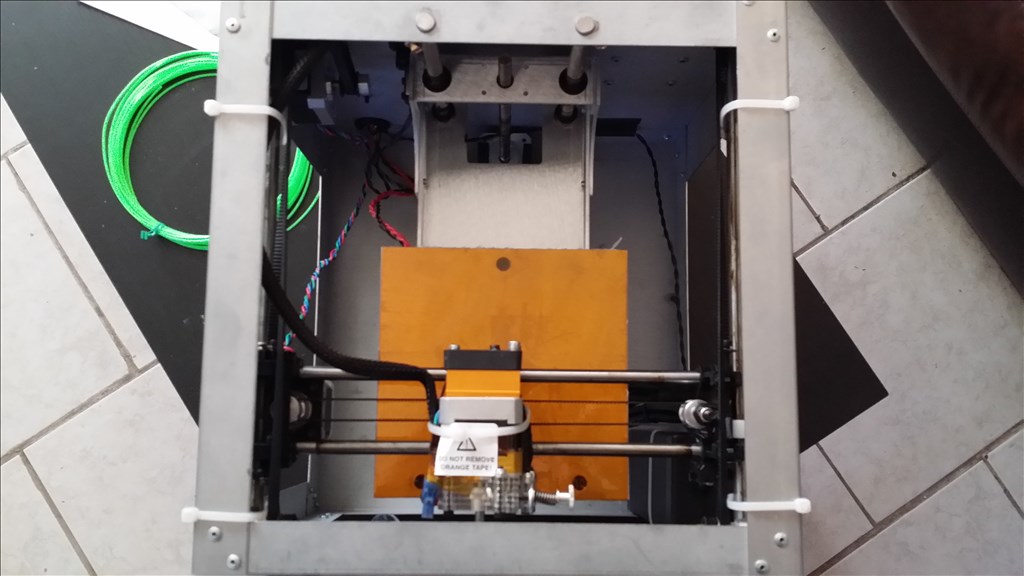

I anticipate having to calibrate and fine tune it for a few days to get it really dialed in and printing great. I'm going to get a mirror to put on my heated bed. Getting a good first layer and, getting it to stick is one of the keys to a good print. That's why the raft helps. You're now kind of printing onto it so if its a little messed up it may not mess the part up since it just get scrapped anyway.

I didn't find the software too difficult. There's alot of settings for fine tuning the print process but weather you'll need to use them or not just kind of depends on a little bit of luck I think. Some people claim to pull them out of the box and being super happy with default settings and others have to do a lot of calibrating. The cool thing about settings is that it's better to have them and not need them then to need them and not have them.

You can download the software in a link provided earlier in this thread. There's actually a few pieces of software you need. All free.

A 3d design (CAD) program. Ie Sketch-up or 123DDesign. I recommend 123 because it exports stls. Sketch-up does too with a plug-in and I had issues importing those stls into ARC so I switched to 123D. Design your object and export it out to an stl file.

Netfab, once you make an stl you want to check the item to make sure it's printable. Netfab will check and fix the model and export a fixed stl.

3d Printer software. Solidoodle uses one called Repetier-Host but you can use others. Once you've imported your stl you can place it where you'd like on the bed. For single items you'll probably just want to center them. Then there's number 4: Your slicer program. this is the one that slices your file up into layers and converts it to the G-Code that get sent to the 3d printer.

I recommend going to you tube and searching for solidoodle ans well as 3d printing. I spent the past week or so absorbing as much as possible. If you want, export some ez-bits and put those through netfab then import them into Repetier-Host and slice them. Once you slice them you can go through and look at the individual layers so you can look at just the bottom layer or a range of layers. You can also modify the slicer settings and go through the part and see how it affects the construction. I think it's cool if anything.

I learned most of this in the last week. I just did intense research. Do some you tubing and you'll get a good grip on it. I recommend playing with the software as you discover new things about it. Infill is lots of fun to play with if you want to go looking through the layers.

Anyway Tech, I'm going with the SD2 Pro because it's the best for my budget. And honestly based on my research it's the only one I'd buy under $2000. That's just my opinion on the matter.

Thanks so much Antron for your research on SD2 Pro....your evaluation helps others!

Thanks Irobot. I really tried very hard to find a printer worth getting at a cheaper price. I kind of tried to find a different brand. I was kind of hoping to find some lesser known company like ez robot sort of was when I discovered them. It's done me good so far so I figured I'd try to continue the trend and find another new, going places, company but, "when it comes down to the numbers" the Solidoodle is the best overall value. IMHO

The software is free and open source , slic3r is already built in as well as skienforge 3d. You can download it from wiki.solidoodle.com on the right hand side click downloads. You can see how it slices and how positioning works ect.

I would recommend it but it takes hours of patience to get things right and learn how to use tools. I have learned to use netlab cloud to fix models with holes or non manifold. In many cases the slicer in solidoodle will not fix them so you need to get the mesh repaired before trying to slice it.

I repaired 2 models one being the ironman thumb and next a servo blank and the processed and sliced in seconds. Better results than before. I will update pics when I get home.

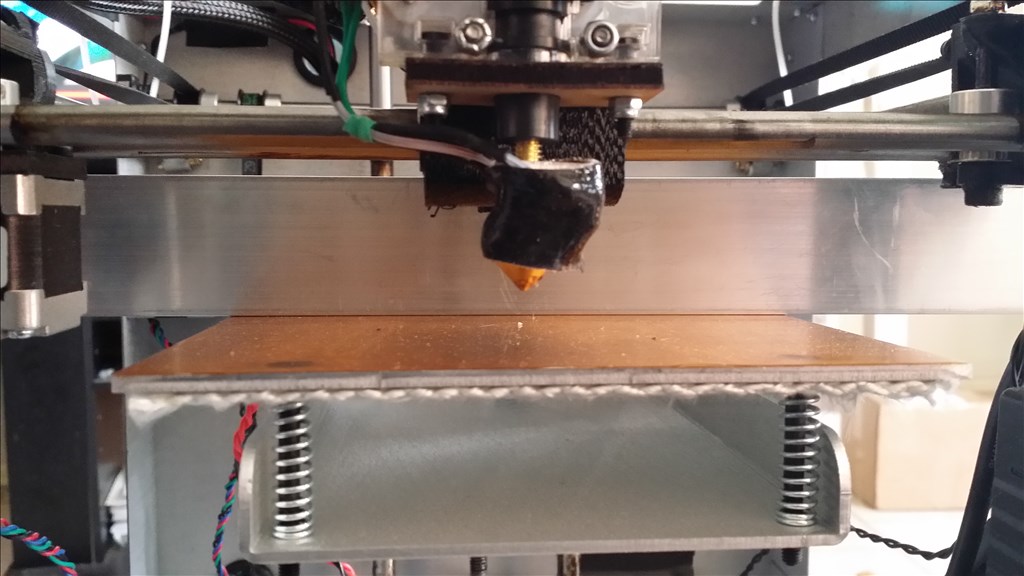

Ok these are all prints I tried after Dj suggested I use a spritzer of wd40 in the extruder before starting. WOW what a difference it appears to have made. I did close up shots and you can see how much tighter the laters were. No other changes to settings were made. The servo is 1 to 2 mm longer than its real counterpart as you can see from top view. I may keep that ratio as servos can vary by that much anyways.

Also a today was a first. I completely sliced and initiated a print remotely first I printed the servo blank then sliced the ironman thumb in a different location of the bed and started another print. I monitored it through a wireless cam that comes with the ez robot kit from a top view since I have plexiglass on top too. It was a bit of a nerdy rush , crossing my fingers the initial raft laid down correctly since I wasn't there for a do over.

The prints seem to be working a lot better now?! Did you correct or do anything different?