jstarne1

USA

Asked

— Edited

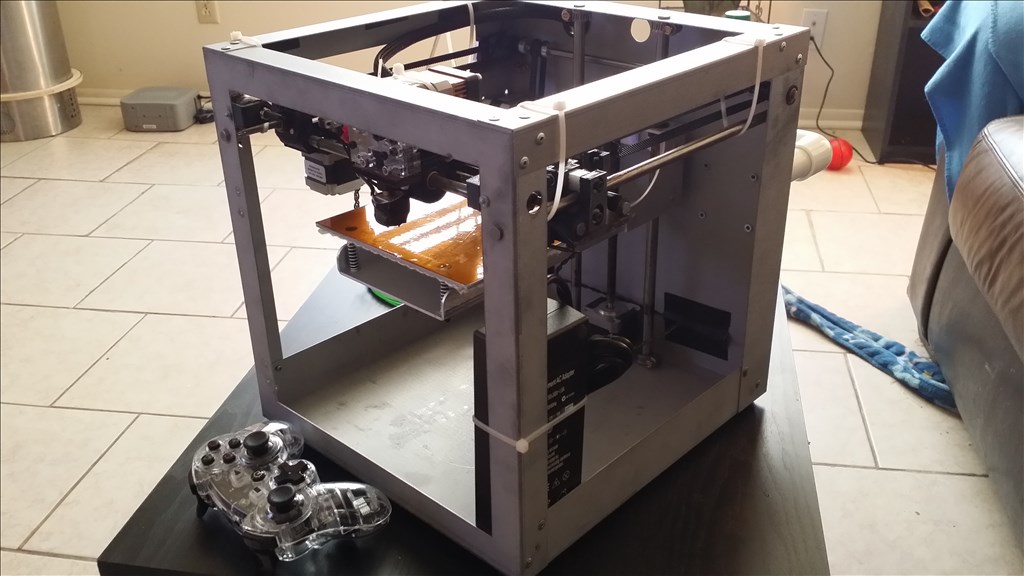

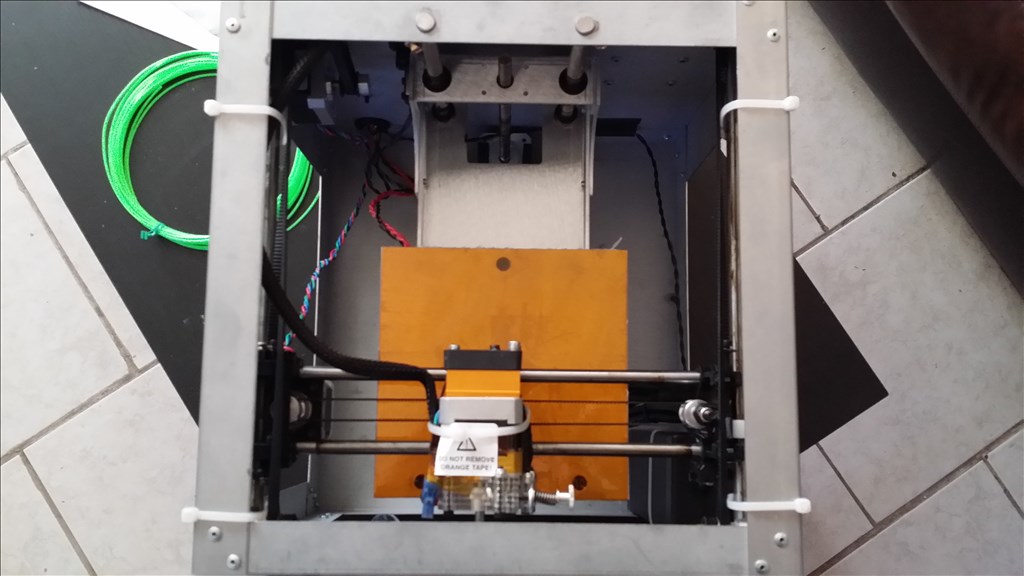

I ordered a Solidoodle 2 Pro which arrived today. I also ordered with that 2 rolls of filament. It should be 4 total pounds of material to start with.

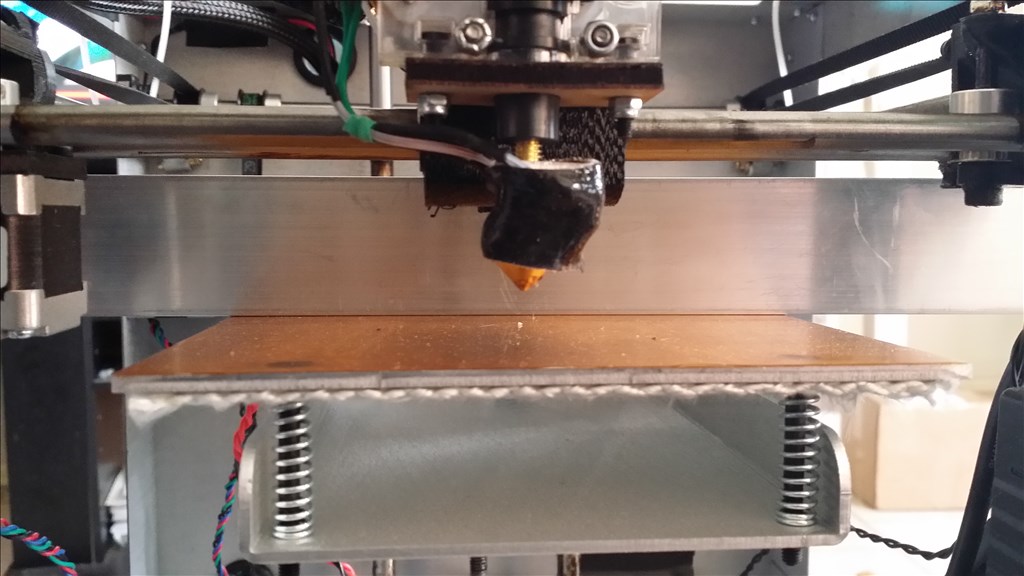

I just used Dj suggestion , a spritz of wd40 on the filament going into the extruder and it seems to not have the crazy pattern gaps. I'm not sure what role the wd40 plays but on 2 prints back to back it performed much better than the last 3 or 4 where there were layer delamination and gaps.

For me, at the price, I'd be happy with pictures 1 & 3.

I'm no expert by any means but, in regards to picture 2. I've only done a lot of research but, it looks like maybe you need to either lower your speed or lower your extruder temp. Unfortunately, I can't tell you how much or which as I don't own one yet so I've no personal data to use but, based on all of the videos and things I've read, that's what it seems to look like.

Also, I see you are using support material. Now, I can't explain it but, a lot of the stuff I've seen on ye ol' internet, didn't use support material and seemed to come out pretty good. I'm not exaggerating when I say I've watched hundreds of videos on the SD2 and 3d printing. I just want to know as much as I feel I need to about something I'm gonna spend $600+ on.

I'm sorry I suck at keeping track of the best of my research to share. In the future I will try to remember to keep track of my sources. i just sort of cram everything I can into my brain. Needless to say, sometimes my brain can be a mess. eek

It's alright, I appreciate the feedback. I too watched many good prints on solidoodles. The question is how they did them lol. The lower temp with abs started having trouble feeding and popping noise can be heard from the extruder loosing it's grip and stripping the filament. Once that happens you gotta clean out the extruder mechanism from filament dust so it grips the filament agian properly. Then cut that mangled piece of filament out and refeed fresh filament. Micro maintenance is a bear and I wish they made a comprehensive guide for these simple fixes.

@josh until you receive some answers from the SD 2 company and your quote " I just used Dj suggestion , a spritz of wd40 on the filament going into the extruder and it seems to not have the crazy pattern gaps. I'm not sure what role the wd40 plays but on 2 prints back to back it performed much better than the last 3 or 4 where there were layer delamination and gaps. " If you could make/create a "drip" feed onto the in feed of the filament perhaps that would help with making better prints (without voiding any warranty issues of course) just a thought and trying to build on your better success!

just a thought and trying to build on your better success!

On my mig welder I lube the wire with some thick felt and a clothspin . I'm not sure the printer would be able to pull it through that as I have never 3D printed. Could cut i grove on the felt though to reduce friction.

I received two spools of ABS when I purchased a FlashForge dual extruder. The white ABS caused the extruder to jam up alot. Switching to the black ABS worked much better. Then obtained the upgraded extruder pair and started printing PLA (red) and really liked the results. I'm still using the stock firmware but lots of folks are upgrading to the Swordfish firmware for more flexibility and control of their 3D prints.

@josh, now that you have had your solidoodle for a while, Would you purchase another one if you did not have one and know what you know now? How do you like it. If I got one, It would not work with makerware and repG, I guess. And, are the replacement parts high? I like the metal frame. Have you had any problems? and they are not Opensource are they? What is their program called and can I play with it.

@moviemaker- You have a mekerbot now correct?

The solidoodle recommends, Repetier Host (Click to download). I believe you can also use repG and a few others as well. My solidoodle was just marked OK to Ship today so I don't have one to speak from experience but I've done tons of research. I'm not sure if the hardware is Open Source or not but some of the software is. Like slic3r for example, I know is open source.

I can't tell you about part cost but I'm assuming that they're the same as or cheaper than Makerbot. (Based on the fact that SD's most expensive printer is still $400ish less than Makerbots cheapest one. They proboably use the same parts. A lot of 3d printers seem to spawn from RepRap printers which, are also open source. I believe Cartesian 3d Printer is the generic term.

Being on team Solidoodle I hate to say it but, I would have gone Makerbot if I had the money but, I wanted a 3d printer, NOW, and for what I can afford, the Solidoodle is the best option for me.

I hope this can get you started playing with the software at least, until Josh can fill in some more details.