jstarne1

USA

Asked

— Edited

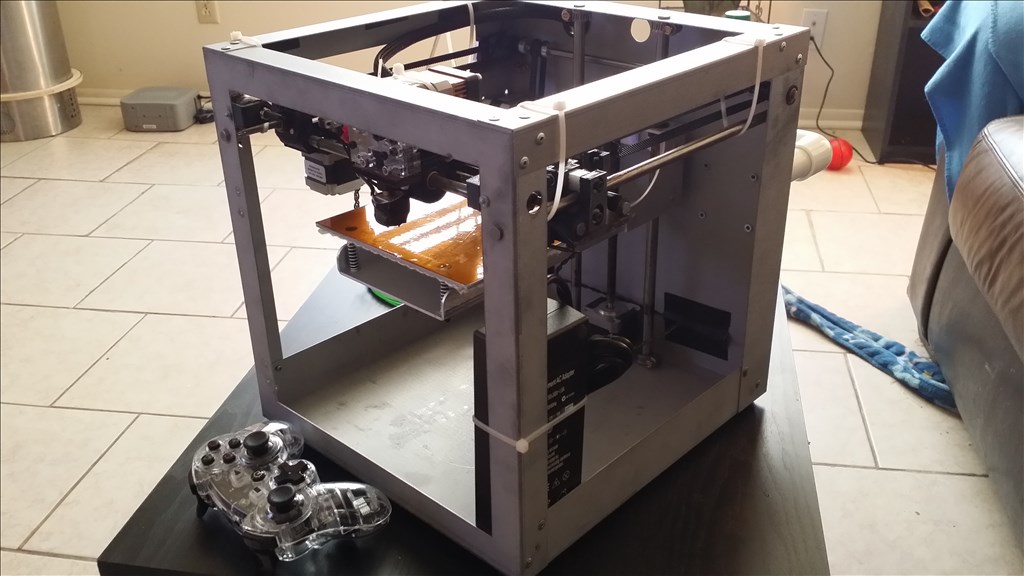

I ordered a Solidoodle 2 Pro which arrived today. I also ordered with that 2 rolls of filament. It should be 4 total pounds of material to start with.

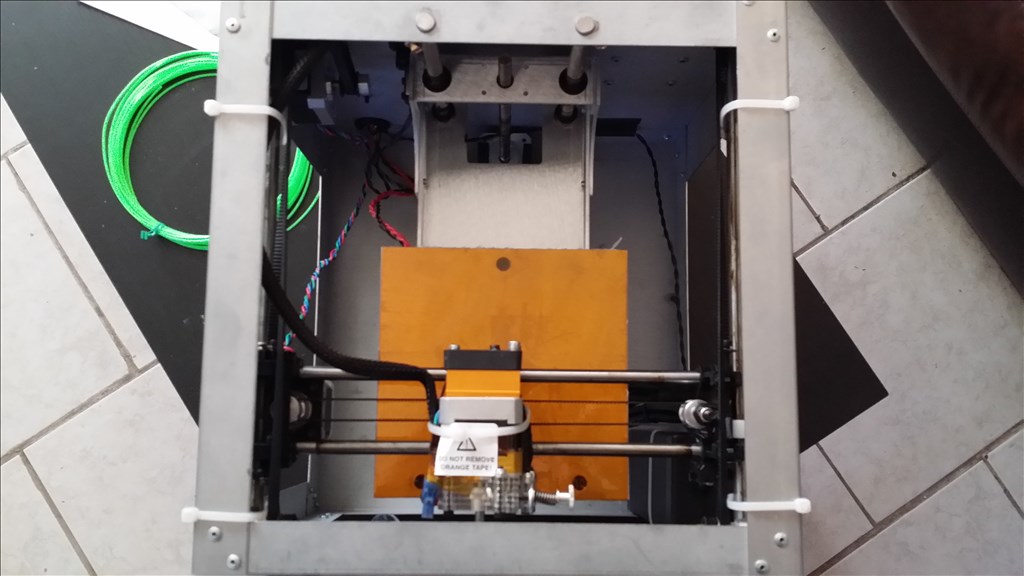

You gotta go to wiki.solidoodle.com to go through the start guide. I printed two fingers last night. After the second finger it did something wierd. The bed started going down and never stopped. It doesn't have a limit switch going down. It moved down until the platform was against the bottom of the machine and the knobs were against the bottom. The platform started to flex I guess it's hard to explain but it looked like it was about to break itself. After that I tried to test print and the bed was out of level. I will follow up tonight when I check to make sure it's just the bed out of level.

I believe with the knobs on the bottom of the platform keep is from lowering completely and it appears it may need that space to print an object 6 inches high. I will remove the knobs tonight.

@Josh I'm sorry to hear about your issue. Having problems printing more than six inches huh? There's a bad joke in there somewhere. Anyway, I look forward to your follow up later.

@jdebay, Thanks, I see it now. Duh. -1 for me.

I pulled the knobs off the bed screws and did a quick print test and came out okay, the front of the bed was mildly out of level. It 30 min I leveled the bed agian and adjusted the Z to tighten the squish on the first layer.

Without the knobs the bed can drop the full 6 inches. So word of advice. DO NOT KEEP the knobs on the adjustment screws like recommend in the start guide to prevent the platform from bottoming out.

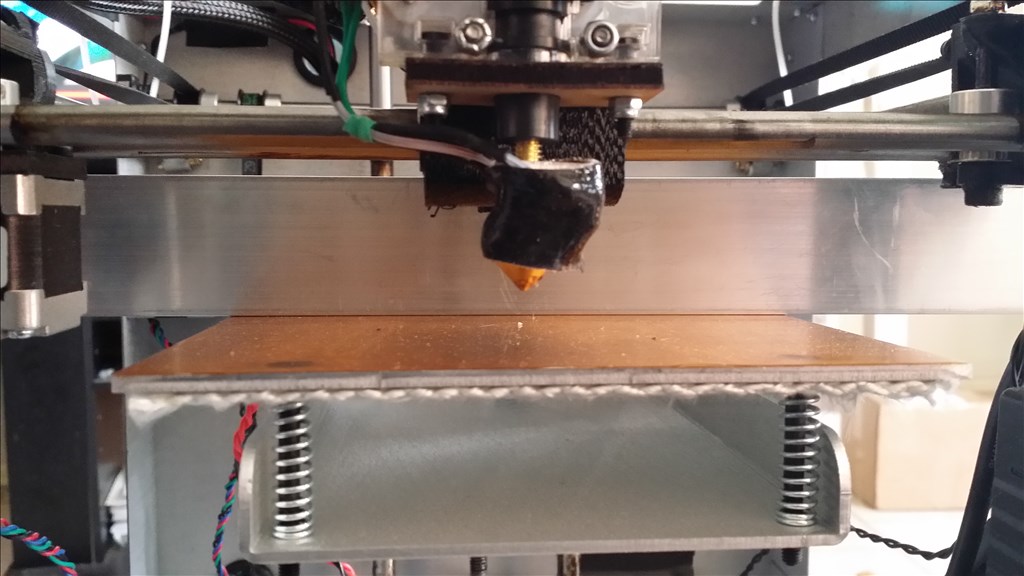

Ok so after that scare I continued printing but it does seem like something is off. It has a strange extruding pattern using .1mm and .3mm the filament sometimes doesn't adhere and leaves a stringy mess. I did a tiny test print for a cube. The prints are ironman costume fingers by the way before anyone gets the inappropriate ideas.

Here are just individual finger segments Anthony drew up using white abs.

Here is the test cube with only a 6 mm brim added for stability. One side of the cube came out fine but not the other.

Here is a ironman costume finger that started having some issues , you can see at the bottom of the print it was fine but the higher it went things got rough.

I have emailed solidoodle with my concerns today and I went through the more basic steps but I certainly don't want to void warranty with mods if there was something else I could do to make it print well.

On a positive note , a good 3d print can take between 2 hours and all night or all day. No one realistically has time to physically monitor progress. I highly recommend setting up a remote desktop from your phone or even laptop if you carry one. I use splash top 2 I bought for 1.99 app on my android device and it is working very well. It allows me to swith between multiple monitors and also between several computers from anywhere. Here is a screen shot of my most recent print which did fail. The camera is the one that comes with the ez robot kit and I removed the ir filter so there is more yellow hue to the image.

Here is the last good print that was done. It was a couple days before the bed dropped down until the stepper stalled. Its A servo Blank At 105 Percent To scale. This is standard .3mm print with 4 layer raft and brim.

thanks for the update and warning Josh. Ill be ordering my SD2 as soon as the funds become available. I appreciate the heads up. i know it,s a little late but have you considered using a lower profile thumb screw? im at work so i dont have any links right now but if you'd like i can post at least one i saw later this evening.

I hope you didn't strip your stepper motor when it bottomed out. Are you still using ABS? have you tried PLA yet? Im just curious as to whether you need anything special to print PLA. everything I've read just says use lower temps and maybe a fan. Is that true? it would be great if temp control was all that is needed. im just leary. if it sounds too good....

it's good to here from you again Josh. I was starting to wonder where you've been.

@Antron , i later figured out that it didn't matter if the knobs were on the bottom the machine can still bottom out. There's no limit switch on the X axis going down. I thought of wiring one in by tapping the other limit switch to trigger emergency stop but I need to resolve print quality issues first in case I need to ship the solidoodle to them.