jstarne1

USA

Asked

— Edited

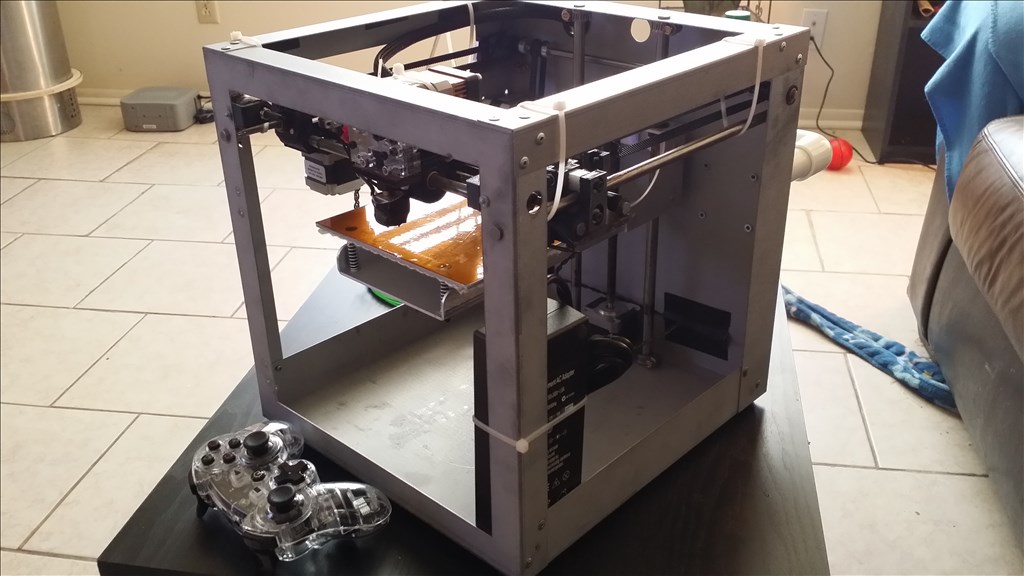

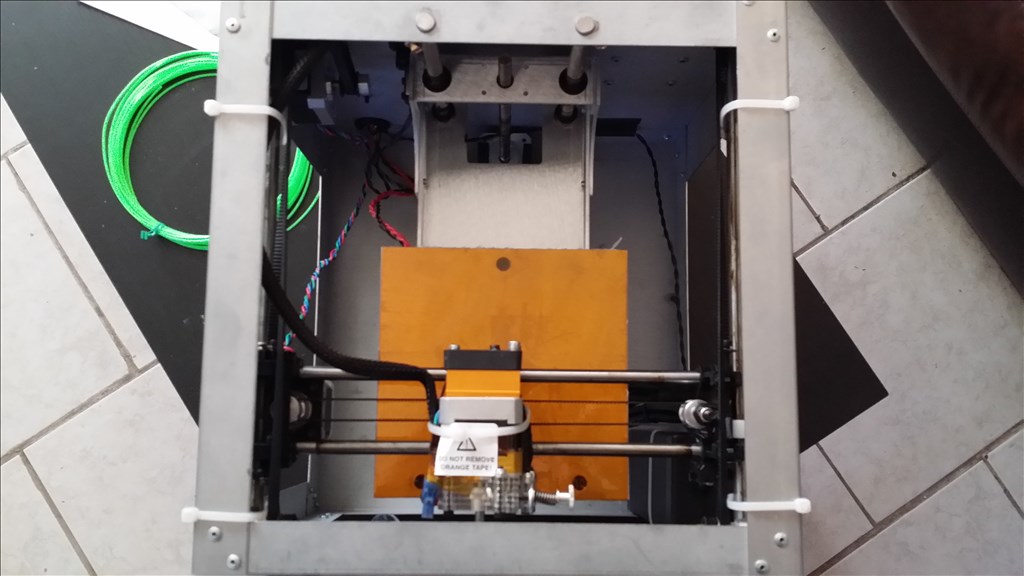

I ordered a Solidoodle 2 Pro which arrived today. I also ordered with that 2 rolls of filament. It should be 4 total pounds of material to start with.

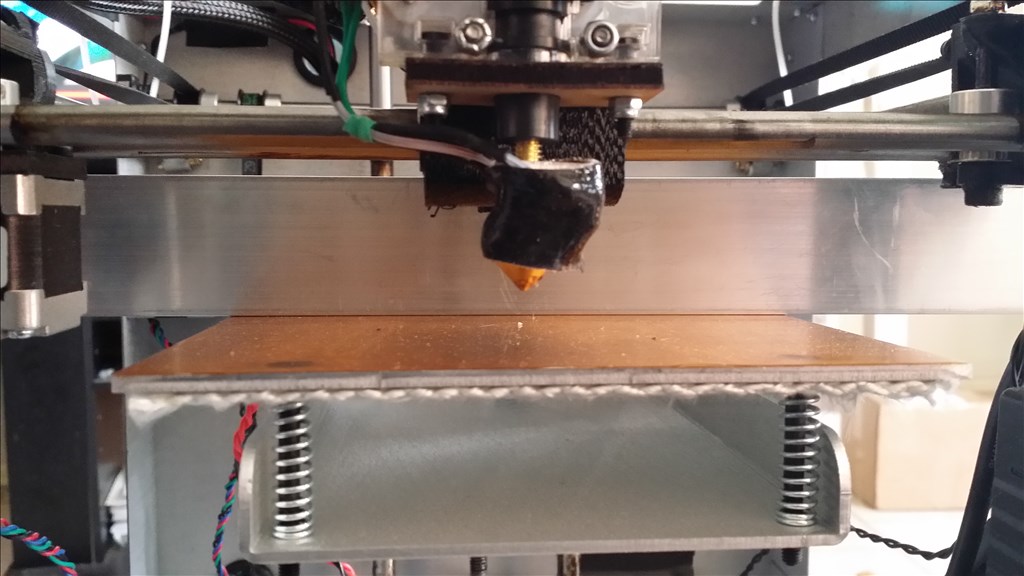

I picked up a couple accessories from Silhouette that were intended for my Cameo Paper cutter however I noticed they did a superb job at prying a part off the print bed gently and without scratching the painters tape. I can use the same layer of printer tape over and over for a handful of prints which saves money. The tool was 7 dollars on amazon.com but it's a excellent deal. It is stainless steel and works better than the plastic spatula.

So far there is a learning curve with the solidoodle but it isn't too bad. Once you take the time to daily in a setting it repeats this well. So far the biggest complaints are printing perfect arcs and perfect circles but this is common among 3d printers. There are mods to improve this and it usually caused by vibrations called "wobble". There are belt tensioners, z axis supports and a couple other things that practically eliminate these issues so I am really not concerned. At this point I feel like the 480 spent of the printer was well spent.

@josh, you are doing good son. I wanted to say that after you preheat it, adjust the bed level screws again for a perfect setting. With my printer, it's Extruders get closer to the bed when hot.

How to keep your 3d printing ABS or PLA filament fresh , dry and free of contaminants.

Both these materials can collect dust and other contamination from the air that can clog your extruder later. Also the filament can absorb water from the humidity in the air. I want to keep my filament fresh long enough to use it all up. I picked up a cheap plastic toolbox that is near airtight and a roll of water strip.

Home Depot -Homer 19" orange tool box -16 oz of desiccant with carbon absorber -.25" wide weather strip

The 2 pound filament roll fits nicely. Looks like I can fit 4 rolls of filament in here for storage between printing.

Thanks for sharing about using a 3d printer and all pictures, plus tips.

J

I needed a box to keep my filament in anyways and the moisture absorbing thing makes me feel better lol. A lot of people on forums have complained of humidity getting to the filament and causing problems with keeping the material temps up.

I picked up the box and damp aid while I was on the way to pickup 1/4" lexan and magnets to enclose the solidoodle.

Ok almost done with the insulated foam topper. I may do a outside coat of resin so i can paint it but that's only for looks. It is just meant to keep the heat from flying right out of the top of the solidoodle.

I have a dual temp lcd I may install so i can monitor inside and outside case temperature.

I notice when you're printing there is like a plastic screen or grid on the bottom. Is that part of the print like you're printing it on a tree and snapping it off afterwards or, is that a seperate thing that you have on the bed to keep the part from sticking to it?