jstarne1

USA

Asked

— Edited

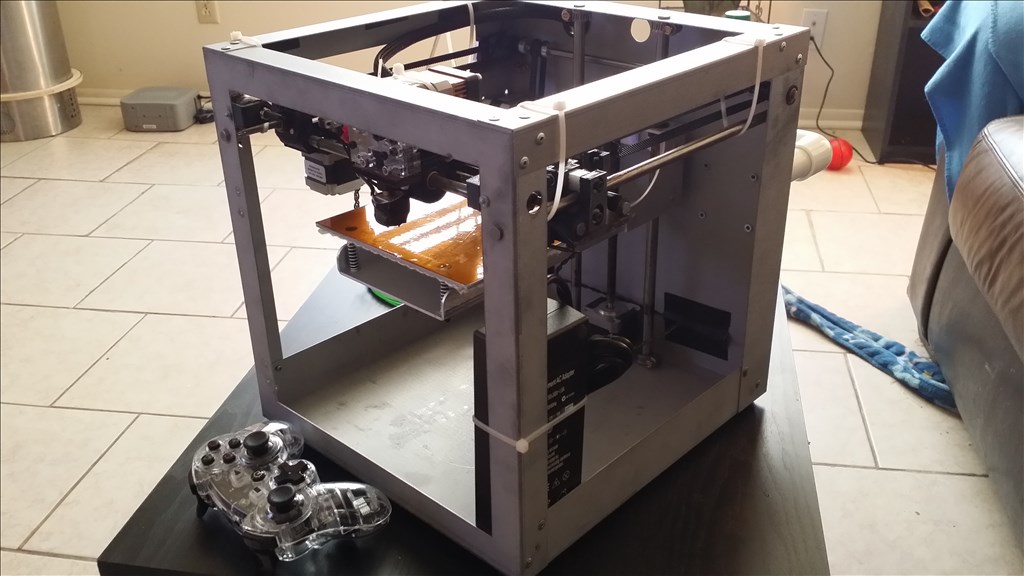

I ordered a Solidoodle 2 Pro which arrived today. I also ordered with that 2 rolls of filament. It should be 4 total pounds of material to start with.

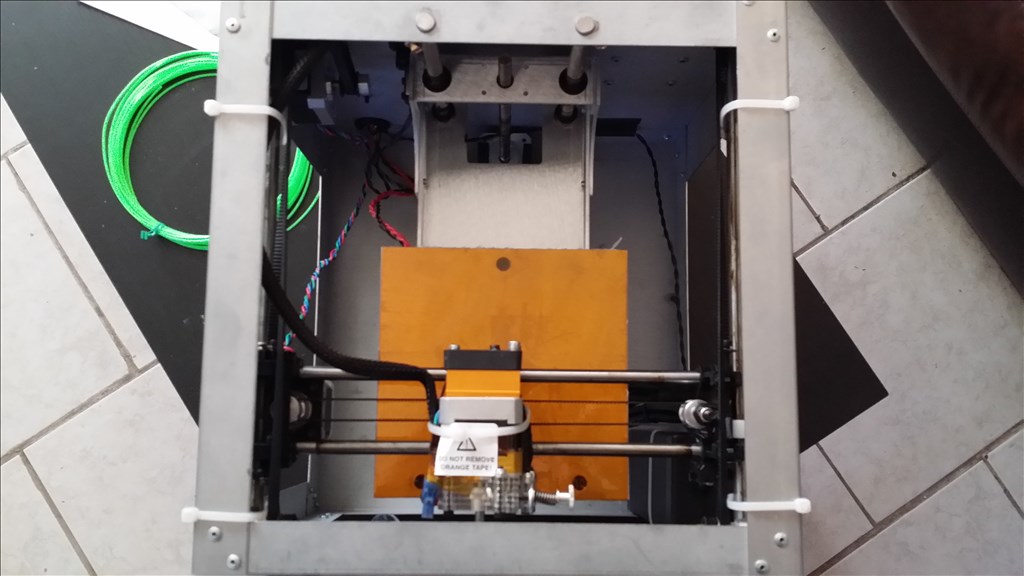

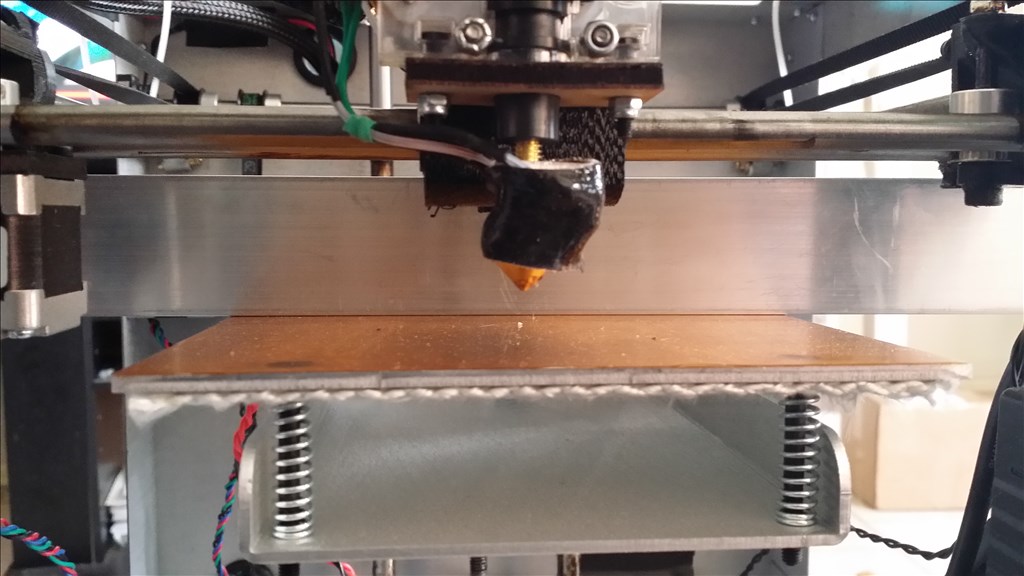

Looks like the print bed is warped a bit from the factory

https://www.youtube.com/watch?v=_8yqM-2DsD0&feature=youtube_gdata_player

Here's the start guide , there were not any instructions included with the machine. Only a piece of paper with the URL for soliforum.com , wiki.solidoodle.com , solidoodle.com/blog and their facebook.

Wiki.solidoodle.com

Awesome Josh, I can't wait to see what you do with your new toy. Lucky dog

Welcome to the land of 3D printers and warped print beds. Most owners of the Makerbot and Flashforge 3D printers have added a glass plate bed to solve that un-even print bed and get much better extrusion which then helps make better 3d models.

@Robotdoc , i have heard of cutting glass beds. Any idea where to buy them or will any pane glass do?

Since you print bed is not heated you can use regular glass from your local hardware store. You can order pre-cut Heat-Resistant Borosilicate Glass from McMaster-Carr HERE

I ordered the heat resistant glass for the Flshforge since it has a heated bed. Since I now use mostly PLA I only heat to 50 C so it's not very hot. I used a 1/8 inch diamond drill bit to cut a hole in each end to mount the glass to the heat bed but other 3D hackers use silicon pads from Amazon.com to hold the glass in place.

I have a heated bed , it runs 100 degrees Celsius. So I will look at those bed options. My material is ABS , higher extruding temps , stronger material , chemical resistant as well. Definitely not arguing anything because PLA has its benefits.

No problem, I got lazy and run one extruder with ABS and the other with PLA. Just have to keep them straight in my mind when I slice a 3D model so that the temps match the extruder.