Hi all,

I thought I'd throw this out to our talented community and see if anyone has some good ideas on how to build a self tensioning motor mount. It's not really a plea for help but more of an idea swap looking for different ideas.

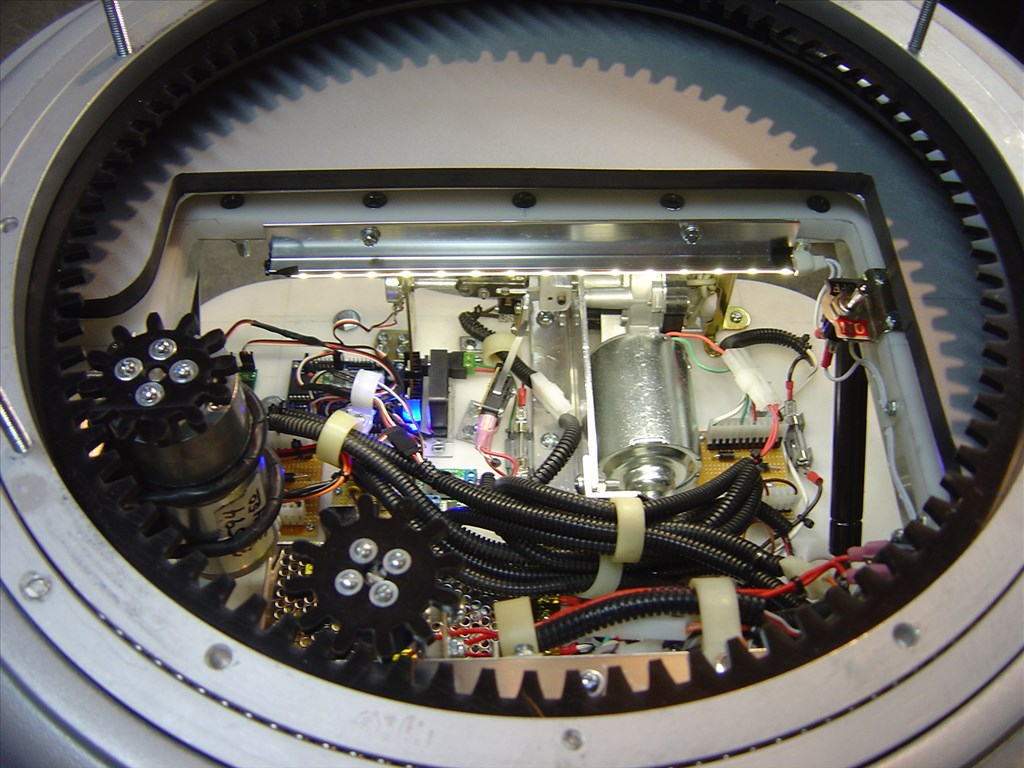

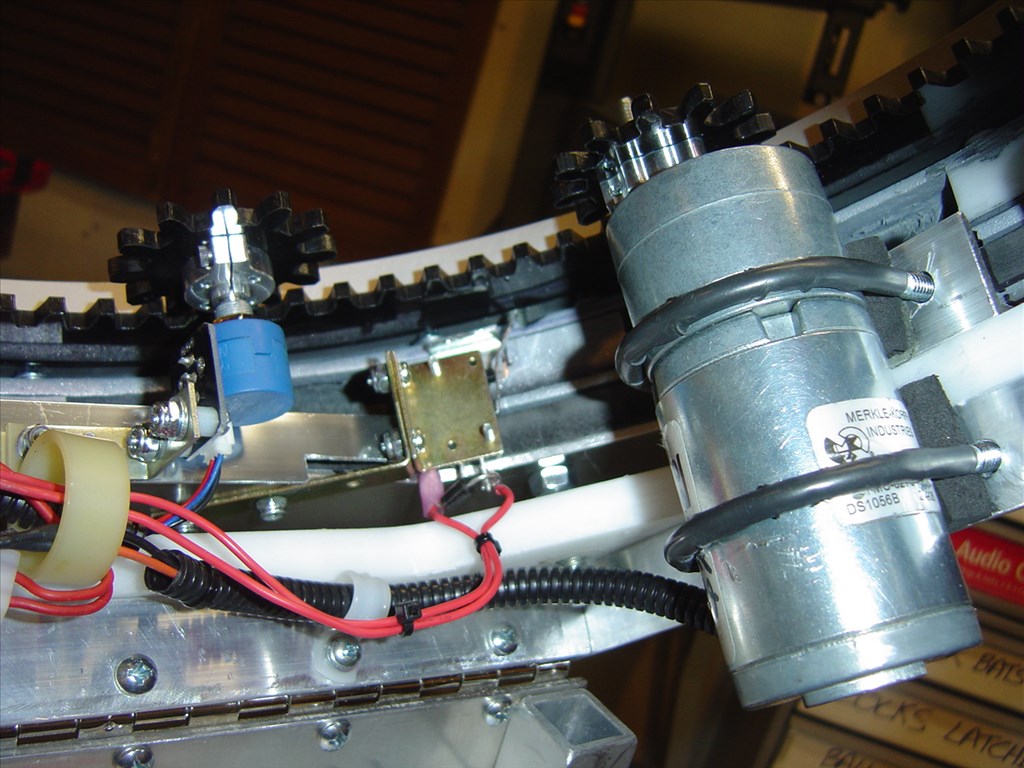

Here's the application and need; I have a lazy Susan that is turned by a set of gears. The outer gear is attached to one ring of the Lazy Suzan and the inner drive gear is attached to a shaft of a motor. Because of human error while building the rotations are a little off so when the gear turns and gets to on one side of the rotation the drive gear sits nicely and firm in the teeth and there is no play or slop. When it rotates the other way the drive gear will be a little out of the teeth and allow a little slop in the gears and the Lazy Suzan will wiggle a little. To illustrate here's a couple pictures of my setup:

Well, I want it to be nice and tight all the way around the rotation so there is no play anywhere when the robot stops at any given point. My idea is to make a tensioner of some kind that will be either spring or gas strut loaded and pushing the drive gear into the main gear. This way when the gears rotate, the teeth of each gear will always be completely engaged.

The drive motor I want to mount is about 4" long and 2" across. My first idea is to make this out of either a large hinge or a piece of aluminum plate with a hinge attached. I can then use a "U" pipe bolt to attach the motor to the hinge (kinda like I have my existing motor mounted in the pic above). I'd have to set it up in a 90 degree angle so the "U" bolt wouldn't hit anything when it moves and let a spring pull the "Door" part where the drive motor and gear is attached into the main gear. I'd have to get the spring or gas strut strength just right to keep the rotation from stalling or the gears from jumping teeth.

Anyway, that's my first thought on a design. If anyone has a different idea, a design change to my plan or knows of any supplier already selling something like this please chime in.

Thanks!

Unless I misunderstand, the outer gear ring is off-center from the lazy susan so it's fully seated at one part of the rotation and loose at 180 degrees from the tightest point.

I take it that you dont want to remove the ring rotate it an inch to drill new mount holes and reinstall?

At first I was looking at something using swivel mounts. and some sort of tensioner. You may be better off remounting the gear ring.

What if you wrapped the small motor gear in a rubbery material? Or wrapped the inside of the big ring with rubber weather stripping?

Also, ask Toymaker(Tony). He is good at that sort of stuff. It is my weakness, unfortunately.

Not really my area of expertise but thought I'd jump in...

First though, that is so neat and tidy! I am in awe of the workmanship in this B9 so far!

What about some type of pivoting mount with a spring which pulls the motor towards the outside of the body? I'll sketch what I mean if that description wasn't good enough...

You probably already thought of this Dave, but I thought I would throw it out there anyway... Any chance you can get a better sprocket for your drive motor? With more angular teeth? The teeth on the drive sprocket don't quite mess properly with the outer lazy susan ring gear... The teeth on the motor sprocket are more rounded so (judging by your pics) they leave "slop" in your gear mechanism....Maybe completely rubber mounting your motor might help too... Just a thought... Motorcycles have a rubber cush drive mounted inside the rear wheel hub, this allows the sprocket to absorb shock of the chain tensioning (whip effect) and loosening as the bikes engine engages and disengages.... This helps reduce noticeable slop in the bikes drive train...

Just a thought. Have you ever seen a self closing door hinge?

www.ebay.com/itm/like/171182951135?lpid=82

I put one on my bathroom closet door and it works great. You can adjust the tension from very weak closing to a slam if wanted. You might be able to mount the motor to the hinge and use it that way. Since the motor main shaft is not centered, I believe, that's a plus. Turning it away will make up the difference of the hinge depth. Hope I'm making sense here ... lol.

Anyways, just a thought for you to think about or catch another idea from this one.

Herr

Dave,

Sounds like you have a problem with gear backlash. Some clearance is needed or you'll destroy the gears, but it sounds like you have more clearance than you want/need.

In the photo, it appears that the distance between the drive pinion and the gear on the lazy susan is greater than it should be. Can you locate the drive motor a bit closer to reduce the backlash?

Also - they look like B9 Club parts. You might want to check with the maker and find out what tolerance the gears were designed for.

Otherwise, mount the motor on a hinge and use a hinge to keep the pinion engaged. The trick will be determining the amount of tension that will keep slop to a minimum and not cause the gears to bind.

Dave, My thought when you first posted was a very simple hinged motor mount with a medium spring tension that will follow any irregularities. This simple idea has worked on many furnace and large blower units for years. Your build has been first class, Steve S