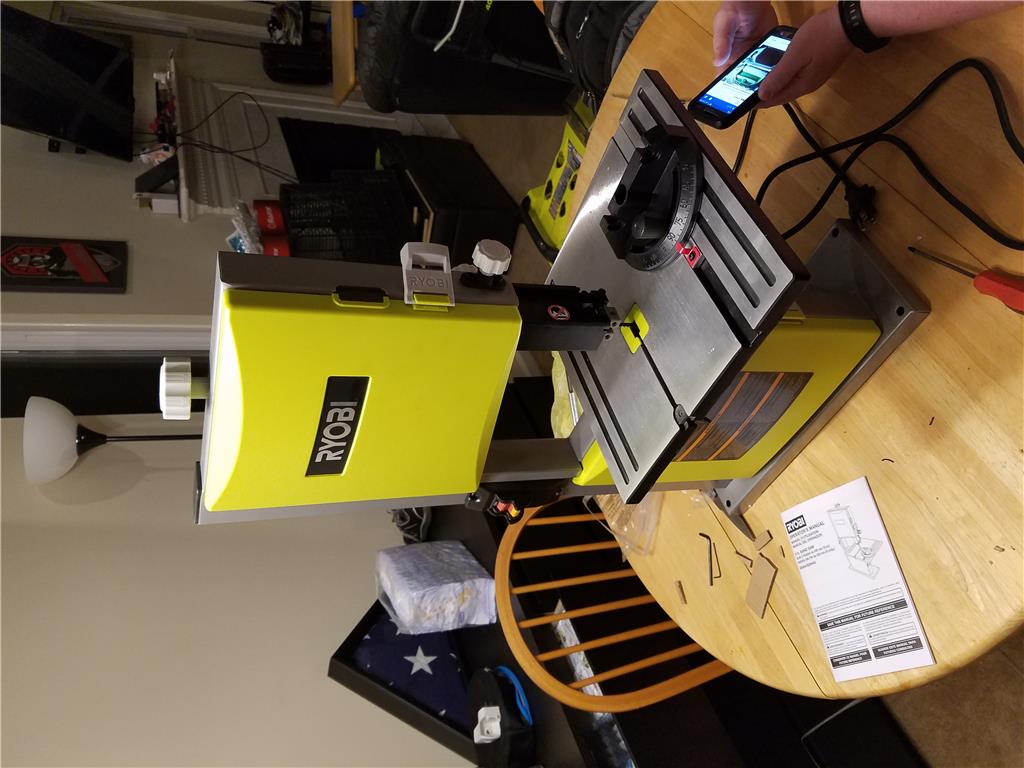

Hello all, I am getting back in the saddle making robots now that I am moved into my new home and settled into my new job as a technician maintaining the Fiber Optics network in Chattanooga TN.

IM BACK !

By jstarne1

— Last update

Other robots from Synthiam community

Mereyes's Mereyes WALL-E

WallE replica using EZB v3 controller: wheel/arm/head servos, BlinkM eye, 2.4GHz camera, SparkFun MP3 trigger, 6V...

Justinratliff's Jd Spock

JD Spock 3D-printed Star Trek TOS phaser sized for JD, color-matched EZ_OST_phaser.stl and printable paper headpiece...

Ezang's My New Adventure Bot

Modified Adventure Bot with ultrasonic radar and RGB back wheels for improved sensing and colorful illumination.

-635971125254815084.png)

-635971009768280111.jpg)

-636393423097260688.jpg)

-636337988865509663.jpg)

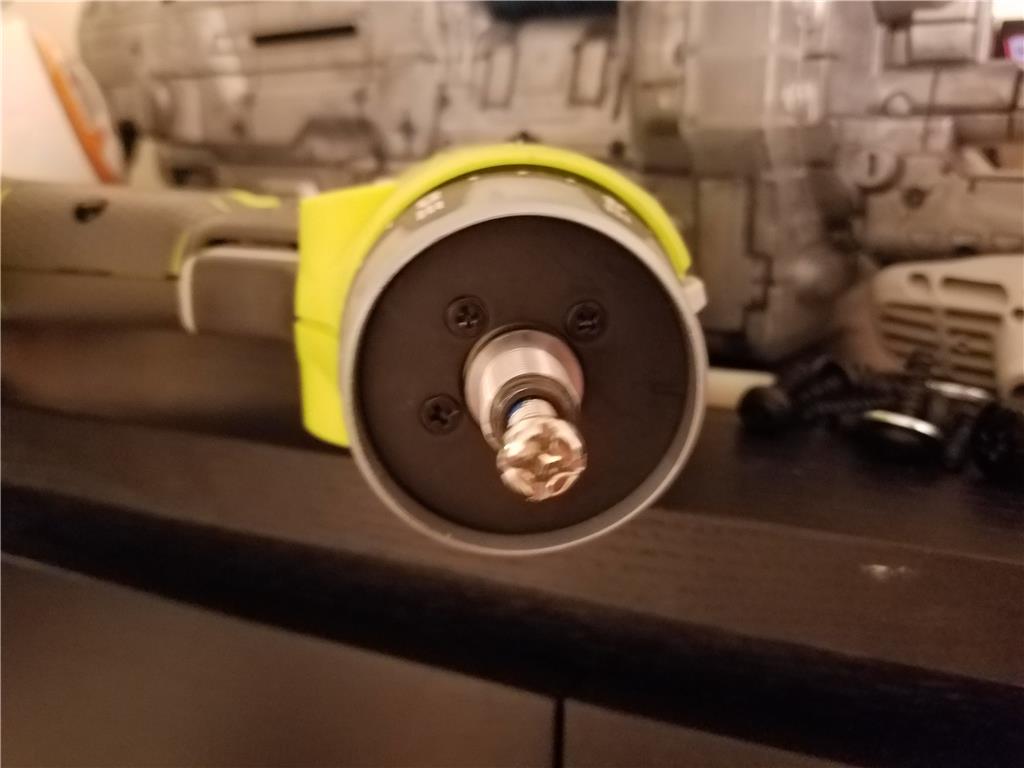

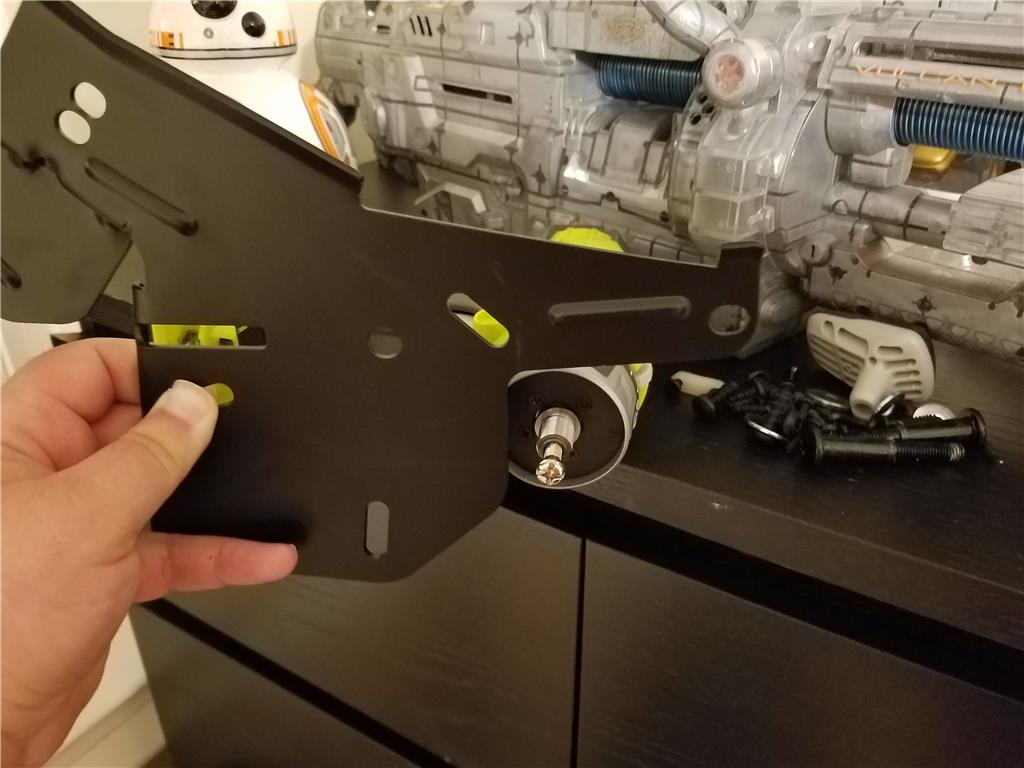

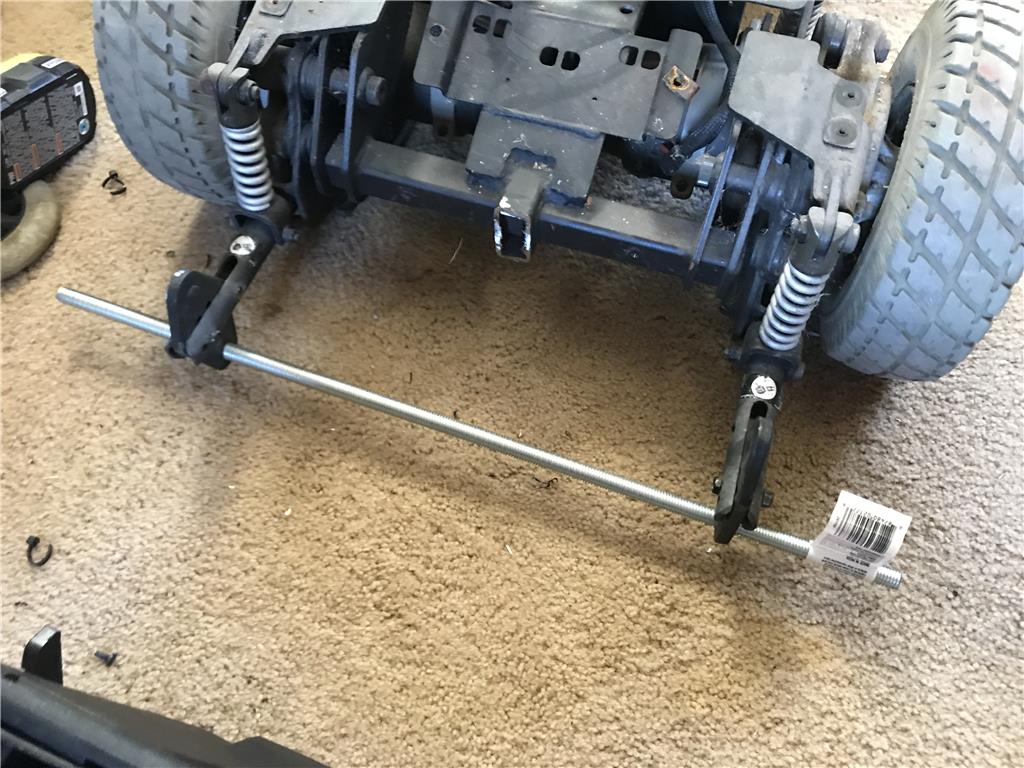

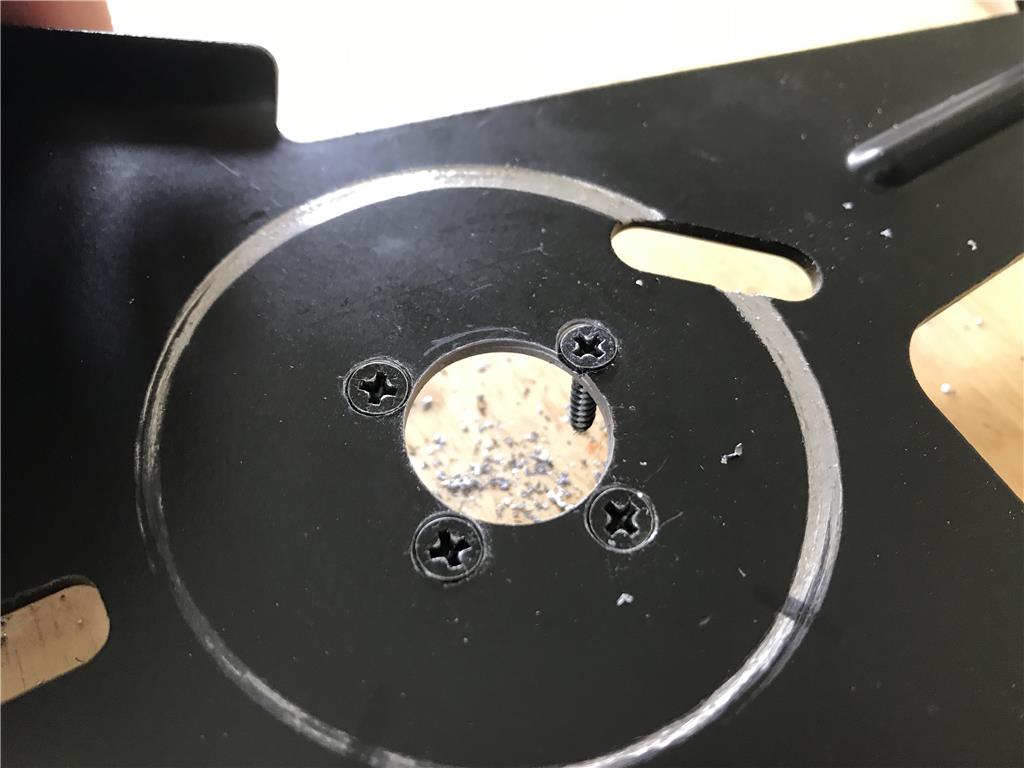

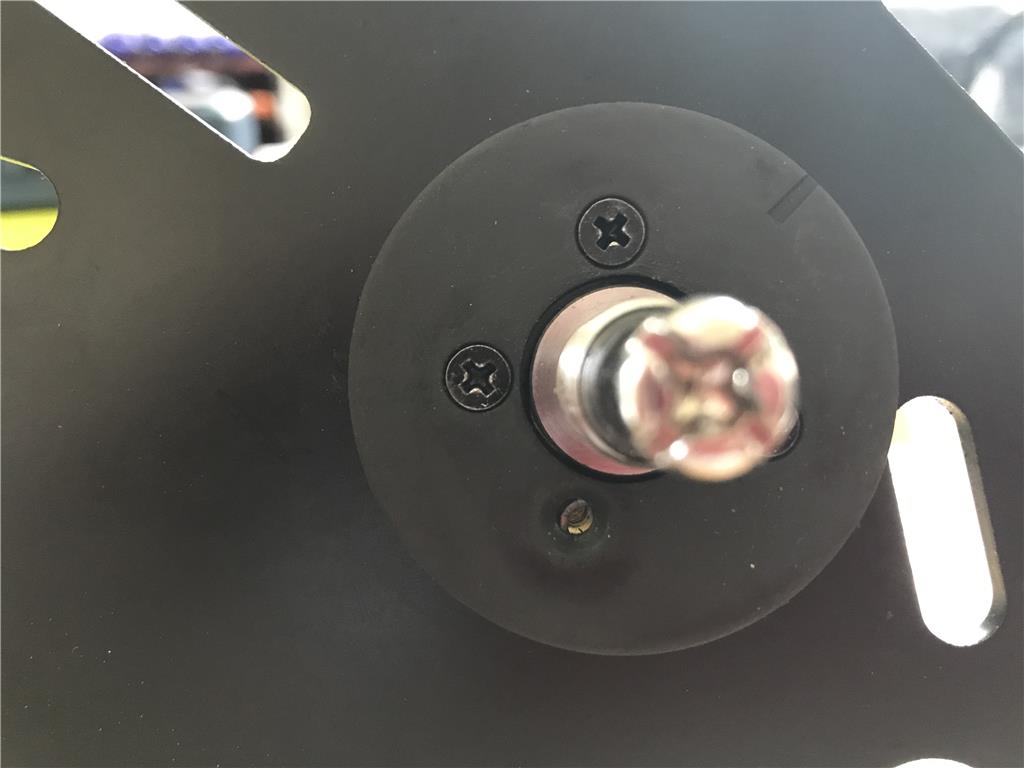

The screws are aligned with the gearbox holes but these screws require a counter sink to screw all the way in. I will use the tip of the stepper /uni-bit to make a counter sink.

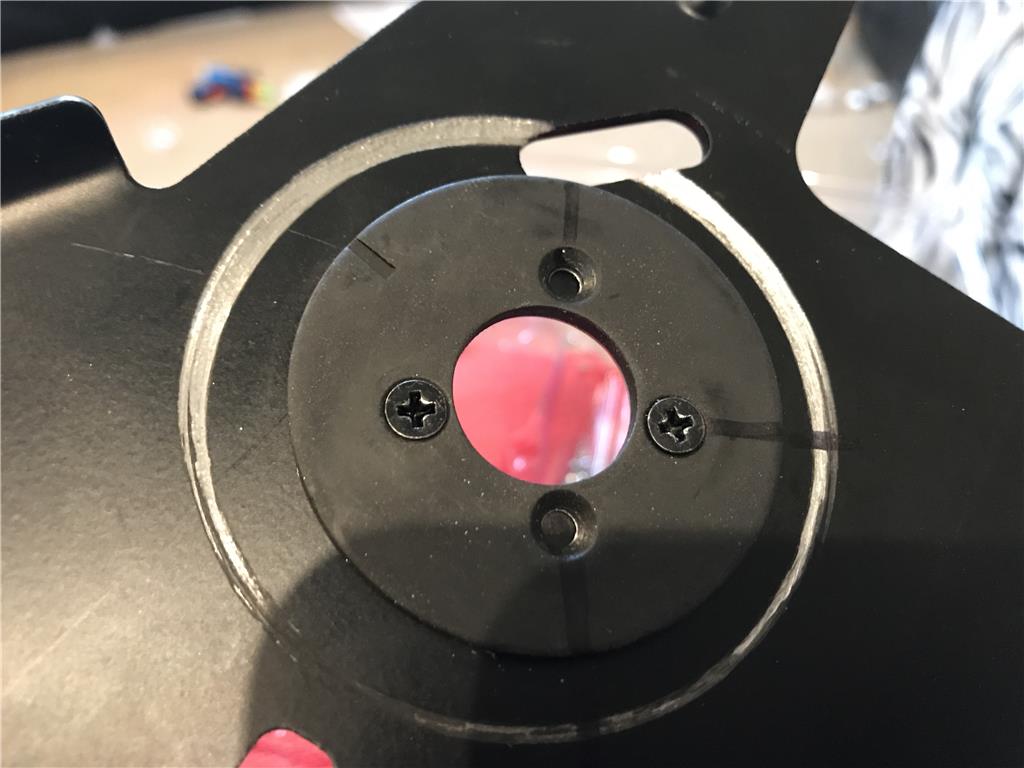

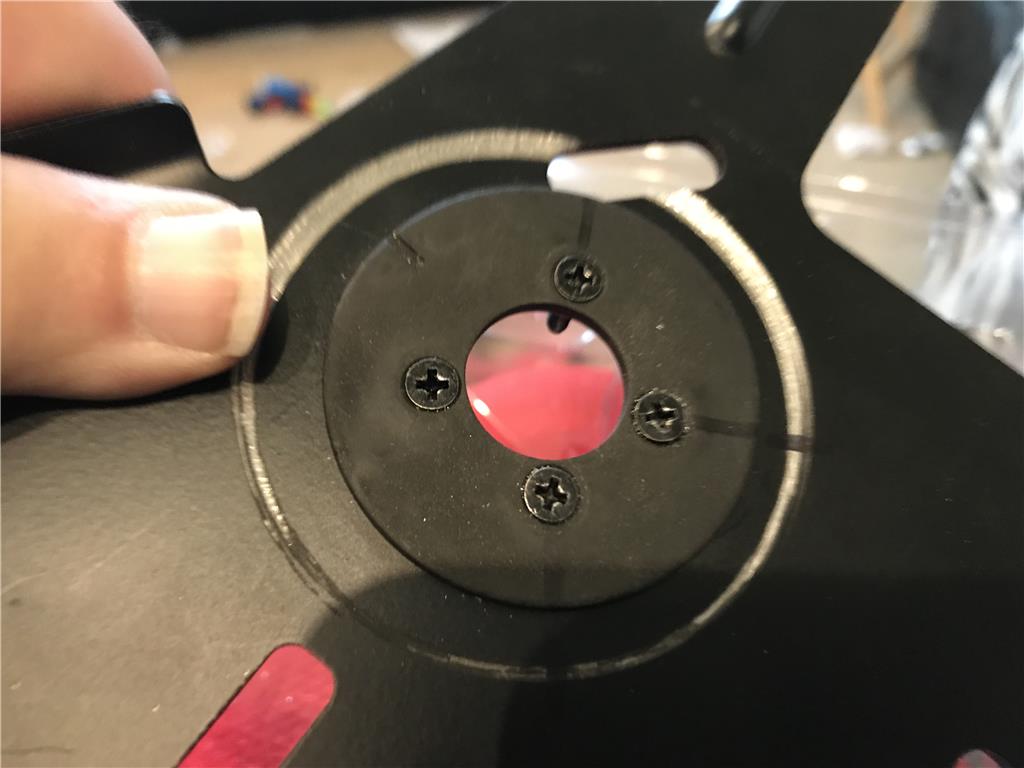

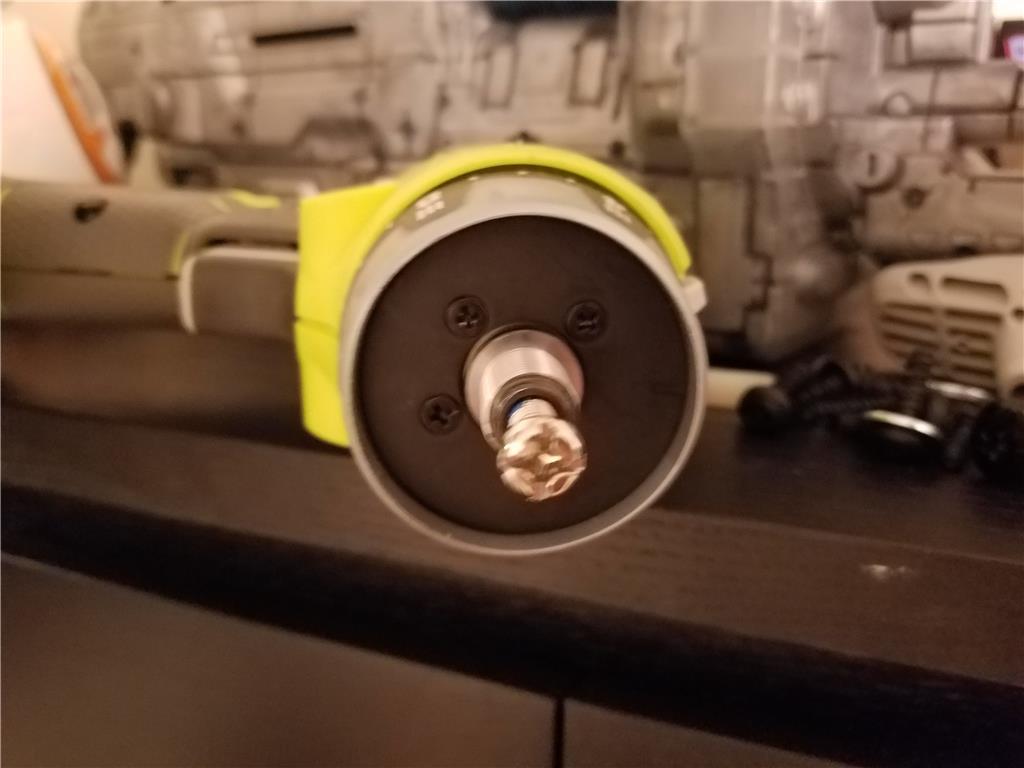

The motor unhooks from the gearbox with a simple 1/8 twist. I believe I will use a portion of the original casing to keep them mated together.

I will add a large hole at the end for the power wires to feed through

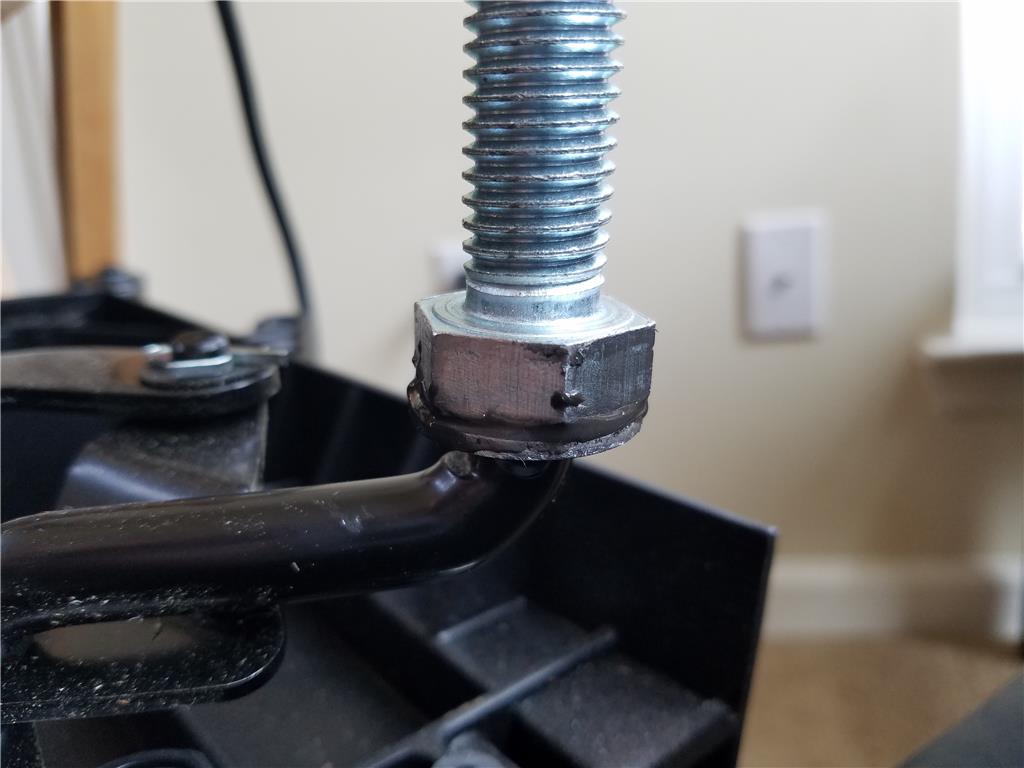

After measuring I found that there is too much plastic lip on the clutch sleeve. I will need to find the dremel and trim down the clutch so that I can fit it behind the metal plate and still be able to screw it all the way down to the face of the gearbox.

On a side note I am going to go find those nail clippers! Those are scary.

Those nails will work well for stripping wire.....

Project is going well. Looking forward to more.

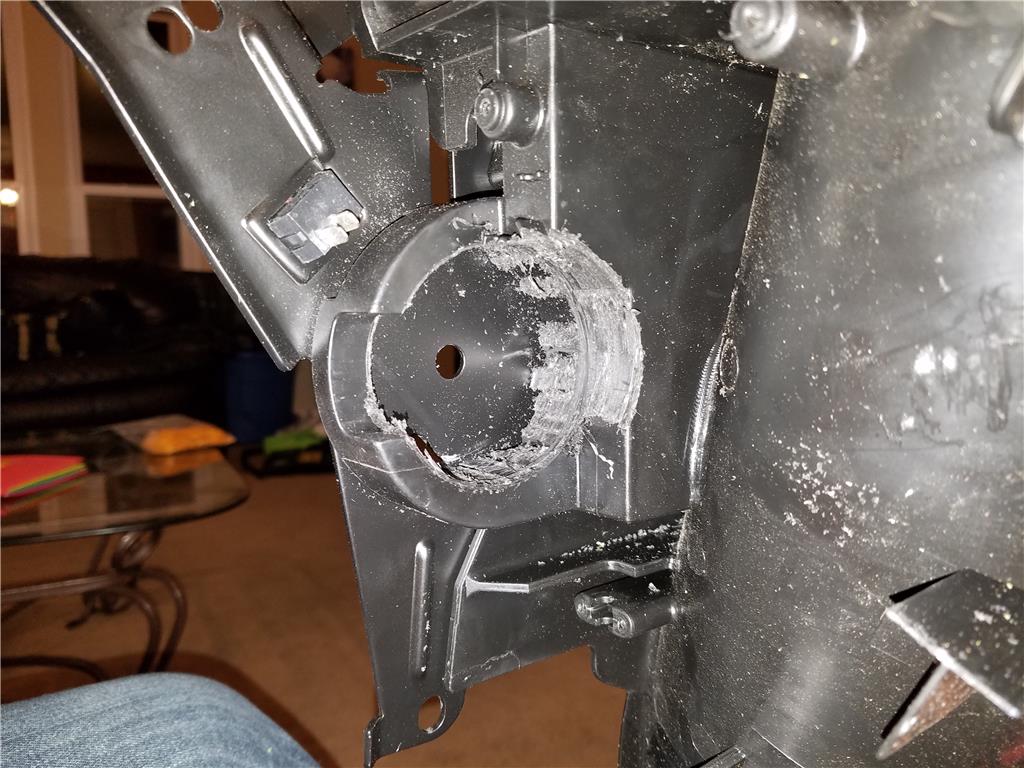

Ok so I used a larger bit and slowly machined out the holes to countersink the screws.

They sink in well now

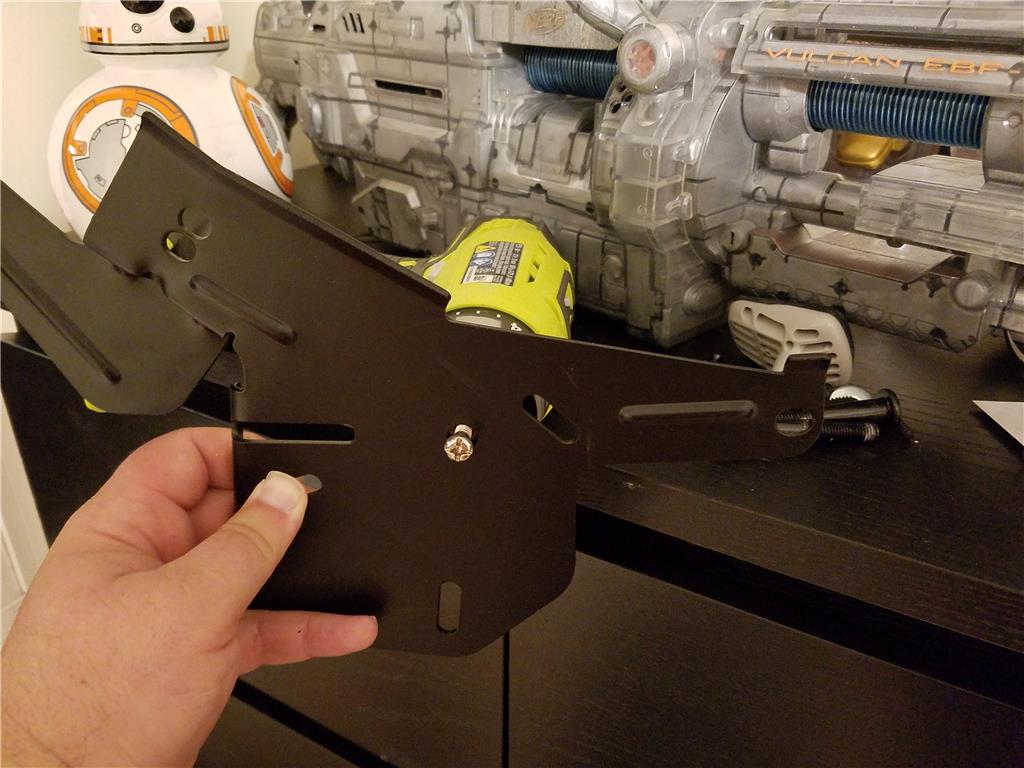

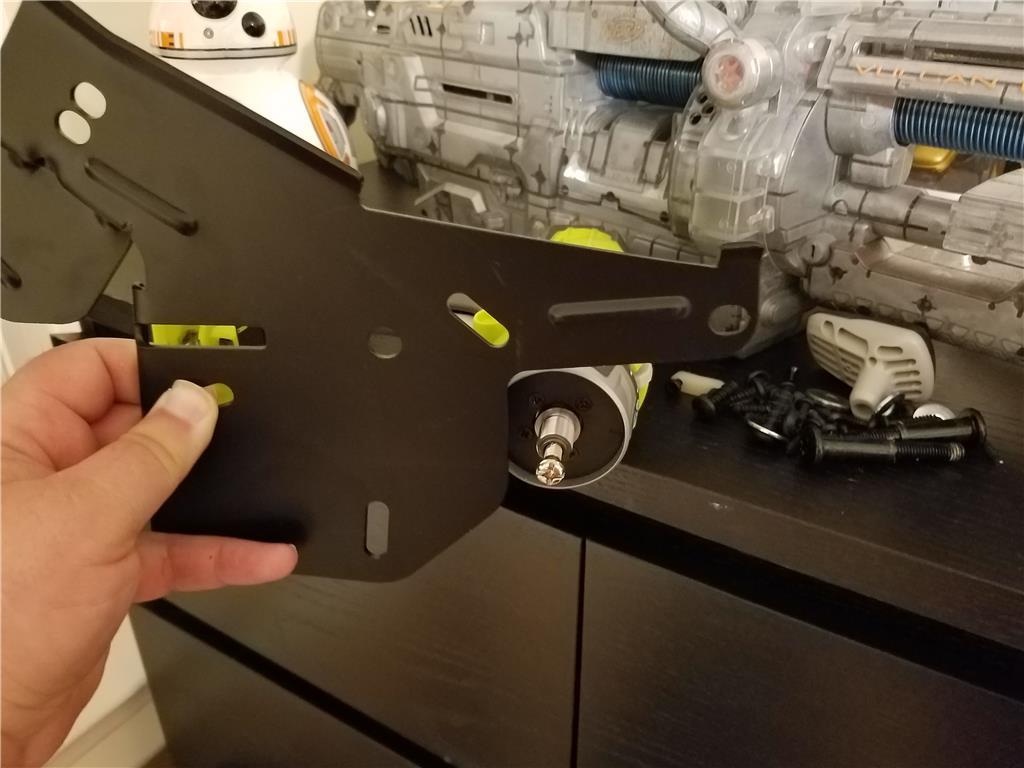

Ok so you are going to laugh but I drilled the pattern from the WRONG side on the left bracet. At first I thought it would be ok till I found the holes are not symmetrical. So I had to make some adjustments. Ugh

You can see they are a couple mm off, it is fixable but I am still grumpy