Hey Guys,

I've read lots on the forum, and posted a hand full of times, but I thought it was about time I launched my first major project (well, my second really, I converted a wall-e, but I thought there was enough of those on here).

So here is announcing OmniMC, an Omnibot 2000 media centre

The idea is to make him all RC and to also house a Raspberry PI running RaspBMC as the media centre bit. I'll then add some speakers and maybe some under-bot lighting

I'm wondering if then I can control the whole thing with one of these:

Other than that, I'm kinda just winging it and seeing what other bits and pieces I come up with.

To start with though, I've done the usual thing of gutting him and sticking him through the dishwasher

So right now, he is prepped and ready to go.

I've already got my EZ-Robot kit, and a few components such as 6v battery

Some blue replacement bulbs

My Raspberry PI (which arrived today) and I've just won a screen for his chest

While I'm waiting for some other bits, I've also been looking at making some replacement tires which you can see details of in one of my other posts

So that's pretty much the state of play at the moment. I'm pretty much a novice at all this, so I'm looking forward to the challenge. Lets see if I've bitten off more than I can chew

Other robots from Synthiam community

Edison2's Spy Robot V2!!! Here It Is! The New Version!

Drephreak's New Robot

Doesnt the ez kit supply the 360 degrees servos? If you want to use your own stronger servo, i am sure you can make it to a 360 degrees servo. Hasnt dj even put up a video for that...?

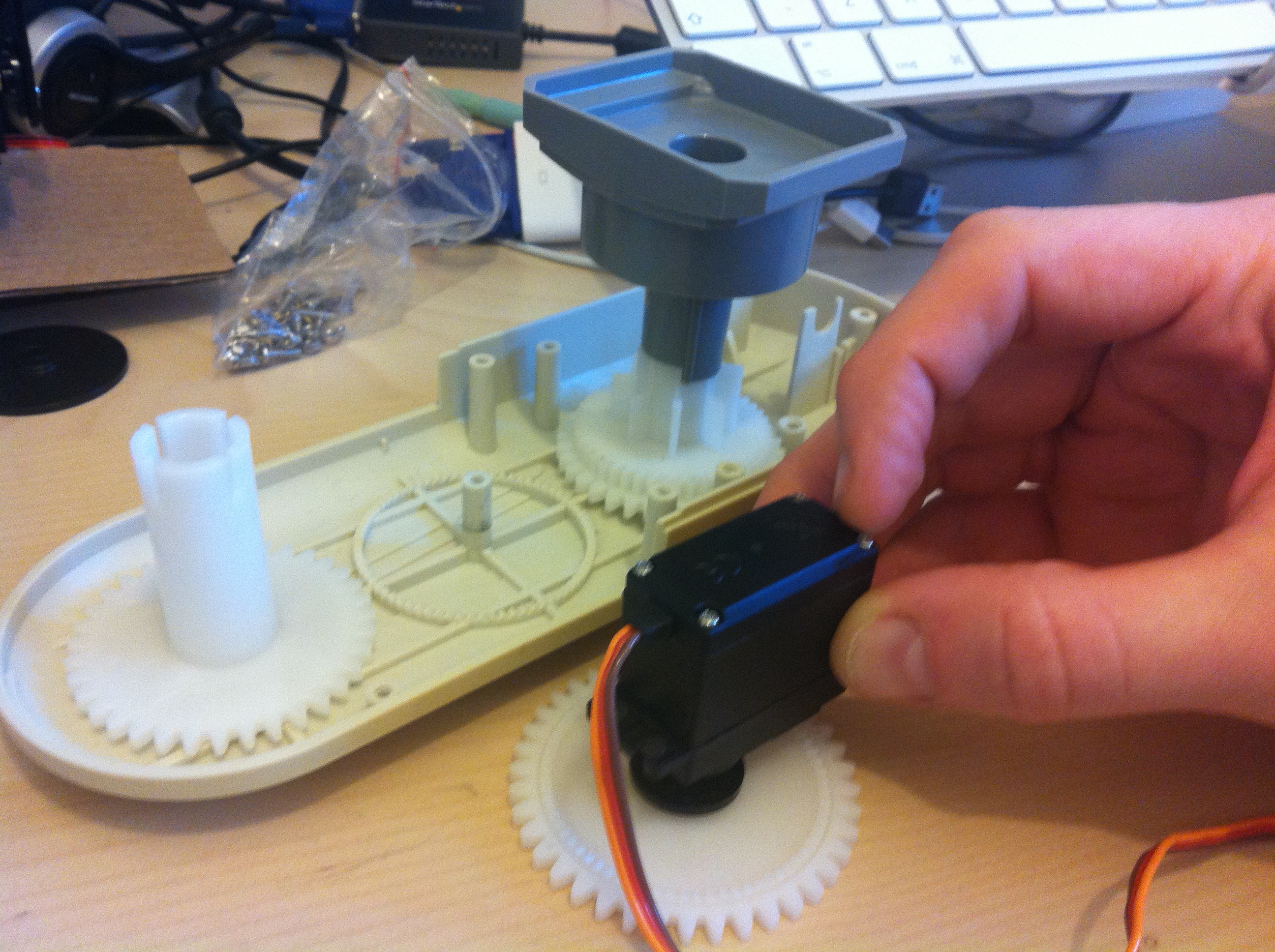

P.s. This picture doesnt make it easy to think about a solution for mounting the servo. Could you put up the opposite half of the arm? From this point of view, it just looks like you will have to make a bit of room for the servo, thus dremel a hole into the inner upper arm. What do you think?

One more thought: how easy is it to move your servo manually. I am just thinking, in the original concept of the arm, the gears not only made loud noise but also keep the arm steady in whatever position it was, sorta like a break. Lets say you put your servo in with just one or two gears in between - and let the robot hold something like a heavy glas in its hand, will the arm remain in its , lets say outstrettched, position or will it slwoly move down, because of the gears and servo not preventing it from doing so? Just a thought.....

Hey mike, the small gear in the picture currently is too large, but I would cast / cut it down so it fits flush (it actually needs to meet up with a slightly smaller gear on the underside of the larg one you can see). I'll try and take some other shots to show what I'm thinking.

Regarding the arms ability to hold a load, I'm really not sure, so would have to try it and see really. The main aim is just to try and reuse the upper / lower arm linkage so I don't have to have a) more servos or b) something external to do the same job.

Man, thinking of how best to do the arms has been doing my head in I'm also wondering whether something could be fashioned in a similar vain to how the omnibot arms work using some metal rods.

I'm also wondering whether something could be fashioned in a similar vain to how the omnibot arms work using some metal rods.

In the mean time though, I've added some reflective disks to the inside of his eyes to soften the light when looking straight on. I think it's a slight improvement, and what is cool is that the disks are silver, so when the lights aren't on, you hardly notice them, as the blend into the reflective backing.

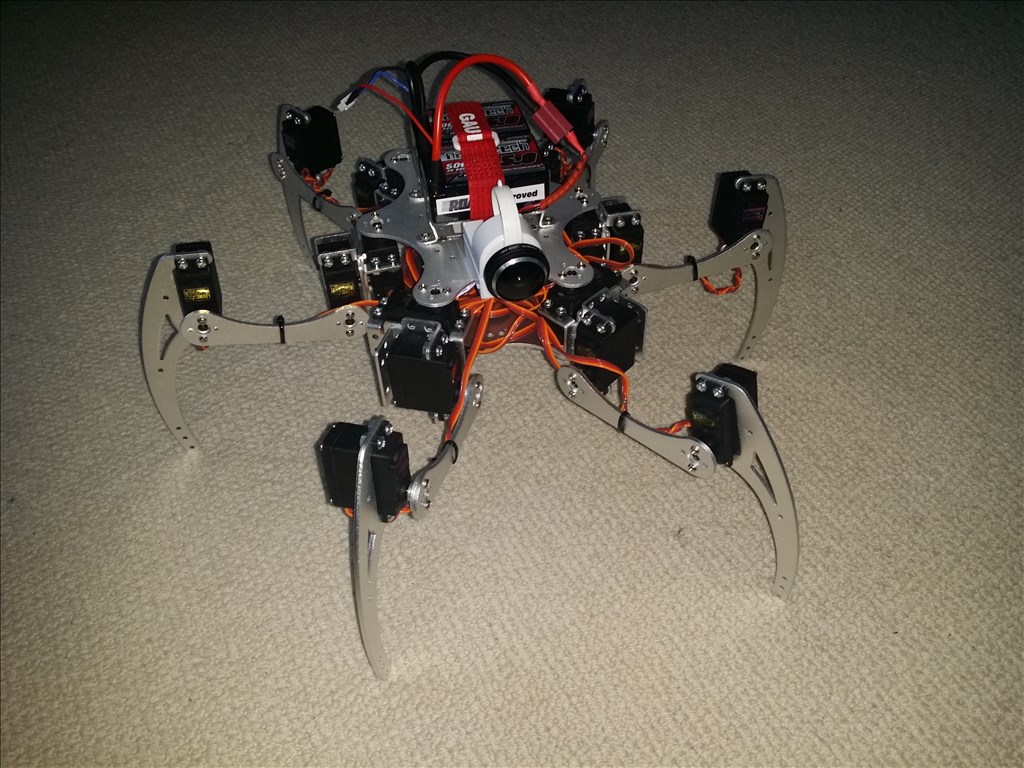

I've also started work on the head pan / tilt mechanism. I'm using one of these from ebay which the guys said should take up to 2lbs of weight. I've compared these to the c brackets from lynxmotion too and it is a little thicker, so hopefully that'll add to it's robustness.

These show it offered up and a test piece installed to see how it all fits. The pan tilt mech is a lot taller than the usual lynxmotion ones, but it actually makes it fit almost exactly to the original neck height, which is lucky

These images show a widened neck hole on the torsoe, and a slimmer neck on the head + screw posts removed ready for filling.

I've got some filler and fiberglass on order, so that will be the next bit to do.

The last thing I've done is just marked up where the camera will go

So some small, disjointed updates, but progress non the less

Great progress actually. And very nice work. I am anxious to see how well that pan/tilt set up works.

Hehe, me too. I was reading how josh uses a gearbox to take the stress off the servos which I'd love to do but the budget is getting tight (there's a big difference between what I want to do and what I can afford to do ). With the servos being pretty cheap though, I thought I might as well just try directly on the servo before splashing out. I don't think it's going to tilt massively, so hopefully doesn't put too much stress on the mechanism. Will report back with a video when I have it fitted though

). With the servos being pretty cheap though, I thought I might as well just try directly on the servo before splashing out. I don't think it's going to tilt massively, so hopefully doesn't put too much stress on the mechanism. Will report back with a video when I have it fitted though

Hi Matt nice build looking forward to more pics