Hey Guys,

I've read lots on the forum, and posted a hand full of times, but I thought it was about time I launched my first major project (well, my second really, I converted a wall-e, but I thought there was enough of those on here).

So here is announcing OmniMC, an Omnibot 2000 media centre

The idea is to make him all RC and to also house a Raspberry PI running RaspBMC as the media centre bit. I'll then add some speakers and maybe some under-bot lighting

I'm wondering if then I can control the whole thing with one of these:

Other than that, I'm kinda just winging it and seeing what other bits and pieces I come up with.

To start with though, I've done the usual thing of gutting him and sticking him through the dishwasher

So right now, he is prepped and ready to go.

I've already got my EZ-Robot kit, and a few components such as 6v battery

Some blue replacement bulbs

My Raspberry PI (which arrived today) and I've just won a screen for his chest

While I'm waiting for some other bits, I've also been looking at making some replacement tires which you can see details of in one of my other posts

So that's pretty much the state of play at the moment. I'm pretty much a novice at all this, so I'm looking forward to the challenge. Lets see if I've bitten off more than I can chew

Other robots from Synthiam community

Thecrustychicken's Crustybot 1.2

Jstarne1's Calling All 3D Printers! Get The Stls While They...

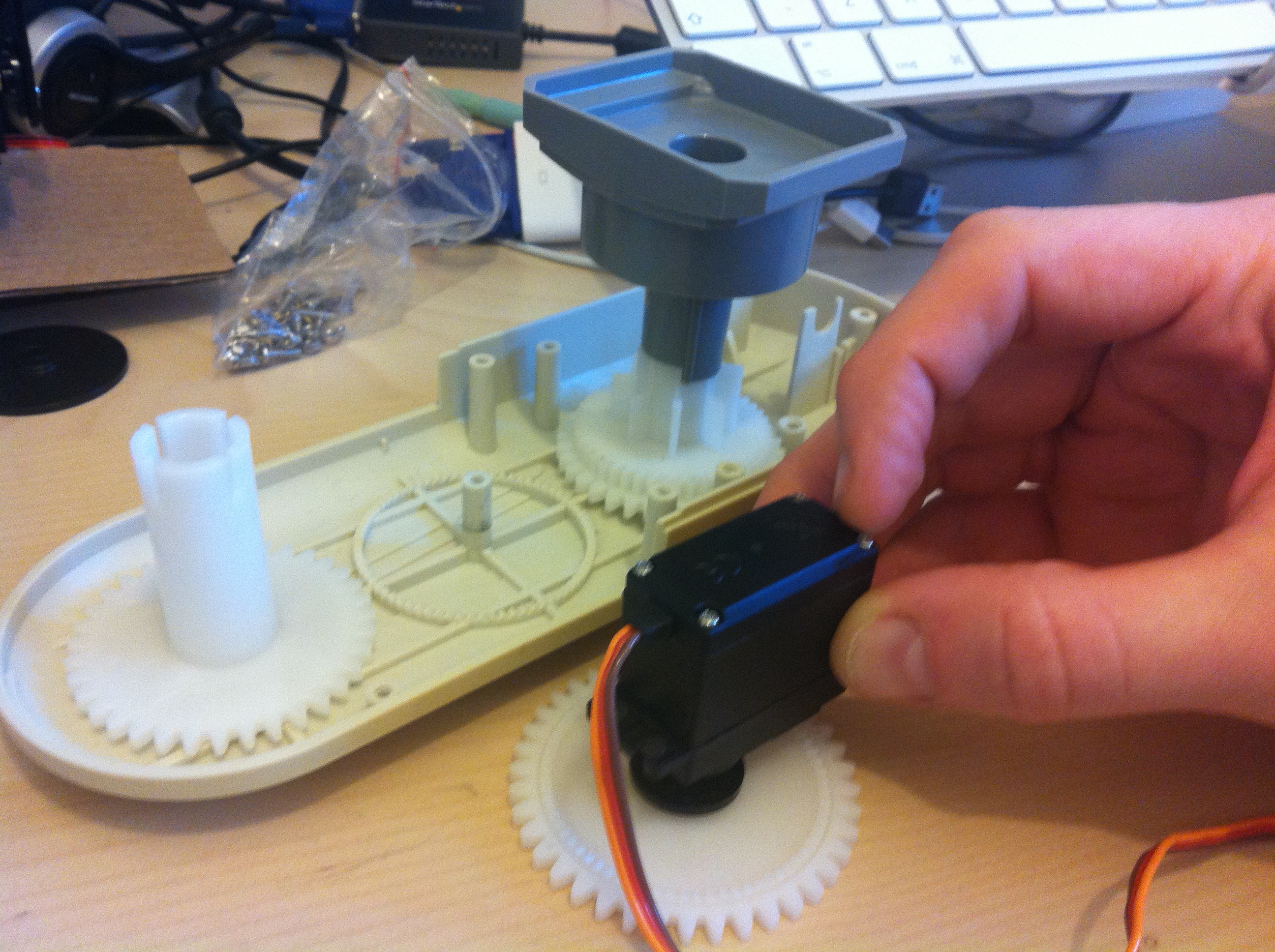

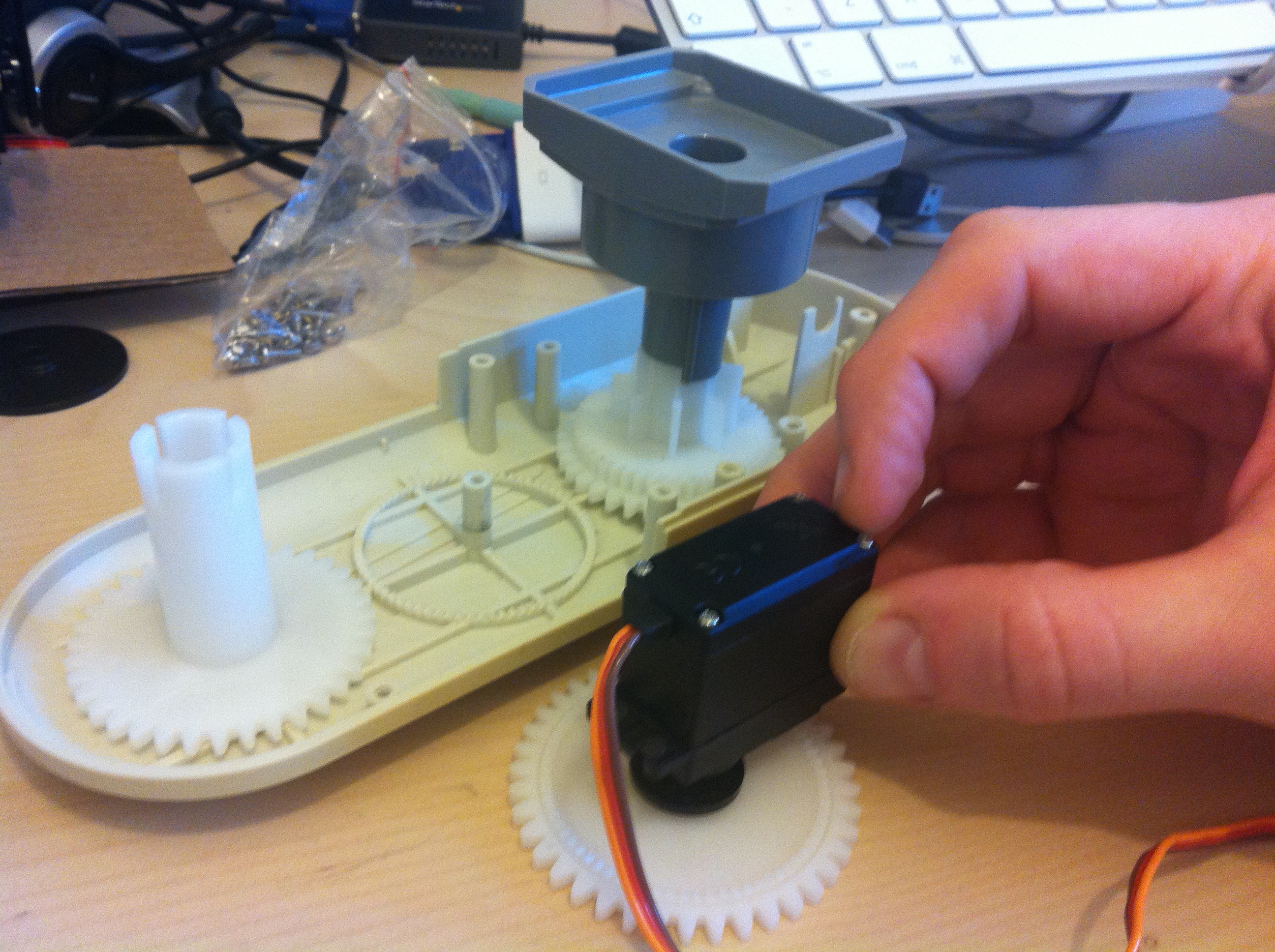

Ok, I think I might have come up with a way to power the arms.

My idea is to attach a servo to the centre cog which, when turned, should raise and lower the arm and forearm at the same time. The beauty of this is also that the arm woul then use the original joints meaning there should be less stress put on the servo. On the flip side, room is a little tight meaning I'm gonna have to cut off the brackets on the servo and hold it in position some other way. What that is, I'm not quite sue yet.Today I think I'm going to make a mould for the centre cog so I can mod it without the risk of ruining the original. If it all fits, then I'll need to make some cuts in the arm casing, at which point there is no going back

Can anybody see any flaws in my plan?

Ok, well, it's sunday, I was bored / impatient and don't have any resin to cast the cog yet, so decided to go ahead and do the cutout in the arm. It does mean that I'm committed to this method, but hey, I can't think of a better way and it's something a bit different to everyone else, so lets see what happens

Because the servo will poke out of the bottom a bit, it does means that I can't have the lower arms at their full extents, but I can still manage 90 degrees at both extremes, so I'm going to fashion some stops to prevent them from over extending and breaking off the servo.

Other than that, if it works, I think it's a fairly unobtrusive way of converting the arms and keeping the internal cog system for keeping the arms in sync.

I think I am going to have to cut the tabs off the servo ends though so I'm going to have to fix it from the inside in some other way. Maybe epoxy some small L brackets to the servo and just screw it into place?

Here is a shot of the inside to see what space I have to play with for fixing the servo into place

Bit more progress and a test video. I screwed the current cog to a servo hub and tested it out. Click To Watch Video I think it works pretty well. Not sure why the servo is humming so much though? Is that normal?

Look pretty cool -only thing is that the lower arm can not got the whole way. Could you use another servo to avoid that problem?

Yea, that's the compromise I had to make. I don't think it's a huge deal though, as they can still sit at 90 degrees. I'm just gonna glue some stoppers in place to prevent it from pushing on the servo if it is turned too far.

Actually, I think you can limit servo rotation in the ARC software when you set up the servo. But I like this modification.

Hey @bret I noticed that when I did the video, cool feature. Think I'll still add the stoppers as a fail safe though.

Maybe you could put switches with lever inside that interrupts the current going to the servo. kinda like what has been in there originaly.