Hey Guys,

I've read lots on the forum, and posted a hand full of times, but I thought it was about time I launched my first major project (well, my second really, I converted a wall-e, but I thought there was enough of those on here).

So here is announcing OmniMC, an Omnibot 2000 media centre

The idea is to make him all RC and to also house a Raspberry PI running RaspBMC as the media centre bit. I'll then add some speakers and maybe some under-bot lighting

I'm wondering if then I can control the whole thing with one of these:

Other than that, I'm kinda just winging it and seeing what other bits and pieces I come up with.

To start with though, I've done the usual thing of gutting him and sticking him through the dishwasher

So right now, he is prepped and ready to go.

I've already got my EZ-Robot kit, and a few components such as 6v battery

Some blue replacement bulbs

My Raspberry PI (which arrived today) and I've just won a screen for his chest

While I'm waiting for some other bits, I've also been looking at making some replacement tires which you can see details of in one of my other posts

So that's pretty much the state of play at the moment. I'm pretty much a novice at all this, so I'm looking forward to the challenge. Lets see if I've bitten off more than I can chew

Other robots from Synthiam community

Dave's Hello All

Steve's Affirmative. K-9 2.0, Online And Fully Operational....

I really like the work you are doing on this. It is a nice build.

If the bulbs are incandescent then polarity at the bulb end does not matter, so it is just a simple series circuit, wired strangely, but working. Typical incandescent bulbs have one end of the filament in the center and the other on the casing.

But you would have to redo the wiring for proper polarity if you want to use LEDs... you could probably just wire each LED separately so you could have it "blink" an eye.

Thanks gunner. That makes sense. I'll go about rewiring it then.

Matt

Ok, so time for the obligatory LED wiring question. So i have 2 bulbs which are 6v with a 20ma draw which i will connect to a 6v battery. I intend to connect them in paralel, so used a calculator to work out the resistors needed which comes out at 0ohms or 1ohm when rounding up. So, the question is, is a 1 ohm resistor really going to do / protect anything? Ive searched around and there seems to be a split of opinion.

Anyone got any compelling reasons for / against?

I thought I'd just test it without resistors for the time being, so here are the test shots

I think it may be a tad bright straight on, so I might look at diffusing the light. I'm wondering if mirrored window tint film could be a good option? Dimming the light in the centre, but reflecting it back to bounce around the inner mirrors making them a bit brighter from the side viewing angle.that looks really good

Adding in a resistor (depending on value, enough to drop voltage draw to 5v for example) will give a lower current draw, potential longer LED life and some control over the brightness.

You could also briefly dip the LEDs into acetone as that should etch the lens and give you LED diffusion but still allow full reflector value.

Regarding the lights, I've thrown in a couple of 1ohm resistors as the online calculators say. Didn't make a huge difference, so can't see the harm in them being there.

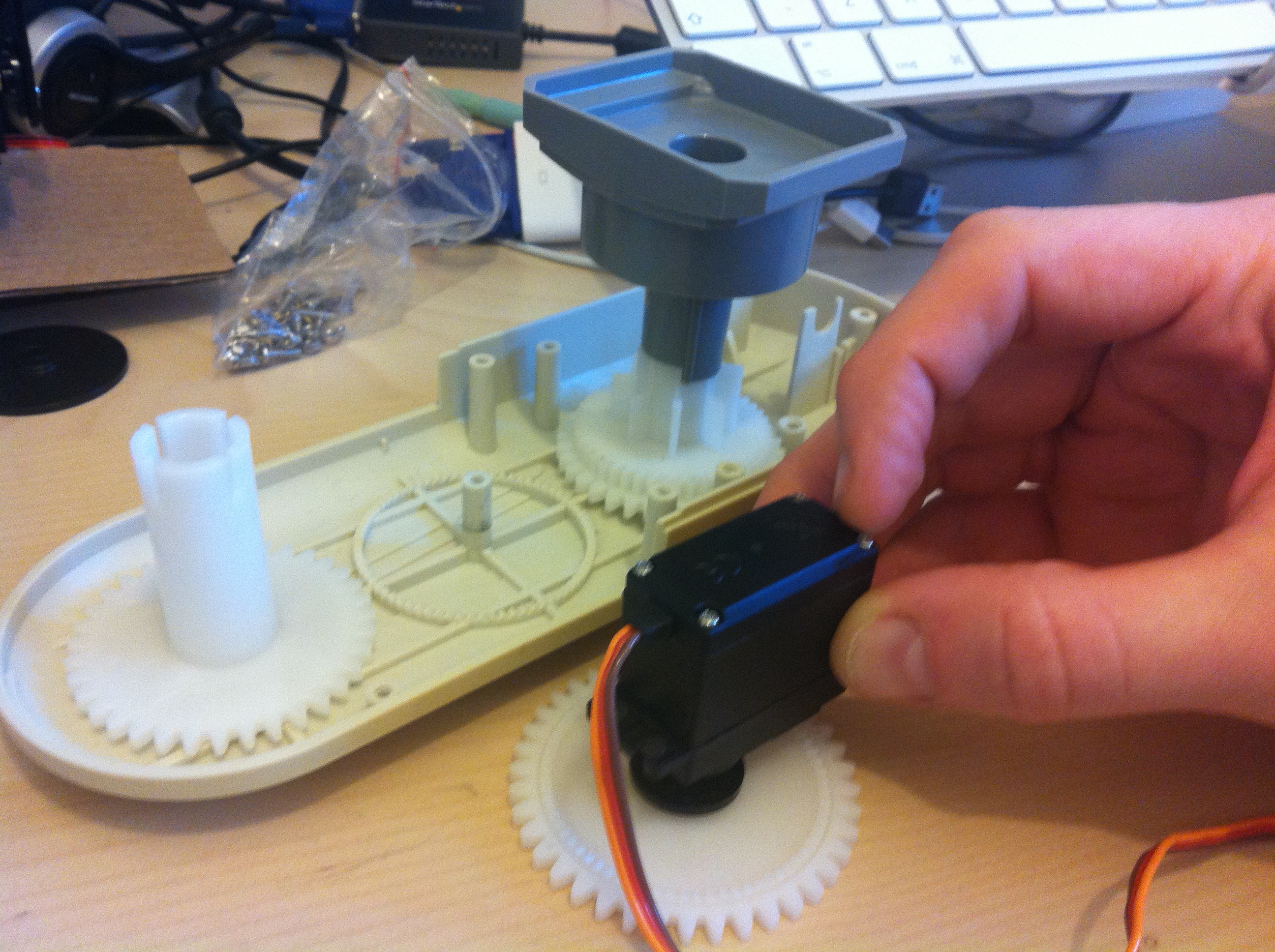

Whilst I'm waiting on some other stuff, I've been pondering how to do the arms to be powered by servos. The thing I would really like to do though is to try and use the 3 large gears in the upper arm to keep the lower arm parallel to the ground (ie lower arms always horizontal regardless of the angle of the upper arm). I've been playing, and I think there is an interesting possibility which I've mocked up in the following shot:

The idea is to reuse one of the smaller gears from the upper arm to attach to the servo which is in turn mounted inside the arm. When the servos turns then, it forces the arm up in much the same way as the original motors did. The only issues I can foresee are 1) how to mount the servo 2) how to mount the gear and 3) from my tests, it would require the servo to be able to do almost a full 360 to have a decent range of motion.If number 3 is a real big issue, it could be possible to design a custom gear and get it fabricated online (Shapeways or something).

What do people think? Any suggestions on the 3 issues?